The Abrasive Wear Resistance of the Segmented Linear Polyurethane Elastomers Based on a Variety of Polyols as Soft Segments

Abstract

:1. Introduction

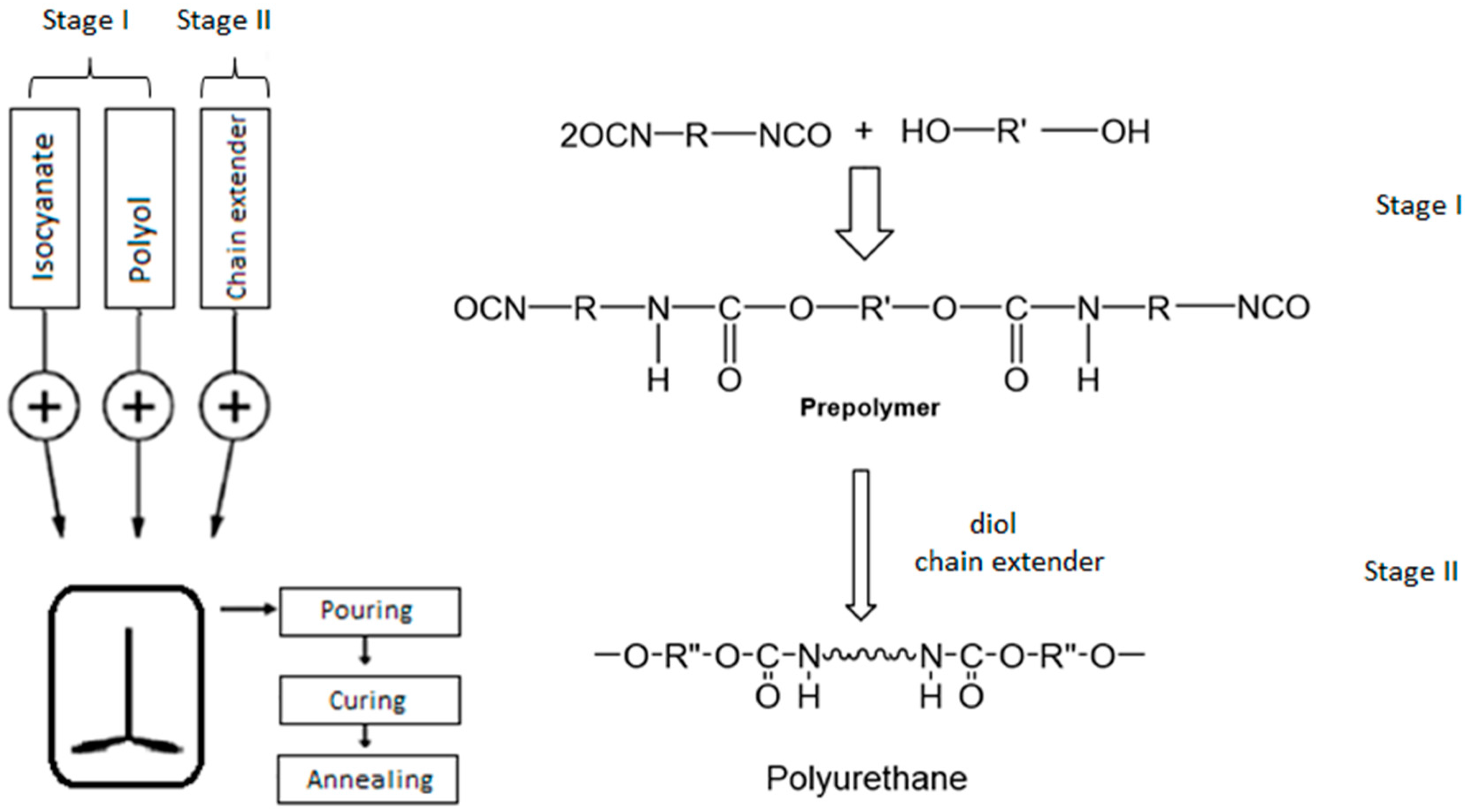

2. Materials and Experimental Methods

2.1. Materials and Synthesis

2.2. Methods

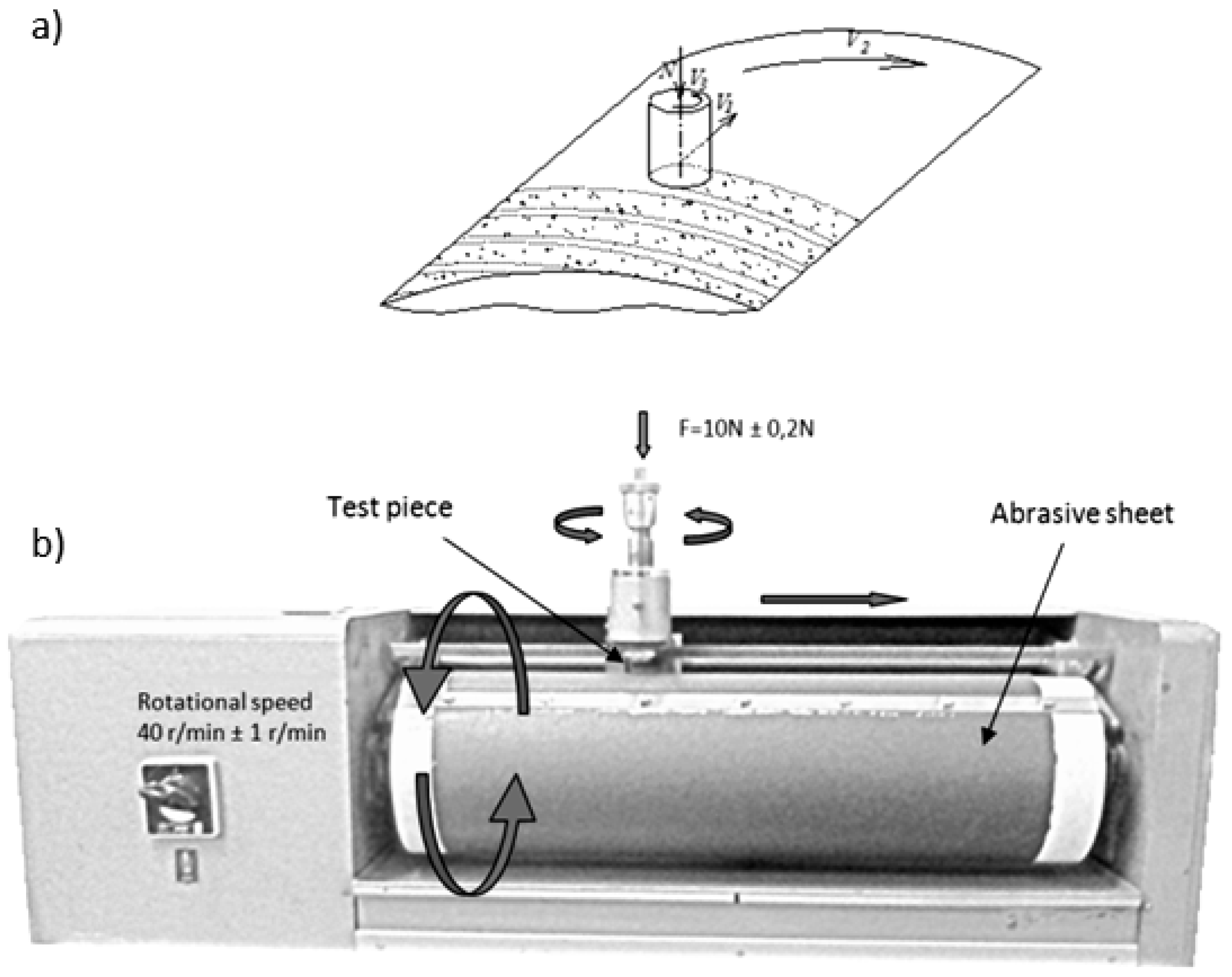

2.2.1. The Abrasion Resistance

2.2.2. The Density

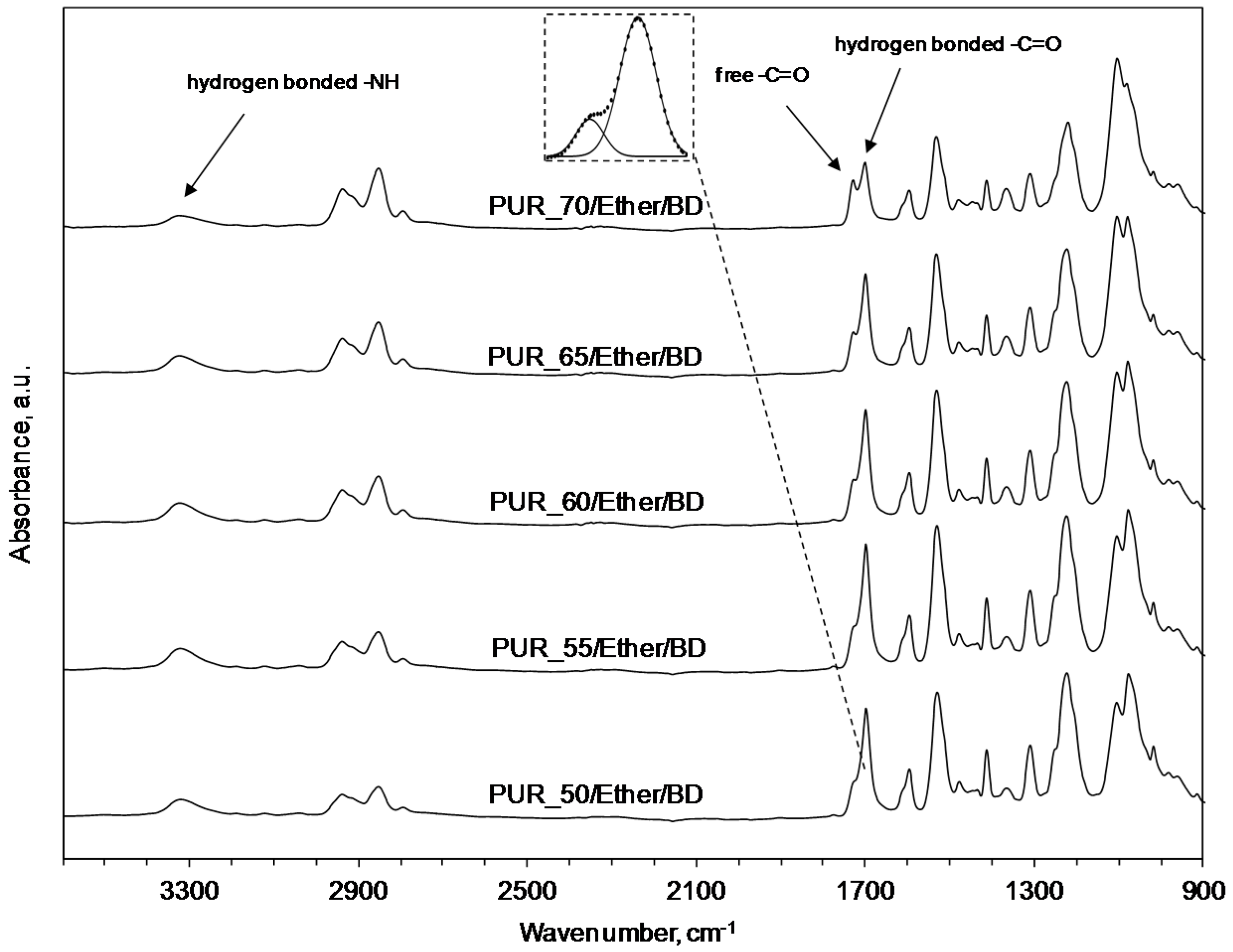

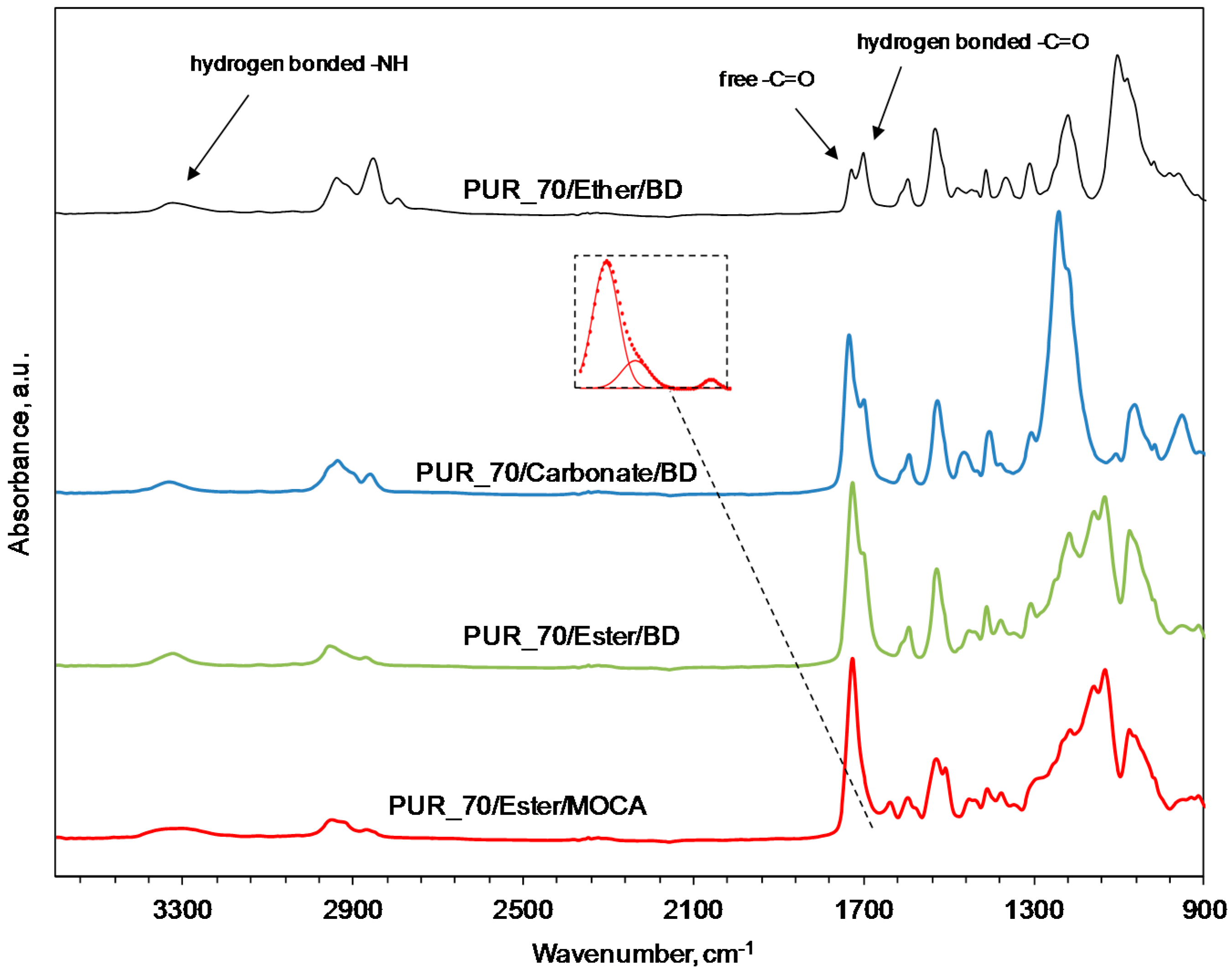

2.2.3. The Fourier Transform Infrared (FTIR) Spectroscopy

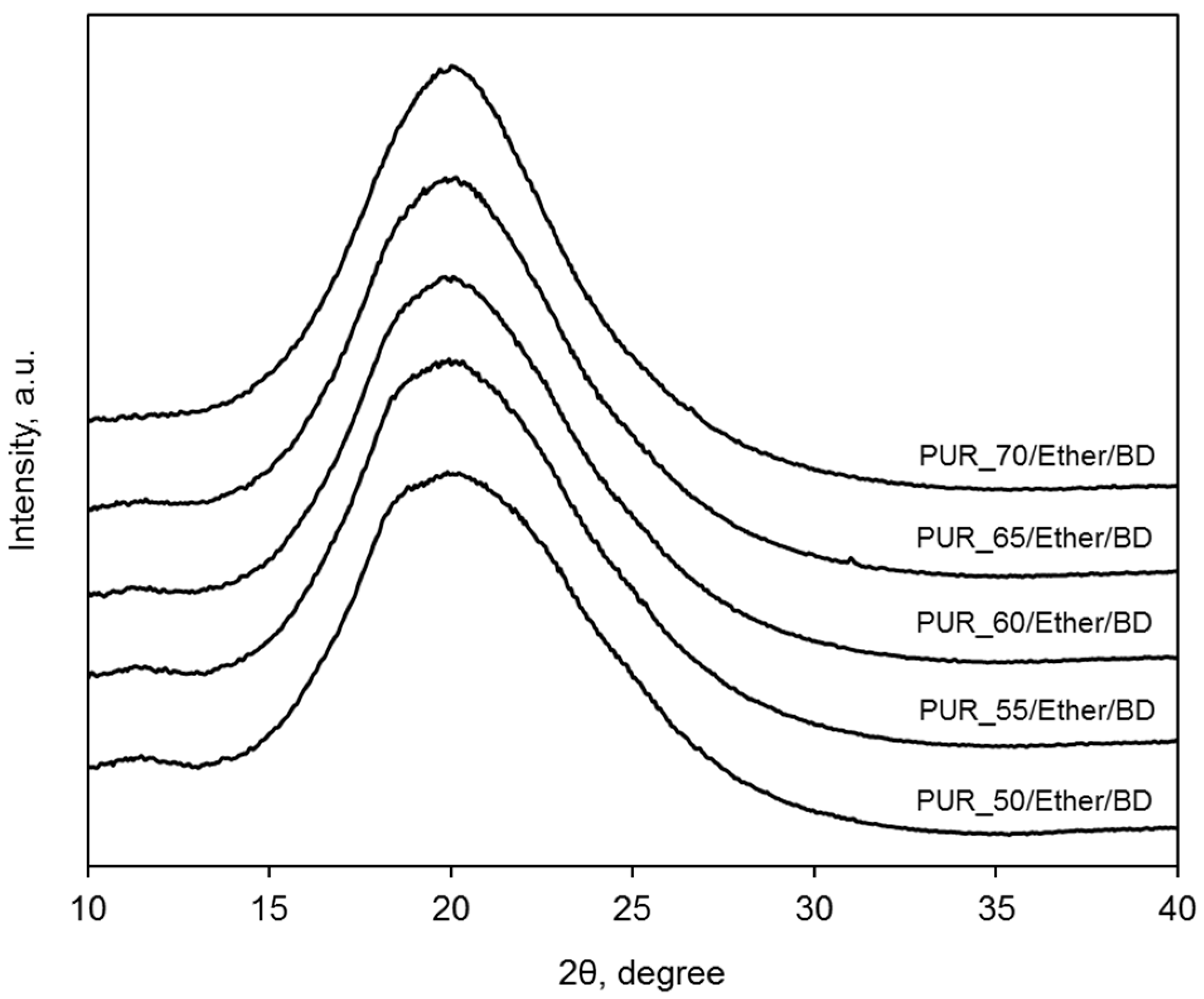

2.2.4. The Wide-Angle X-ray Scattering (WAXS)

2.2.5. The Differential Scanning Calorimetry (DSC)

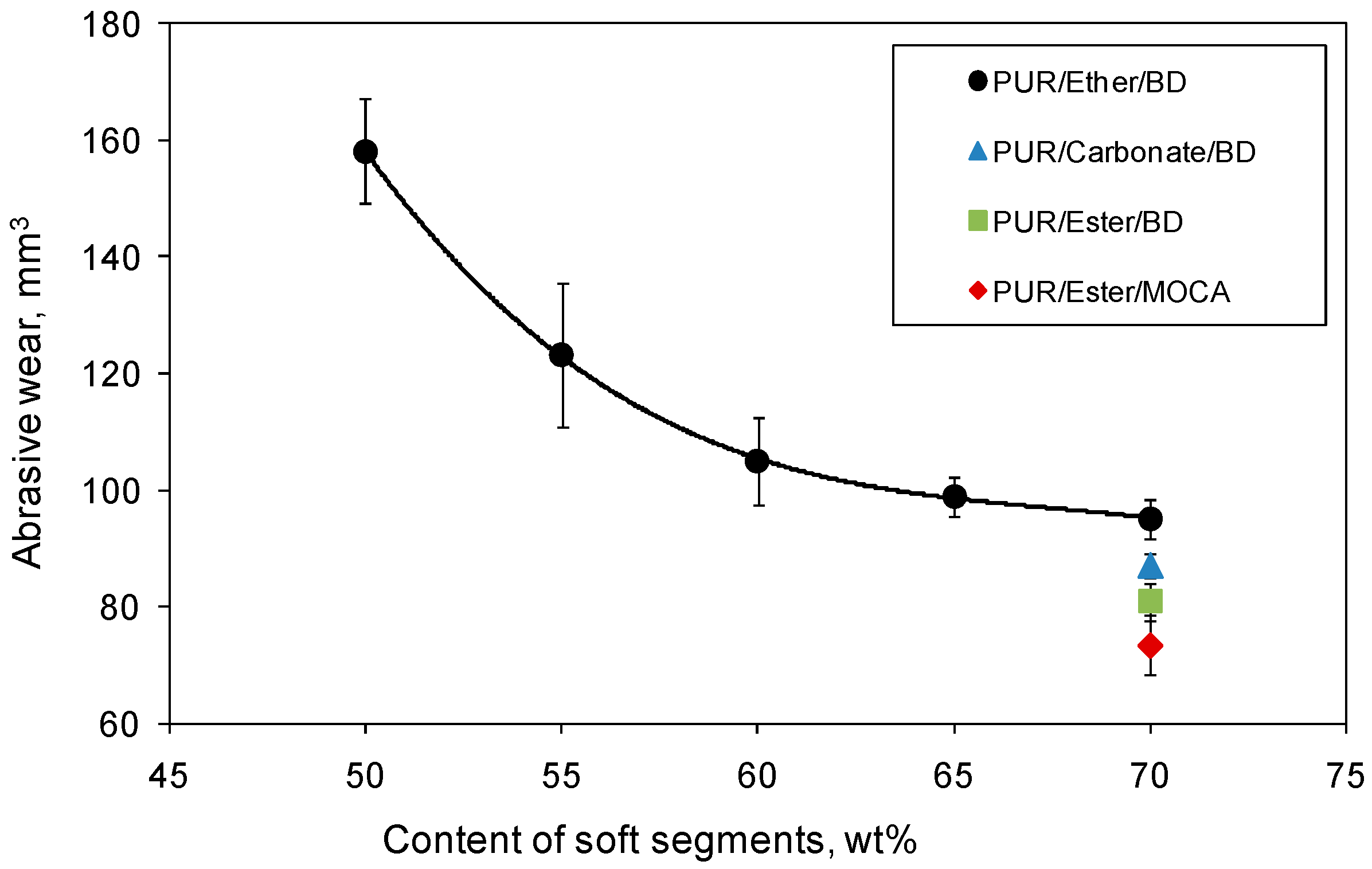

