How Does Sowing Rate Affect Plant and Stem Density, Forage Yield, and Nutritive Value in Glyphosate-Tolerant Alfalfa?

Abstract

:1. Introduction

2. Material and Methods

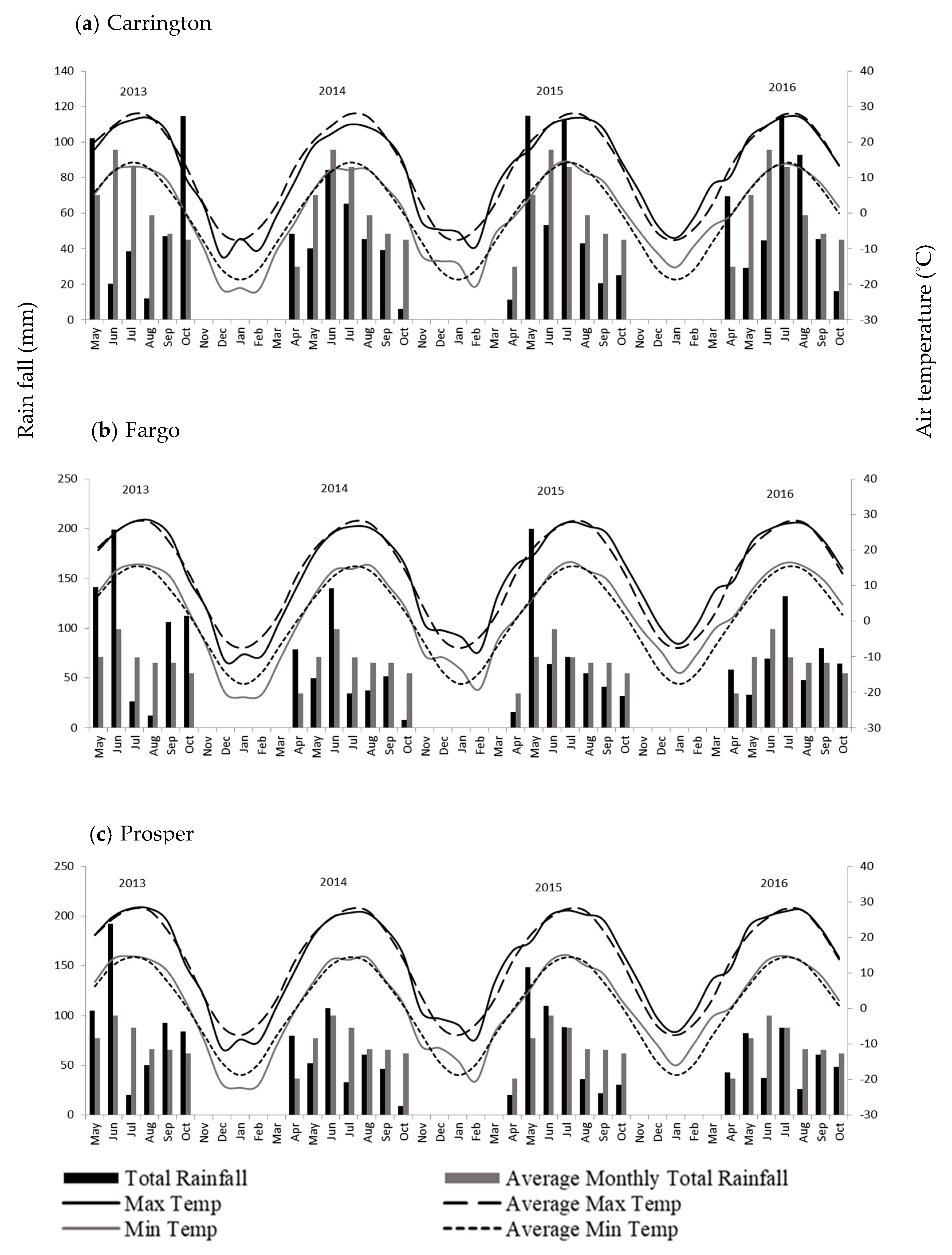

2.1. Field Establishment and Experimental Design

