Preparation of Esterified Bacterial Cellulose for Improved Mechanical Properties and the Microstructure of Isotactic Polypropylene/Bacterial Cellulose Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

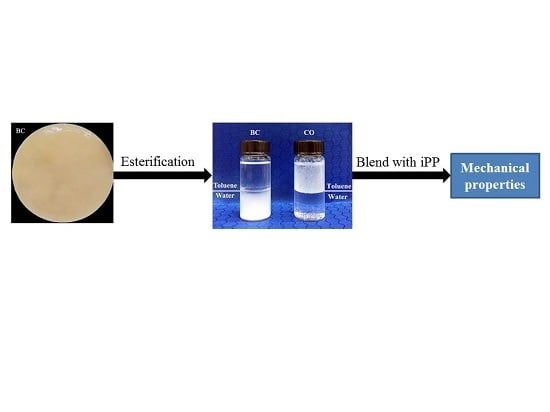

2.2. Preparation of CO

2.3. Characterization of CO

2.4. Preparation of the iPP/BC and the iPP/CO Composites

2.5. Mechanical Test

2.6. Scanning Electron Microscopy

3. Results and Discussion

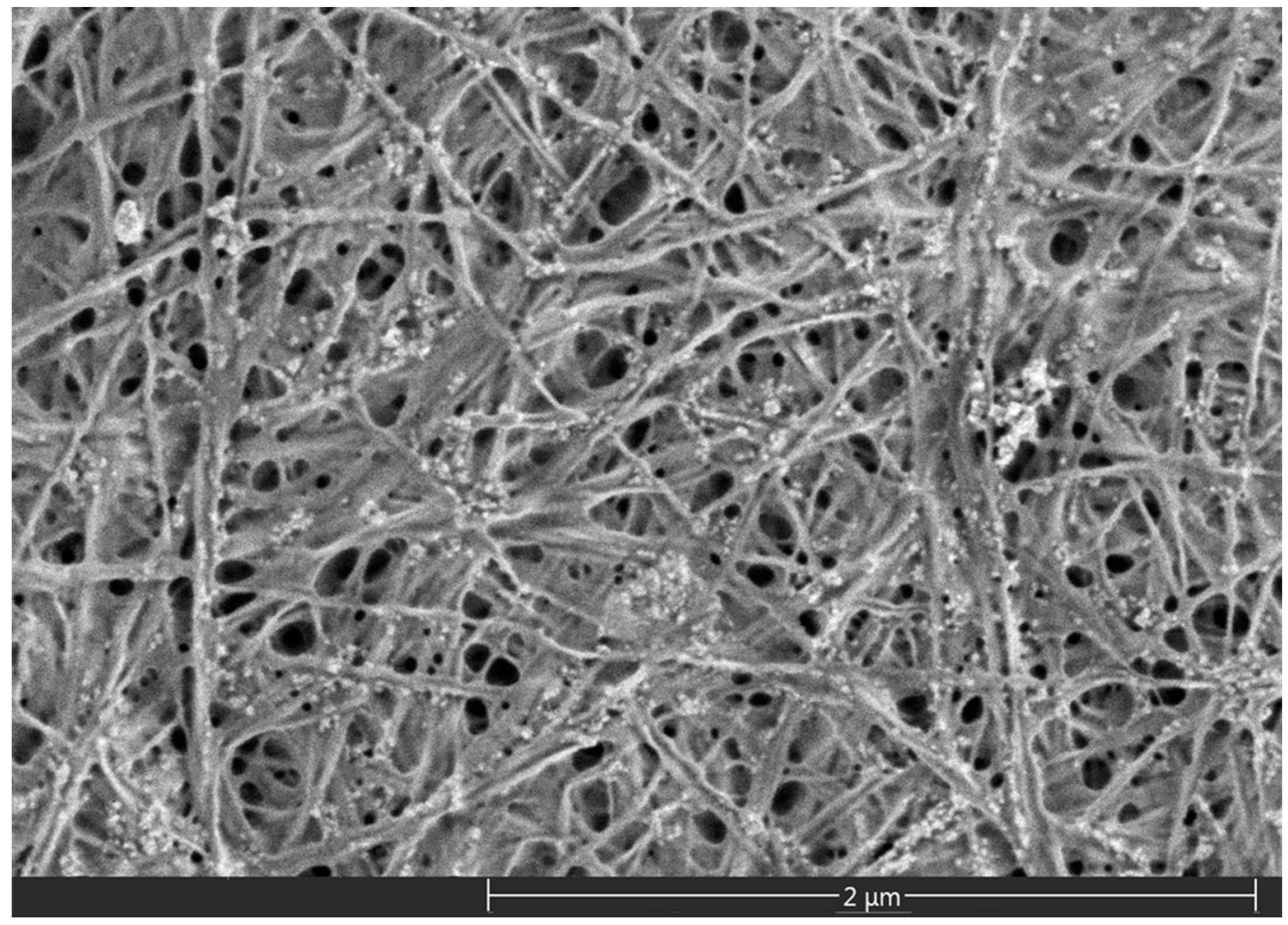

