3. Research Methods and Experimental Design

The goal of the experiment described in this article was to test the hypothesis that image processing could be utilized to characterize differences in 3D printed objects. To this end, a system for imaging objects during the printing process was required. An experimental setup was created using a MakerBot Replicator 2 3D printer and five camera units. The camera units were comprised of a Raspberry Pi and Raspberry Pi camera and were networked using Ethernet cable and a switch to a central server which triggered imaging. These cameras were configured and controlled in the same manner as used for the larger-size 3D scanner described in [

24].

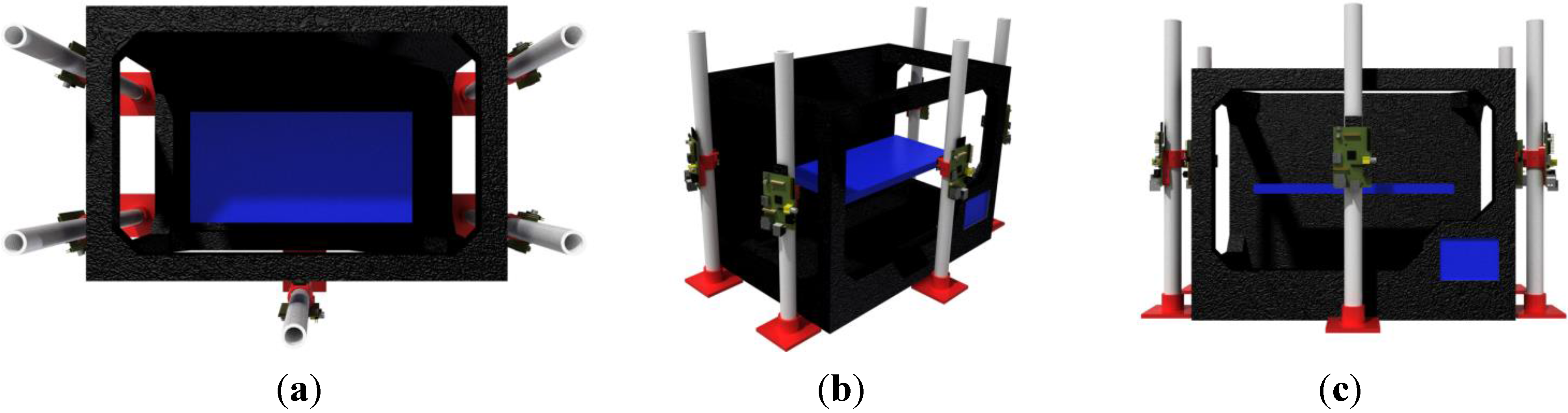

The cameras were positioned around the 3D printer, as shown in

Figure 1 and placed on stands comprised of a 3D printed base and a polyvinyl chloride (PVC) pipe. These stands were affixed to the table utilizing double-sided tape. Three different views of a CAD model depicting the stands, printer and their relative placement are presented in

Figure 1a–c.

Figure 1.

CAD renderings of system from (a) top; (b) side-angle and (c) front.

Figure 1.

CAD renderings of system from (a) top; (b) side-angle and (c) front.

An Ethernet cable and power cable were run to each camera. The power cables were connected to a variable DC power supply (shown in the far left of

Figure 2). The Ethernet cables were connected to a server via a switch. Imaging is triggered from the server’s console, avoiding the inadvertent imaging of researchers.

Figure 2.

Image of experimental setup.

Figure 2.

Image of experimental setup.

To facilitate comparison, it was desirable to have the images taken at a single 3D printer configuration. This would reduce the level of irrelevant data in the image from non-printed-object changes (in a system taking images continuously and not at a rest position, position changes as well as operating vibration would introduce discrepancies that would need to be corrected for). Data was collected by stopping the printing process at numerous points and placing the printer in sleep mode, which moved the printing plate to a common position. It was believed that this was the same position as the printer returns to when a job is complete; unfortunately, this was found to be inaccurate (as this final position is a slightly lower level. For this reason, the image that was supposed to serve as the final in-process image (in which the structure is very nearly done) has been used as the target object for comparison purposes. Image data from eight positions from each of five angles (for a total of 40 images) was thus collected and analyzed using custom-developed software created using C# and the Dot Net Framework for comparing images and generating the results presented in the subsequent section.

