4.1. Productivity

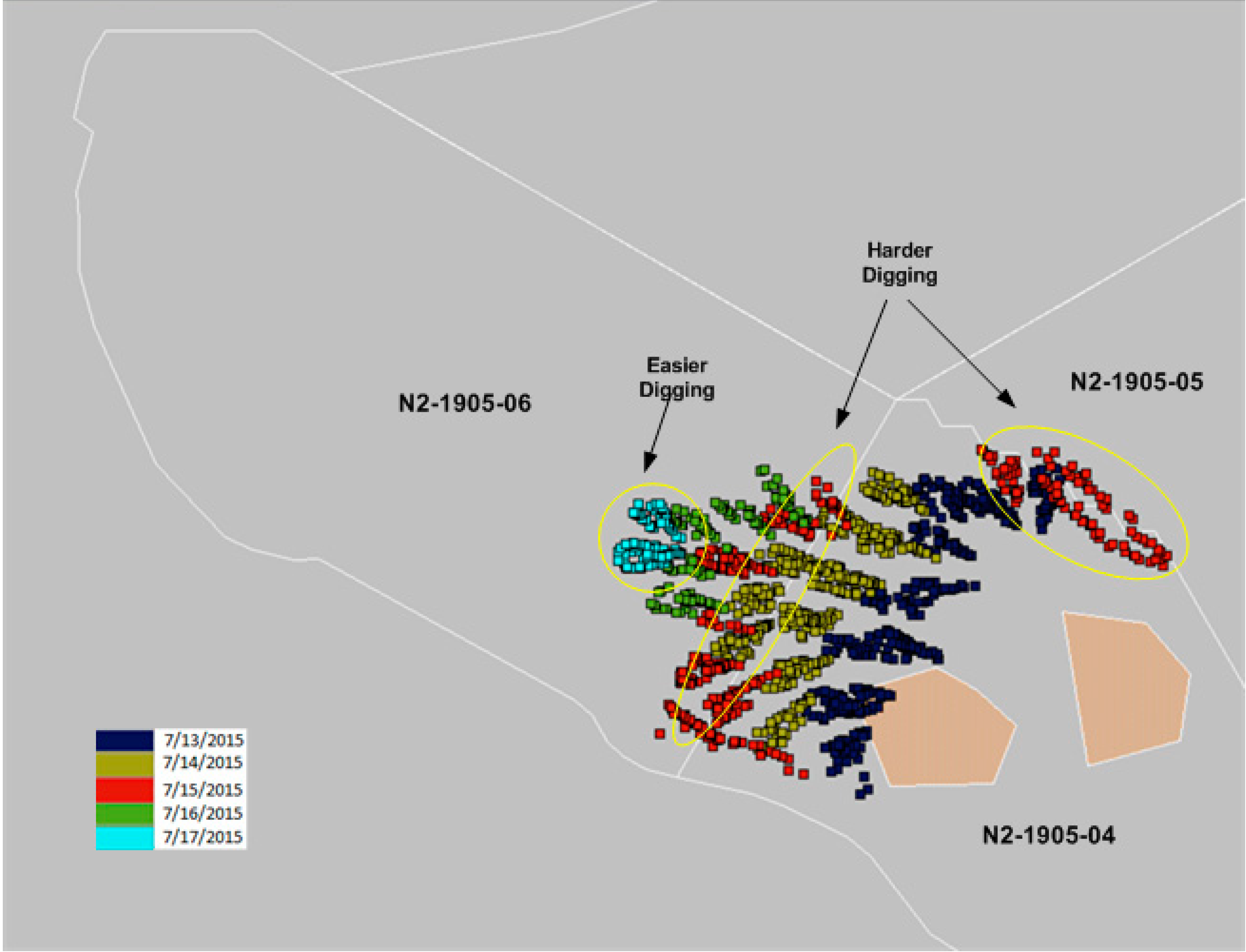

A total of 4791 shovel cycles were monitored during the course of the field trial. As discussed in

Section 3.1 a commercial monitoring system was used to record different shovel activities such as digging, swinging and returning. Additionally, the monitoring system detects and records activities that are not associated with loading the truck such as cleaning up the face. In this paper, such activities are not included in the analysis. As the current study mainly focuses on the digging part of each loading cycle,

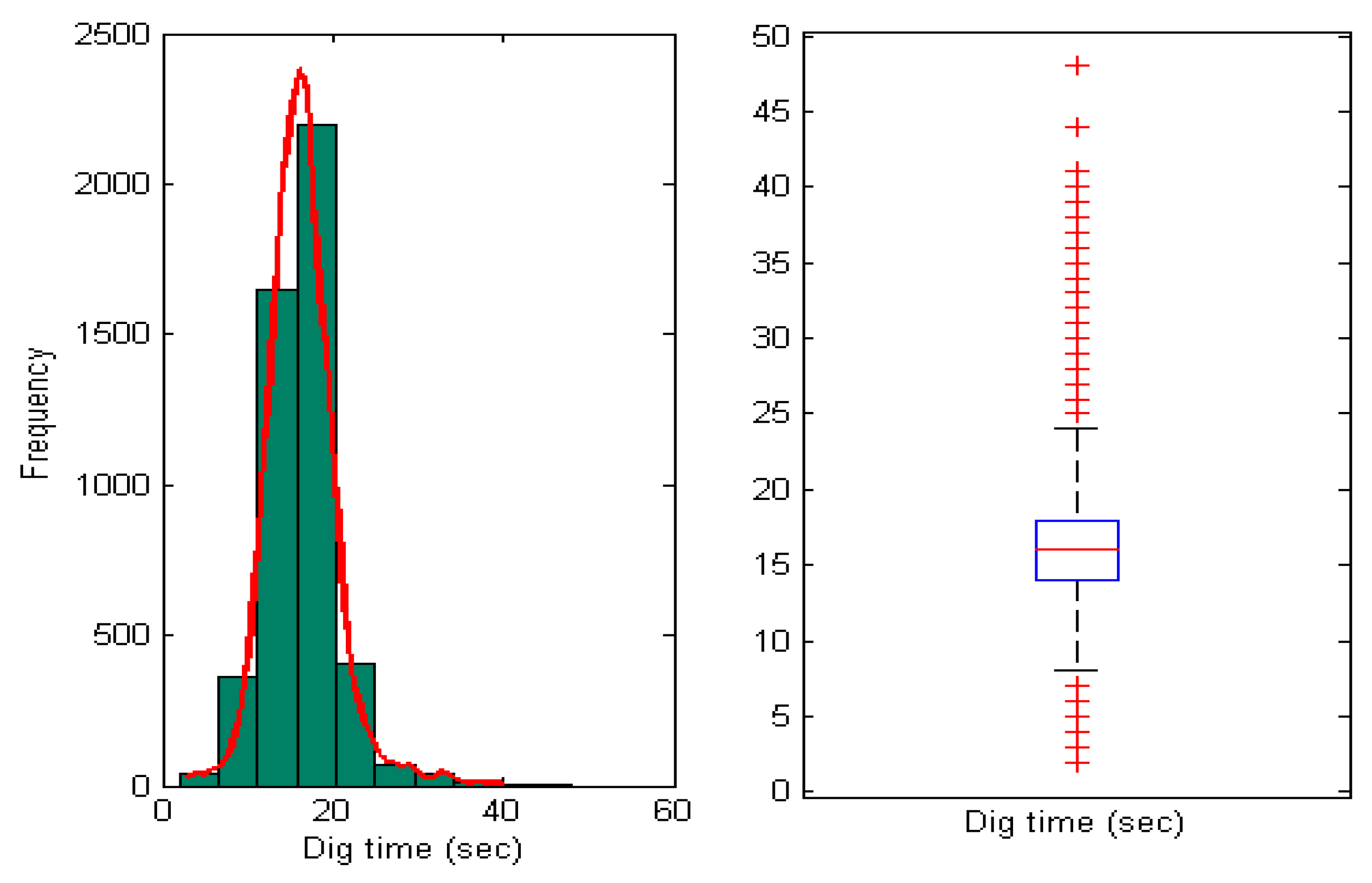

Figure 3 illustrates a histogram and a box plot of dig time values. The histogram indicates that dig times are positively skewed and they range from 2 to 48 s. The box plot also describes the spread of data and highlights outliers. In this paper an outlier is defined as a value that is more than 1.5 times the interquartile range away from the top or bottom of the box in the boxplot.