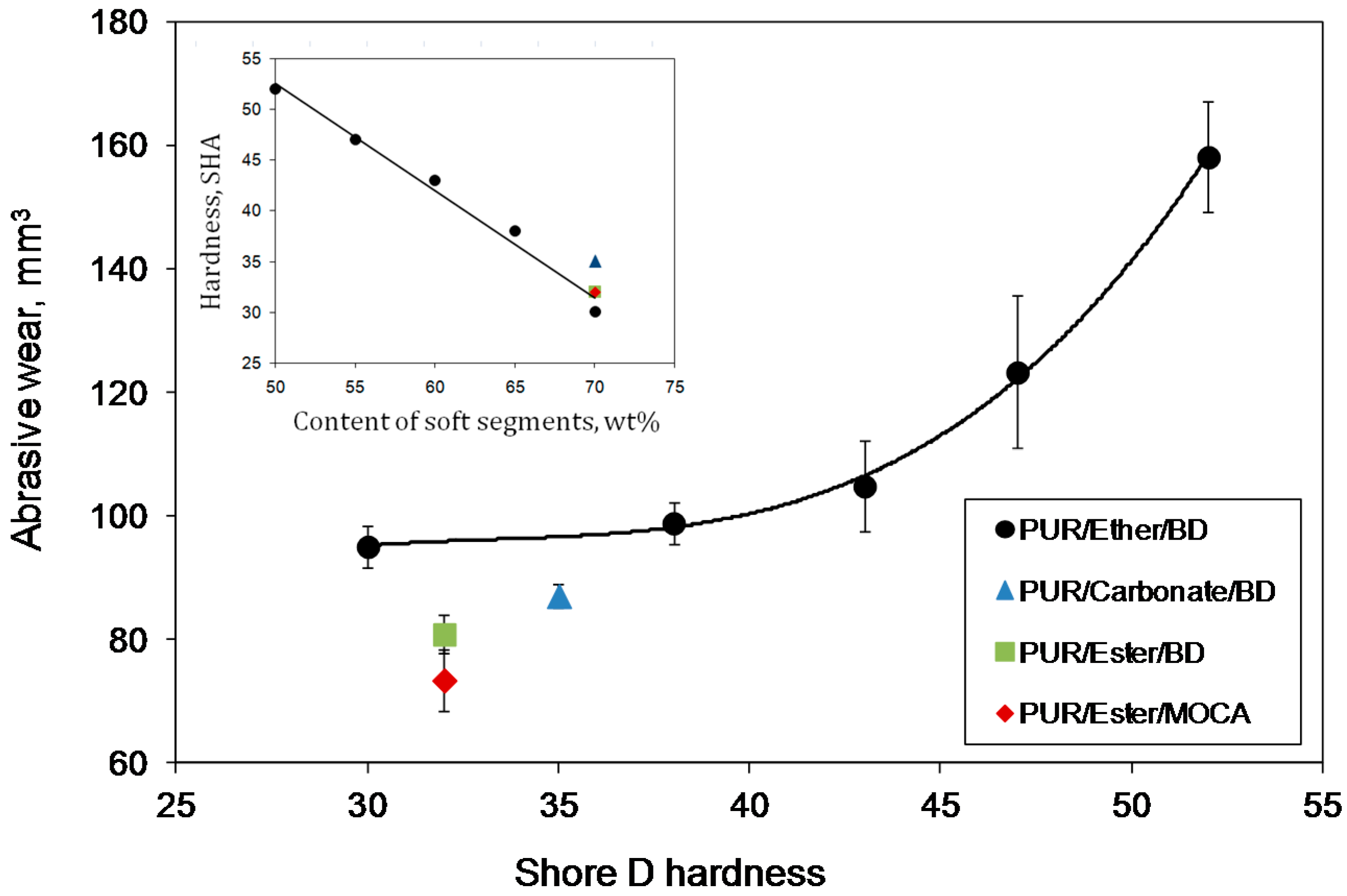

3. Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Stachowiak, G.W.; Batchelor, A.W. 16-wear of non-metallic materials. In Engineering Tribology, 3rd ed.; Butterworth-Heinemann: Butterworth-Heinemann, Burlington, 2006; pp. 651–704. [Google Scholar]

- Bayer, R.G. Mechanical Wear Prediction and Prevention; Marcel Dekker: New York, NY, USA, 1994. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Materiały Inżynierskie. Właściwości I Zastosowania; WNT: Warszawa, Poland, 1995. [Google Scholar]

- Bhushan, B. Principles and Applications of Tribology; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Moore, D.F. The Friction and Lubrication of Elastomers; Pergamon Press: Oxford, UK, 1972. [Google Scholar]

