Acknowledgments

The research presented in this work was carried out as a part of “Swedish Hydropower Centre—SVC”. SVC has been established by the Swedish Energy Agency, Energiforsk, and Svenska Kraftnät together with Luleå University of Technology, KTH Royal Institute of Technology, Chalmers University of Technology, and Uppsala University. Participating companies and industry associations are: Alstom Hydro Sweden, Andritz Hydro, E.ON Vattenkraft Sverige, Falu Energi and Vatten, Fortum Generation, Holmen Energi, Jämtkraft, Jönköping Energi, Karlstads Energi, Mälarenergi, Norconsult, Rainpower, Skellefteå Kraft, Sollefteåforsens, Statkraft Sverige, Sweco Energuide, Sweco Infrastructure, SveMin, Umeå Energi, Vattenfall Research and Development, Vattenfall Vattenkraft, VG Power, WSP Samhällsbyggnad, and ÅF Industry.

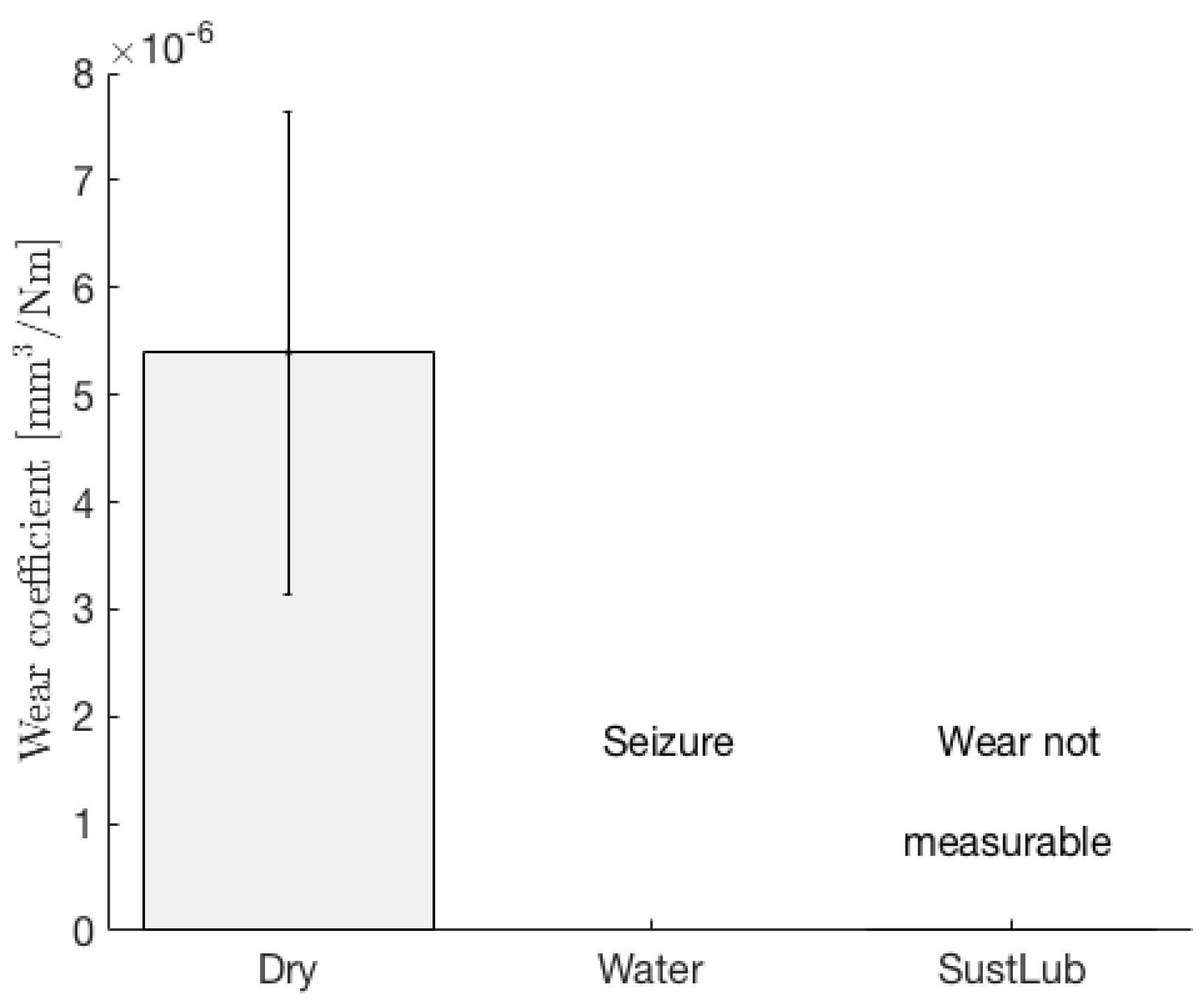

Figure 1.

Wear rate of the deva.bm bearing material.

Figure 1.

Wear rate of the deva.bm bearing material.

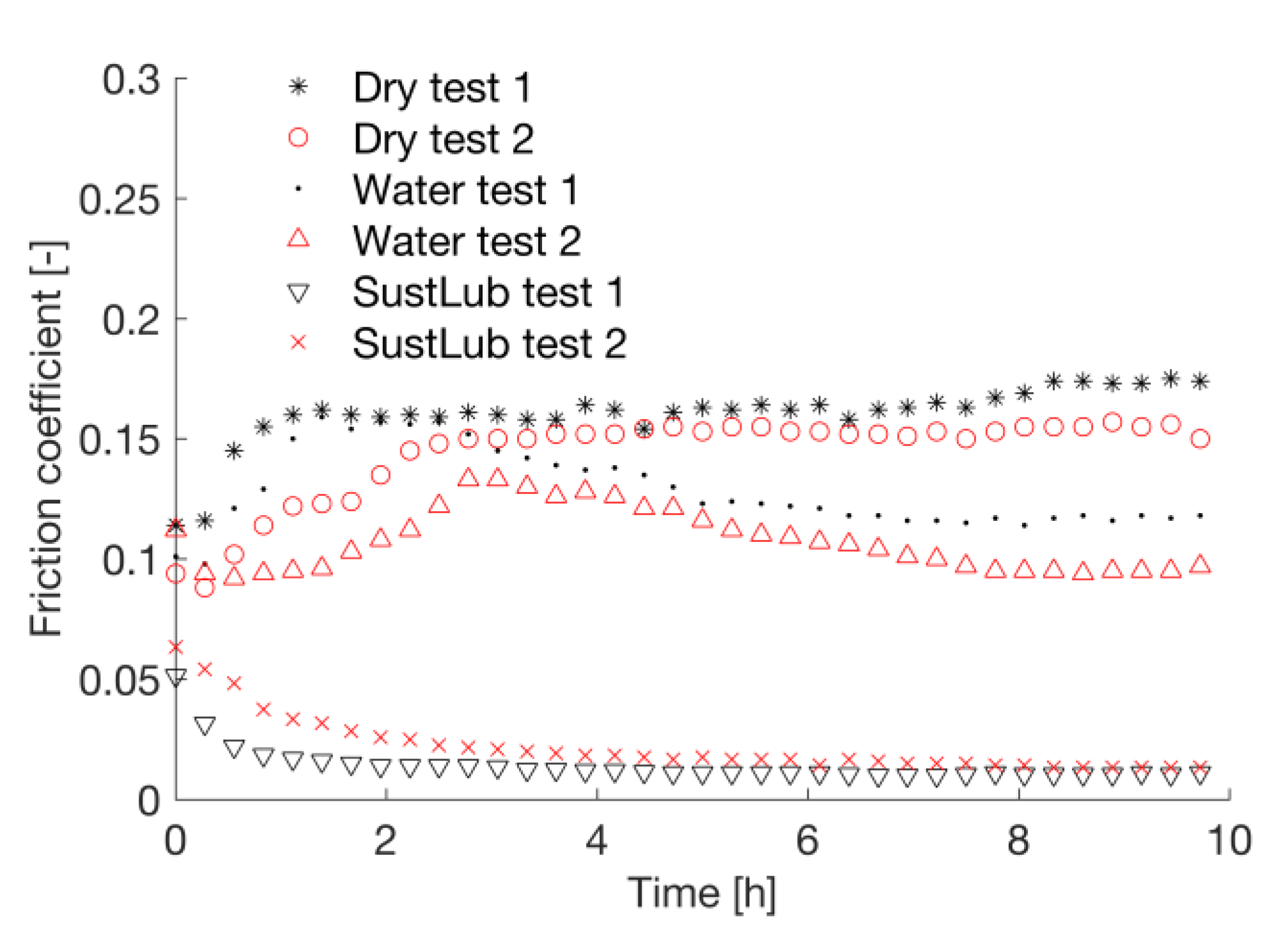

Figure 2.

