Characterization of a Fine-Grained Interstratification of Turbostratic Talc and Saponite

Abstract

:1. Introduction

- Stevensite: ;

- Saponite: type I; ;

- type II: ;

- type III: .

2. Material

3. Methods

3.1. Sample Preparation and Size Fractionation

3.2. X-ray Diffraction (XRD) Analysis

3.3. Modeling of the One-Dimensional X-ray Pattern

3.4. Infrared Spectroscopy—Attenuated Total Reflection Spectroscopy (ATR)

3.5. X-ray Fluorescence (XRF) Analysis

3.6. Simultaneous Thermal Analysis (STA)

3.7. Cation Exchange Capacity (CEC) and Exchangeable Cations

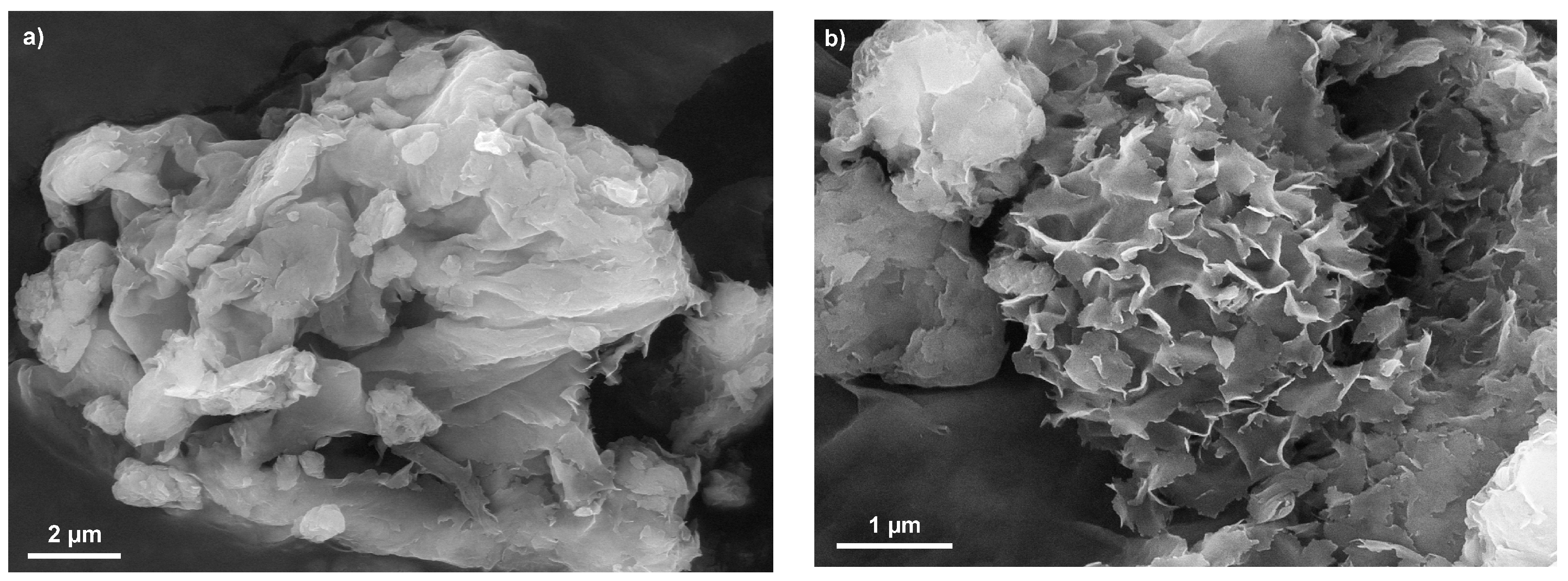

3.8. Environmental Scanning Electron Microscope (ESEM)

