Advanced Classification of Coffee Beans with Fatty Acids Profiling to Block Information Loss

Abstract

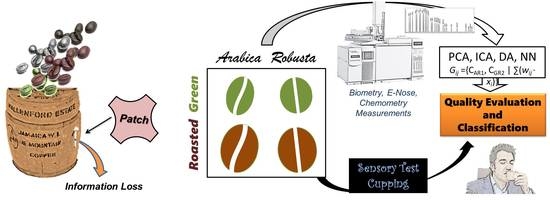

:1. Introduction

2. Materials and Methods

2.1. Sample Collection and Preparation

2.2. Lipid Extraction and Crude Fat

2.3. Preparation of Fatty Acid Methyl Esters

2.4. Fatty Acids Profile by GC–FID Analysis

2.5. Statistics Software and Calculations

3. Results and Discussion

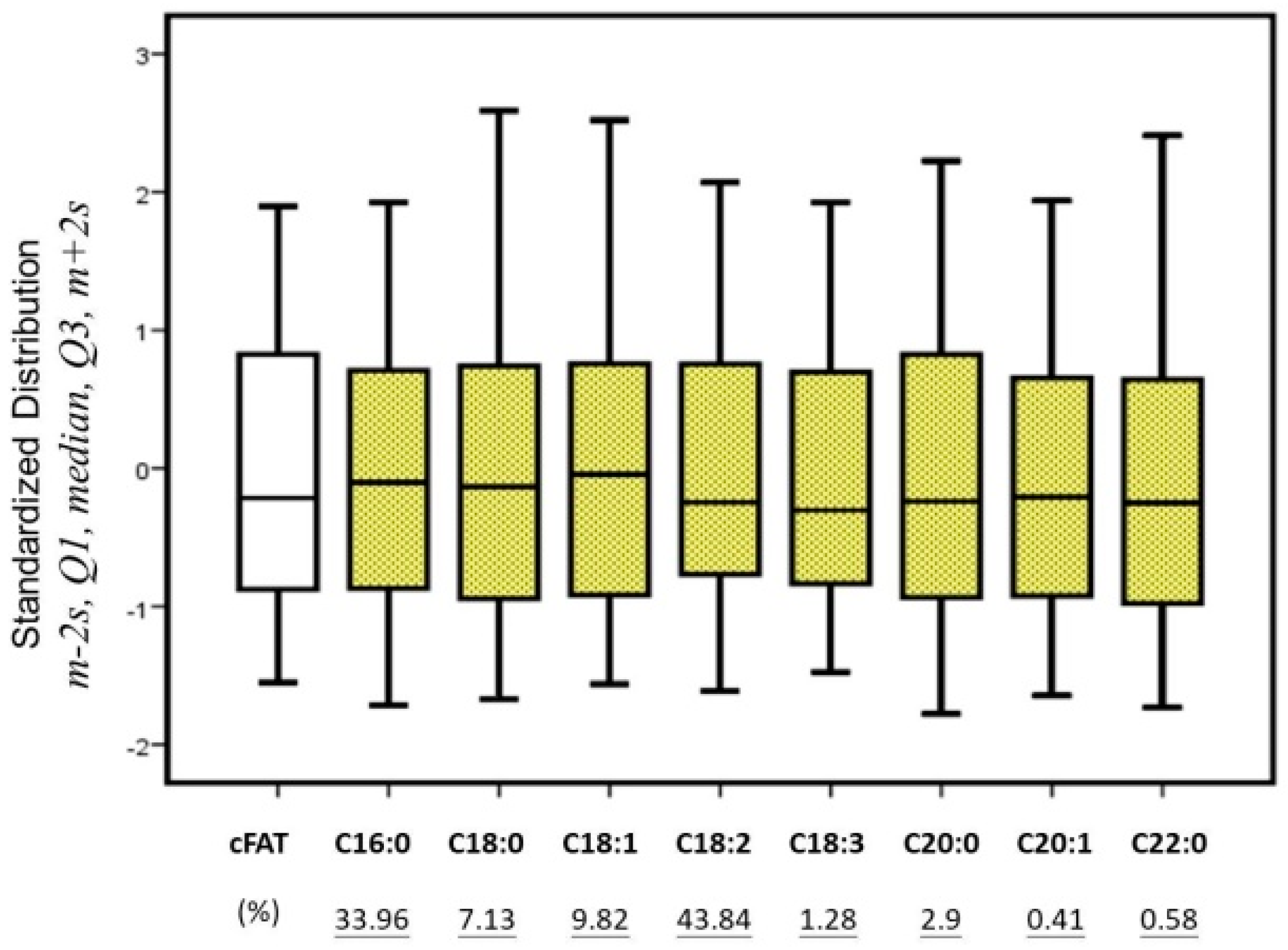

3.1. Fatty Acids Analysis by GC–FID

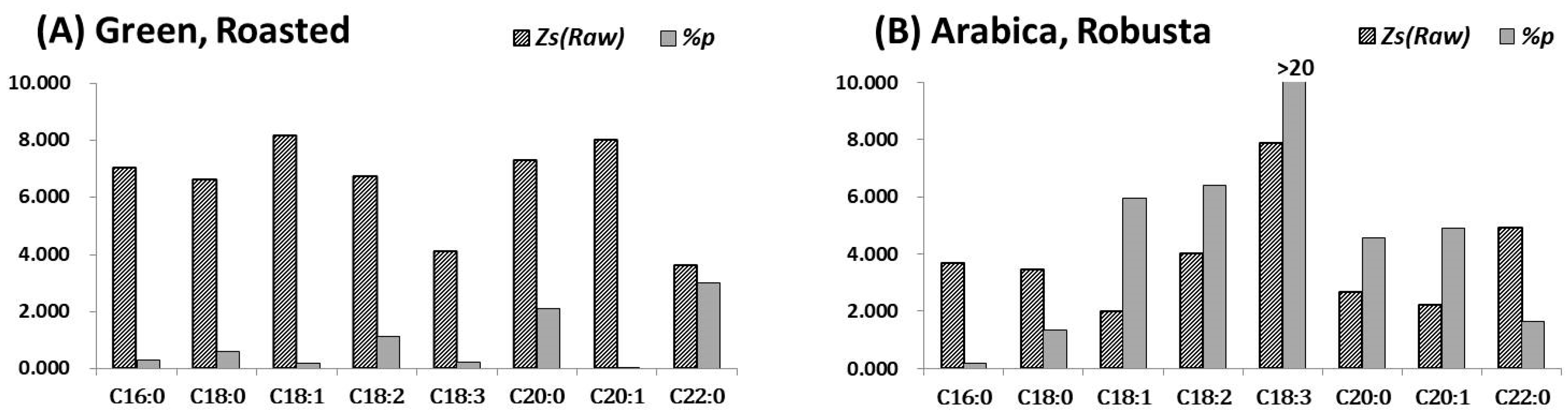

3.2. Normalization (Percentile) and Standardization (Z-Score)

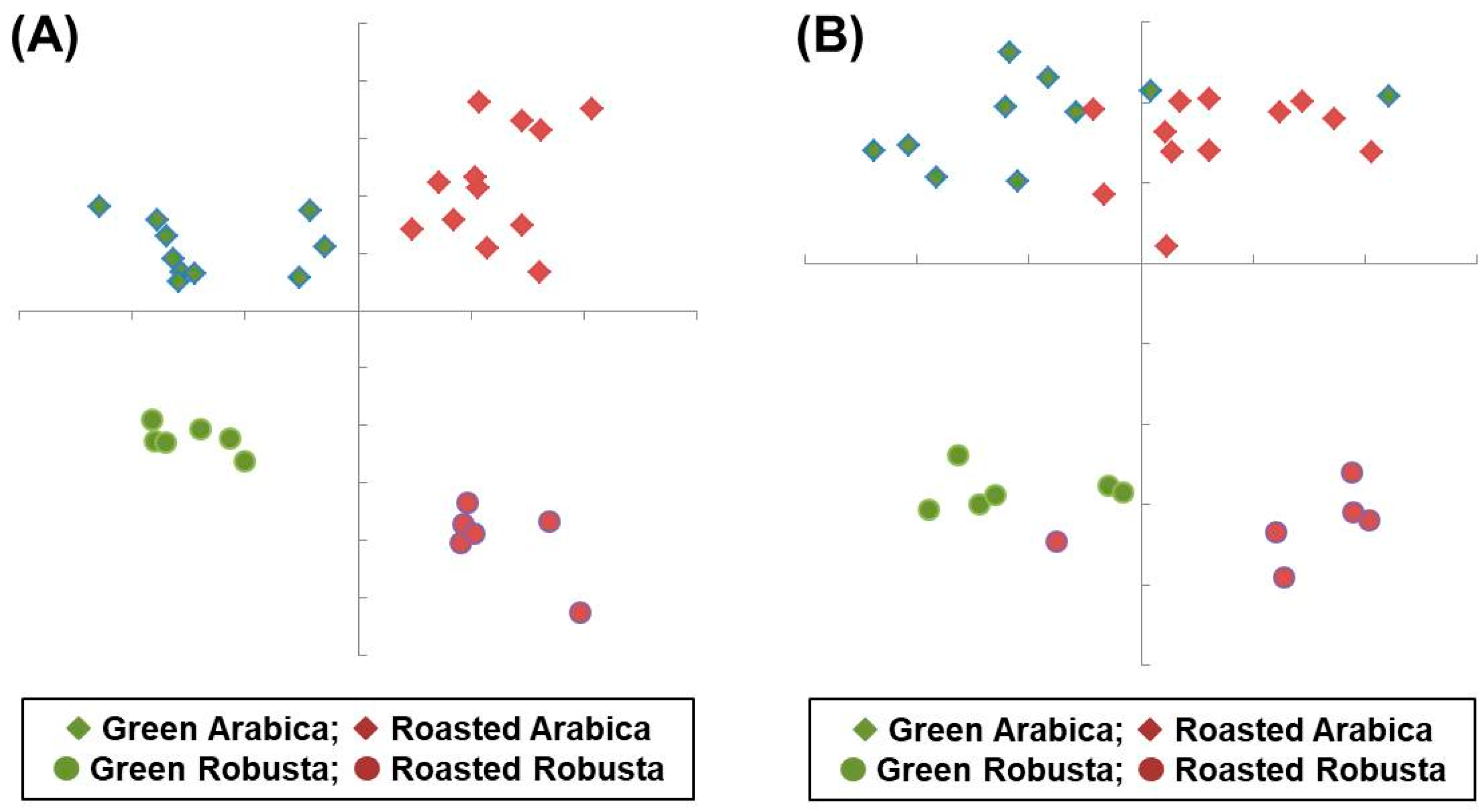

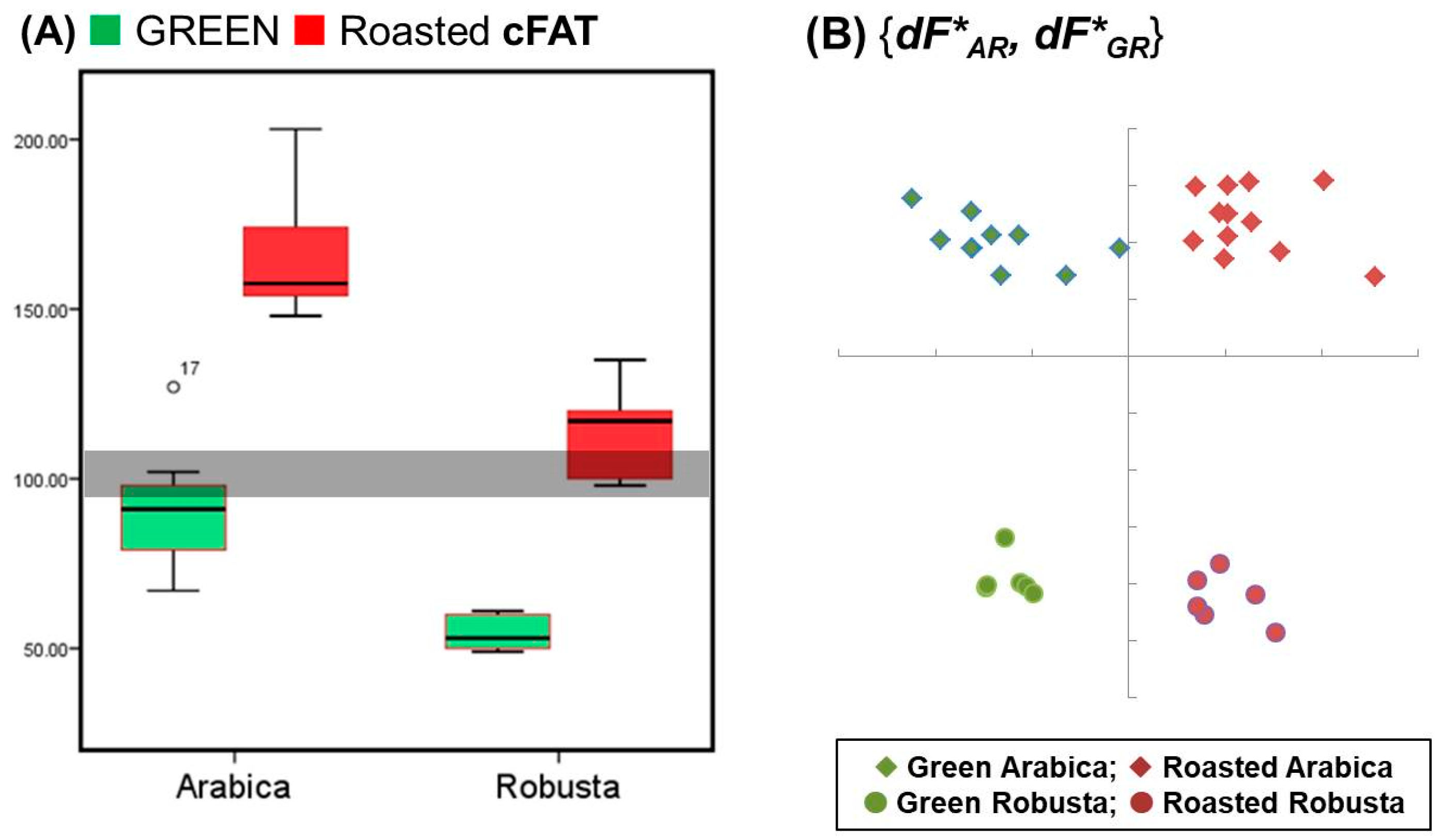

3.3. Discrimination Analysis

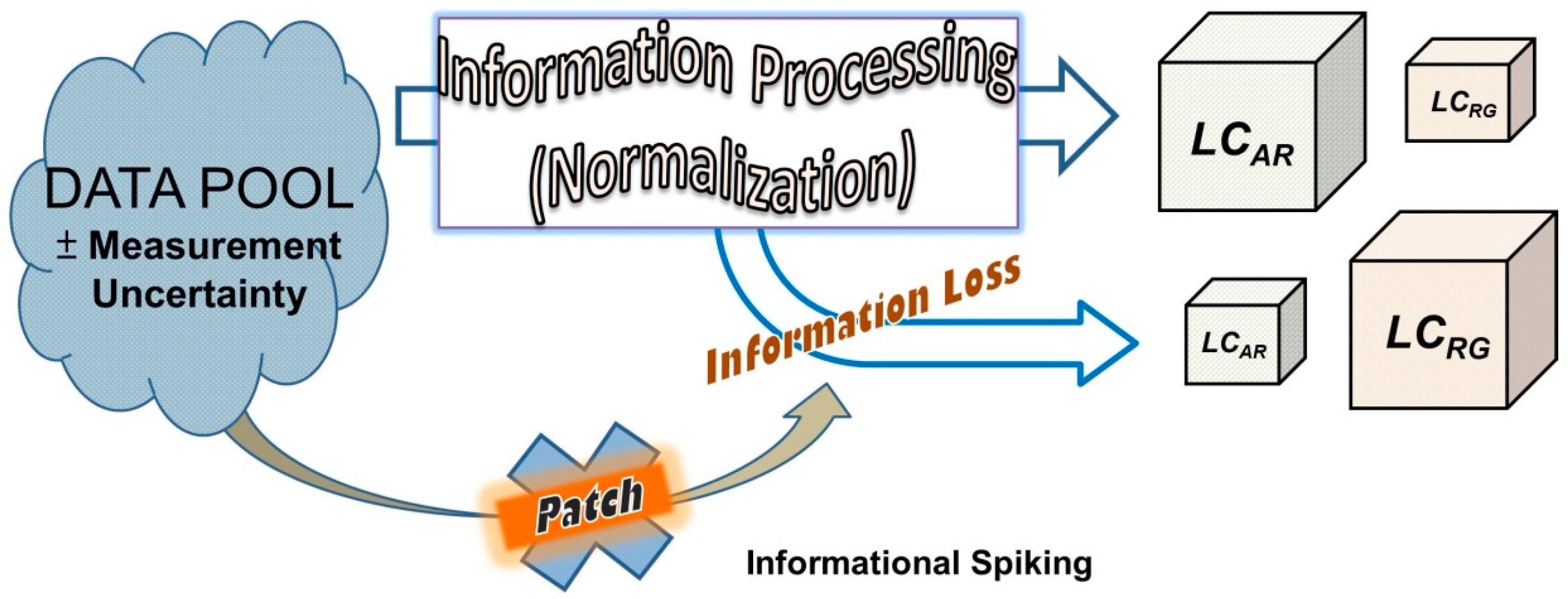

3.4. Information Loss in Data Processing