Friction coefficient during test for the deva.bm bearing material.

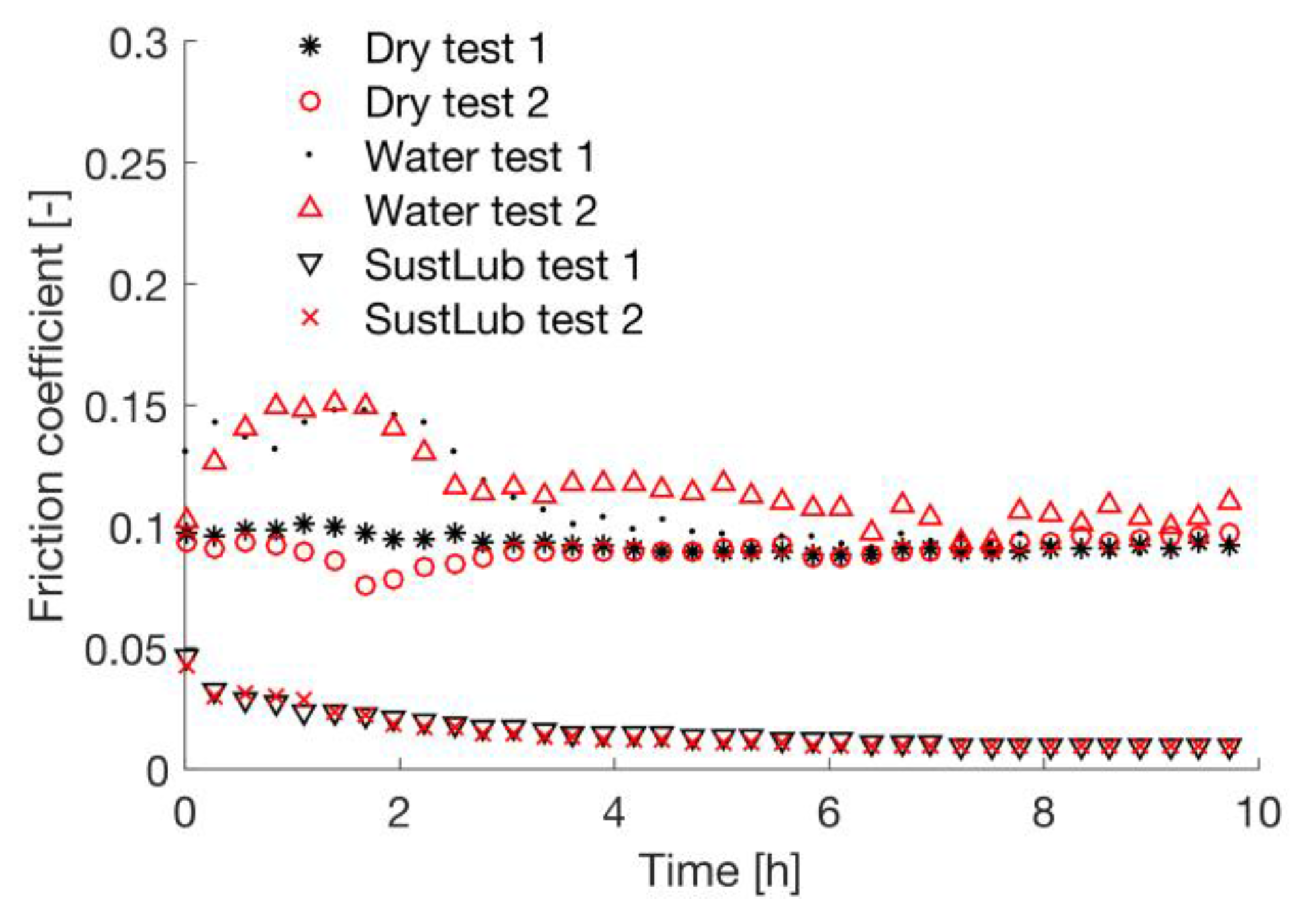

Figure 2.

Friction coefficient during test for the deva.bm bearing material.

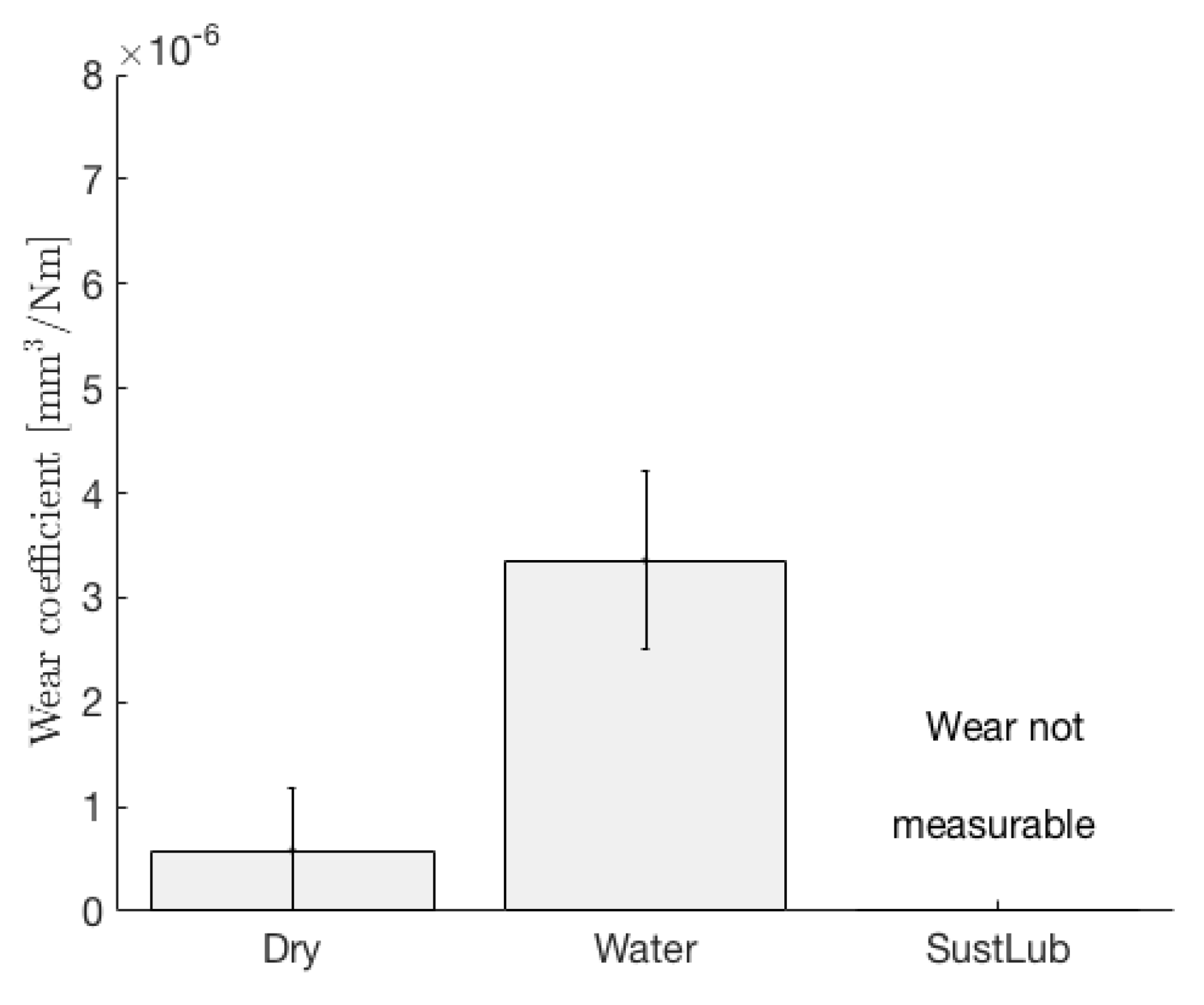

Figure 3.

Wear rate of the deva.tex bearing material.

Figure 3.

Wear rate of the deva.tex bearing material.

Figure 4.

Friction coefficient during test for the deva.tex bearing material.

Figure 4.

Friction coefficient during test for the deva.tex bearing material.

Figure 5.

Wear rate of the Thordon bearing material.

Figure 5.

Wear rate of the Thordon bearing material.