3.9. Specific Surface Area (AS)

4. Results and Discussion

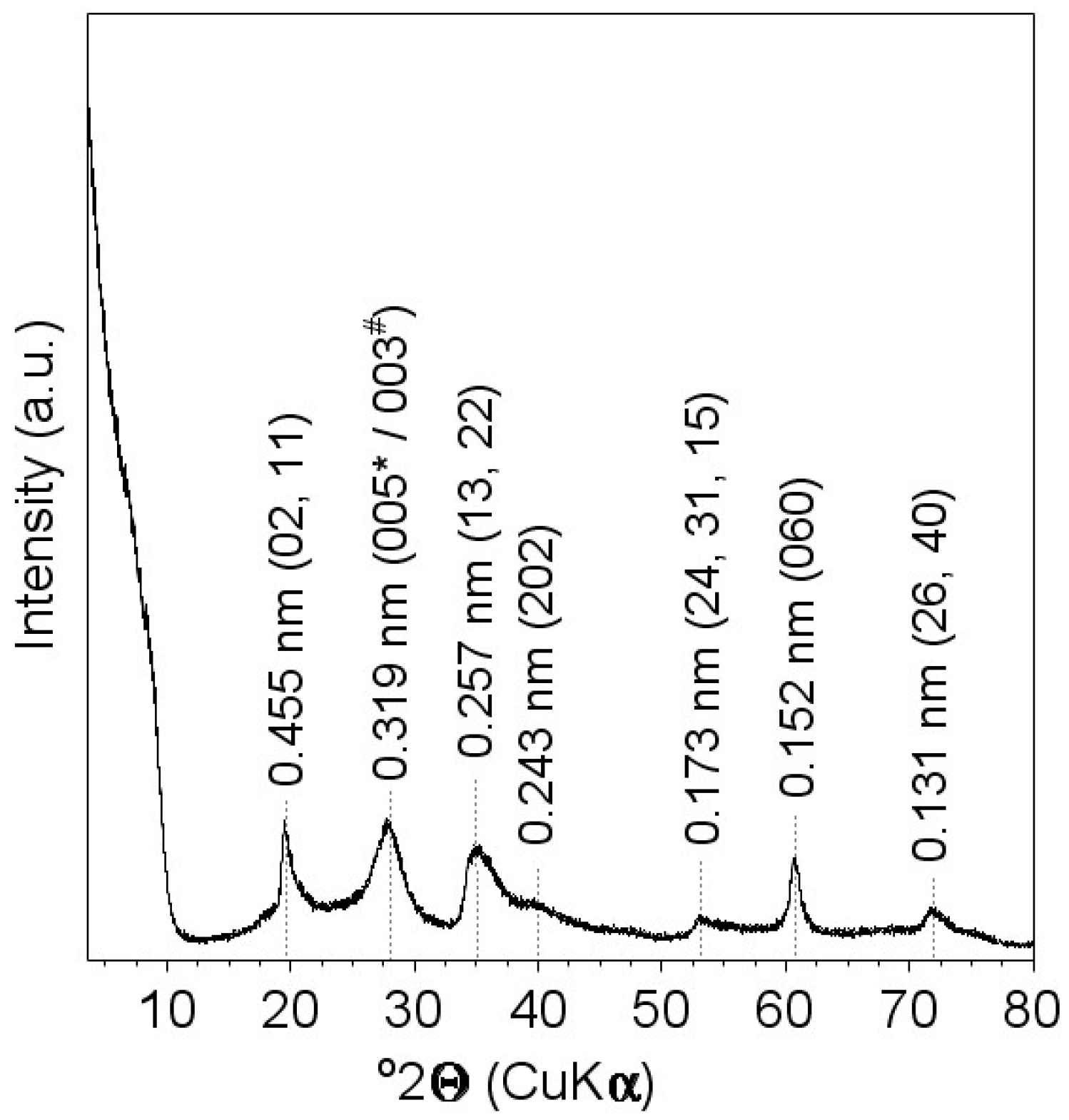

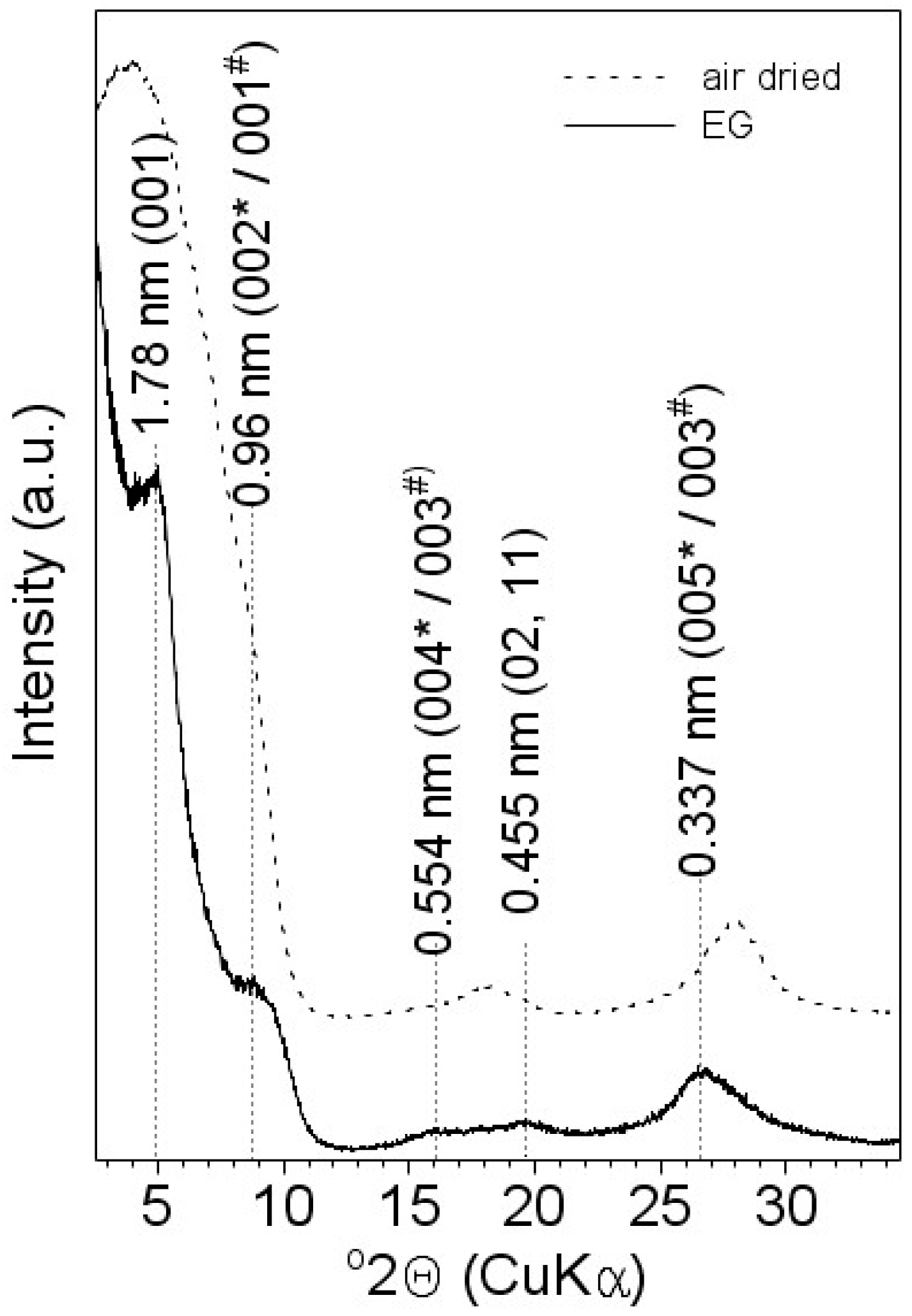

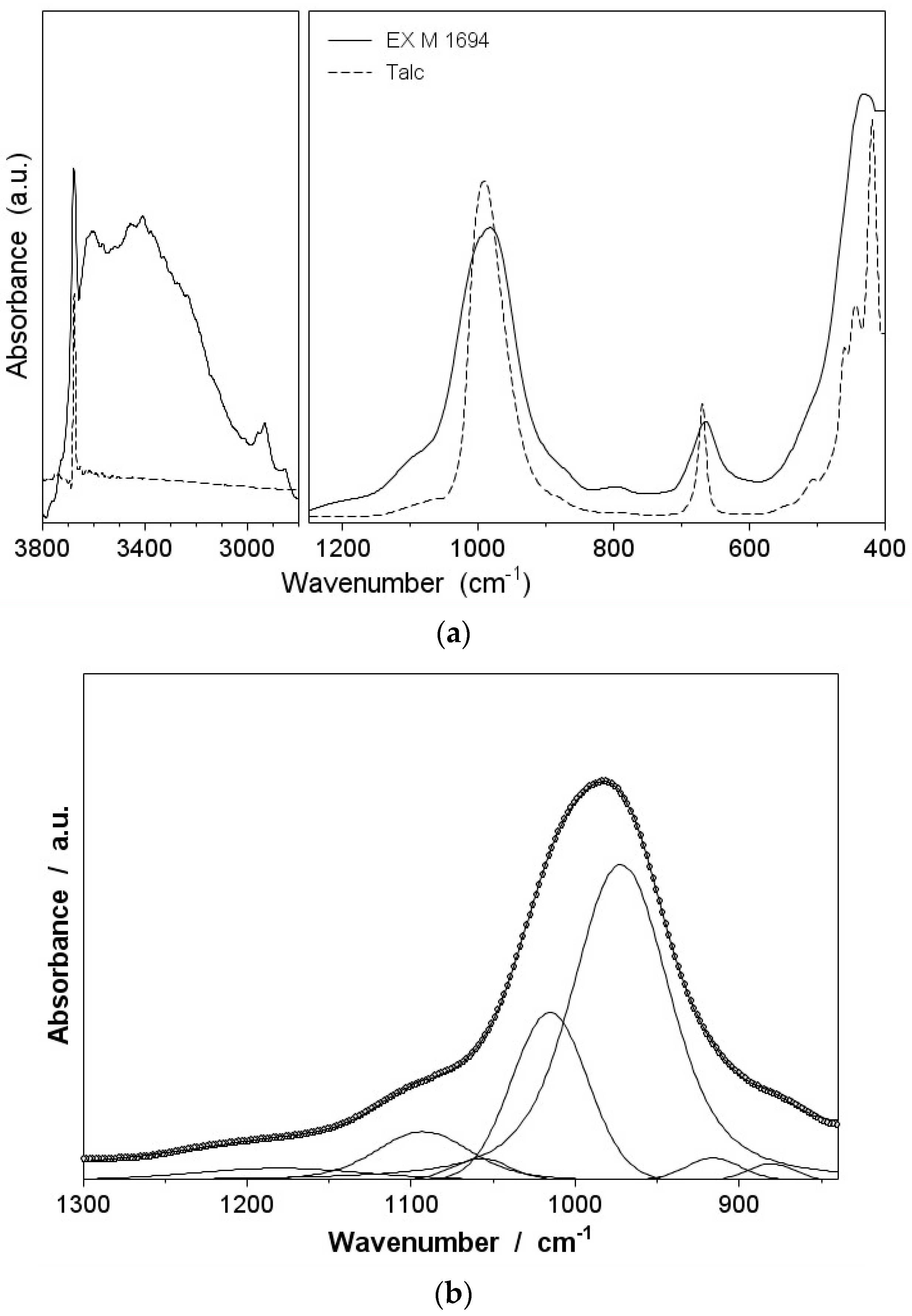

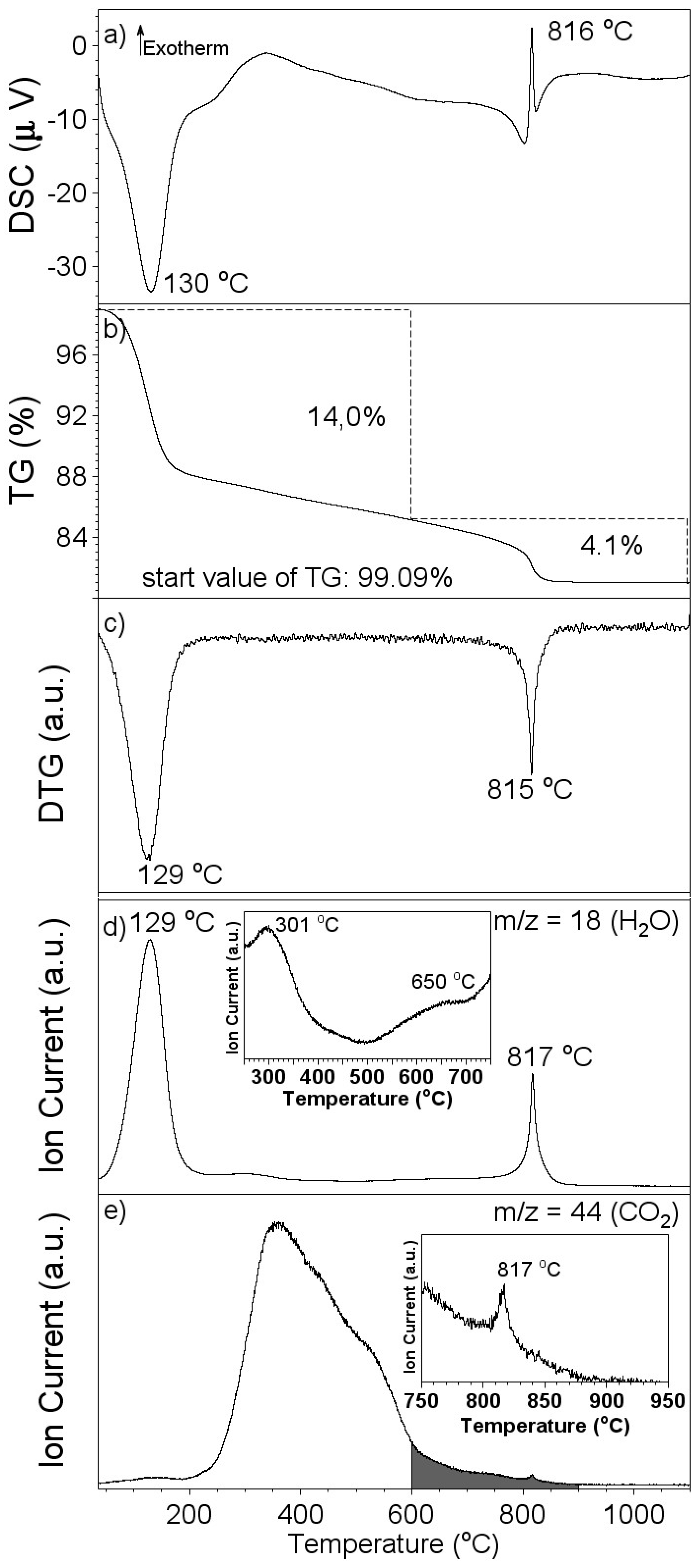

4.1. Mineralogy

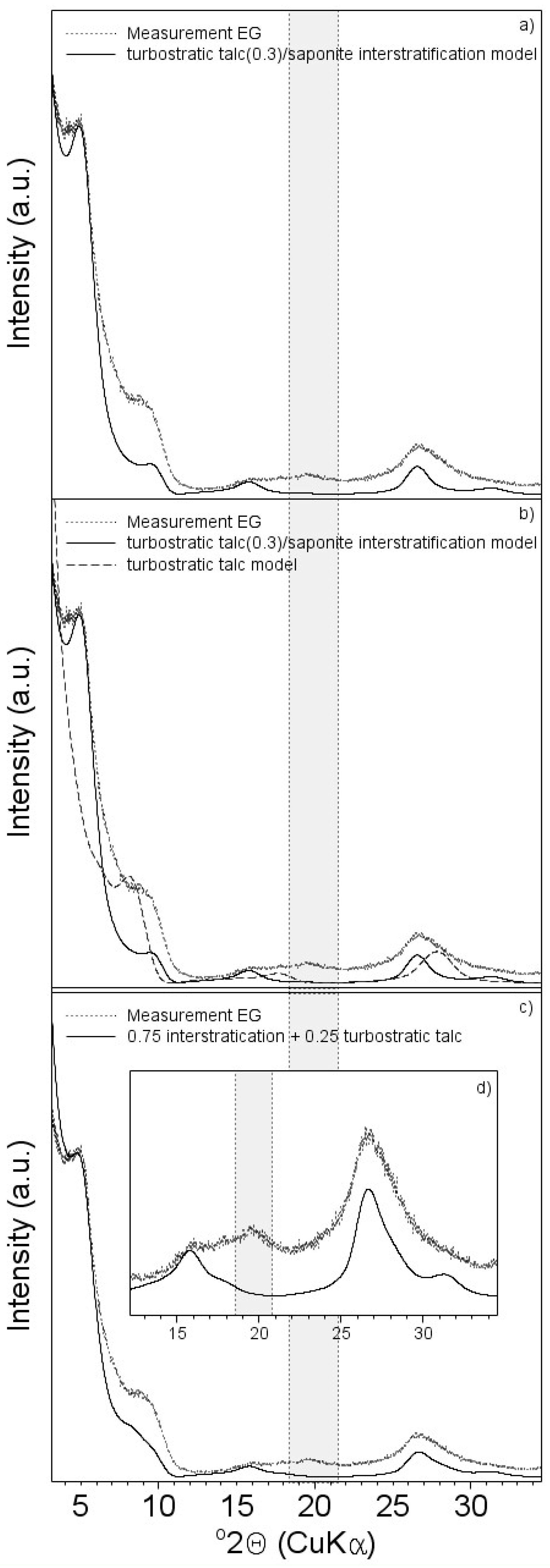

4.2. Interstratification Studies

4.3. Surface Properties of the Interstratification

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Alietti, A.; Mejsner, J. Structure of a talc/saponite mixed-layer mineral. Clays Clay Miner. 1980, 28, 388–390. [Google Scholar] [CrossRef]

- Eberl, D.D.; Jones, G.; Khoury, H.N. Mixed-layer kerolite/stevensite from the Amargosa Desert, Nevada. Clays Clay Miner. 1982, 57, 115–133. [Google Scholar] [CrossRef]

- De Vidales, J.L.M.; Pozo, M.; Alia, J.M.; Garcia-Navarro, F.; Rull, F. Kerolite-stevensite mixed-layers from the Madrid basin, Central Spain. Clay Miner. 1991, 26, 329–342. [Google Scholar] [CrossRef]