Outliers were removed from the data and statistics for different KPIs were calculated. The KPIs include payload, cycle time components, swing and return angles, equivalent digging energy, loading rate and mucking rate. In this paper, productive cycle time is defined as the interval between two consecutive dumps excluding waiting times. Dump time and the positioning of the bucket before digging have been included in return time (The shovel monitoring system has been coded in this way). Equivalent digging energy, loading rate and mucking rate are also given by Equation (2) to Equation (4), respectively:

where

t0 and

t1 are the start and the end of digging respectively,

Fb is the bail force (bail pull) and crowd rate is the rate of change of crowd arm angle with respect to horizon. It should be noted that all these KPIs are being estimated by the commercial monitoring system on-board the shovel using a suit of sensors such as load cells and gyro sensors. As Equation (2) shows the digging energy estimated by the monitoring system on-board the shovel is an equivalent mechanical energy

during the digging part of the cycle. The equivalent digging energy is measured at the bail and is a measure of mechanical energy transferred to the bucket teeth. This energy is provided by electrical DC motors on-board the shovel. A summary of the aforementioned KPIs for all of the operators is presented in

Table 1.

Table 1 shows that the largest component of the cycle is the dig phase which on average accounts for about 50% of the productive cycle time. Swing time and return time each accounts for 25% of the productive cycle time which is lower than dig time portion. This could be due to low swing and return angles (<90°).

Among the parameters presented in

Table 1, waiting time has the highest variation (highest COV) which is independent of machine performance. Furthermore, the largest variations within each cycle occur in the swing and return phases which are mainly controlled by the operator. Payload also has the lowest variation which demonstrates that operators try to adapt their digging technique to current digging conditions to achieve the desired payload which is the highest target load per pass without exceeding the truck capacity; therefore, it is mainly consistent from cycle to cycle. It should be noted that current loading practice is not an automated process and machine monitoring systems only help the operators to more consistently fill the bucket. The variations in payload can also be a representation of variations in productivity of the machine. Generally, operations are interested in lower variations in their shovel productivity which should be reflected in a narrow distribution of truck loads.

Table 1 also shows that although different operators have different average equivalent digging energy per cycle, they have similar average loading rates as well as mucking rates. Among the four operators, Operator A has the lowest digging rate and mucking rate while he has the highest average equivalent digging energy per cycle. It should be noted that Operator A encountered one of the easier digging conditions during the field trial. Operator B has the highest loading and mucking rates while he was digging one of the harder digging conditions during the field trial. The digging practice of these two operators will be compared in

Section 4.3 using recorded signals from PLC to better understand the effect of different operational parameters on the shovel performance. Operators C and D have not been chosen for comparison due to technical issues that caused the PLC signals not to be recorded while they operated the shovel.

In order to further investigate the effect of operator on the machine productivity, especially digging component, a clustering analysis is performed and operators’ techniques during digging are compared. The results are presented next.

4.2. Clustering of Shovel Cycles

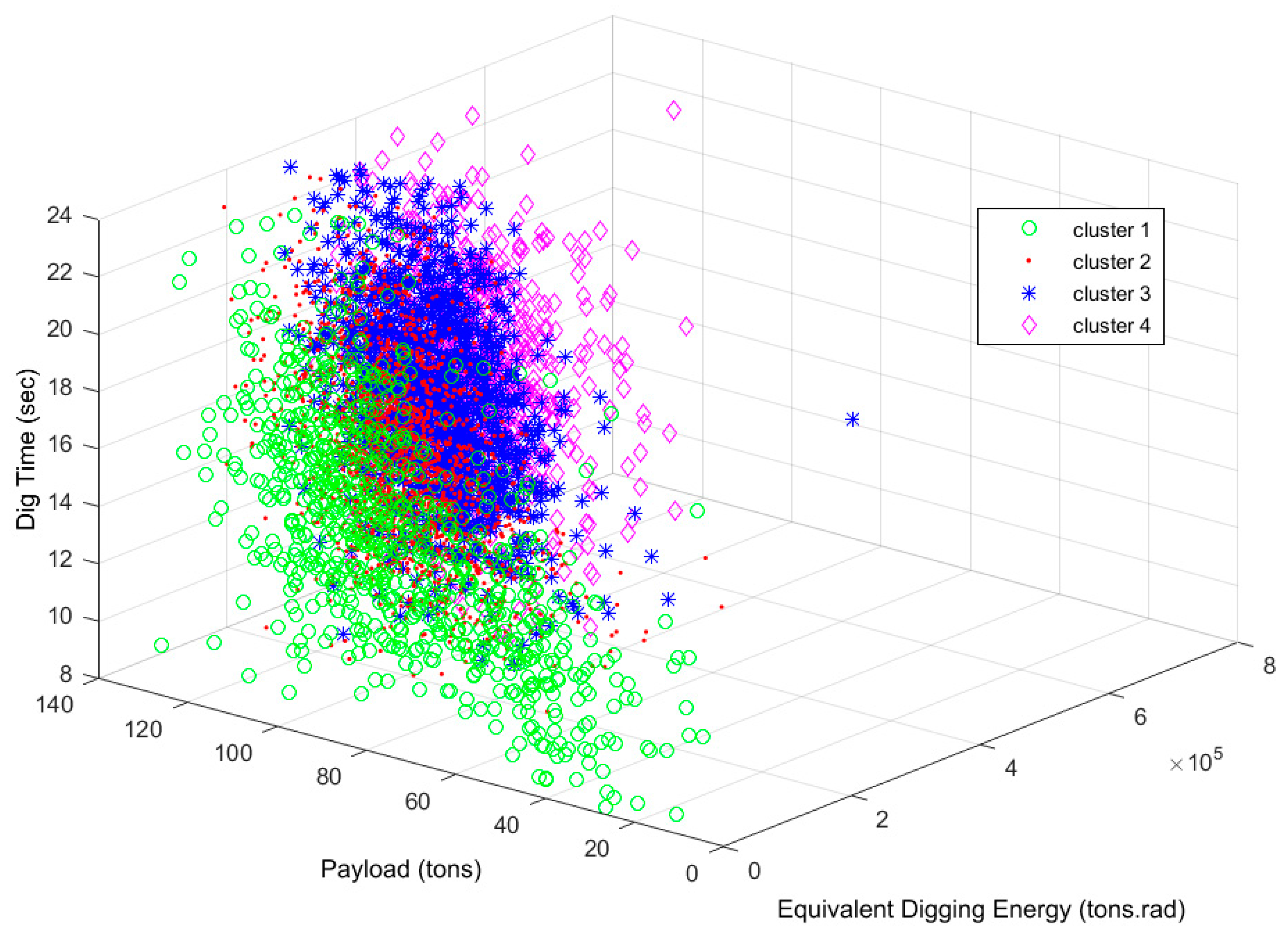

To classify shovel digging behavior and effort, first a 3D space of digging energy, dig time and payload for total of 4522 cycles is built. These three parameters or a combination of them have been widely used as a measure of digging efficiency or shovel performance [

4,

5,

7,

8,

16]. Then, using the K-means method [

17], this space is divided into four clusters.

