Influence of Different Light-Emitting Diode Colors on Growth and Phycobiliprotein Generation of Arthrospira platensis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microalgae Strain and Growth Medium

2.2. Experimental Design

2.3. Determination of Arthrospira Platensis Dry Weight

2.4. Preparation of Arthrospira Platensis Extracts for Pigment Measurements

2.5. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kovda, V.A.; Glantz, M.H. (Eds.) Desertification: Environmental Degradation in and around Arid Lands, 1st ed.; CRC Press: New York, NY, USA, 2019; ISBN 978-0-429-05089-3. [Google Scholar]

- Smith, P.; Calvin, K.; Nkem, J.; Campbell, D.; Cherubini, F.; Grassi, G.; Korotkov, V.; Le Hoang, A.; Lwasa, S.; McElwee, P.; et al. Which Practices Co-deliver Food Security, Climate Change Mitigation and Adaptation, and Combat Land Degradation and Desertification? Glob. Chang. Biol. 2020, 26, 1532–1575. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Henchion, M.; Hayes, M.; Mullen, A.; Fenelon, M.; Tiwari, B. Future Protein Supply and Demand: Strategies and Factors Influencing a Sustainable Equilibrium. Foods 2017, 6, 53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Myers, R.A.; Hutchings, J.A.; Barrowman, N.J. Why Do Fish Stocks Collapse? The Example of Cod in Atlantic Canada. Ecol. Appl. 1997, 7, 91–106. [Google Scholar] [CrossRef]

- Muehe, E.M.; Wang, T.; Kerl, C.F.; Planer-Friedrich, B.; Fendorf, S. Rice Production Threatened by Coupled Stresses of Climate and Soil Arsenic. Nat. Commun. 2019, 10, 4985. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- López, J.; Way, D.A.; Sadok, W. Systemic Effects of Rising Atmospheric Vapor Pressure Deficit on Plant Physiology and Productivity. Glob. Chang. Biol. 2021, 27, 1704–1720. [Google Scholar] [CrossRef]

- Muller, A.; Schader, C.; El-Hage Scialabba, N.; Brüggemann, J.; Isensee, A.; Erb, K.-H.; Smith, P.; Klocke, P.; Leiber, F.; Stolze, M.; et al. Strategies for Feeding the World More Sustainably with Organic Agriculture. Nat. Commun. 2017, 8, 1290. [Google Scholar] [CrossRef] [Green Version]

- Berend, J.; Simovitch, E.; Ollian, A. Economic Aspects of Algal Animal Food Production. In Algae Biomass: Production and Use; Shelef, G., Soeder, C.J., Eds.; Sponsored by the National Council for Research and Development, Israel and the Gesellschaft fur Strahlen-und Umweltforschung (GSF), Munich, Germany; Elsevier/North-Holland Biomedical Press: Amsterdam, The Netherlands, 1980. [Google Scholar]

- Richmond, A.; Preiss, K. The Biotechnology of Algaculture. Interdiscip. Sci. Rev. 1980, 5, 60–70. [Google Scholar] [CrossRef]

- Durand-Chastel, H. Production and Use of Spirulina in Mexico. In Algae Biomass: Production and Use; Shelef, G., Soeder, C.J., Eds.; Sponsored by the National Council for Research and Development, Israel and the Gesellschaft fur Strahlen-und Umweltforschung (GSF), Munich, Germany; Elsevier/North-Holland Biomedical Press: Amsterdam, The Netherlands, 1980. [Google Scholar]

- Weigel, I.; Gensberger-Reigl, S. Proteine Nicht Tierischer Herkunft als Fleischersatz-eine Aktuelle Literaturübersicht; Friedrich-Alexander University Erlangen-Nürnberg: Nürnberg, Germany, 2017; p. 28. [Google Scholar]

- Mekonnen, M.M.; Hoekstra, A.Y. A Global Assessment of the Water Footprint of Farm Animal Products. Ecosystems 2012, 15, 401–415. [Google Scholar] [CrossRef] [Green Version]

- Mekonnen, M.M.; Hoekstra, A.Y. The Green, Blue and Grey Water Footprint of Crops and Derived Crop Products. Hydrol. Earth Syst. Sci. 2011, 15, 1577–1600. [Google Scholar] [CrossRef] [Green Version]