2.2. Sampling and Analysis

2.3. Statistical Analysis

3. Results and Discussion

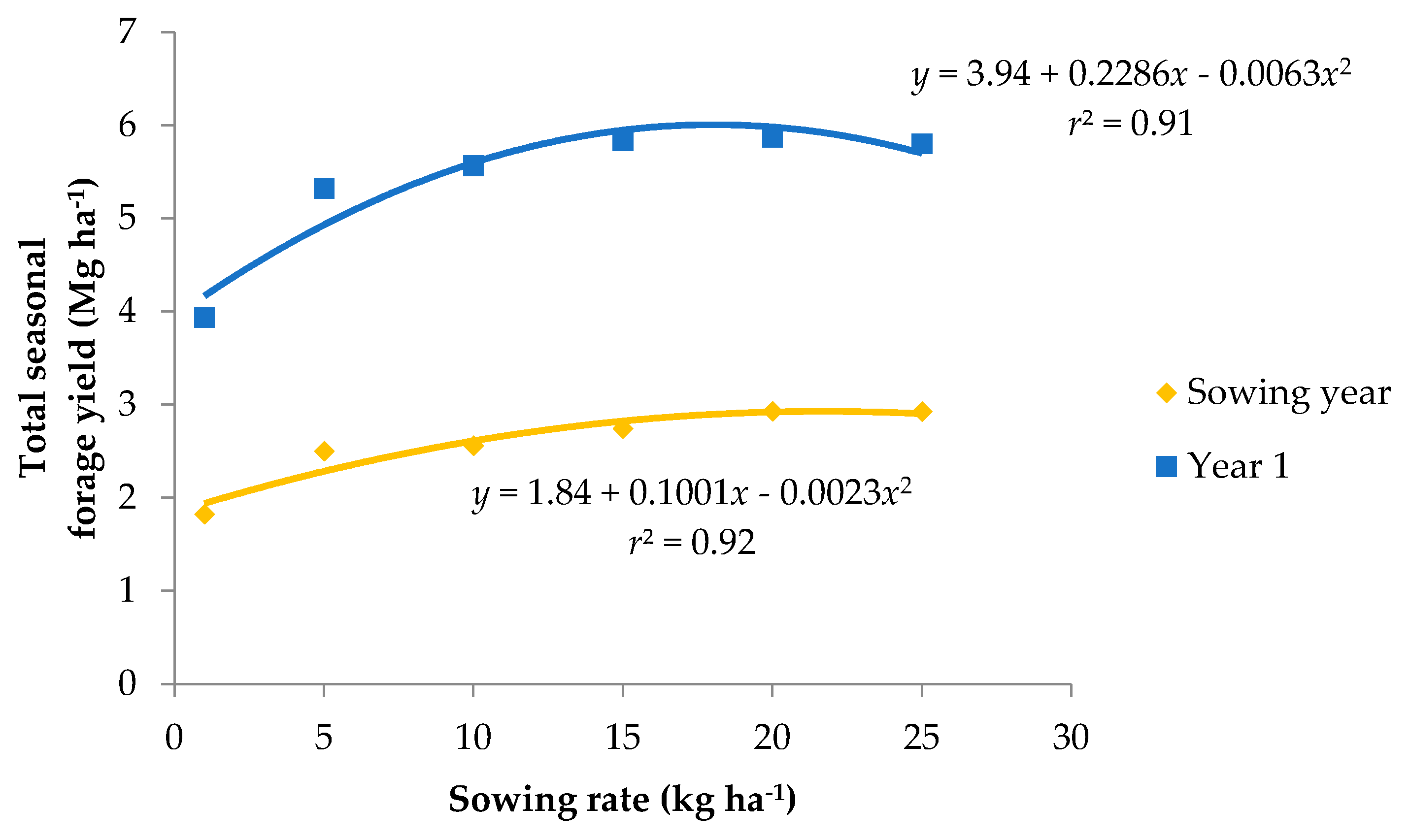

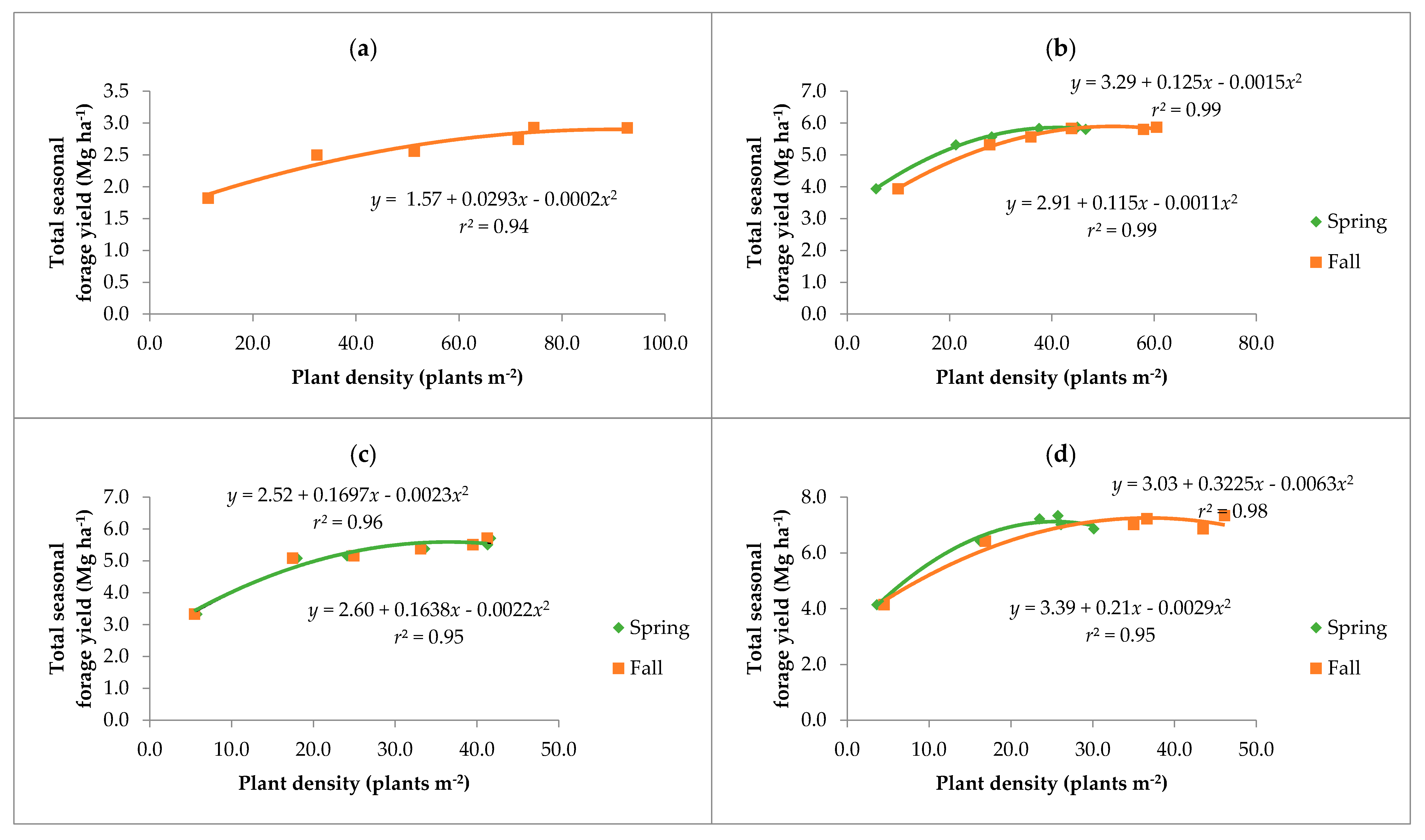

3.1. Total Seasonal Forage Yield

3.2. Forage Nutritive Quality Components

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- NASS, National Agriculture Statistics Service. Published Estimate Data Base. 2016. Available online: http://www.nass.usda.gov/ (accessed on 20 April 2018).

