An Investigation of the Uniaxial Compressive Strength of a Cemented Hydraulic Backfill Made of Alluvial Sand

Abstract

:1. Introduction

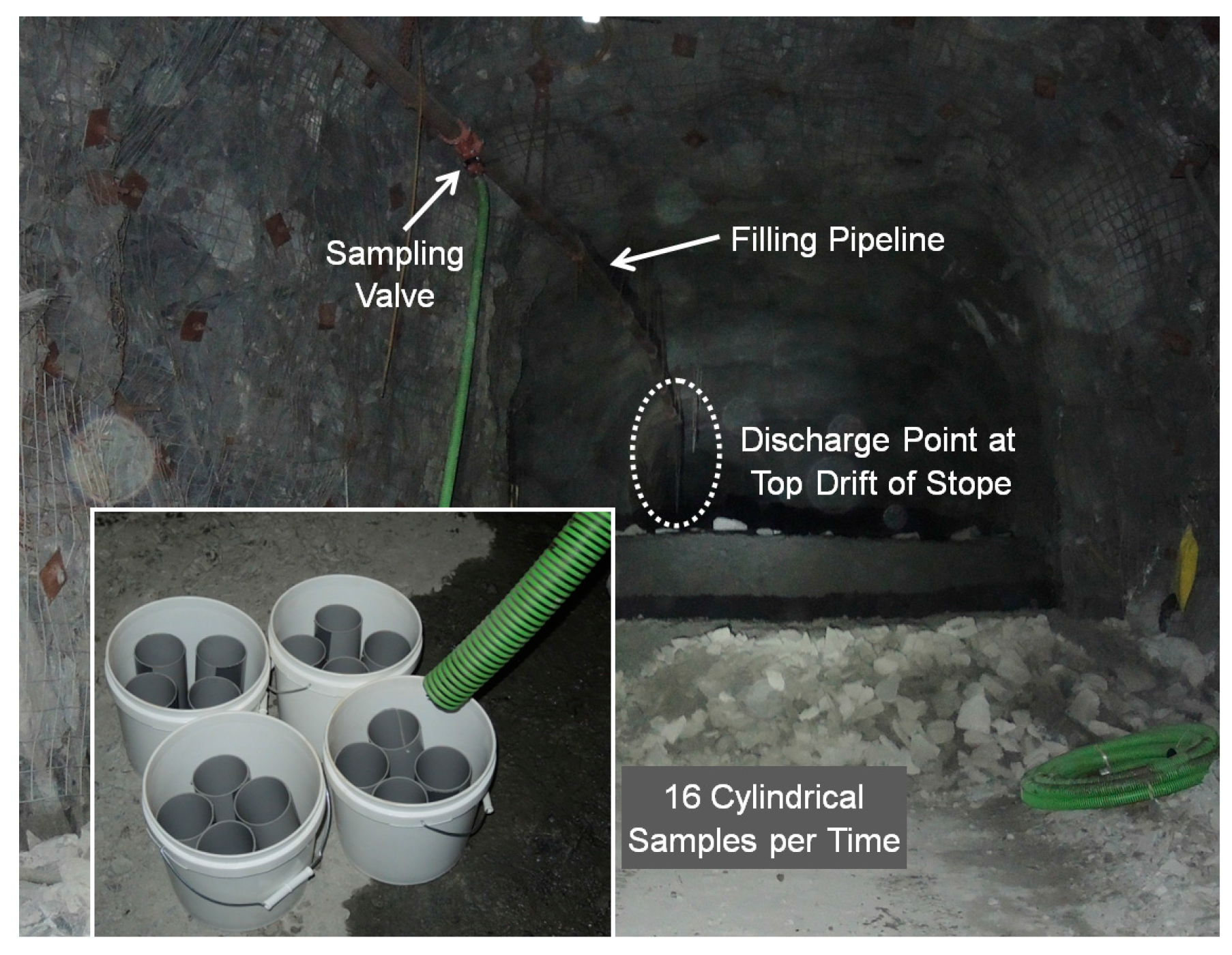

2. Tested Materials and Experimental Results

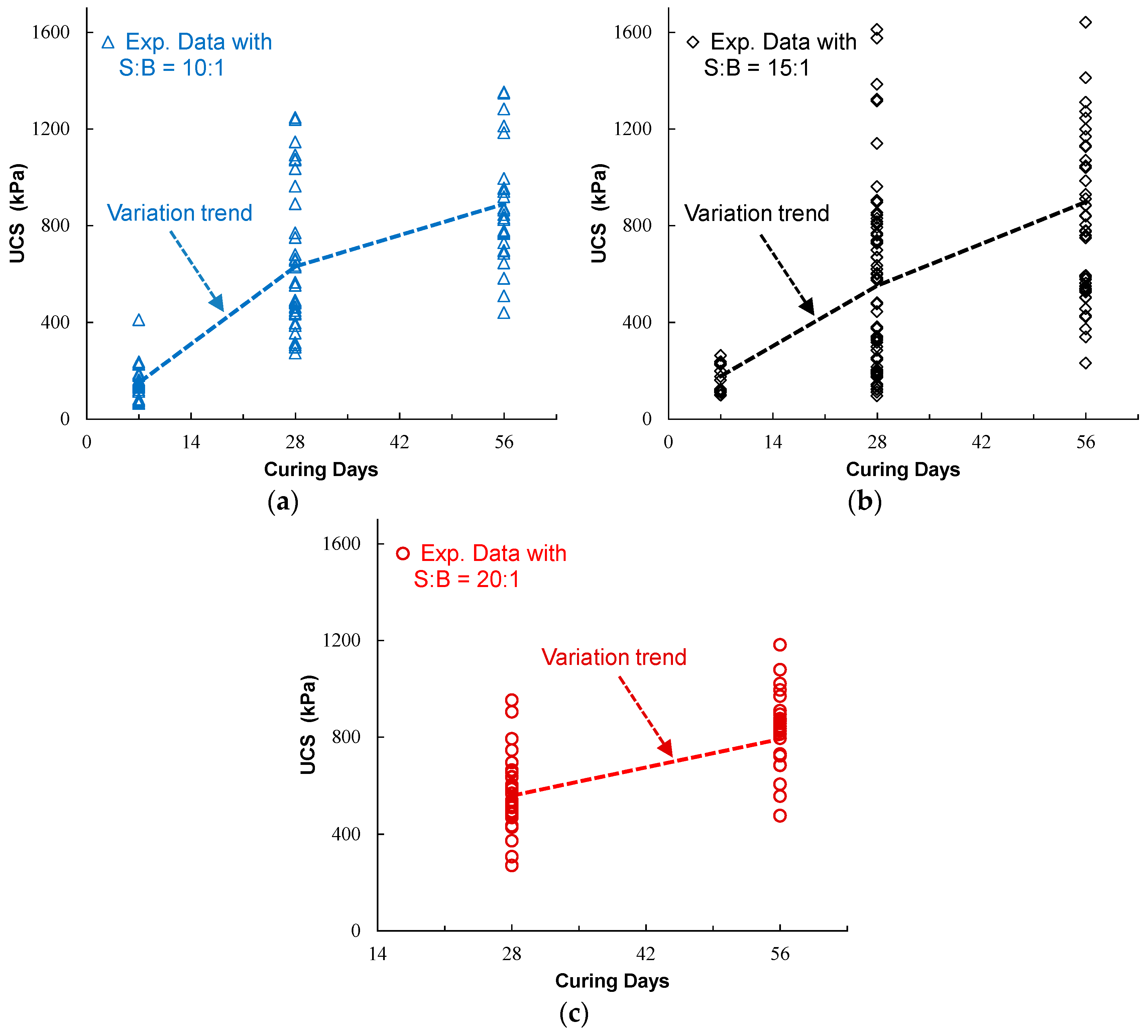

3. Analysis of the Experimental Results

3.1. Correction Due to Shape Effect

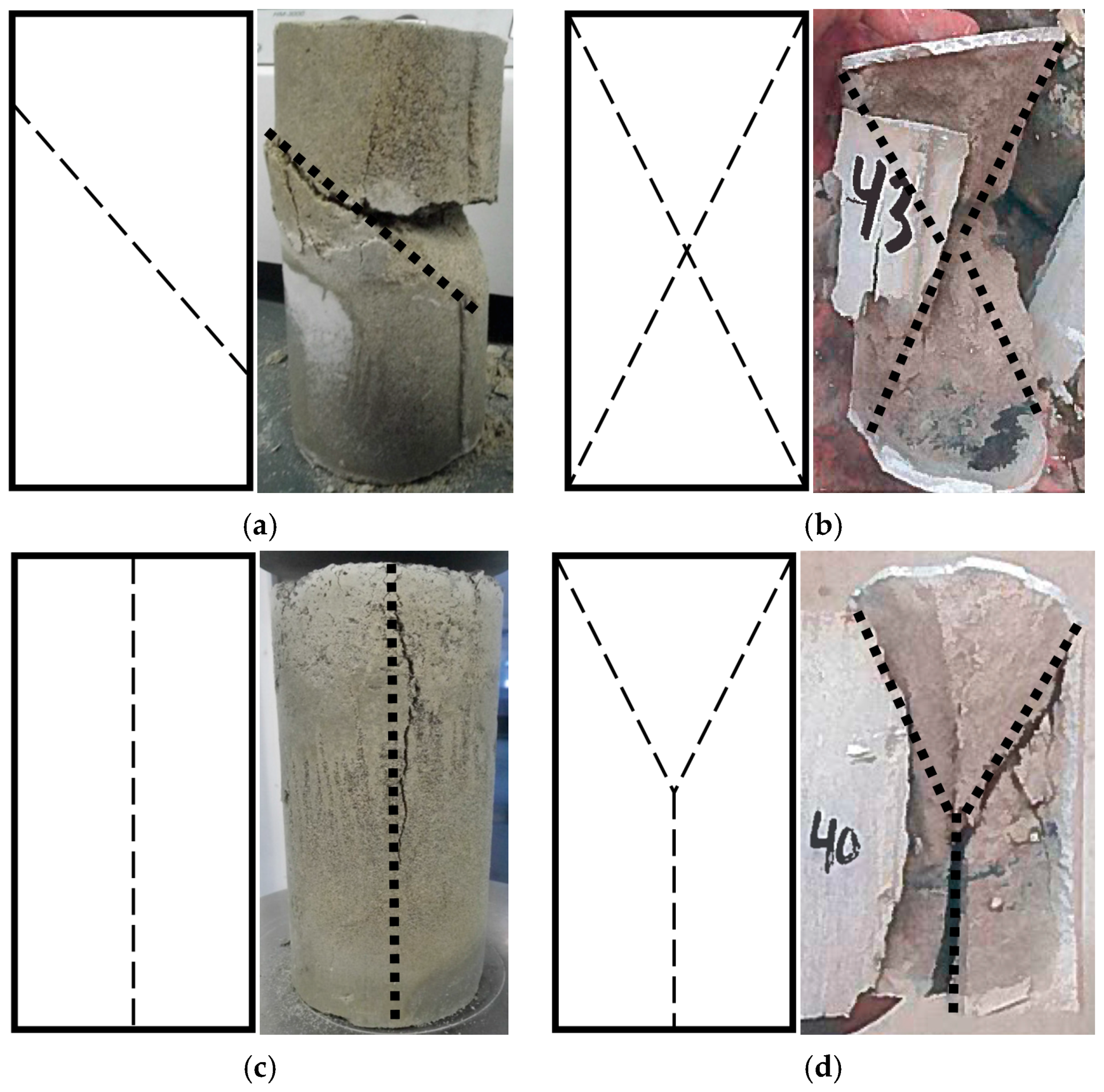

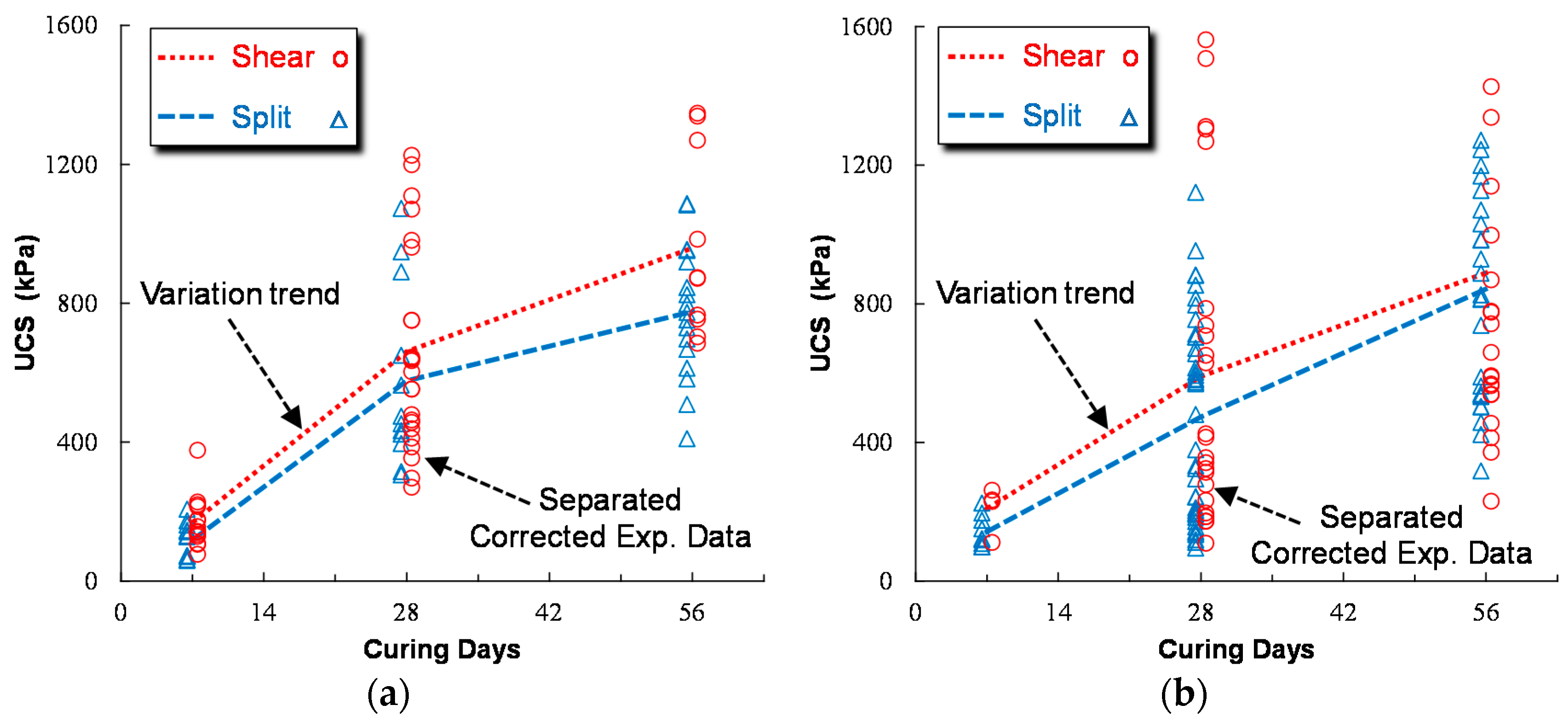

3.2. UCS Values Accounting for the Failure Modes