- Piccolo, A. Spirulina—A Livelihood and a Business Venture. Implementation of a Regional Fisheries Strategy for the Eastern-Southern Africa and India Ocean Region; REPORT: SF/2012/16; Smart Fish Programme 43; European Union: Luxembourg, 2012. [Google Scholar]

- Chacón-Lee, T.L.; González-Mariño, G.E. Microalgae for “Healthy” Foods-Possibilities and Challenges. Compr. Rev. Food Sci. Food Saf. 2010, 9, 655–675. [Google Scholar] [CrossRef]

- Jung, F.; Krüger-Genge, A.; Waldeck, P.; Küpper, J.-H. Spirulina platensis, a Super Food? JCB 2019, 5, 43–54. [Google Scholar] [CrossRef]

- FAO; World Health Organization (Eds.) Protein Quality Evaluation: Report of the Joint FAO/WHO Expert Consultation, Bethesda, MD, USA, 4–8 December 1989; FAO Food and Nutrition Paper; Food and Agriculture Organization of the United Nations: Rome, Italy, 1991; ISBN 978-92-5-103097-4. [Google Scholar]

- Michalak, I.; Chojnacka, K. Algae as Production Systems of Bioactive Compounds. Eng. Life Sci. 2015, 15, 160–176. [Google Scholar] [CrossRef]

- Galasso, C.; Gentile, A.; Orefice, I.; Ianora, A.; Bruno, A.; Noonan, D.M.; Sansone, C.; Albini, A.; Brunet, C. Microalgal Derivatives as Potential Nutraceutical and Food Supplements for Human Health: A Focus on Cancer Prevention and Interception. Nutrients 2019, 11, 1226. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ramos-Romero, S.; Torrella, J.R.; Pagès, T.; Viscor, G.; Torres, J.L. Edible Microalgae and Their Bioactive Compounds in the Prevention and Treatment of Metabolic Alterations. Nutrients 2021, 13, 563. [Google Scholar] [CrossRef] [PubMed]

- McCarty, M.F.; Iloki Assanga, S.B.; Lewis Luján, L.; O’Keefe, J.H.; DiNicolantonio, J.J. Nutraceutical Strategies for Suppressing NLRP3 Inflammasome Activation: Pertinence to the Management of COVID-19 and Beyond. Nutrients 2020, 13, 47. [Google Scholar] [CrossRef]

- Braune, S.; Krüger-Genge, A.; Kammerer, S.; Jung, F.; Küpper, J.-H. Phycocyanin from Arthrospira platensis as Potential Anti-Cancer Drug: Review of in Vitro and in Vivo Studies. Life 2021, 11, 91. [Google Scholar] [CrossRef]

- Cho, J.A.; Baek, S.Y.; Cheong, S.H.; Kim, M.R. Spirulina Enhances Bone Modeling in Growing Male Rats by Regulating Growth-Related Hormones. Nutrients 2020, 12, 1187. [Google Scholar] [CrossRef]

- Santos, H.O.; Price, J.C.; Bueno, A.A. Beyond Fish Oil Supplementation: The Effects of Alternative Plant Sources of Omega-3 Polyunsaturated Fatty Acids upon Lipid Indexes and Cardiometabolic Biomarkers—An Overview. Nutrients 2020, 12, 3159. [Google Scholar] [CrossRef]

- Krüger-Genge, A.; Steinbrecht, S.; Jung, C.G.H.; Westphal, S.; Klöpzig, S.; Waldeck, P.; Küpper, J.-H.; Storsberg, J.; Jung, F. Arthrospira platensis Accelerates the Formation of an Endothelial Cell Monolayer and Protects against Endothelial Cell Detachment after Bacterial Contamination. Clin. Hemorheol. Microcirc. 2021, 78, 151–161. [Google Scholar] [CrossRef]

- Blanken, W.; Cuaresma, M.; Wijffels, R.H.; Janssen, M. Cultivation of Microalgae on Artificial Light Comes at a Cost. Algal Res. 2013, 2, 333–340. [Google Scholar] [CrossRef]

