Weeding Effectiveness and Changes in Soil Physical Properties Using Inter-Row Hoeing and a Robot

Abstract

:1. Introduction

1.1. Ecological Sugar Beet Production

1.2. Weed Control Methods and Their Effectiveness

1.2.1. Mechanical Weed Control

1.2.2. Camera-Steered Weed Control

1.2.3. Intra-Row Weeding Technologies

1.2.4. Robotic Weed Control

1.3. Correlation with Soil Properties

2. Materials and Methods

2.1. Experimental Site

2.2. Experimental Design and Treatments

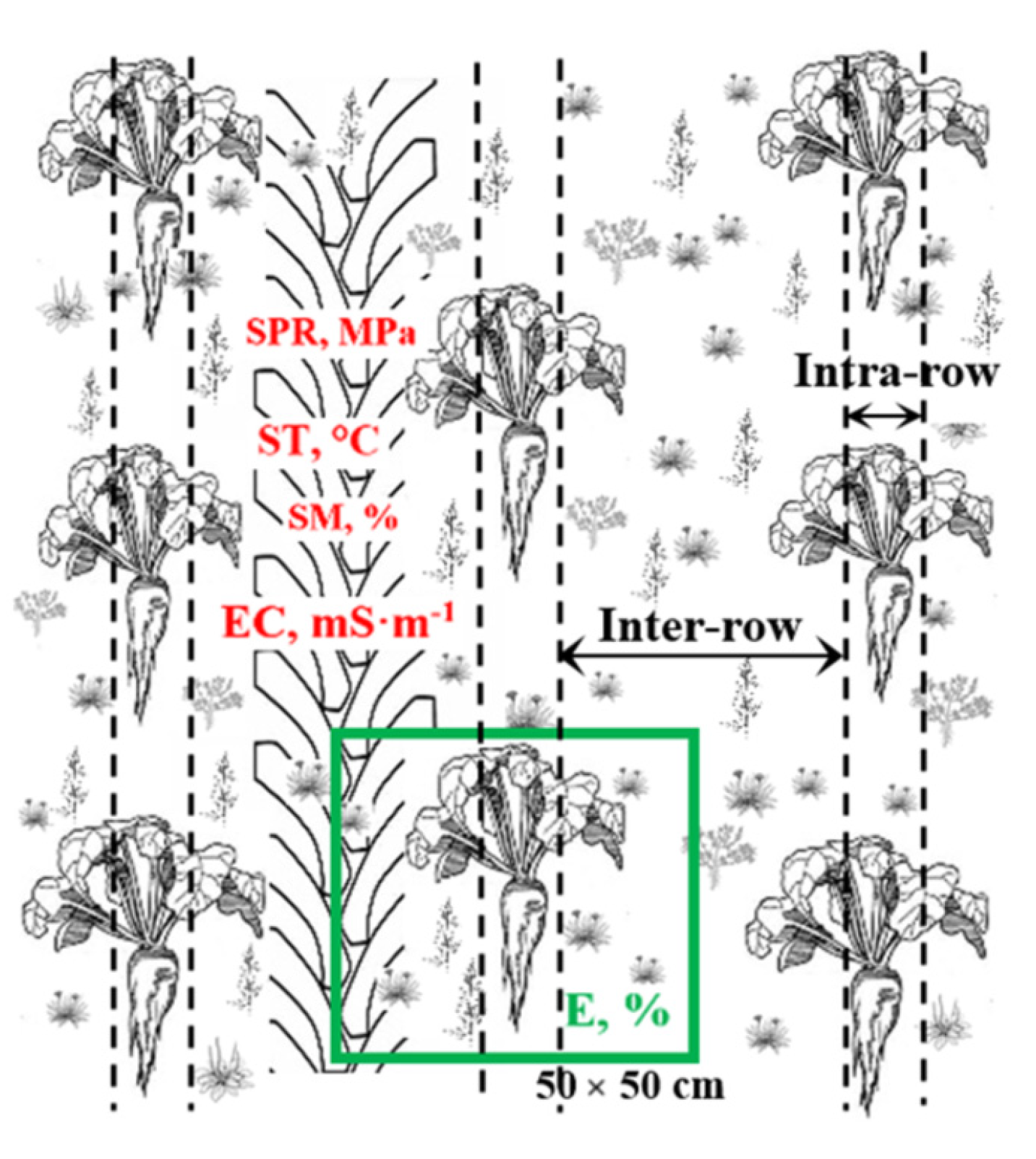

2.3. The Effects of Machinery on Soil Physical Properties

2.4. Effectiveness of Different Weed Control Systems

2.5. Statistical Analysis

3. Results

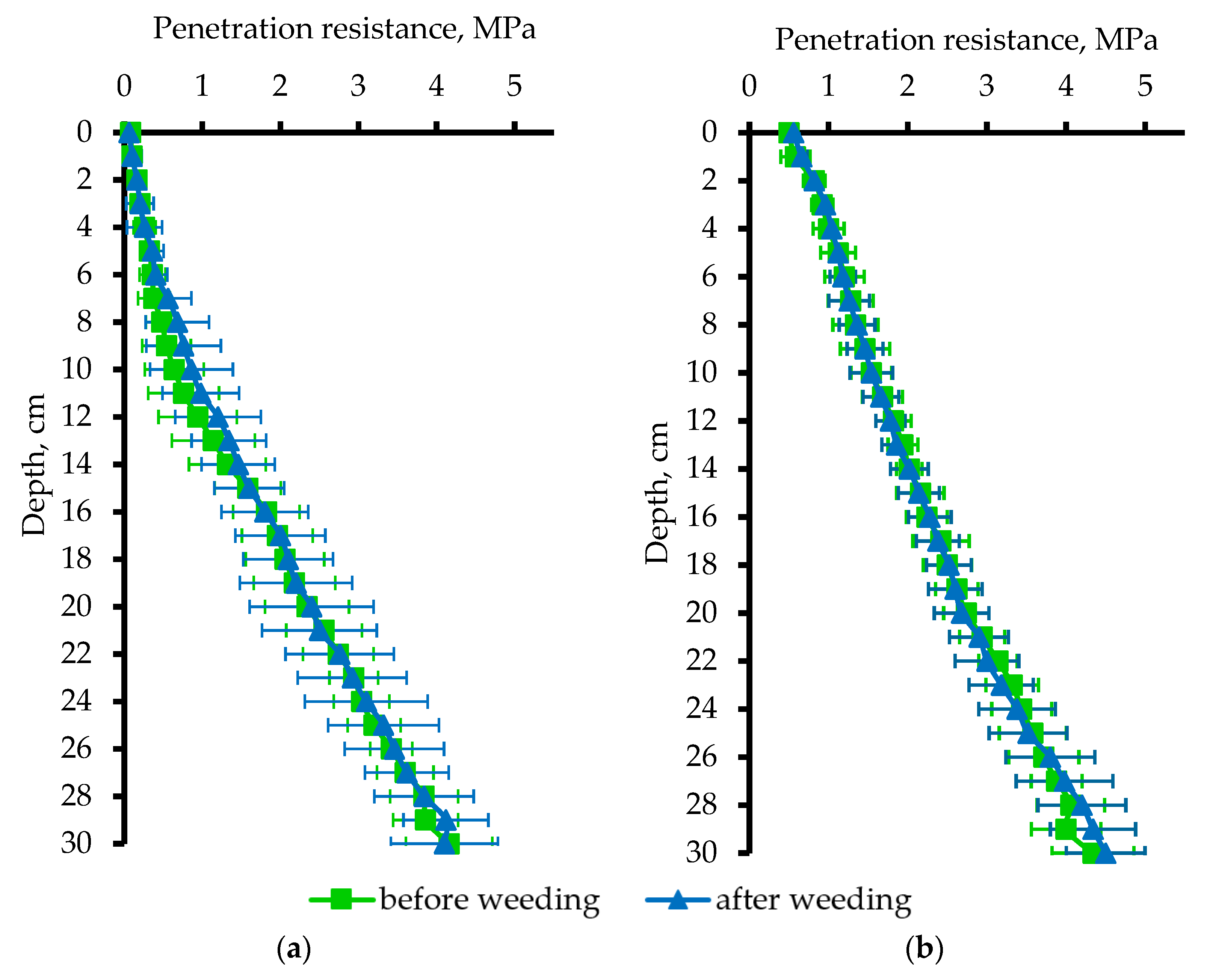