- Lloveras, J.; Chocarro, C.; Freixes, O.; Arque, E.; Moreno, A.; Santiveri, F. Yield, yield components, and forage nutritive value of alfalfa as affected by seeding rate under irrigated conditions. Agron. J. 2008, 100, 191–197. [Google Scholar] [CrossRef]

- Bolger, T.P.; Meyer, D.W. Influence of plant density on alfalfa yield and quality. In Proceedings of the American Forage and Grassland Council, Eau Claire, WI, USA, 23–26 January 1983; pp. 37–41. [Google Scholar]

- Rankin, M. Determining the Optimum Alfalfa Seeding Rate. Available online: https://fyi.uwex.edu/forage/files/2014/01/AlfSeedingRate-FOF.pdf (accessed on 18 August 2018).

- Hall, M.H.; Nelso, C.J.; Coutts, J.H.; Stout, R.C. Effect of seeding rate on alfalfa stand longevity. Agron. J. 2004, 96, 717–722. [Google Scholar] [CrossRef]

- Hall, M.H.; Hebrock, N.S.; Pierson, P.E.; Caddel, J.L.; Owens, V.N.; Sulc, R.M.; Undersander, D.J.; Whitesides, R.E. The effects of glyphosate-tolerant technology on reduced alfalfa seeding rates. Agron. J. 2010, 102, 911–916. [Google Scholar] [CrossRef]

- Volenec, J.J.; Cherney, J.H.; Johnson, K.D. Yield components, plant morphology, and forage quality of alfalfa as influenced by plant-population. Crop Sci. 1987, 27, 321–326. [Google Scholar] [CrossRef]

- Krueger, C.R.; Hansen, L.H. Establishment method, variety and seeding rate affect quality and production of alfalfa under dryland and irrigation. SD Farm Home Res. 1974, 25, 10–13. [Google Scholar]

- Kephart, K.D.; Twidwell, E.K.; Bortnem, R.; Boe, A. Alfalfa yield component responses to seeding rate several years after establishment. Agron. J. 1992, 84, 827–831. [Google Scholar] [CrossRef]

- Tesar, M.B.; Marble, V.L. Alfalfa establishment. In Alfalfa and Alfalfa Improvement; Hanson, A.A., Barnes, D.K., Hill, J.R.R., Eds.; ASA, CSSA, and SSSA: Madison, WI, USA, 1988; pp. 303–332. [Google Scholar]

- Glaspie, C.F.; McCordick, S.A.; Dietz, T.S.; Kells, J.J.; Leep, R.H.; Everman, W.J. Effect of seeding rate and weed control on glyphosate-resistant alfalfa establishment. Weed Technol. 2011, 25, 230–238. [Google Scholar] [CrossRef]

- Wells, M.S.; Martinson, K.L.; Undersander, D.J.; Sheaffer, C.C. A survey investigating alfalfa winter injury in Minnesota and Wisconsin from the winter of 2012–2013. Forage Grazinglands. 2014. Available online: https://dl.sciencesocieties.org/publications/fg/abstracts/12/1/FG-2013-0051-RS (accessed on 18 August 2018).

- Hesterman, O.B.; Durling, J.C. Avoiding Winter Injury to Alfalfa (E2310). Available online: http://msue.anr.msu.edu/resources/avoiding_winter_injury_to_alfalfa_e2310 (accessed on 6 April 2018).

- Berti, M.; Nudell, R.; Meyer, D.W. Fall harvesting of alfalfa in North Dakota impacts planr density, yield, and nutritive value. Forage Grazinglands. 2012. Available online: https://dl.sciencesocieties.org/publications/fg/abstracts/10/1/2012-0925-01-RS (accessed on 14 April 2018).

- Hakl, J.; Fuksa, P.; Santrucek, J.; Maskova, K. The development of lucerne root morphology traits under high initial stand density within a seven year period. Plant Soil Environ. 2011, 57, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Durling, J.C.; Hesterman, O.B.; Rotz, C.A. Predicting first-cut alfalfa yields from preceding winter weather. J. Prod. Agric. 1992, 8, 254–259. [Google Scholar] [CrossRef]

- Risk Management Agency, Forage seeding Montana, North Dakota, South Dakota, and Wyoming. Available online: https://www.rma.usda.gov/fields/mt_rso/2018/2018forageseeding.pdf (accessed on 14 April 2018).