- Brostow, W.; Deborde, J.-L.; Jaklewicz, M.; Olszynski, P. Tribology with emphasis on polymers: Friction, scratch resistance and wear. J. Mater. Educ. 2003, 24, 119–132. [Google Scholar]

- Brostow, W.; Kovačević, V.; Vrsaljko, D.; Whitworth, J. Tribology of polymers and polymer based composites. J. Mater. Educ. 2010, 32, 273–290. [Google Scholar]

- Trofimovich, A.N.; Anisimov, V.N.; Kurachenkov, V.N.; Strakhov, V.V.; Letunovskii, M.P.; Egorov, S.F. Role of structure factor in evaluating polyurethane wear resistance. Sov. J. Frict. Wear 1987, 8, 87–92. [Google Scholar]

- Semenets, A.A.; Anisimov, V.N. Development of triboengineering composite materials based on thermoplastic polyurethanes. J. Frict. Wear 2010, 31, 208–213. [Google Scholar] [CrossRef]

- Beck, R.A.; Truss, R.W. Effect of chemical structure on the wear behaviour of polyurethane-urea elastomers. Wear 1998, 218, 145–152. [Google Scholar] [CrossRef]

- Zhou, R.; Lu, D.H.; Jiang, Y.H.; Li, Q.N. Mechanical properties and erosion wear resistance of polyurethane matrix composites. Wear 2005, 259, 676–683. [Google Scholar] [CrossRef]

- Sare, I.R.; Mardel, J.I.; Hill, A.J. Wear-resistant metallic and elastomeric materials in the mining and mineral processing industries—An overview. Wear 2001, 250, 1–10. [Google Scholar] [CrossRef]