- Wang, S.-K.; Stiles, A.R.; Guo, C.; Liu, C.-Z. Microalgae Cultivation in Photobioreactors: An Overview of Light Characteristics. Eng. Life Sci. 2014, 14, 550–559. [Google Scholar] [CrossRef] [Green Version]

- Jung, C.H.G.; Braune, S.; Waldeck, P.; Küpper, J.-H.; Petrick, I.; Jung, F. Morphology and Growth of Arthrospira platensis during Cultivation in a Flat-Type Bioreactor. Life 2021, 11, 536. [Google Scholar] [CrossRef] [PubMed]

- Jung, F.; Jung, C.G.H.; Krüger-Genge, A.; Waldeck, P.; Küpper, J.-H. Factors Influencing the Growth of Spirulina platensis in Closed Photobioreactors under CO2–O2 Conversion. JCB 2019, 5, 125–134. [Google Scholar] [CrossRef]

- Furmaniak, M.A.; Misztak, A.E.; Franczuk, M.D.; Wilmotte, A.; Waleron, M.; Waleron, K.F. Edible Cyanobacterial Genus Arthrospira: Actual State of the Art in Cultivation Methods, Genetics, and Application in Medicine. Front. Microbiol. 2017, 8, 2541. [Google Scholar] [CrossRef] [PubMed]

- Chanquia, S.N.; Vernet, G.; Kara, S. Photobioreactors for Cultivation and Synthesis: Specifications, Challenges, and Perspectives. Eng. Life Sci. 2021. [Google Scholar] [CrossRef]

- Lüning, K. Critical Levels of Light and Temperature Regulating the Gametogenesis of Three Laminaria Species (Phaeophyceae). J. Phycol. 1980, 16, 1–15. [Google Scholar] [CrossRef]

- Hurd, C.L.; Harrison, P.J.; Bischof, K.; Lobban, C.S. Seaweed Ecology and Physiology; Cambridge University Press: Cambridge, UK, 2014; ISBN 978-1-139-95201-9. [Google Scholar]

- Chen, H.-B.; Wu, J.-Y.; Wang, C.-F.; Fu, C.-C.; Shieh, C.-J.; Chen, C.-I.; Wang, C.-Y.; Liu, Y.-C. Modeling on Chlorophyll a and Phycocyanin Production by Spirulina platensis under Various Light-Emitting Diodes. Biochem. Eng. J. 2010, 53, 52–56. [Google Scholar] [CrossRef]

- Ho, S.-H.; Liao, J.-F.; Chen, C.-Y.; Chang, J.-S. Combining Light Strategies with Recycled Medium to Enhance the Economic Feasibility of Phycocyanin Production with Spirulina platensis. Bioresour. Technol. 2018, 247, 669–675. [Google Scholar] [CrossRef] [PubMed]

- Madhyastha, H.K.; Vatsala, T.M. Pigment Production in Spirulina Fussiformis in Different Photophysical Conditions. Biomol. Eng. 2007, 24, 301–305. [Google Scholar] [CrossRef]

- Prates, D.d.F.; Radmann, E.M.; Duarte, J.H.; de Morais, M.G.; Costa, J.A.V. Spirulina Cultivated under Different Light Emitting Diodes: Enhanced Cell Growth and Phycocyanin Production. Bioresour. Technol. 2018, 256, 38–43. [Google Scholar] [CrossRef] [PubMed]

- Ravelonandro, P.H.; Ratianarivo, D.H.; Joannis-Cassan, C.; Isambert, A.; Raherimandimby, M. Influence of Light Quality and Intensity in the Cultivation of Spirulina platensis from Toliara (Madagascar) in a Closed System. J. Chem. Technol. Biotechnol. 2008, 83, 842–848. [Google Scholar] [CrossRef]

- Kula, M.; Rys, M.; Saja, D.; Tys, J.; Skoczowski, A. Far-Red Dependent Changes in the Chemical Composition of Spirulina platensis. Eng. Life Sci. 2016, 16, 777–785. [Google Scholar] [CrossRef]

