Fuzzy Pattern Classification Based Detection of Faulty Electronic Fuel Control (EFC) Valves Used in Diesel Engines

Abstract

:1. Introduction

2. System Identification

2.1. Experimental Set Up

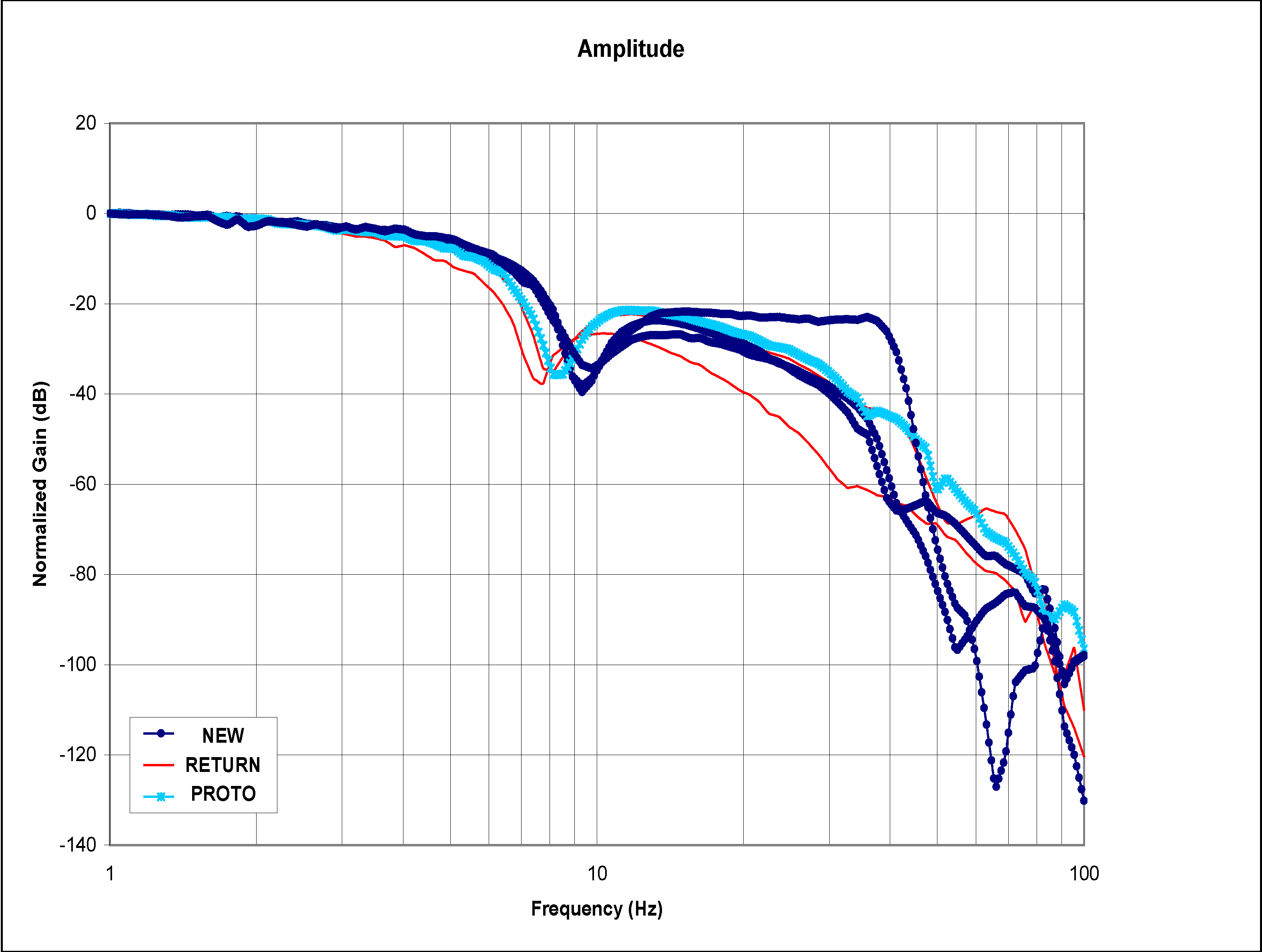

