Soft Roof Failure Mechanism and Supporting Method for Gob-Side Entry Retaining

Abstract

:1. Introduction

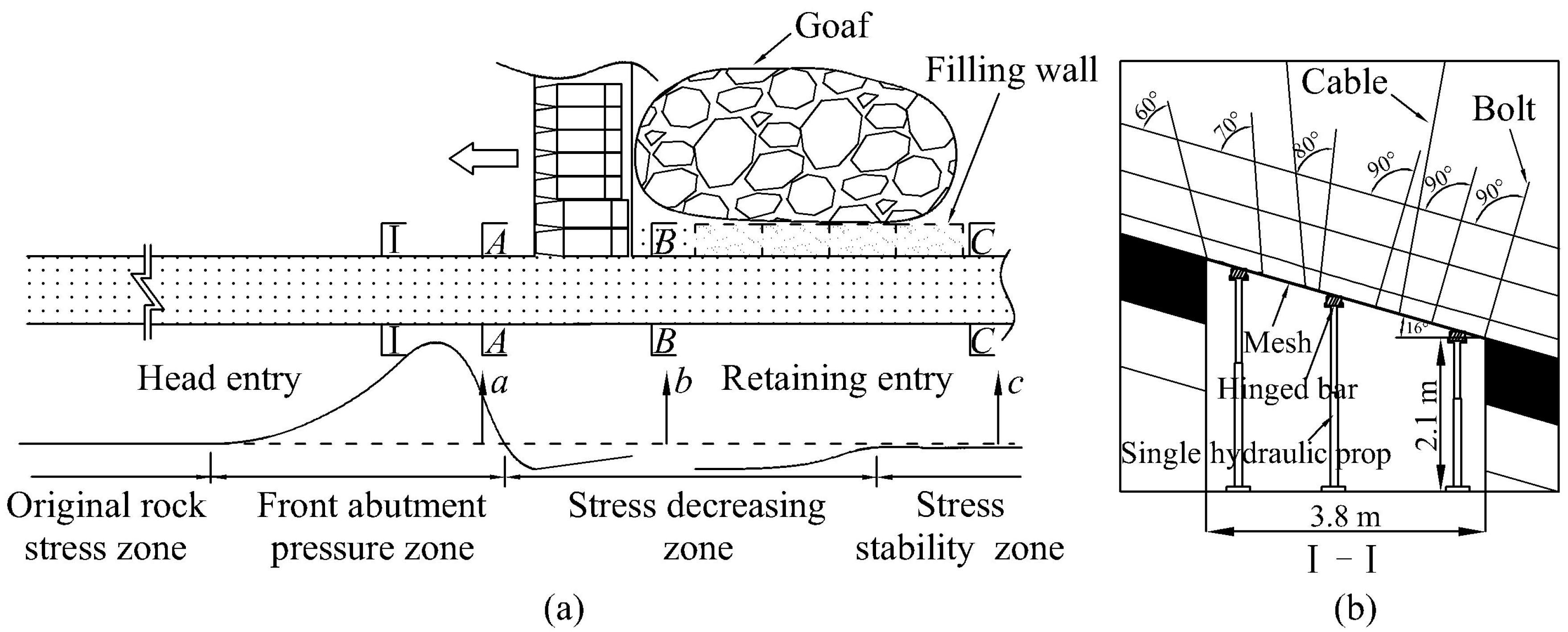

2. Description of Field Observation

2.1. Survey of Study Site

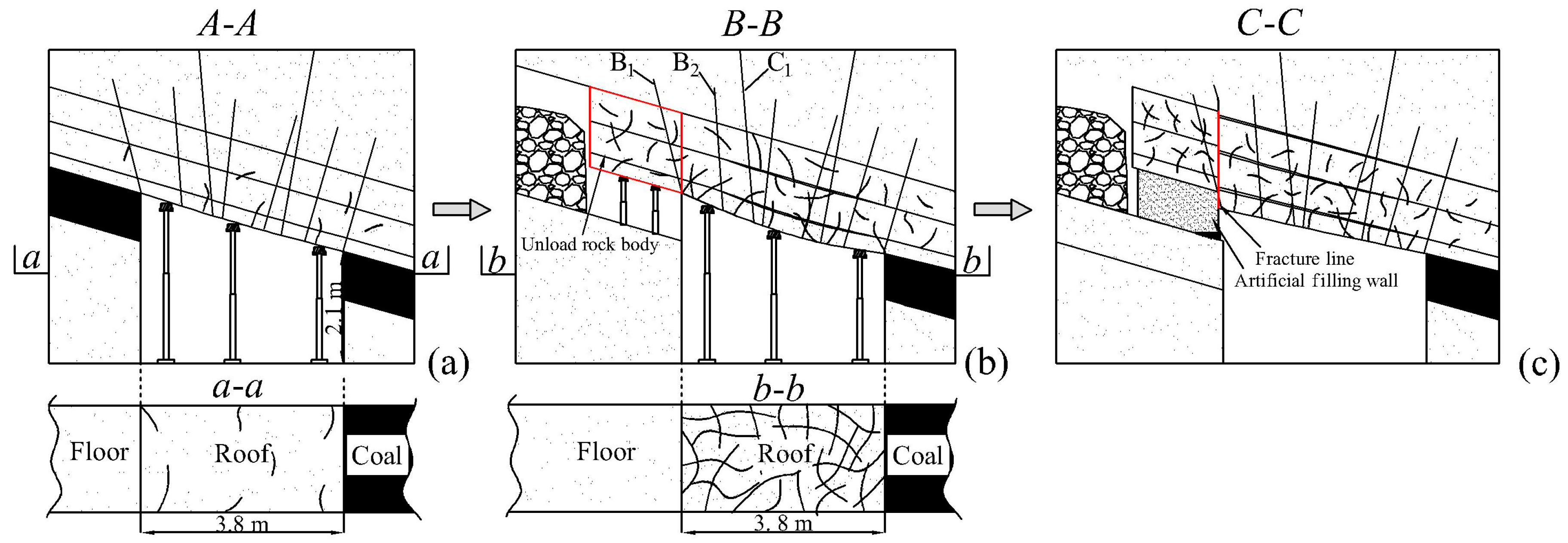

2.2. The Survey Results of Soft Roof Failure Characteristics

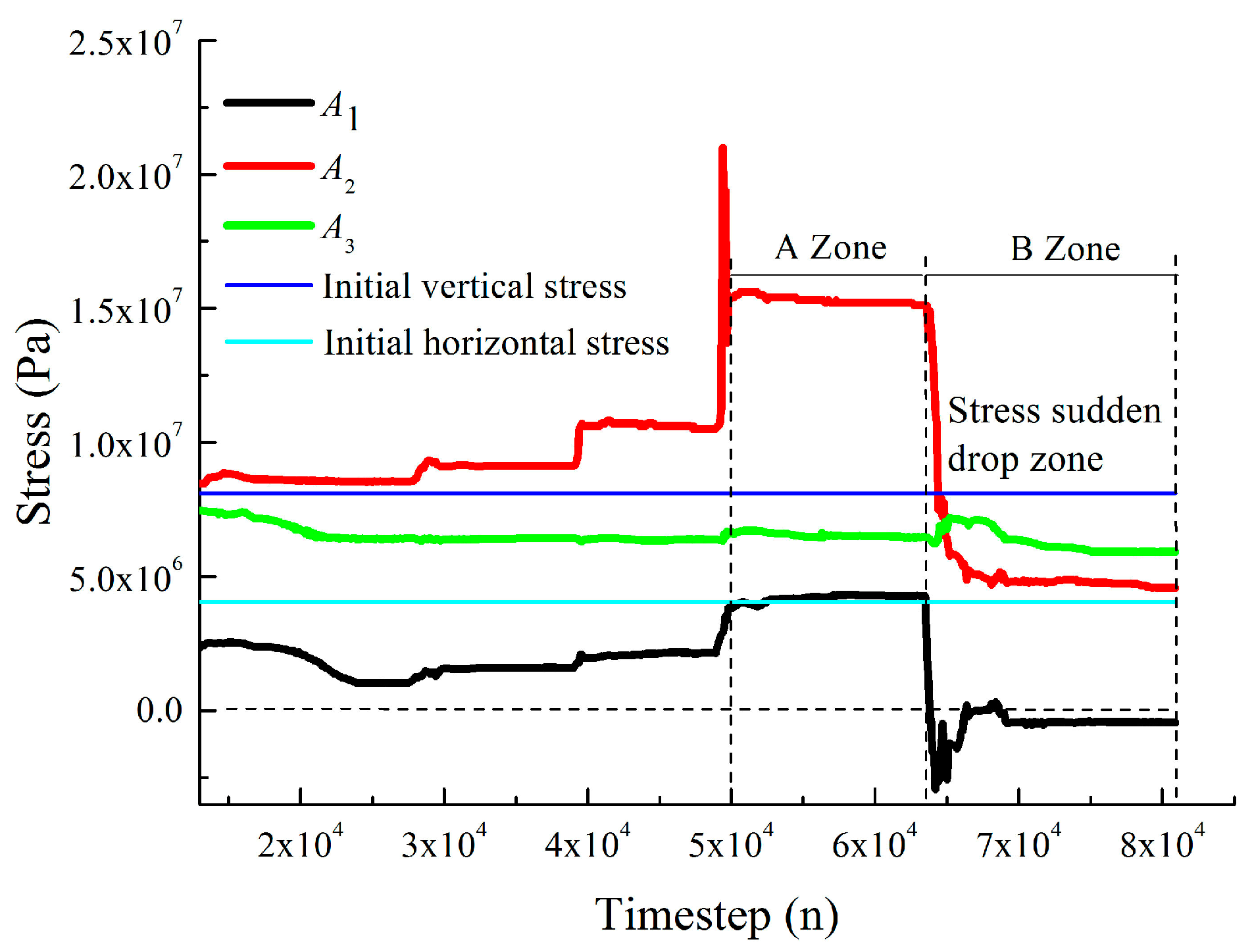

3. Stress Evolution Law in Roof