3.5. Patching the Breach in the Classification System

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Romano, R.; Santini, A.; Le Grottaglie, L.; Manzo, N.; Visconti, A.; Ritieni, A. Identification markers based on fatty acid composition to differentiate between roasted Arabica and Canephora (Robusta) coffee varieties in mixtures. J. Food Compos. Anal. 2014, 35, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Abad, M.; Abkar, A.; Mojaradi, B. Effect of the temporal gradient of vegetation indices on early-season wheat classification using the random forest classifier. Appl. Sci. 2018, 8, 1216. [Google Scholar] [CrossRef]

- Niimi, J.; Tomic, O.; Naes, T.; Jeffery, D.W.; Bastian, S.E.P.; Boss, P.K. Application of sequential and orthogonalised-partial least squares (SO-PLS) regression to predict sensory properties of Cabernet Sauvignon wines from grape chemical composition. Food Chem. 2018, 256, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Pramudya, R.C.; Seo, H.S. Influences of product temperature on emotional responses to, and sensory attributes of, coffee and green tea beverages. Front. Psychol. 2017, 8, 2264. [Google Scholar] [CrossRef] [PubMed]

- Lange, C.; Combris, P.; Issanchou, S.; Schlich, P. Impact of information and in-home sensory exposure on liking and willingness to pay: The beginning of Fairtrade labeled coffee in France. Food Res. Int. 2015, 76, 317–324. [Google Scholar] [CrossRef] [PubMed]

- Lindinger, C.; Labbe, D.; Pollien, P.; Rytz, A.; Juillerat, M.A.; Yeretzian, C.; Blank, I. When machine tastes coffee: Instrumental approach to predict the sensory profile of espresso coffee. Anal. Chem. 2008, 80, 1574–1581. [Google Scholar] [CrossRef] [PubMed]

