Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement

Abstract

:1. Introduction

2. Results

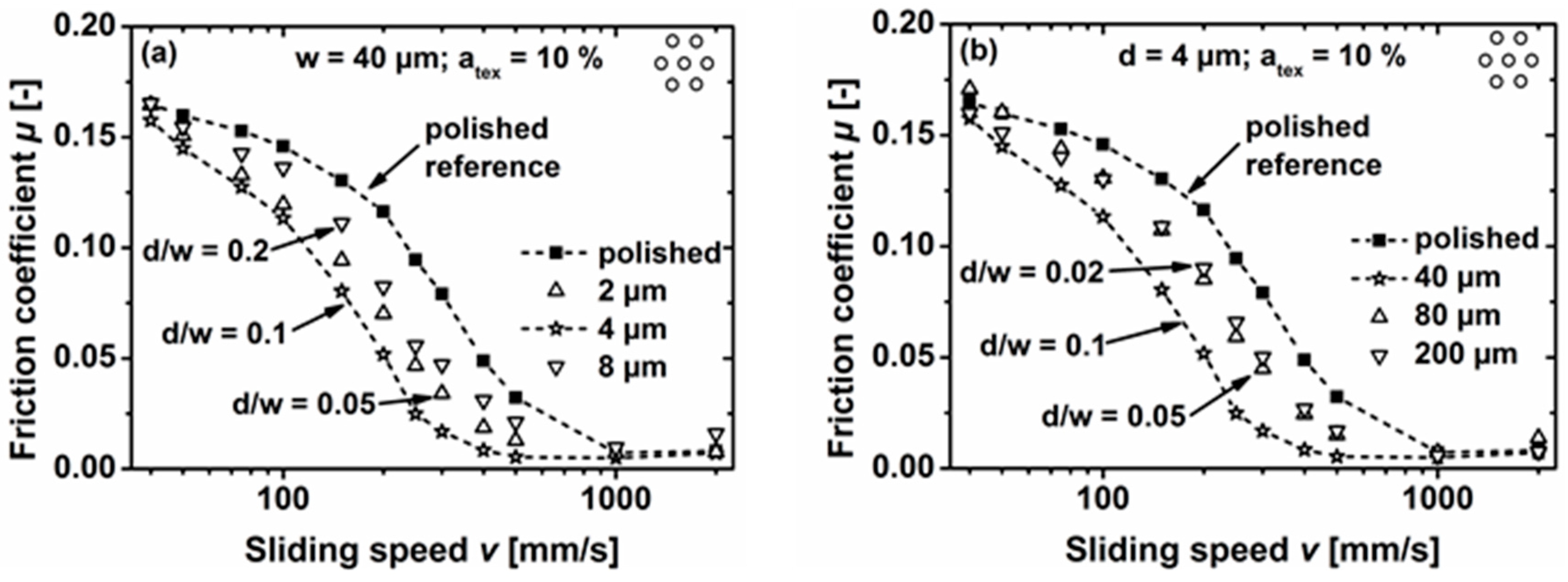

2.1. Influence of the Aspect Ratio

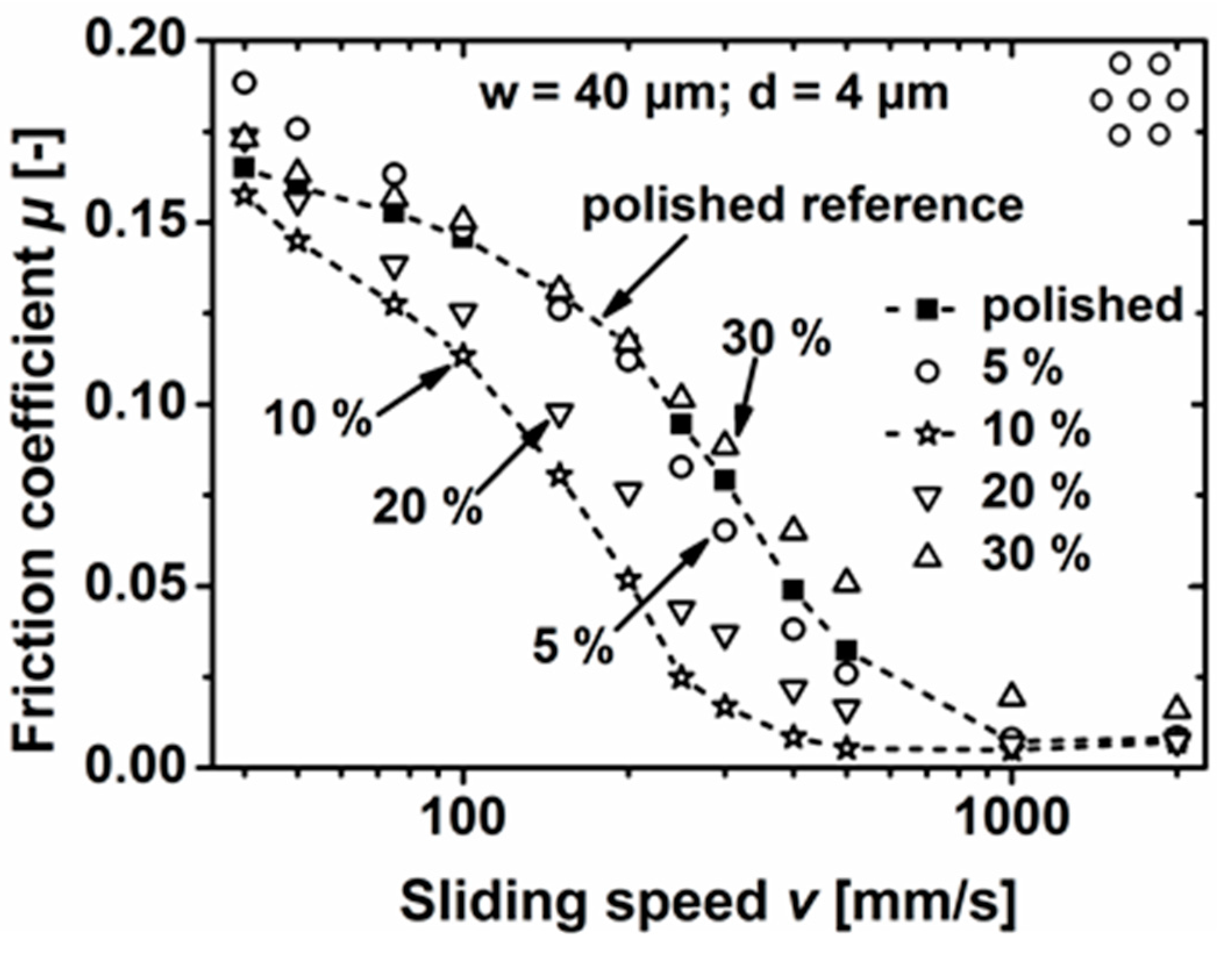

2.2. Influence of the Textured Area

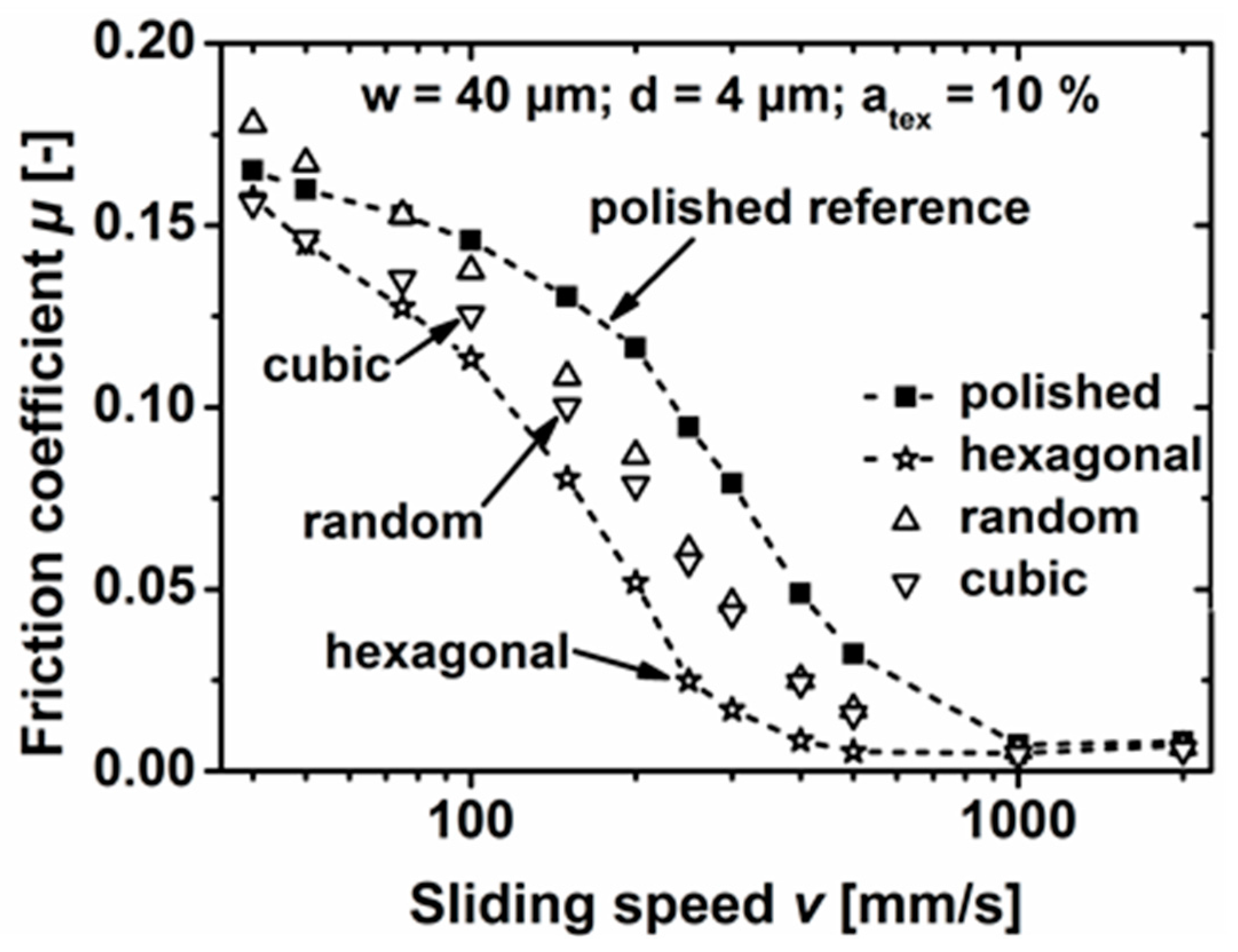

2.3. Influence of the Dimple Arrangement

3. Discussion

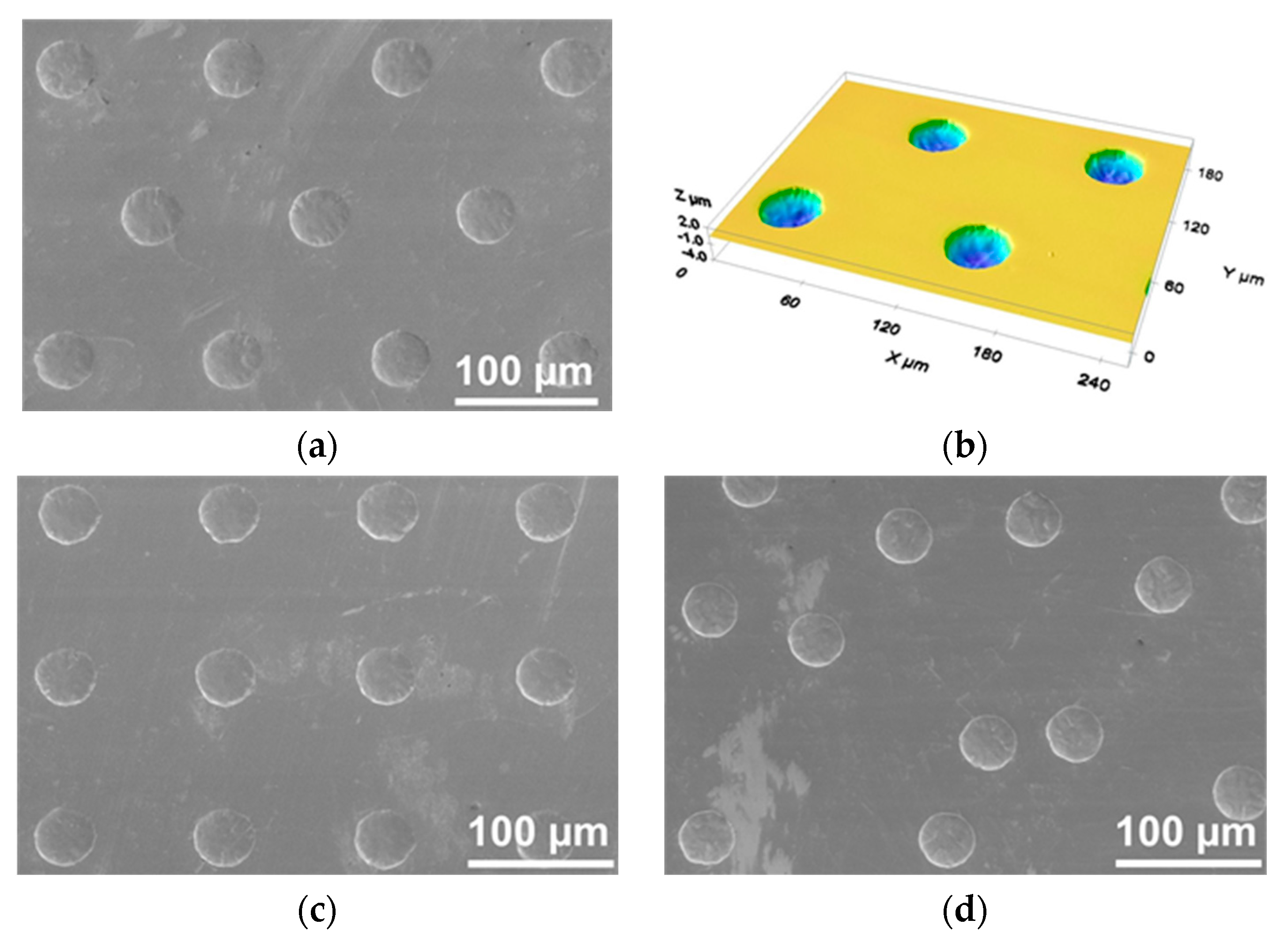

4. Materials and Methods

4.1. Sample Material

4.2. Laser Surface Texturing

4.3. Tribological Testing

5. Conclusions

- Friction reduction is the highest for a dimple aspect ratio of 0.1, regardless whether one changes the aspect ratio by varying the dimple diameter or the dimple depth.

- A dimple packing density of 10% leads to the maximum reduction in friction forces.