3.1. Soil Penetration Resistance

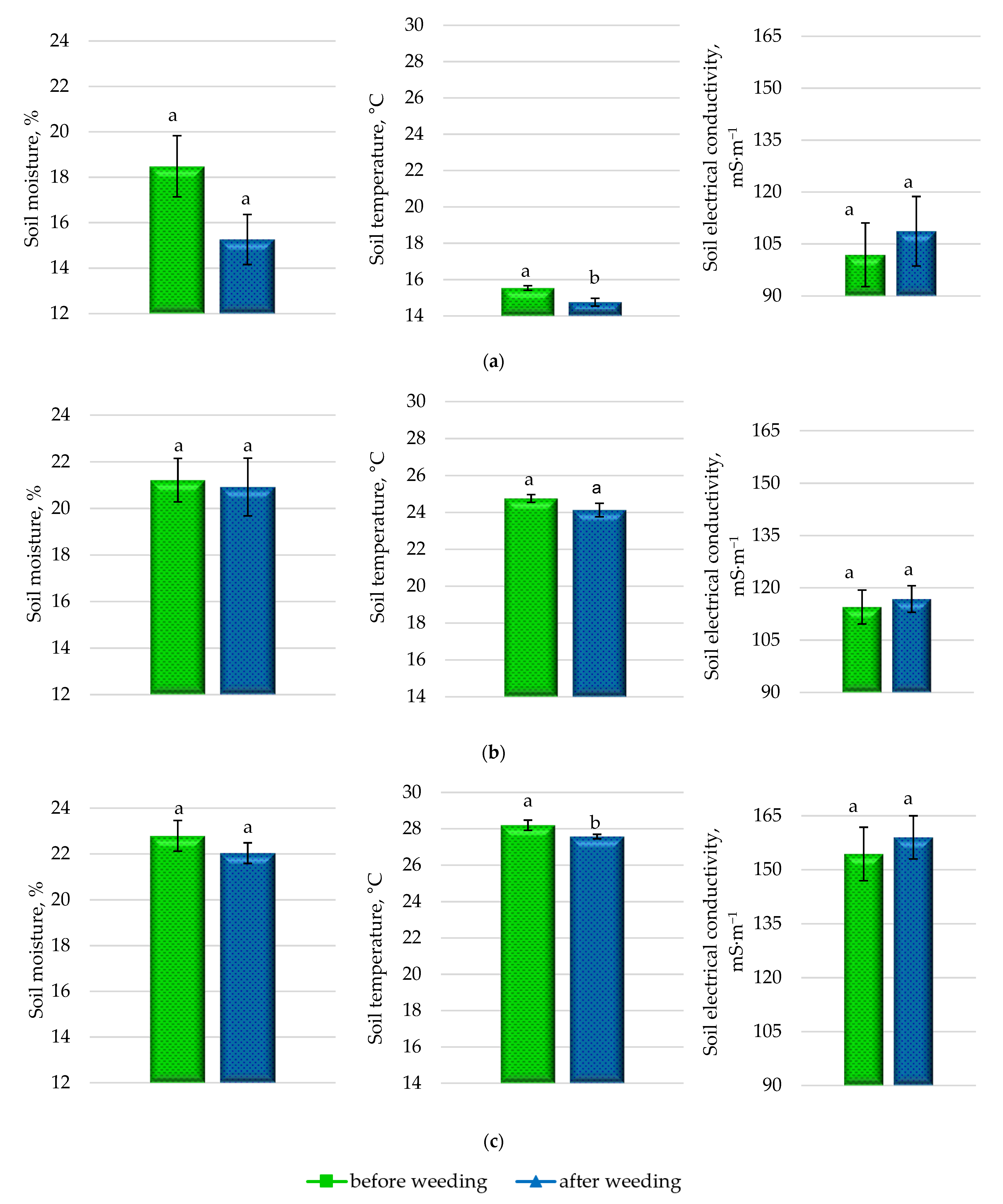

3.2. Soil Moisture, Temperature, Electrical Conductivity, and Bulk Density

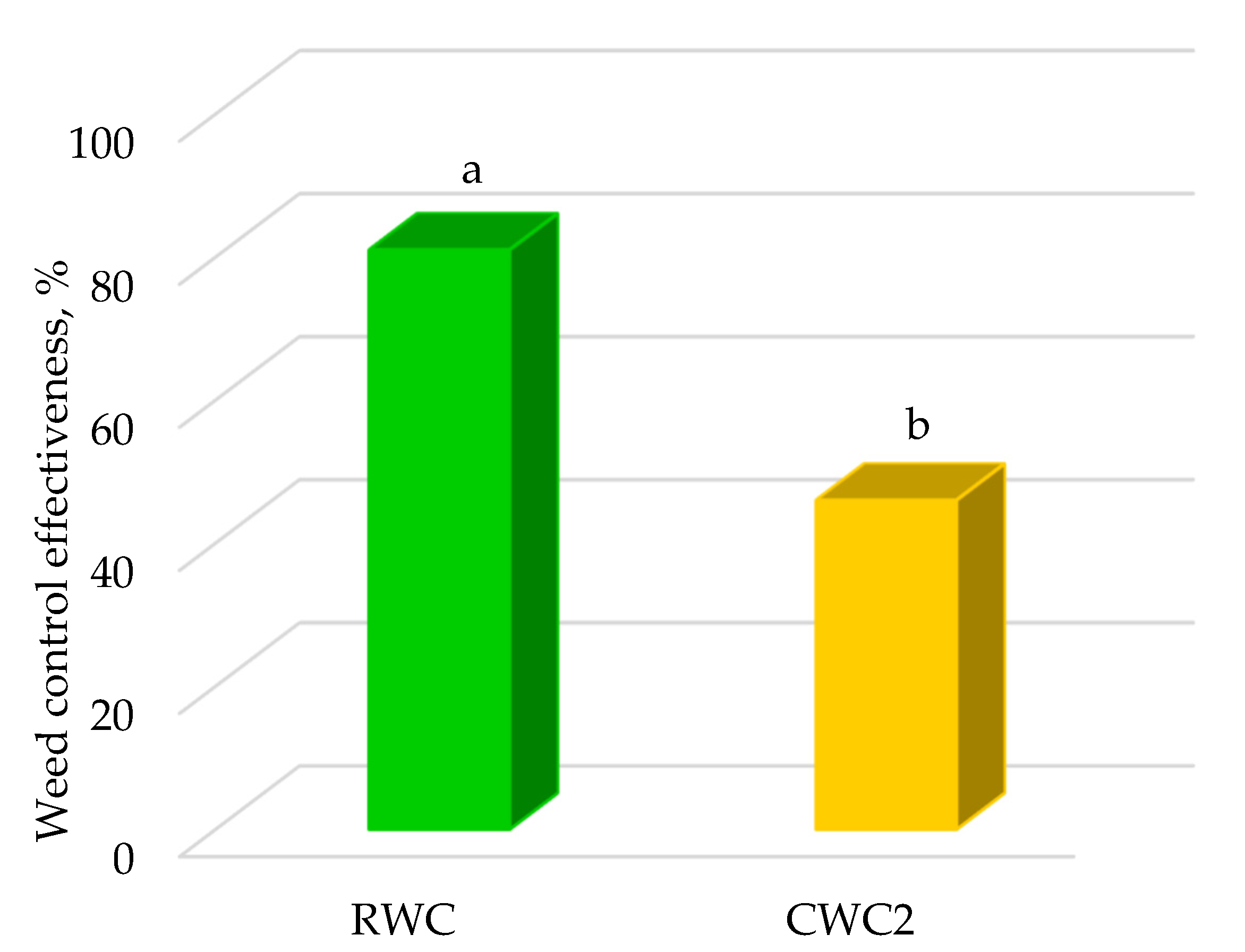

3.3. Effectiveness of Weed Control Systems

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eurostat. 2020. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Organic_farming_statistics#Total_organic_area (accessed on 23 April 2022).

- Eurostat. 2020. Available online: https://ec.europa.eu/eurostat/data/database?node_code=org (accessed on 24 April 2022).

- Abouziena, H.F.; Haggag, W.M. Weed control in clean agriculture: A review. Planta Daninha 2016, 34, 377–392. [Google Scholar] [CrossRef]