- Hall, M.H.; Dillon, J.M.; Stambaugh, H.J.; Hebrock, N.S.; Caddel, J.L.; Owens, V.N.; Sulc, R.M.; Undersander, D.J.; Whitesides, R.E. The Effects of Seeding Rate on Older Stands of Glyphosate-Tolerant Alfalfa. Agron. J. 2012, 104, 1096–1099. [Google Scholar] [CrossRef]

- Web Soil Survey. National Resources Conservation Service. United States Dep. of Agric.: Washington, DC, USA, 2009. Available online: http://websoilsurvey.nrcs.usda.gov/app/WebSoilSurvey.aspx (accessed on 12 April 2018).

- NDAWN. North Dakota Agricultural Weather Network. Available online: http://ndawn.ndsu.nodak.edu (accessed on 14 April 2018).

- Abrams, S.M.; Shenk, J.; Westerhaus, F.E. Determination of forage quality by near infrared reflectance spectroscopy: Efficacy of broad-based calibration equations. J. Dairy Sci. 1987, 70, 806–813. [Google Scholar] [CrossRef]

- SAS Institute. SAS User’s Guide: Statistics; SAS Inst.: Cary, NC, USA, 2014. [Google Scholar]

- Cooper, C.S.; Ditterline, R.L.; Welty, L.E. Seed size and seeding rate effects upon stand density and yield of alfalfa. Agron. J. 1979, 71, 83–85. [Google Scholar] [CrossRef]

- Stout, D.G. Effect of high lucerne (Medicago sativa L.) sowing rates on establishment year yield, stand persistence and forage quality. J. Agron. Crop Sci. 1998, 180, 39–43. [Google Scholar] [CrossRef]

- Dhont, C.; Castonguay, Y.; Nadeau, P.; Belanger, G.; Drapeau, R.; Chalifour, F.P. Untimely fall harvest affects dry matter yield and root organic reserves in field-grown alfalfa. Crop Sci. 2004, 44, 144–157. [Google Scholar] [CrossRef]

- Berti, M.; Aponte, A.; Samarappuli, D.; Teuber, O.; Lukacheswsky, J.; Nudell, R. Seeding Rates, and Plant and Stem Density as Tools to Estimate Forage Yield in Glyphosate-Tolerant Alfalfa. Available online: http://www.midwestforage.org/pdf/1010.pdf (accessed on 12 April 2018).

- Brothers, B.A.; Schmidt, J.R.; Kells, J.J.; Hesterman, O.B. Alfalfa establishment with and without spring-applied herbicides. J. Prod. Agric. 1994, 7, 494–501. [Google Scholar] [CrossRef]

- Dillehay, B.L.; Curran, W.S. Comparison of herbicide programs for weed control in glyphosate-resistant alfalfa. Weed Technol. 2010, 24, 130–138. [Google Scholar] [CrossRef]

- Kallenbach, R.L.; Nelson, C.J.; Coutts, J.H. Yield, quality, and persistence of grazing- and hay-type alfalfa under three harvest frequencies. Agron. J. 2002, 94, 1094–1103. [Google Scholar] [CrossRef]

- Iwaasa, A.D.; Beauchemin, K.A.; Acharya, S.N.; Bowley, S.R.; Buchanan-Smith, J.G. Shearing force of alfalfa stems as affected by seeding rate. Can. J. Plant Sci. 1998, 78, 273–280. [Google Scholar] [CrossRef] [Green Version]

| Site/Year Establishment | Sowing Year | Year 1 | Year 2 | Year 3 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H1 | H2 | H1 | H2 | H3 | H4 | H1 | H2 | H3 | H4 | H1 | H2 | H3 | H4 | |

| Fargo 2013 | 16-Jul | 30-Aug | 13-Jun | 17-Jul | 14-Aug | 8-Oct | 19-Jun | 14-Jul | 8-Aug | 16-Sep | 2-Jun | 28-Jun | 28-Jul | 26-Aug |

| Fargo 2014 | 31-Jul | 29-Aug | 19-Jun | 14-Jul | 10-Aug | 16-Sep | 2-Jun | 28-Jun | 28-Jul | 26-Aug | 2-Jun | 28-Jun | 28-Jul | 26-Aug |

| Prosper 2013 | 15-Jul | 23-Aug | 10-Jun | 16-Jul | 13-Aug | 9-Oct | 10-Jun | 7-Jul | 4-Aug | 11-Sep | 2-Jun | 28-Jun | 27-Jul | 29-Aug |