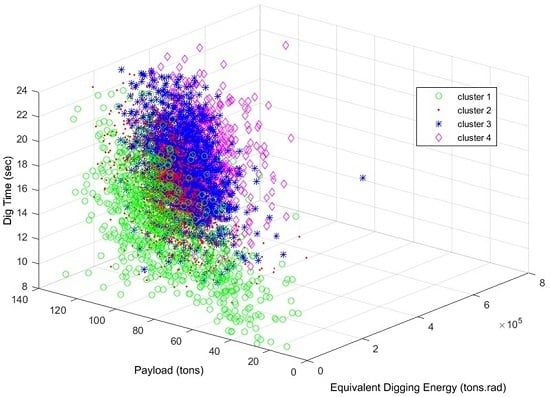

Figure 4 shows different clusters in the 3D space.

As the results of clustering show (

Figure 4), clusters have been generated based on the digging energy which means that digging energy explains the majority of variability in the data. Therefore, a classification for digging energy based on the results of clustering analysis is presented in

Table 2. This table illustrates that most cycles are within the range of average to high digging energy. Among all operators, Operator C has the highest percentage of cycles in the low energy class and the lowest percentage of cycles in the extremely high energy class while Operator A has the lowest percentage of cycles in the low energy class and the highest percentage of cycles in the extremely high energy class.