4. Discussion

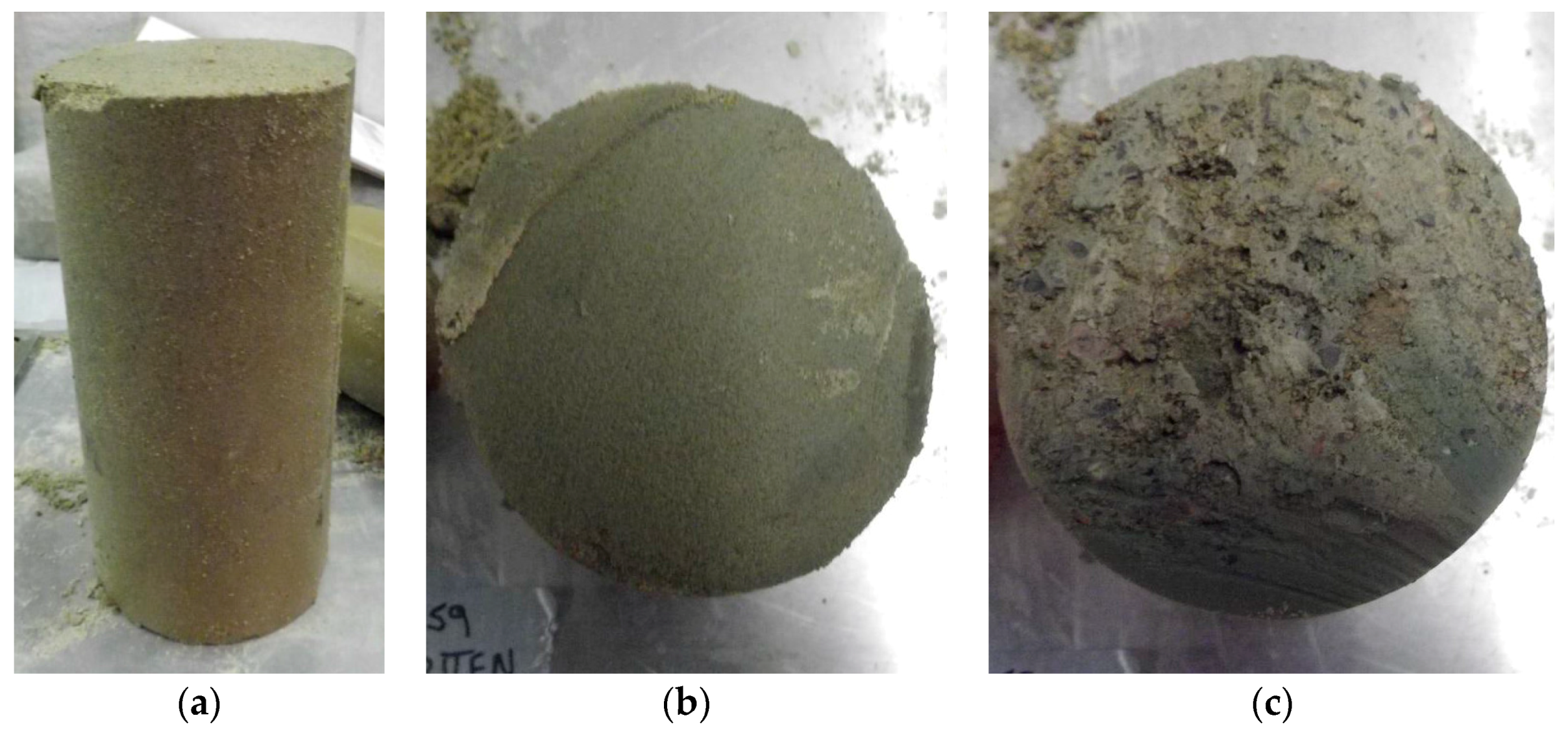

4.1. Effect of Ends Flatness in Cylindrical Samples

4.2. Effect of Hydraulic Segregation

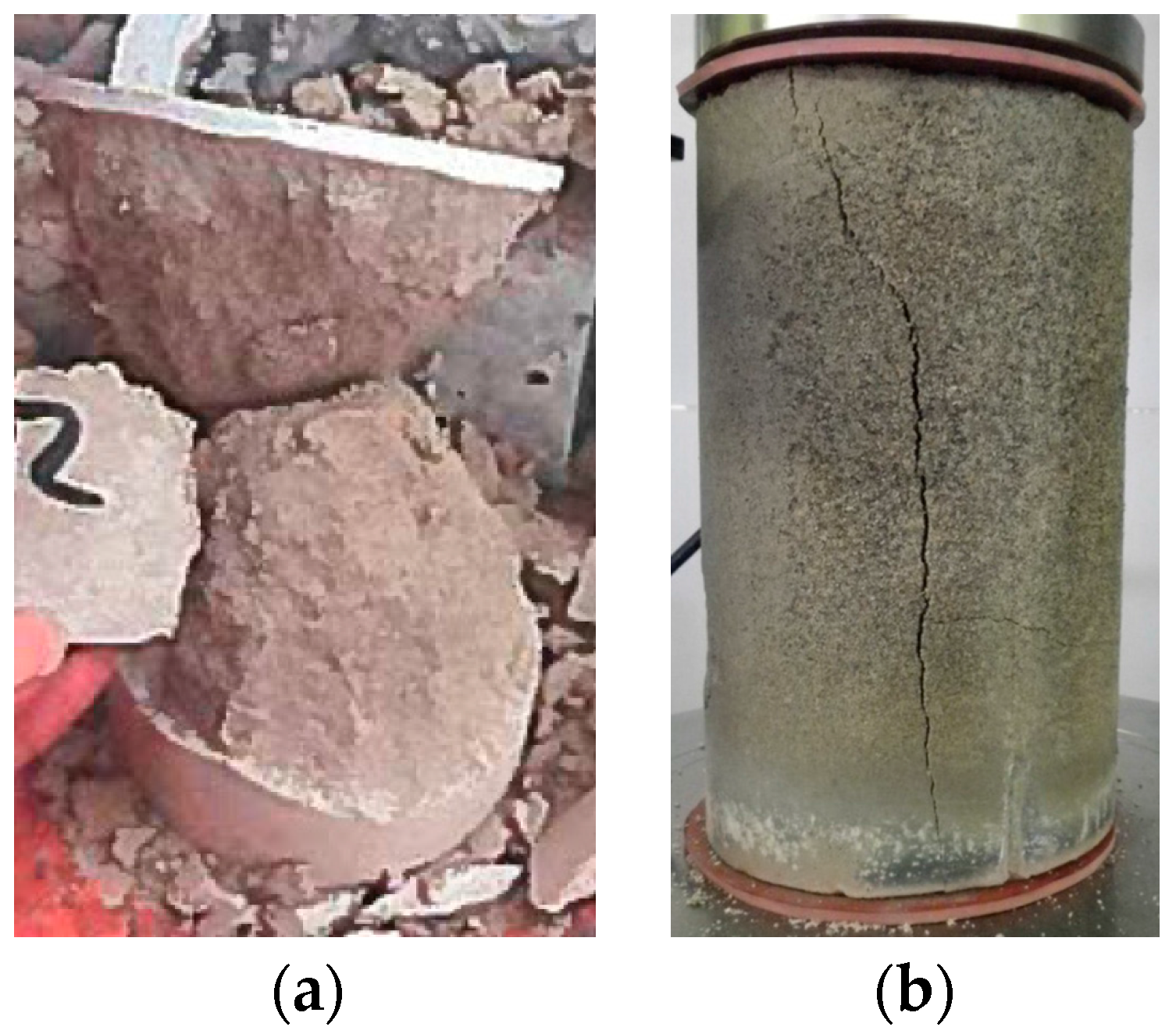

4.3. Particle Size Distribution and Binder Content

5. Conclusions

- ■

- The uniaxial compressive strengths obtained by axially loading cylindrical samples to failure by shear (UCSshear) are generally higher than those obtained by loading the samples to failure by split (UCSsplit). These results suggest that it is necessary to distinguish the uniaxial compressive strength obtained by shear from split failure modes. The uniaxial compressive strength of the cemented backfill can be underestimated by samples axially loaded to failure by split. These conclusions drawn from experimental tests on cemented hydraulic backfill made of alluvial sand may be valid for other types of cemented backfill like paste backfill. More work is needed to confirm this hypothesis. For the cemented hydraulic backfill made of alluvial sand, the ratio between the uniaxial compressive strength by split (UCSsplit) and that by shear (UCSshear) can vary between 0.65 and 0.90, with an average value of about 0.80.

- ■

- The above conclusion does not mean that split failure is considered as a legitimate failure mode. It is well known that the failure of homogeneous geomaterials under uniaxial compressions should be cone shear failure. Split failure observed in many experimental tests is mostly of a random nature and caused by imperfections in sample preparation or in loading. In such cases, the test results are mostly erroneous and should not be used for backfill design.

- ■

- Care is needed in sample preparation to ensure that the samples meet the pertinent standard for UCS testing. The cutting and grinding of samples to ensure flat and smooth end faces is a particularly sensitive item.

