Breakage Function for HPGR: Mineral and Mechanical Characterization of Tantalum and Tungsten Ores

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

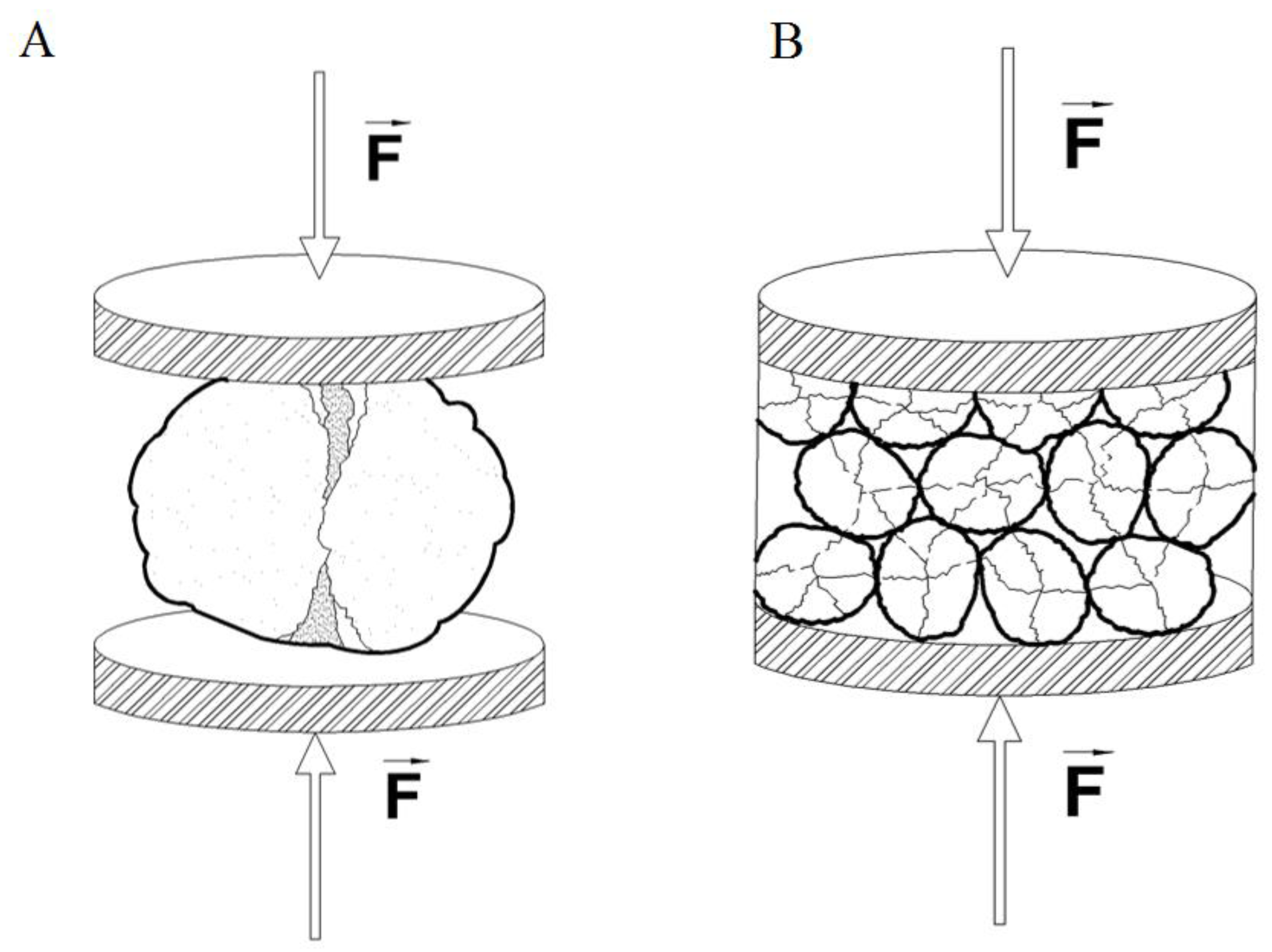

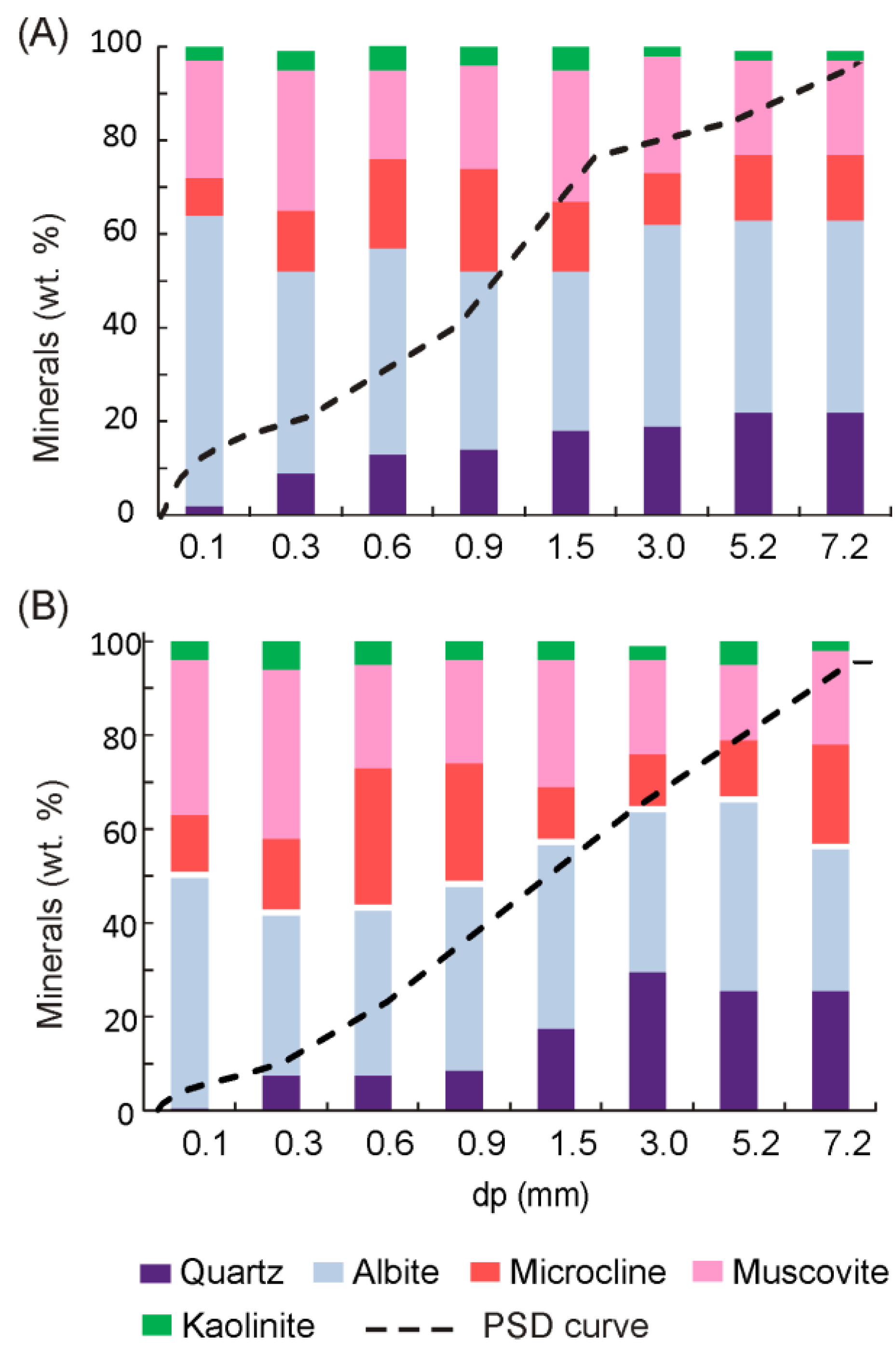

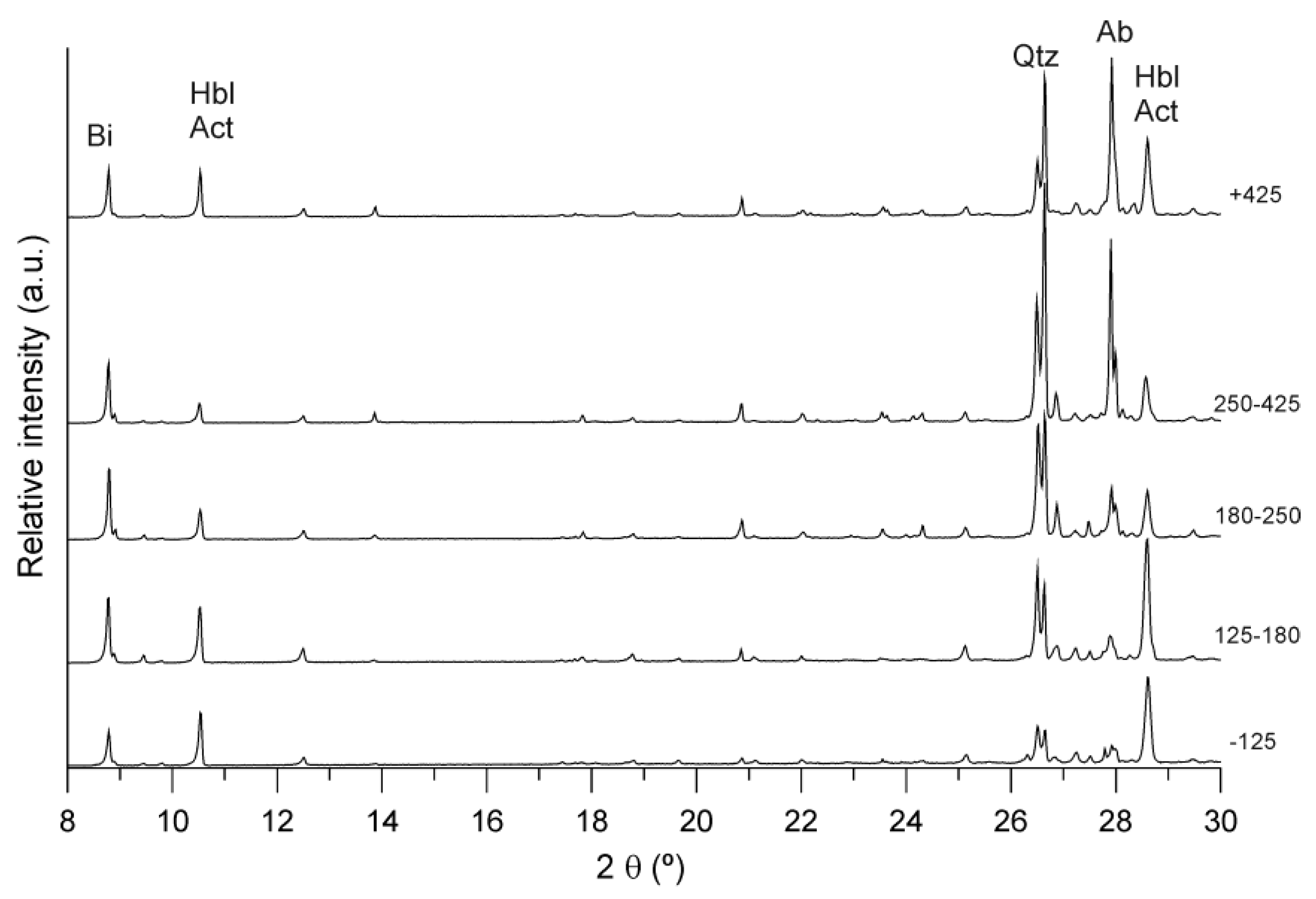

2.2. Mineral Characterization

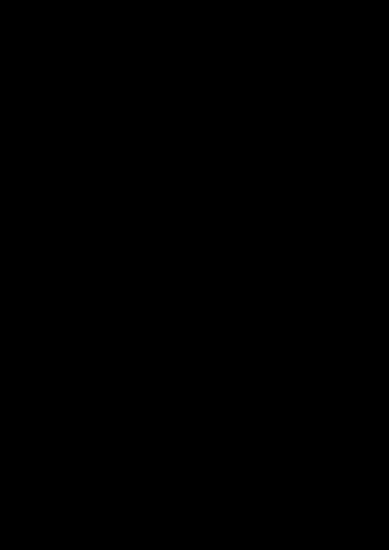

2.3. Piston Press Test

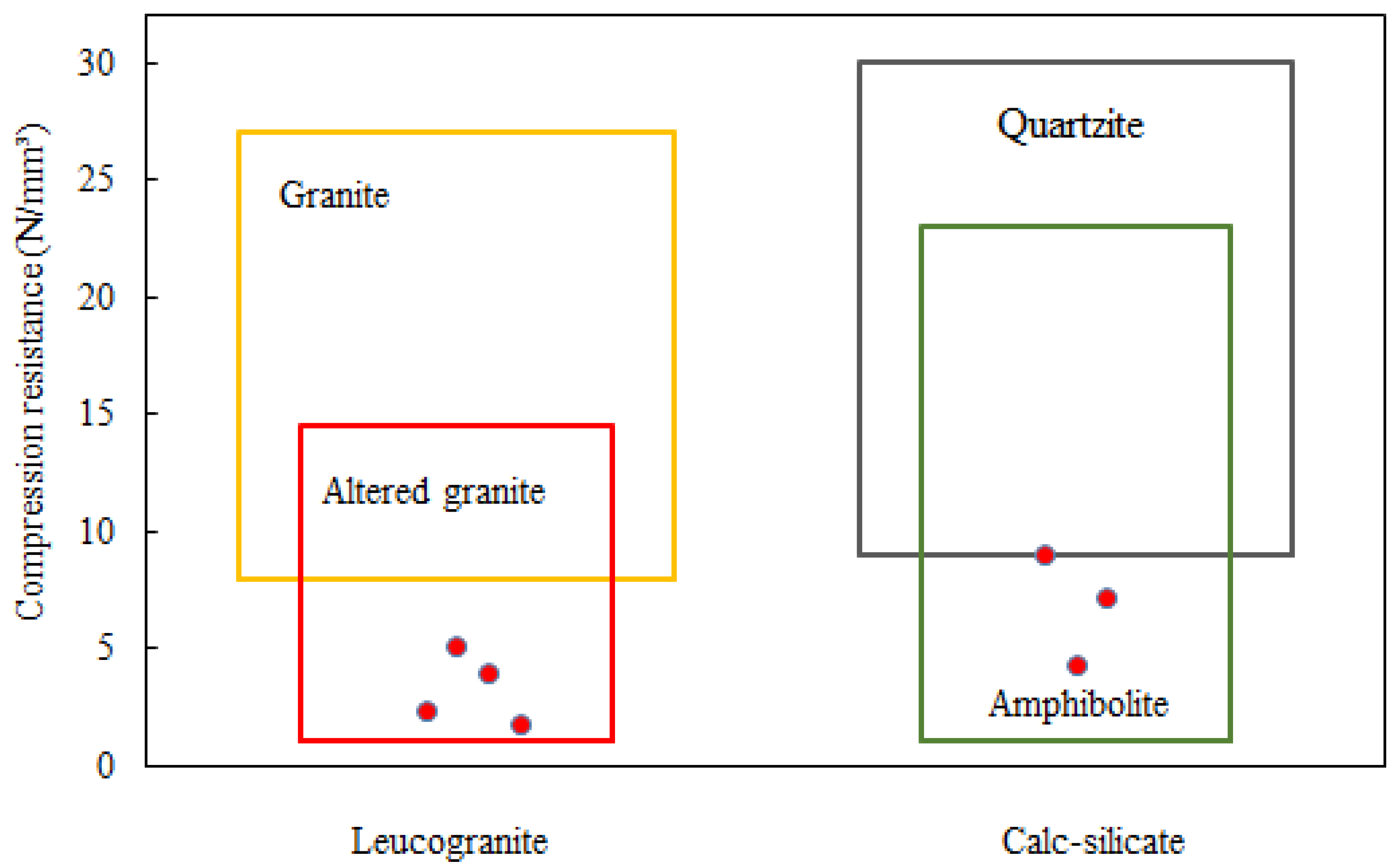

2.4. Single Compression Strength Tests

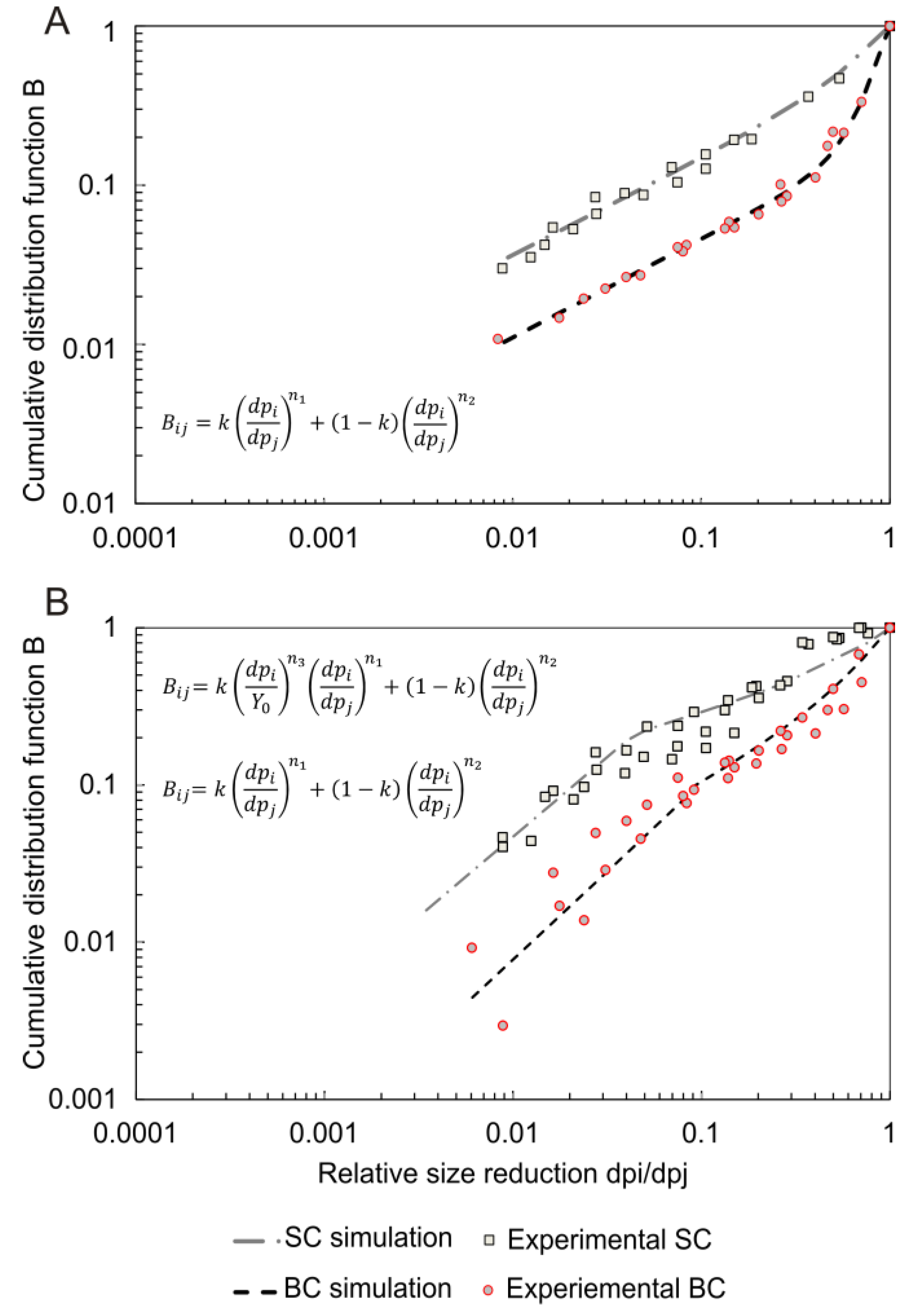

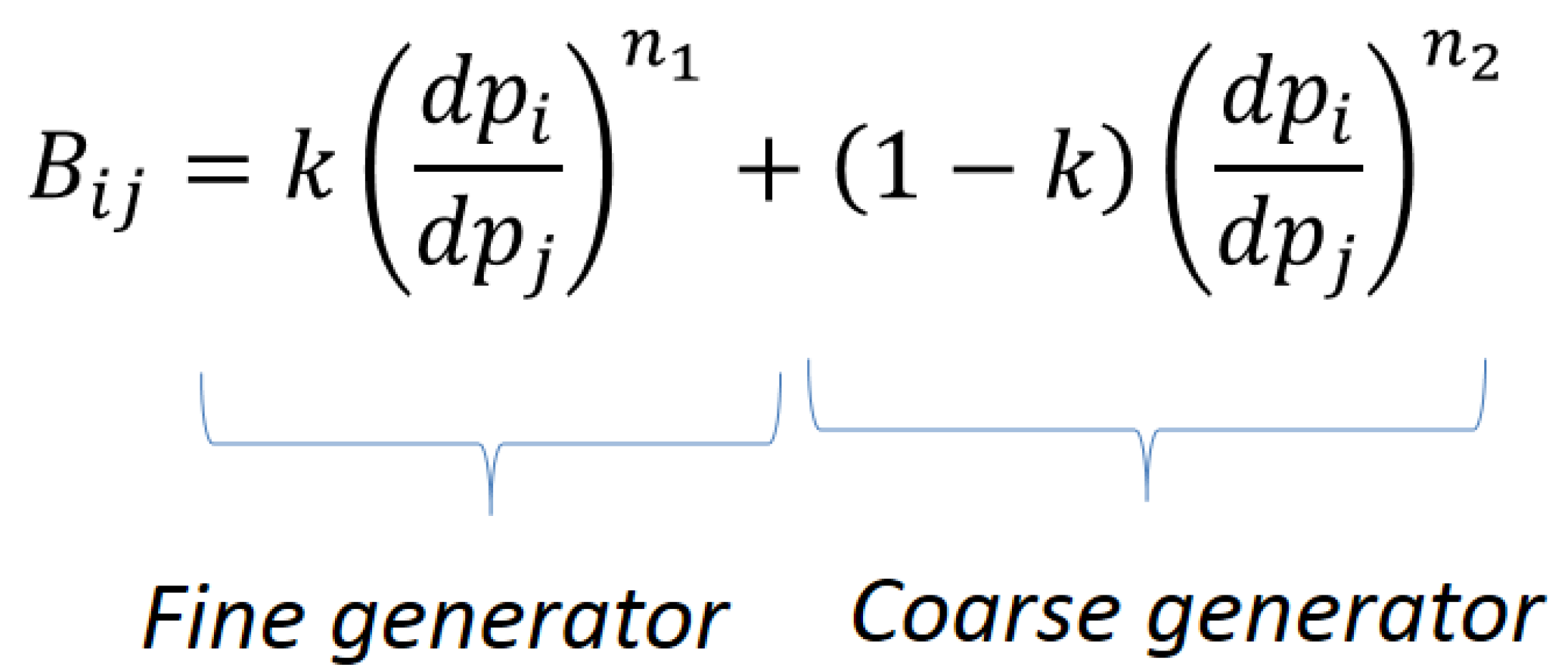

2.5. Back-Calculation

3. Results