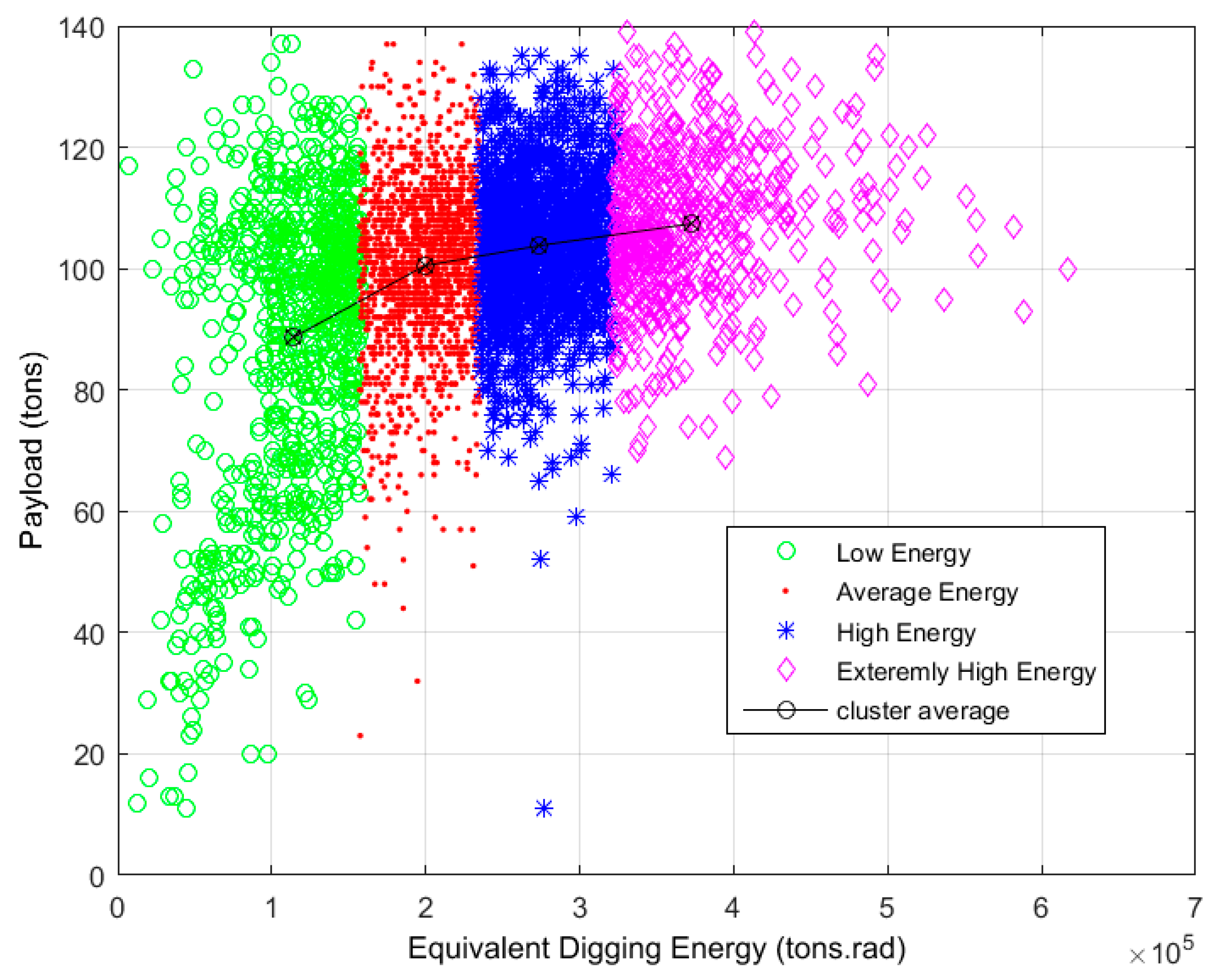

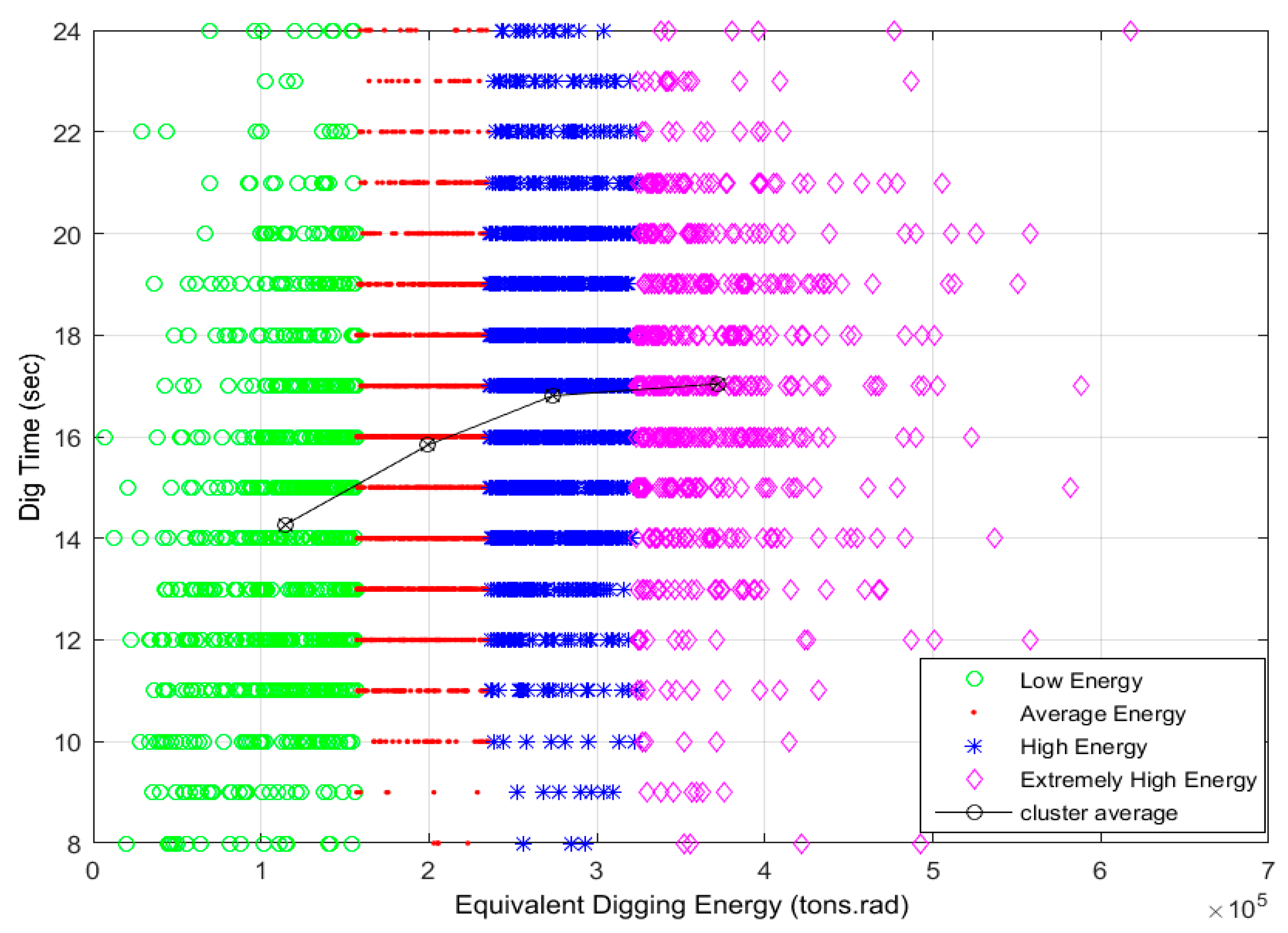

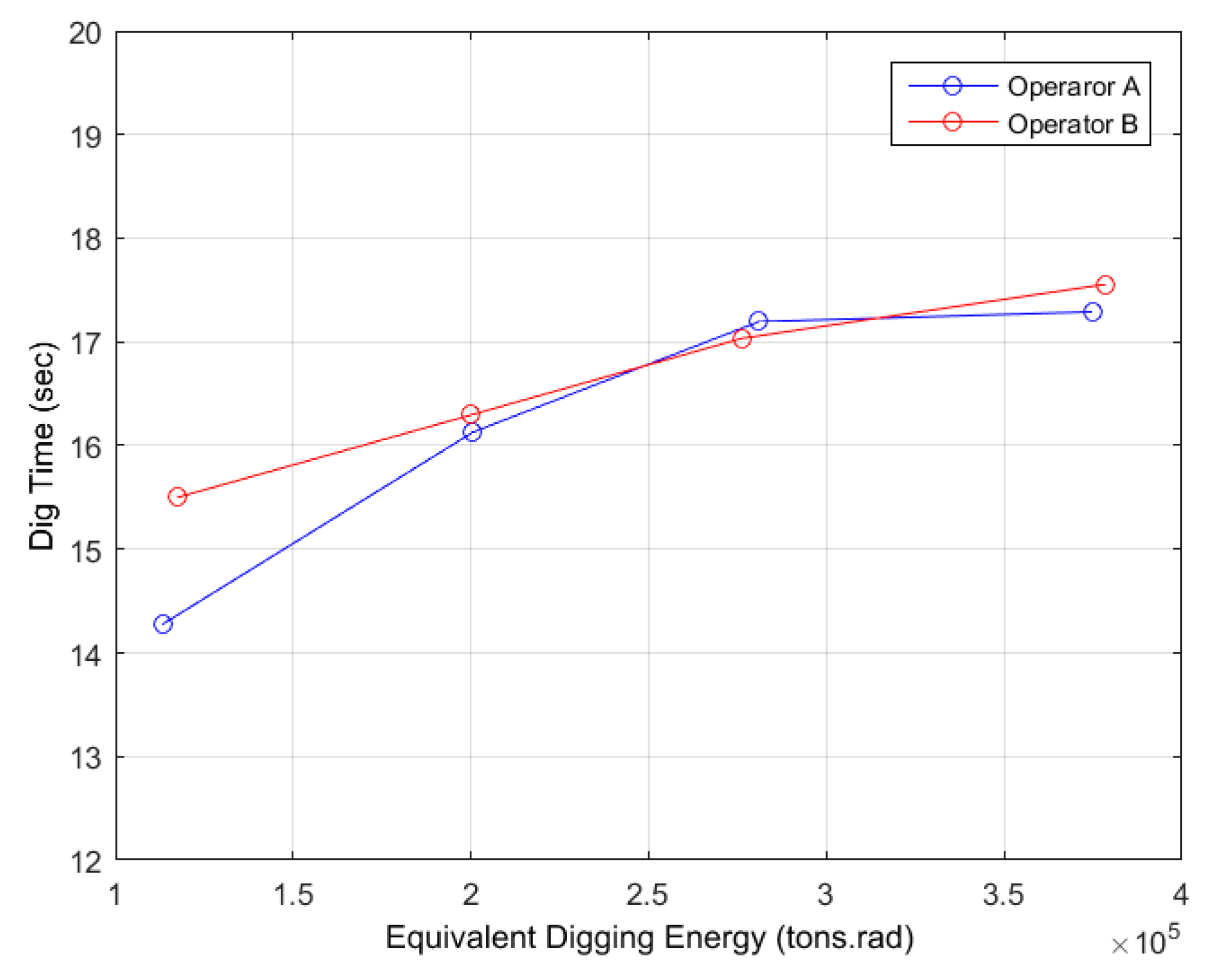

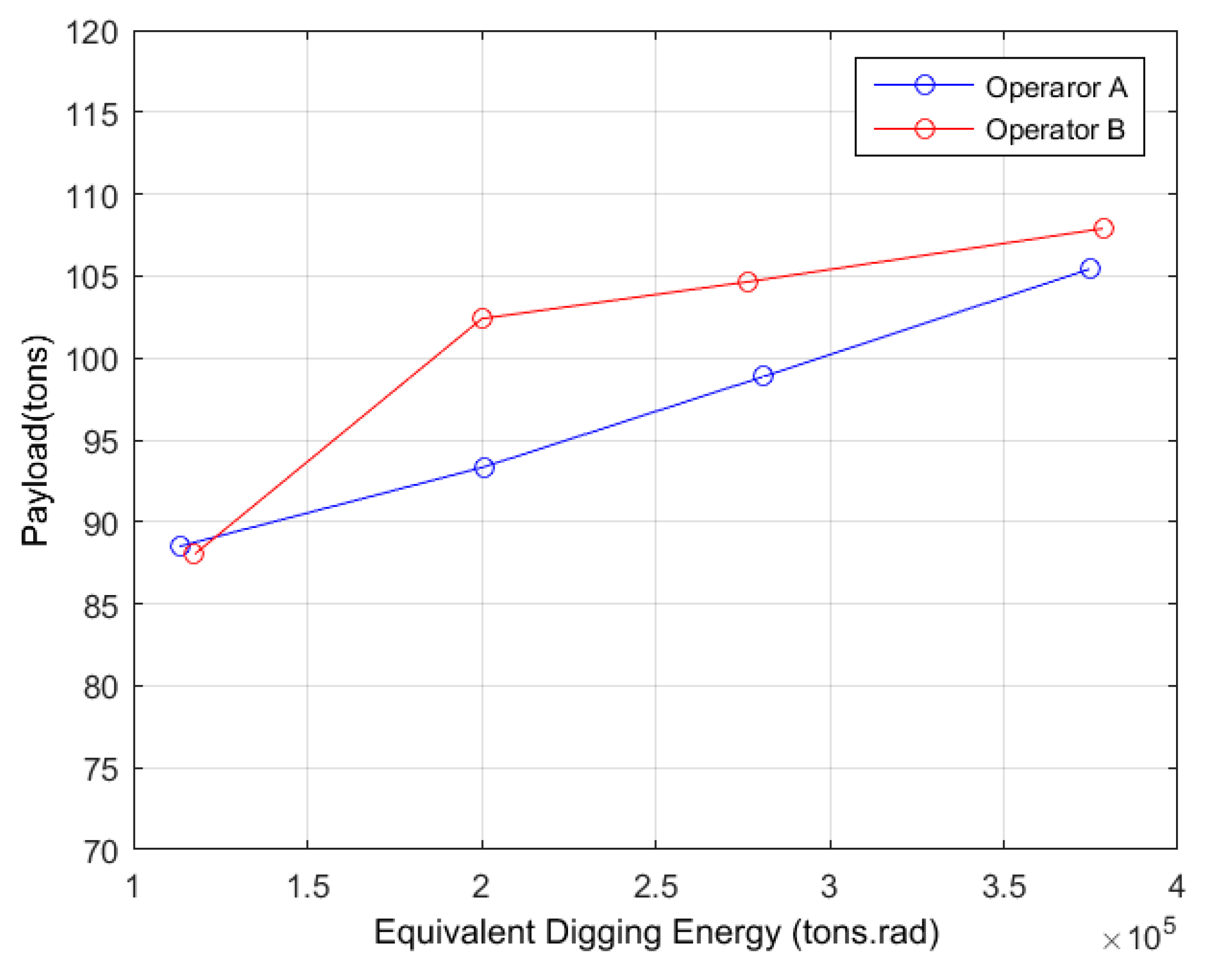

In order to further investigate the relationship between digging energy, payload and dig time,

Figure 5 and

Figure 6 compare dig time and payload for the different classes of digging energy from

Table 2.