3.1. Numerical Simulation Model

3.2. Numerical Results

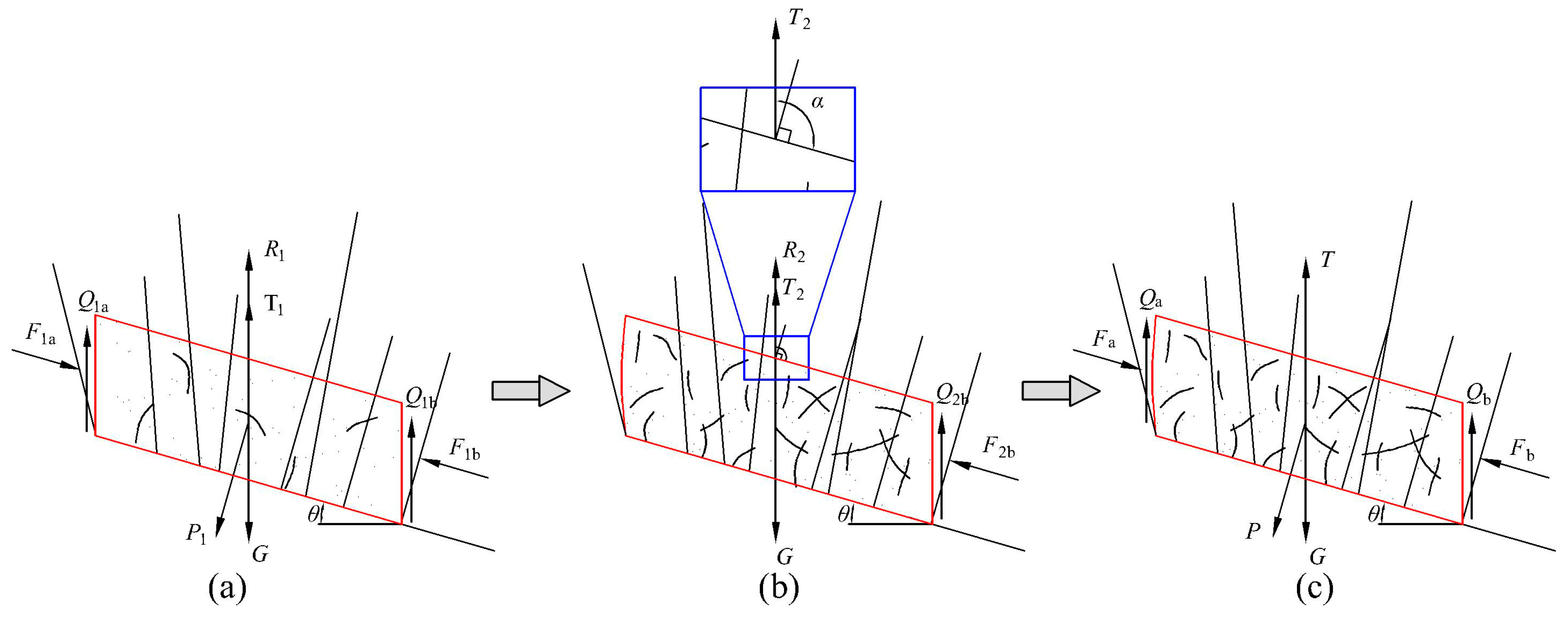

4. Force States of Roof Rock Mass

5. Mechanism for Failure of Roof Rock Mass

5.1. Mechanism for Failure of Roof Rock Mass in Working Face End

5.1.1. Unloading Effect of the Lateral Stress

5.1.2. Tensile and Shear Failure of the Working Face End Lower Layer Rock Mass

- (1)