- Zia ur Rehman, M.; Gilani, S.; Waris, A.; Niazi, I.; Slabaugh, G.; Farina, D.; Kamavuako, E. Stacked Sparse Autoencoders for EMG-Based Classification of Hand Motions: A Comparative Multi Day Analyses between Surface and Intramuscular EMG. Appl. Sci. 2018, 8, 1126. [Google Scholar] [CrossRef]

- Masi, C.; Dinnella, C.; Barnaba, M.; Navarini, L.; Monteleone, E. Sensory properties of under-roasted coffee beverages. J. Food Sci. 2013, 78, S1290–S1300. [Google Scholar] [CrossRef] [PubMed]

- Spaniolas, S.; May, S.T.; Bennett, M.J.; Tucker, G.A. Authentication of coffee by means of PCR-RFLP analysis and lab-on-a-chip capillary electrophoresis. J. Agric. Food Chem. 2006, 54, 7466–7470. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, J.S.; Ferreira, M.M.; Salva, T.J. Chemometric models for the quantitative descriptive sensory analysis of Arabica coffee beverages using near infrared spectroscopy. Talanta 2011, 83, 1352–1358. [Google Scholar] [CrossRef] [PubMed]

- Dias, R.; Benassi, M. Discrimination between Arabica and Robusta Coffees Using Hydrosoluble Compounds: Is the Efficiency of the Parameters Dependent on the Roast Degree? Beverages 2015, 1, 127–139. [Google Scholar] [CrossRef] [Green Version]

- Dong, W.; Tan, L.; Zhao, J.; Hu, R.; Lu, M. Characterization of Fatty Acid, Amino Acid and Volatile Compound Compositions and Bioactive Components of Seven Coffee (Coffea robusta) Cultivars Grown in Hainan Province, China. Molecules 2015, 20, 16687–16708. [Google Scholar] [CrossRef] [PubMed]