As the above figures show, dig time and payload vary widely across all the clusters, but

Figure 5 indicates that the average payload increases with increasing digging energy. Similarly,

Figure 6 shows that the higher energy clusters have higher average dig time. To combine the effect of dig time and payload, loading rate given by Equation (3) is analyzed.

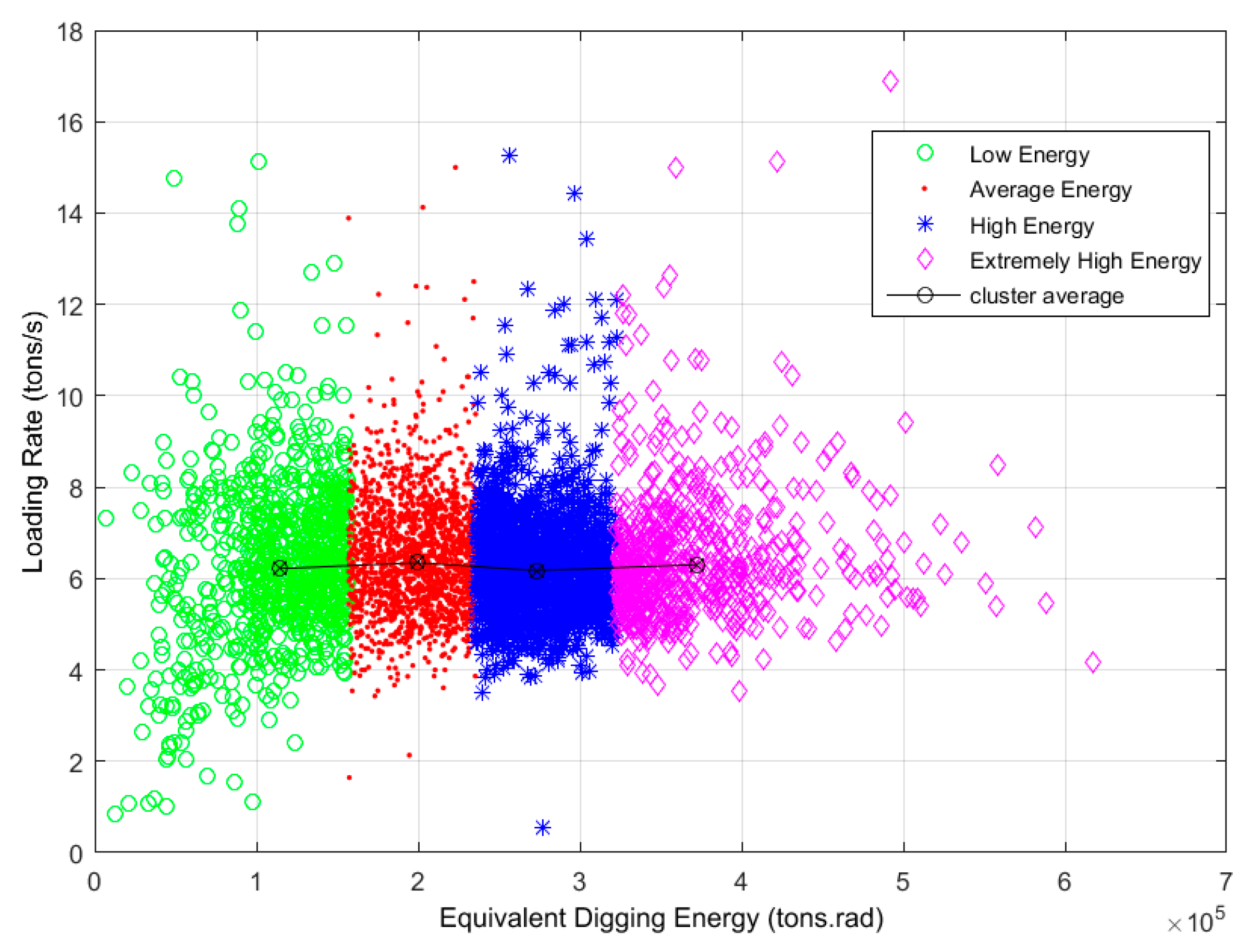

Figure 7 shows how loading rate changes as digging energy increases. This figure indicates that there is no relationship between loading rate and digging energy (correlation coefficient = 0.0302). In addition, average loading rate is almost the same for all of the clusters (all digging energy classes). Therefore, one would conclude that variations in digging energy are caused by variations in muck-pile digging conditions or operators. However, even for one operator working in the same location (nearly same digging condition), digging energy will vary from cycle to cycle while average loading rate is almost constant. This can be explained by the effect of operator digging practice and its variability.

