Integrating the Theory of Sampling into Underground Mine Grade Control Strategies

Abstract

:1. Introduction

1.1. Overview

1.2. Grade Control Paradigm

1.3. Sampling for Grade Control

1.4. Mineralisation Characteristics

1.5. Sampling: Decisions, Financial Loss, and Compliance

1.6. Current Practice and Focus of this Contribution

2. Theory of Sampling

2.1. TOS Overview

2.2. Correct Sampling Errors

2.3. Incorrect Sampling Errors

2.4. FSE Equation and Application to Gold Ores

2.4.1. Background

2.4.2. Calibration of FSE Equation Inputs

- Realisation of gold deportment, in particular the partitioning of gold as free gold, gold in sulphides, and refractory gold.

- Gold particle size curve(s), including effects of clustering and relationship between gold particle size and grade (e.g., high grade versus background grade).

- Definition of key FSE equation inputs (d95Au versus dAuclus) and the sampling constant K.

- Recommendations as to optimum in-situ sample mass requirements.

2.4.3. Applicability to Gold Ores

2.5. TOS and Geostatistics

2.6. Sample Representativity

2.6.1. Representative Sampling

2.6.2. Data Quality Objectives

2.6.3. Fit-for-Purpose Samples

2.7. Sample Spatial Distribution

2.7.1. Primary Sample Mass

2.7.2. Sampling Domains

2.7.3. Sample Density

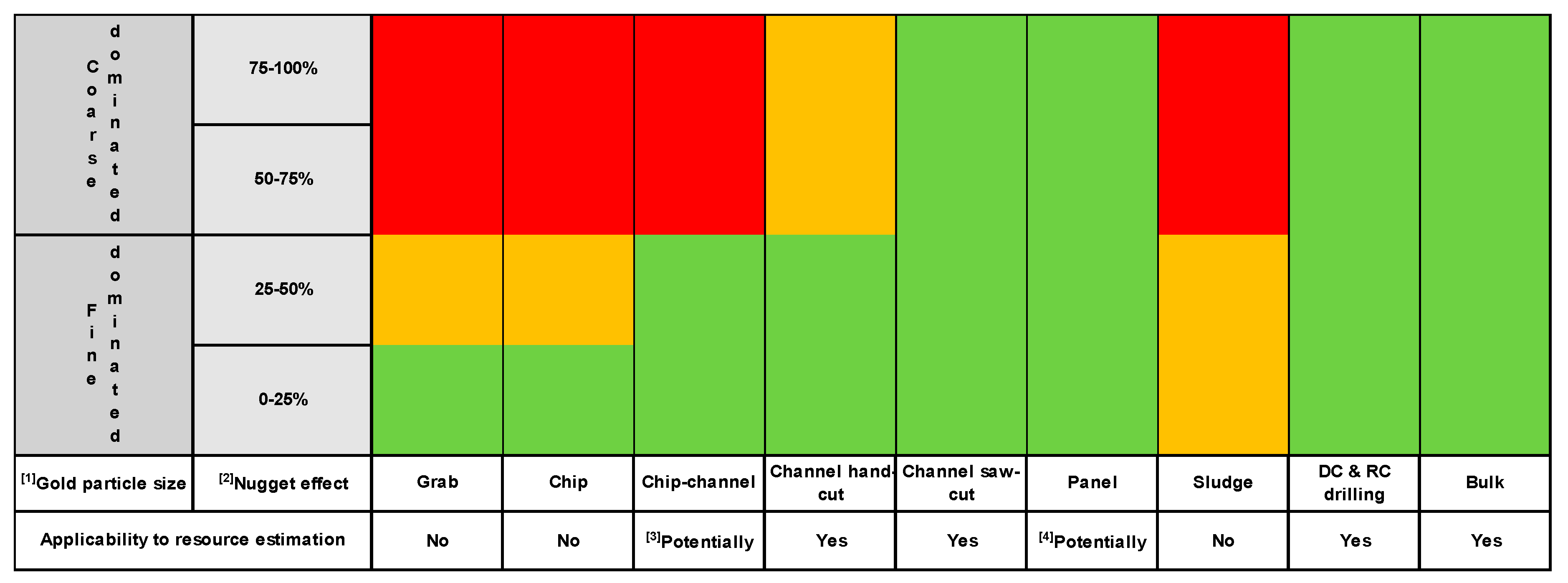

3. Grade Control Sampling Methods

3.1. Type of Samples

3.2. Linear Sampling

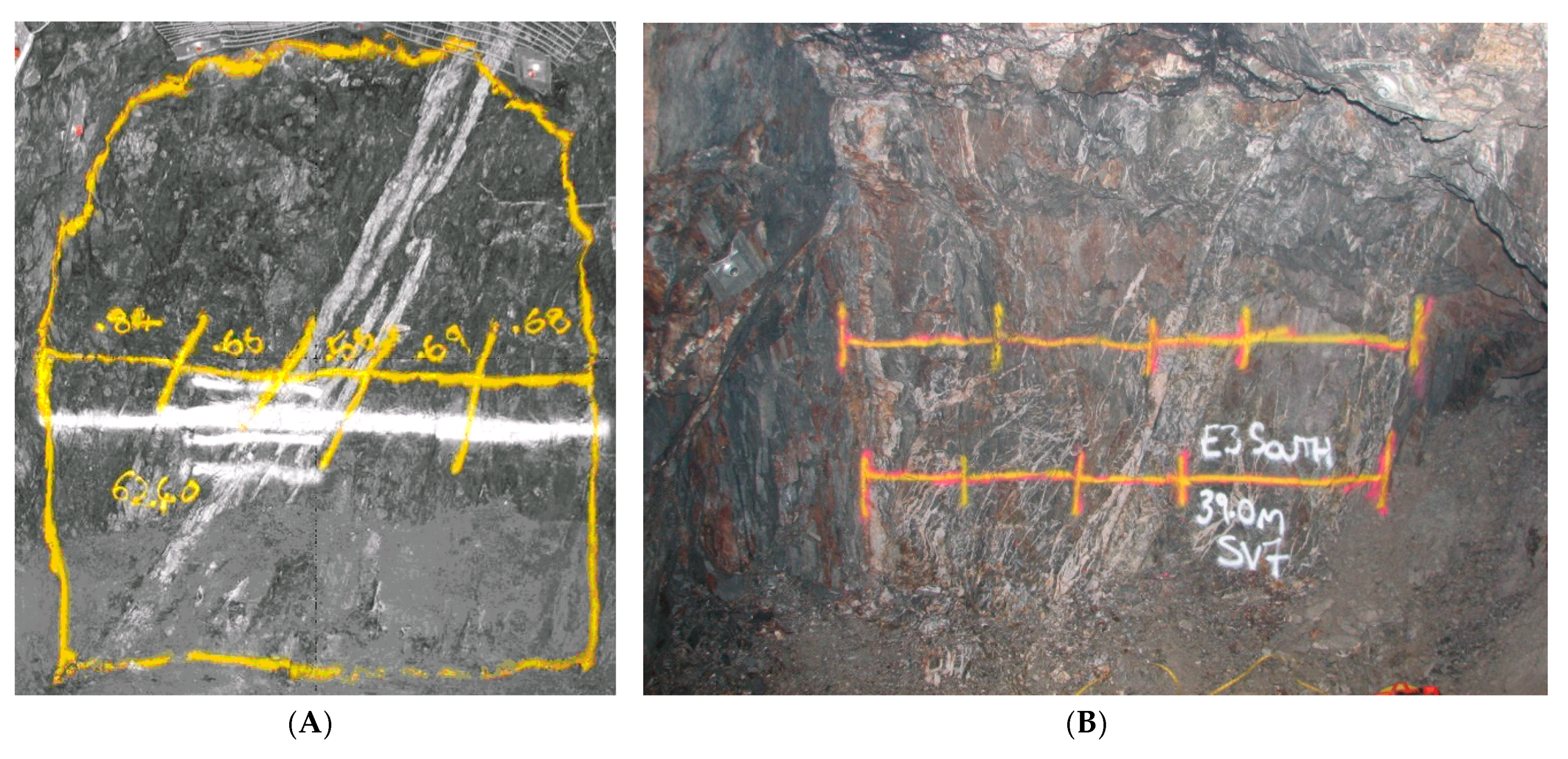

3.2.1. Chip Sampling

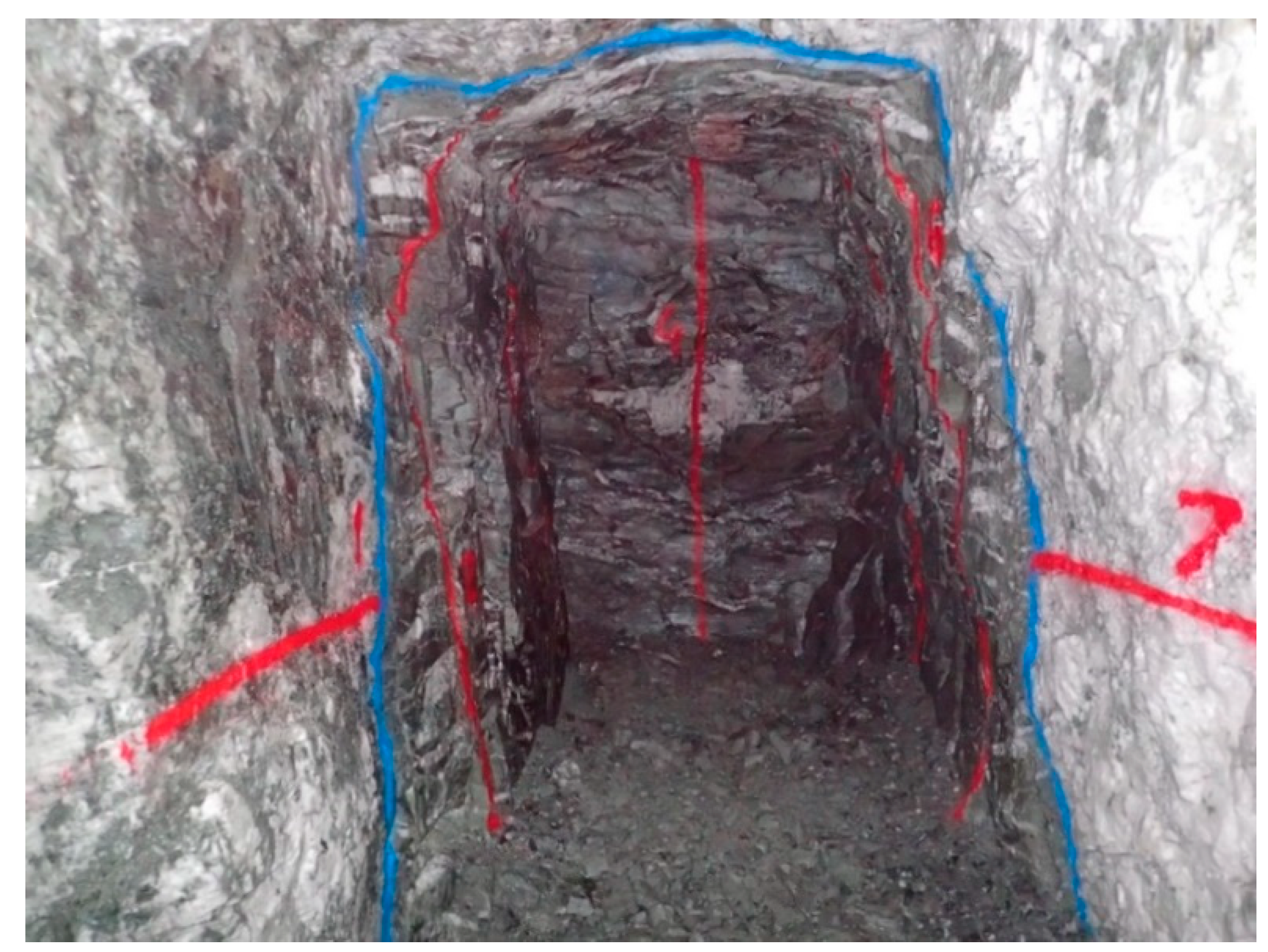

3.2.2. Channel Sampling

3.2.3. Panel Sampling

3.3. Discussion: Practical Issues of Linear Sampling Methods

3.3.1. Integration with Geological Mapping

3.3.2. Sample Collection and Methodology

3.3.3. Sampling under Production Conditions

3.3.4. Sampling and the Geological Context

3.3.5. Recording Sampling Quality

3.3.6. Sample Support

4. Grab Sampling

4.1. Introduction

4.2. Collecting Grab Samples

4.3. Grab Sampling in Block Cave Mines

4.4. Grab Sampling and Errors

4.4.1. Error Generation

4.4.2. Comparison Between Contrasting Ore Types

4.5. Summary

5. Drilling Methods

5.1. Diamond Core Drilling

5.2. Reverse Circulation Drilling

5.3. Sludge Drilling

5.4. Comment

6. Other Sampling Methods

6.1. Bulk Sampling

6.2. Conveyor Belt Sampling

7. Sample Preparation and Assay

8. Quality Assurance/Quality Control and Error Quantification

8.1. Quality Assurance and Quality Control

8.2. Chain of Custody

8.3. Errors along the Sampling Value Chain

9. Integration into the Mining Process

9.1. Mining Method and Grade Control

9.2. Safety Aspects of Grade Control

9.3. Grade Estimation

9.4. Reconciliation

9.5. Sampling Historical Mine Workings

10. Future of Grade Control

10.1. Making Efficiency Gains

10.2. Ore Control versus Grade Control

11. Public Reporting of Grade Control Sampling