- The dimples do not act individually, but as a collective. Arranging them in a hexagonal pattern is superior to a cubic, or random layout.

- The samples did not exhibit any significant amount of wear.

- A maximum friction reduction of over 80% was realized, demonstrating the tremendous potential of laser surface texturing for reducing friction and increasing energy efficiency.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Olivier, J.G.J.; Janses-Maenhout, G. CO2 Emissions from Fossile Fuel Combustion Part III: Total Green House Gas Emissions; International Energy Agency: Paris, France, 2015. [Google Scholar]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Carpick, R.W.; Jackson, A.; Sawyer, W.G.; Argibay, N.; Lee, P.; Pachon, A.; Gresham, R.M. Can tribology save a quad. Tribol. Lubr. Technol. 2016, 72, 44–45. [Google Scholar]

- Etsion, I. State of the Art in Laser Surface Texturing; Tsinghua University Press: Beijing, China, 2009; pp. 761–762. [Google Scholar]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Ibatan, T.; Uddin, M.; Chowdhury, M. Recent development on surface texturing in enhancing tribological performance of bearing sliders. Surf. Coat. Technol. 2015, 272, 102–120. [Google Scholar] [CrossRef]

- Pettersson, U.; Jacobson, S. Tribological texturing of steel surfaces with a novel diamond embossing tool technique. Tribol. Int. 2006, 39, 695–700. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Development of a maskless electrochemical texturing method. J. Mater. Process. Technol. 2009, 209, 3869–3878. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Sedlaček, M.; Podgornik, B.; Vižintin, J.; Babnik, A.; Možina, J. Surface texturing by pulsed Nd:YAG laser. Tribol. Int. 2009, 42, 1496–1504. [Google Scholar] [CrossRef]

- Anno, J.N.; Walowit, J.A.; Allen, C.M. Microasperity lubrication. J. Lubr. Technol. 1968, 90, 351–355. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372, 21–41. [Google Scholar] [CrossRef]

- Etsion, I.; Burstein, L. A model for mechanical seals with regular microsurface structure. Tribol. Trans. 1996, 39, 677–683. [Google Scholar] [CrossRef]

- Etsion, I.; Kligerman, Y.; Halperin, G. Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol. Trans. 1999, 42, 511–516. [Google Scholar] [CrossRef]

- Kligerman, Y.; Etsion, I.; Shinkarenko, A. Improving tribological performance of piston rings by partial surface texturing. J. Tribol. 2005, 127, 632–638. [Google Scholar] [CrossRef]