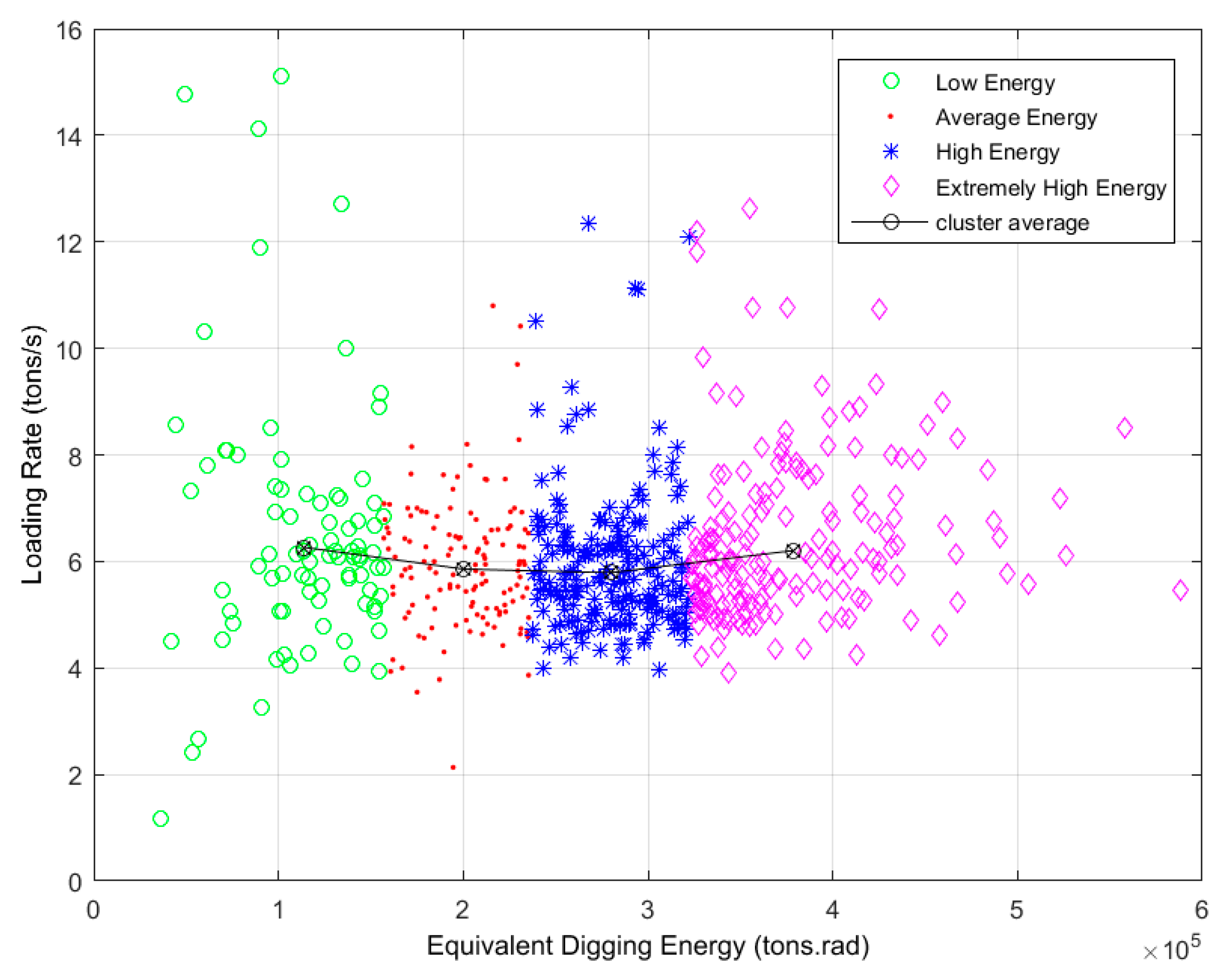

Figure 8 compares loading rate values for different digging energy classes for Operator A. These results indicate that for this case the loading rate is independent of operator or digging condition.

In order to further understand the effect of operator digging practice on the shovel performance, the digging practice of two operators (A and B) are compared in the next section. In addition to the data presented in

Section 4.2 (from the commercial monitoring system), the joysticks reference signals, as well as hoist rope retraction and crowd arm extension (from the Octagon computer), are analyzed for Operators A and B.

4.3. Operator Digging Practice

As mentioned in

Section 1, digging is mainly a combination of hoist and crowd actions. There are two joysticks in the operator’s cab that allow operators to control the machine. To study the effect of operator practice on digging efficiency, an evaluation of their hoist and crowd practices based on joystick signals is done.