- ■

- Segregation is a commonly observed phenomenon in cemented hydraulic backfill that may significantly contribute to the large dispersion of the UCS data obtained by laboratory tests. More work is needed to fully understand the variation of the strength with segregation. Alternatively, the segregation can be minimized by increasing the slurry density, adding more flocculant in the backfill, changing pouring practice such as continuous pouring or ultimately changing the hydraulic backfill to paste backfill.

- ■

- The segregation of the cemented hydraulic backfill observed with small samples tends to indicate that segregation can also take place in the stopes filled with the same backfill. More work is needed to understand the in-situ distributions and evolution of the sand particles and binder content in the stope environment.

- ■

- Future work is required to improve the reliability of the extrapolation procedure by which the strength of the cemented hydraulic backfill in the stopes is represented by the strength obtained in the laboratory from samples collected and cured at a much reduced size (scale).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Darling, P. SME Mining Engineering Handbook, 3rd ed.; Society for Mining, Metallurgy, and Exploration (SME): Englewood, CO, USA, 2011. [Google Scholar]

- Mitchell, R.J.; Olsen, R.S.; Smith, J.D. Model studies on cemented tailings used in mine backfill. Can. Geotech. J. 1982, 19, 14–28. [Google Scholar] [CrossRef]

- Li, L.; Aubertin, M. A modified solution to assess the required strength of exposed backfill in mine stopes. Can. Geotech. J. 2012, 49, 994–1002. [Google Scholar] [CrossRef]

- Li, L.; Aubertin, M. An improved method to assess the required strength of cemented backfill in underground stopes with an open face. Int. J. Min. Sci. Technol. 2014, 24, 549–558. [Google Scholar] [CrossRef]

- Li, L. Generalized solution for mining backfill design. Int. J. Geomech. 2014, 14, 1–11. [Google Scholar] [CrossRef]

- Li, L. Analytical solution for determining the required strength of a side-exposed mine backfill containing a plug. Can. Geotech. J. 2014, 51, 508–519. [Google Scholar] [CrossRef]

- Liu, G.S.; Li, L.; Yang, X.C.; Guo, L.J. Stability analyses of vertically exposed cemented backfill: A revisit to Mitchell’s physical model tests. Int. J. Min. Sci. Technol. 2016, 26, 1135–1144. [Google Scholar] [CrossRef]

- Mitchell, R.J. Sill mat evaluation using centrifuge models. Min. Sci. Technol. 1991, 13, 301–313. [Google Scholar] [CrossRef]

- Caceres, C.A. Effect of Delayed Backfill on Open Stope Mining Methods. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, 2005. [Google Scholar]

- Donovan, J.; Dawson, J.; Bawden, W.F. David Bell mine underhand cut and fill sill mat test. In Minefill 2007, Proceedings of the 9th International Symposium on Mining with Backfill, Montreal, QC, Canada, 29 April–3 May 2007; Canadian Institute of Mining, Metallurgy and Petroleum (CIM): Westmount, QC, Canada, 2007. [Google Scholar]

- Oulbacha, Z. Analyse Numérique de la Stabilité des Piliers-Dalles en Remblai Cimenté: Une Vérification des Modèles de Mitchell [Numerical Analysis on the Stability of Cemented Backfill Sill Mats: Verification on Mitchell Models]. Master’s Thesis, École Polytechnique de Montréal, Montreal, QC, Canada, 2014. [Google Scholar]

- Stone, D.M.R. The optimization of mix designs for cemented rockfill. In Minefill 1993; South African Institute of Mining and Metallurgy (SAIMM): Johannesburg, South Africa, 1993; pp. 249–253. [Google Scholar]

- Yao, M.; Forsythe, A.; Punkkinen, A. Examples of ground support practice in challenging ground conditions at Vale’s operations in Sudbury. In Deep Mining 2014, Proceedings of the 7th International Conference on Deep and High Stress Mining, Sudbury, ON, Canada, 16–18 September 2014; Australian Centre for Geomechanics: Crawley, Australia, 2014; pp. 291–304. [Google Scholar]

- Belem, T.; Benzaazoua, M.; Bussière, B. Mechanical behaviour of cemented paste backfill. In Proceedings of the 53rd Canada Geotechnical Conference, Montreal, QC, Canada, 15–18 October 2000; pp. 373–380.

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented pastefill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B.; Alp, I.; Deveci, H. Effect of properties of tailings and binder on the short-and long-term strength and stability of cemented paste backfill. Mater. Lett. 2005, 59, 3703–3709. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Ouellet, S. Experimental characterization of the influence of tailings fineness and density on the quality of cemented paste backfill. Miner. Eng. 2005, 18, 41–44. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Saa, E.G. Mix proportioning of underground cemented tailings backfill. Tunn. Undergr. Space Technol. 2008, 23, 80–90. [Google Scholar] [CrossRef]

- Klein, K.; Simon, D. Effect of specimen composition on the strength development in cemented paste backfill. Can. Geotech. J. 2006, 43, 310–324. [Google Scholar] [CrossRef]

- Yilmaz, E.; Benzaazoua, M.; Belem, T.; Bussière, B. Effect of curing under pressure on compressive strength development of cemented paste backfill. Miner. Eng. 2009, 22, 772–785. [Google Scholar] [CrossRef]