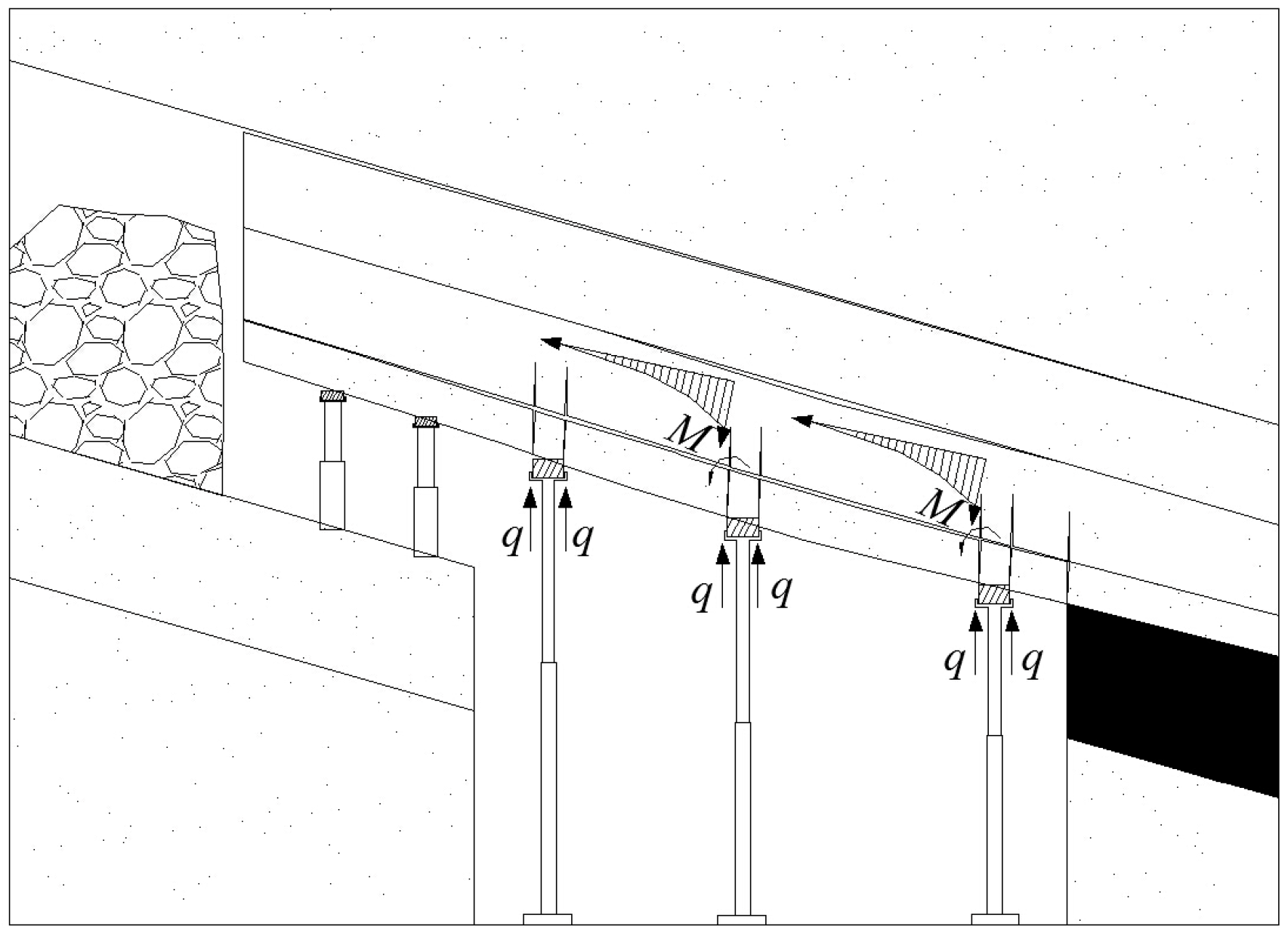

- An uneven supporting at the working face end roof. A strong mine ground pressure appeared, causing the significant sinking of the working face end roof in the working face advancing process, so a single hydraulic prop with an articulated roof beam was usually set as a reinforcement support. There is uneven pressure on the roof surface due to the low strength and stiffness of the sandy mudstone and mudstone and the higher strength and stiffness strengthening the support body, resulting in part of the support body inserting the roof and leading to a roof rock shear failure with shear stress q, as shown in Figure 7. In addition, the passive supporting force is too large and does not couple support with the bolts (cables), causing part of the bolts (cables) to be loosened, affecting the roof rock mass local stress state and resulting in ultimate rock mass failure.

- (2)

- Effect of local moment. Treating the reinforcement body (individual hydraulic prop and articulated roof beam, etc.) as the fulcrum, the lower roof strata produced a local bending on a small scale, but when the fulcrum bending moment (M) is too large, the layered roof strata cause tensile and compressive damage to the upper surface and lower surface, respectively, additionally increased the possibility of the support body inserting the upper roof and leading to rock mass shear failure, as shown in Figure 7.