12. Planning and Implementing a Grade Control Programme

13. Conclusions

- (1)

- Practitioners can be justifiably critical of linear and grab sampling methods, given their potential for poor precision and high bias. However, they have a role to play in underground grade control, depending on their ultimate use and effort put into making them representative. Maintaining representative samples is advantageous; however, there will always have to be a balance between what is theoretical, practical, and safe. It is important to understand what decisions the sample data will be used for and the inherent risks involved both in collection and decision-making. Critical end-member applications are (a) to support a reserve estimate for short-term mine planning, or (b) as ”indicators” to map grade trends and/or deportment along development and in specific geological domains.

- (2)

- A range of sampling methods are available, all of which require evaluation before routine acceptance. The greatest error is generally introduced during sample collection (e.g., DE and EE). A cost-effective way to reduce sample collection error involves staff training in TOS and correct collection methods. Whilst correctly collected channel samples are of a higher quality than chip samples, chip samples will continue to have importance given their relative ease of collection. A reduction in the need for linear samples will only come from innovation or the use of more pre-development drilling at a spacing to allow local estimation.

- (3)

- Where grade control samples support a reserve estimate, a QAQC programme must be introduced to ensure on-going quality of sampling and assaying. Written protocols and procedures, periodic auditing of protocols and people, and training are required. DS3077 provides a framework on which to compile transparent protocols [38].

- (4)

- Sample protocol optimisation is best undertaken at the breakeven cut-off grade given that it is the ore/waste decision point. An optimised sampling programme will never be perfect and as a result, ore/waste misclassification will occur particularly where the nugget effect is high; thus a low-grade stockpile is recommended. Many small mines do not have drilling, therefore the most practical and representative linear samples are required.

- (5)

- Samples feed into reserve and grade control models that are reconciled with plant performance. All errors along the sampling value chain are additive and impart data variability making estimation less reliable. Errors should be evaluated by empirical means to quantify their impact on the estimation and decision making process. Where sets of mixed data such as channel and drill core samples are used for estimation, it is important to ensure that any bias between the samples is identified and acted upon if appropriate.