- Jia, X.; Ling, R. Two-body free-abrasive wear of polyethylene, nylon1010, expoxy and polyurethane coatings. Tribol. Int. 2007, 40, 1276–1283. [Google Scholar] [CrossRef]

- Wirpsza, Z. Poliuretany. Chemia, Technologia, Zastosowanie; WNT: Warszawa, Poland, 1991. [Google Scholar]

- Prociak, A.; Rokicki, G.; Ryszkowska, J. Materiały Poliuretanowe; WNT: Warszawa, Poland, 2014. [Google Scholar]

- Prisacariu, C. Polyurethane Elastomers: From Morphology to Mechanical Aspect; Springer: New York, NY, USA, 2011. [Google Scholar]

- Król, P. Synthesis methods, chemical structures and phase structures of linear polyurethanes. Properties and applications of linear polyurethanes in polyurethane elastomers, copolymers and ionomers. Prog. Mater. Sci. 2007, 52, 915–1015. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction and Wear of Materials, 2nd ed.; Wiley: New York, NY, USA, 1995. [Google Scholar]

- Anisimov, V.N.; Semenets, A.A.; Letunovskii, M.P.; Strakhov, V.V. Effect of rigid blocks on the mechanical characteristics and abrasive resistance of polyurethanes. Mater. Sci. 2002, 38, 95–98. [Google Scholar] [CrossRef]

- Ryszkowska, J. Supermolecular structure, morphology and physical properties of urea-urethane elastomers. Polimery 2012, 57, 775–902. [Google Scholar] [CrossRef]