5.1.3. Dynamic Failure

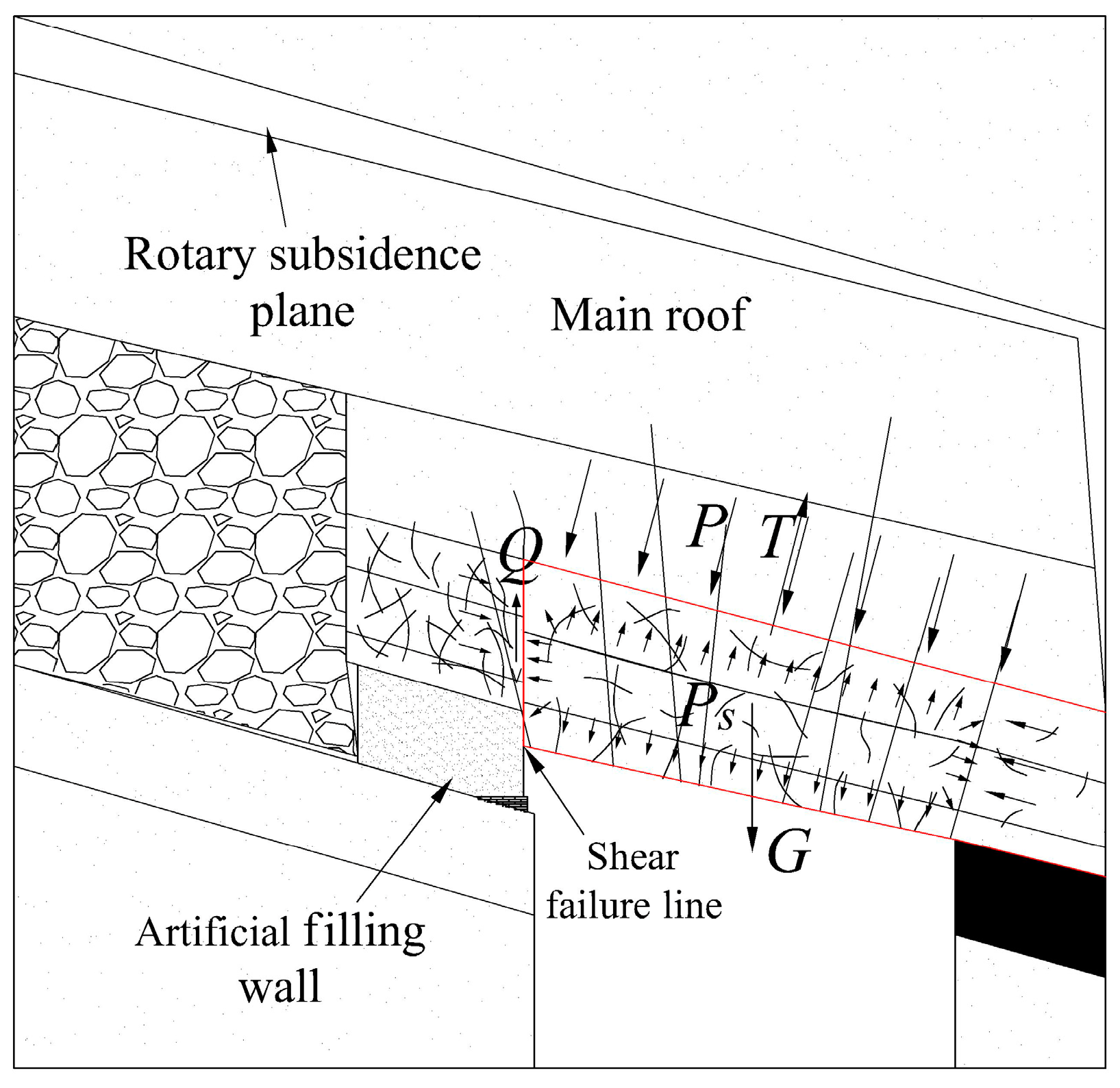

5.2. Mechanism for Failure of the Roof Rock Mass in Retaining Roadway

6. Roof Support Countermeasures

6.1. Deformation Analysis of Working Face End Roof

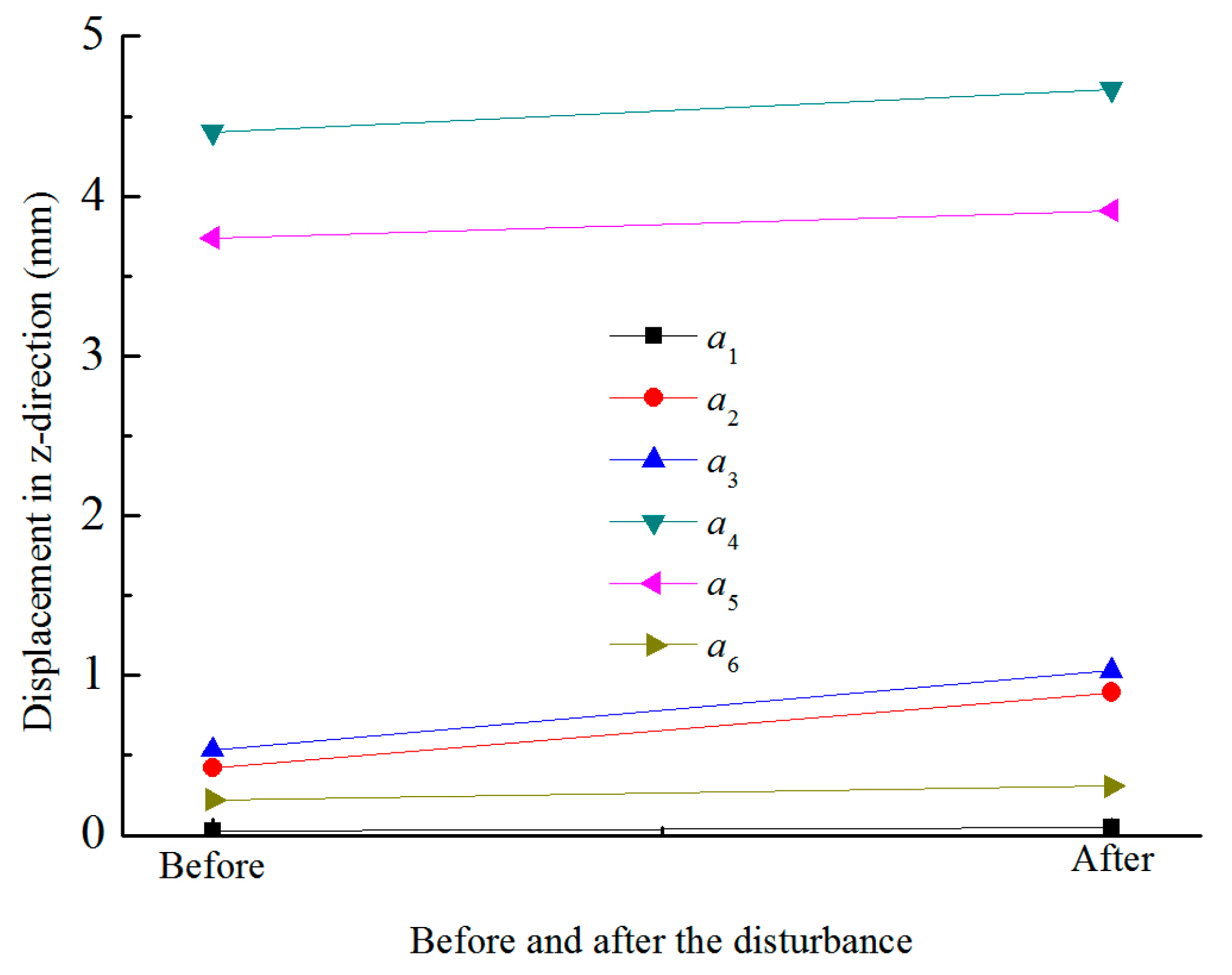

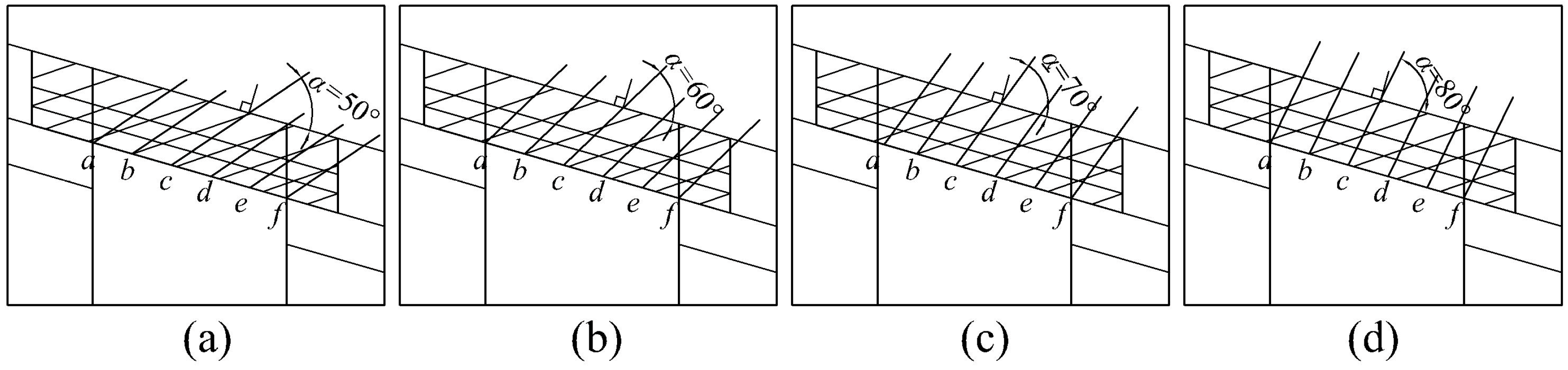