- (6)

- The human impact on sampling is great, given that the operating environment is generally unforgiving and hazardous. The sampling process is a physical one and often carried out by relatively junior and inexperienced staff. Team training is critical to improve sample quality and representativity.

- (7)

- Geologists must appreciate the rigors of the TOS and also understand the needs of production. The “ideal” is advantageous, but not always practical. However, where the ideal becomes impractical, the potential effects of the non-ideal on the decision making process must be understood. Management and technical staff should be educated to ‘sample better’ throughout the mine value chain.

- (8)

- In some cases, the application of grade control samples is an exercise in futility. This usually reflects extreme-nugget effect coarse-gold mineralisation. Challenges are particularly exacerbated when grades are low (<5 g/t Au) and/or where the dominant gold particle size is >1 mm or clusters. In these cases, the best option is likely to be bulk (or mini-bulk) sampling and strong geological control during mining.

- (9)

- In context of other mineral deposits, particularly those of base metals, the application of TOS and its error evaluation is relevant. Additionally, use of the FSE equation is also relevant, though the original FSE equation is usually applied in this case. The challenges of applying the various sample types are the same. QAQC is required, particularly when samples feed into a resource estimate.

- (10)

- Company management in their pursuit to reduce costs, often reduce grade control expenditure with no consideration of the impact on the quality of samples and decisions made thereon. Persuading managers to spend the money to rectify the problems, even when they are clearly identified, can be challenging.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Pitard, F.F. Pierre Gy’s Sampling Theory and Sampling Practice; CRC Press: Boca Raton, FL, USA, 1993; p. 488. [Google Scholar]

- Glass, H.J.; Zegers, T.W. Statistical aspects of sampling particulate matter. In Proceedings of the Surface Mining Conference, Johannesburg, South Africa, 30 September–4 October 1996; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 1996; pp. 157–164. [Google Scholar]

- Minnitt, R.C.A. Sampling: The impact on costs and decision making. J. South. Afr. Inst. Min. Metall. 2007, 107, 451–462. [Google Scholar]

- Dominy, S.C. Importance of good sampling practice throughout the gold mine value chain. Min. Technol. 2016, 125, 129–141. [Google Scholar] [CrossRef]

- Holmes, R.J. Sampling procedures. In Advances in Gold Ore Processing; Elsevier: Amsterdam, The Netherlands, 2016; pp. 45–56. [Google Scholar]

- Dominy, S.C.; O’Connor, L.; Glass, H.J.; Purevgerel, S.; Xie, Y. Towards representative metallurgical sampling and recovery testwork programmes. Minerals 2018, 8, 193. [Google Scholar] [CrossRef]

- Dominy, S.C.; O’Connor, L.; Glass, H.J.; Xie, Y. Geometallurgical study of a gravity recoverable gold orebody. Minerals 2018, 8, 186. [Google Scholar] [CrossRef]

- Carrasco, P.C.; Carrasco, P.; Jara, E. The economic impact of incorrect sampling and analysis practices in the copper mining industry. Chemom. Intell. Lab. Syst. 2004, 74, 209–214. [Google Scholar] [CrossRef]

- Joint Ore Reserves Committee (JORC). Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves—The JORC Code; Joint Ore Reserves Committee of the Australasian Institute of Mining and Metallurgy, Australian Institute of Geoscientists and Minerals Council of Australia: Melbourne, Australia, 2012; p. 44. [Google Scholar]

- Gy, P.M. Sampling of Particulate Materials: Theory and Practice; Elsevier: Amsterdam, The Netherlands, 1982; p. 431. [Google Scholar]

- Storrar, C.D. Underground sampling with special reference to gold reefs. In South African Mine Valuation; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 1981; pp. 36–63. [Google Scholar]

- Dominy, S.C.; Platten, I.M.; Fraser, R.M.; Dahl, O.; Collier, J.B. Grade control in underground gold vein operations: The role of geological mapping and sampling. In Proceedings of the International Mining Geology Conference, Perth, Australia, 17–19 August 2009; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 291–307. [Google Scholar]

- Pitard, F.F. The in-situ nugget effect: A major component of the random term of a variogram. In Proceedings of the World Conference on Sampling and Blending, Porto Alegre, Brazil, 23–25 October 2007; Fundacao Luiz Englert: Porto Alegre, Brazil, 2007; pp. 91–110. [Google Scholar]

- Dominy, S.C. Predicting the unpredictable—Evaluating high-nugget effect gold deposits. In Mineral Resource and Ore Reserve Estimation; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 659–678. [Google Scholar]

- Dominy, S.C.; Xie, Y.; Platten, I.M. Gold particle characteristics in narrow vein deposits: Implications for evaluation and metallurgy. In Proceedings of the Narrow Vein Mining Conference, Ballarat, Australia, 14–15 October 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 91–104. [Google Scholar]

- Dominy, S.C.; Platten, I.M. Clustering of gold particles and implications for sampling. Appl. Earth Sci. 2007, 116, 130–142. [Google Scholar] [CrossRef]

- Lyman, G.J.; Robertson, I.G.; Day, T. The simple facts about sampling gold ores. In Proceedings of the Mill Operators Conference, Perth, Australia, 10–12 October 2016; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2016; pp. 159–172. [Google Scholar]

- François-Bongarçon, D.M. A brief history of Pierre Gy’s sampling theory and current trends in its acceptance in the mining world. In Proceedings of the Sampling Conference, Perth, Australia, 27–29 May 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 13–14. [Google Scholar]

- Freese, B.; Flitton, T.; Pillay, A. Quality control and assurance of underground chip sampling at Kopanang Mine, South Africa. In Proceedings of the Sampling and Analysis Conference, Muldersdrift, South Africa, 4–6 June 2013; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2013; pp. 277–278. [Google Scholar]

- Fourie, D.; Minnitt, R.C.A. The simulated chip-sample model as a method for qualifying error and bias in sampling thin carboniferous reef types. J. South. Afr. Inst. Min. Metall. 2014, 114, 19–30. [Google Scholar]

- Fourie, D.; Minnitt, R.C.A. Review of gold reef sampling and its impact on the mine call factor. J. South. Afr. Inst. Min. Metall. 2016, 116, 1001–1009. [Google Scholar] [CrossRef]

- François-Bongarçon, D.M.; Gy, P.M. The most common error in applying Gy’s formula in the theory of mineral sampling and the history of the Liberation factor. J. South. Afr. Inst. Min. Metall. 2002, 102, 475–479. [Google Scholar]

- Pitard, F.F. Pierre Gy’s Theory of Sampling and Ingamells Poisson Process Approach: Pathways to Representative Sampling and Appropriate Industry Standards; Aalborg University: Esbjerg, Denmark, 2009; p. 309. [Google Scholar]

- Royle, A.G. Splitting gold assay pulps containing coarse gold. J. Leeds Univ. Min. Assoc. 1989, 89, 63–68. [Google Scholar]

- Minnitt, R.C.A.; Assibey-Bonsu, W. A comparison between the duplicate series method and the heterogeneity test as methods for calculating the sampling constants. J. South. Afr. Inst. Min. Metall. 2010, 110, 251–268. [Google Scholar]

- Minnitt, R.C.A. Calibrating K and Alpha in Gy’s formula: A new approach. Math. Geosci. 2016, 48, 211–232. [Google Scholar] [CrossRef]

- Dominy, S.C.; Xie, Y. Optimising sampling protocols via the heterogeneity test: Challenges in coarse gold mineralisation. Min. Technol. 2016, 125, 103–113. [Google Scholar] [CrossRef]