- Mesbah, A.; Miller, S.D.; Fornstrom, K.J.; Legg, D.E. Sugar Beet-Weed Interactions; Agricultural Experiment Station, B-998; University of Wyoming: Laramie, WY, USA, 1994. [Google Scholar]

- Cioni, F.; Maines, G. Weed control in sugarbeet. Sugar Tech. 2010, 12, 243–255. [Google Scholar] [CrossRef]

- Guglielmini, A.C.; Verdú, A.M.C.; Satorre, E.H. Competitive ability of five common weed species in competition with soybean. Int. J. Pest Manag. 2017, 63, 30–36. [Google Scholar] [CrossRef]

- Oerke, E.C. Crop losses to pests. J. Agric. Sci. 2006, 144, 31–43. [Google Scholar] [CrossRef]

- Pimentel, D. Pest control in world agriculture. Agric. Sci. 2009, 2, 272–293. [Google Scholar]

- Jalali, A.H.; Salehi, F. Sugar beet yield as affected by seed priming and weed control. Arch. Agron. Soil. Sci. 2013, 59, 281–288. [Google Scholar] [CrossRef]

- Majidi, M.; Heidari, G.; Emam, Y. Qualitative characteristics of sugar beet as affected by different broadleaf herbicides combinations. Iran Agric. Res. 2017, 36, 1–6. [Google Scholar]

- Gerhards, R.; Bezhin, K.; Santel, H.J. Sugar beet yield loss predicted by relative weed cover, weed biomass and weed density. Plant Prot. Sci. 2017, 53, 118–125. [Google Scholar]

- Jursik, M.; Holec, J.; Soukup, J.; Venclova, V. Competitive relationships between sugar beet and weeds in dependence on time of weed control. Plant Soil Environ. 2018, 5, 108–116. [Google Scholar] [CrossRef] [Green Version]

