Municipal Waste Degradation by Vermicomposting Using a Combination of Eisenia fetida and Lumbricus rubellus Species

Abstract

:1. Introduction

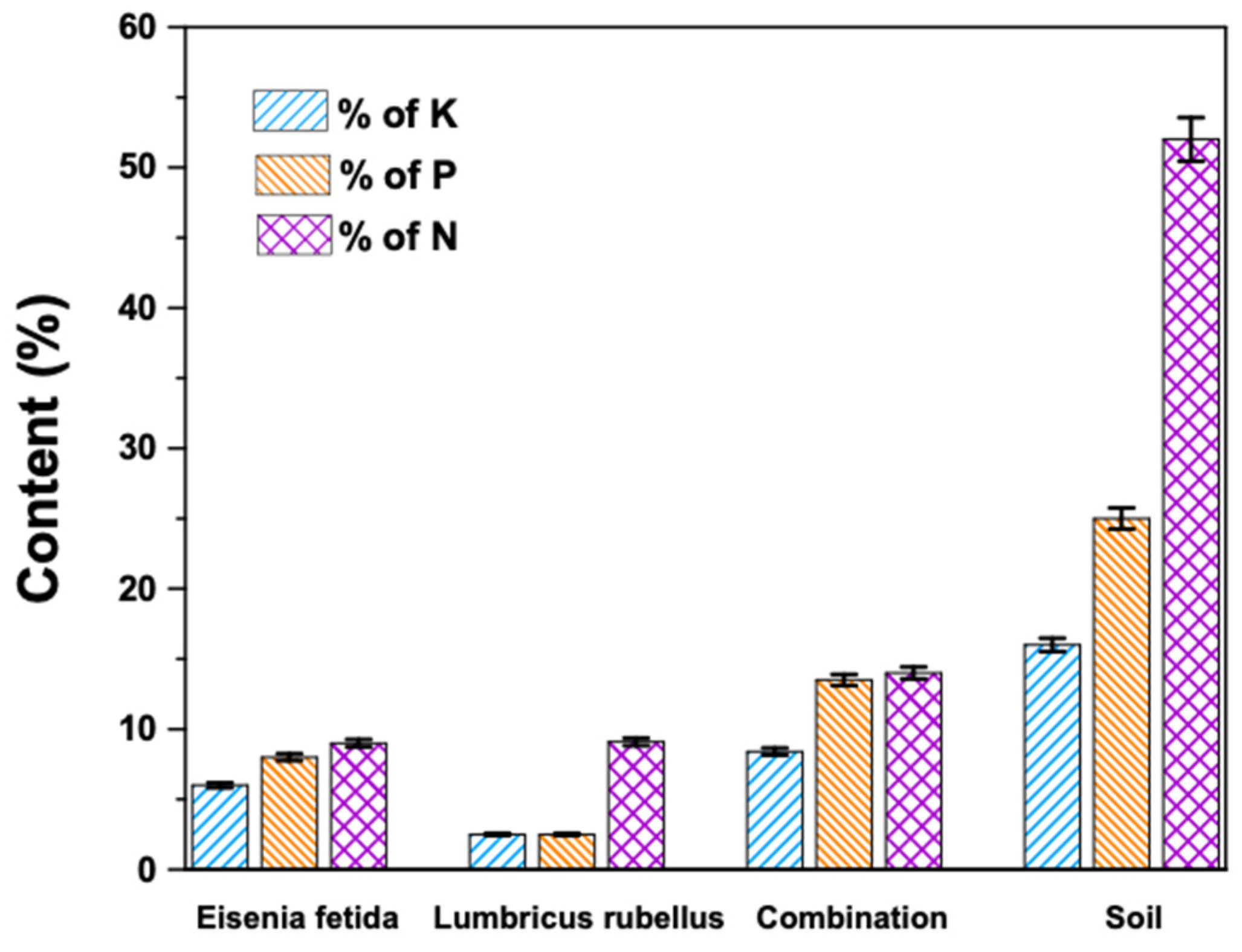

2. Materials and Methods

2.1. Collection of Waste

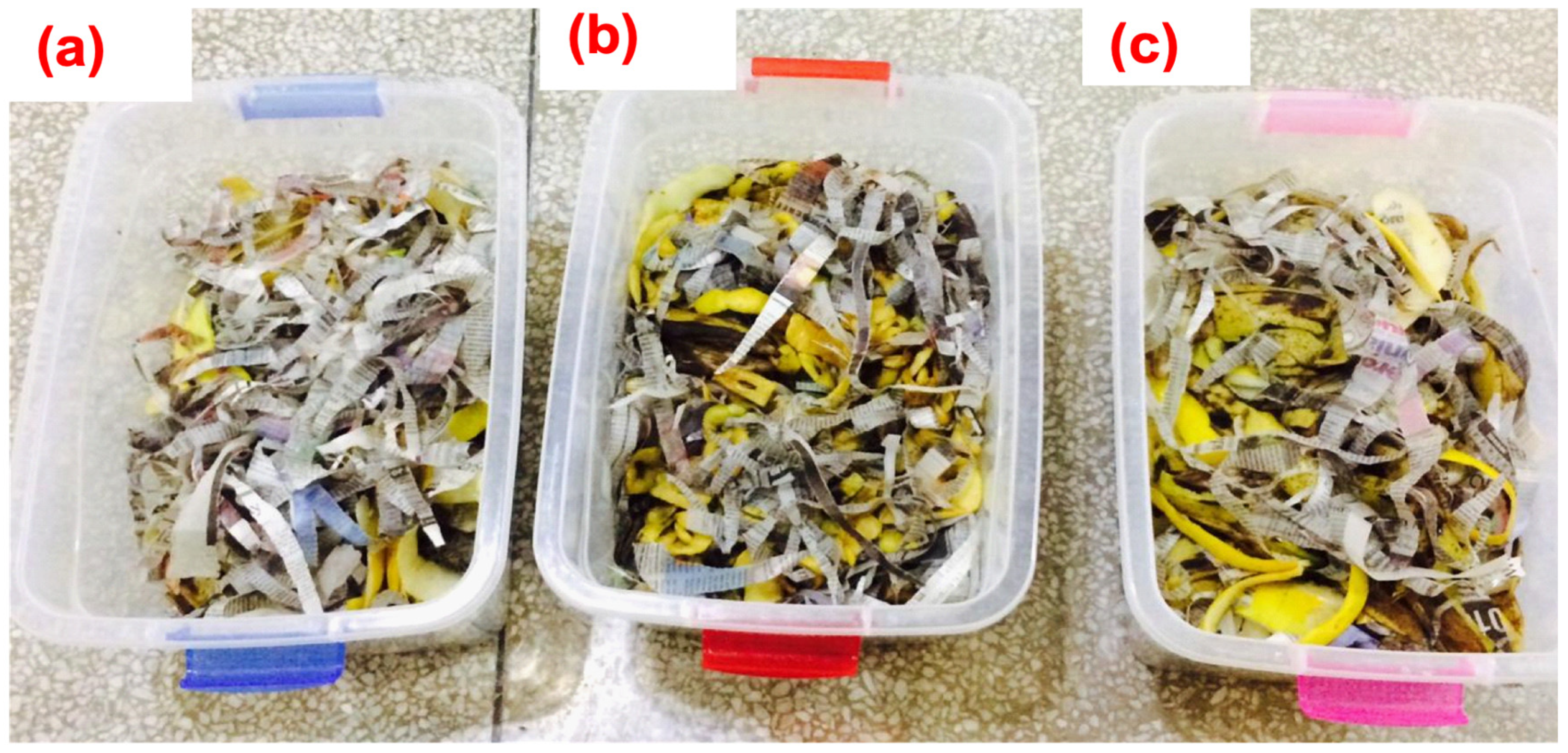

2.2. Initiation of Vermicomposting

2.3. Application of Vermicompost in Agricultural Fields

2.4. Sampling of Vegetables

2.5. Methods of Measuring Different Characteristics

2.5.1. Harvesting Time

2.5.2. Plant Height

2.5.3. Yield

2.5.4. Characterization of Nutrients in the Soil and the Compost

3. Results and Discussion

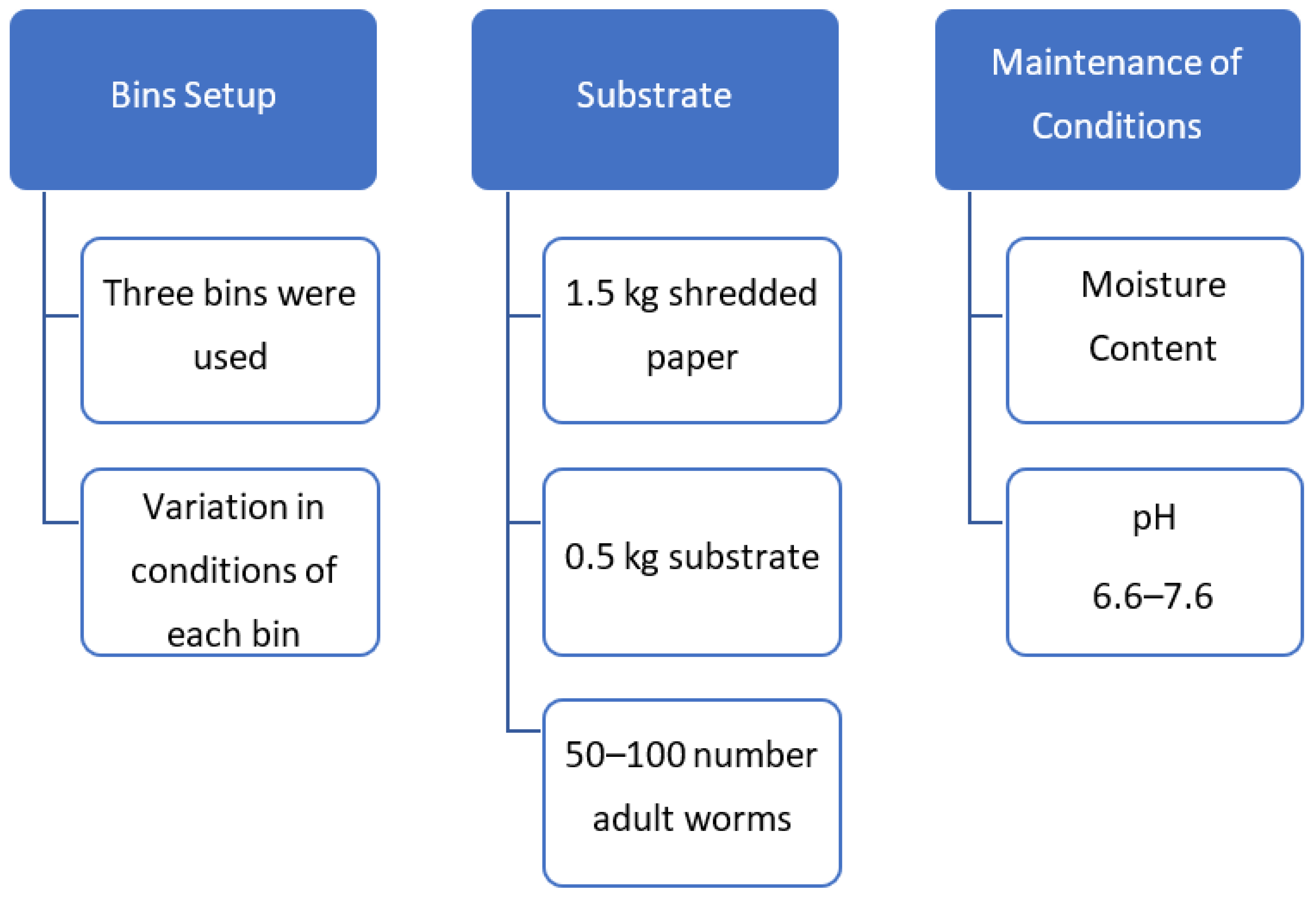

3.1. Variation of the Conditions of the Compost under Different Worm Exposures

3.1.1. pH Variation with Time

3.1.2. Temperature Variation with Time

3.1.3. Moisture Content (MC)