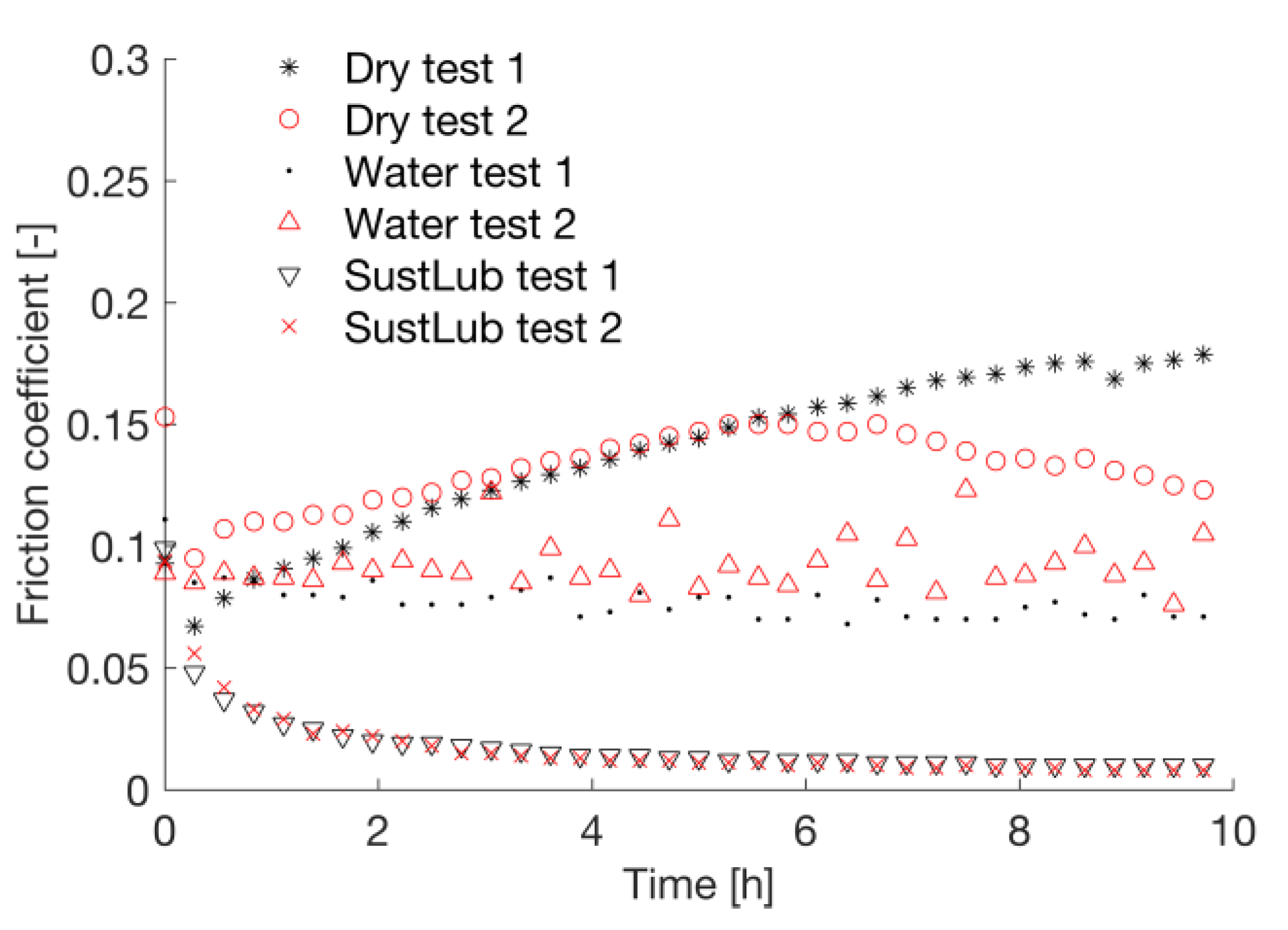

Figure 6.

Friction coefficient during test for the Thordon bearing material.

Figure 6.

Friction coefficient during test for the Thordon bearing material.