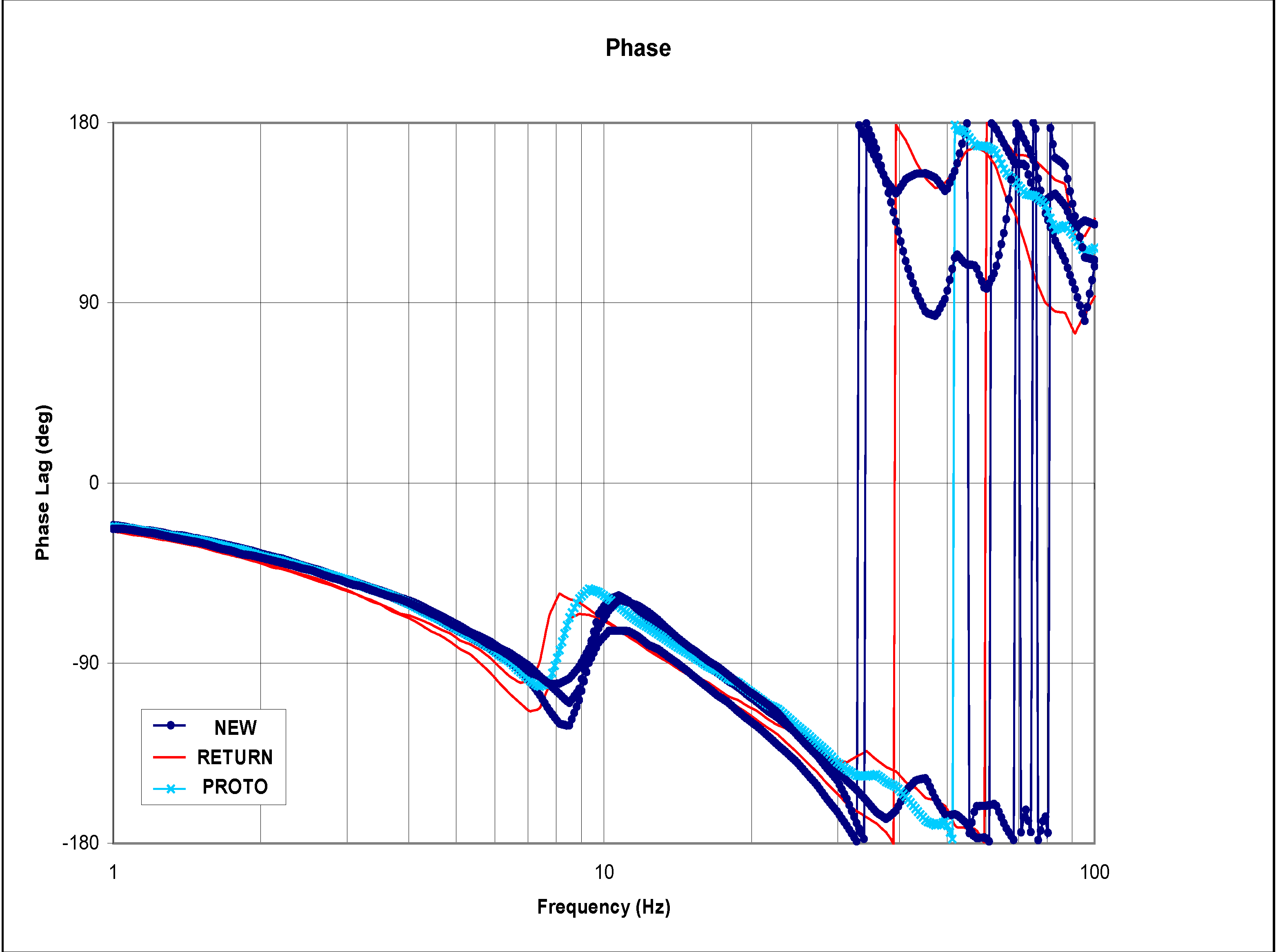

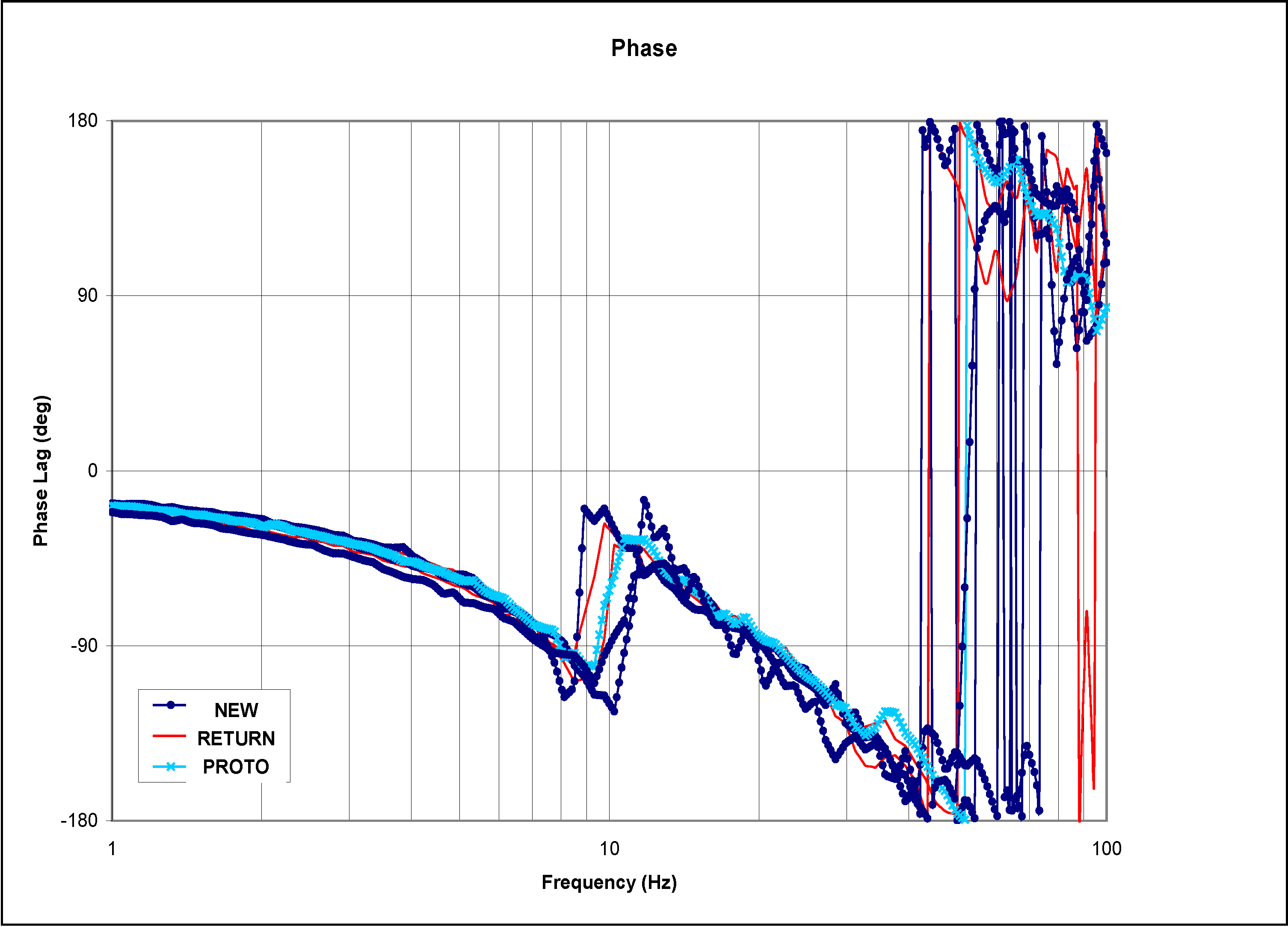

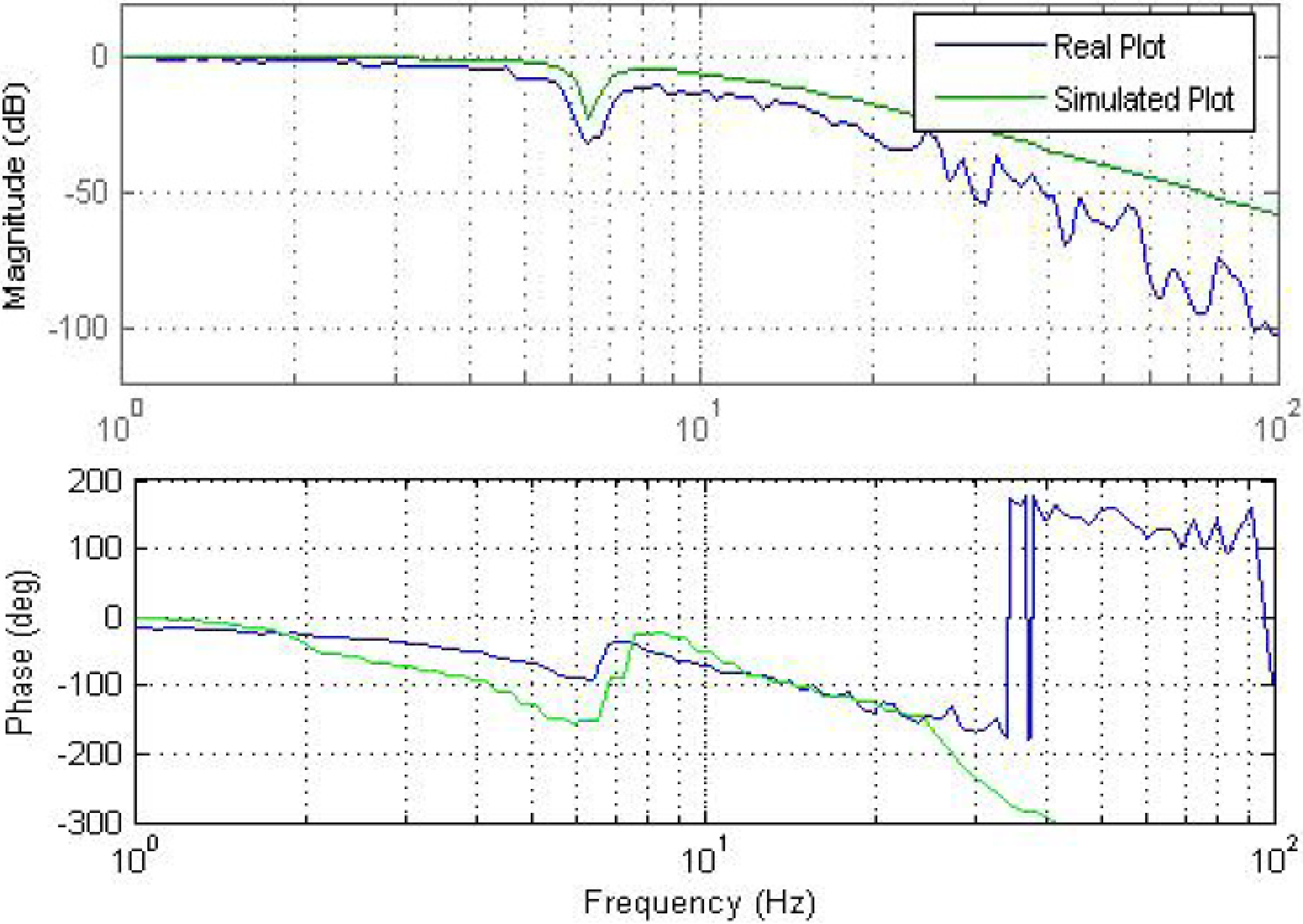

2.2. Frequency Response

, k = 1,…,N denotes the Frequency Response data, and B/A denotes the estimated transfer function.

, k = 1,…,N denotes the Frequency Response data, and B/A denotes the estimated transfer function.2.2.1. Model Structure

tj = 1, j = 1,…,np

tj = 1, j = 1,…,np tj = −1, j = 1,…,nz

And the asymptote is given by:

tj = −1, j = 1,…,nz

And the asymptote is given by:

2.2.2. Asymptotic Approximation to the Bode Diagram

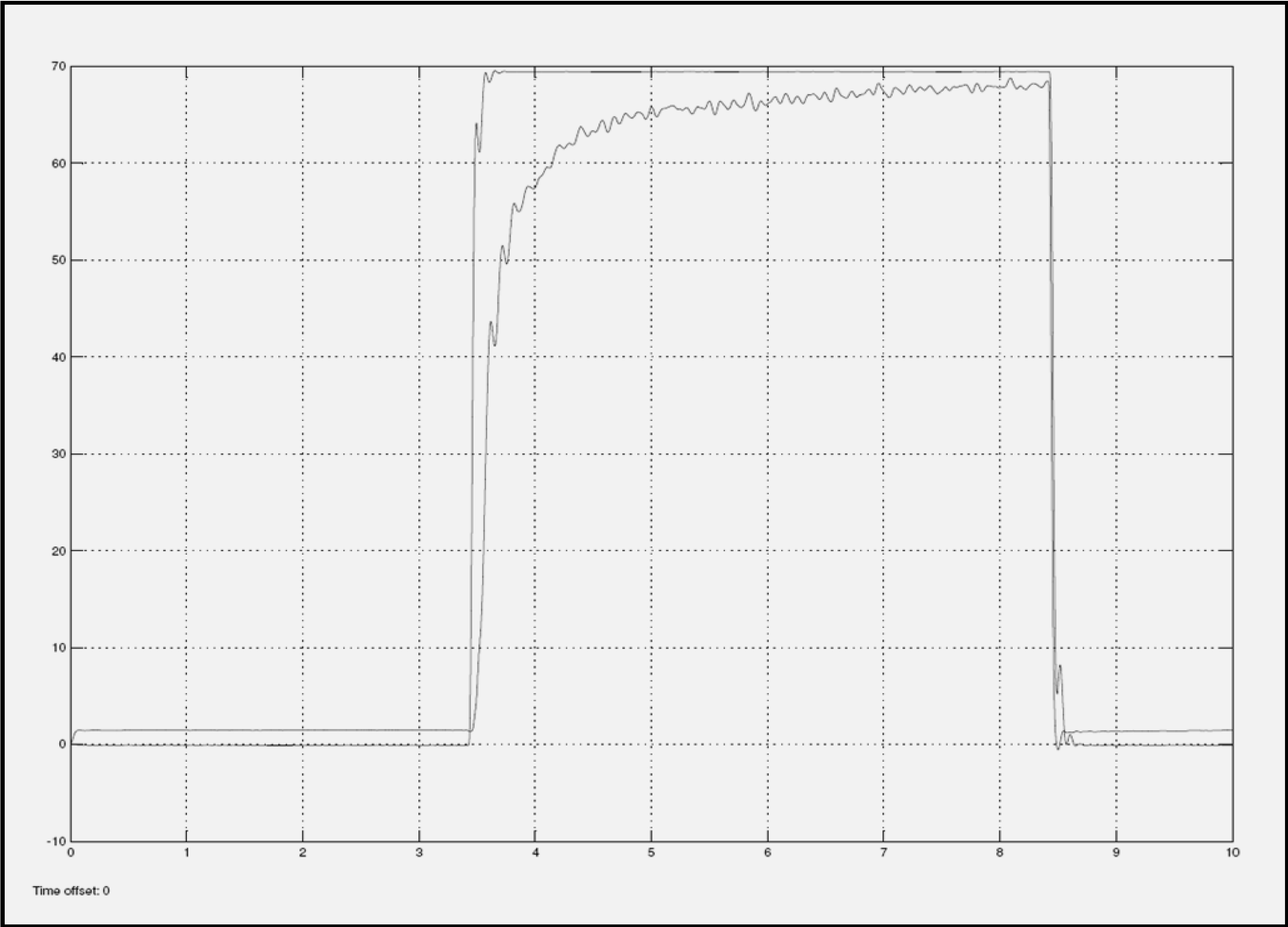

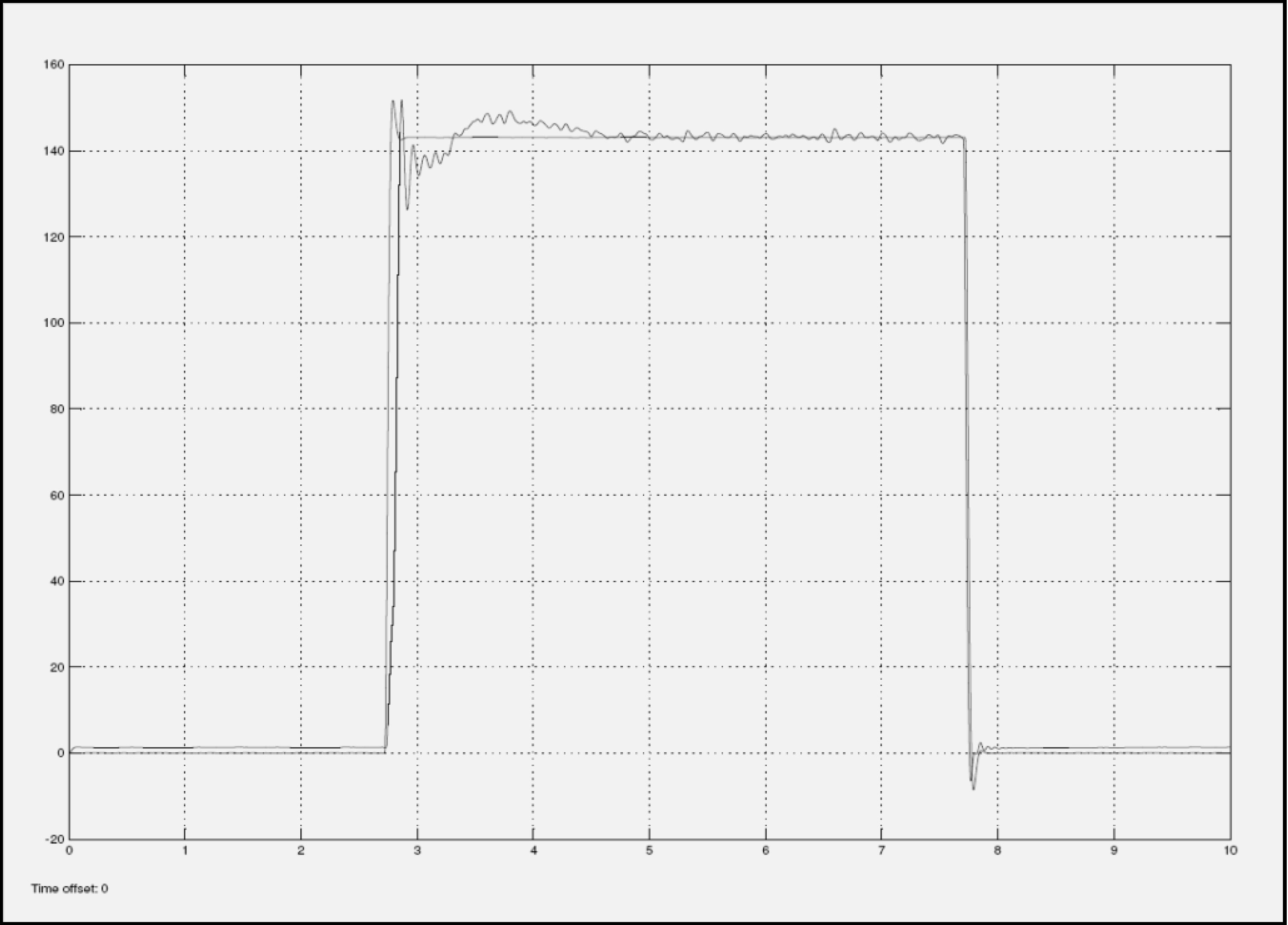

2.3. Step Response

2.3.1. Recursive Least Squares (RLS) Algorithm

are the regression vector and parameter vector respectively, and are defined as

are the regression vector and parameter vector respectively, and are defined as

of the unknown parameter vector θ that will minimize the error function:

of the unknown parameter vector θ that will minimize the error function:

follows from Equation (8) for ε(t) = 0, and K(t) is the Kalman filter gain, which multiplies the prediction error in order to portray the correction term for the model parameter vector. Equation (13) requires an initial estimate of the parameter vector

follows from Equation (8) for ε(t) = 0, and K(t) is the Kalman filter gain, which multiplies the prediction error in order to portray the correction term for the model parameter vector. Equation (13) requires an initial estimate of the parameter vector  , and Equations (14) and (15) require an initial estimate of P(0).

, and Equations (14) and (15) require an initial estimate of P(0).