3.1.4. Carbon to Nitrogen (C/N) Ratio

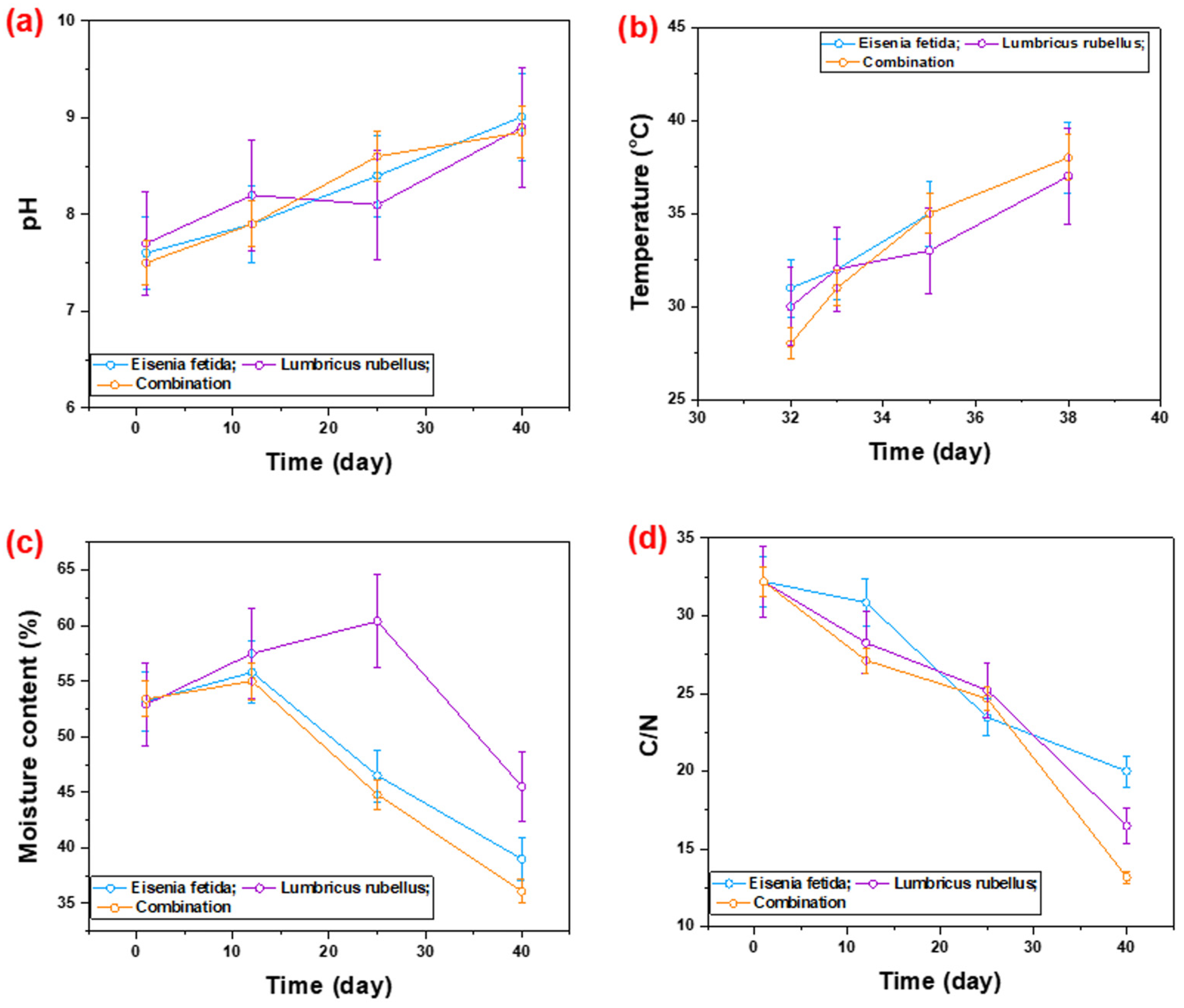

3.2. Characterization of the Compost

3.2.1. Percentage of Potassium

3.2.2. Percentage of Phosphorus

3.2.3. Percentage of Nitrogen

3.3. Evaluation of Compost Efficiency

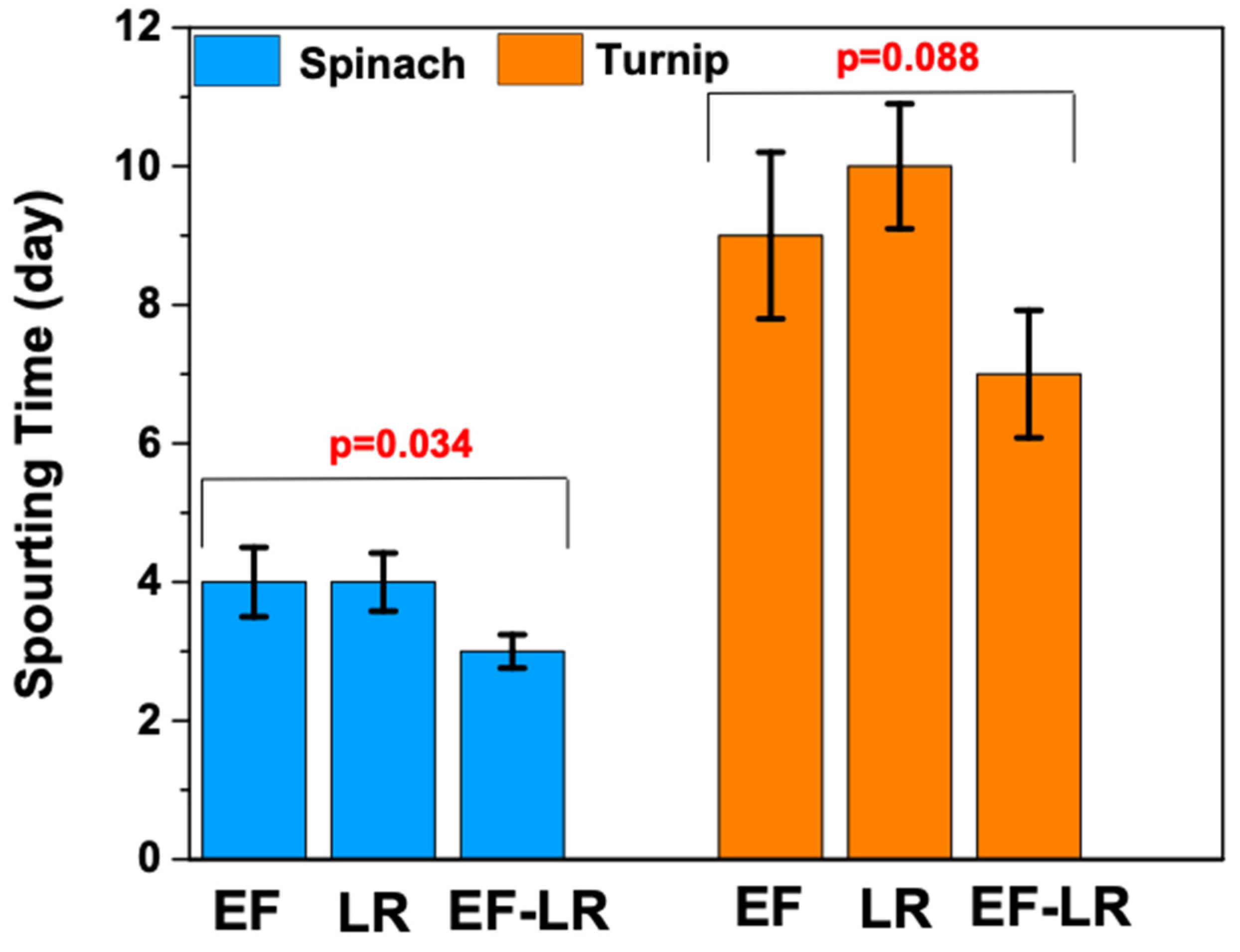

3.3.1. Sprouting Time

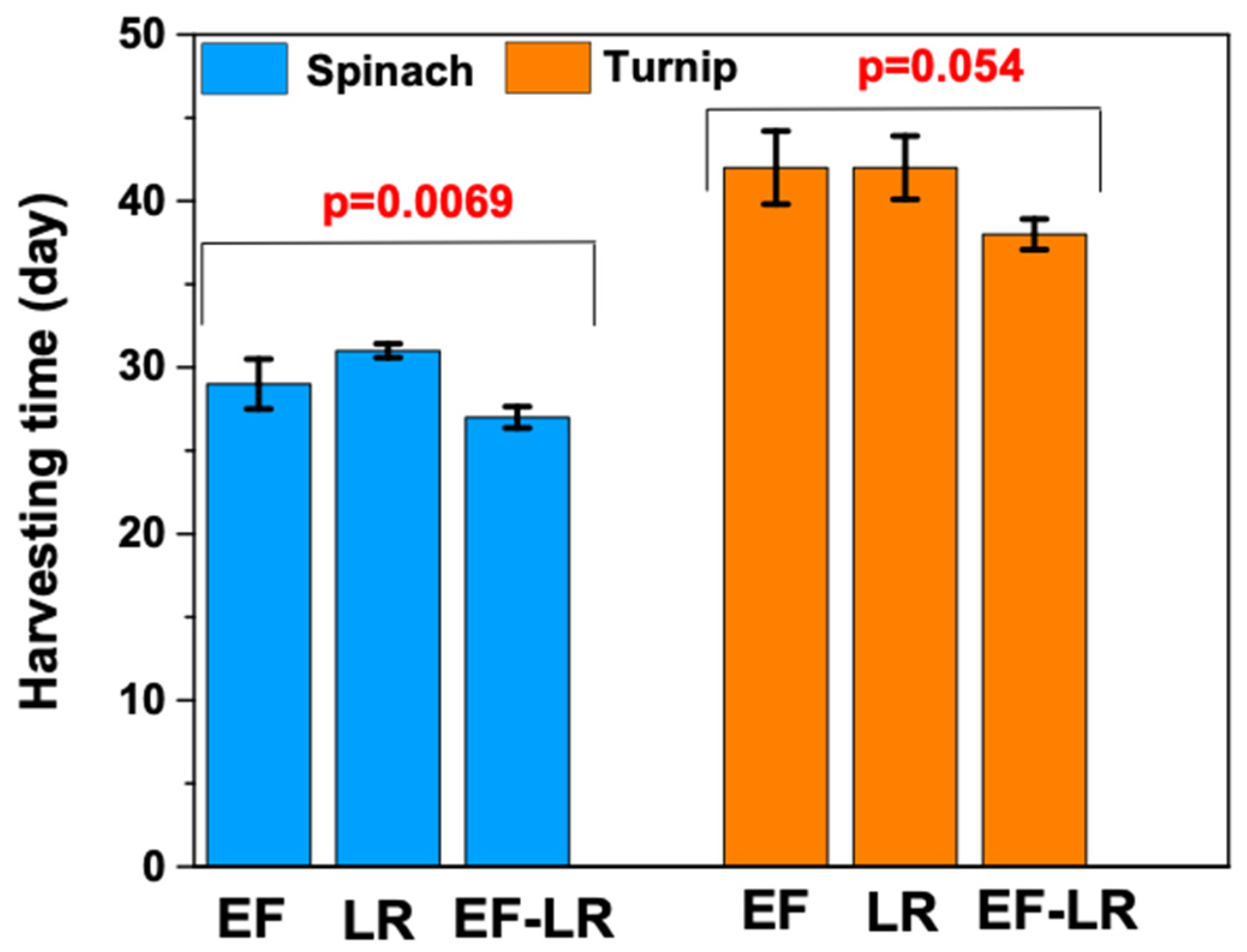

3.3.2. Harvesting Time

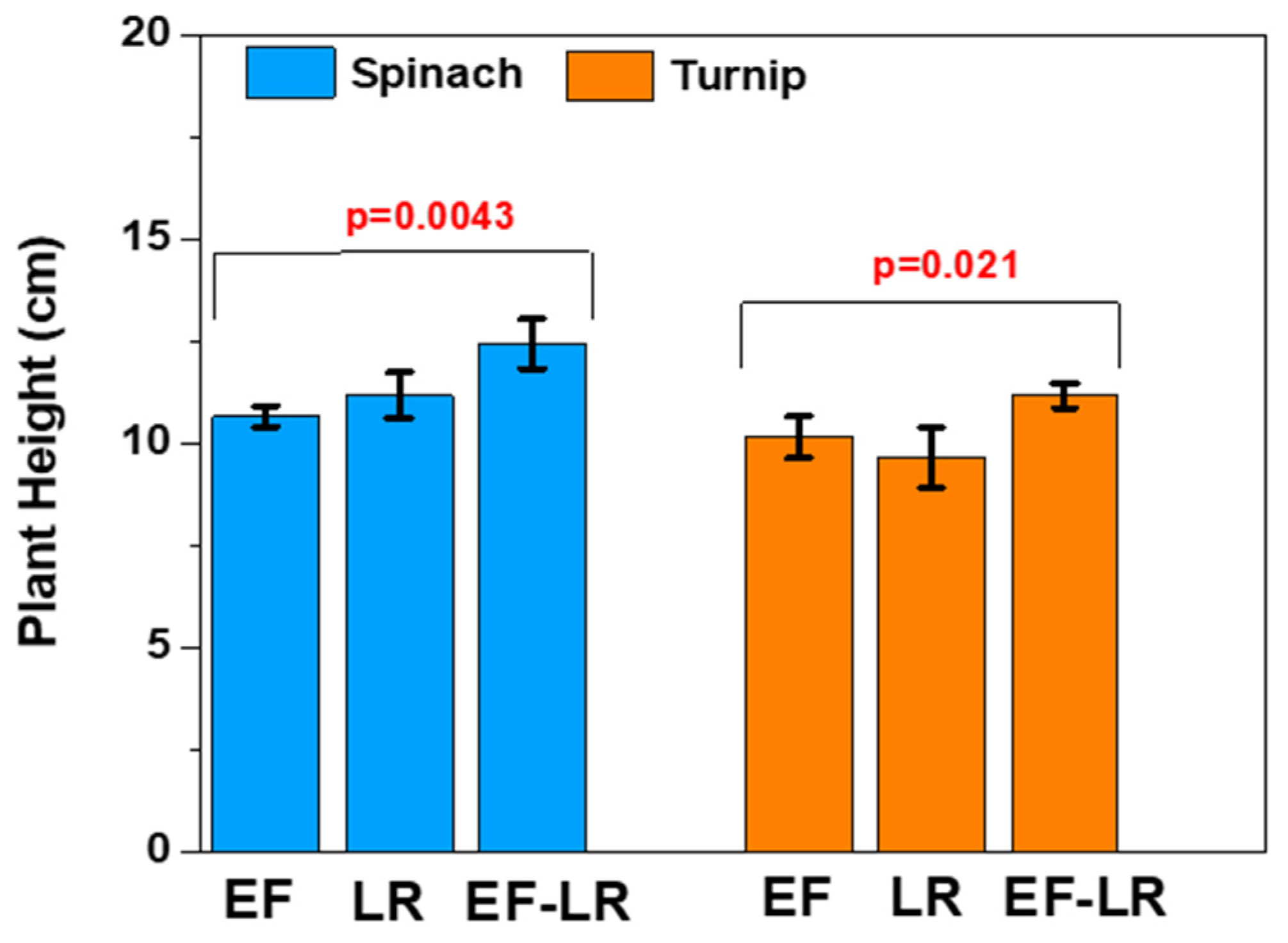

3.3.3. Plant Height

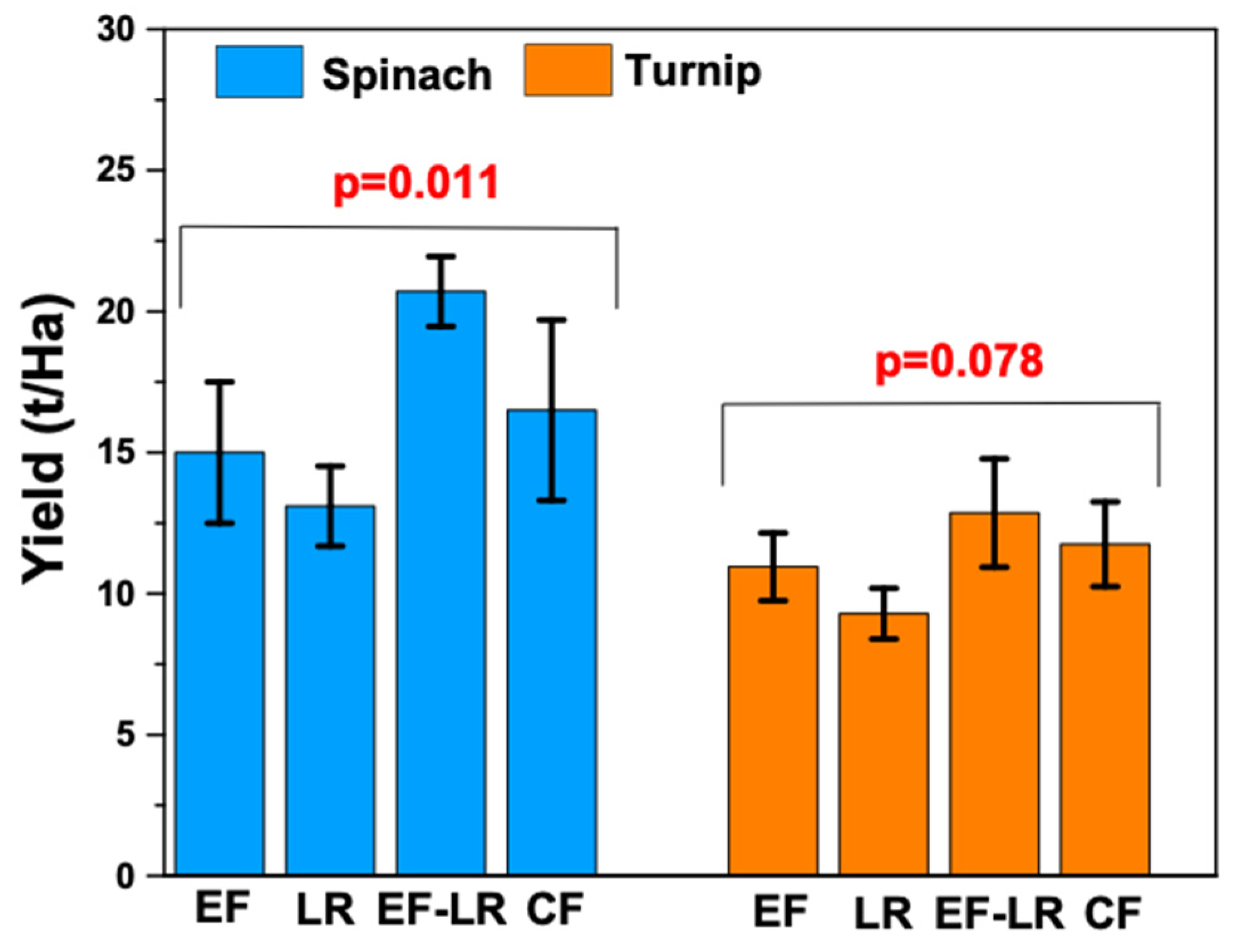

3.3.4. Plant Yield

4. Conclusions

- The efficiency of the composts was found to be in the following order in terms of utilization as an alternative fertilizer: EF–LR compost > Eisenia fetida (EF) compost > Lumbricus rubellus (LR) compost. The potassium, phosphorus, and nitrogen ratio of the EF–LR combined compost was (8.4 ± 0.20%, 13.5 ± 0.35%, 14 ± 0.42%), greater than those of the EF compost (6 ± 0.18%, 8 ± 0.20%, 9 ± 0.23%) and the LR compost (2.5%, 2.5%, 9.1%).