It is important to note that no action was taken to exclude factors, which could introduce noise into the data. For example, panels could have been installed around the scanner or another method for blocking changes outside of the scanner could have been implemented. Modifications could also have been made to aspects of the scanner itself (such as covering logos) to make it more consistent (and less likely to cause confusion with the orange colored filament); however, in both cases, this would have impaired the assessment of the operation of this approach in real world conditions.

4. Data Collected

Data analysis involved a comparison of the in-process object to the final object. Note that, in addition to the obvious application of characterizing build progress, this comparison could prospectively detect two types of potential error: when a build has been stopped mid-progress resulting in an incomplete object and when an issue with the printer results in a failure to dispense or deposit filament.

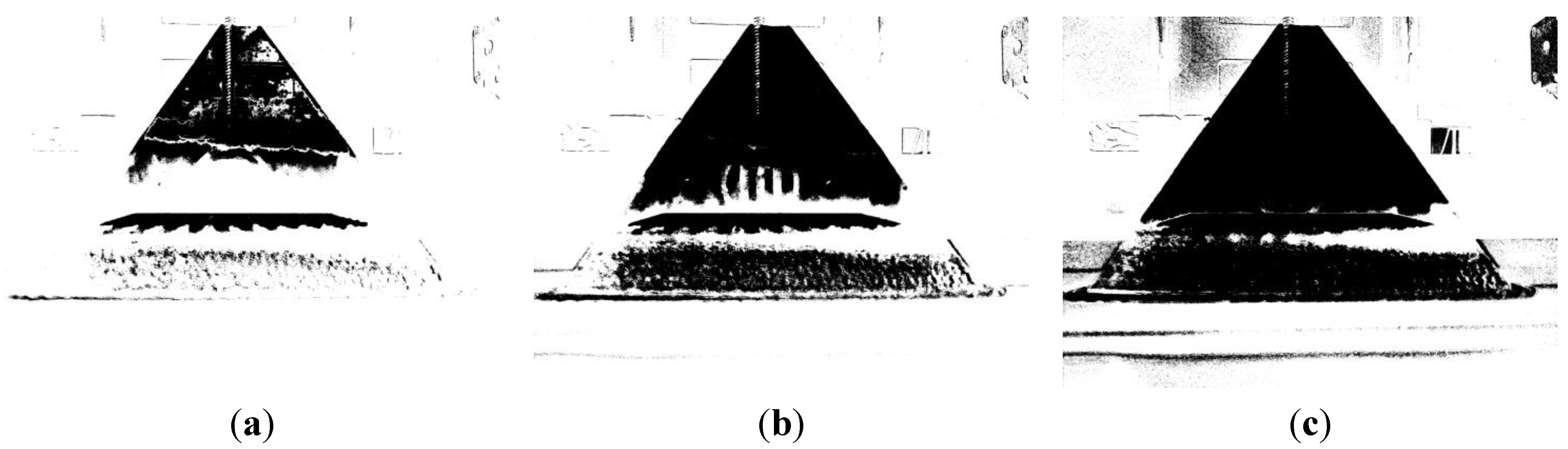

Figure 3a shows the image (for the front camera position) that was used as the complete object and

Figure 3b shows partial object from the first progress step.

The final and in-progress images are next compared on a pixel-by-pixel basis. The result of this comparison is the identification of differences between the two images.

Figure 4c characterizes the level of difference in the image: brighter areas represent the greatest levels of difference. This image is created by placing, for each pixel, a brightness value (the same red, green and blue values), which correspond to a scaled level of difference. The scale factor is calculated via:

MaxDifference is the maximum level of the summed difference of the red, green and blue values for any single pixel anywhere in the image. This is determined, for the pixel at position x = i, y = j, by calculating this summed difference:

where MaxDifference is the largest value of Difference

i,j recorded for any position. Using this, the brightness value for the pixel at position x = i, y = j is computed using:

As is clear from

Figure 3c, not all difference levels are salient. Areas outside of the pyramid area are not completely black (as they would be if there was absolutely no difference), but should not be considered. Thus, a threshold is utilized to determine salient levels of difference from presumably immaterial ones. Pixels exceeding this difference threshold are evaluated; those failing to exceed this value are ignored. Given the importance of this value, several prospective values were evaluated for this application.

Figure 3d–f show the pixels included at threshold levels of 50, 75 and 100. In these images, the black areas are the significant ones and white areas are ignored.