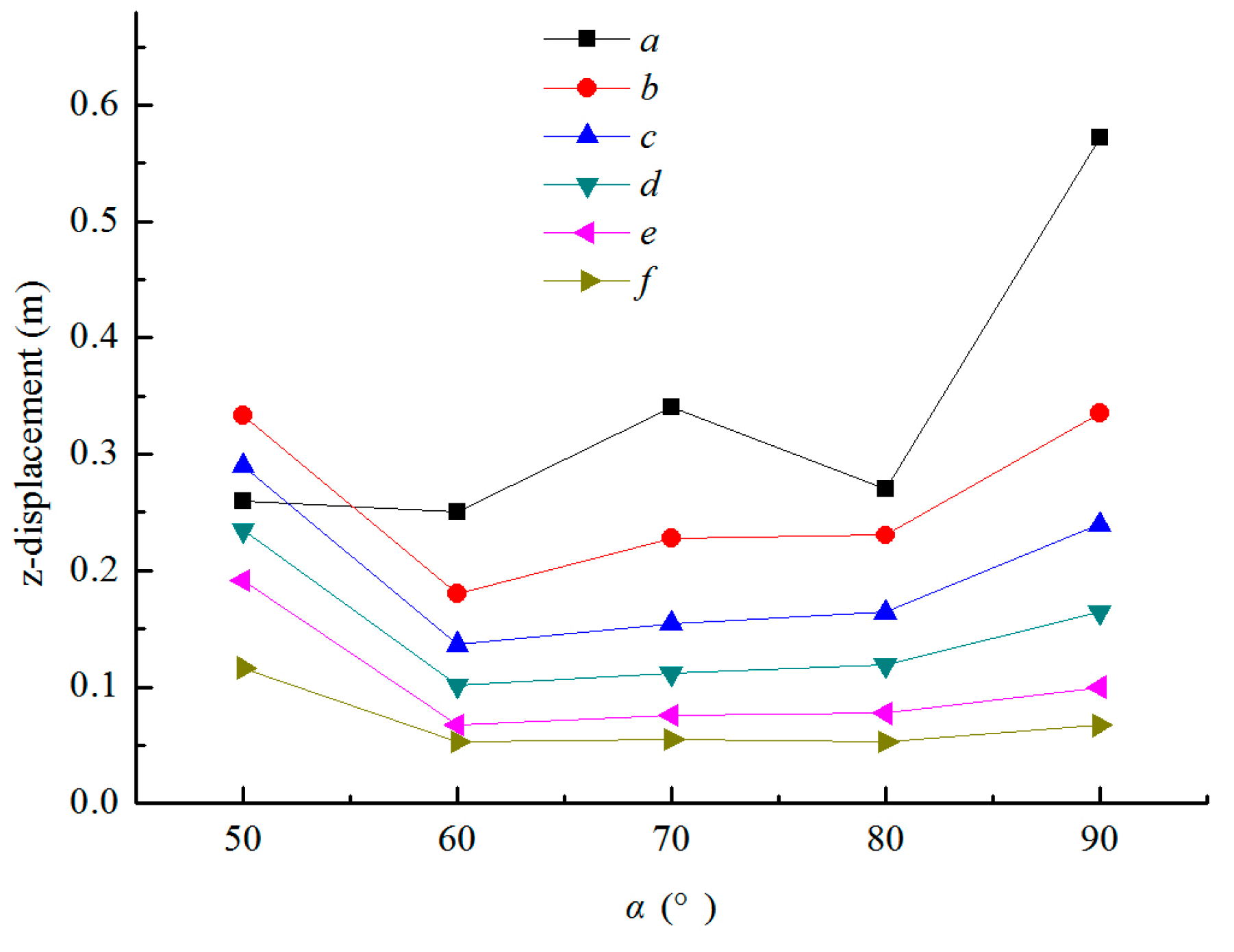

- (1)

- The monitored displacement had a good regularity and the displacement curve showed a trend of a “concave” type with α increasing as a whole; the vertical displacement of roof was minimal when α = 60°, and the displacement increased when α = 70° and 80°, but it had a smaller increment;

- (2)

- For a certain α, the point displacement increased as the distance to the gob decreased, that is to say, the roof rotated and sank; and

- (3)

- The displacement is larger under the current anchor installation angle (α = 90°) condition; its differences were 155 and 321 mm from the minimum displacement.