- Cuevas, J.; Pelayo, M.; Rivas, P.; Leguey, S. Characterization of Mg-clays from the Neogene of the Madrid basin and their potential as backfilling and sealing material in high level radioactive waste disposal. Appl. Clay Sci. 1993, 7, 383–406. [Google Scholar] [CrossRef]

- Pozo, M.; Casas, J. Origin of kerolite and associated Mg clays in palustrine-lacustrine environments. The Esquivias deposit (Neogene Madrid Basin, Spain). Clay Miner. 1999, 34, 395–418. [Google Scholar] [CrossRef]

- De Santiago Buey, C.; Suarez Barrios, M.; Garcia Romero, E.; Dominiguez Diaz, M.C.; Doval Montoya, M. Electron microscopic study of the illite-smectite transformation in the bentonites from Cerro del Aquila (Toledo, Spain). Clay Miner. 1998, 33, 501–510. [Google Scholar] [CrossRef]

- Brindley, G.W.; Bish, D.L.; Wan, H.-M. The nature of kerolite, its relation to talc and stevensite. Mineral. Mag. 1977, 41, 443–452. [Google Scholar] [CrossRef]

- Bailey, S.W. Summary of recommendations of AIPEA nomenclature committee on clay minerals. Am. Mineral. 1980, 65, 1–7. [Google Scholar]

- Brindley, G.W.; Brown, G. Crystal Structures of Clay Minerals and Their X-ray Identification; Monograph 5; Mineralogical Society: London, UK, 1980; p. 539. [Google Scholar]

- Cuadros, J.; Vesselin, M.D.; Fiore, S. Crystal chemistry of the mixed-layer sequence talc-talc-smectite-smectite from submarine hydrothermal vents. Am. Mineral. 2008, 93, 1338–1348. [Google Scholar] [CrossRef]

- Nickel, E.H.; Nichols, M.C. IMA/CNMNC List of Mineral Names. Available online: http://nrmima.nrm.se//MINERALlist.pdf (accessed on 22 May 2008).

- Guggenheim, S. Introduction to Mg-rich clay minerals: Structure and composition. In Magnesian Clays: Characterization, Origin and Applications; Pozo, M., Galan, E., Eds.; AIPEA Educational Series: Bari, Italy, 2015; pp. 1–62. [Google Scholar]

- Perdikatsis, B.; Burzlaff, H. Strukturverfeinerung am Talk Mg3[(OH)2Si4O10]. Z. Kristallogr. 1981, 156, 177–186. [Google Scholar] [CrossRef]

- Guggenheim, S.; Adams, J.M.; Bain, D.C.; Bergaya, F.; Brigatti, M.F.; Drits, V.A.; Formoso, M.L.L.; Galán, E.; Kogure, T.; Stanjek, H. Summary of recommendations of nomenclature committees relevant to clay mineralogy: Report of the association Internationale pour l’etude des argiles (aipea) nomenclature committee for 2006. Clays Clay Miner. 2006, 54, 761–772. [Google Scholar] [CrossRef]

- Newman, A.C.D. Chemistry of Clays and Clay Minerals; Monograph 6; Mineralogical Society: London, UK, 1987; p. 480. [Google Scholar]

- Köster, H.M.; Schwertmann, U. Beschreibung einzelner Tonminerale. In Tonminerale und Tone: Struktur, Eigenschaften, Anwendung und Einsatz in Industrie und Umwelt; Jasmund, K., Lagaly, G., Eds.; Steinkopff Verlag: Darmstadt, Germany, 1993; pp. 33–88. [Google Scholar]

- Mackenzie, R.C. Saponite from Allt Ribhein, Fiskavaig Bay, Skye. Mineral. Mag. 1957, 31, 672–680. [Google Scholar] [CrossRef]

- Moore, D.M.; Reynolds, R.C., Jr. X-ray Diffraction and the Identification and Analysis of Clay Minerals; Oxford University Press: New York, NY, USA, 1997; p. 378. [Google Scholar]

- Ferrage, E.; Sakharov, B.A.; Michot, L.J.; Lanson, B.; Delville, A.; Cuello, G.J. Water organization in Na-saponite: An experimental validation of numerical data. Geochim. Cosmochim. Acta 2010, 74, A289. [Google Scholar]

- Ferrage, E.; Lanson, B.; Sakharov, B.A.; Geoffroy, N.; Jacquot, E.; Drits, V.A. Investigation of dioctahedral smectite hydration properties by modeling of X-ray diffraction profiles: Influence of layer charge and charge location. Am. Mineral. 2007, 92, 1731–1743. [Google Scholar] [CrossRef] [Green Version]