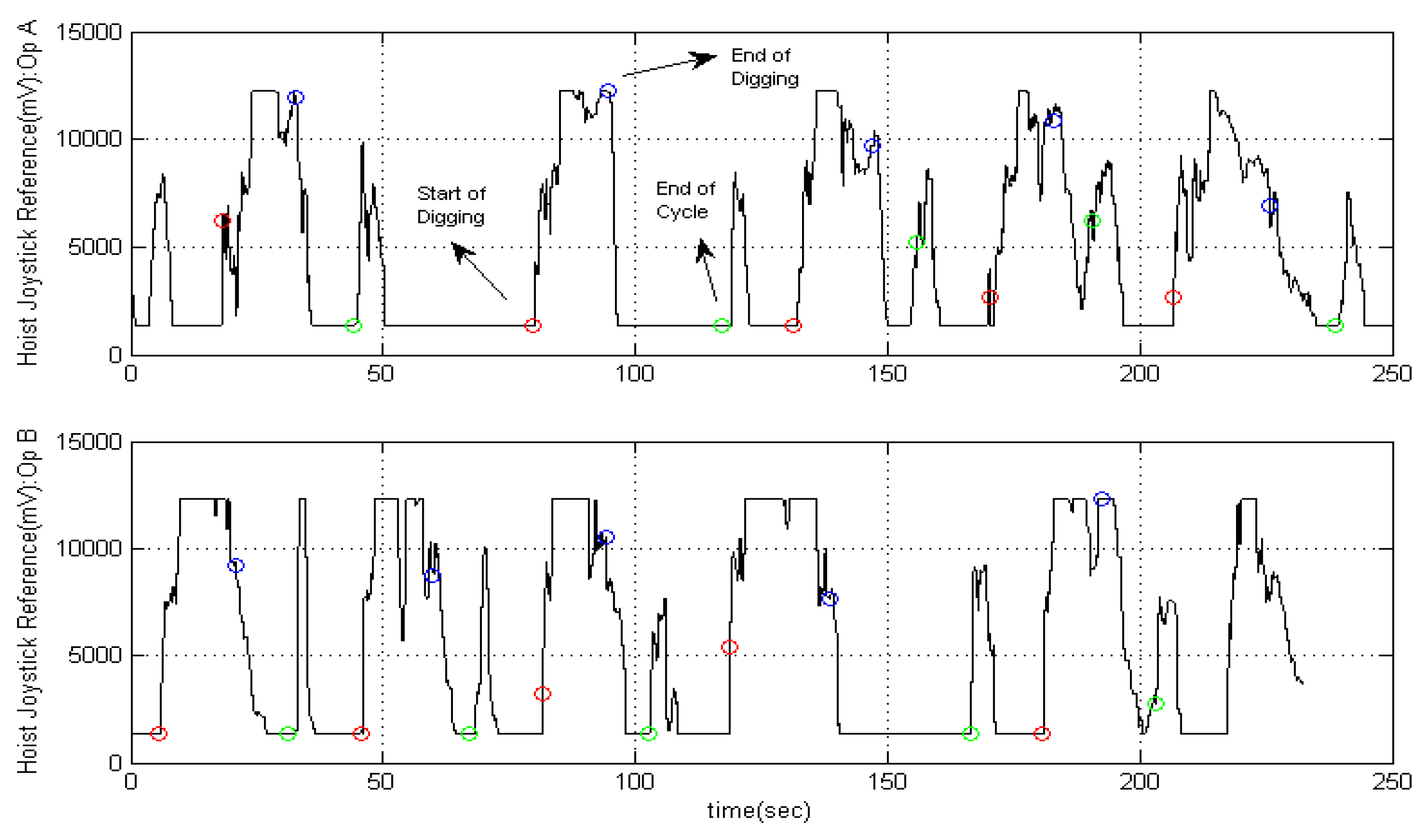

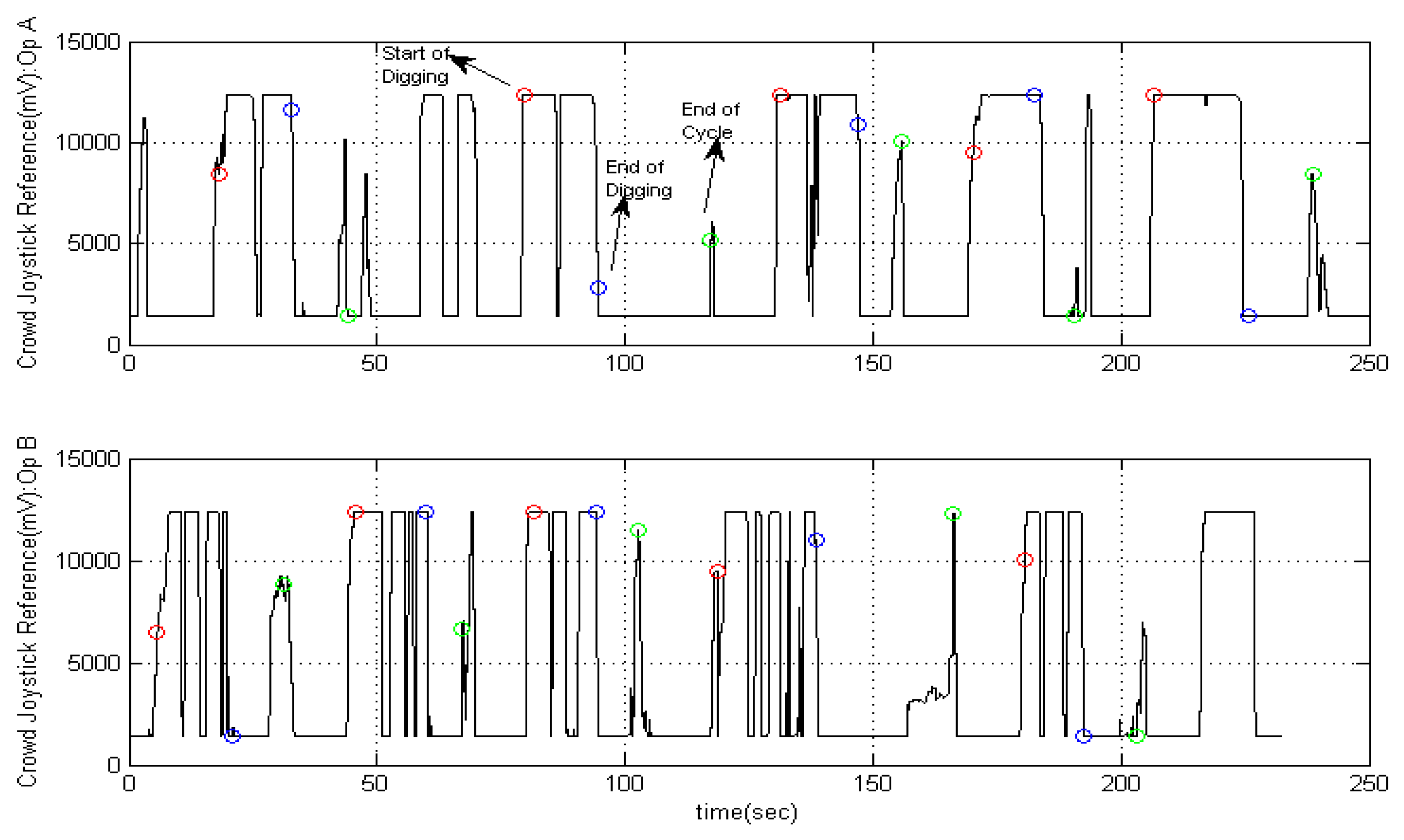

Figure 9 shows the hoist joystick reference signal for Operators A and B during a period of 250 s (5 cycles). The signals for Operators A and B have been annotated to show the start of digging (red circles), the end of digging (blue circles) and the end of the cycle (green circles). Similarly,

Figure 10 shows the crowd joystick reference signals for Operators A and B for the same period of time.

The above figures show that each operator has a unique style in filling the dipper. Operator B has a smoother hoist action during digging while he frequently pulls the crowd joystick towards himself (retraction) which is shown as valleys in the crowd joystick reference signal. Although, the above signals exhibit some similar trends, it is clear that each operator has different digging habits/techniques. To better understand the effect of operator digging techniques on shovel performance,

Figure 11 and

Figure 12 compare the average dig time and payload respectively for the different digging energy classes presented in

Table 2. These figures show that average dig time and payload increase with higher digging energy classes.

Figure 11 shows that Operators A and B have similar average dig time values except for the low energy class where Operator A has slightly lower (~1 s) average dig time.

In contrast to dig time,

Figure 12 shows that for average to extremely high digging energy classes, Operator B has a higher average payload. In other words, to fill the bucket to the same payload, the shovel consumed more energy when Operator A worked. One might conclude that Operator A worked in harder digging conditions since the shovel consumed more energy during digging for the same payload as Operator B (

Figure 12); however, based on the authors’ field observations, the blast engineer’s comments and operators comments, as mentioned in

Section 3.1, muck-pile digging conditions were easier for Operator A. Therefore, to understand the differences in digging energy,

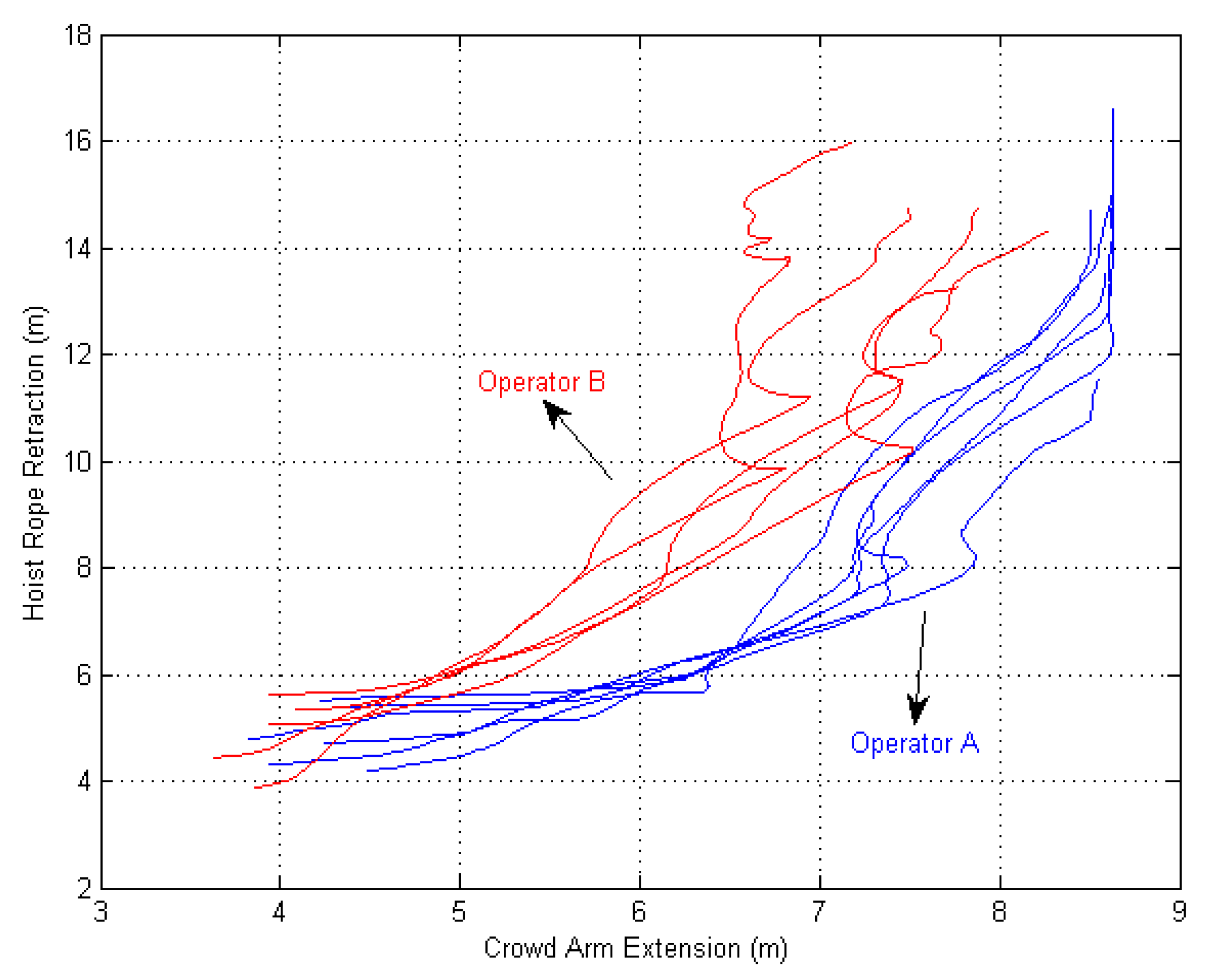

Figure 13 compares the digging trajectories of 5 consecutive cycles for each of the operators. This figure indicates that Operator A takes deeper cuts compared to Operator B which causes higher energy consumption.

According to past studies [

16,

19] the best operator digging practice is achieved by lower crowd extension speed and higher hoist rope retraction speed, which result in a decrease in the depth of cut. Such a practice should result in lower digging energy consumption per unit of loading rate known as specific digging energy. However, a limit of using specific digging energy as a measure of shovel performance is the inability to determine causes for its variations. In

Section 4.1 it was shown that there is no relationship between digging energy and loading rate; therefore, based on the definition of specific digging energy, digging energy is not normalized for the effect of loading rate. Additionally, digging energy can be affected by other factors, such as muck-pile digging conditions and machine type and conditions.