- Villarreal, D.; Laffargue, A.; Posada, H.; Bertrand, B.; Lashermes, P.; Dussert, S. Genotypic and environmental effects on coffee (Coffea arabica L.) bean fatty acid profile: Impact on variety and origin chemometric determination. J. Agric. Food Chem. 2009, 57, 11321–11327. [Google Scholar] [CrossRef] [PubMed]

- Kalschne, D.L.; Viegas, M.C.; De Conti, A.J.; Corso, M.P.; Benassi, M.T. Steam pressure treatment of defective Coffea canephora beans improves the volatile profile and sensory acceptance of roasted coffee blends. Food Res. Int. 2018, 105, 393–402. [Google Scholar] [CrossRef] [PubMed]

- Marx, Í.; Rodrigues, N.; Dias, L.G.; Veloso, A.C.A.; Pereira, J.A.; Drunkler, D.A.; Peres, A.M. Sensory classification of table olives using an electronic tongue: Analysis of aqueous pastes and brines. Talanta 2017, 162, 98–106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rendon, M.Y.; de Jesus Garcia Salva, T.; Bragagnolo, N. Impact of chemical changes on the sensory characteristics of coffee beans during storage. Food Chem. 2014, 147, 279–286. [Google Scholar] [CrossRef] [PubMed]

- Bicho, N.C.; Leitao, A.E.; Ramalho, J.C.; de Alvarenga, N.B.; Lidon, F.C. Impact of roasting time on the sensory profile of arabica and robusta coffee. Ecol. Food Nutr. 2013, 52, 163–177. [Google Scholar] [CrossRef] [PubMed]

- Borras, E.; Ferre, J.; Boque, R.; Mestres, M.; Acena, L.; Calvo, A.; Busto, O. Prediction of olive oil sensory descriptors using instrumental data fusion and partial least squares (PLS) regression. Talanta 2016, 155, 116–123. [Google Scholar] [CrossRef] [PubMed]

- Shin, E.C.; Hwang, C.E.; Lee, B.W.; Kim, H.T.; Ko, J.M.; Baek, I.Y.; Lee, Y.B.; Choi, J.S.; Cho, E.J.; Seo, W.T.; et al. Chemometric Approach to Fatty Acid Profiles in Soybean Cultivars by Principal Component Analysis (PCA). Prev. Nutr. Food Sci. 2012, 17, 184–191. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El-Abassy, R.M.; Donfack, P.; Materny, A. Discrimination between Arabica and Robusta green coffee using visible micro Raman spectroscopy and chemometric analysis. Food Chem. 2011, 126, 1443–1448. [Google Scholar] [CrossRef]

- Dong, W.; Hu, R.; Chu, Z.; Zhao, J.; Tan, L. Effect of different drying techniques on bioactive components, fatty acid composition, and volatile profile of robusta coffee beans. Food Chem. 2017, 234, 121–130. [Google Scholar] [CrossRef] [PubMed]

- Wei, F.; Furihata, K.; Miyakawa, T.; Tanokura, M. A pilot study of NMR-based sensory prediction of roasted coffee bean extracts. Food Chem. 2014, 152, 363–369. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Kim, M.K.; Lee, K.G. Furan Levels and Sensory Profiles of Commercial Coffee Products Under Various Handling Conditions. J. Food Sci. 2017, 82, 2759–2766. [Google Scholar] [CrossRef] [PubMed]

- Frank, O.; Blumberg, S.; Kunert, C.; Zehentbauer, G.; Hofmann, T. Structure determination and sensory analysis of bitter-tasting 4-vinylcatechol oligomers and their identification in roasted coffee by means of LC-MS/MS. J. Agric. Food Chem. 2007, 55, 1945–1954. [Google Scholar] [CrossRef] [PubMed]

- Martin, M.X.; Pablos, F.; Gonzalez, A.G.; Valdenebro, M.X.; Leon-Camacho, M. Fatty acid profiles as discriminant parameters for coffee varieties differentiation. Talanta 2001, 54, 291–297. [Google Scholar] [CrossRef]