2.4. Transfer Function Estimations

2.4.1. Frequency Domain Method

2.4.2. Time Domain Method

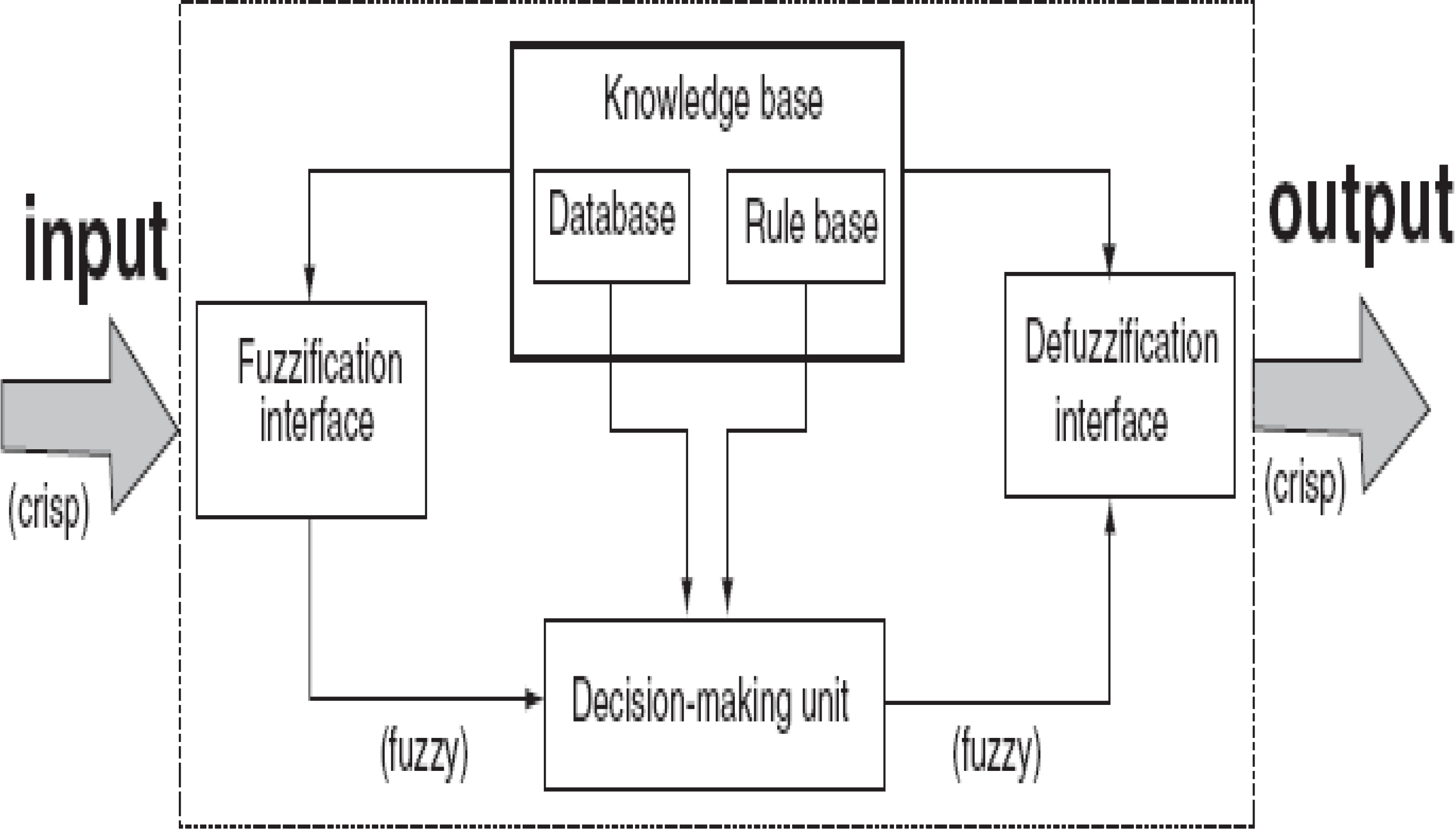

3. Fuzzy Pattern Classification

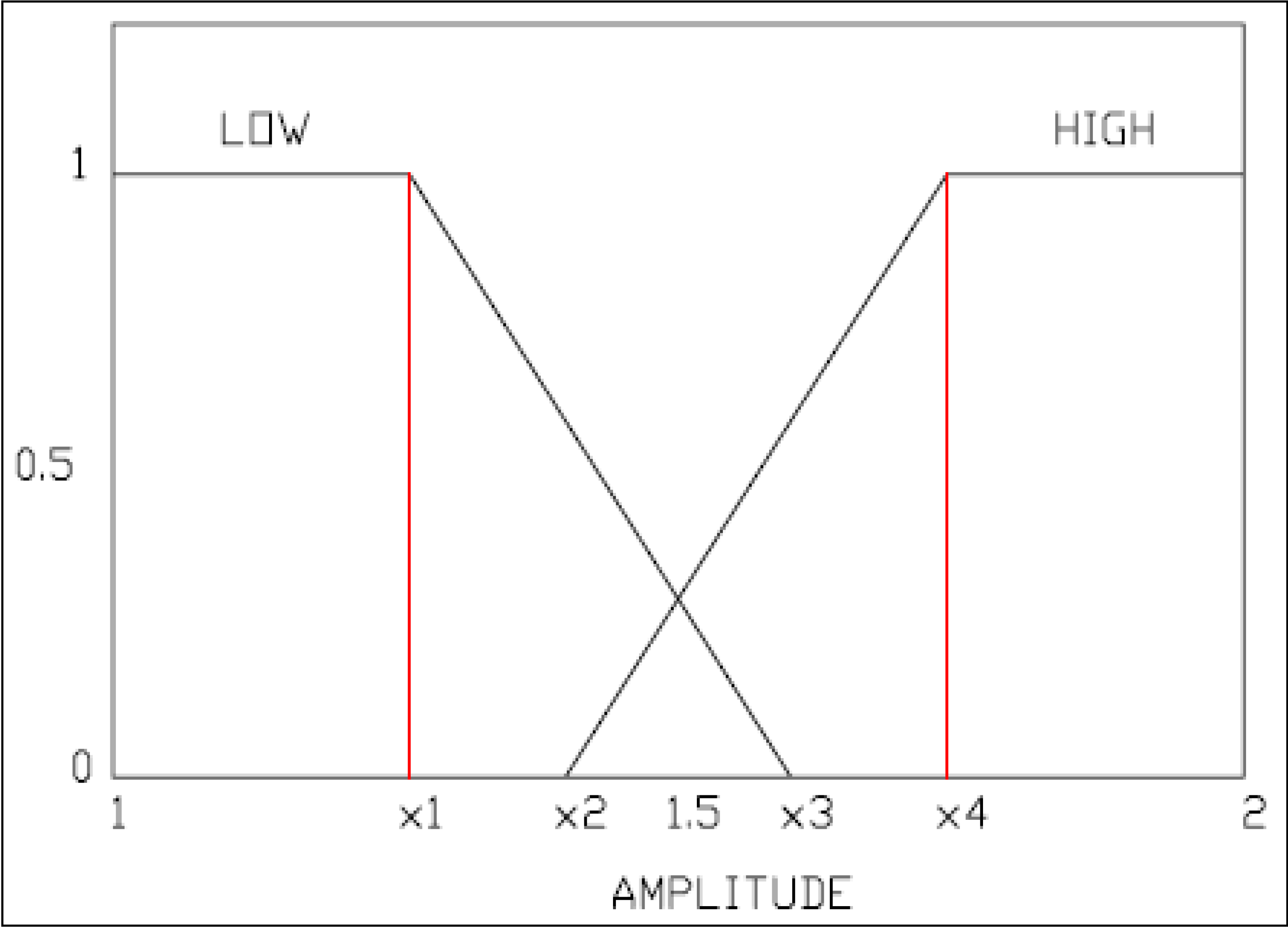

3.1. Initialization of the Fuzzy Decision System

4. Experimental Results

| Serial # | Condition | Error | |

|---|---|---|---|

| Low A | High A | ||

| Valve Type 1 | New | 1.0156 | 0.9048 |

| 1.0030 | 0.9174 | ||

| 1.0378 | 0.9229 | ||

| 1.0396 | 0.8740 | ||

| 1.0233 | 0.8837 | ||

| 1.0611 | 0.8788 | ||

| 1.0634 | 0.8328 | ||

| 1.0476 | 0.9143 | ||

| 1.0536 | 0.8498 | ||

| 1.0249 | 0.9128 | ||

| Valve Type 2 | New | 1.0025 | 0.8931 |

| 0.9742 | 0.8553 | ||

| 0.9740 | 0.8388 | ||

| 0.9810 | 0.8046 | ||

| 0.9746 | 0.8814 | ||

| 0.9682 | 0.8076 | ||

| 0.9704 | 0.8168 | ||

| 0.9704 | 0.8321 | ||

| 0.9793 | 0.7948 | ||

| 0.9695 | 0.8158 | ||

| Valve Type 1 | Return | 1.8048 | 1.0689 |

| 1.8048 | 1.0659 | ||

| 1.6242 | 1.0763 | ||

| 1.5982 | 1.0706 | ||

| 1.6573 | 1.1234 | ||

| 1.6254 | 1.0779 | ||

| 1.5485 | 1.1019 | ||

| 1.6291 | 1.0546 | ||

| 1.7645 | 1.0782 | ||

| 1.6671 | 1.0934 | ||

| Valve Type 2 | Return | 1.2697 | 0.9865 |

| 1.2176 | 1.0326 | ||

| 1.3267 | 1.0139 | ||

| 1.3357 | 1.0078 | ||

| 1.2477 | 0.9998 | ||

| 1.2507 | 1.0061 | ||

| 1.1917 | 1.0025 | ||

| 1.2510 | 0.9852 | ||

| 1.2268 | 1.0106 | ||

| 1.2363 | 0.9862 | ||

| Serial # | Condition | Error | |

|---|---|---|---|

| Low A | High A | ||

| Valve Type 1 New | Good | Good | |

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Valve Type 2 New | Good | Good | |