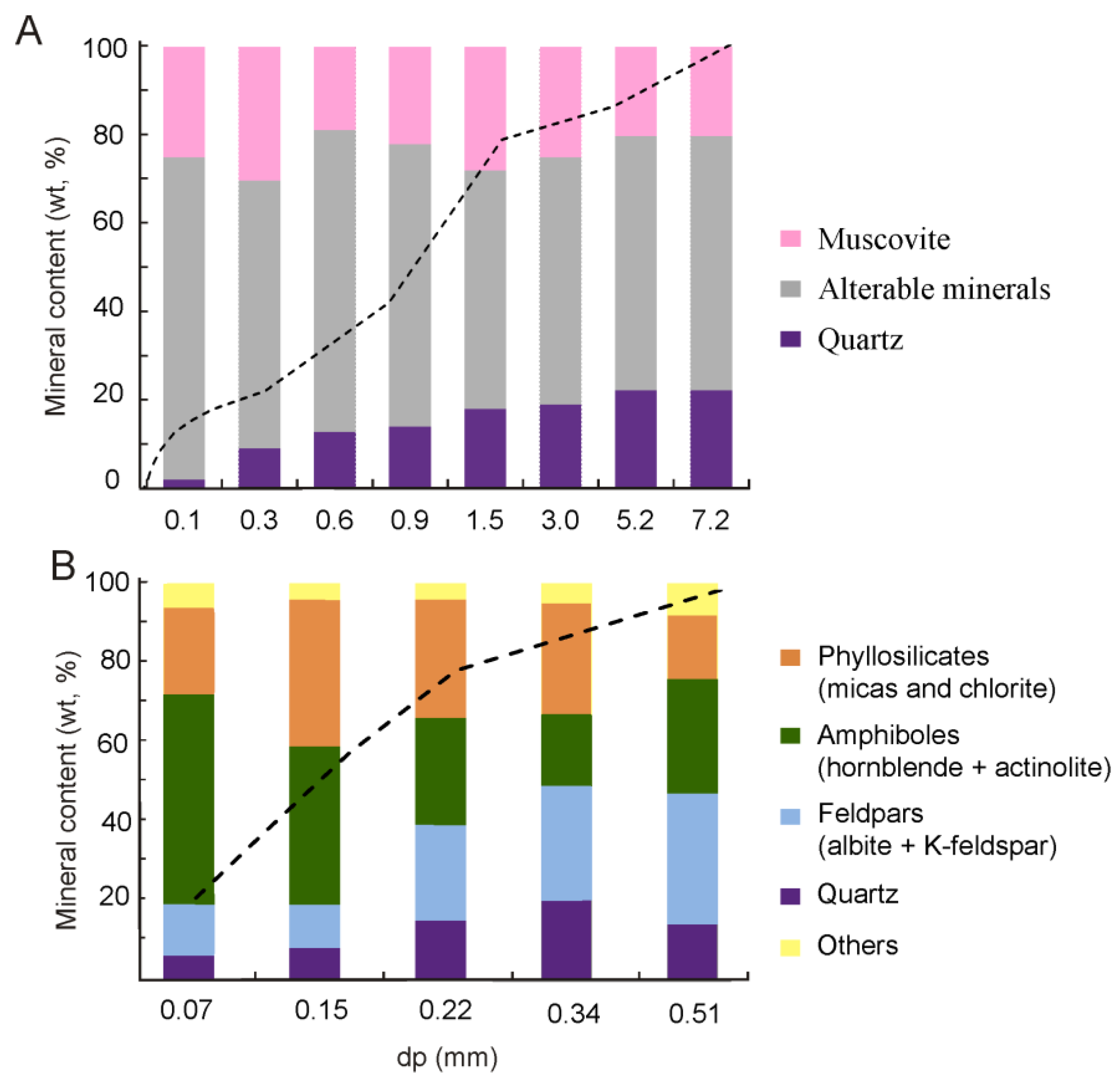

3.1. Mineralogical Characteristics

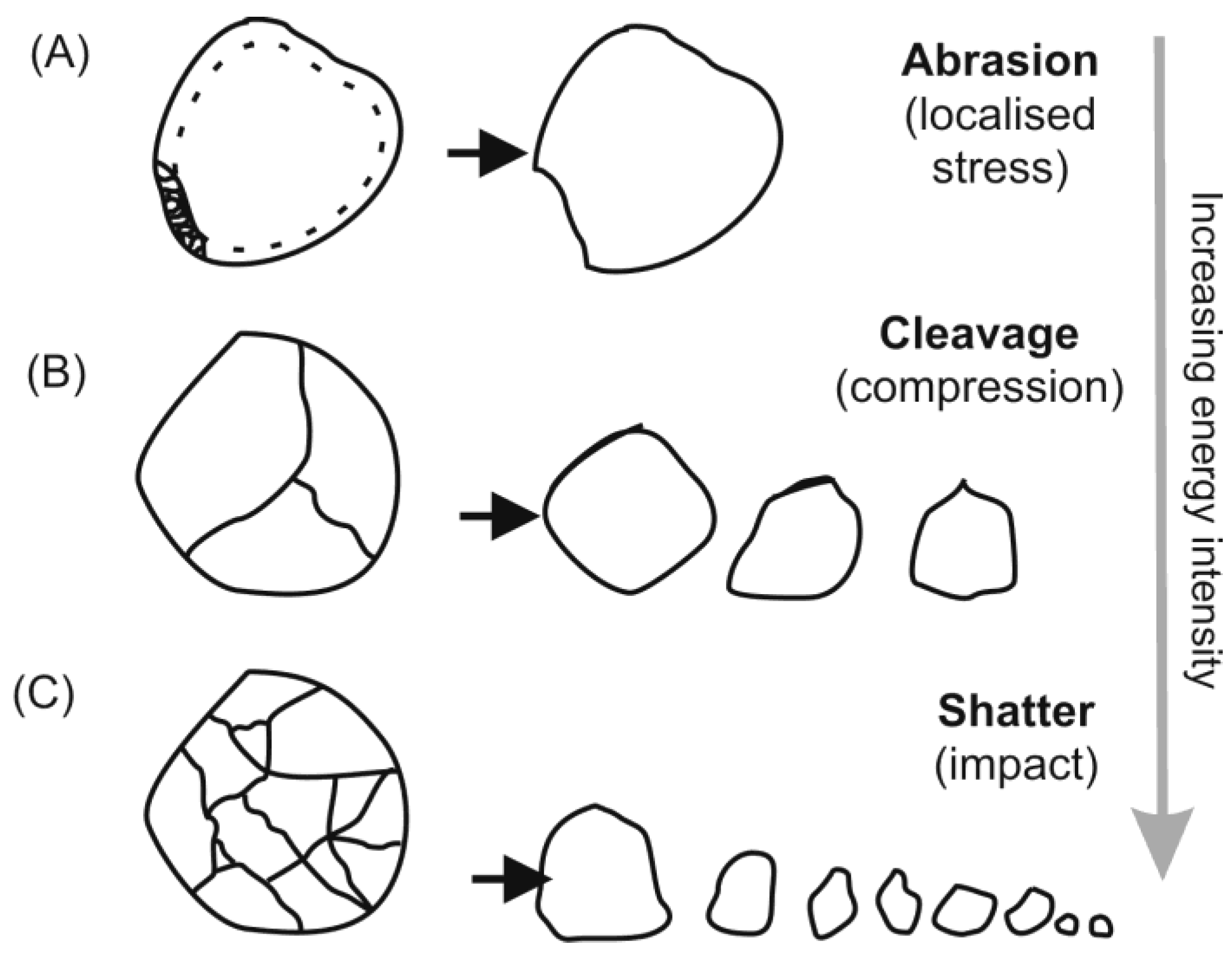

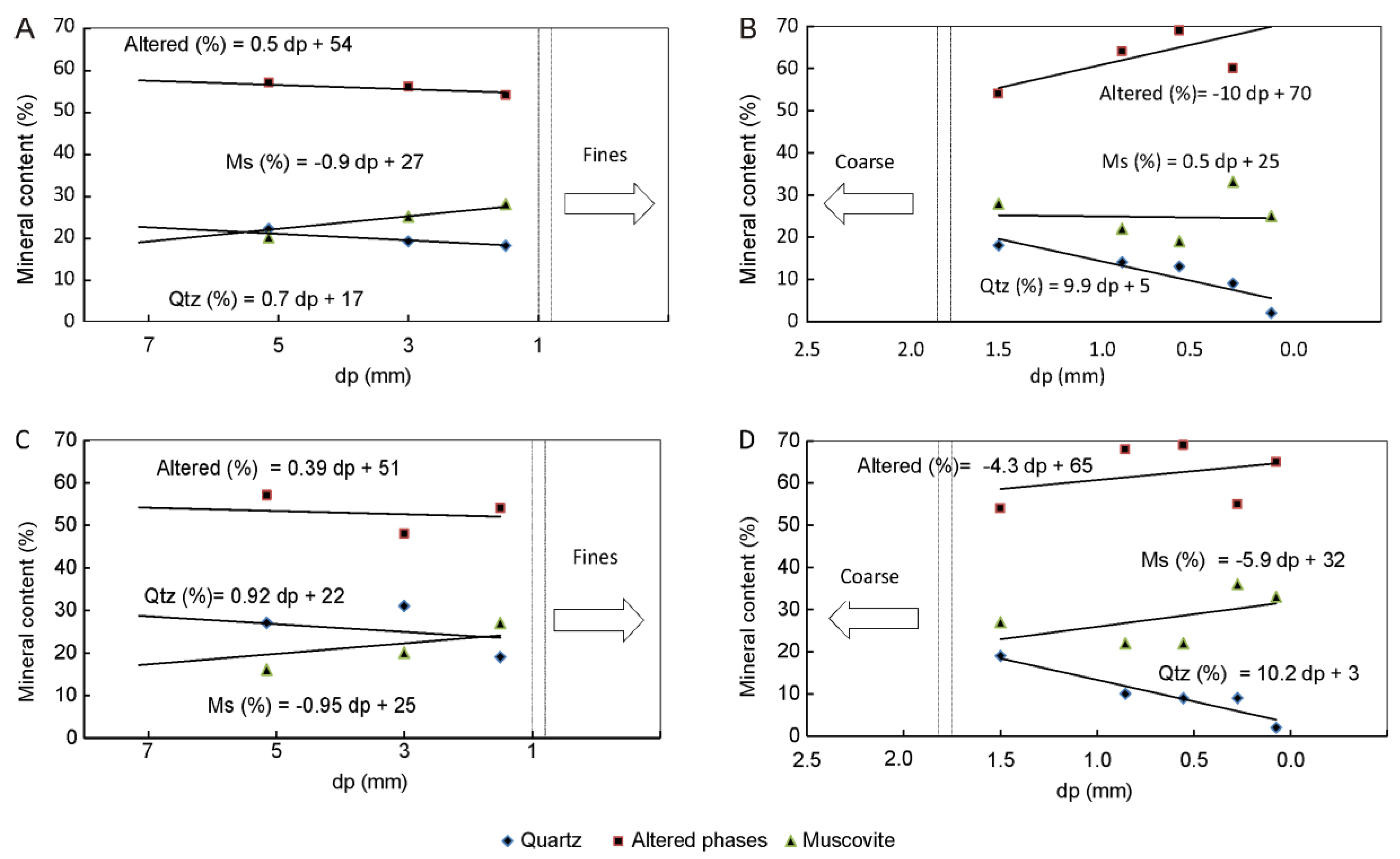

3.2. Breakage Function

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lee, H.; Kim, K.; Kim, J.; You, K.; Lee, H. Breakage characteristic of heat-treated limestone determined via kinetic modeling. Minerals 2018, 8, 18. [Google Scholar] [CrossRef]

- King, R.P. Modelling and Simulation of Mineral Processing Systems; Butterworth-Heinemann: Oxford, UK, 2001. [Google Scholar]