- Zarrouk, C. Contribution a l’etude d’une Cianophycee: Influence de Divers Facteurs Physiques et Chimiques Sur La Croissance et La Photosynthese de Spirulina Maxima (Setch. et Garndner) Geitler. Ph.D. Thesis, Faculté des Sciences, Universite de Paris, Paris, France, 1966. [Google Scholar]

- Bennett, A.; Bogorad, L. Complementary Chromatic Adaptation in a Filamentous Blue-Green Alga. J. Cell Biol. 1973, 58, 419–435. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, A.P.; Silva, S.O.; Baptista, J.M.; Malcata, F.X. Light Requirements in Microalgal Photobioreactors: An Overview of Biophotonic Aspects. Appl. Microbiol. Biotechnol. 2011, 89, 1275–1288. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Yeh, K.-L.; Aisyah, R.; Lee, D.-J.; Chang, J.-S. Cultivation, Photobioreactor Design and Harvesting of Microalgae for Biodiesel Production: A Critical Review. Bioresour. Technol. 2011, 102, 71–81. [Google Scholar] [CrossRef]

- Chang, M.-H.; Das, D.; Varde, P.V.; Pecht, M. Light Emitting Diodes Reliability Review. Microelectron. Reliab. 2012, 52, 762–782. [Google Scholar] [CrossRef]

- Beale, S.I. Biosynthesis of Phycobilins. Chem. Rev. 1993, 93, 785–802. [Google Scholar] [CrossRef]

- Básaca-Loya, G.; Valdez, M.A.; Enríquez-Guevara, E.; Gutiérrez-Millán, L.E.; Encinas, L.; Rosales, S. Extraction and Purification of B-Phycoerythrin from the Red Microalga Rhodosorus Marinus Extracción y Purificación de B-Ficoeritrina de La Microalga Roja Rhodosorus Marinus. Cienc. Mar. 2009, 35, 359–368. [Google Scholar] [CrossRef] [Green Version]

- Bermejo Román, R.; Alvárez-Pez, J.M.; Acién Fernández, F.G.; Molina Grima, E. Recovery of Pure B-Phycoerythrin from the Microalga Porphyridium Cruentum. J. Biotechnol. 2002, 93, 73–85. [Google Scholar] [CrossRef]

- Hohmann-Marriott, M.F.; Blankenship, R.E. Evolution of Photosynthesis. Annu. Rev. Plant Biol. 2011, 62, 515–548. [Google Scholar] [CrossRef] [Green Version]

- Markou, G. Effect of Various Colors of Light-Emitting Diodes (LEDs) on the Biomass Composition of Arthrospira platensis Cultivated in Semi-Continuous Mode. Appl. Biochem. Biotechnol. 2014, 172, 2758–2768. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-Y.; Fu, C.-C.; Liu, Y.-C. Effects of Using Light-Emitting Diodes on the Cultivation of Spirulina platensis. Biochem. Eng. J. 2007, 37, 21–25. [Google Scholar] [CrossRef]

- Milia, M.; Corrias, F.; Addis, P.; Chini Zitelli, G.; Cicchi, B.; Torzillo, G.; Andreotti, V.; Angioni, A. Influence of Different Light Sources on the Biochemical Composition of Arthrospira spp. Grown in Model Systems. Foods 2022, 11, 399. [Google Scholar] [CrossRef] [PubMed]

- Tayebati, H.; Pajoum Shariati, F.; Soltani, N.; Sepasi Tehrani, H. Effect of Various Light Spectra on Amino Acids and Pigment Production of Arthrospira platensis Using Flat-Plate Photobioreactor. Prep. Biochem. Biotechnol. 2021, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Dinh, T.B. Contrasting Effects of Monochromatic LED Lighting on Growth, Pigments and Photosynthesis in the Commercially Important Cyanobacterium Arthrospira Maxima. Bioresour. Technol. 2019, 291, 121846. [Google Scholar] [CrossRef] [PubMed]

- Niangoran, U.; Tian, F.; Canale, L.; Haba, C.T.; Buso, D.; Zissis, G. Study of the LEDs Spectrums Influence on the Spirulina platensis Growth in Batch Culture. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–4. [Google Scholar]