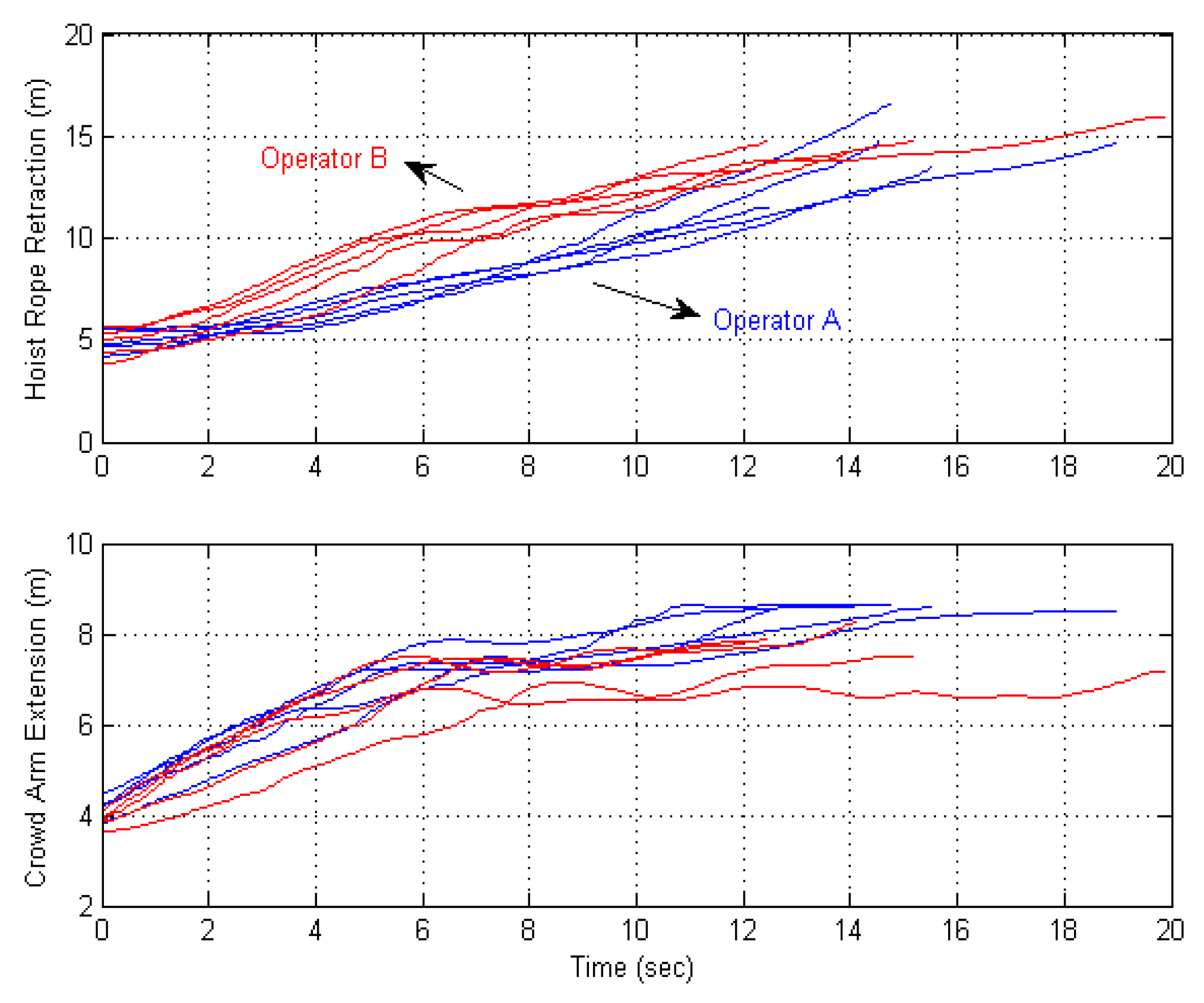

To demonstrate how operators control the machine during digging,

Figure 14 shows the crowd arm extension and hoist rope retraction during digging for 5 consecutive cycles for Operators A and B. In this figure, the slope of hoist rope retraction represents hoist speed and the slope of crowd arm extension represents crowd speed.

Figure 14 shows that the slope of the hoist rope retraction is almost constant for each cycle and a straight line can be fitted on the data for each cycle to estimate the hoist speed. Comparing the two operators, Operator A has a lower hoist speed. The hoist speeds and associated R-squared values for cycles in

Figure 14 are presented in

Table 3. In contrast to the hoist rope retraction,

Figure 14 shows that the crowd arm extension exhibits two different trends:

Constant crowd speed until the desired dipper depth of penetration is achieved (the first part of the digging);

Once the dipper penetrates into the bank, digging is mainly accomplished by hoist action, and the crowd speed is approximately zero.

This observation confirms that the dipper is mainly filled through the hoist action and the crowd action only helps to maintain a proper dipper depth of penetration into the bank. However, depth of penetration and crowd speed (in the first part of the digging) have effects on digging energy and shovel performance. The crowd speed values are estimated based on the slope of a straight line fitted on the crowd arm extension values in the first part of the digging. Crowd speeds and the associated R-squared values are presented in

Table 3.

Table 3 shows that the average hoist speed is higher for operator B while the average crowd speeds are almost the same for both operators. The R-squared values indicate that a straight line is the best fit to describe the data. A combination of crowd and hoist speeds generates different digging trajectories, as shown in

Figure 13, which directly affects the energy consumption and consequently shovel performance.

Therefore, to compare the digging performance of different operators, in contrast to the common approach of using one indicator, such as loading rate or specific digging energy, in this paper, a rating system similar to surface excavating classification systems [

20,

21,

22] developed in the past is proposed based on the product of digging energy, loading rate, crowd speed and hoist speed:

where

a1,

a2,

a3,

a4 are the numerical ratings of digging energy, loading rate, crowd speed and hoist speed, respectively. Because of high variability in digging energy, a weighted average based on the percentage of cycles within each class can be used to calculate the numerical rating of digging energy (

a1):

where

p1,

p2,

p3,

p4 denote the percentage of cycles in low, average, high and extremely high energy classes, respectively.

Despite the fact that it was shown in

Section 4.1 that loading rate is independent of the operator, to have a more generic equation it has been included in this approach. Additionally, digging energy is influenced by not only operator practices (crowd and hoist speeds) but also digging conditions and machine type and conditions. Therefore, to ensure that other factors such as digging conditions don’t mislead the assessment, it is essential to include crowd and hoist speeds in addition to digging energy. It should be noted that the proposed formulation has operational purposes and is an experimentally derived approach that can be employed by different operations to assess digging performance of electric rope shovels operators.

The rating of each of the parameters in Equation (5) is subjective and their weights can change according to management policies. For example, if the focus of an operation is mainly on the volume produced, loading rate should have the highest weight in the rating system.

Table 4 suggests an example of the rating system based on the observed data during the field trial. The ratings may vary from mine to mine with different types of operations and management strategies, and can be modified by operations as more data is collected. In this study, the classification for digging energy is based on the clustering analysis performed, and the classes for loading rate, hoist speed and crowd speed have been defined based on the observed distribution of data and the discussion with mine senior engineers. To be able to have a universal classification data needs to be collected from different types of operations and from different machines. The proposed rating/classification in

Table 4 can only be used as a guideline. In this table, higher loading rates, lower digging energy, higher hoist speed and lower crowd speed should have higher rating numbers. Such a rating will result in higher

N values for operators with a better performance.

N values can be calculated for each operator per shift. To validate the proposed approach,

Table 5 compares the

N values for Operators A and B. Although Operator B was digging harder conditions, he has a higher

N value compared to Operator A which means he has a better digging performance.