- Dominy, S.C.; Platten, I.M.; Xie, Y.; Minnitt, R.C.A. Underground grade control protocol design: Case study from the Liphichi gold project, Larecaja, Bolivia. Appl. Earth Sci. 2011, 119, 205–219. [Google Scholar] [CrossRef]

- Cintra, E.C.; Scabora, J.A.; Viegas, E.P.; Barata, R.; Maia, G.F. Coarse gold sampling at Sao Francisco mine, Brazil. In Proceedings of the World Conference on Sampling and Blending, Porto Alegre, Brazil, 23–25 October 2007; Fundacao Luiz Englert: Porto Alegre, Brazil, 2007; pp. 187–197. [Google Scholar]

- Gonzalez, P.; Cossio, S. A review of sampling protocol for a gold ore based on liberation study. In Proceedings of the World Conference on Sampling and Blending, Porto Alegre, Brazil, 23–25 October 2007; Fundacao Luiz Englert: Porto Alegre, Brazil, 2007; pp. 163–174. [Google Scholar]

- François-Bongarçon, D.M. Extensions to the demonstration of Gy’s formula. Explor. Min. Geol. 1998, 7, 149–154. [Google Scholar]

- Dominy, S.C.; Petersen, J.S. Sampling coarse gold-bearing mineralisation-developing effective protocols and a case study from the Nalunaq mine, Southern Greenland. In Proceedings of the World Conference on Sampling and Blending, Sunshine Coast, Australia, 10–12 May 2005; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2005; pp. 151–165. [Google Scholar]

- Fallon, M.; Rowley, M.; Du Plessis, E.; Golenya, F.; Robertson, I.; Swanson, R. Confirming the sampling, sample preparation and assaying protocols at two Yilgarn gold deposits. In Proceedings of the Sampling Conference, Perth, Australia, 21–22 August 2012; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2012; pp. 47–62. [Google Scholar]

- Stanley, C.R.; Smee, B.W. Strategies for reducing sampling errors in exploration and resource definition drilling programmes for gold deposits. Geochem. Explor. Environ. Anal. 2007, 7, 329–340. [Google Scholar] [CrossRef]

- Simon, A.; Gosson, G. Considerations on quality assurance/quality control and sample security. In Proceedings of the Sampling Conference, Perth, Australia, 27–29 May 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 135–140. [Google Scholar]

- François-Bongarçon, D.M. Theory of sampling and geostatistics: An intimate link. Chemom. Intell. Lab. Syst. 2004, 74, 143–148. [Google Scholar] [CrossRef]

- Pitard, F.F. Guidelines for acceptable allotted sampling uncertainty. In Proceedings of the World Conference on Sampling and Blending, Lima, Peru, 19–22 November 2013; Gecamin: Santiago, Chile, 2013; pp. 89–98. [Google Scholar]

- DS3077. Representative Sampling–Horizontal Standard; Danish Standards Foundation: Copenhagen, Denmark, 2013; p. 41. [Google Scholar]

- Carswell, J.T.; Yulia, K.; Lesmana, D.; Steamy, K. Grade control sampling quality assurance/quality control in a high-grade gold mine—Gosowong, Indonesia. In Proceedings of the International Mining Geology Conference, Perth, Australia, 17–19 August 2009; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 285–290. [Google Scholar]

- Sims, D.A.; Benton, R. Life on the Rollercoaster—Mining and milling the Kencana K1 orebody, Indonesia. In Proceedings of the International Mining Geology Conference, Perth, Australia, 17–19 August 2009; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 319–327. [Google Scholar]

- Stanley, C.R.; Lawrie, D. Average relative error in geochemical determinations: clarification, calculation and a plea for consistency. Explor. Min. Geol. 2007, 16, 267–275. [Google Scholar] [CrossRef]

- Dominy, S.C. Sampling and Evaluation of Vein Gold Deposits; Final Technical Report for DevR-MIDAS Project; University of Greenwich: Chatham, UK; Welsh Gold PLC: Dolgellau, UK, September 1998; p. 230. [Google Scholar]

- François-Bongarçon, D.M. Fishy samples: How big a sample to avoid the infamous Poisson effect. In Proceedings of the World Conference on Sampling and Blending, Cape Town, South Africa, 21–23 October 2009; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2009; pp. 43–46. [Google Scholar]

- Gouws, J. The use of diamond saws in underground sampling at Randfontein Estates Gold Mining Company, Witwatersrand. J. Inst. Mine Surv. S. Afr. 1986, 23, 85–97. [Google Scholar]

- Magri, E.J.; McKenna, A.P. A geostatistical study of diamond saw sampling versus chip sampling. J. South. Afr. Inst. Min. Metall. 1986, 86, 335–347. [Google Scholar]

- Potter, D.; Sheriff, C.; Collins, P. Significance of geological control on assay data in the narrow, high-grade gold quartz veins at the Sand Queen mine, Comet Vale, Western Australia. In Proceedings of the Narrow Vein Mining Conference, Ballarat, Australia, 14–15 October 2008; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2008; pp. 71–78. [Google Scholar]

- Rowland, R.S.; Sichel, H.S. Statistical quality control of routine underground sampling. J. South. Afr. Inst. Min. Metall. 1960, 60, 251–284. [Google Scholar]

- Van Der Merwe, H.C. Sirovision: A proposed solution for the implementation of a digital geological mapping system at AngloGold Ashanti’s Moab Khotsong mine. In Proceedings of the World Gold Conference, Misty Hills, South Africa, 26–30 October 2009; Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2009; pp. 183–191. [Google Scholar]

- Lerm, C. Evaluation of chip sampling vs the gold analyser. J. Inst. Mine. Surv. S. Afr. 1994, 27, 77–87. [Google Scholar]

- Cawood, F.T. Underground face sampling on narrow reefs—Sampling practice and its impact on the mine call factor on Witwatersrand gold mines. J. Inst. Mine Surv. S. Afr. 2003, 31, 202–224. [Google Scholar]

- Dominy, S.C. Grab sampling for underground gold mine grade control. J. South. Afr. Inst. Min. Metall. 2010, 110, 277–287. [Google Scholar]

- Ross, I.T. Sampling in block cave mines. In Proceedings of the Sampling Conference, Perth, Australia, 21–22 August 2012; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2012; pp. 81–85. [Google Scholar]

- Arslan, N.; Ozkayhan, M. Diamond drilling at Efemcukuru gold mine, Turkey—A case study on the benefits of timely and cost-effective drilling to short-term planning. In Proceedings of the International Mining Geology Conference, Hobart, Australia, 20–22 September 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 285–290. [Google Scholar]

- Dominy, S.C. Sampling coarse gold-bearing mineralisation-developing effective protocols and a case study from the Ballarat mine, Australia. In Proceedings of the World Conference on Sampling and Blending, Perth, Australia, 9–11 May 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 3–19. [Google Scholar]

- McBeath, R.; Whitworth, D. What drilling density is optimal—A case study from the Golden Pig mine. In Proceedings of the Underground Operators Conference, Townsville, Australia, 29–31 July 2002; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2002; pp. 33–37. [Google Scholar]

- Clark, F.; Carswell, J.T. Using reverse circulation drilling to improve sampling in a complex underground gold operation, Sunrise Dam mine, Western Australia. In Proceedings of the International Mining Geology Conference, Adelaide, Australia, 18–20 August 2014; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2014; pp. 143–152. [Google Scholar]

- Prouhet, J.-P. A quick method of sampling development headings. In Proceedings of the Ore Reserve Estimation and Grade Control Conference, Ville d’Esterel, QC, Canada, 25–27 September 1967; CIM: Montreal, QC, Canada, 1968; pp. 97–102. [Google Scholar]

- Ovalle, A.; Magri, E.; Zuniga, P.; Pitard, F.F. Sampdrill. Quant. Geol. Geostat. 1997, 8, 767–779. [Google Scholar]