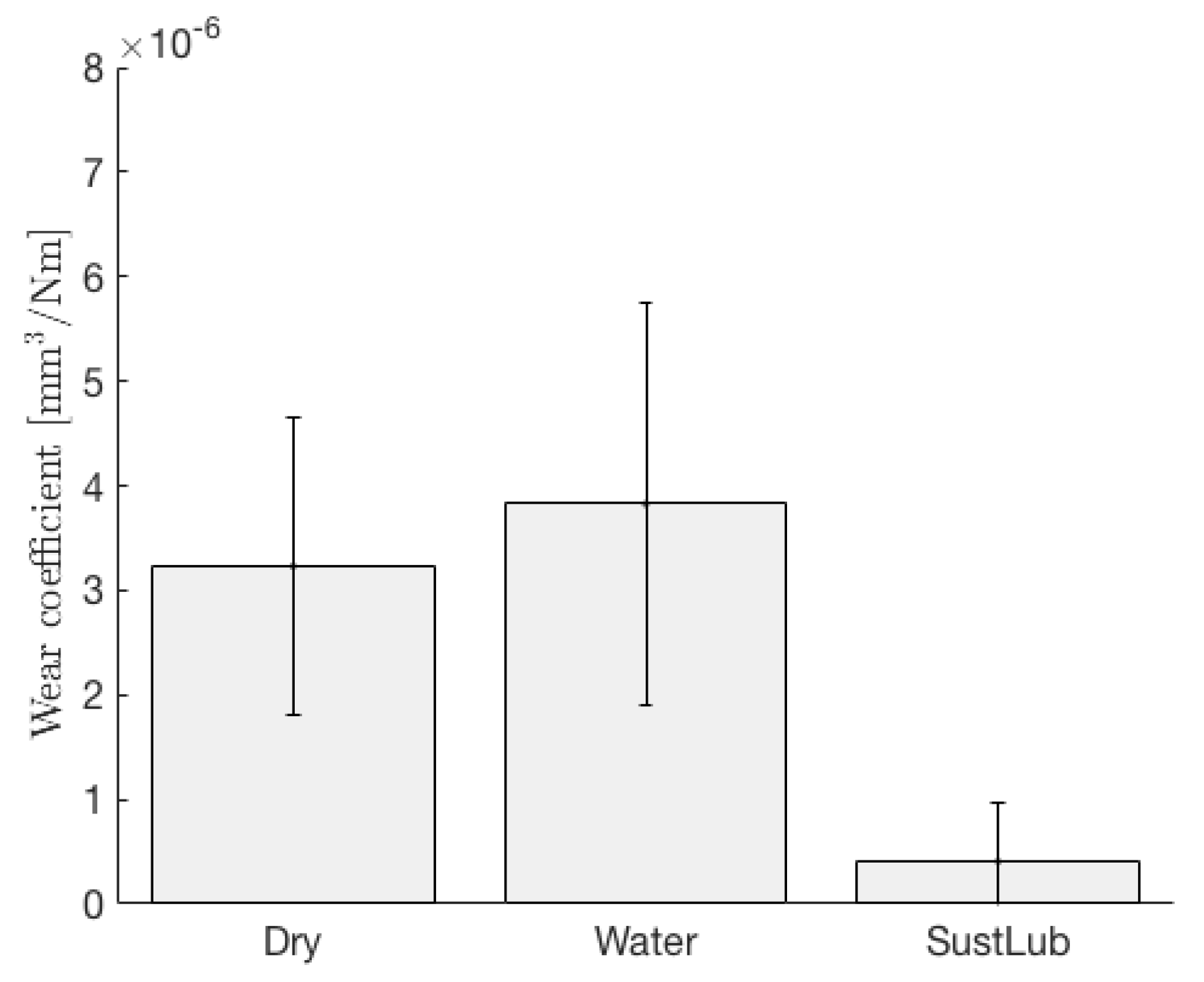

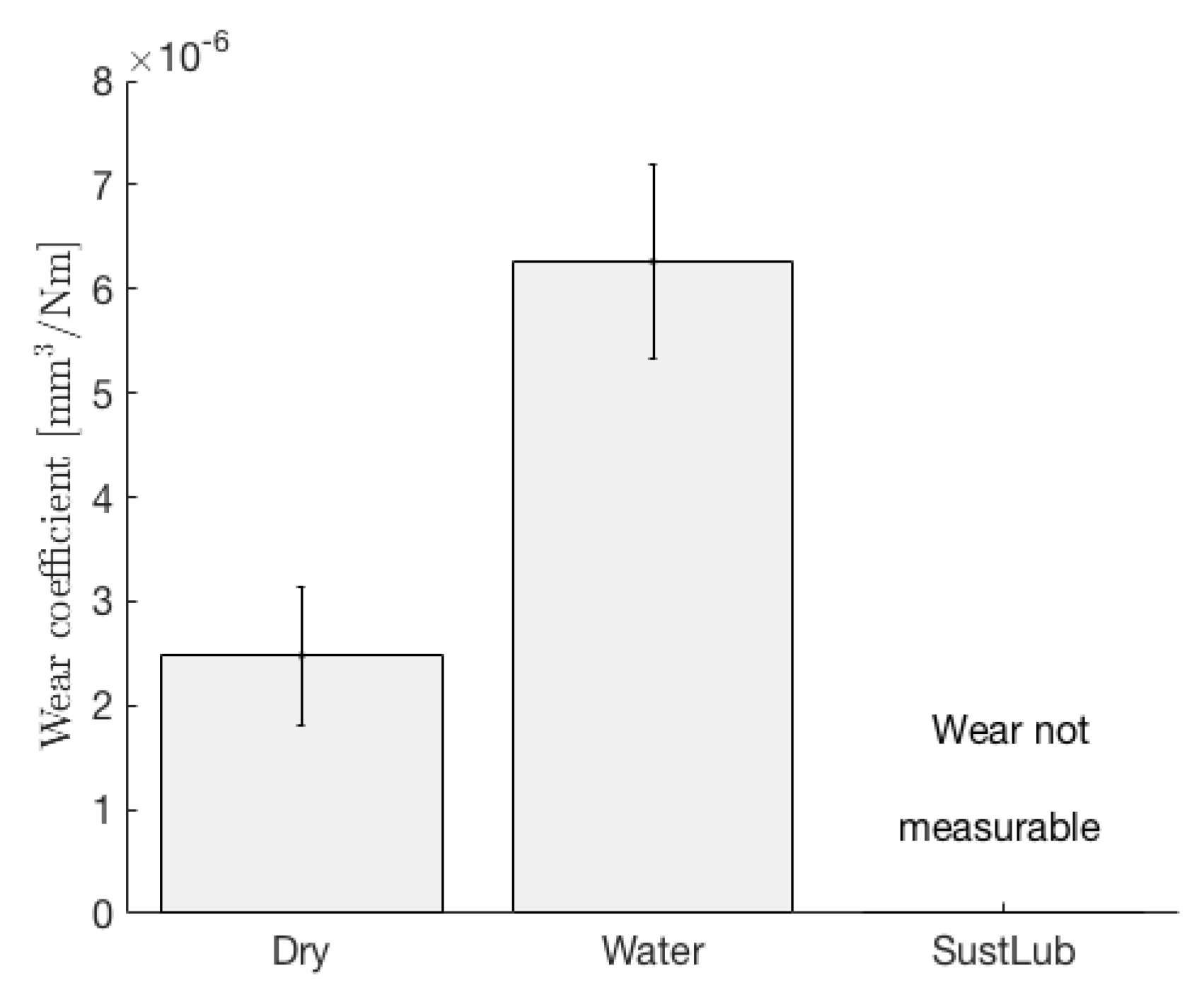

Figure 7.

Wear rate of the Orkot bearing material.

Figure 7.

Wear rate of the Orkot bearing material.

Figure 8.

Friction coefficient during test for the Orkot bearing material.

Figure 8.

Friction coefficient during test for the Orkot bearing material.

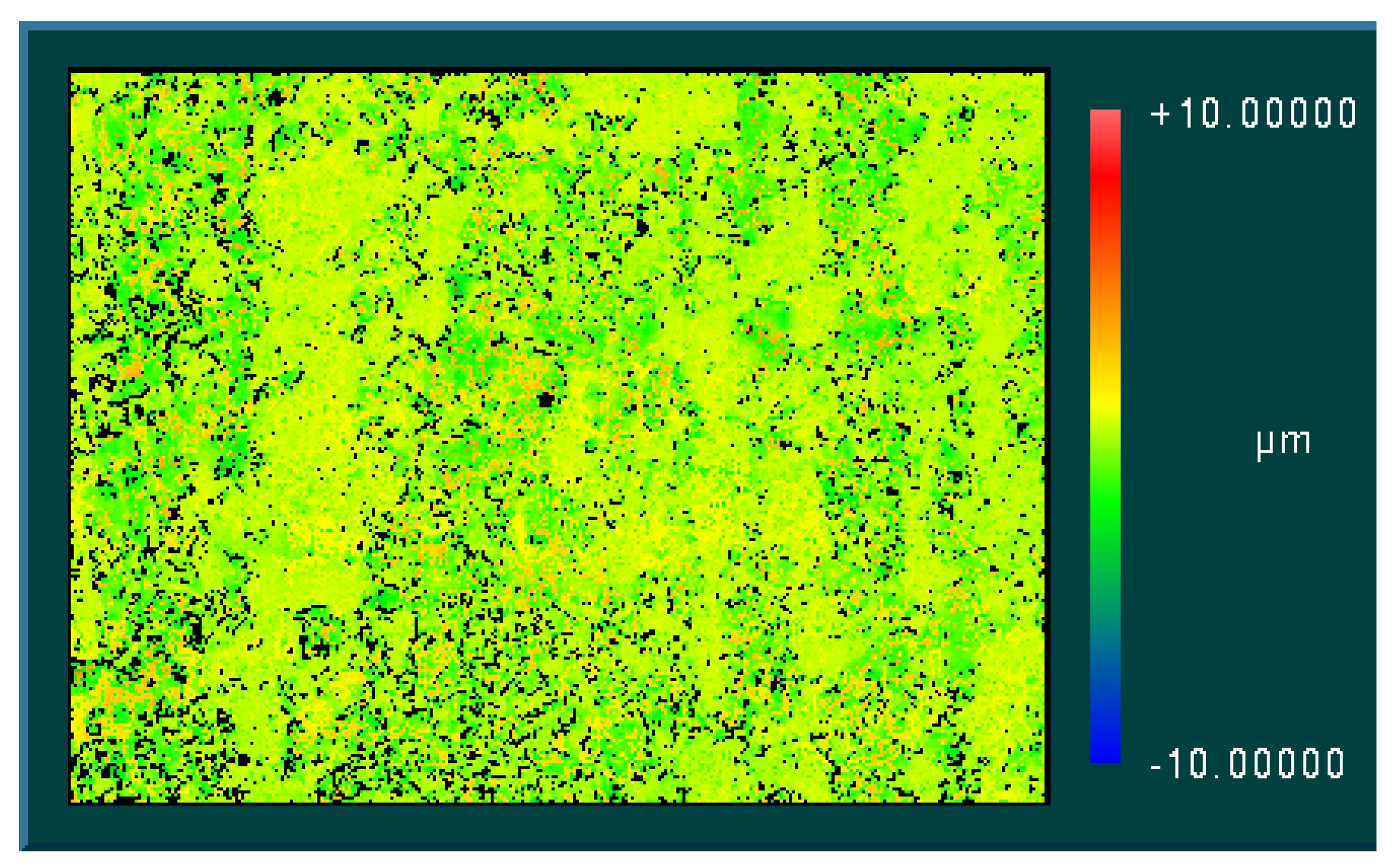

Figure 9.

Surface topography of the stainless steel counter-surface after an 8-h test with water and Thordon Thorplas. Magnification: 10×.

Figure 9.

Surface topography of the stainless steel counter-surface after an 8-h test with water and Thordon Thorplas. Magnification: 10×.