- Yin, S.H.; Wu, A.X.; Hu, K.J.; Wang, Y.; Zhang, Y.K. The effect of solid components on the rheological and mechanical properties of cemented paste backfill. Miner. Eng. 2012, 35, 61–66. [Google Scholar] [CrossRef]

- Ke, X.; Hou, H.B.; Zhou, M.; Wang, Y.; Zhou, X. Effect of particle gradation on properties of fresh and hardened cemented paste backfill. Constr. Build. Mater. 2015, 96, 378–382. [Google Scholar] [CrossRef]

- Behera, B.; Mishra, M.K. Strength assessment and compositional analysis of lime stabilized fly ash and mine overburden mixes upon curing. J. Solid Waste Technol. Manag. 2012, 38, 211–221. [Google Scholar] [CrossRef]

- Snyman, B.J.; van der Spuy, B.; Correia, L.D.C. A critical look at uniaxial test procedures applied in the backfill industry. In Mine Fill 2014, Proceedings of the 11th International Symposium on Mining with Backfill, Perth, Australia, 20–22 May 2014; Australian Centre for Geomechanics: Crawley, Australia, 2014. [Google Scholar]

- Chen, S.J.; Wang, H.L.; Wang, H.Y.; Xing, H.L.; Zhang, J.W. Low-Strength similar materials for backfill mining: Insight from experiments on components and influence mechanism. Geotech. Test. J. 2015, 38, 1–7. [Google Scholar] [CrossRef]

- Chen, S.J.; Wang, H.L.; Zhang, J.W.; Xing, H.L.; Wang, H.L. Experimental study on low-strength similar-material proportioning and properties for coal mining. Adv. Mater. Sci. Eng. 2015, 2015, 696501. [Google Scholar] [CrossRef]

- Amaratunga, L.M.; Yaschyshyn, D.N. Development of a high modulus paste fill using fine gold mill tailings. Geotech. Geol. Eng. 1997, 15, 205–219. [Google Scholar] [CrossRef]

- Cao, S.; Song, W.D.; Xue, G.L.; Wang, Y.; Zhu, P.R. Tests of strength reduction of cemented tailings filling considering layering character. Rock Soil Mech. 2015, 36, 2869–2876. (In Chinese) [Google Scholar]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Turan, A.; Deveci, H. Utilisation of alkali-activated blast furnace slag in paste backfill of high-sulphide mill tailings: Effect of binder type and dosage. Miner. Eng. 2012, 30, 33–43. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill. Eng. Geol. 2014, 168, 23–37. [Google Scholar] [CrossRef]

- Yi, X.W.; Ma, G.W.; Fourie, A. Compressive behaviour of fibre-reinforced cemented paste backfill. Geotext. Geomembr. 2015, 43, 207–215. [Google Scholar] [CrossRef]

- Del Viso, J.R.; Carmona, J.R.; Ruiz, G. Shape and size effects on the compressive strength of high-strength concrete. Cem. Concr. Res. 2008, 38, 386–395. [Google Scholar] [CrossRef]

- Güllü, H. Factorial experimental approach for effective dosage rate of stabilizer: Application for fine-grained soil treated with bottom ash. Soils Found. 2014, 54, 462–477. [Google Scholar] [CrossRef]

- Aubertin, M.; Li, L.; Simon, R.; Khalfi, S. Formulation and application of a short-term strength criterion for isotropic rocks. Can. Geotech. J. 1999, 36, 947–960. [Google Scholar] [CrossRef]

- Aubertin, M.; Li, L.; Simon, R. A multiaxial stress criterion for short-and long-term strength of isotropic rock media. Int. J. Rock Mech. Min. Sci. 2000, 37, 1169–1193. [Google Scholar] [CrossRef]

- Aubertin, M.; Li, L. A porosity-dependent inelastic criterion for engineering materials. Int. J. Plast. 2004, 20, 2179–2208. [Google Scholar] [CrossRef]

- Li, L.; Aubertin, M.; Simon, R.; Bussière, B. Formulation and application of a general inelastic locus for geomaterials with variable porosity. Can. Geotech. J. 2005, 42, 601–623. [Google Scholar] [CrossRef]

- Li, L.; Aubertin, M.; Simon, R. Invited chapter: The MSDPu multiaxial criterion for the strength of rocks and rock masses. Rock Mech. Eng. 2016, 1, 397–424. [Google Scholar]

- Consoli, N.C.; Cruz, R.C.; Floss, M.F.; Festugato, L. Parameters controlling tensile and compressive strength of artificially cemented sand. J. Geotech. Geoenviron. Eng. 2009, 136, 759–763. [Google Scholar] [CrossRef]

- Kahraman, S.; Fener, M.; Kozman, E. Predicting the compressive and tensile strength of rocks from indentation hardness index. J. South. Afr. Inst. Min. Metall. 2012, 112, 331–339. [Google Scholar]

- Chen, X.D.; Wu, S.X.; Zhou, J.K. Influence of porosity on compressive and tensile strength of cement mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Correia, A.A.; Oliveira, P.J.V.; Custódio, D.G. Effect of polypropylene fibres on the compressive and tensile strength of a soft soil, artificially stabilised with binders. Geotext. Geomembr. 2015, 43, 97–106. [Google Scholar] [CrossRef]

- Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM Standard D2487; Annual Book of ASTM Standards 04.08; American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; Annual Book of ASTM Standards 04.02; ASTM Standard C39/C39M; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- Elwell, D.J.; Fu, G.K. Compression Testing of Concrete: Cylinders vs. Cubes; Special Report 119; New York State Department of Transportation: New York, NY, USA, 1995.