- Lee, L.C.; Liong, C.Y.; Jemain, A.A. Partial least squares-discriminant analysis (PLS-DA) for classification of high-dimensional (HD) data: A review of contemporary practice strategies and knowledge gaps. Analyst 2018, 143, 3526–3539. [Google Scholar] [CrossRef] [PubMed]

- Corrales, D.; Ledezma, A.; Corrales, J. From Theory to Practice: A Data Quality Framework for Classification Tasks. Symmetry 2018, 10, 248. [Google Scholar] [CrossRef]

- Pacheco, F.; Rangel, C.; Aguilar, J.; Cerrada, M.; Altamiranda, J. Methodological framework for data processing based on the Data Science paradigm. In Proceedings of the 2014 XL Latin American Computing Conference (CLEI), Montevideo, Uruguay, 15–19 September 2014; pp. 1–12. [Google Scholar]

- Thiex, N.J.; Anderson, S.; Gildemeister, B. Crude fat, diethyl ether extraction, in feed, cereal grain, and forage (Randall/Soxtec/submersion method): Collaborative study. J. AOAC Int. 2003, 86, 888–898. [Google Scholar] [PubMed]

- Eder, K. Gas chromatographic analysis of fatty acid methyl esters. J. Chromatogr. B Biomed. Appl. 1995, 671, 113–131. [Google Scholar] [CrossRef]

- Carvalho, A.P.; Malcata, F.X. Preparation of fatty acid methyl esters for gas-chromatographic analysis of marine lipids: Insight studies. J. Agric. Food Chem. 2005, 53, 5049–5059. [Google Scholar] [CrossRef] [PubMed]

- Bishop, C.M. Pattern Recognition and Machine Learning (Information Science and Statistics); Springer-Verlag: Berlin, Germany, 2006. [Google Scholar]

| ID | GR | AR | cFAT | C16:0 | C18:0 | C18:1 | C18:2 | C18:3 | C20:0 | C20:1 | C22:0 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mg/g | |||||||||||

| 01 | Roasted | Arabica | 159 | 45.342 | 8.985 | 10.610 | 62.466 | 2.109 | 3.691 | 0.508 | 0.714 |

| 02 | Green | Arabica | 67 | 20.736 | 4.118 | 4.792 | 27.942 | 0.947 | 1.797 | 0.232 | 0.408 |

| 03 | Roasted | Arabica | 155 | 37.909 | 7.301 | 9.247 | 47.871 | 1.603 | 2.952 | 0.427 | 0.563 |

| 04 | Green | Arabica | 88 | 20.512 | 4.002 | 4.848 | 25.234 | 0.911 | 1.921 | 0.245 | 0.399 |

| 05 | Roasted | Arabica | 153 | 36.507 | 7.242 | 11.355 | 47.960 | 1.552 | 2.788 | 0.414 | 0.556 |

| 06 | Green | Arabica | 102 | 25.639 | 4.984 | 7.582 | 32.942 | 1.116 | 2.075 | 0.299 | 0.425 |

| 07 | Roasted | Arabica | 148 | 36.101 | 8.461 | 10.067 | 46.857 | 1.539 | 3.436 | 0.412 | 0.644 |

| 08 | Green | Arabica | 94 | 30.897 | 6.971 | 8.341 | 39.461 | 1.257 | 2.967 | 0.345 | 0.675 |

| 09 | Roasted | Arabica | 203 | 44.440 | 10.410 | 13.355 | 59.340 | 1.683 | 4.243 | 0.554 | 0.905 |

| 10 | Green | Arabica | 98 | 25.490 | 5.650 | 6.501 | 32.136 | 1.023 | 2.366 | 0.280 | 0.631 |

| 11 | Roasted | Arabica | 203 | 54.853 | 13.219 | 17.271 | 74.899 | 2.461 | 4.691 | 0.647 | 1.060 |

| 12 | Green | Arabica | 88 | 23.757 | 5.644 | 7.224 | 31.549 | 1.113 | 2.169 | 0.288 | 0.636 |

| 13 | Roasted | Arabica | 173 | 41.413 | 9.778 | 12.421 | 55.083 | 1.777 | 3.408 | 0.451 | 0.749 |

| 14 | Green | Arabica | 98 | 22.405 | 5.184 | 6.245 | 28.209 | 1.000 | 2.012 | 0.243 | 0.476 |

| 15 | Roasted | Arabica | 175 | 50.168 | 9.712 | 12.828 | 66.230 | 2.067 | 3.439 | 0.564 | 0.713 |