6.2. Bolt Limit Equilibrium Tension Force

- (1)

- If the T value is small, the right value becomes greater than the left maximum value, so it cannot meet the balance relationship, and the bolts are not able to play their role in supporting. This shows that when having a certain bolt installation angle α, there must be some tensile force T of the bolts to make the right value equal the left value in Equation (7). It also illustrates the importance of the bolts being pre-tensioned when used in the rock mass.

- (2)

7. Discussion

8. Conclusions

- (1)

- After the working face advances, it is found that the horizontal stress of the soft rock mass at the working face end does not exhibit a large magnitude unloading on the coal wall side, but the horizontal stress momentarily fell, and a tensile stress appeared on the gob side. The vertical stress in the gateway central dropped significantly, almost down to zero.

- (2)

- The sinking and separation of the soft roof rock mass in the gently inclined coal seam working face end is affected by the front abutment pressure and the hanging roof on gob side. The initiation and propagation of cracks and the fractures of the rock mass are produced by the actions of the lateral stress unloading loose, tensile, and shear stresses in the low layer caused by uneven support and no coupling support and dynamic disturbances.

- (3)

- The roof rock mass failed in shear mode along the inside of man-made constructed wall in the stability zone of the retained gateway, due to the overburden pressure, bulking force, roof gravity, and combined supporting force. The failed roof forms a “similar cantilever beam” structure.

- (4)

- The equation of the bolt ultimate equilibrium tension force, a function of the seam inclination, gateway width, soft roof thickness, and bolt installation angle, was established according to the stress balance analysis of the roof rock.

- (5)

- To prevent the working face end soft roof rock mass from increasing its deformation and becoming significantly fractured, and also to maintain the gob-side entry retaining roof’s stability, it is suggested that the gateway roof bolt installation angle be 70° to provide an extrusion stress, change the rock mass stress state, and improve their strength for better entry maintenance.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yuan, L. Theory and Practice of Integrated Pillarless Coal Production and Methane Extraction in Multiseams of Low Permeability; China Coal Industry Publishing: Beijing, China, 2008. [Google Scholar]

- Zhang, N.; Yuan, L.; Han, C.L.; Xueb, J.; Kan, J. Stability and Deformation of Surrounding Rock in Pillarless Gob-Side Entry Retaining. Saf. Sci. 2012, 50, 593–599. [Google Scholar] [CrossRef]

- He, T.J. The Breaking Place Prediction of Face End Main Roof Flap Top in the Gob-Side Entry Retaining. J. China Coal Soc. 2000, 25, 28–31. [Google Scholar]

- Zhang, G.H. Roof cracking reason analysis about gob-side entry retaining under initiative support. J. China Coal Soc. 2005, 30, 429–432. [Google Scholar]

- Gou, P.F.; Zhang, Z.P.; Wei, S.J. Physical Simulation Test of Damage Character of Surrounding Rock under Different Levels of the Horizontal Stress. J. China Coal Soc. 2009, 34, 1328–1332. [Google Scholar]

- Coggan, J.; Gao, F.Q.; Stead, D.; Elmo, D. Numerical Modelling of the Effects of Weak Immediate Roof Lithology on Coal Mine Roadway Stability. Int. J. Coal Geol. 2012, 90, 100–109. [Google Scholar] [CrossRef]

- Zhang, D.S.; Mao, X.B.; Ma, W.D. Testing study on deformation Features of Surrounding Rocks of Gob-Side Entry Retaining in Fully-Mechanized Coal Face with Top-Coal Caving. Chin. J. Rock Mech. Eng. 2002, 21, 331–334. [Google Scholar]

- Xie, W.B. Influence Factors on Stability of Surrounding Rocks of Gob-Side Entry Retaining in Top-Coal Caving Mining Face. Chin. J. Rock Mech. Eng. 2004, 23, 3059–3065. [Google Scholar]

- Nemcik, J.; Ma, S.Q.; Aziz, N.; Rena, T.; Geng, X. Numerical Modelling of Failure Propagation in Fully Grouted Rock Bolts Subjected to Tensile Load. Int. J. Rock Mech. Min. Sci. 2014, 71, 293–300. [Google Scholar] [CrossRef]

- Ma, S.Q.; Nemcik, J.; Aziz, N. An Analytical Model of Fully Grouted Rock Bolts Subjected to Tensile Load. Constr. Build Mater. 2013, 49, 519–526. [Google Scholar]

- Yang, S.S.; Cao, J.P. Evolution Mechanism of Anchoring Stress and Its Correlation with Anchoring Length. J. Min. Saf. Eng. 2010, 27, 2–7. [Google Scholar]

- Zheng, X.G.; Zhang, N.; Xue, F. Study on Stress Distribution Law in Anchoring Section of Prestressed Bolt. J. Min. Saf. Eng. 2012, 29, 365–370. [Google Scholar]