3.1. Characterization of CO

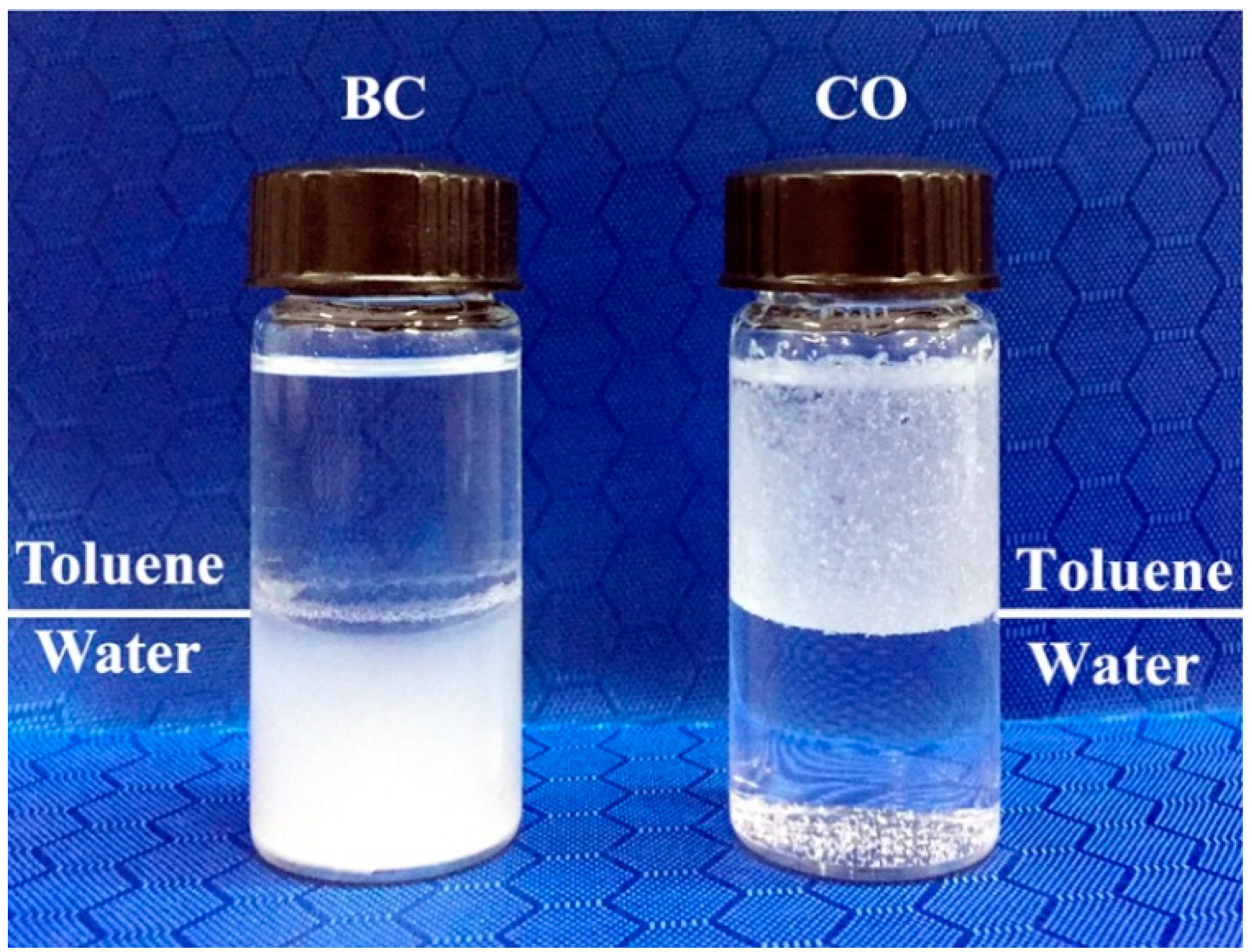

3.1.1. Infiltration of BC and CO

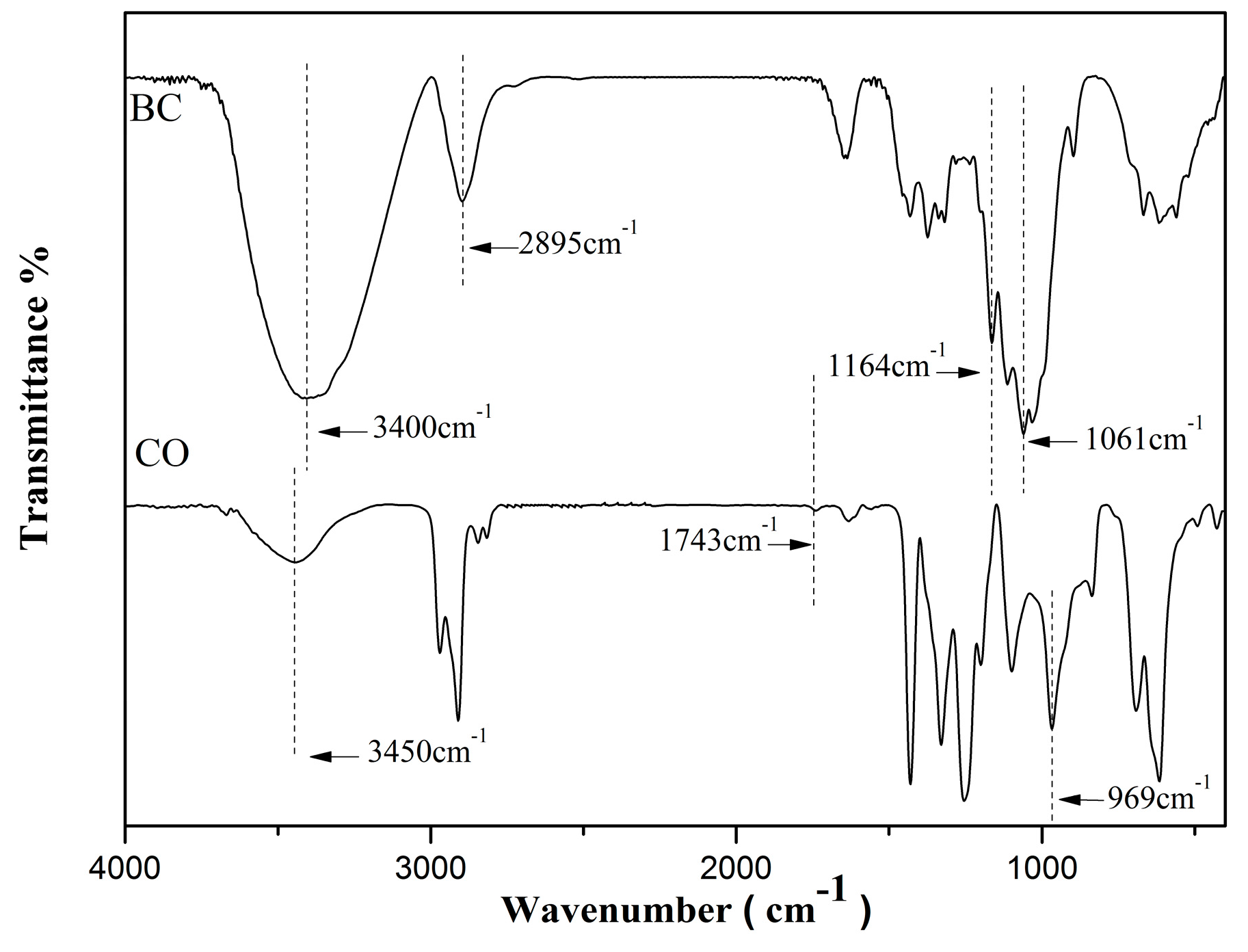

3.1.2. FT-IR Spectra of BC and CO

3.1.3. X-ray Analysis of BC and CO

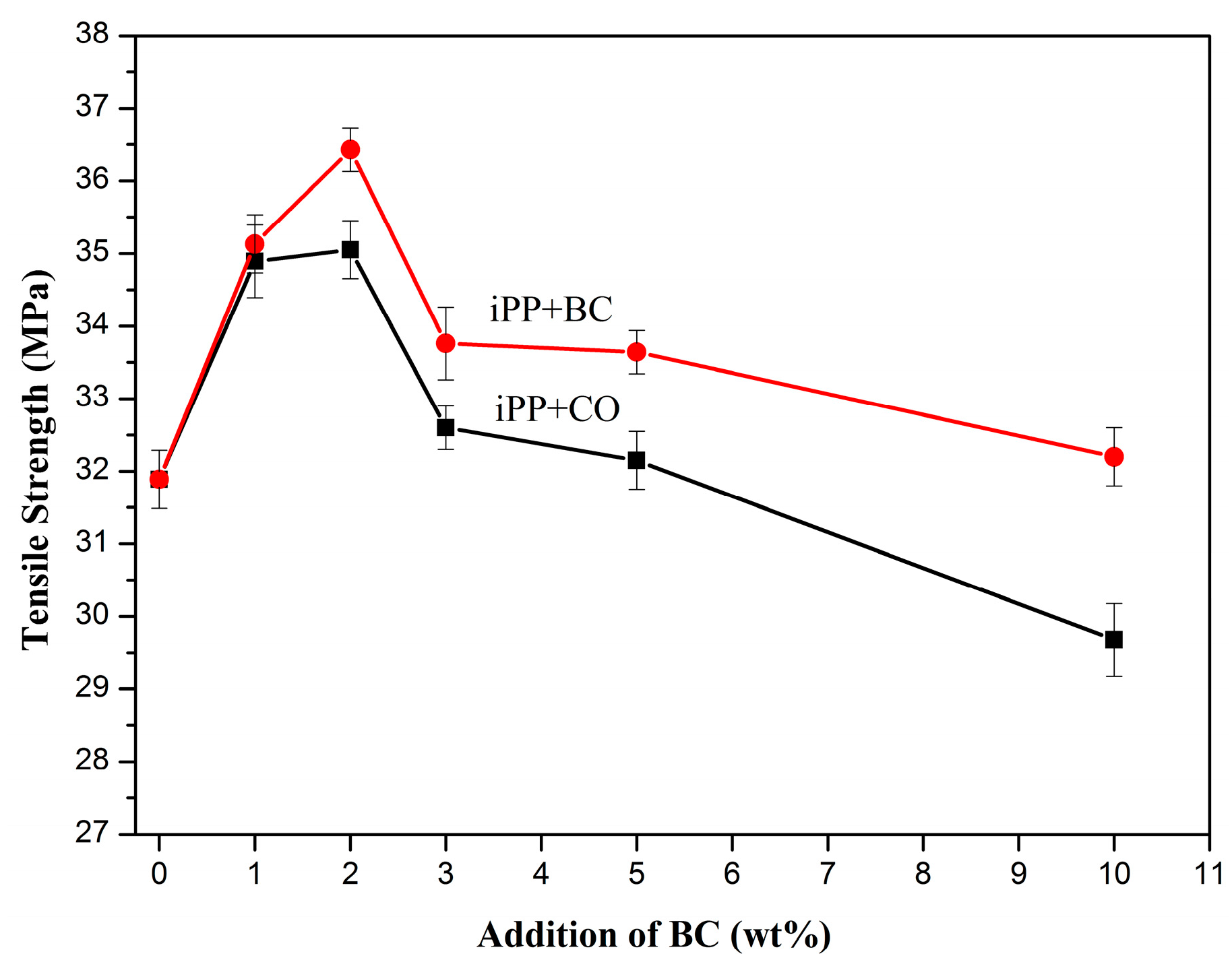

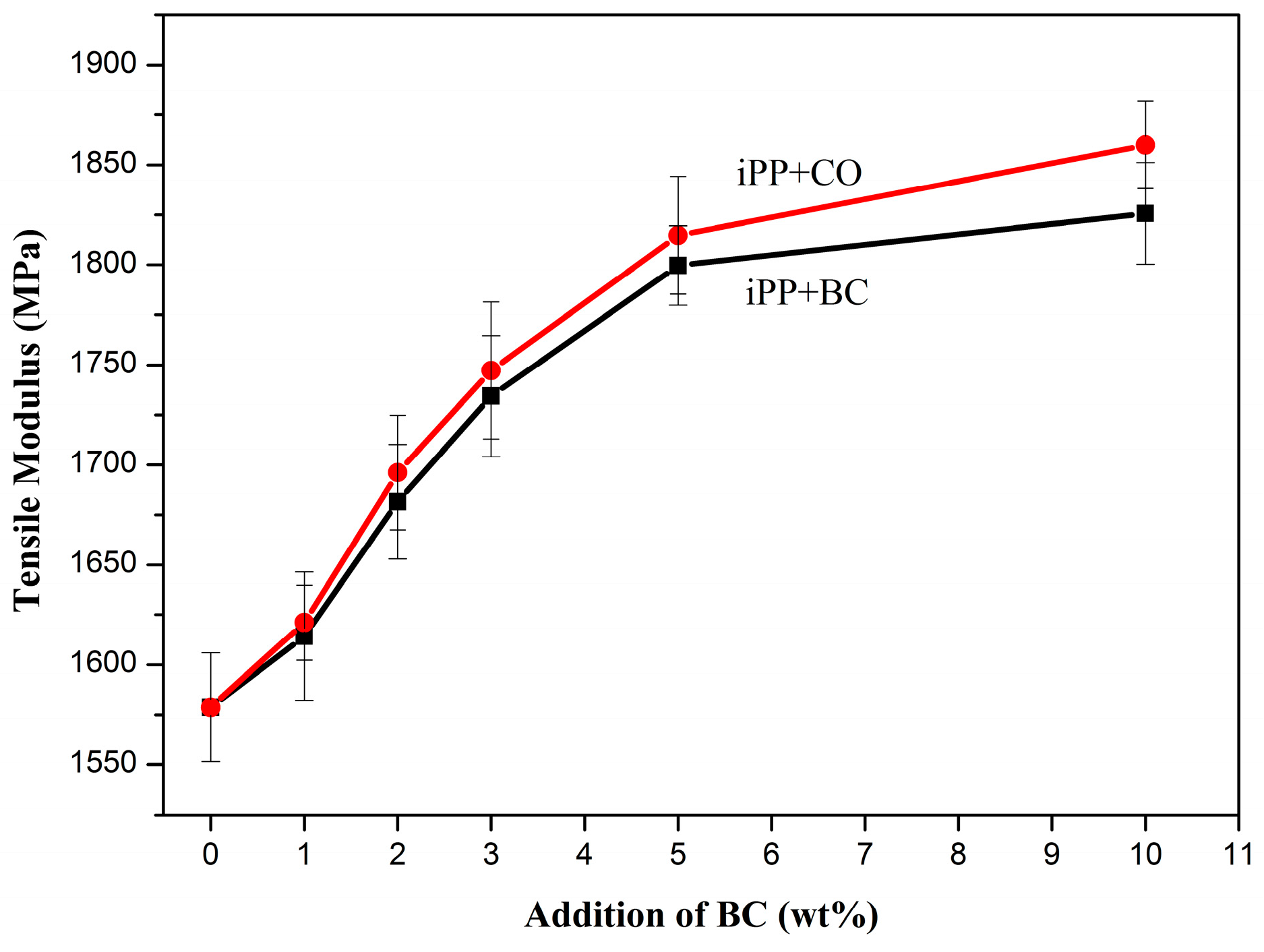

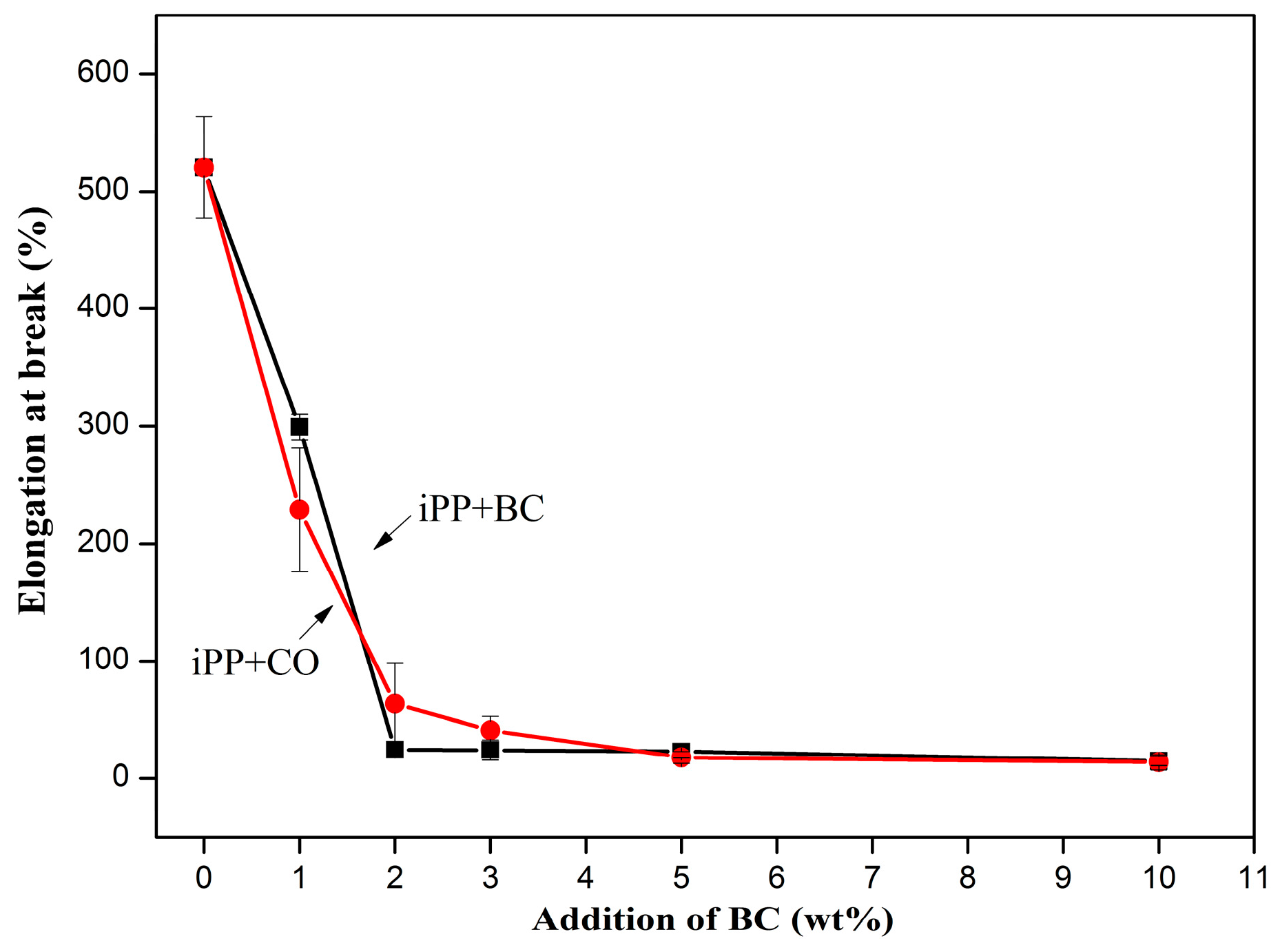

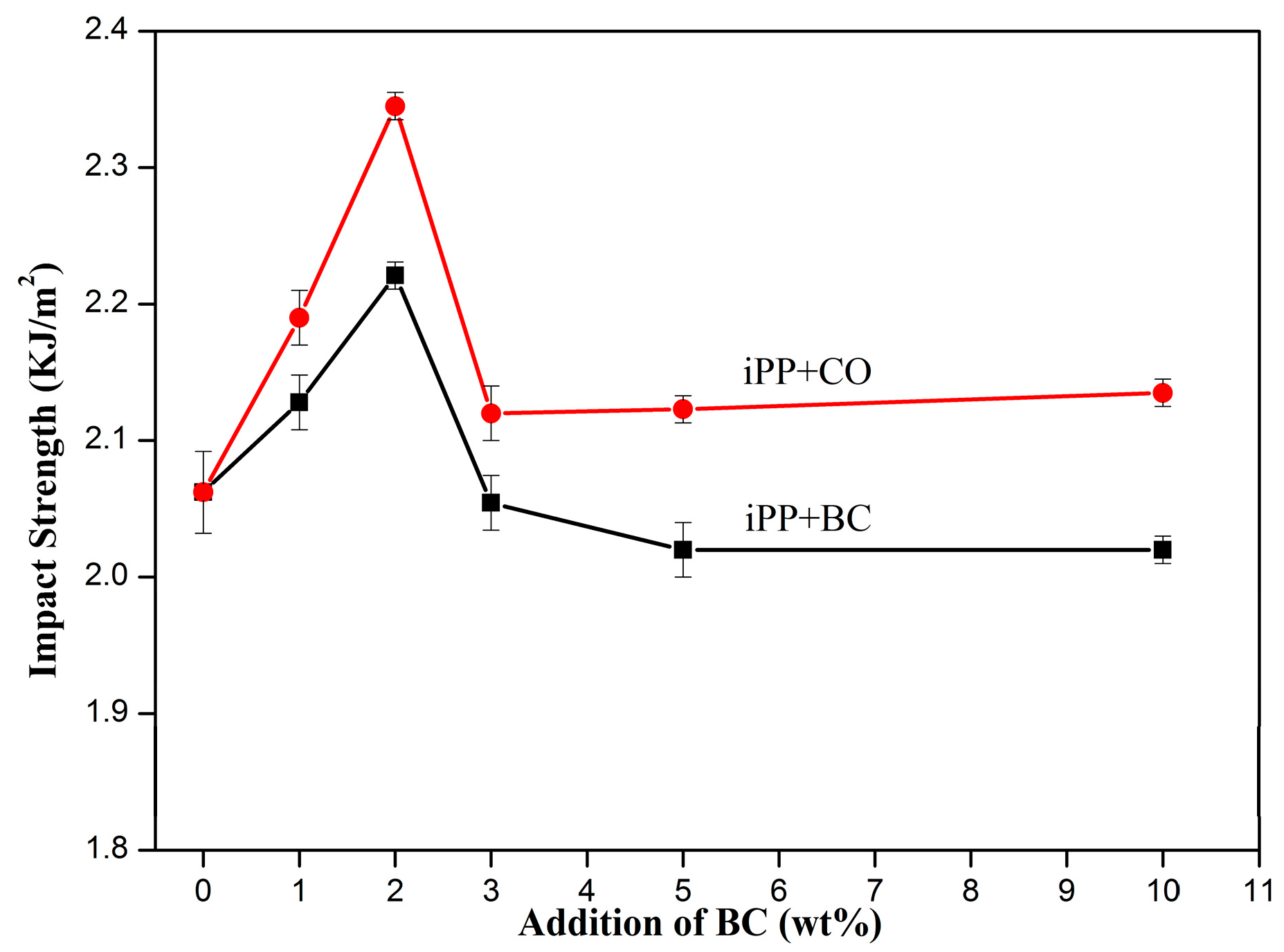

3.2. Mechanical Properties of the Composites

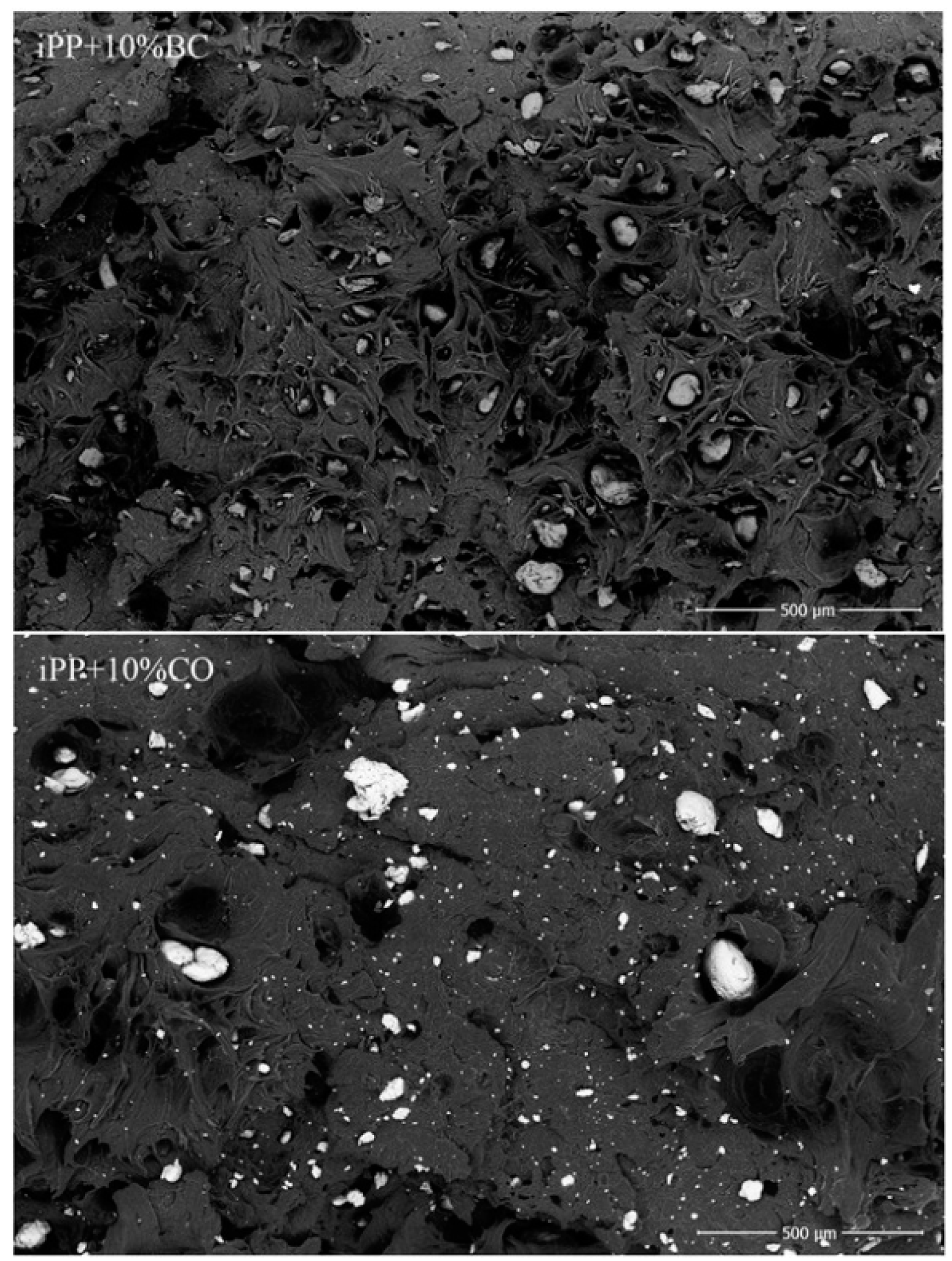