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Good | Good | ||

| Valve Type 1 Return | Severely Malf. | Severely Malf. | |

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Severely Malf. | Severely Malf. | ||

| Valve Type 2 Return | Malfunctioned | Malfunctioned | |

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

| Malfunctioned | Malfunctioned | ||

5. Conclusions

Acknowledgment

Conflicts of Interest

References

- Isermann, R. Model-based fault-detection and diagnosis—Status and applications. Annu. Rev. Control 2005, 29, 71–85. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Kavuri, S.N.; Yin, K. A review of process fault detection and diagnosis Part III: Process history based methods. Comput. Chem. Eng. 2003, 27, 327–346. [Google Scholar] [CrossRef]

- He, Q.P.; Wang, J. Large-Scale Semiconductor Process Fault Detection Using a Fast Pattern Recognition-Based Method. IEEE Trans. Semicond. Manuf. 2010, 23, 194–200. [Google Scholar] [CrossRef]

- Lou, X.; Loparo, K.A. Bearing fault diagnosis based on wavelet transform and fuzzy inference. Mech. Syst. Signal Process. 2004, 18, 1077–1095. [Google Scholar] [CrossRef]

- He, H.; Wang, D.; Ma, S. Application of fuzzy pattern recognition in intelligent fault diagnosis systems. Proc. SPIE 2001, 4554, 262–267. [Google Scholar] [CrossRef]

- Bhushan, B.; Romagnoli, J.A. Self-organizing self-clustering network: A strategy for unsupervised pattern classification with its application to fault diagnosis. Ind. Eng. Chem. Res. 2008, 47, 4209–4219. [Google Scholar] [CrossRef]

- Podvin, H. A fuzzy-logic-based fault recognition method using phase angles between current symmetrical components in automatic DFR record analysis. In Proceedings of the 2005 IEEE Russia Power Tech, St. Petersburg, Russia, 27–30 June 2005.

- Detroja, K.P.; Gudi, R.D.; Patwardhan, S.C. A possibilistic clustering approach to novel fault detection and isolation. J. Process Control 2006, 16, 1055–1073. [Google Scholar] [CrossRef]

- Operator’s Manual—EFC Test Stand; 38078; Cummins Engine Company, Inc.: Columbus, IN, USA, 1995.

- Hand Book on Dynamic Performance Test Method on EFC Valve Test Bench; Cummins, Inc.: Columbus, IN, USA, 2007.

- Tugsal, U. Fault Diagnosis of Electronic Fuel Control (EFC) Valves via Dynamic Performance Test Method. M.Sc. Thesis, Purdue School of Engineering and Technology, IUPUI, Indianapolis, IN, USA, December 2009. [Google Scholar]

- Pintelon, R.; Schoukens, J. System Identification: A Frequency Domain Approach; Wiley—IEEE Press: Hoboken, NJ, USA, 2012. [Google Scholar]

- Pintelon, R.; Guillaume, P.; Rolain, Y.; Schoukens, J.; Hamme, H.V. Parametric Identification of Transfer Functions in the Frequency Domain, a Survey. IEEE Trans. Autom. Control 1994, 39, 2245–2260. [Google Scholar] [CrossRef]

- Lopes dos Santos, P.; de Carvalho, J.L.M. Automatic Transfer Function Synthesis from a BodePlot. IEEE Proc. Decis. Control 1990, 2, 1093–1098. [Google Scholar]

- Gustavsson, I.; Ljung, L.; Soderstrom, T. Identification of Processes in Closed Loop-Identifiability and Accuracy Aspects. Automatica 1977, 13, 59–75. [Google Scholar] [CrossRef]

- Astrom, K.J.; Wittenmark, B. Self Tuning Controllers Based on Pole-Zero Placement. IEEE Proc. D 1980, 127, 120–130. [Google Scholar] [CrossRef]

- Young, P. Recursive Estimation and Time Series Analysis—An Introduction; Springer-Verlag: Berlin, Germany, 1984. [Google Scholar]

- Ljung, L. System Identification: Theory for the User, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Ross, T.J. Fuzzy Logic with Engineering Applications, 3rd ed.; John Wiley & Sons, Ltd: West Sussex, UK, 2010. [Google Scholar]

- MATLAB Fuzzy Logic Toolbox; Mathworks, Inc.: Natick, MA, USA, 2009.

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Tugsal, U.; Anwar, S. Fuzzy Pattern Classification Based Detection of Faulty Electronic Fuel Control (EFC) Valves Used in Diesel Engines. Machines 2014, 2, 99-119. https://doi.org/10.3390/machines2020099

Tugsal U, Anwar S. Fuzzy Pattern Classification Based Detection of Faulty Electronic Fuel Control (EFC) Valves Used in Diesel Engines. Machines. 2014; 2(2):99-119. https://doi.org/10.3390/machines2020099

Chicago/Turabian StyleTugsal, Umut, and Sohel Anwar. 2014. "Fuzzy Pattern Classification Based Detection of Faulty Electronic Fuel Control (EFC) Valves Used in Diesel Engines" Machines 2, no. 2: 99-119. https://doi.org/10.3390/machines2020099