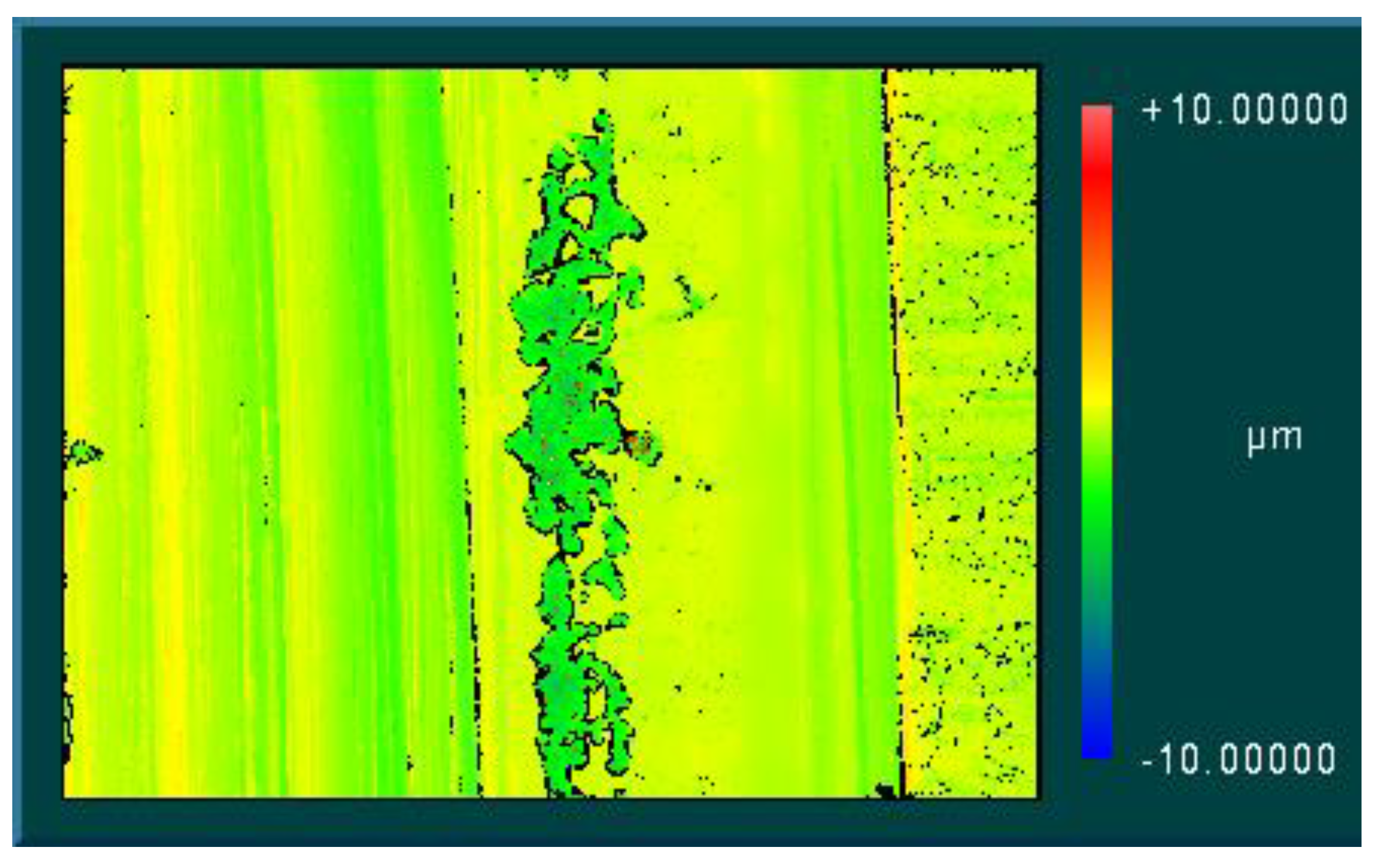

Figure 10.

Surface topography of the stainless steel counter-surface after an 8-h test with SustainaLube and Thordon Thorplas. Magnification: 10×.

Figure 10.

Surface topography of the stainless steel counter-surface after an 8-h test with SustainaLube and Thordon Thorplas. Magnification: 10×.

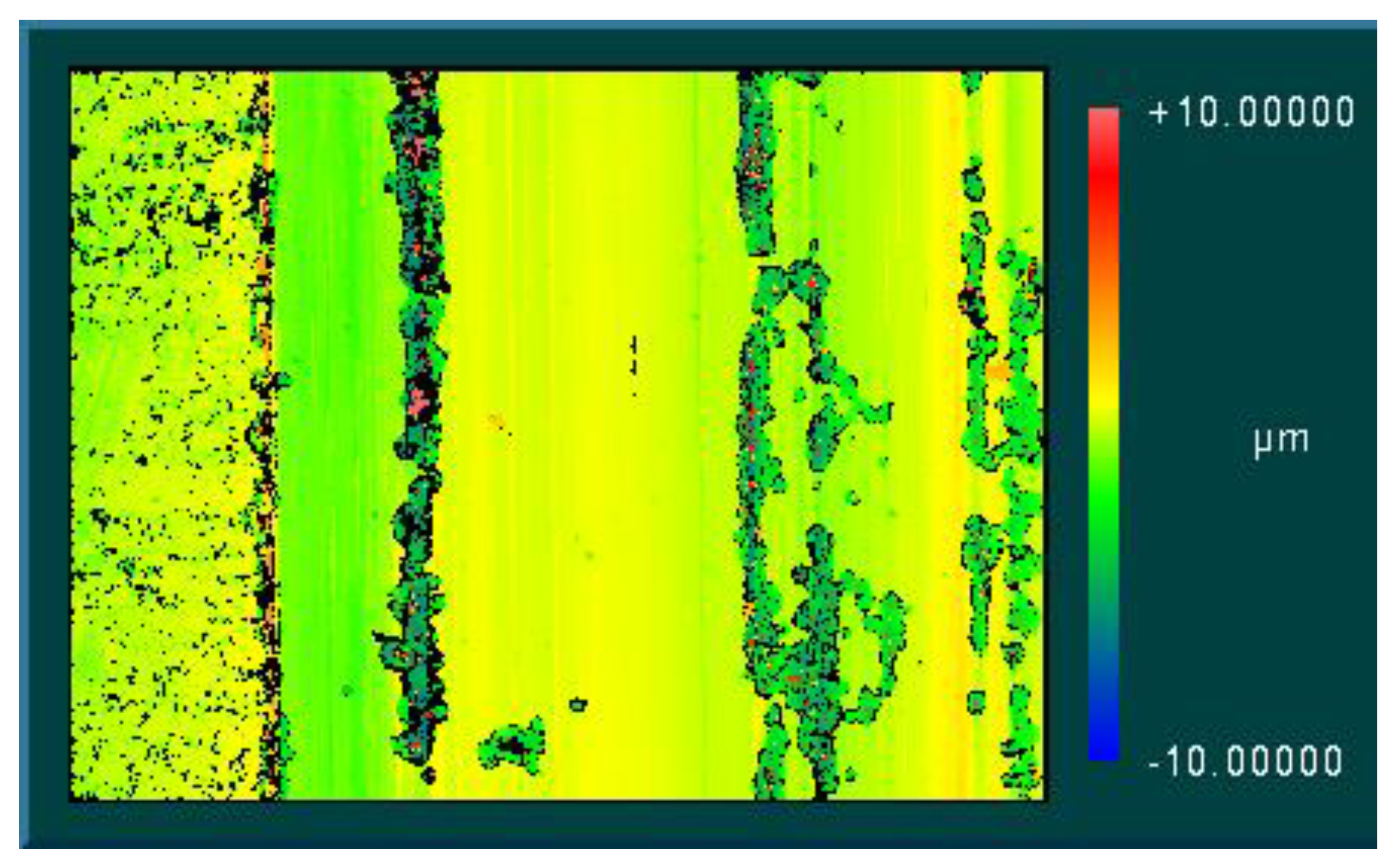

Figure 11.

Surface topography of the stainless steel counter-surface after a 0.5-h test with water and deva.bm. Magnification: 10×.

Figure 11.

Surface topography of the stainless steel counter-surface after a 0.5-h test with water and deva.bm. Magnification: 10×.