- Johansen, G.F.; Dominy, S.C. Development of sampling and assaying protocols at the new Bendigo gold project, Victoria, Australia. In Proceedings of the World Conference on Sampling and Blending, Sunshine Coast, Australia, 10–12 May 2005; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2005; pp. 175–183. [Google Scholar]

- Roberts, L.S.; Dominy, S.C.; Nugus, M.J. Problems of sampling and assaying in lode-gold deposits—Case studies from Australia and north America. In Proceedings of the International Mining Geology Conference, Bendigo, Australia, 17–19 November 2003; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2004; pp. 387–400. [Google Scholar]

- Dominy, S.C. Effects of sample mass on gravity recoverable gold test results in low grade ores. Appl. Earth Sci. 2014, 123, 234–242. [Google Scholar] [CrossRef]

- Dominy, S.C.; Annels, A.E.; Johansen, G.F.; Cuffley, B.W. General considerations of sampling and assaying in a coarse gold environment. Appl. Earth Sci. 2000, 109, 145–167. [Google Scholar] [CrossRef]

- Hutchison, R. Geology and definition of the Wattle Dam coarse gold deposit. In Proceedings of the Gravity Gold Conference, Ballarat, Australia, 21–22 September 2010; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2010; pp. 109–118. [Google Scholar]

- Elder, D.J. Leachwell versus fire assay: Comments from assay quality assurance at Tarmoola gold mine. In Proceedings of the International Mining Geology Conference, Coolum, Australia, 14–17 May 2000; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 43–52. [Google Scholar]

- Pitard, F.F. Sampling correctness: A comprehensive guide. In Proceedings of the World Conference on Sampling and Blending, Sunshine Coast, Australia, 10–12 May 2005; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2005; pp. 55–66. [Google Scholar]

- Sims, D.A. Sampling practices at Vera Nancy gold mine. In Proceedings of the International Mining Geology Conference, Coolum, Australia, 14–17 May 2000; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2009; pp. 35–42. [Google Scholar]

- Benndorf, J.; Buxton, M.W.N. Sensor-based real-time resource model reconciliation for improved mine production control—A conceptual framework. Min. Technol. 2016, 125, 54–64. [Google Scholar] [CrossRef]

- Kurth, H. Measuring ore quality using real-time on-belt elemental analysis—More than grade control. In Proceedings of the International Mining Geology Conference, Hobart, Australia, 20–22 September 2017; Australasian Institute of Mining and Metallurgy: Melbourne, Australia, 2017; pp. 213–220. [Google Scholar]

- Rifai, K.; Laflamme, M.; Constantin, M.; Vidal, F.; Sabsabi, M.; Blouin, A.; Bouchard, P.; Fytas, K.; Castello, M.; Nguegang Kamwa, B. Analysis of gold in rock samples using laser-induced breakdown spectroscopy: Matrix and heterogeneity effects. Spectrochim. Acta B 2017, 134, 33–41. [Google Scholar] [CrossRef]

- Tickner, J.; Ganly, B.; Lovric, B.; O’Dwyer, J. Improving the sensitivity and accuracy of gamma activation analysis for the rapid determination of gold in mineral ore. Appl. Radiat. Isot. 2017, 122, 28–36. [Google Scholar] [CrossRef] [PubMed]

| Stage | Planning | Collection | Transport | Laboratory Preparation | Assaying |

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Activity | Scope Develop Execute | Observe Collect Bag and tag QAQC Integrity/security Chain of custody | Integrity/security Chain of custody | Equipment operation Equipment clean QAQC Integrity/security | Equipment operation Equipment clean QAQC Integrity/security |

| Sampling errors | In-situ nugget effect FSE, GSE DE, EE, WE | PE | FSE, GSE DE, EE, WE, PE | PE AE | |

| Dominant effect on results | Precision Bias | Bias | Precision (if splitting) Bias | Bias | |

| Sampling Error | Acronym | Error Type | Effect on Sampling | Source of Error | Error Definition |

|---|---|---|---|---|---|

| Fundamental | FSE | Correct Sampling Error (CSE) | Random Errors—Precision Generator | Characteristics of the ore type. Relates to constitution and distribution heterogeneity | Results from grade heterogeneity of the broken lot. Of all sampling errors, the FSE does not cancel out and remains even after a sampling operation is perfect. Experience shows that the total nugget effect can be artificially high because sample masses are not optimal. |

| Grouping and Segregation | GSE | Relates to the error due to the combination of grouping and segregation of rock fragments in the lot. Once rock is broken, there will be segregation of particles at any scale (e.g., surface stockpile or laboratory pulp). | |||

| Delimitation | DE | Incorrect Sampling Error (ISE) | Systematic Errors—Bias Generator | Sampling equipment and materials handling | Results from an incorrect shape of the volume delimiting a sample. |

| Extraction | EE | Results from the incorrect extraction of a sample. Extraction is only correct when all fragments within the delimited volume are taken into the sample. | |||

| Weighting | WE | Samples should represent a consistent mass per unit (e.g., kg/m). | |||

| Preparation | PE | Refers to issues during sample transport and storage (e.g., mix-up, damage, loss and alteration), preparation (contamination and/or losses), and intentional (sabotage and salting), and unintentional (careless actions and non-adherence of protocols) actions. | |||

| Analytical | AE | - | Analytical process | Relates to all errors during the assay and analytical process, including issues related to rock matrix effects, careless actions, and analytical machine maintenance and calibration. |

| Sample Type | Error Type | Cause | Error | Effect | Nugget Effect Component | Solution |

|---|---|---|---|---|---|---|

| In-situ (e.g., linear samples and core) | Random | In-situ heterogeneity | Local representativity | Poor precision | GNE | Larger samples More samples |

| Broken rock (from rock chips to blasted material and laboratory pulps) | Constitution Heterogeneity | FSE | Poor precision | SNE | Optimised protocols Larger samples More samples | |

| Constitution and Distribution Heterogeneity | GSE | Poor precision | SNE | Optimised protocols More sample increments | ||

| Systematic | Poor quality sampling protocols | DE, EE, WE, PE, and AE | High bias | SNE | Optimised protocols Efficient training Strict QAQC |

| Error | SVC Stage | Sample Type/Activity | TOS Errors | 1 Duplicate Component Error Range | 2 FSE | 3 Other TOS Errors |

|---|---|---|---|---|---|---|

| Sampling | 2 & 3 | In-situ sampling (e.g., core and linear samples) | GNE, DE, EE, WE, PE | ±20–70% | GNE | |

| ±16% | ±23% | |||||

| Broken rock sampling (e.g., grab, sludge, and RC samples) | FSE, GSE, DE, EE, WE, PE | |||||

| Preparation | 4 | Drying | PE | ±5–20% | ±11% | |

| Crushing/grinding | PE | |||||

| Splitting | FSE, GSE, DE, EE, PE | |||||

| Analytical | 5 | Splitting | FSE, GSE, DE, EE, PE | ±1–15% | ±8% | |

| Analysis | AE | |||||

| Total error | ±20–70% | ±21% | ±23% | |||

| Target error (fine-gold)/coarse-gold | (±20%) ±40% | ±32% | ||||

| Parameter/Domain | Wall Rocks | Central Vein |

|---|---|---|

| Mineralisation Characteristics | ||

| Geology | Quartz vein stockwork hosted in black shale. Individual veins to 10 mm width | Composite laminated quartz vein |