Figure 3.

Examination of various threshold levels: (a) complete object; (b) partially printed object; (c) showing difference between partial and complete object; (d) threshold of 50; (e) threshold of 75; (f) threshold of 100.

Figure 3.

Examination of various threshold levels: (a) complete object; (b) partially printed object; (c) showing difference between partial and complete object; (d) threshold of 50; (e) threshold of 75; (f) threshold of 100.

In this particular example, a threshold level of 50 incorrectly selects the base of the object (which is the same as the final object) as different. The 75 threshold level correctly characterizes this base as the same, while (perhaps) detecting a slight pulling away of the object from the build plate (the indicated-significant area on the bottom left). It also (incorrectly) identifies a small area in the middle of the in-progress object and (correctly) the visible lattice from construction. A clear demarcation between the remainder of the object that hasn’t yet printed and the already printed area is also clear. The 100 threshold (incorrectly) ignores a small bottom area of this region. The MakerBot logo is not identified as a different, given the closeness of its red color to the orange filament.

Given the results of this experiment, the 75 difference threshold level was selected for use going forward. This was applied to all of the images from all five cameras and eight progress levels. In

Figure 5, the processing of the progress level 1 image for all five camera positions is shown. The leftmost column shows the finished object. The second column shows the current progress of printing of this object. The third and fourth columns characterize the areas of greatest difference (brightest white) from areas of less significant (darker) difference and the identification of pixels exceeding the difference threshold, respectively.

Figure 4.

Images from all angles (at a 75 threshold level). The first column is the finished object image, the second column is the partial (stage 1) object. The third and fourth columns depict the partial-complete difference comparison and threshold-exceeding pixels identification.

Figure 4.

Images from all angles (at a 75 threshold level). The first column is the finished object image, the second column is the partial (stage 1) object. The third and fourth columns depict the partial-complete difference comparison and threshold-exceeding pixels identification.

The impact of excluding the consideration of certain colors was, next considered.

Figure 6 shows the impact of excluding the blue, green and red channels.

Figure 5a shows the exclusion of blue and

Figure 5b shows the exclusion of green. Neither exclusion corrects the MakerBot logo issue (though the blue exclusion creates greater difference levels around two indentations to either side of it). Excluding red has a significant impact on MakerBot logo; however, it places many different pixels below the significant pixel detection threshold.

Given that the total difference is a summed and not an averaged value, it makes sense to adjust the threshold when part of the difference level is excluded.

Figure 7 shows the impact of manipulating the threshold value.

Figure 6a shows a threshold value of 75, while

Figure 6b,c show the impact of threshold values of 62 and 50, respectively.

Figure 5.

Depicting the impact of excluding (a) blue; (b) green; and (c) red from the difference assessment. The top row depicts the partial-complete object difference and the bottom depicts the threshold-exceeding areas (using a 75 threshold level).

Figure 5.

Depicting the impact of excluding (a) blue; (b) green; and (c) red from the difference assessment. The top row depicts the partial-complete object difference and the bottom depicts the threshold-exceeding areas (using a 75 threshold level).

Figure 6.

Impact of excluding red at threshold levels of (a) 75; (b) 62; and (c) 50.

Figure 6.

Impact of excluding red at threshold levels of (a) 75; (b) 62; and (c) 50.

As the MakerBot logo issue could be easily corrected via applying tape or paint over the logo (or through explicit pre-processing of the images), this was not considered further (and color exclusion is not used in subsequent experimentation, herein). However, it has been included in the discussion to demonstrate the efficacy of the technique for dealing with erroneously classified pixels. Additional manipulation of the threshold level (as well as a more specific color exclusion/inclusion approach) could potentially be useful in many applications.