- Temme, H.; Sohling, U.; Suck, K.; Ruf, F.; Niemeyer, B. Separation of aromatic alcohols and aromatic ketones by selective adsorption on kerolite-stevensite clay. Colloids Surf. A 2011, 377, 290–296. [Google Scholar] [CrossRef]

- Sohling, U.; Haimerl, A. Use of Stevensite for Mycotoxin Adsorption. Patent WO 2006119967, 17 July 2012. [Google Scholar]

- Ureña-Amate, M.D.; Socías-Viciana, M.; González-Pradas, E.; Saifi, M. Effects of ionic strength and temperature on adsorption of atrazine by a heat treated kerolite. Chemosphere 2005, 59, 69–74. [Google Scholar] [CrossRef] [PubMed]

- Sohling, U.; Ruf, F. Stevensite and/or Kerolite Containing Adsorbents for Binding Interfering Substances during the Manufacture of Paper. Patent WO 200702941, 1 March 2007. [Google Scholar]

- Wolters, F.; Lagaly, G.; Kahr, G.; Nüesch, R.; Emmerich, K. A comprehensive characterization of dioctahedral smectites. Clays Clay Miner. 2009, 57, 115–133. [Google Scholar] [CrossRef]

- Steudel, A.; Batenburg, L.; Fischer, H.; Weidler, P.G.; Emmerich, K. Alteration of swellable clays by acid treatment. Appl. Clay Sci. 2009, 44, 105–115. [Google Scholar] [CrossRef]

- Tributh, H.; Lagaly, G. Aufbereitung und Identifizierung von Boden- und Lagerstättentonen Teil I: Aufbereitung der Proben im Labor. GIT Fachzeitschrift für das Laboratorium 1986, 30, 524–529. [Google Scholar]

- Whitney, D.L.; Evans, B.W. Abbreviations for names of rock-forming minerals. Am. Mineral. 2010, 95, 185–187. [Google Scholar] [CrossRef]

- NEWMOD for WindowsTM: The Calculation of One-Dimensional X-ray Diffraction Patterns of Mixed-Layered Clay Minerals; Reynolds, R.C., Jr. and Reynolds, R.C., III.: Hanover, NH, USA, 1996; p. 25.

- Emmerich, K. Thermal analysis in the characterization and processing of industrial minerals. In Advances in the Characterization of Industrial Minerals; EMU, Notes in Mineralogy: London, UK, 2011; pp. 129–170. [Google Scholar]

- Meier, L.P.; Kahr, G. Determination of the cation exchange capacity (CEC) of clay minerals using the complexes of copper(II) ion with triethylenetetramine and tetraethylenepentamine. Clays Clay Miner. 1999, 47, 386–388. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of porous solids and powders. In Surface Area, Pore Size and Density; Springer: Berlin, Germany, 2006; p. 347. [Google Scholar]

- White, G.N.; Zelazny, L.W. Analysis and implications of the edge structure of dioctahedral phyllosilicates. Clays Clay Miner. 1988, 36, 141–146. [Google Scholar] [CrossRef]

- Tournassat, C.; Neaman, A.; Villiéras, F.; Bosbach, D.; Charlet, L. Nanomorphology of montmorillonite particles: Estimation of the clay edge sorption site density by low-pressure gas adsorption and AFM observations. Am. Miner. 2003, 88, 1989–1995. [Google Scholar] [CrossRef]

- Delavernhe, L.; Steudel, A.; Darbha, G.K.; Schäfer, T.; Schuhmann, R.; Wöll, C.; Geckeis, H.; Emmerich, K. Influence of mineralogical and morphological properties on the cation exchange behavior of dioctahedral smectites. Colloids Surf. A 2015, 481, 591–599. [Google Scholar] [CrossRef]

- Russel, J.D.; Fraser, A.R. Infrared methods. In Clay Mineralogy: Spectroscopic and Chemical Determinative Methods; Wilson, M.J., Ed.; Chapman & Hall: London, UK, 1994; pp. 11–67. [Google Scholar]

- Farmer, V.C. The Infrared Spectra of Minerals; Monograph 4; Mineralogical Society: London, UK, 1974; p. 331. [Google Scholar]

- Gates, W.P. Infrared Spectroscopy and the Chemistry of Dioctahedral Smectites. In The Application of Vibrational Spectroscopy to Clay Minerals and Layered Double Hydroxides; Workshop Lectures; Kloprogge, J.T., Ed.; The Clay Mineral Society: Boulder, CO, USA, 2005; Volume 13, pp. 125–168. [Google Scholar]