- Guasch, E.; Anticoi, H.; Hamid, S.A.; Alfonso, P.; Oliva, J.; Escobet, T. New approach to ball mill modelling as a piston flow. Miner. Eng. 2018, 116, 82–87. [Google Scholar] [CrossRef]

- Esnault, V.P.B.; Zhou, H.; Heitzmann, D. New population balance model for predicting particle size evolution in compression grinding. Miner. Eng. 2015, 73, 7–15. [Google Scholar] [CrossRef]

- Austin, L.G.; Weller, K.R.; Lim, I.L. Phenomenological Modelling of the High Pressure Grinding Rolls. In Proceedings of the XVIII International Mineral Processing Congress, Sydney, Australia, 23–28 May 1993; pp. 87–95. [Google Scholar]

- Torres, M.; Casali, A. A novel approach for the modelling of high-pressure grinding rolls. Miner. Eng. 2009, 22, 1137–1146. [Google Scholar] [CrossRef]

- Austin, L.G.; Luckie, P.T. The estimation of Non-normalized breakage distribution parameters from batch grinding test. Powder Technol. 1971, 5, 267–271. [Google Scholar] [CrossRef]

- Austin, L.G.; Luckie, P.T. Methods for determination of breakage distribution parameters. Powder Technol. 1972, 5, 215–222. [Google Scholar] [CrossRef]