| Prosper 2014 | 21-Jul | 13-Aug | 9-Jun | 7-Jul | 4-Aug | 11-Sep | 2-Jun | 28-Jun | 28-Jul | 26-Aug | 2-Jun | 28-Jun | 27-Jul | 29-Aug |

| Carrington 2013 | 17-Jul | 15-Sep | 17-Jun | 25-Jul | 3-Sep | 18-Jun | 23-Jul | 2-Sep | 8-Jun | |||||

| Production Year | Maximum Yield † (kg ha−1) | Plant Density (plants m−2) | RMA Plant Density (plants m−2) | Maximum Yield ± (kg ha−1) | Stem Density (stems m−2) |

|---|---|---|---|---|---|

| Sowing | 2.64 | 73 | 107 | 2.90 | 575 |

| First | 5.92 | 52 | 81 | 5.01 | 495 |

| Second | 5.65 | 37 | 54 | 5.34 | 435 |

| Third | 7.19 | 36 | 41 | 7.38 | 427 |

| Sowing Rate | CP | ADF | NDF | NDFD | Ash |

|---|---|---|---|---|---|

| kg ha−1 | g kg−1 | ||||

| Sowing Year | |||||

| 1 | 251 | 287 | 317 | 352 | 144 |

| 5 | 244 | 284 | 322 | 380 | 137 |

| 10 | 240 | 290 | 327 | 395 | 132 |

| 15 | 246 | 287 | 325 | 388 | 136 |

| 20 | 240 | 283 | 322 | 403 | 131 |

| 25 | 241 | 286 | 329 | 405 | 133 |

| LSD (p = 0.05) | NS | NS | NS | NS | NS |

| First Production Year | |||||

| 1 | 248 | 294 | 358 | 386 | 108 |

| 5 | 239 | 306 | 370 | 375 | 113 |

| 10 | 238 | 311 | 380 | 383 | 108 |

| 15 | 239 | 317 | 386 | 375 | 110 |

| 20 | 240 | 308 | 375 | 387 | 109 |

| 25 | 239 | 313 | 384 | 387 | 109 |

| LSD (p = 0.05) | NS | 14 | 14 | NS | NS |

| Second Production Year | |||||

| 1 | 233 | 329 | 448 | 433 | 74 |

| 5 | 231 | 337 | 457 | 436 | 74 |

| 10 | 228 | 339 | 461 | 431 | 76 |

| 15 | 232 | 332 | 456 | 428 | 74 |

| 20 | 232 | 332 | 456 | 430 | 74 |

| 25 | 229 | 335 | 458 | 429 | 75 |

| LSD (p = 0.05) | NS | NS | NS | NS | NS |

| Third Production Year | |||||

| 1 | 225 | 339 | 463 | 449 | 74 |

| 5 | 229 | 333 | 456 | 451 | 76 |

| 10 | 221 | 347 | 470 | 440 | 79 |

| 15 | 220 | 349 | 468 | 438 | 84 |

| 20 | 223 | 340 | 461 | 442 | 82 |

| 25 | 224 | 336 | 460 | 446 | 82 |

| LSD (p = 0.05) | NS | NS | NS | NS | NS |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Berti, M.T.; Samarappuli, D. How Does Sowing Rate Affect Plant and Stem Density, Forage Yield, and Nutritive Value in Glyphosate-Tolerant Alfalfa? Agronomy 2018, 8, 169. https://doi.org/10.3390/agronomy8090169

Berti MT, Samarappuli D. How Does Sowing Rate Affect Plant and Stem Density, Forage Yield, and Nutritive Value in Glyphosate-Tolerant Alfalfa? Agronomy. 2018; 8(9):169. https://doi.org/10.3390/agronomy8090169

Chicago/Turabian StyleBerti, Marisol T., and Dulan Samarappuli. 2018. "How Does Sowing Rate Affect Plant and Stem Density, Forage Yield, and Nutritive Value in Glyphosate-Tolerant Alfalfa?" Agronomy 8, no. 9: 169. https://doi.org/10.3390/agronomy8090169