- Chainapong, T.; Traichaiyaporn, S.; Deming, R.L. Effect of Light Quality on Biomass and Pigment Production in Photoautotrophic and Mixotrophic Cultures of Spirulina platensis. J. Agric. Technol. 2012, 8, 1593–1604. [Google Scholar]

- Bahman, M.; Aghanoori, M.; Jalili, H.; Bozorg, A.; Danaee, S.; Bidhendi, M.E.; Amrane, A. Effect of Light Intensity and Wavelength on Nitrogen and Phosphate Removal from Municipal Wastewater by Microalgae under Semi-Batch Cultivation. Environ. Technol. 2022, 43, 1352–1358. [Google Scholar] [CrossRef]

- Figueroa, F.L.; Aguilera, J.; Niell, F.X. Red and Blue Light Regulation of Growth and Photosynthetic Metabolism in Porphyra Umbilicalis (Bangiales, Rhodophyta). Eur. J. Phycol. 1995, 30, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Szwarc, D.; Szwarc, K.; Zieliński, M. Effect of Light Spectrum on the Phycocyanin Production by Arthrospira platensis. Pol. J. Nat. Sci. 2020, 35, 209–218. [Google Scholar]

- Boussiba, S.; Richmond, A.E. C-Phycocyanin as a Storage Protein in the Blue-Green Alga Spirulina platensis. Arch. Microbiol. 1980, 125, 143–147. [Google Scholar] [CrossRef]

- Lönneborg, A.; Lind, L.K.; Kalla, S.R.; Gustafsson, P.; Öquist, G. Acclimation Processes in the Light-Harvesting System of the Cyanobacterium Anacystis Nidulans Following a Light Shift from White to Red Light. Plant Physiol. 1985, 78, 110–114. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tandeau de Marsac, N. Occurrence and Nature of Chromatic Adaptation in Cyanobacteria. J. Bacteriol. 1977, 130, 82–91. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akimoto, S.; Yokono, M.; Hamada, F.; Teshigahara, A.; Aikawa, S.; Kondo, A. Adaptation of Light-Harvesting Systems of Arthrospira platensis to Light Conditions, Probed by Time-Resolved Fluorescence Spectroscopy. Biochim. Biophys. Acta (BBA)-Bioenerg. 2012, 1817, 1483–1489. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ogawa, T. Growth Kinetics of Spirulina platensis in Autotrophic and Mixotrophic Cultures. Proc. IV IFS Ferment. Technol. Today 1972, 50, 543–549. [Google Scholar]