- Nachman, M.; Kwiatkowski, K. The effect of thermal annealing on the abrasion resistance of a segmented block copolymer urethane elastomers. Wear 2013, 306, 113–118. [Google Scholar] [CrossRef]

- Michalski, P.; Nachman, M.; Kwiatkowski, K. Abrasive wearofurethane elastomers based on monomeric or polymeric diisocyanate mdi. Polimery 2012, 57, 839–845. [Google Scholar] [CrossRef]

- Kwiatkowski, K.; Rosłaniec, Z. The relationship between hardness and abrasive wear resistance. In Proceedings of the Materiały Polimerowe Pomerania Plast 2010, Szczecin, Poland, 7–10 June 2016; pp. 387–390. [Google Scholar]

- Kojio, K.; Nakashima, S.; Furukawa, M. Microphase-separated structure and mechanical properties of norbornane diisocyanate-based polyurethanes. Polymer 2007, 48, 997–1004. [Google Scholar] [CrossRef]

- Velankar, S.; Cooper, S.L. Microphase separation and rheological properties of polyurethane melts. 1. Effect of block length. Macromolecules 1998, 31, 9181–9192. [Google Scholar] [CrossRef]

- Velankar, S.; Cooper, S.L. Microphase separation and rheological properties of polyurethane melts. 2. Effect of block incompatibility on the microstructure. Macromolecules 2000, 33, 382–394. [Google Scholar] [CrossRef]

- Nachman, M.; Kwiatkowski, K. The effect of annealing temperature on the phase structure of multiblock urethane elastomers. Przem. Chem. 2013, 92, 2010–2012. [Google Scholar]

- Tocha, E.; Janik, H.; Debowski, H.; Vancso, G.J. Morphology of polyurethanes revisited by complementary afm and tem. J. Macromol. Sci. Part B 2002, 41, 1291–1304. [Google Scholar] [CrossRef]

- Król, P.; Pilch-Pitera, B. Phase structure and thermal stability of crosslinked polyurethane elastomers based on well-defined prepolymers. J. Appl. Polym. Sci. 2007, 104, 1464–1474. [Google Scholar] [CrossRef]

- Janik, H.; Vancso, J. The influence of hard segment crosslinking on the morphology and mechanical properties of segmented poly(ester-urethanes). Polimery 2005, 2, 139–142. [Google Scholar]

- Bagdi, K.; Molnár, K.; Sajó, I.; Pukánszky, B. Specific interactions, structure and properties in segmented polyurethane elastomers. Express Polym. Lett. 2011, 5, 417–427. [Google Scholar] [CrossRef]

- Sonnenschein, M.F.; Lysenko, Z.; Brune, D.A.; Wendt, B.L.; Schrock, A.K. Enhancing polyurethane properties via soft segment crystallization. Polymer 2005, 46, 10158–10166. [Google Scholar] [CrossRef]

- Eceiza, A.; de la Caba, K.; Kortaberria, G.; Gabilondo, N.; Marieta, C.; Corcuera, M.A.; Mondragon, I. Influence of molecular weight and chemical structure of soft segment in reaction kinetics of polycarbonate diols with 4,4′-diphenylmethane diisocyanate. Eur. Polym. J. 2005, 41, 3051–3059. [Google Scholar] [CrossRef]

- Hernandez, R.; Weksler, J.; Padsalgikar, A.; Choi, T.; Angelo, E.; Lin, J.S.; Xu, L.-C.; Siedlecki, C.A.; Runt, J. A comparison of phase organization of model segmented polyurethanes with different intersegment compatibilities. Macromolecules 2008, 41, 9767–9776. [Google Scholar] [CrossRef]

- Rueda-Larraz, L.; Fernandez d’Arlas, B.; Tercjak, A.; Ribes, A.; Mondragon, I.; Eceiza, A. Synthesis and microstructure-mechanical property relationships of segmented polyurethanes based on a PCL-PTHF-PCL block copolymer as soft segment. Eur. Polym. J. 2009, 45, 2096–2109. [Google Scholar] [CrossRef]

- Garrett, J.T.; Xu, R.; Cho, J.; Runt, J. Phase separation of diamine chain-extended poly(urethane) copolymers: Ftir spectroscopy and phase transitions. Polymer 2003, 44, 2711–2719. [Google Scholar] [CrossRef]

- Pretsch, T.; Jakob, I.; Müller, W. Hydrolytic degradation and functional stability of a segmented shape memory poly(ester urethane). Polym. Degrad. Stab. 2009, 94, 61–73. [Google Scholar] [CrossRef]

- Seymour, R.W.; Estes, G.M.; Cooper, S.L. Infrared studies of segmented polyurethan elastomers. I. Hydrogen bonding. Macromolecules 1970, 3, 579–583. [Google Scholar] [CrossRef]

- Coleman, M.M.; Skrovanek, D.J.; Hu, J.; Painter, P.C. Hydrogen bonding in polymer blends. 1. Ftir studies of urethane-ether blends. Macromolecules 1988, 21, 59–65. [Google Scholar] [CrossRef]

- Ayres, E.; Oréfice, R.L.; Yoshida, M.I. Phase morphology of hydrolysable polyurethanes derived from aqueous dispersions. Eur. Polym. J. 2007, 43, 3510–3521. [Google Scholar] [CrossRef]