- Kunz, C.; Weber, J.F.; Peteinatos, G.G.; Sokefeld, M.; Gerhards, R. Camera steered mechanical weed control in sugar beet, maize and soybean. Precis. Agric. 2018, 19, 708–720. [Google Scholar] [CrossRef]

- Bhadra, T.; Mahapatra, C.K.; Paul, S.K. Weed management in sugar beet: A review. Fundam. Appl. Agric. 2020, 5, 147–156. [Google Scholar] [CrossRef]

- Dyrmann, M.; Karstoft, H.; Midtiby, H.S. Plant species classification using deep convolutional neural network. Biosyst. Eng. 2016, 151, 72–80. [Google Scholar] [CrossRef]

- Astrand, B.; Baerveldt, A.J. An agricultural mobile robot with vision-based perception for mechanical weed control. Auton. Robot. 2002, 13, 21–35. [Google Scholar] [CrossRef]

- Loddo, D.; McElroy, J.S.; Giannini, V. Problems and perspectives in weed management. Ital. J. Agron. 2021, 16, 1854. [Google Scholar] [CrossRef]

- Gobor, Z. Mechatronic system for mechanical weed control of the intra-row area in row crops. KI Kunstl. Intell. 2013, 27, 379–383. [Google Scholar] [CrossRef]

- Spaeth, M.; Machleb, J.; Peteinatos, G.G.; Saile, M.; Gerhards, R. Smart Harrowing—Adjusting the Treatment Intensity Based on Machine Vision to Achieve a Uniform Weed Control Selectivity under Heterogeneous Field Conditions. Agronomy 2020, 10, 1925. [Google Scholar] [CrossRef]

- Naruhn, G.P.; Peteinatos, G.G.; Butz, A.F.; Möller, K.; Gerhards, R. Efficacy of Various Mechanical Weeding Methods—Single and in Combination—In Terms of Different Field Conditions and Weed Densities. Agronomy 2021, 11, 2084. [Google Scholar] [CrossRef]

- Kunz, C.; Weber, J.F.; Gerhards, R. Comparison of different mechanical weed control strategies in sugar beets. In Proceedings of the Conference 27th Deutsche Arbeitsbesprechung über Fragen der Unkrautbiologie und -Bekämpfung, Braunschweig, Germany, 23–25 February 2016. [Google Scholar]

- Peruzzi, A.; Martelloni, L.; Frasconi, C.; Fontanelli, M.; Pirchio, M.; Raffaelli, M. Machines for non-chemical intra-row weed control in narrow and wide-row crops: A review. J. Agric. Eng. 2017, 48, 57–70. [Google Scholar] [CrossRef] [Green Version]

- Cook, S.K.; Davies, L.R.; Pickering, F.; Tatnell, L.V.; Huckle, A.; Newman, S.; Whiteside, C.; White, C.; Talbot, D.; Holmes, H.; et al. Weed Control Options and Future Opportunities for UK Crops; Research Review No. CP 182/1807258; Agriculture and Horticulture Development Board: Kenilworth, UK, 2019. [Google Scholar]

- Spaeth, M.; Schumacher, M.; Gerhards, R. Comparing Sensor-Based Adjustment of Weed Harrowing Intensity with Conventional Harrowing under Heterogeneous Field Conditions. Agronomy 2021, 11, 1605. [Google Scholar] [CrossRef]

- Van der Weide, R.; Bleeker, P.; Achten, V.T.; Plotz, L.; Fogelberg, F.; Melander, B. Innovation in mechanical weed control in crop rows. Weed Res. 2008, 48, 215–224. [Google Scholar] [CrossRef]

- Šarauskis, E. Mechaninę Pasėlių Priežiūrą Lengvina Automatinės Valdymo Sistemos; Mano Ūkis; Lietuvos Žemės Ūkio Konsultavimo Tarnyba; Akademija (Kėdainių r.): Kaunas, Lithuania, 2019; Volume 8, p. 2019. [Google Scholar]

- Langsenkamp, F.; Sellmann, F.; Kohlbrecher, M.; Kielhorn, A.; Strothmann, W.; Michaels, A.; Trautz, D. Tube Stamp for mechanical intra-row individual Plant Weed Control. In Proceedings of the 18th World Congress of CIGR, Beijing, China, 16–19 September 2014; pp. 16–19. [Google Scholar]

- Melander, B.; Lattanzi, B.; Pannacci, E. Intelligent versus non-intelligent mechanical intra-row weed control in transplanted onion and cabbage. Crop Prot. 2015, 72, 1–8. [Google Scholar] [CrossRef]

- Pannacci, E.; Farneselli, M.; Guiducci, M.; Tei, F. Mechanical weed control in onion seed production. Crop Prot. 2020, 135, 105221. [Google Scholar] [CrossRef]