| 16 | Roasted | Arabica | 166 | 49.224 | 9.548 | 12.642 | 65.296 | 2.168 | 3.579 | 0.587 | 0.771 |

| 17 | Green | Arabica | 127 | 34.747 | 6.697 | 8.720 | 45.076 | 1.524 | 2.336 | 0.383 | 0.471 |

| 18 | Roasted | Arabica | 156 | 40.016 | 7.953 | 9.955 | 53.152 | 1.727 | 3.051 | 0.411 | 0.606 |

| 19 | Green | Arabica | 79 | 19.075 | 3.779 | 4.780 | 25.878 | 0.852 | 1.466 | 0.194 | 0.321 |

| 20 | Roasted | Arabica | 150 | 49.182 | 9.066 | 12.606 | 62.721 | 2.259 | 3.807 | 0.587 | 0.850 |

| 21 | Roasted | Arabica | 156 | 49.529 | 9.303 | 12.610 | 63.325 | 2.308 | 3.890 | 0.599 | 0.789 |

| 22 | Green | Arabica | 79 | 22.622 | 4.185 | 5.751 | 28.787 | 1.078 | 1.794 | 0.278 | 0.368 |

| 23 | Roasted | Robusta | 135 | 33.076 | 6.439 | 8.844 | 38.228 | 0.694 | 2.510 | 0.340 | 0.306 |

| 24 | Roasted | Robusta | 119 | 29.308 | 5.971 | 8.068 | 34.897 | 0.756 | 2.503 | 0.353 | 0.316 |

| 25 | Green | Robusta | 55 | 16.041 | 3.236 | 4.584 | 18.805 | 0.391 | 1.482 | 0.188 | 0.271 |

| 26 | Green | Robusta | 50 | 15.729 | 3.129 | 4.634 | 18.589 | 0.436 | 1.555 | 0.205 | 0.239 |

| 27 | Roasted | Robusta | 100 | 23.971 | 5.272 | 8.634 | 31.999 | 0.656 | 2.247 | 0.343 | 0.288 |

| 28 | Green | Robusta | 49 | 10.410 | 2.248 | 3.598 | 13.947 | 0.310 | 1.026 | 0.141 | 0.157 |

| 29 | Roasted | Robusta | 120 | 31.304 | 6.863 | 11.588 | 40.807 | 0.796 | 3.198 | 0.500 | 0.484 |

| 30 | Roasted | Robusta | 115 | 30.900 | 6.753 | 11.288 | 39.856 | 0.793 | 3.111 | 0.466 | 0.633 |

| 31 | Green | Robusta | 61 | 16.730 | 3.943 | 5.936 | 21.800 | 0.466 | 1.792 | 0.243 | 0.322 |

| 32 | Green | Robusta | 60 | 15.400 | 3.598 | 5.472 | 19.844 | 0.404 | 1.620 | 0.223 | 0.363 |

| 33 | Roasted | Robusta | 98 | 23.786 | 5.277 | 8.634 | 31.356 | 0.665 | 2.247 | 0.333 | 0.269 |

| 34 | Green | Robusta | 51 | 10.46 | 2.248 | 3.598 | 13.958 | 0.325 | 1.021 | 0.131 | 0.171 |

| Categories | Green | Roasted | LCAR |

|---|---|---|---|

| Arabica | 8/10 | 10/12 | 22/22 (100) |

| Robusta | 6/6 | 5/6 | 12/12 (100) |

| LCRG | 14/16 (87.5) | 15/18 (83.3) | Correct (%) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, Y.-C.; Chen, P.; Chen, L.-Y. Advanced Classification of Coffee Beans with Fatty Acids Profiling to Block Information Loss. Symmetry 2018, 10, 529. https://doi.org/10.3390/sym10100529

Hung Y-C, Chen P, Chen L-Y. Advanced Classification of Coffee Beans with Fatty Acids Profiling to Block Information Loss. Symmetry. 2018; 10(10):529. https://doi.org/10.3390/sym10100529

Chicago/Turabian StyleHung, Ying-Che, Ping Chen, and Liang-Yü Chen. 2018. "Advanced Classification of Coffee Beans with Fatty Acids Profiling to Block Information Loss" Symmetry 10, no. 10: 529. https://doi.org/10.3390/sym10100529