- Xiong, J.; Zheng, Z.; Song, W.; Zhou, D.; Wang, X. Microstructure and properties of polyurethane nanocomposites reinforced with methylene-bis-orthochloroanilline-grafted multi-walled carbon nanotubes. Compos. A Appl. Sci. Manuf. 2008, 39, 904–910. [Google Scholar] [CrossRef]

- Demarest, C. Life beyond moca. In Proceedings of the the Polyurethane Manufacturers Association Annual Meeting Phoenix, Las Vegas, NV, USA, 5–8 May 2014. [Google Scholar]

- Lamba, N.M.K.; Woodhouse, K.A.; Cooper, S.L. Polyurethanes in Biomedical Application; CRC Press: New York, NY, USA, 1997. [Google Scholar]

| Raw materials | Molecular structure | Molecular weight, g/mol | Hydroxyl value, mg KOH/g | Melting temperature, °C |

|---|---|---|---|---|

| Polyether, Terathane® 2000 (PTMO) |  | 2000 | 53.4–59.1 | 28–40 |

| Polycarbonate, Desmophen® C 2200 |  | 2000 | 53–59 | 39–52 |

| Polyester, Polios 60/20 |  | 2000 | 54–58 | 40–53 |

| Diisocyanate, 4,4′-MDI |  | 250 | - | 38–42 |

| 1,4-butanodiol, BD |  | 90 | - | 20.4 |

| Diamine, MOCA |  | 267 | - | 102–107 |

| Materials | Composition | Molar ratio: polyol/MDI/chain extender | Soft segment (SS), wt % | Hardness, ShD |

|---|---|---|---|---|

| PUR_50/Ether/BD | PTMO, BD, MDI | 1.00/6.45/5.15 | 50 | 52 |

| PUR_55/Ether/BD | PTMO, BD, MDI | 1.00/5.33/4.08 | 55 | 47 |

| PUR_60/Ether/BD | PTMO, BD, MDI | 1.00/4.40/3.19 | 60 | 43 |

| PUR_65/Ether/BD | PTMO, BD, MDI | 1.00/3.60/2.43 | 65 | 38 |

| PUR_70/Ether/BD | PTMO, BD, MDI | 1.00/2.93/1.79 | 70 | 30 |

| PUR_70/Carbonate/BD | Desmophen 2000, BD, MDI | 1.00/2.93/1.79 | 70 | 37 |

| PUR_70/Ester/BD | Polios 60/20, BD, MDI | 1.00/2.93/1.79 | 70 | 32 |

| PUR_70/Ester/MOCA | Polios 60/20, MOCA, MDI | 1.00/2.28/1.17 | 70 | 32 |

| Materials | Density, g/cm3 | 95% Confidence interval, g/cm3 |

|---|---|---|

| PUR_50/Ether/BD | 1.1274 | 0.0191 |

| PUR_55/Ether/BD | 1.1158 | 0.0126 |

| PUR_60/Ether/BD | 1.1032 | 0.0070 |

| PUR_65/Ether/BD | 1.0912 | 0.0074 |

| PUR_70/Ether/BD | 1.0740 | 0.0027 |

| PUR_70/Carbonate/BD | 1.1535 | 0.0082 |

| PUR_70/Ester/BD | 1.2416 | 0.0158 |

| PUR_70/Ester/MOCA | 1.2508 | 0.0071 |

| Sample | A1730 * | A1700 ** | R *** | DPS | DPM |

|---|---|---|---|---|---|

| PUR_50/Ether/BD | 1.40 | 6.65 | 4.74 | 0.83 | 0.17 |

| PUR_55/Ether/BD | 1.73 | 7.33 | 4.25 | 0.81 | 0.19 |

| PUR_60/Ether/BD | 1.70 | 6.56 | 3.86 | 0.79 | 0.21 |

| PUR_65/Ether/BD | 1.57 | 5.74 | 3.65 | 0.79 | 0.21 |

| PUR_70/Ether/BD | 1.79 | 3.94 | 2.20 | 0.69 | 0.31 |

| PUR_70/Carbonate/BD | 10.7 | 7.29 | 0.683 | 0.41 | 0.59 |

| PUR_70/Ester/BD | 13.0 | 5.62 | 0.433 | 0.30 | 0.70 |

| PUR_70/Ester/MOCA | 11.7 | 3.21 + | 0.275 | 0.22 | 0.78 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwiatkowski, K.; Nachman, M. The Abrasive Wear Resistance of the Segmented Linear Polyurethane Elastomers Based on a Variety of Polyols as Soft Segments. Polymers 2017, 9, 705. https://doi.org/10.3390/polym9120705

Kwiatkowski K, Nachman M. The Abrasive Wear Resistance of the Segmented Linear Polyurethane Elastomers Based on a Variety of Polyols as Soft Segments. Polymers. 2017; 9(12):705. https://doi.org/10.3390/polym9120705

Chicago/Turabian StyleKwiatkowski, Konrad, and Małgorzata Nachman. 2017. "The Abrasive Wear Resistance of the Segmented Linear Polyurethane Elastomers Based on a Variety of Polyols as Soft Segments" Polymers 9, no. 12: 705. https://doi.org/10.3390/polym9120705