- The EF–LR combined compost showed a sprouting time of 7 ± 0.92 days for turnips and 3 ± 0.24 days for spinach, which was comparatively shorter than that of the EF compost (9 ± 1.2 days for turnips and 4 ± 0.50 days for spinach) and the LR compost (10 ± 0.92 days for turnips and 4 ± 0.50 days for spinach). Similarly, a shorter harvesting time was observed for the EF–LR compost (38 ± 0.92 days for turnips and 27 ± 0.64 days for spinach), with higher plant height (4.4 ± 0.12 inches for turnips and 4.9 ± 0.24 inches for spinach) compared to the other two individually. The individual composts had a harvesting time of 31 ± 0.42 and 42 ± 1.9 days, and 29 ± 1.5 and 42 ± 2.2 days, for the EF- and LR-based composts for turnips and spinach, respectively, and they had shorter plant heights.

- For turnips, the EF–LR compost yielded 38% and 58%, respectively, more than the compost obtained using EF and LR. For spinach, the EF–LR compost produced similar results, with 17.4% and 37.9% more yield than the other two. The results of our study confirmed that to increase production of crops with resulting lower residual chemical pollutants, compost obtained by the combination of EF and LR worms is more promising for use on a large scale than compost obtained from a single species.

- Statistical analysis also confirmed that for a better option in the comparative production of spinach and turnip growth using the EF–LR compost, our study confirms that spinach growth shows higher variability in the EF–LR compost compared to compost from a single species.