| Gold deportment | Free gold in quartz and pyrite | Free gold in quartz |

| Domain width (m) | 5 | 1 |

| Grade (g/t Au) | 5 | 16 |

| Nugget effect (%) | 25 | 60 |

| Sampling Characteristics | ||

| >100 µm (%) | >2 | 50 |

| d95Au (µm) | 75 | 650 |

| Sampling constant (K: g/cm1.5) | 630 | 2500 |

| Theoretical sample mass (kg) | 5 | 20 |

| Theoretical mass per unit length (kg/m) | 1 | 20 |

| 1 Duplicate Channel Sample Analysis | ||

| Field component error (%) | 14 | 33 |

| Preparation component error (%) | 8 | 14 |

| Analytical component error (%) | 8 | 11 |

| Total error (%) | 18 | 37 |

| No. pairs (field, preparation, and pulp) | 50 | 50 |

| Sample Type | Sampling Method | Definition | Photograph |

|---|---|---|---|

| Linear | Chip | Individual punctual chip specimens collected in a discontinuous fashion aggregated to form a sample | Figure 2A |

| Chip-channel | Series of continuous chips aggregated to form a sample | Figure 2B, Figure 3 and Figure 4 | |

| Channel | Consistent volume cut across sample zone, can be hand or diamond saw cut | Figure 5A,B | |

| Panel | Large and/or multiple chip or chip-channel samples | ||

| Broken rock | Grab | Hand “grab” of sample from a rock pile | Figure 6 and Figure 7 |

| Drill hole | Diamond core | Solid core of sample over a given length | - |

| Reverse circulation | Chippings over a given length recovered though the centre of the drill string | - | |

| Blast hole/sludge | Chippings over a given length recovered up the outside of the drill string | Figure 8 |

| Stoping Method | Stoping Type [Selectivity] | Development and Pre-Production Stage | Production (Stoping) Stage | Post-Production (Mucking and Transport) Stage |

|---|---|---|---|---|

| Shrinkage | Entry [Selective] | Linear samples Grab samples Diamond core Reverse circulation Blast hole/sludge | Linear samples Grab samples Blast hole/sludge | Grab samples |

| Cut and fill | ||||

| Room and pillar | ||||

| Drift and fill | ||||

| Longhole (open and sub-level variants) | Non-entry [Non-selective] | Grab samples | ||

| Sub-level caving | ||||

| Block caving |

| Sampling Error | 1 Error Magnitude | Error Effect |

|---|---|---|

| DE | Moderate-high | Often high as the sample is generally poorly demarcated. |

| EE | Moderate-high | Expected to be high, as the sample is chipped out and generally leaves an irregular band in 3D. May be extreme if very different rock properties are encountered across a sample. Prone to operator bias for high-grade/shiny sections and/or soft material. |

| WE | Moderate | Dependent upon EE and specifically rock hardness. Can be variable. |

| Attribute | Comment |

|---|---|

| Logistics and planning | Easy: can be collected with minimum preparation, though can be time consuming if rock is hard. |

| Frequency of collection | Moderate–high: any reasonable number of samples can be collected, but will take time. |

| Hazard exposure | Low–high: Depends upon sampling location. Local safety protocols must be applied. Requires sampler to be at rock face. Risk of fly rock during collection. |

| Flexibility of method | High: can be undertaken at relatively short notice. |

| Cost | Low–moderate: labour intensive though relatively fast. |

| Sample quality | Low: generally low quality sample. |

| Value proposition | Moderate–low: whilst relatively quick in the production setting, the poor quality sample provides a low value that may lead to ore/waste misclassification. |

| Sampling Error | 1 Error Magnitude | Error Effect | |

|---|---|---|---|

| Hand Cut | Saw Cut | ||

| DE | Moderate | Moderate | Generally good as the sample is similar to a drill hole. |

| EE | High | Moderate–low | High if different rock properties are encountered across a sample. For hand collected samples, hard rock leads to loss of sample in hard rock as fly particles. In soft/friable material will lead to bias due to oversampling or loss. Saw-cut channels generally better, though cooling water may lead to loss in soft/friable areas. |

| WE | Moderate | Low | Dependent upon EE and specifically rock hardness. Can be variable. Reduced if saw-cut channel. |

| Attribute | Comment |

|---|---|

| Logistics and planning | Moderate–difficult: requires time and/or compressed air saw to collect. |

| Frequency of collection | Moderate: any reasonable number of samples can be collected, but will take more time than chip |

| Hazard exposure | Low–high: Depends upon sampling location. Local safety protocols must be applied. Requires sampler to be at rock face. Risk of fly rock if collected by hand or air pick. Care required if a diamond saw is used due to rotating parts. |

| Flexibility of method | High: can be undertaken at short notice. Slow to cut by hand, 30 min or more for 1 m sample. Can be quite quick to collect a saw-cut sample once the saw is set up. |

| Cost | High: labour intensive and can require compressed air saw. |

| Sample quality | High: potentially a high quality sample. |

| Value proposition | Moderate–high: whilst relatively time consuming and costly, the higher quality sample provides increased value. |

| Sampling Error | 1 Error Magnitude | Error Effect |

|---|---|---|

| DE | Low–moderate | Generally good as the sample is delineated on the face. |

| EE | Moderate–high | Can be acceptable, but may be locally high as rock chips are collected. May be very high if different rock properties are encountered across a panel. Oversampling of “shiny” and/or soft/friable material. |

| WE | Low–moderate | Dependent upon EE and specifically rock hardness. Can be variable. |

| Attribute | Comment |

|---|---|

| Logistics and planning | Moderate–difficult: requires time to collect by hand. |

| Frequency of collection | Low–moderate: any number of samples can be collected, but will take time and depend upon sample size. |

| Hazard exposure | Low–high: Depends upon sampling location. Local safety protocols must be applied. Requires sampler to be at rock face. Risk of fly rock during collection. |

| Flexibility of method | High: can be undertaken at short notice, but may take at least 30 min per sample to collect. |

| Cost | Moderate–high: potentially cost intensive for large samples. |

| Sample quality | Moderate–high: potentially a high quality sample with large area of face coverage. |

| Value proposition | Moderate–high: whilst relatively time consuming and costly, will provide a large sample mass. |

| Sample Quality | Code | Definition |

|---|---|---|

| High | HQ | Well-defined and extracted/recovered sample. Clear cut channel or paneled area. Sample mass >90% of target mass |

| Medium | MQ | Moderate to well-defined and moderately extracted/recovered sample. Sample mass 70–90% of target mass |

| Low | LQ | Moderately defined and poorly extracted/recovered sample. Sample mass <70% of target mass |

| Sample Type | No. Samples | 1 Expected (kg/m) | 2 Data Range (kg/m) | 3 Under-Sampled (%) | 4 Target (%) [within ±5%] | 5 Over-Sampled (%) | 6 Quality Rating (%) |

|---|---|---|---|---|---|---|---|

| Chip | 105 | 2.0 | 0.4–1.8 | 100 | 0 | 0 | 0 |

| Chip-channel | 135 | 2.0 | 1.0–3.2 | 50 | 24 | 26 | 24 |

| Panel (hand cut) | 45 | 6.0 | 4.7–7.1 | 50 | 41 | 9 | 41 |

| Channel (air-pick cut) | 135 | 2.5 | 1.3–2.8 | 43 | 42 | 5 | 42 |

| Channel (hand cut) | 120 | 3.0 | 1.8–3.9 | 36 | 53 | 11 | 53 |

| Channel (saw cut) | 125 | 3.0 | 2.2–3.5 | 20 | 75 | 5 | 75 |

| Parameter | Mine I | Mine II |

|---|---|---|

| Characteristics of Mineralisation | ||

| Mineralisation style | Epithermal vein | Mesothermal vein |

| Gold deportment | Free gold disseminated through quartz | Free gold within quartz and pyrite |