- Zum Gahr, K.H.; Wahl, R.; Wauthier, K. Experimental study of the effect of microtexturing on oil lubricated ceramic/steel friction pairs. Wear 2009, 267, 1241–1251. [Google Scholar] [CrossRef]

- Yan, D.; Qu, N.; Li, H.; Wang, X. Significance of dimple parameters on the friction of sliding surfaces investigated by orthogonal experiments. Tribol. Trans. 2010, 53, 703–712. [Google Scholar] [CrossRef]

- Greiner, C.; Merz, T.; Braun, D.; Codrignani, A.; Magagnato, F. Optimum dimple diameter for friction reduction with laser surface texturing: The effect of velocity gradient. Surf. Topogr. Metrol. Prop. 2015, 3, 044001. [Google Scholar] [CrossRef]

- Braun, D.; Greiner, C.; Schneider, J.; Gumbsch, P. Efficiency of laser surface texturing in the reduction of friction under mixed lubrication. Tribol. Int. 2014, 77, 142–147. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerman, Y.; Etsion, I. The validity of linear elasticity in analyzing surface texturing effect for elastohydrodynamic lubrication. J. Tribol. 2009, 131, 021503. [Google Scholar] [CrossRef]

- Wang, X.L.; Kato, K.; Adachi, K.; Aizawa, K. The effect of laser texturing of sic surface on the critical load for transition of water lubrication mode from hydrodynamic to mixed. Tribol. Int. 2001, 34, 703–711. [Google Scholar] [CrossRef]

- Ronen, A.; Etsion, I.; Kligerman, Y. Friction-reducing surface-texturing in reciprocating automotive components. Tribol. Trans. 2001, 44, 359–366. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerman, Y.; Etsion, I. The effect of elastomer surface texturing in soft elasto-hydrodynamic lubrication. Tribol. Lett. 2009, 36, 95–103. [Google Scholar] [CrossRef]

- Scaraggi, M.; Mezzapesa, F.P.; Carbone, G.; Ancona, A.; Sorgente, D.; Lugarà, P.M. Minimize friction of lubricated laser-microtextured-surfaces by tuning microholes depth. Tribol. Int. 2014, 75, 123–127. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K.; Adachi, K.; Aizawa, K. Loads carrying capacity map for the surface texture design of sic thrust bearing sliding in water. Tribol. Int. 2003, 36, 189–197. [Google Scholar] [CrossRef]

- Peng, X.D.; Sheng, S.E.; Li, J.Y.; Pan, X.M.; Bai, S.X. Effects of dimple geometric parameters on the performance of a laser-textured mechanical seal. Key Eng. Mater. 2008, 373–374, 766–769. [Google Scholar] [CrossRef]

- Ramesh, A.; Akram, W.; Mishra, S.P.; Cannon, A.H.; Polycarpou, A.A.; King, W.P. Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication. Tribol. Int. 2013, 57, 170–176. [Google Scholar] [CrossRef]

- Brizmer, V.; Kligerman, Y.; Etsion, I. A laser surface textured parallel thrust bearing. Tribol. Trans. 2003, 46, 397–403. [Google Scholar] [CrossRef]

- Wakuda, M. Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 2003, 254, 356–363. [Google Scholar] [CrossRef]

- Chae, Y.H. In Effect of size for micro-scale dimples on surface under lubricated sliding contact. Key Eng. Mater. 2007, 345, 765–768. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerman, Y.; Etsion, I. The effect of surface texturing in soft elasto-hydrodynamic lubrication. Tribol. Int. 2009, 42, 284–292. [Google Scholar] [CrossRef]

- Kim, B.; Chae, Y.H.; Choi, H.S. Effects of surface texturing on the frictional behavior of cast iron surfaces. Tribol. Int. 2014, 70, 128–135. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerman, Y.; Etsion, I. Theoretical analysis of surface-textured elastomer sleeve in lubricated rotary sliding. Tribol. Trans. 2010, 53, 376–385. [Google Scholar] [CrossRef]

- Wahl, R.; Schneider, J.; Gumbsch, P. In situ observation of cavitation in crossed microchannels. Tribol. Int. 2012, 55, 81–86. [Google Scholar] [CrossRef]

- Ma, C.H.; Bai, S.X.; Peng, X.D.; Meng, Y.G. Improving hydrophobicity of laser textured sic surface with micro-square convexes. Appl. Surf. Sci. 2013, 266, 51–56. [Google Scholar] [CrossRef]