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Visvanathan, C.; Adhikari, R.; Ananth, A.P. 3R practices for municipal solid waste management in Asia. Linnaeus Eco-Tech 2007, 11–22. [Google Scholar] [CrossRef]

- Khan, A.A.; Ahmed, Z.; Siddiqui, M.A. Issues with solid waste management in South Asian countries: A situational analysis of Pakistan. J. Environ. Occup. Health 2012, 1, 129–131. [Google Scholar] [CrossRef]

- Muhammad, A.M.; Zhonghua, T. Municipal solid waste and its relation with groundwater contamination in Lahore, Pakistan. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 1551–1560. [Google Scholar] [CrossRef]

- Murtaza, G.; Zhonghua, T. Municipal solid waste and its relation with groundwater contamination in Multan, Pakistan. IJAR 2017, 3, 434–441. [Google Scholar]

- Mahar, A.; Malik, R.N.; Qadir, A.; Ahmed, T.; Khan, Z.; Khan, M.A. Review and analysis of current solid waste management situation in urban areas of Pakistan. In Proceedings of the International Conference on Sustainable Solid Waste Management, Anna, India, 5–7 September 2007. [Google Scholar]

- Masood, M.; Barlow, C.Y.; Wilson, D.C. An assessment of the current municipal solid waste management system in Lahore, Pakistan. Waste Manag. Res. 2014, 32, 834–847. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Barlow, C.Y.; Wilson, D. A case study of groundwater contamination due to open dumping of municipal solid waste in Faisalabad, Pakistan. Earth Sci. Pak. 2017, 1, 15–16. [Google Scholar] [CrossRef]

- Costi, P.; Yasin, H.; Nasir, A.; Mehmood, W. An environmentally sustainable decision model for urban solid waste management. Waste Manag. 2004, 24, 277–295. [Google Scholar] [CrossRef]