| Percentage > 100 µm | 0 | 45 |

| Liberation diameter (µm) | 50 | 850 |

| Sampling constant (K) | 90 | 7400 |

| Nugget effect (from drilling) (%) | 17 | 72 |

| Granulometric Characteristics 1 | ||

| Screened tonnage (t) | 51 | 54 |

| −3 mm grade (g/t Au) | 10.1 | 49.4 |

| +3–6 mm grade (g/t Au) | 9.6 | 36.9 |

| +6–12 mm grade (g/t Au) | 9.2 | 28.6 |

| +12–25 mm grade (g/t Au) | 9.0 | 19.7 |

| +25–50 mm grade (g/t Au) | 8.8 | 4.6 |

| +50 mm grade (g/t Au) | 8.4 | 2.2 |

| Weighted lot mean grade | 9.2 | 12.2 |

| Grab Sample Duplicate Analysis 2 | ||

| Field component error (%) | 27 | 68 |

| Preparation component error (%) | 10 | 26 |

| Analytical component error (%) | 7 | 8 |

| Total error (%) | 30 | 73 |

| No. of pairs (each of field, preparation and pulp duplicates) | 50 | 50 |

| Test Stope Reconciliation 3 | ||

| Grab sample mass (kg) | 3–4 | 4–6 |

| Sample location | Underground re-muck pile | Surface stockpile |

| No. grab samples collected | 285 | 325 |

| Stope tonnage (t) | 8000 | 9400 |

| Plant reconciled head grade (g/t Au) | 9.0 | 10.9 |

| Grab sample mean grade (g/t Au) | 9.6 | 24.7 |

| Grab/mill head grade (%) | 107 | 227 |

| Grab sample RSV (%) | 75 | 335 |

| Sampling Error | 1 Error Magnitude | Error Effect During Grab Sampling |

|---|---|---|

| FSE | High | Relates to collection of a sample that is generally too small for the lot and is biased to the finer fractions. |

| GSE | High | The muckpile bears a natural segregation particularly of fines that settle to the pile base. |

| DE | High | Routine grab samples only sample the surface of the muckpile. Delimited zone is not representative of the pile. Large tracts of the pile go effectively unsampled. |

| EE | High | The poorly delimited sample does not extract all the rock fragments within the sample zone due to differential fragment sizes. |

| WE | Moderate | Consistent mass usually collected, though can be variable from sample to sample. |

| Attribute | Comment |

|---|---|

| Logistics and planning | Easy: relatively easy to undertake. |

| Frequency of collection | High: numerous small (<6 kg) samples can be collected. |

| Hazard exposure | Low–high: Depends upon sampling location; risk with multiple small samples as composite high mass results in manual handling issues. Sampling of surface or underground stockpiles may pose traffic hazards. May require sampler to be at the rock face if collecting from a muck pile. |

| Flexibility of method | High: can be undertaken quickly and at relatively short notice. |

| Cost | Low: relatively easy and quick to collect, cost principally sample preparation and assaying. |

| Sample quality | Poor: prone numerous sampling errors. |

| Value proposition | Low: strong likelihood of bias, and thus ore/waste misclassification. |

| 1 Assay Type | Assay Charge | Nature of Method | Application | Outcome |

|---|---|---|---|---|

| Fire assay (FA) | 30–50 g | The standard method of fire assaying for gold. | Small charge mass. Poor reproducibility in the presence of coarse gold. | Grade |

| Screen fire assay (SFA) | 0.5–2 kg | A variant of FA, the SFA reduces the coarse-gold problem by sieving out the coarse fraction (100–150 μm screens) and assaying it separately. | An effective method for dealing with coarse gold. Can be used on samples up to 10 kg. | Grade Per cent coarse gold |

| LeachWELL (LW) | 0.5–5 kg | Method overcomes the problem of coarse particles by assaying the entire sample. 24 h leach time effective for most coarse gold deposits. | Large charge mass. Effective method for dealing with coarse gold. The method needs to be controlled by assaying the undissolved residues to check for partly dissolved gold. | Grade Leach recovery (if tails assayed) |

| Pulverise and leach (PAL) | 1 kg | Essentially same as LeachWELL. Crushed (approx. P80 −10 mm) sample is leached and pulverised at the same time. 1–1.5 h leach time. | Smaller charge mass. Potentially effective method for dealing with coarse gold. Some issues relate to contamination of pulverise/leach pots. Method needs to be controlled by assaying the undissolved residues to check for partly dissolved gold. | Grade Leach recovery (if tails assayed) |

| Gamma activation (Chrysos Photon Assay) | 0.5 kg | Novel method based on bombarding the sample with high-energy X-rays to produce gamma rays, which are measured across a given energy for gold. | Moderate charge mass. Sample preparation requires just coarse crush. Reported 1–2 min analysis time. | Grade |

| Whole sample gravity processing (GRAV) | >5–500 kg | Takes a large sample and processes entirely via gravity (e.g., Knelson and/or Wilfley table) to produce a gold concentrate and tails for assay. | Very large charge mass. Effective method for dealing with coarse gold. Method needs to be managed to ensure maximisation of gold recovery. Not useful for fine gold, unless gravity used for gold-rich sulphide concentration and/or clustered fine gold is present, hence larger sample warranted. | Grade GRG (single-stage) Leach recovery (if tails leached) Gold particle size profile (if GRG screened) |

| 1 Preparation-Assay Protocol | 2 FSE (%) | Comments | 3 Total Error | |||

|---|---|---|---|---|---|---|

| Fine Gold | Coarse Gold | Fine Gold | Coarse Gold | |||

| (A) | (1) 2.5 kg crush to P80 −3 mm (2) Pulverise to P90 −75 µm, scoop off 30 g (3) Take for FA30 | ±5 | ±8–30 | Coarse gold FSE range reflects potential efficiency of the pulverising process, where coarse gold (>100 µm) may remain after pulverising Scooping of 30 g from pulp will promote DE, EE and GSE | Low | High |

| (B) | (1) 2.5 kg crush to P80 −3 mm, riffle split off 500 g (2) Pulverise to P90 −75 µm (3) Take for LW500 | ±17 | ±165 | High FSE in both cases indicates splitting at P80 −3 mm As entire 0.5 g sample is pulverised and LW500, then minimal errors at this stage | Mod | High |

| (C) | (1) 2.5 kg crush to P80 −3 mm (2) Pulverise to P90 −75 µm, riffle split off 0.5 kg (3) Take for LW500 | ±1 | ±2–10 | Scooping of 0.5 kg from 2.5 kg of pulp will promote DE, EE and GSE Splitting of 0.5 kg from 2.5 kg must be undertaken using a rotary splitter, particularly in the coarse gold case to minimise DE, EE, and GSE | Low | High |

| (D) | (1) 2.5 kg crush to P80 −3 mm (2) Pulverise to P90 −75 µm, riffle split off 2 kg (3) Take for LW2000 | ±1 | ±1–5 | Approach minimises all sampling errors including FSE Splitting of 2 kg from 2.5 kg should be undertaken using a rotary splitter, particularly in the coarse gold case to minimise DE, EE, and GSE | Low | Low |

| QAQC Action | 11 Rate | Instigator | Key Performance Indicators Fine Gold/[Coarse Gold] | |

|---|---|---|---|---|

| 1 Field duplicates | 1 in 20 | Operation | 90% ±10–25% HARD 10 [90% ±25–50% HARD] | 90% ±13–35% RSV [90% ±35–70% RSV] |

| 2 Sample quality index | All | Operation | Depends upon sample type; for saw-cut channels >80%; for diamond drill core >85% recovery | |

| 3 Coarse reject duplicates | 1 in 20 | Laboratory | 90% ±10–20% HARD [90% ±20–50% HARD] | 90% ±13–28% RSV [90% ±26–70% RSV] |

| 4 Pulp duplicates | 1 in 20 | Laboratory | 90% ±10% HARD [90% ±10–20% HARD] | 90% ±13% RSV [90% ±13–28% RSV] |

| 5 Certified Reference Materials | 1 in 20 | Operation and laboratory | <2δ (“safe zone”) no action required 2δ–3δ (“warning”) investigate (re-assay 25% of batch if required) >3δ (“action”) re-assay 100% of batch | |