3.3. Scanning Electron Microscopy Observations

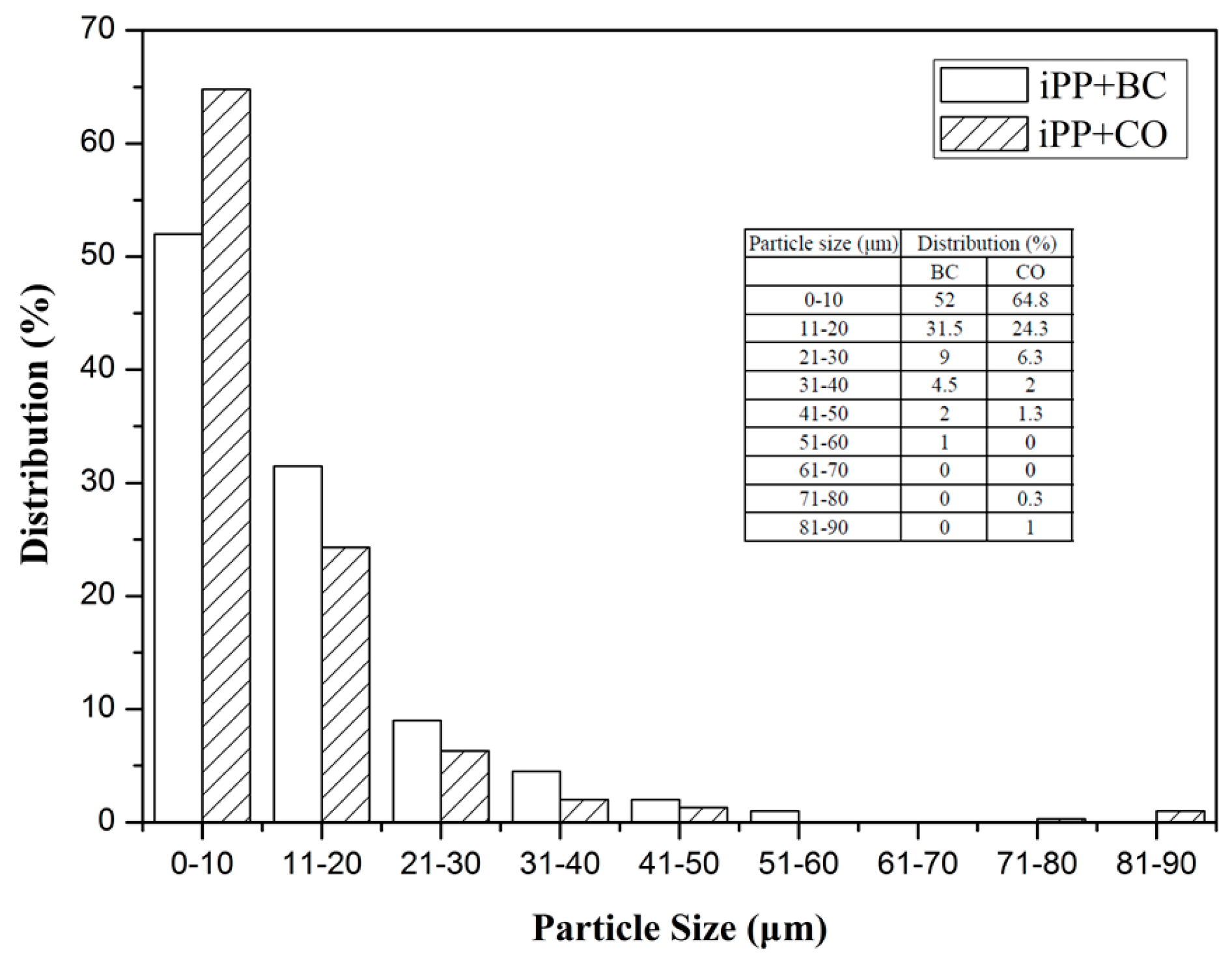

3.4. Particle Size Distribution of Bacterial Cellulose (BC) or Cellulose Octoate (CO) in the iPP Matrix

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kontopoulou, M.; Wang, W.; Gopakumar, T.; Cheung, C. Effect of composition and comonomer type on the rheology, morphology and properties of ethylene-α-olefin copolymer/polypropylene blends. Polymer 2003, 44, 7495–7504. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. New insight into lamellar branching of β-nucleated isotactic polypropylene upon melt-stretching: Waxd and saxs study. J. Mater. Sci. 2015, 50, 599–604. [Google Scholar] [CrossRef]

- Van der Wal, A.; Nijhof, R.; Gaymans, R. Polypropylene–rubber blends: 2. The effect of the rubber content on the deformation and impact behaviour. Polymer 1999, 40, 6031–6044. [Google Scholar] [CrossRef]

- Weng, W.; Hu, W.; Dekmezian, A.H.; Ruff, C.J. Long chain branched isotactic polypropylene. Macromolecules 2002, 35, 3838–3843. [Google Scholar] [CrossRef]

- Liang, J.; Li, R. Rubber toughening in polypropylene: A review. J. Appl. Polym. Sci. 2000, 77, 409–417. [Google Scholar] [CrossRef]

- Chan, C.-M.; Wu, J.; Li, J.-X.; Cheung, Y.-K. Polypropylene/calcium carbonate nanocomposites. Polymer 2002, 43, 2981–2992. [Google Scholar] [CrossRef]

- Qin, H.; Zhang, S.; Liu, H.; Xie, S.; Yang, M.; Shen, D. Photo-oxidative degradation of polypropylene/montmorillonite nanocomposites. Polymer 2005, 46, 3149–3156. [Google Scholar] [CrossRef]