- Davies, D.H.K.; Welsh, J.P. Weed control in organic cereals and pulses. In Organic Cereals and Pulses: Papers presented at Conferences Held at the Heriot-Watt University, Edinburgh, and at Cranfield University Silsoe Campus, Bedfordshire, 6 and 9 November 2001; Chalcombe Publications: Bedfordshire, UK, 2002; pp. 77–114. [Google Scholar]

- Gerhards, R.; Weber, J.F.; Kunz, C. Evaluation of weed control efficacy and yield response of inter-row and intra-row hoeing technologies in maize, sugar beet and soybean. Landtechnik 2020, 75, 247–260. [Google Scholar]

- Tillett, N.D.; Hague, T.; Miles, S.J. Inter-row vision guidance for mechanical weed control in sugar beet. Comput. Electron. Agric. 2002, 33, 163–177. [Google Scholar] [CrossRef]

- Griepentrog, H.W.; Noerremark, M.; Nielsen, J.; Ibarra, J.S. Autonomous inter-row hoeing using GPS-based side-shift control. In Proceedings of the Automation Technology for Off-Road, Bonn, Germany, 1–2 September 2006; pp. 117–124. [Google Scholar]

- Kunz, C.; Weber, J.F.; Gerhards, R. Benefits of Precision Farming Technologies for Mechanical Weed Control in Soybean and Sugar Beet—Comparison of Precision Hoeing with Conventional Mechanical Weed Control. Agronomy 2015, 5, 130–142. [Google Scholar] [CrossRef] [Green Version]

- Gerhards, R.; Kollenda, B.; Machleb, J.; Möller, K.; Butz, A.; Reiser, D.; Griegentrog, H.W. Camera-guided weed hoeing in winter cereals with narrow row distance. Gesunde Pflanz. 2020, 72, 403–411. [Google Scholar] [CrossRef]

- Nørremark, M.; Griepentrog, H.W.; Nielsen, J.; Søgaard, H.T. Evaluation of an autonomous GPS-based system for intra-row weed control by assessing the tilled area. Precis. Agric. 2012, 13, 149–162. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, J.; Huang, X.; Li, N.; Chen, Z.; Li, W. System integration design of intra-row weeding robot. In Proceedings of the American Society of Agricultural and Biological Engineers, St. Joseph, MI, USA, 21–24 July 2013; p. 1. [Google Scholar]

- Gerhards, R.; Andújar Sanchez, D.; Hamouz, P.; Peteinatos, G.G.; Christensen, S.; Fernandez-Quintanilla, C. Advances in site-specific weed management in agriculture—A review. Weed Res. 2022, 62, 123–133. [Google Scholar] [CrossRef]

- Wiltshire, J.J.J.; Tillett, N.D.; Hague, T. Agronomic evaluation of precise mechanical hoeing and chemical weed control in sugar beet. Weed Res. 2003, 43, 236–244. [Google Scholar] [CrossRef]

- Tillett, N.D.; Hague, T.; Grundy, A.C.; Dedousis, A.P. Mechanical within-row weed control for transplanted crops using computer vision. Biosyst. Eng. 2008, 99, 171–178. [Google Scholar] [CrossRef]

- Norremark, M.; Sorenson, C.G.; Jorgenson, R.N. HortiBot: Comparison of present and future phytotechnologies for weed control—Part III. In Proceedings of the 2006 ASAE Annual Meeting. American Society of Agricultural and Biological Engineers, St. Joseph, MI, USA; 2006; p. 1. [Google Scholar]

- Rasmussen, J.; Griepentrog, H.W.; Nielsen, J.; Henriksen, C.B. Automated intelligent rotor tine cultivation and punch planting to improve the selectivity of mechanical intra-row weed control. Weed Res. 2012, 52, 327–337. [Google Scholar] [CrossRef]

- Perez-Ruiz, M.; Slaughter, D.C.; Gliever, C.; Upadhyaya, S.K. Tractor-based Real-time Kinematic-Global Positioning System (RTK-GPS) guidance system for geospatial mapping of row crop transplant. Biosyst. Eng. 2012, 111, 64–71. [Google Scholar] [CrossRef]

- Perez-Ruiz, M.; Slaughter, D.C.; Fathallah, F.A.; Gliever, C.J.; Miller, B.J. Co-robotic intra-row weed control system. Biosyst. Eng. 2014, 126, 45–55. [Google Scholar] [CrossRef]

- Pannacci, E.; Tei, F. Effects of mechanical and chemical methods on weed control, weed seed rain and crop yield in maize, sunflower and soyabean. Crop Prot. 2014, 64, 51–59. [Google Scholar] [CrossRef]

- Heno, S.; Viou, L.; Khan, M.F.R. Sugar beet production in France. Sugar Tech. 2018, 20, 392–395. [Google Scholar] [CrossRef]