- Lim, S.L.; Lee, L.H.; Wu, T.Y. Sustainability of using composting and vermicomposting technologies for organic solid waste biotransformation: Recent overview, greenhouse gases emissions and economic analysis. J. Clean. Prod. 2016, 111, 262–278. [Google Scholar] [CrossRef]

- Berkun, M.; Aras, E.; Nemlioglu, S. Disposal of solid waste in Istanbul and along the Black Sea coast of Turkey. Waste Manag. 2005, 25, 847–855. [Google Scholar] [CrossRef]

- Srivastava, V.; Ismail, S.A.; Singh, P.; Singh, R.P. Urban solid waste management in the developing world with emphasis on India: Challenges and opportunities. Rev. Environ. Sci. Bio/Technol. 2015, 14, 317–337. [Google Scholar] [CrossRef]

- Singh, R.P.; Singh, P.; Araujo, A.S.; Ibrahim, M.H.; Sulaiman, O. Management of urban solid waste: Vermicomposting a sustainable option. Resour. Conserv. Recycl. 2011, 55, 719–729. [Google Scholar] [CrossRef]

- Hoornweg, D.; Thomas, L.; Otten, L. Composting and its applicability in developing countries. World Bank Work. Pap. Ser. 1999, 8, 1–46. [Google Scholar]

- Narkhede, S.D.; Jadhav, R.N.; Khatik, V.A.; Ingle, S.T.; Attarde, S.B. Composting and its applicability in developing countries. Int. J. Agric. Sci. 2010, 6, 343–349. [Google Scholar]

- Ahmad, I. Alternative approaches for solid waste management: A case study in faisalabad pakistan. Earth Sci. Pak. 2017, 1, 7–9. [Google Scholar]

- Suthar, S. Vermicomposting of vegetable-market solid waste using Eisenia fetida: Impact of bulking material on earthworm growth and decomposition rate. Ecol. Eng. 2009, 35, 914–920. [Google Scholar] [CrossRef]

- Domínguez, J.; Aira, M.; Kolbe, A.R.; Gómez-Brandón, M.; Pérez-Losada, M. Changes in the composition and function of bacterial communities during vermicomposting may explain beneficial properties of vermicompost. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Das, S.K.; Avasthe, R.; Gopi, R. Vermiwash: Use in organic agriculture for improved crop production. Pop. Kheti 2014, 2, 45–46. [Google Scholar]

- Karmegam, N.; Vijayan, P.; Prakash, M.; Paul, J.A.J. Vermicomposting of paper industry sludge with cowdung and green manure plants using Eisenia fetida: A viable option for cleaner and enriched vermicompost production. J. Clean. Prod. 2019, 228, 718–728. [Google Scholar] [CrossRef]

- Ghosh, S.; Goswami, A.J.; Ghosh, G.K.; Pramanik, P. Quantifying the relative role of phytase and phosphatase enzymes in phosphorus mineralization during vermicomposting of fibrous tea factory waste. Ecol. Eng. 2018, 116, 97–103. [Google Scholar] [CrossRef]

- Swati, A.; Hait, S. Fate and bioavailability of heavy metals during vermicomposting of various organic wastes—A review. Process Saf. Environ. Prot. 2017, 109, 30–45. [Google Scholar] [CrossRef]

- Soobhany, N.; Gunasee, S.; Rago, Y.P.; Joyram, H.; Raghoo, P.; Mohee, R.; Garg, V.K. Spectroscopic, thermogravimetric and structural characterization analyses for comparing Municipal Solid Waste composts and vermicomposts stability and maturity. Bioresour. Technol. 2017, 236, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Soobhany, N. Preliminary evaluation of pathogenic bacteria loading on organic Municipal Solid Waste compost and vermicompost. J. Environ. Manag. 2018, 206, 763–767. [Google Scholar] [CrossRef] [PubMed]

- Ramnarain, Y.I.; Ansari, A.A.; Ori, L. Vermicomposting of different organic materials using the epigeic earthworm Eisenia foetida. Int. J. Recycl. Org. Waste Agric. 2019, 8, 23–36. [Google Scholar] [CrossRef]

- Choudhary, A.K.; Suri, V.K. Low-cost vermi-composting technology and its application in bio-conversion of obnoxious weed flora of north-western Himalayas into vermi-compost. Commun. Soil Sci. Plant Anal. 2018, 49, 1429–1441. [Google Scholar] [CrossRef]

- Kochakinezhad, H.; Peyvast, G.A.; Kashi, A.K.; Olfati, J.A.; Asadi, A. A comparison of organic and chemical fertilizers for tomato production. J. Org. Syst. 2012, 7, 14–25. [Google Scholar]

- Cao, W.; Vaddella, V.; Biswas, S.; Perkins, K.; Clay, C.; Wu, T.; Zheng, Y.; Ndegwa, P.; Pandey, P. Assessing the changes in E. coli levels and nutrient dynamics during vermicomposting of food waste under lab and field scale conditions. Environ. Sci. Pollut. Res. 2016, 23, 23195–23202. [Google Scholar] [CrossRef]

- Smil, V. Enriching the Earth: Fritz Haber, Carl Bosch, and the Transformation of World Food Production; MIT Press: Cambridge, MA, USA, 2004. [Google Scholar]

- Peyvast, G.; Kharazi, P.R.; Tahernia, S.; Nosratierad, Z.; Olfati, J.A. Municipal solid waste compost increased yield and decreased nitrate amount of broccoli. J. Appl. Hort 2008, 10, 129–131. [Google Scholar] [CrossRef]

- Karungi, J.; Ekbom, B.; Kyamanywa, S. Effects of organic versus conventional fertilizers on insect pests, natural enemies and yield of Phaseolus vulgaris. Agric. Ecosyst. Environ. 2006, 115, 51–55. [Google Scholar] [CrossRef]

- Drinkwater, L.; Letourneau, D.K.; Workneh, F.A.H.C.; Van Bruggen, A.H.C.; Shennan, C. Fundamental differences between conventional and organic tomato agroecosystems in California. Ecol. Appl. 1995, 5, 1098–1112. [Google Scholar] [CrossRef]