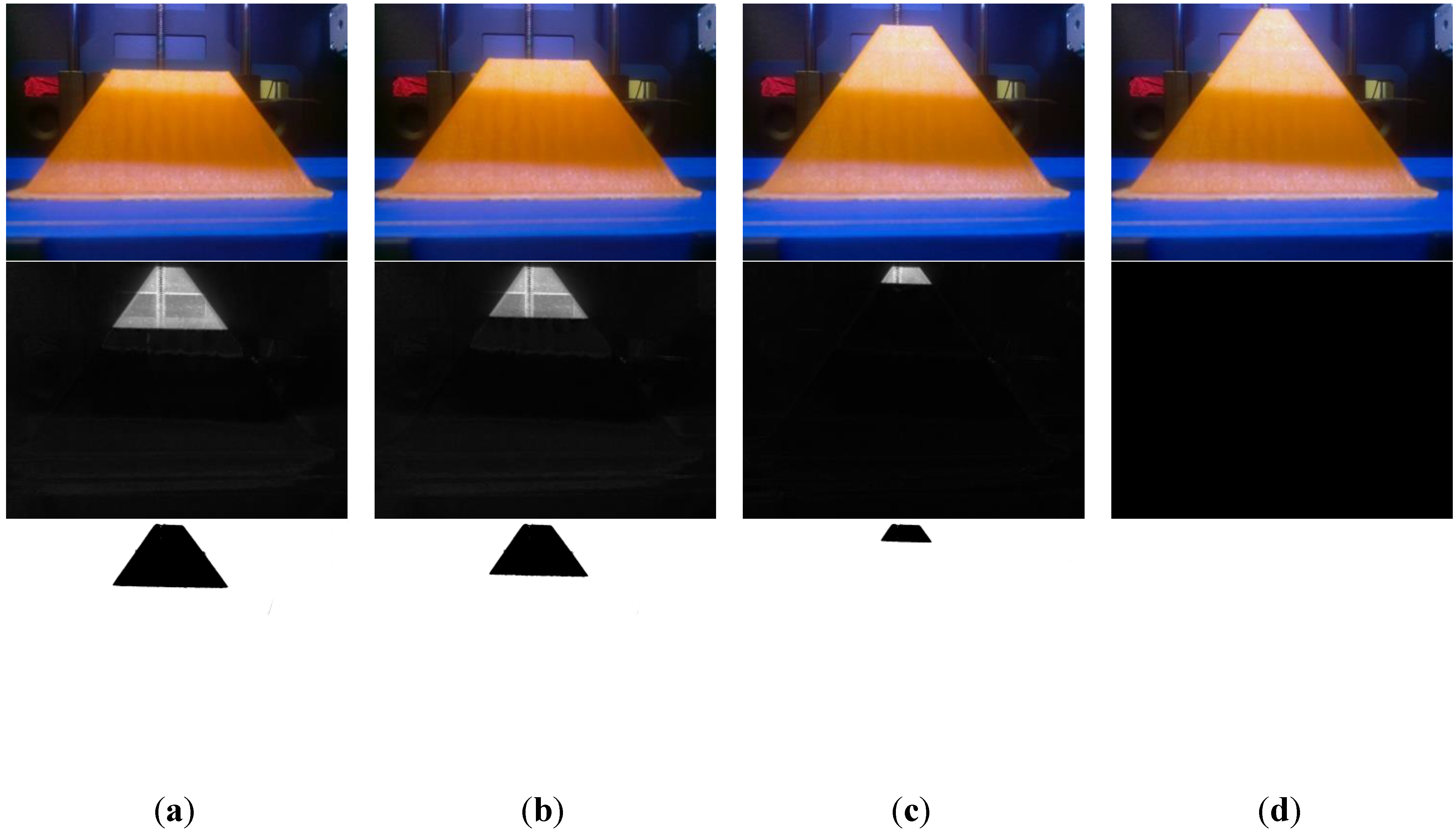

Work now turned to detecting the level of completeness of the object (also relevant to assessing build progress). To this end, data from all eight progress levels was compared to the final image. The difference was depicted visually as well as assessed quantitatively.

Figure 7 and

Figure 8 present all eight progress levels for angle 3 (the front view). The top row shows the captured image. The second row displays the characterization of the difference level and the bottom row shows the pixels that are judged, via the use of the threshold, to be significantly different.

Figure 7.

Progression of object through the printing process: (a) progress point 1; (b) progress point 2; (c) progress point 3; (d) progress point 4.

Figure 7.

Progression of object through the printing process: (a) progress point 1; (b) progress point 2; (c) progress point 3; (d) progress point 4.

Figure 8.

Progression of object through the printing process: (a) progress point 5; (b) progress point 6; (c) progress point 7; (d) progress point 8 (this is also used as the complete object).

Figure 8.

Progression of object through the printing process: (a) progress point 5; (b) progress point 6; (c) progress point 7; (d) progress point 8 (this is also used as the complete object).