| 6 Blanks | 1 in 20 | Operation and laboratory | Less than 0.05 g/t Au | |

| 7 Pulp quality | 1 in 20 | Laboratory | 95% to be P95 −75 µm | |

| 8 Barren flush | 1 in 20–50 | Laboratory | <<0.5% gold loss | |

| 9 Umpire | 1 in 20 | Operation | 90% ±10% HARD | 90% ±13% RSV |

| Laboratory audit | Quarterly | Operation | Full adherence to agreed practices and performance levels | |

| QAQC review | Monthly | Operation and laboratory | Compliance across all metrics | |

| Type | Mean Support (kg/m) [Range] | Target Support (%) [within ±5%] | Mean Grade (g/t Au) | Percent of Mined Grade (%) | RSV (%) | Nugget Effect (%) | 1 Sample Collection Errors | 2 Preparation and Assay Errors |

|---|---|---|---|---|---|---|---|---|

| Chip-channel | 2.1 [1.4–3.4] | 22 | 21.3 | +55 | 198 | 68 | High: DE, EE, and WE | Low: entire sample crushed and pulverised prior to total sample screen fire assay with triplicate fine-fraction fire assay. All equipment cleaned between samples. |

| Channel (hand cut) | 2.6 [2.1–3.3] | 63 | 16.7 | +22 | 135 | 54 | Low-moderate: DE, EE, and WE | |

| Channel (saw-cut) | 2.8 [2.3–3.1] | 77 | 16.3 | +19 | 81 | 41 | Low: DE, EE, and WE |

| Sample Type/Error (Preparation Route) | Sampling (%) | Preparation (%) | Analytical (%) | Total (%) |

|---|---|---|---|---|

| 1 m 3 kg Field Sample | Crushed to <1.5 mm; Riffle Split into 1.5 kg Sub-Samples | Pulverised to 75 µm; 50 g Riffle Split from 1.5 kg for Fire Assay | 1 m 3 kg Sample to Duplicate 50 g Fire Assay | |

| Chip | 67 | 31 | 17 | 76 |

| Channel (hand) | 48 | 29 | 14 | 58 |

| Channel (saw) | 21 | 27 | 15 | 37 |

| Estimated stage FSE | - | 23 | 18 | 29 |

| Parameter | Mine A | Mine B |

|---|---|---|

| Characteristics of Mineralisation | ||

| Mineralisation style | Epithermal vein | Mesothermal vein |

| Mining method | Underground (long-hole open stoping) | Underground (shrinkage stoping) |

| GRG component (%) | 20 | 55 |

| Grade (g/t Au) | 10 | 15 |

| Grade RSV (%) | 67 | 117 |

| Nugget effect (%) | 20 | 65 |

| Liberation diameter (µm) | 70 | 750 |

| Sampling Constant (K) | 115 | 2600 |

| Routine sample type used | Chip | Channel (hand cut) |

| Pairwise RSV for Each Error | ||

| No. of duplicate pairs used | 50 | 50 |

| Chip (sampling error) | 31% | 67% |

| Channel [hand] (sampling error) | 27% | 48% |

| Channel [saw-cut] (sampling error) | 25% | 21% |

| Range of preparation errors | 10–14% | 27–31% |

| Range of analytical errors | 7–11% | 14–17% |

| Sample Type/Geomet Parameter | In-Situ Rock | Broken Rock | ||||

|---|---|---|---|---|---|---|

| Drill | Linear | |||||

| Core | RC | Sludge | Chip | Channel 1 | Grab | |

| Geochemistry/mineralogy | ||||||

| Rock mass | ||||||

| Comminution | ||||||

| Metallurgical recovery | ||||||

| Geoenvironmental | ||||||

| Key Parameter | Comment | Material Error | 1 Total Error Rating | |

|---|---|---|---|---|

| 1 | Spatial distribution and number of samples | Samples collected at approx. 2 m intervals along drives. Raises not sampled Each stope block informed by around 20–25 samples | GNE | Moderate |

| 2 | Sample mass | Each face composite sample approx. 2–4 kg; total sample mass collected approx. 65–70 kg Indicated optimum mass around 450 kg to achieve 90% ±15% | GNE | High |

| 3 | Degree of domaining | Wall rock and central shear sampled separately | - | Low |

| 4 | Collection and handling | Samples collected by chip-channel Uneven weighting across the face, where the soft narrow central-shear is oversampled (approx. 5–6 kg/m) compared to the wall rocks (approx. 2–3 kg/m) All samples placed into calico bags and tied | EE, WE | High |

| 5 | Transport and security | No chain of custody recorded between mine and off-site laboratory | PE | Moderate |

| 6 | Preparation | Entire sample lot crushed and pulverised, and 30 g riffle split for fire assay Equipment cleaning variable | FSE, GSE, DE, EE, PE | High |

| 7 | Assay | Fire assay process undertaken correctly, but together with 6 not appropriate for coarse gold ore | - | Moderate |

| 8 | QAQC | One CRM used at high grade (70% within 3δ; 30% above 3δ) Few blanks used No written protocols for the sampling-assaying process | PE, AE | High |

| 9 | Validation | Plant recovers 35% less gold than estimate | - | High |

| Sample representativity (1)–(4) | Poor | |||

| Assay quality (5)–(8) | Poor | |||

| Fit-for-purpose rating (1)–(9) | Poor | |||

| Stage | Key Activity |

|---|---|

| 1: Scope |

|

| 2: Develop |

|

| 3: Execute |

|

| 4: Validate |

|

| 5: Refine |

|

| Sample Type | Summary | 1 Sampling Errors | 2 Total Error Rating | ||

|---|---|---|---|---|---|

| DE | EE | WE | |||

| Linear | |||||

| Chip | Easy to collect, relatively fast High number can be collected Cheap | High | |||

| Chip-channel | Relatively easy to collect and fast Moderately high number can be collected Moderately cheap | High | |||

| Channel (hand-cut) | Less easy to collect, requires effort Moderately high number can be collected Higher cost | Mod | |||

| Channel (saw-cut) | Requires effort and specialist equipment Moderate number can be collected Higher cost | Low | |||

| Panel | Medium-large sample size (>25 kg) Large sample size Less easy to collect Moderate number can be collected | Mod | |||

| Broken Rock | |||||

| Grab | Relatively easy to collect Moderate number can be collected Cheap | High | |||

| Drilling | |||||

| Diamond core | Well established method Good geological information Relatively costly | Low | |||

| Reverse circulation | FSE potentially mod-high when sub-sample split from original, though modern technology much improved Cheaper than core drilling | Low | |||

| Sludge (blasthole) | FSE potentially mod-high when sub-sample split from original Sample collection/splitting at the rig problematic, though some mines have devised a reasonable catcher system Cheap | Mod | |||

| Mini-bulk (<1 t)/Bulk (>1 t) | |||||

| Bulk | Comprise (i) panel or (ii) blasted/excavated blocks Careful planning required Good geological and geotechnical information Relatively costly depending upon mass | Low | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dominy, S.C.; Glass, H.J.; O’Connor, L.; Lam, C.K.; Purevgerel, S.; Minnitt, R.C.A. Integrating the Theory of Sampling into Underground Mine Grade Control Strategies. Minerals 2018, 8, 232. https://doi.org/10.3390/min8060232

Dominy SC, Glass HJ, O’Connor L, Lam CK, Purevgerel S, Minnitt RCA. Integrating the Theory of Sampling into Underground Mine Grade Control Strategies. Minerals. 2018; 8(6):232. https://doi.org/10.3390/min8060232

Chicago/Turabian StyleDominy, Simon C., Hylke J. Glass, Louisa O’Connor, Chloe K. Lam, Saranchimeg Purevgerel, and Richard C.A. Minnitt. 2018. "Integrating the Theory of Sampling into Underground Mine Grade Control Strategies" Minerals 8, no. 6: 232. https://doi.org/10.3390/min8060232