- Machleb, J.; Peteinatos, G.G.; Kollenda, B.L.; Andújar, D.; Gerhards, R. Sensor-based mechanical weed control: Present state and prospects. Comput. Electron. Agric. 2020, 176, 105638. [Google Scholar] [CrossRef]

- Chandel, N.S.; Chandel, A.K.; Roul, A.K.; Solanke, K.R.; Mehta, C.R. An integrated inter-and intra-row weeding system for row crops. Crop Prot. 2021, 145, 105642. [Google Scholar] [CrossRef]

- Sabanci, K.; Aydin, C. Smart robotic weed control system for sugar beet. J. Agric. Sci. Technol. 2017, 19, 73–83. [Google Scholar]

- Bawden, O.; Ball, D.; Kulk, J.; Perez, T.; Russell, R. A lightweight, modular robotic vehicle for the sustainable intensification of agriculture. In Proceedings of the 16th Australasian Conference on Robotics and Automation 2014, Melbourne, Australia, 2–4 December 2014; Australian Robotics and Automation Association Inc.: Brisbane, Australia, 2014; pp. 1–9. [Google Scholar]

- Bawden, O.; Kulk, J.; Russell, R.; McCool, C.; English, A.; Dayoub, F.; Perez, T. Robot for weed species plant-specific management. J. Field Robot. 2017, 34, 1179–1199. [Google Scholar] [CrossRef]

- Jensen, K.; Larsen, M.; Nielsen, S.H.; Larsen, L.B.; Olsen, K.S.; Jorgensen, R.N. Towards an Open Software Platform for Field Robots in Precision Agriculture. Robotics 2014, 3, 207–234. [Google Scholar] [CrossRef] [Green Version]

- Choi, K.H.; Han, S.K.; Han, S.H.; Park, K.; Kim, K.; Kim, S. Morphology-based guidance line extraction for an autonomous weeding robot in paddy fields. Comput. Electron. Agric. 2015, 113, 266–274. [Google Scholar] [CrossRef]

- Grimstad, L.; Johan, P. The thorvald II agricultural robotic system. Robotics 2017, 6, 24. [Google Scholar] [CrossRef] [Green Version]

- Utstumo, T.; Urdal, F.; Brevik, A.; Dorum, J.; Netland, J.; Overskeid, O.; Berge, T.W.; Gravdahl, J.T. Robotic in-row weed control in vegetables. Comput. Electron. Agric. 2018, 154, 36–45. [Google Scholar] [CrossRef]

- Lottes, P.; Khanna, R.; Pfeifer, J.; Siegwart, R.; Stachniss, C. UAV-based crop and weed classification for smart farming. In Proceedings of the 2017 IEEE international conference on robotics and automation (ICRA), Singapore, 29 May–3 June 2017; pp. 3024–3031. [Google Scholar]

- Merfield, C.N. Robotic weeding’s false dawn? Ten requirements for fully autonomous mechanical weed management. Weed Res. 2016, 56, 340–344. [Google Scholar] [CrossRef]

- Bogužas, V.; Arvasas, J.; Šniauka, P. Žemdirbystė; Aleksandras Stulginskis University: Akademija, Lithuania, 2013; pp. 1–176. [Google Scholar]

- Lal, R. Degradation and resilience of soils. Philos. Trans. R. Soc. London. Ser. B Biol. Sci. 1997, 352, 997–1010. [Google Scholar] [CrossRef]

- Araujo-Junior, C.F.; Rodrigues, B.N.; Chaves, J.C.D.; Yada Junior, G.M. Soil physical quality and carbon stocks related to weed control and cover crops in a Brazilian Oxisol. In Weed and Pest Control: Conventional and New Challenges; InTech: Rijeka, Croatia, 2013; pp. 181–205. [Google Scholar]

- Araujo-Junior, C.F.; Junior, M.D.S.D.; de Alcântara, E.N.; Guimarães, P.T.G.; Ajayi, A.E. Interrelationships Among Weed Management in Coffee Plantation and Soil Physical Quality. In Weed Control; IntechOpen: London, UK, 2012. [Google Scholar]

- Gajda, A.M.; Czyz, E.A.; Dexter, A.R. Effects of long-term use of different farming systems on some physical, chemical and microbiological parameters of soil quality. Int. Agrophys. 2016, 30, 165–172. [Google Scholar] [CrossRef]

- Koch, H.J.; Heuer, H.; Tomanová, O.; Märländer, B. Cumulative effect of annually repeated passes of heavy agricultural machinery on soil structural properties and sugar beet yield under two tillage systems. Soil Tillage Res. 2008, 101, 69–77. [Google Scholar] [CrossRef]