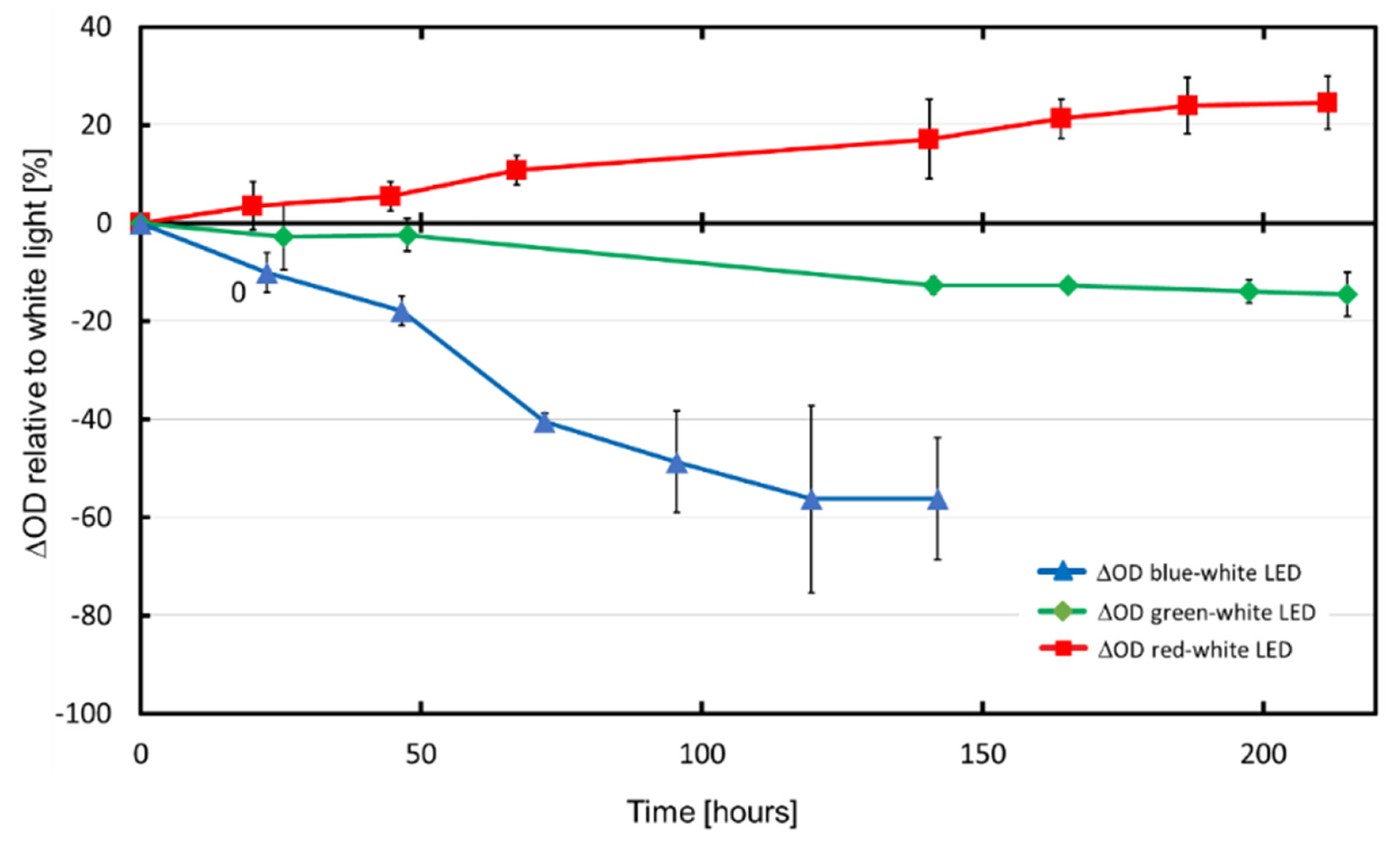

| A. | Dry Weight [g/L] | ||

|---|---|---|---|

| LED Color | Experiment 1 | Experiment 2 | Experiment 3 |

| White | 0.38 ± 0.02 | 0.33 ± 0.03 | 0.41 ± 0.02 |

| Blue | 0.21 ± 0.08 | ||

| Green | 0.29 ± 0.05 | ||

| Red | 0.52 ± 0.06 | ||

| B. | Differences of Pigment Concentrations [%] | ||

| LED color | Phycocyanin (PC) | Allophycocyanin (APC) | Phycoerythrin (PE) |

| Δ Blue-White | +15.73 p < 0.001 | −0.675 ns | +14.72 p < 0.001 |

| Δ Green-White | −8.53 p < 0.001 | +0.92 ns | +3.51 ns |

| Δ Red-White | −6.97 p < 0.001 | −1.63 ns | −2.44 ns |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, C.H.G.; Waldeck, P.; Sykora, S.; Braune, S.; Petrick, I.; Küpper, J.-H.; Jung, F. Influence of Different Light-Emitting Diode Colors on Growth and Phycobiliprotein Generation of Arthrospira platensis. Life 2022, 12, 895. https://doi.org/10.3390/life12060895

Jung CHG, Waldeck P, Sykora S, Braune S, Petrick I, Küpper J-H, Jung F. Influence of Different Light-Emitting Diode Colors on Growth and Phycobiliprotein Generation of Arthrospira platensis. Life. 2022; 12(6):895. https://doi.org/10.3390/life12060895

Chicago/Turabian StyleJung, Conrad H. G., Peter Waldeck, Shadi Sykora, Steffen Braune, Ingolf Petrick, Jan-Heiner Küpper, and Friedrich Jung. 2022. "Influence of Different Light-Emitting Diode Colors on Growth and Phycobiliprotein Generation of Arthrospira platensis" Life 12, no. 6: 895. https://doi.org/10.3390/life12060895