- Bieniawski, Z.T.; Bernede, M.J. Suggested methods for determining the uniaxial compressive strength and deformability of rock materials. Int. J. Rock Mech. Min. Sci. 1979, 16, 138–140. [Google Scholar] [CrossRef]

- Standard Test Method for Unconfined Compressive Strength of Cohesive Soil, ASTM Standard D2166/D2166M; Annual Book of ASTM Standards 04.08; American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- Li, S.L.; Sang, Y.F. The fracture mechanism and damage constitutive equation of cemented tail filling. Gold 1997, 18, 24–29. (In Chinese) [Google Scholar]

- Murray, Y.D.; Abu-Odeh, A.Y.; Bligh, R.P. Evaluation of LS-DYNA Concrete Material Model 159; U.S. Department of Transportation, Federal Highway Administration: McLean, VA, USA, 2007.

- Bogas, J.A.; Gomes, A. Compressive behavior and failure modes of structural lightweight aggregate concrete—Characterization and strength prediction. Mater. Des. 2013, 46, 832–841. [Google Scholar] [CrossRef]

| Physical Properties | Sand (Normal Case) |

|---|---|

| Specific gravity | 2.72 |

| Bulk density (t/m3) | 1.78 |

| Normal water content, w (%) | 7–8 |

| Fines content (<20 μm; %) | 10.8 |

| D10 (effective particle size; μm) | 19.2 |

| D30 (μm) | 57.5 |

| D50 (average particle size; μm) | 126.9 |

| D60 (μm) | 165.4 |

| D90 (μm) | 489.5 |

| Coefficient of uniformity Cu = D60/D10 | 8.6 |

| Coefficient of curvature Cc = D230/(D60 × D10) | 1.04 |

| Uniformity of graduation U = (D90 − D60)/D50 | 2.6 |

| Items | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | SO3 |

|---|---|---|---|---|---|---|---|---|---|

| Content (%) | 34.6 | 11.2 | 0.4 | 38.2 | 11.5 | 0.2 | 0.4 | 0.4 | 2.5 |

| Items | Values |

|---|---|

| Chemical Requirements, by CSA A3003-13 | |

| Sulphur trioxide (SO3), % | 1.0 |

| Sulphide sulphur (S), % | 0.5 |

| Physical Requirements | |

| Fineness, by CSA A3004-A3-13 and ASTM C204-11 | |

| Amount retained on 45 μm sieve, % | 3.2 |

| Specific surface (Blaine), m2/kg | 464 |

| Autoclave expansion, %, by CSA A3004-B5-13 | 0.04 |

| Vicat time of setting, initial, min, by A3004-B2-13 | 285 |

| Uniaxial Compressive Strength, by CSA A3004-C2-13 | |

| 7 days, MPa | 22.2 |

| 28 days, MPa | 46.8 |

| H/D | 2.00 | 1.75 | 1.50 | 1.25 | 1.00 |

| Factor | 1.00 | 0.98 | 0.96 | 0.93 | 0.87 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Li, L.; Yao, M.; Landry, D.; Malek, F.; Yang, X.; Guo, L. An Investigation of the Uniaxial Compressive Strength of a Cemented Hydraulic Backfill Made of Alluvial Sand. Minerals 2017, 7, 4. https://doi.org/10.3390/min7010004

Liu G, Li L, Yao M, Landry D, Malek F, Yang X, Guo L. An Investigation of the Uniaxial Compressive Strength of a Cemented Hydraulic Backfill Made of Alluvial Sand. Minerals. 2017; 7(1):4. https://doi.org/10.3390/min7010004

Chicago/Turabian StyleLiu, Guangsheng, Li Li, Mike Yao, David Landry, Farid Malek, Xiaocong Yang, and Lijie Guo. 2017. "An Investigation of the Uniaxial Compressive Strength of a Cemented Hydraulic Backfill Made of Alluvial Sand" Minerals 7, no. 1: 4. https://doi.org/10.3390/min7010004

APA StyleLiu, G., Li, L., Yao, M., Landry, D., Malek, F., Yang, X., & Guo, L. (2017). An Investigation of the Uniaxial Compressive Strength of a Cemented Hydraulic Backfill Made of Alluvial Sand. Minerals, 7(1), 4. https://doi.org/10.3390/min7010004