- Austin, L.G.; Concha, L. Diseño de Simulación de Circuitos de Molienda y Clasificación; Programa Iberoamericano de Ciencia y Tecnología Para el Desarrollo; CYTED: Concepción, Chile, 1994. (In Spanish) [Google Scholar]

- Benzer, H.; Aydogan, N.; Dundar, H. Investigation of the breakage of hard and soft components under high compression: HPGR application. Miner. Eng. 2011, 22, 303–307. [Google Scholar] [CrossRef]

- Dundar, H.; Benzer, H.; Aydogan, N. Application of population balance model to HPGR crushing. Miner. Eng. 2013, 50–51, 114–120. [Google Scholar] [CrossRef]

- Tavares, L. Particle weakening in high-pressure roll grinding. Miner. Eng. 2005, 18, 651–657. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Buscanera, G.; Einav, I. Grain size dependence of yielding in granular soils interpreted using fracture mechanics, breakage mechanics and Weibull statistics. Géotechnique 2016, 66, 149–160. [Google Scholar] [CrossRef]

- Chimwani, N.; Glasser, D.; Hildebrandt, D.; Metzger, M.J.; Mulenga, F.K. Determination of the milling parameters of a platinum group minerals ore to optimize product size distribution for flotation purposes. Miner. Eng. 2013, 43–44, 67–78. [Google Scholar] [CrossRef]

- Hasanzadeh, V.; Farzanegan, A. Robust HPGR model calibration using genetic algorithms. Miner. Eng. 2011, 24, 424–432. [Google Scholar] [CrossRef]

- Sohn, C.; Zhang, Y.D.; Cil, M.; Buscarnera, G. Experimental assessment of continuum breakage models accounting for mechanical interactions at particle contacts. Granul. Matter 2017, 19, 67. [Google Scholar] [CrossRef]

- Petrakis, E.; Komnitsas, K. Improved modelling of the grinding process through the combined use of matrix and population balance models. Minerals 2017, 7, 67. [Google Scholar] [CrossRef]