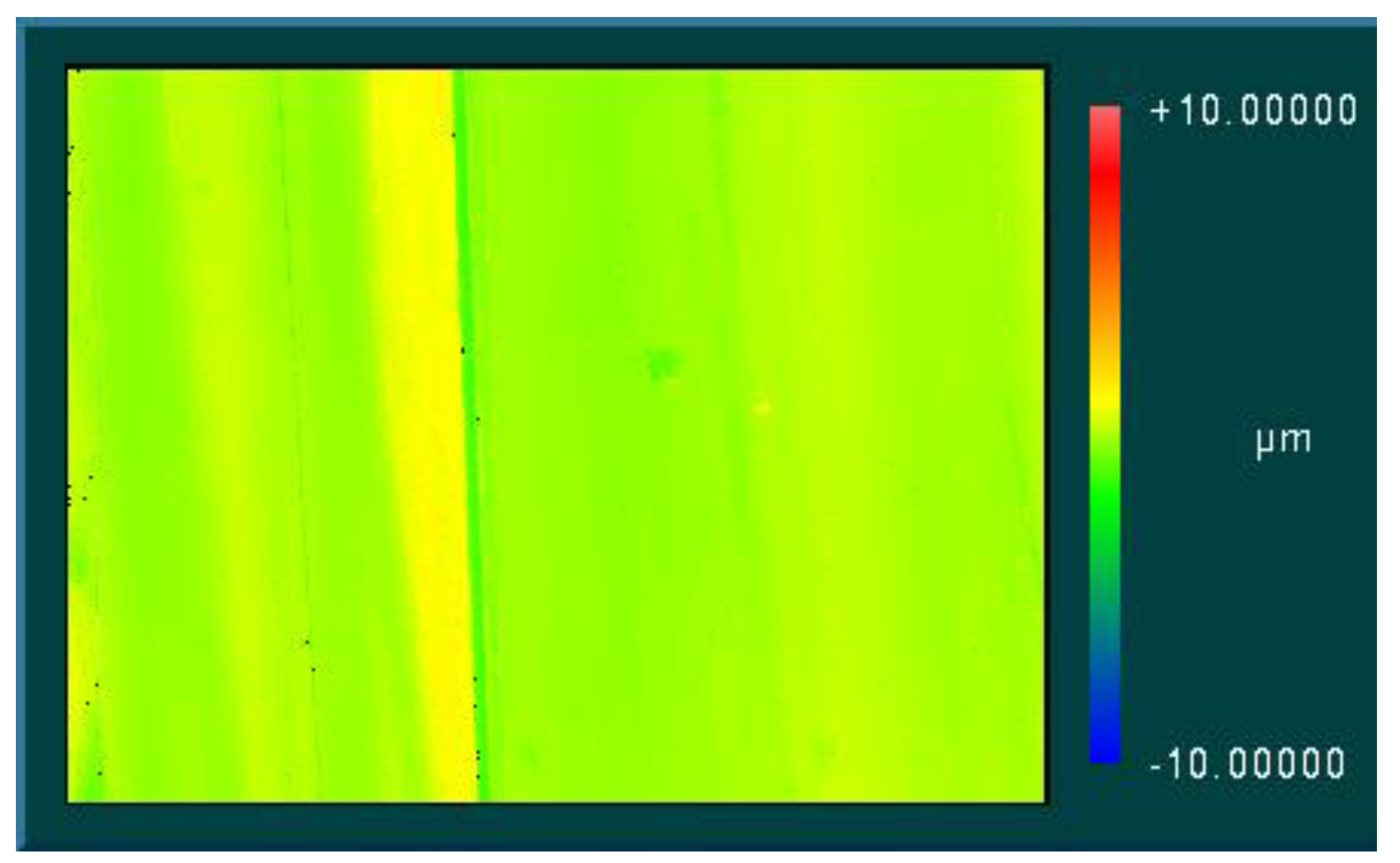

Figure 12.

Surface topography of the stainless steel counter-surface after a 0.5-h test with SustainaLube and deva.bm. Magnification: 10×.

Figure 12.

Surface topography of the stainless steel counter-surface after a 0.5-h test with SustainaLube and deva.bm. Magnification: 10×.

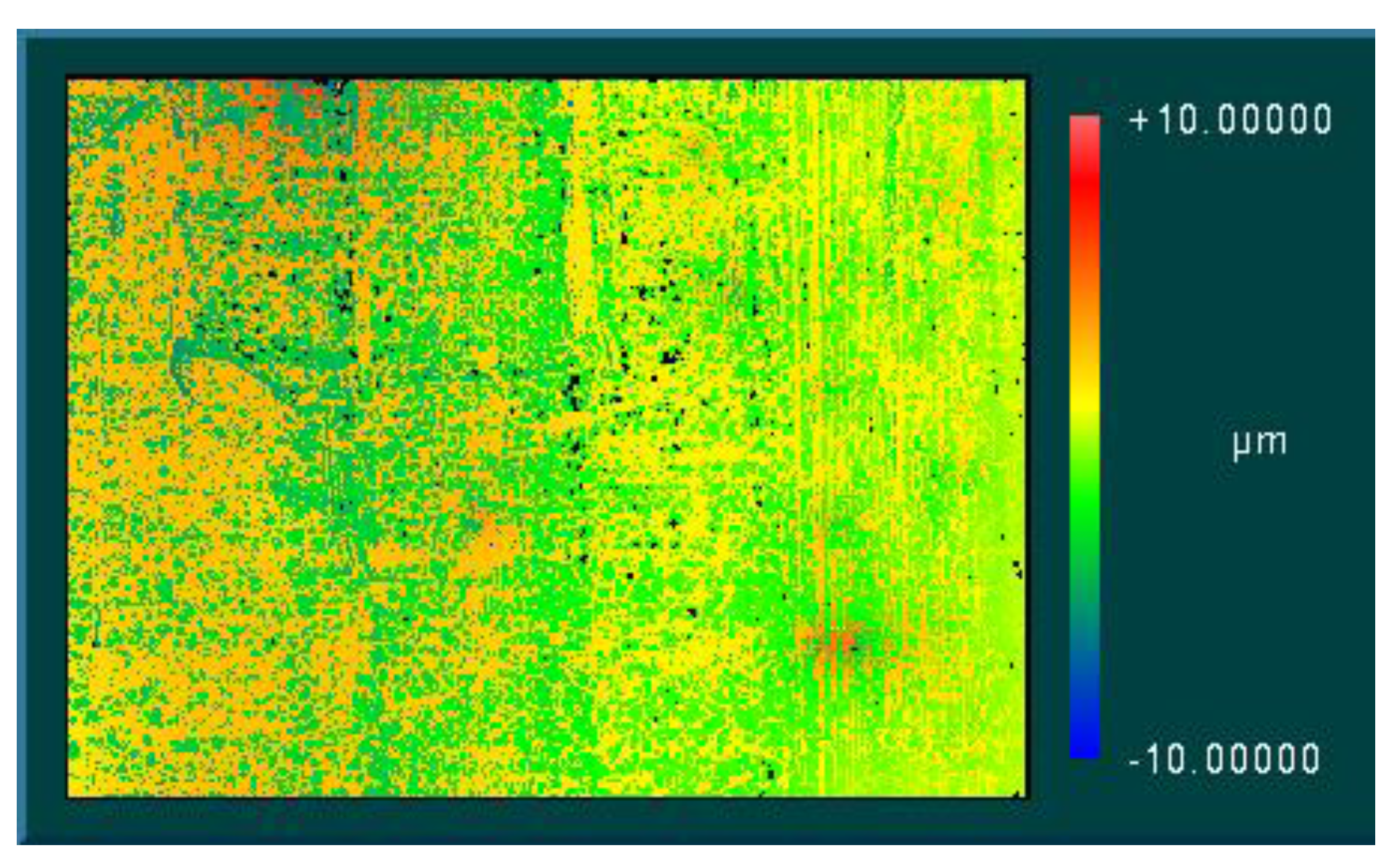

Figure 13.

Surface topography of stainless steel counter-surface after an 8-h test with SustainaLube and deva.bm. Magnification: 10×.

Figure 13.

Surface topography of stainless steel counter-surface after an 8-h test with SustainaLube and deva.bm. Magnification: 10×.

Figure 14.

SEM micrograph of stainless steel counter-surface after an 8-h test with water and Thordon Thorplas.

Figure 14.

SEM micrograph of stainless steel counter-surface after an 8-h test with water and Thordon Thorplas.

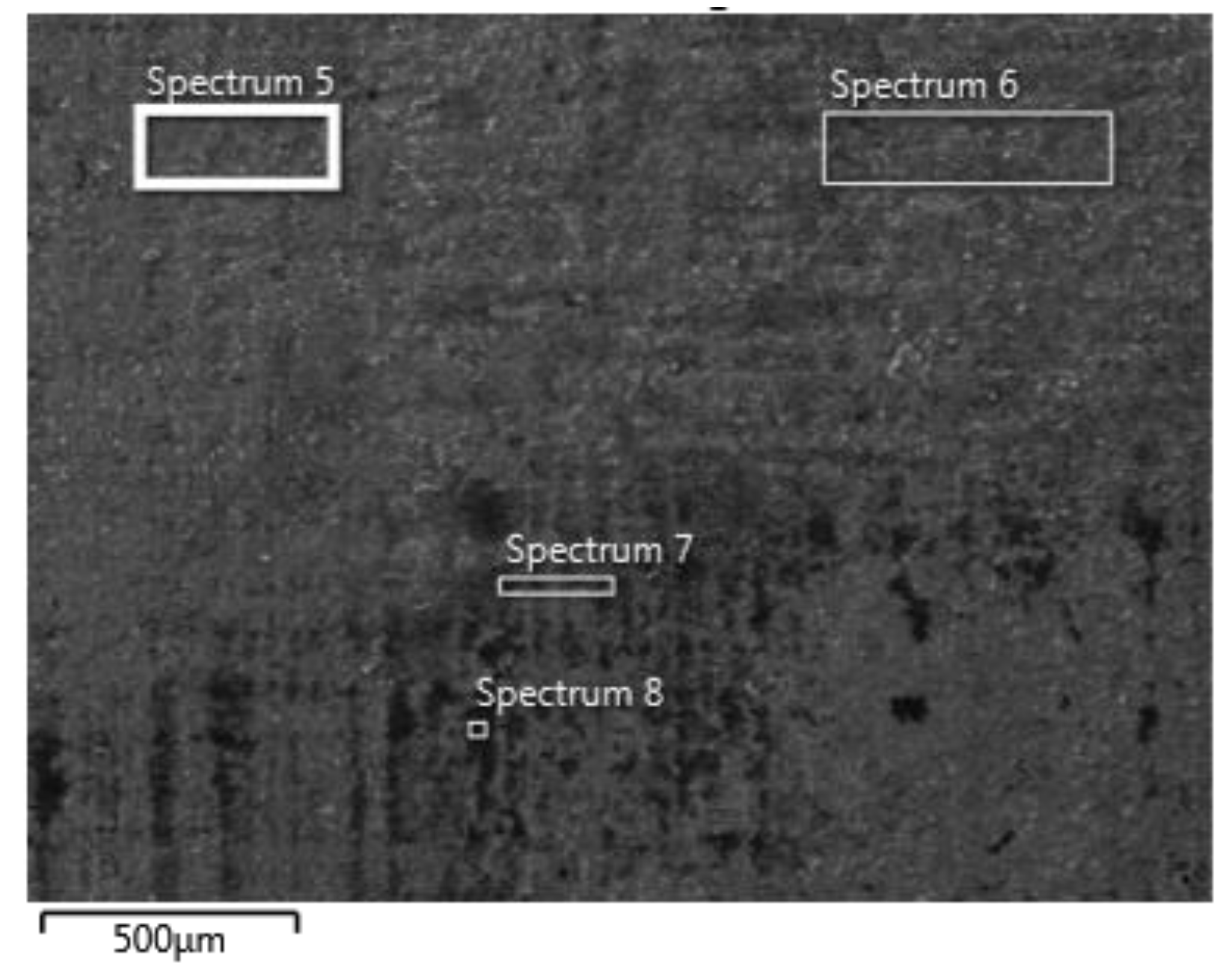

Figure 15.