The build progress/object completeness is, thus, quite clear with a visible progression from

Figure 7a to

Figure 8d. It is also notable that some very minor background movement/movement relative to the background may have occurred between progress points two and three, resulting in the elimination of the limited points detected in the background in the third rows of

Figure 7a,b.

The quantitative data from this collection process is presented in

Table 1 (and depicted visually in

Figure 9), which shows the aggregate level of difference (calculated via summation of the difference levels of each pixel, using Equation (4)) by progress level and camera position.

where difference

i,j is the difference between values at pixel i, j and m and n are the maximum values for x and y. A clear progression of declining difference can also be seen in this numeric data.

Table 1.

Aggregate difference by level of progress and angle.

Table 1.

Aggregate difference by level of progress and angle.

| | | Angle |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| Progress | 1 | 201575263 | 154742364 | 606260772 | 211214209 | 386909779 |

| 2 | 159074877 | 120966265 | 529193273 | 180098380 | 338718052 |

| 3 | 128796927 | 100588139 | 284574631 | 135275350 | 300301392 |

| 4 | 95224509 | 78451958 | 213765197 | 96921027 | 310651833 |

| 5 | 83581787 | 59900209 | 196817866 | 89931596 | 302212892 |

| 6 | 72126962 | 58127383 | 169154720 | 77356784 | 303391576 |

| 7 | 43090774 | 47638489 | 48088649 | 49056229 | 289977798 |

Figure 9.

Visual depiction of data from

Table 1.

Figure 9.

Visual depiction of data from

Table 1.

Table 2 presents the maximum difference, which is calculated:

where Max() is a function that selects the maximum value within the set of values from the proscribed range. While there is decline in maximum difference as the progress levels advance, the correlation is not absolute, as there are instances where the difference increases from a progress level to the next subsequent one.

Table 2.

Maximum difference level by level of progress and angle.

Table 2.

Maximum difference level by level of progress and angle.

| | | Angle |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| Progress | 1 | 633 | 568 | 542 | 604 | 669 |

| 2 | 631 | 477 | 539 | 665 | 663 |

| 3 | 613 | 489 | 584 | 661 | 648 |

| 4 | 583 | 476 | 568 | 656 | 624 |

| 5 | 562 | 485 | 559 | 658 | 625 |

| 6 | 555 | 473 | 561 | 667 | 606 |

| 7 | 502 | 435 | 446 | 609 | 564 |

Additional analysis of this data is presented in

Table 3 and

Table 4 which present the average level of difference for each progress level and angle and the percentage of difference relative to total difference, respectively. The aggregate difference (

Table 1) and average difference (

Table 3) for angle 3 are higher for most levels due to the fact that the object fills significantly more of the image area from this angle. Looking at the difference from a percentage perspective (in

Table 4) demonstrates that the object completion values (ignoring the amount of image space covered) are much closer to the other angles. This is calculated via:

where Avg() is a function that returns the average for the set of values from the range provided. The average

Table 4 percentage of distance values are calculated using:

where TotalDifference is the summation of the difference at all of the progress levels.

Table 3.

Average level of difference per-pixel by level of progress and angle.

Table 3.

Average level of difference per-pixel by level of progress and angle.

| | | Angle |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| Progress | 1 | 40.00 | 30.71 | 120.32 | 41.92 | 76.79 |

| 2 | 31.57 | 24.01 | 105.02 | 35.74 | 67.22 |

| 3 | 25.56 | 19.96 | 56.48 | 26.85 | 59.60 |

| 4 | 18.90 | 15.57 | 42.42 | 19.23 | 61.65 |

| 5 | 16.59 | 11.89 | 39.06 | 17.85 | 59.98 |

| 6 | 14.31 | 11.54 | 33.57 | 15.35 | 60.21 |

| 7 | 8.55 | 9.45 | 9.54 | 9.74 | 57.55 |

Table 4.

Percentage of difference by level of progress and angle.

Table 4.