- Varenberg, M.; Halperin, G.; Etsion, I. Different aspects of the role of wear debris in fretting wear. Wear 2002, 252, 902–910. [Google Scholar] [CrossRef]

- Lu, X.; Khonsari, M. An experimental investigation of dimple effect on the stribeck curve of journal bearings. Tribol. Lett. 2007, 27, 169. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser texturing of steel surfaces and speed-load parameters on the transition of lubrication regime from boundary to hydrodynamic. Tribol. Trans. 2004, 47, 299–307. [Google Scholar] [CrossRef]

- Greiner, C.; Schaefer, M.; Popp, U.; Gumbsch, P. Contact splitting and the effect of dimple depth on static friction of textured surfaces. ACS Appl. Mater. Interface 2014, 6, 7986–7990. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Huang, W.; Wang, X. Dimple patterns design for different circumstances. Lubr. Sci. 2013, 25, 67–78. [Google Scholar] [CrossRef]

- Yu, H.; Deng, H.; Huang, W.; Wang, X. The effect of dimple shapes on friction of parallel surfaces. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 2011, 225, 693–703. [Google Scholar] [CrossRef]

- Wöppermann, M.; Zum Gahr, K.H. Surface textured steel/ceramic and ceramic/ceramic pairs sliding in isooctane. In Friction, Wear and Wear Protection; Wiley-VCH: Weinheim, Germany, 2009; pp. 362–368. [Google Scholar]

- Karuppiah, K.K.; Sundararajan, S.; Xu, Z.-H.; Li, X. The effect of protein adsorption on the friction behavior of ultra-high molecular weight polyethylene. Tribol. Lett. 2006, 22, 181–188. [Google Scholar] [CrossRef]

- Knoll, G. Elastohydrodynamic simulationtechnology with integrated mixed lubrication. Materialwissenschaft und Werkstofftechnik 2003, 34, 946–952. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K.; Gee, M.G.; Wang, L.; Pfleging, W. The use of anisotropic texturing for control of directional friction. Tribol. Int. 2017, 113, 169–181. [Google Scholar] [CrossRef]

- Li, X.; Bhushan, B. Micromechanical and tribological characterization of hard amorphous carbon coatings as thin as 5 nm for magnetic recording heads. Wear 1998, 220, 51–58. [Google Scholar] [CrossRef]

- Gao, Y.; Wu, B.; Zhou, Y.; Tao, S. A two-step nanosecond laser surface texturing process with smooth surface finish. Appl. Surf. Sci. 2011, 257, 9960–9967. [Google Scholar] [CrossRef]

- Stribeck, R. Die wesentlichen Eigenschaften der Gleit- und Rollenlager. Z. Verein. Deut. Ing. 1902, 46, 1341–1348 (pt I), 1432–1438 (pt II), 1463–1470 (pt III). [Google Scholar]

| Diameter (w) [µm] | Depth (d) [µm] | Aspect Ratio (d/w) | Textured Area (atex) [%] | Arrangement |

|---|---|---|---|---|

| 40 | 2 | 0.05 | 10 | Hexagonal |

| 40 | 4 | 0.10 | 10 | Hexagonal |

| 40 | 8 | 0.20 | 10 | Hexagonal |

| 80 | 4 | 0.05 | 10 | Hexagonal |

| 200 | 4 | 0.02 | 10 | Hexagonal |

| 40 | 4 | 0.10 | 10 | Random |

| 40 | 4 | 0.10 | 10 | Cubic |

| 40 | 4 | 0.10 | 5 | Hexagonal |

| 40 | 4 | 0.10 | 20 | Hexagonal |

| 40 | 4 | 0.10 | 30 | Hexagonal |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schneider, J.; Braun, D.; Greiner, C. Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement. Lubricants 2017, 5, 32. https://doi.org/10.3390/lubricants5030032

Schneider J, Braun D, Greiner C. Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement. Lubricants. 2017; 5(3):32. https://doi.org/10.3390/lubricants5030032

Chicago/Turabian StyleSchneider, Johannes, Daniel Braun, and Christian Greiner. 2017. "Laser Textured Surfaces for Mixed Lubrication: Influence of Aspect Ratio, Textured Area and Dimple Arrangement" Lubricants 5, no. 3: 32. https://doi.org/10.3390/lubricants5030032