- Cuadros, J.; Altaner, S.P. Compositional and structural features of the octahedral sheet in mixed-layer illite/smectite from bentonites. Eur. J. Miner. 1988, 10, 111–124. [Google Scholar]

- Farmer, V.C. The infra-red spectra of talc, saponite, and hectorite. Mineral. Mag. 1958, 31, 829–844. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Frost, R.L. The effect of synthesis temperature on the FT-Raman and FT-IR spectra of saponites. Vib. Spectrosc. 2000, 23, 119–127. [Google Scholar] [CrossRef]

- Van der Marel, H.W.; Beutelspacher, H. Atlas of Infrared Spectroscopy of Clay Minerals and Their Admixtures; Elsevier: Amsterdam, The Netherlands, 1976; p. 191. [Google Scholar]

- Lagaly, G. Layer Charge Determination by Alkylammonium Ions. In Layer Charge Characteristics of 2:1 Silicate Clay Minerals; Mermut, A.R., Ed.; The Clay Minerals Society: Aurora, CO, USA, 1994; Volume 6, pp. 1–46. [Google Scholar]

- Stevens, R.E. A system for calculating analyses of micas and related minerals to end members. US Geol. Surv. Bull. 1945, 950, 101–119. [Google Scholar]

- Faust, G.T.; Murata, K.J. Stevensite, redefined as a member of the montmorillonite group. Am. Mineral. 1953, 38, 973–978. [Google Scholar]

- Veniale, F.; Van der Marel, H.W. A regular Talc-Saponite mixed layer mineral from Ferriere, Nure Valley (Piacenza Province, Italy). Contrib. Mineral. Petrol. 1968, 17, 237–254. [Google Scholar] [CrossRef]

- Grimshaw, R.W. The Chemistry and Physics of Clays and Allied Ceramic Materials, 4th ed.; Ernest Benn Limited: London, UK, 1971; p. 1024. [Google Scholar]

- Post, J.L. Saponite from Near Ballarat, California. Clays Clay Miner. 1984, 32, 147–153. [Google Scholar] [CrossRef]

- Sohling, U.; Ruf, F.; Schurz, K.; Emmerich, K.; Steudel, A.; Schuhmann, R.; Weidler, P.G.; Ralla, K.; Riechers, D.; Kasper, C.; et al. Natural mixture of silica and smectite as a new clayey material for industrial applications. Clay Miner. 2009, 44, 525–537. [Google Scholar] [CrossRef]

- Komadel, P.; Madejová, J. Acid activation of clay minerals. In Handbook of Clay Science, 2nd ed.; Bergaya, F., Theng, B.K.G., Lagaly, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2006; pp. 263–287. [Google Scholar]

| EX M 1694 | SiO2 | Al2O3 | MgO | Fe2O3 | Na2O | CaO | K2O | Total |

|---|---|---|---|---|---|---|---|---|

| Raw material (wt %) | 62.76 | 1.76 | 33.56 | 0.61 | 0.04 | 0.86 | 0.41 | 100 |

| Clay fraction * (wt %) | 63.82 | 1.84 | 32.20 | 0.55 | 1.36 | 0.04 | 0.18 | 100 |

| Parameters | EX M 1694 Bulk | EX M 1694 <2 µm | Ca-Saturated Bentonite Acid-Modified |

|---|---|---|---|

| As BET (m2/g) | 278 | 283 | 236 |

| AMicroP (m2/g) | 139 | 140 | 44 |

| AMesoP (m2/g) | 138 | 142 | 189 |

| AMacroP (m2/g) | 1 | 1 | 3 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Steudel, A.; Friedrich, F.; Schuhmann, R.; Ruf, F.; Sohling, U.; Emmerich, K. Characterization of a Fine-Grained Interstratification of Turbostratic Talc and Saponite. Minerals 2017, 7, 5. https://doi.org/10.3390/min7010005

Steudel A, Friedrich F, Schuhmann R, Ruf F, Sohling U, Emmerich K. Characterization of a Fine-Grained Interstratification of Turbostratic Talc and Saponite. Minerals. 2017; 7(1):5. https://doi.org/10.3390/min7010005

Chicago/Turabian StyleSteudel, Annett, Frank Friedrich, Rainer Schuhmann, Friedrich Ruf, Ulrich Sohling, and Katja Emmerich. 2017. "Characterization of a Fine-Grained Interstratification of Turbostratic Talc and Saponite" Minerals 7, no. 1: 5. https://doi.org/10.3390/min7010005