- Vadiunina, A.F.; Korchagina, Z.A. Methods for Investigation Soil Physical Properties; Agropromizdat: Moskva, Russia, 1986; pp. 1–416. (In Russian) [Google Scholar]

- Hossain, M.F.; Chen, W.; Zhang, Y. Bulk density of mineral and organic soils in the Canada’s arctic and sub-arctic. Inf. Process. Agric. 2015, 2, 183–190. [Google Scholar] [CrossRef] [Green Version]

- Tukey, J.W. Methodology, and the statistician’s responsibility for both accuracy and relevance. J. Am. Stat. Assoc. 1979, 74, 786–793. [Google Scholar] [CrossRef]

- Keller, T.; Arvidsson, J. Technical solutions to reduce the risk of subsoil compaction: Effects of dual wheels, tandem wheels and tyre inflation pressure on stress propagation in soil. Soil Tillage Res. 2004, 79, 191–205. [Google Scholar] [CrossRef]

- Zabrodskyi, A.; Šarauskis, E.; Kukharets, S.; Juostas, A.; Vasiliauskas, G.; Andriušis, A. Analysis of the impact of soil compaction on the environment and agricultural economic losses in Lithuania and Ukraine. Sustainability 2021, 13, 7762. [Google Scholar] [CrossRef]

- Mileusnić, Z.I.; Saljnikov, E.; Radojević, R.L.; Petrović, D.V. Soil compaction due to agricultural machinery impact. J. Terramechanics 2022, 100, 51–60. [Google Scholar] [CrossRef]

- Gürsoy, S.; Sessiz, A.; Kiliç, H.; Bayram, N. Tillage system and cotton residue management effects on soil physical and chemical properties of an Anatolian clay loam sown within a wheat-cotton sequence. Arch. Acker Pflanzenbau Bodenkd. 2011, 57, 391–400. [Google Scholar] [CrossRef]

- Stelluti, M.; Maiorana, M.; De Giorgio, D. Multivariate approach to evaluate the penetrometer resistance in different tillage systems. Soil Tillage Res. 1998, 46, 145–151. [Google Scholar] [CrossRef]

- Newton, A.C.; Guy, D.C.; Bengough, A.G.; Gordon, D.C.; McKenzie, B.M.; Sun, B.; Hallett, P.D. Soil tillage effects on the efficacy of cultivars and their mixtures in winter barley. Field Crop. Res. 2012, 128, 91–100. [Google Scholar] [CrossRef]

- Arvidsson, J. Effects of cultivation depth in reduced tillage on soil physical properties, crop yield and plant pathogens. Eur. J. Agron. 1998, 9, 79–85. [Google Scholar] [CrossRef]

- Lati, R.N.; Siemens, M.C.; Rachuy, J.S.; Fennimore, S.A. Intrarow weed removal in broccoli and transplanted lettuce with an intelligent cultivator. Weed Technol. 2016, 30, 655–663. [Google Scholar] [CrossRef]

- Bleeker, P.; van der Weide, R.; Kurstjens, D.; Cloutier, D.C. Experiences and experiments with new intra-row weeders. In Proceedings of the 5th EWRS Workshop on Physical and Cultural Weed Control, Pisa, Italy, 11–13 March 2002; pp. 97–100. [Google Scholar]

- Rueda-Ayala, V.; Peteinatos, G.; Gerhards, R.; Andújar, D. A non-chemical system for online weed control. Sensors 2015, 15, 7691–7707. [Google Scholar] [CrossRef] [Green Version]

- Pannacci, E.; Tei, F.; Guiducci, M. Evaluation of mechanical weed control in legume crops. Crop Prot. 2018, 104, 52–59. [Google Scholar] [CrossRef]

- Benaragama, D.; Shirtliffe, S.J. Integrating cultural and mechanical methods for additive weed control in organic systems. Agron. J. 2013, 105, 1728–1734. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bručienė, I.; Buragienė, S.; Šarauskis, E. Weeding Effectiveness and Changes in Soil Physical Properties Using Inter-Row Hoeing and a Robot. Agronomy 2022, 12, 1514. https://doi.org/10.3390/agronomy12071514

Bručienė I, Buragienė S, Šarauskis E. Weeding Effectiveness and Changes in Soil Physical Properties Using Inter-Row Hoeing and a Robot. Agronomy. 2022; 12(7):1514. https://doi.org/10.3390/agronomy12071514

Chicago/Turabian StyleBručienė, Indrė, Sidona Buragienė, and Egidijus Šarauskis. 2022. "Weeding Effectiveness and Changes in Soil Physical Properties Using Inter-Row Hoeing and a Robot" Agronomy 12, no. 7: 1514. https://doi.org/10.3390/agronomy12071514