SEM micrograph of the stainless steel counter-surface after an 8-h test with SustainaLube and Thordon Thorplas.

Figure 15.

SEM micrograph of the stainless steel counter-surface after an 8-h test with SustainaLube and Thordon Thorplas.

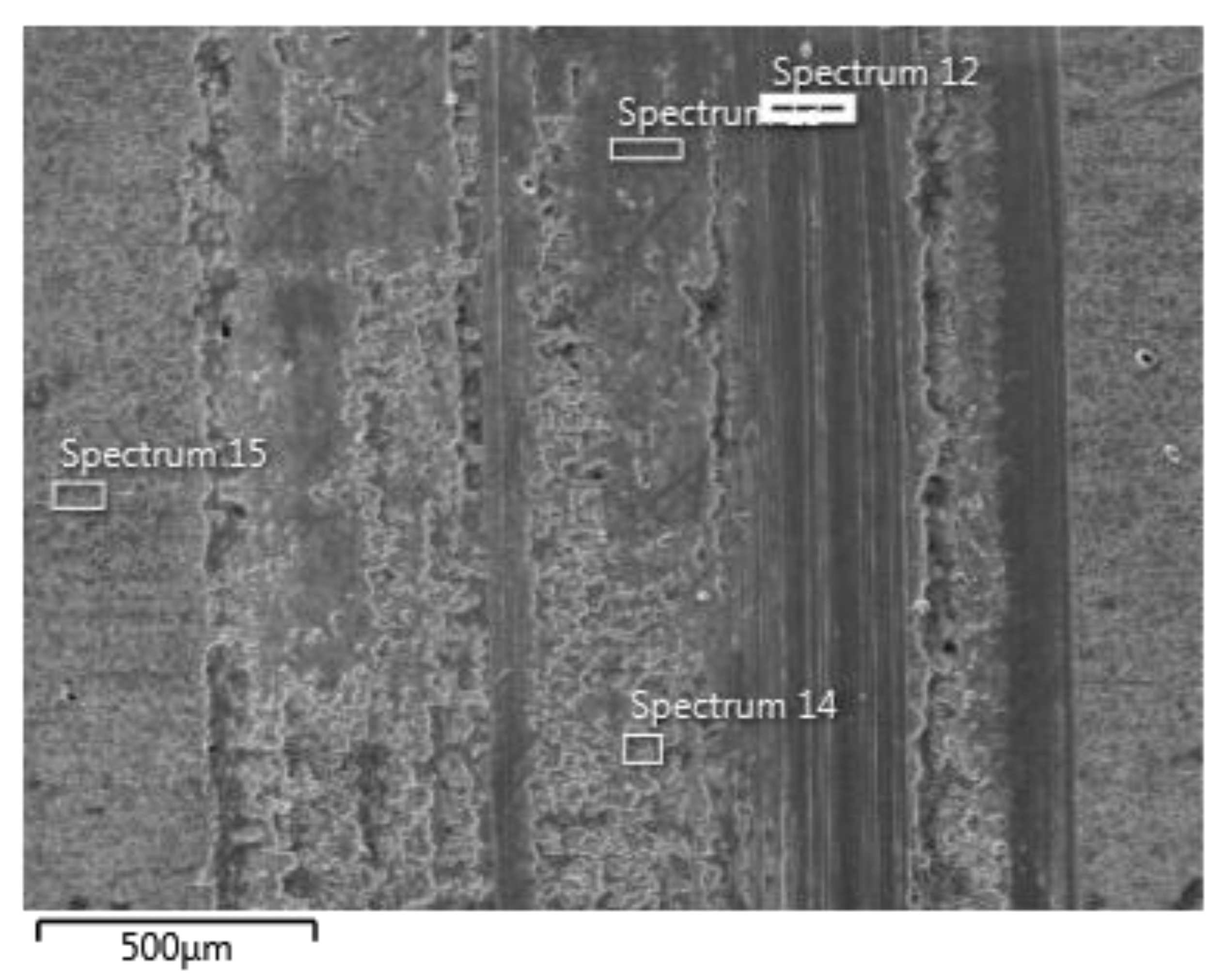

Figure 16.

SEM micrograph of the stainless steel counter-surface after a 0.5-h test with water and deva.bm.

Figure 16.

SEM micrograph of the stainless steel counter-surface after a 0.5-h test with water and deva.bm.

Figure 17.

SEM micrograph of the stainless steel counter-surface after a 0.5-h test with SustainaLube and deva.bm.

Figure 17.

SEM micrograph of the stainless steel counter-surface after a 0.5-h test with SustainaLube and deva.bm.

Figure 18.

SEM micrograph of the stainless steel counter-surface after an 8-h test with SustainaLube and deva.bm.

Figure 18.

SEM micrograph of the stainless steel counter-surface after an 8-h test with SustainaLube and deva.bm.

Table 1.

EDS spectra of the stainless steel counter-surface after an 8-h test with water and Thordon Thorplas.

Table 1.

EDS spectra of the stainless steel counter-surface after an 8-h test with water and Thordon Thorplas.

| Spectrum Number |

|---|

| 9 | 10 | 11 |

| Element | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ |

| C | 46.68 | 0.26 | C | 29.63 | 0.35 | C | 24.11 | 0.38 |

| O | 12.54 | 0.18 | O | 6.36 | 0.17 | O | 6.09 | 0.17 |

| F | 1.35 | 0.10 | Al | 0.09 | 0.03 | Al | 0.02 | 0.04 |

| Al | 0.03 | 0.02 | Si | 0.26 | 0.03 | Si | 0.32 | 0.03 |

| Si | 0.19 | 0.02 | Ti | 0.00 | 0.00 | Ti | 0.00 | 0.00 |

| Ti | 0.00 | 0.00 | V | 0.11 | 0.03 | V | 0.09 | 0.03 |

| V | 0.02 | 0.02 | Cr | 12.76 | 0.11 | Cr | 13.74 | 0.12 |

| Cr | 7.84 | 0.07 | Fe | 45.87 | 0.27 | Fe | 50.06 | 0.29 |

| Fe | 28.16 | 0.17 | Ni | 4.93 | 0.09 | Ni | 5.32 | 0.10 |

| Ni | 3.01 | 0.06 | Total | 100.00 | | Zn | 0.25 | 0.07 |

| Zn | 0.18 | 0.05 | | | | Total | 100.00 | |

Table 2.

EDS spectra of stainless steel counter-surface after an 8-h test with SustainaLube and Thordon Thorplas.

Table 2.