- Petrakis, E.; Komnitsas, K. Correlation between Material Properties and Breakage Rate Parameters Determined from Grinding Tests. Appl. Sci. 2018, 8, 220. [Google Scholar] [CrossRef]

- Parian, M.; Mwanga, A.; Lamberg, P.; Rosenkranz, J. Ore texture breakage characterization and fragmentation into multiphase particles. Powder Technol. 2018, 327, 57–69. [Google Scholar] [CrossRef]

- Kelly, E.G.; Spottiswood, D.J. The breakage function; what is it really? Miner. Eng. 1990, 3, 405–414. [Google Scholar] [CrossRef]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- UNE-EN 1926. Métodos de Ensayo Para Piedra Natural: Determinación de la Resistencia a la Compresión; AENOR: Madrid, Spain, 1999. [Google Scholar]

- Alfonso, P.; Hamid, S.A.; Garcia-Valles, M.; Llorens, T.; Tomasa, O.; Calvo, D.; Guasch, E.; Anticoi, H.; Oliva, J.; López Moro, J.; et al. Nb-Ta mineralization from the rare element granite from Penouta, Galicia, Spain. Miner. Mag. 2018, accepted. [Google Scholar]

- Hamid, S.A.; Alfonso, P.; Anticoi, H.; Guasch, E.; Oliva, J.; Garcia-Valles, M. Quantitative mineralogical comparison between HPGR and ball mill products of a Sn-Ta ore. Minerals 2018, 8, 151. [Google Scholar] [CrossRef]

- Gupta, A.S.; Rao, K.S. Weathering effects on the strength and deformational behaviour of crystalline rocks under uniaxial compression state. Eng. Geol. 2000, 56, 257–274. [Google Scholar] [CrossRef]

- Chang, C.; Hairnson, B. True triaxial strength and deformability of the German Continental Deep Drilling Program (KTB) deep hole amphibolite. J. Geophys. Res. 2000, 105, 18999–19013. [Google Scholar] [CrossRef]

- Souček, K.; Vavro, M.; Staš, L.; Vavro, L.; Waclawik, P.; Konicek, P.; Ptáček, J.; Vondrovic, L. Geotechnical Characterization of Bukov Underground Research Facility. Procedia Eng. 2017, 191, 711–718. [Google Scholar] [CrossRef]

- Bowers, L.R.; Broaddus, W.R.; Dwyer, J.; Hines, J.; Stansell, R. Processing Plant Principles. In The Aggregate Handbook, 3rd ed.; Barksdale, R., Ed.; National Stone Association: Washington, DC, USA, 1996; pp. 81–84. [Google Scholar]

| Conditions | Mesh Size (mm) | Granite | Calc-Silicate |

|---|---|---|---|

| SC | 2.0–4.0 | 42.2 | 39.4 |

| 4.0–4.8 | 50.2 | 69.9 | |

| 4.8–6.7 | 81.7 | 11.32 | |

| 6.7–9.5 | 88.2 | 38.5 | |

| 9.5–11.2 | 141.3 | 49.2 | |

| 11.2–12.5 | 194.0 | 58.3 | |

| 12.5–14.0 | 257.9 | 63.4 | |

| 14.0–16.0 | 343.8 | 93.7 | |

| 16.0–19.0 | 489.8 | - | |

| BC | 0.71–1.0 | 73.0 | 35.6 |

| 1.0–2.0 | 88.1 | 88.3 | |

| 2.0–4.0 | 101.7 | 43.3 | |

| 4.0–4.8 | 86.9 | 33.0 |

| Material | Condition | k | n1 | n2 | n3 | Y0 |

|---|---|---|---|---|---|---|

| Granite | SC | 0.68 | 0.37 | 1.95 | 0.64 | 0.0036 |

| BC | 0.47 | 0.66 | 2.16 | 0.45 | 0.0045 | |

| Calc-silicate | SC | 0.60 | 0.61 | 2.32 | - | - |

| BC | 0.19 | 0.62 | 4.37 | - | - |

| Material | Condition | k | n1 | n2 | n3 | Y₀ |

|---|---|---|---|---|---|---|

| Altered granite | SC | 0.99 | 0.92 | 2.53 | 1.00 | 0.21 |

| BC | 0.89 | 0.00 | 2.28 | 0.43 | 0.50 | |

| Calc-silicate | SC | 0.60 | 0.82 | 5.00 | - | - |

| BC | 0.34 | 0.00 | 5.00 | - | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anticoi, H.; Guasch, E.; Hamid, S.A.; Oliva, J.; Alfonso, P.; Garcia-Valles, M.; Bascompta, M.; Sanmiquel, L.; Escobet, T.; Argelaguet, R.; et al. Breakage Function for HPGR: Mineral and Mechanical Characterization of Tantalum and Tungsten Ores. Minerals 2018, 8, 170. https://doi.org/10.3390/min8040170

Anticoi H, Guasch E, Hamid SA, Oliva J, Alfonso P, Garcia-Valles M, Bascompta M, Sanmiquel L, Escobet T, Argelaguet R, et al. Breakage Function for HPGR: Mineral and Mechanical Characterization of Tantalum and Tungsten Ores. Minerals. 2018; 8(4):170. https://doi.org/10.3390/min8040170

Chicago/Turabian StyleAnticoi, Hernan, Eduard Guasch, Sarbast Ahmad Hamid, Josep Oliva, Pura Alfonso, Maite Garcia-Valles, Marc Bascompta, Lluis Sanmiquel, Teresa Escobet, Rosa Argelaguet, and et al. 2018. "Breakage Function for HPGR: Mineral and Mechanical Characterization of Tantalum and Tungsten Ores" Minerals 8, no. 4: 170. https://doi.org/10.3390/min8040170