- Cao, S.G.; Zou, D.J.; Bai, Y.J.; He, P.; Wu, H. Surrounding Rock Control of Mining Roadway in the Thin Coal Seam Group with Short Distance and “Three Soft”. J. Min. Saf. Eng. 2011, 28, 524–529. [Google Scholar]

- Fan, K.G.; Jiang, J.Q. Deformation Failure and Non-Harmonious Control Mechanism of Surrounding Rocks of Roadways with Weak Structures. J. China Univ. Min. Technol. 2007, 36, 54–59. [Google Scholar]

- Hua, X.Z.; Ma, J.F.; Xu, T.J. Study on Controlling Mechanism of Surrounding Rocks of Gob-Side Entry with Combination of Roadside Reinforced Cable Supporting and Roadway Bolt Supporting and Its Application. Chin. J. Rock Mech. Eng. 2005, 24, 2107–2112. [Google Scholar]

- Yan, Y.B.; Shi, J.J.; Jiang, Z.J. Application of Anchor Cable with Bolt and Steel Band Coupling Support Technology in Gob-Side Entry Retaining. J. Min. Saf. Eng. 2010, 27, 273–276. [Google Scholar]

- Chen, Y.; Bai, J.B.; Wang, X.Y.; Ma, S.-Q.; Xu, Y.; Bi, T.F. Support Technology Research and Application inside Roadway of Gob-Side Entry Retaining. J. China Coal Soc. 2012, 37, 903–910. [Google Scholar]

- Jing, L.; Stephansson, O. Fundamentals of Discrete Element Methods for Rock Engineering-Theory and Applications; Elsevier: Amsterdam, The Amsterdam, 2007. [Google Scholar]

- Gao, F.Q.; Stead, D. Discrete Element Modelling of Cutter Roof Failure in Coal Mine Roadways. Int. J. Coal Geol. 2013, 116–117, 158–171. [Google Scholar]

- Cundall, P.A.; Hart, R.D. Development of Generalized 2–D and 3–D Distinct Element Programs for Modelling Jointed Rock; US Army Engineering Waterways Experiment Station: Minneapolis, MN, USA, 1985; SL–85–1. [Google Scholar]

- Firpo, G.; Salvini, R.; Francioni, M.; Ranjith, P.G. Use of Digital Terrestrial Photogrammetry in Rocky Slope Stability Analysis by Distinct Elements Numerical Methods. Int. J. Rock Mech. Min. Sci. 2011, 48, 1045–1054. [Google Scholar] [CrossRef]

- Gao, F.Q.; Stead, D.; Kang, H.P.; Wu, Y.Z. Discrete Element Modelling of Deformation and Damage of a Roadway Driven along an Unstable Goaf—A Case Study. Int. J. Coal Geol. 2014, 127, 100–110. [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, F.; Ju, Y.; Gao, M.Z.; Zhang, R.; Gao, Y.N.; Liu, J.F.; Xie, L.Z. Quantitative definition and investigation of deep mining. J. China Coal Soc. 2015, 40, 1–10. [Google Scholar]

- Hou, C.J.; Guo, L.S.; Gou, P.F. Rock Bolting for Coal Roadway; China University of Mining and Technology Press: Xuzhou, China, 1999; pp. 38–50. [Google Scholar]

- Kang, H.P. Study and Application of Complete Rock Bolting Technology to Coal Roadway. Chin. J. Rock Mech. 2005, 24, 161–166. [Google Scholar]

- Zhang, Y.Q.; Peng, S.S. Design Considerations for Tensioned Bolts. In Proceedings of the 21st International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV, USA, 6–8 August 2002; pp. 131–140.

- Lu, W.B.; Yang, J.H.; Yan, P.; Chen, M.; Zhou, C.; Luo, Y.; Jin, L. Dynamic Response of Rock Mass Induced by the Transient Release of in-situ Stress. Int. J. Rock Mech. Min. Sci. 2012, 53, 129–141. [Google Scholar]

- Felice, J.J.; Beattie, T.A.; Spathis, A.T. Face Velocity Measurements Using a Microwave Radar Technique. In Proceedings of the 7th Research Symposium on Explosives and Blasting Technique, Las Vegas, NV, USA, 6–7 February 1991; pp. 71–77.

- Preece, D.S.; Evans, R.; Richards, A.B. Coupled Explosive Gas Flow and Rock Motion Modeling with Comparison to Bench Blast Field Data. In Proceeding of the 4th International Symposium on Rock Fragmentation by Blasting, Vienna, Austria, 5–8 July 1993; pp. 239–246.

- Peng, S.S. Coal Mine Ground Control, 3rd ed.; China University of Mining and Technology Press: Beijing, China, 2013; pp. 200–203. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Cao, S.; Li, Y.; Sun, C.; Guo, P. Soft Roof Failure Mechanism and Supporting Method for Gob-Side Entry Retaining. Minerals 2015, 5, 707-722. https://doi.org/10.3390/min5040519

Yang H, Cao S, Li Y, Sun C, Guo P. Soft Roof Failure Mechanism and Supporting Method for Gob-Side Entry Retaining. Minerals. 2015; 5(4):707-722. https://doi.org/10.3390/min5040519

Chicago/Turabian StyleYang, Hongyun, Shugang Cao, Yong Li, Chuanmeng Sun, and Ping Guo. 2015. "Soft Roof Failure Mechanism and Supporting Method for Gob-Side Entry Retaining" Minerals 5, no. 4: 707-722. https://doi.org/10.3390/min5040519