EDS spectra of stainless steel counter-surface after an 8-h test with SustainaLube and Thordon Thorplas.

| Spectrum Number |

|---|

| 5 | 6 | 7 | 8 |

| Element | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ |

| C | 12.40 | 0.37 | C | 15.76 | 0.38 | C | 22.88 | 0.36 | C | 37.83 | 0.29 |

| O | 14.59 | 0.18 | O | 10.54 | 0.18 | O | 7.64 | 0.17 | O | 10.16 | 0.16 |

| Na | 4.85 | 0.25 | Na | 3.40 | 0.21 | Na | 1.22 | 0.14 | Al | 0.01 | 0.02 |

| Al | 0.01 | 0.04 | Al | 0.01 | 0.04 | Al | 0.04 | 0.03 | Si | 0.22 | 0.02 |

| Si | 0.23 | 0.04 | Si | 0.29 | 0.03 | Si | 0.28 | 0.03 | Ti | 0.00 | 0.00 |

| Ti | 0.00 | 0.00 | Ti | 0.00 | 0.00 | Ti | 0.00 | 0.00 | V | 0.08 | 0.02 |

| V | 0.08 | 0.03 | V | 0.07 | 0.03 | V | 0.09 | 0.03 | Cr | 10.38 | 0.08 |

| Cr | 11.32 | 0.10 | Cr | 12.56 | 0.11 | Cr | 13.03 | 0.11 | Fe | 37.10 | 0.20 |

| Fe | 40.32 | 0.26 | Fe | 44.86 | 0.27 | Fe | 47.39 | 0.27 | Ni | 3.91 | 0.07 |

| Ni | 4.36 | 0.09 | Ni | 4.79 | 0.09 | Ni | 5.08 | 0.09 | Zn | 0.30 | 0.05 |

| Zn | 11.83 | 0.16 | Zn | 7.72 | 0.13 | Zn | 2.33 | 0.09 | Total | 100.00 | |

| Total | 100.00 | | Total | 100.00 | | Total | 100.00 | | | | |

Table 3.

EDS spectra of the stainless steel counter-surface after a 0.5-h test with water and deva.bm.

Table 3.

EDS spectra of the stainless steel counter-surface after a 0.5-h test with water and deva.bm.

| Spectrum Number |

|---|

| 12 | 13 | 14 | 15 |

| Elem. | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ |

| C | 6.39 | 0.38 | C | 8.44 | 0.39 | C | 11.38 | 0.43 | C | 11.05 | 0.41 |

| O | 0.82 | 0.15 | O | 1.13 | 0.15 | O | 11.41 | 0.20 | O | 1.47 | 0.15 |

| Al | 0.00 | 0.00 | Al | 0.04 | 0.05 | Na | 4.09 | 0.29 | Al | 0.07 | 0.05 |

| Si | 0.48 | 0.05 | Si | 0.37 | 0.05 | Al | 0.00 | 0.00 | Si | 0.39 | 0.05 |

| Ti | 0.00 | 0.00 | Ti | 0.00 | 0.00 | Si | 0.31 | 0.04 | Ti | 0.01 | 0.04 |

| V | 0.13 | 0.04 | V | 0.13 | 0.04 | Ti | 0.03 | 0.03 | V | 0.07 | 0.04 |

| Cr | 18.08 | 0.14 | Cr | 16.64 | 0.14 | V | 0.10 | 0.04 | Cr | 17.10 | 0.14 |

| Fe | 66.56 | 0.33 | Fe | 61.85 | 0.33 | Cr | 11.30 | 0.12 | Fe | 62.61 | 0.35 |

| Ni | 7.54 | 0.13 | Ni | 7.39 | 0.13 | Fe | 39.98 | 0.29 | Ni | 6.93 | 0.13 |

| Total: | 100.00 | | Cu | 4.01 | 0.12 | Ni | 4.46 | 0.10 | Zn | 0.29 | 0.09 |

| | | | Total | 100.00 | | Cu | 2.95 | 0.10 | Total | 100.00 | |

| | | | | | | Zn | 13.99 | 0.19 | | | |

| | | | | | | Total | 100.00 | | | | |

Table 4.

EDS spectra of the stainless steel counter-surface after a 0.5-h test with SustainaLube and deva.bm.

Table 4.

EDS spectra of the stainless steel counter-surface after a 0.5-h test with SustainaLube and deva.bm.

| Spectrum Number |

|---|

| 1 | 2 | 3 | 4 |

| Elem. | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ |

| C | 12.60 | 0.37 | C | 12.48 | 0.38 | C | 6.34 | 0.30 | C | 10.69 | 0.35 |

| O | 22.33 | 0.22 | O | 22.74 | 0.23 | O | 0.98 | 0.13 | O | 9.84 | 0.17 |

| Na | 5.61 | 0.31 | Na | 6.21 | 0.31 | Al | 0.24 | 0.05 | Na | 3.47 | 0.23 |

| Al | 0.12 | 0.04 | Al | 0.20 | 0.04 | Si | 0.48 | 0.04 | Al | 0.11 | 0.04 |

| Ti | 0.00 | 0.03 | Ti | 0.01 | 0.03 | Ti | 0.00 | 0.03 | Si | 0.36 | 0.04 |

| V | 0.03 | 0.03 | V | 0.05 | 0.03 | V | 0.13 | 0.04 | Ti | 0.00 | 0.00 |

| Cr | 6.97 | 0.08 | Cr | 6.32 | 0.08 | Cr | 17.91 | 0.12 | V | 0.07 | 0.03 |

| Fe | 22.84 | 0.18 | Fe | 20.95 | 0.17 | Fe | 65.71 | 0.27 | Cr | 13.14 | 0.11 |

| Ni | 2.52 | 0.07 | Ni | 2.17 | 0.07 | Ni | 7.40 | 0.11 | Fe | 47.45 | 0.27 |

| Cu | 1.45 | 0.07 | Cu | 0.99 | 0.07 | Cu | 0.80 | 0.08 | Ni | 5.16 | 0.10 |

| Zn | 25.54 | 0.22 | Zn | 27.89 | 0.23 | Total | 100.00 | | Zn | 9.71 | 0.14 |

| Total | 100.00 | | Total | 100.00 | | | | | Total | 100.00 | |

Table 5.

EDS spectra of the stainless steel counter-surface after an 8-h test with SustainaLube and deva.bm.

Table 5.

EDS spectra of the stainless steel counter-surface after an 8-h test with SustainaLube and deva.bm.

| Spectrum Number |

|---|

| 16 | 17 | 18 | 19 |

| Elem. | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ | Elem. | wt % | wt % σ |

| C | 11.45 | 0.41 | C | 9.01 | 0.40 | C | 48.66 | 0.38 | C | 40.83 | 0.32 |

| O | 1.82 | 0.16 | O | 1.42 | 0.15 | O | 13.60 | 0.28 | O | 10.51 | 0.20 |

| Al | 0.16 | 0.05 | Al | 0.16 | 0.05 | Na | 1.07 | 0.11 | Al | 0.07 | 0.03 |

| Si | 0.47 | 0.05 | Si | 0.36 | 0.05 | Al | 0.08 | 0.03 | Si | 0.22 | 0.02 |

| Ti | 0.00 | 0.00 | Ti | 0.03 | 0.04 | Si | 0.28 | 0.03 | Ti | 0.02 | 0.02 |

| V | 0.12 | 0.04 | V | 0.05 | 0.04 | S | 0.15 | 0.02 | V | 0.05 | 0.03 |

| Cr | 16.71 | 0.14 | Cr | 17.31 | 0.14 | Ca | 0.83 | 0.03 | Cr | 9.56 | 0.09 |

| Fe | 62.11 | 0.35 | Fe | 64.66 | 0.34 | Ti | 0.00 | 0.03 | Fe | 35.09 | 0.22 |

| Ni | 6.80 | 0.12 | Ni | 6.99 | 0.13 | V | 0.07 | 0.03 | Ni | 3.66 | 0.08 |

| Zn | 0.36 | 0.09 | Total | 100.00 | | Cr | 6.77 | 0.09 | Total | 100.00 | |

| Total | 100.00 | | | | | Fe | 21.57 | 0.20 | | | |

| | | | | | | Ni | 4.58 | 0.09 | | | |

| | | | | | | Zn | 2.33 | 0.09 | | | |

| | | | | | | Total | 100.00 | | | | |

Table 6.

Test conditions: Cameron-Plint machine.

Table 6.

Test conditions: Cameron-Plint machine.

| Parameter | Unit | Value |

|---|

| Frequency | Hz | 2 |

| Stroke length | mm | 5 |

| Polymer test sample dimensions | mm3 | 4 × 4 × 4 |

| Load | N | 320 |

| Surface pressure | MPa | 20 |

| Temperature | | Ambient |

Table 7.

Bearing materials used in this work.

Table 7.

Bearing materials used in this work.

| Bearing Material Trade Name | Description |

|---|

| deva.bm | Sintered bronze sliding layer with solid lubricant. |

| deva.tex | PTFE sliding layer on glass-fibre reinforced carrying layer. |

| Orkot TXM Marine | Reinforced medium weave polymer material with PTFE. |

| Thordon Thorplas | Homogeneous thermoplastic polymer material. |

Table 8.

Selected bearing material and lubricant combinations for the surface analysis.

Table 8.

Selected bearing material and lubricant combinations for the surface analysis.

| Bearing Material | Lubricant | Time |

|---|

| Thordon Thorplas | Water | 8 h |

| Thordon Thorplas | SustainaLube | 8 h |

| deva.bm | Water | 0.5 h |

| deva.bm | SustainaLube | 0.5 h |

| deva.bm | SustainaLube | 8 h |