- Vodounnou, D.; Kpogue, D.N.S.; Tossavi, C.E.; Mennsah, G.A.; Fiogbe, E.D. Effect of animal waste and vegetable compost on production and growth of earthworm (Eisenia fetida) during vermiculture. Int. J. Recycl. Org. Waste Agric. 2016, 5, 87–92. [Google Scholar] [CrossRef]

- Joshi, R.; Singh, J.; Vig, A.P. Vermicompost as an effective organic fertilizer and biocontrol agent: Effect on growth, yield and quality of plants. Rev. Environ. Sci. Bio/Technol. 2015, 14, 137–159. [Google Scholar] [CrossRef]

- Hussain, N.; Abbasi, T.; Abbasi, S. Vermicomposting eliminates the toxicity of Lantana (Lantana camara) and turns it into a plant friendly organic fertilizer. J. Hazard. Mater. 2015, 298, 46–57. [Google Scholar] [CrossRef] [PubMed]

- Soobhany, N.; Mohee, R.; Garg, V.K. Comparative assessment of heavy metals content during the composting and vermicomposting of municipal solid waste employing Eudrilus eugeniae. Waste Manag. 2015, 39, 130–145. [Google Scholar] [CrossRef] [PubMed]

- Baghel, B.; Sahu, R.; Pandey, D. Vermicomposting an economical enterprise for nutrient and waste management for rural agriculture. Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 3754–3758. [Google Scholar] [CrossRef]

- Shrimal, S.; Khwairakpam, M. Effect of C/N ratio on vermicomposting of vegetable waste. Dyn. Soil Dyn. Plant 2010, 4, 123–126. [Google Scholar]

- Alidadi, H.; Hosseinzadeh, A.; Najafpoor, A.A.; Esmaili, H.; Zanganeh, J.; Takabi, M.D.; Piranloo, F.G. Waste recycling by vermicomposting: Maturity and quality assessment via dehydrogenase enzyme activity, lignin, water soluble carbon, nitrogen, phosphorous and other indicators. J. Environ. Manag. 2016, 182, 134–140. [Google Scholar] [CrossRef]

- Huang, K.; Li, F.; Wei, Y.; Fu, X.; Chen, X. Effects of earthworms on physicochemical properties and microbial profiles during vermicomposting of fresh fruit and vegetable wastes. Bioresour. Technol. 2014, 170, 45–52. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.; McClendon, R. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Abrahamsson, S.; Bertoni, F. Compost politics: Experimenting with togetherness in vermicomposting. Environ. Humanit. 2014, 4, 125–148. [Google Scholar] [CrossRef]

- Azarmi, R.; Giglou, M.T.; Taleshmikail, R.D. Influence of vermicompost on soil chemical and physical properties in tomato (Lycopersicum esculentum) field. Afr. J. Biotechnol. 2008, 7. [Google Scholar]

- Atiyeh, R.; Edwards, C.; Subler, S.; Metzger, J. Pig manure vermicompost as a component of a horticultural bedding plant medium: Effects on physicochemical properties and plant growth. Bioresour. Technol. 2001, 78, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Cegarra, J.; Paredes, C.; Roig, A.; Bernal, M.; García, D. Use of olive mill wastewater compost for crop production. Int. Biodeterior. Biodegrad. 1996, 38, 193–203. [Google Scholar] [CrossRef]

- Montemurro, F.; Ferri, D.; Tittarelli, F.; Canali, S.; Vitti, C. Anaerobic digestate and on-farm compost application: Effects on lettuce (Lactuca sativa L.) crop production and soil properties. Compos. Sci. Util. 2010, 18, 184–193. [Google Scholar] [CrossRef]

- Sarwar, G.; Schmeisky, H.; Hussain, N.; Muhammad, S.; Ibrahim, M.; Safdar, E. Improvement of soil physical and chemical properties with compost application in rice-wheat cropping system. Pak. J. Bot. 2008, 40, 275–282. [Google Scholar]

- Li, H.; Xiang, D.; Wang, C.; Li, X.; Lou, Y. Effects of epigeic earthworm (Eisenia fetida) and arbuscular mycorrhizal fungus (Glomus intraradices) on enzyme activities of a sterilized soil–sand mixture and nutrient uptake by maize. Biol. Fertil. Soils 2012, 48, 879–887. [Google Scholar] [CrossRef]

- Eisenhauer, N.; Marhan, S.; Scheu, S. Assessment of anecic behavior in selected earthworm species: Effects on wheat seed burial, seedling establishment, wheat growth and litter incorporation. Appl. Soil Ecol. 2008, 38, 79–82. [Google Scholar] [CrossRef]

- Tripathi, G.; Bhardwaj, P. Decomposition of kitchen waste amended with cow manure using an epigeic species (Eisenia fetida) and an anecic species (Lampito mauritii). Bioresour. Technol. 2004, 92, 215–218. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalid, H.; Ikhlaq, A.; Pervaiz, U.; Wie, Y.-M.; Lee, E.-J.; Lee, K.-H. Municipal Waste Degradation by Vermicomposting Using a Combination of Eisenia fetida and Lumbricus rubellus Species. Agronomy 2023, 13, 1370. https://doi.org/10.3390/agronomy13051370

Khalid H, Ikhlaq A, Pervaiz U, Wie Y-M, Lee E-J, Lee K-H. Municipal Waste Degradation by Vermicomposting Using a Combination of Eisenia fetida and Lumbricus rubellus Species. Agronomy. 2023; 13(5):1370. https://doi.org/10.3390/agronomy13051370

Chicago/Turabian StyleKhalid, Hira, Amir Ikhlaq, Usman Pervaiz, Young-Min Wie, Eui-Jong Lee, and Kang-Hoon Lee. 2023. "Municipal Waste Degradation by Vermicomposting Using a Combination of Eisenia fetida and Lumbricus rubellus Species" Agronomy 13, no. 5: 1370. https://doi.org/10.3390/agronomy13051370