Percentage of difference by level of progress and angle.

| | | Angle |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| Progress | 1 | 25.7% | 24.9% | 29.6% | 25.1% | 17.3% |

| 2 | 20.3% | 19.5% | 25.8% | 21.4% | 15.2% |

| 3 | 16.4% | 16.2% | 13.9% | 16.1% | 13.5% |

| 4 | 12.2% | 12.6% | 10.4% | 11.5% | 13.9% |

| 5 | 10.7% | 9.7% | 9.6% | 10.7% | 13.5% |

| 6 | 9.2% | 9.4% | 8.3% | 9.2% | 13.6% |

| 7 | 5.5% | 7.7% | 2.3% | 5.8% | 13.0% |

The aggregate difference level (and derivative metrics) provide one way to assess the completion; however, this is impacted by lots of small ambient differences as well as the level of difference between the final object and the background (which could be inconsistent across various areas of the object). An alternate approach is to simply count the number of pixels, which have been judged via the use of the threshold value, to be significantly different. This, particularly for cases where lighting changes occur or foreground-background differences are inconsistent, reduces the impact of non-object differences. Data for the number of pixels that are different is presented in

Table 5. and visually depicted in

Figure 10. This is calculated using:

where Count() is a function that determines the number of instances within the range provided where a condition is true. Thres is the specified threshold value used for comparison purposes.

One notable issue exists in this data. A slight movement of a door that falls within the viewing area of angle five occurred between progress points one and two, creating a significantly higher number of difference points in angle five, progress point one. This is a far more pronounced impact than this had on the aggregate difference approach (in

Table 1). This type of movement could be excluded through greater color filtering and/or enclosing the printer in an opaque box or wrap.

Table 5.

Number of pixels with above-threshold difference, by progress level and angle.

Table 5.

Number of pixels with above-threshold difference, by progress level and angle.

| | | Angle |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| Progress | 1 | 328775 | 258901 | 1353743 | 352334 | 503292 |

| 2 | 238267 | 204661 | 755034 | 261407 | 191781 |

| 3 | 166407 | 163139 | 545944 | 190409 | 161034 |

| 4 | 108800 | 100143 | 321195 | 117178 | 105233 |

| 5 | 94427 | 83715 | 261903 | 96687 | 75725 |

| 6 | 68056 | 63622 | 189724 | 70255 | 59148 |

| 7 | 15088 | 14094 | 39813 | 18292 | 16624 |

The

Table 6 percent of pixels value is determined using the equation:

where the TotalPixelCount is determined by multiplying the m and n (maximum x and y) values.

Figure 10.

Visual Depiction of Data from

Table 5.

Figure 10.

Visual Depiction of Data from

Table 5.

Table 6.

Percent of pixels with above-threshold difference, by progress level and angle.

Table 6.

Percent of pixels with above-threshold difference, by progress level and angle.

| | | Angle |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| Progress | 1 | 6.52% | 5.14% | 26.87% | 6.99% | 9.99% |

| 2 | 4.73% | 4.06% | 14.98% | 5.19% | 3.81% |

| 3 | 3.30% | 3.24% | 10.83% | 3.78% | 3.20% |

| 4 | 2.16% | 1.99% | 6.37% | 2.33% | 2.09% |

| 5 | 1.87% | 1.66% | 5.20% | 1.92% | 1.50% |

| 6 | 1.35% | 1.26% | 3.77% | 1.39% | 1.17% |

| 7 | 0.30% | 0.28% | 0.79% | 0.36% | 0.33% |

Table 7 presents the percentage of difference, based on only considering difference values above the identified threshold. The

Table 7 percentage of difference values are calculated via:

where SumIf() is a function that sums the value provided in the first parameter, if the logical statement that is the second parameter evaluates to true.

Table 7.

Percentage of difference at each level of progress and angle.

Table 7.

Percentage of difference at each level of progress and angle.

| | | Angle |

|---|

| 1 | 2 | 3 | 4 | 5 |

|---|

| Progress | 1 | 32.2% | 29.1% | 39.0% | 31.8% | 45.2% |

| 2 | 23.4% | 23.0% | 21.8% | 23.6% | 17.2% |

| 3 | 16.3% | 18.4% | 15.7% | 17.2% | 14.5% |

| 4 | 10.7% | 11.3% | 9.3% | 10.6% | 9.5% |

| 5 | 9.3% | 9.4% | 7.6% | 8.7% | 6.8% |

| 6 | 6.7% | 7.2% | 5.5% | 6.3% | 5.3% |

| 7 | 1.5% | 1.6% | 1.1% | 1.7% | 1.5% |

In addition to looking at the raw number of pixels exhibiting difference, this can also be assessed as a percentage of pixels exhibiting a difference in the image (

Table 6) or, more usefully, as the percentage of total difference level (

Table 7). These values, again, show a consistent decline in difference from progress level to subsequent progress level.