- Yachmenev, V.; Parikh, D.; Calamari, T. Thermal insulation properties of biodegradable, cellulosic-based nonwoven composites for automotive application. J. Ind. Text. 2002, 31, 283–296. [Google Scholar] [CrossRef]

- Huang, C.; Yang, X.-Y.; Xiong, L.; Guo, H.-J.; Luo, J.; Wang, B.; Zhang, H.-R.; Lin, X.-Q.; Chen, X.-D. Utilization of corncob acid hydrolysate for bacterial cellulose production by gluconacetobacter xylinus. Appl. Biochem. Biotechnol. 2015, 175, 1678–1688. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Luo, H.; He, F.; Liang, H.; Huang, Y.; Li, X. Mechanical, moisture absorption, and biodegradation behaviours of bacterial cellulose fibre-reinforced starch biocomposites. Compos. Sci. Technol. 2009, 69, 1212–1217. [Google Scholar] [CrossRef]

- Wang, J.; Jia, H.; Zhang, J.; Ding, L.; Huang, Y.; Sun, D.; Gong, X. Bacterial cellulose whisker as a reinforcing filler for carboxylated acrylonitrile-butadiene rubber. J. Mater. Sci. 2014, 49, 6093–6101. [Google Scholar] [CrossRef]

- Jang, B.Z.; Uhlmann, D.R.; Vander Sande, J.B. Ductile–brittle transition in polymers. J. Appl. Polym. Sci. 1984, 29, 3409–3420. [Google Scholar] [CrossRef]

- Pang, Y.; Dong, X.; Zhao, Y.; Han, C.C.; Wang, D. Time evolution of phase structure and corresponding mechanical properties of iPP/PEOC blends in the late-stage phase separation and crystallization. Polymer 2007, 48, 6395–6403. [Google Scholar] [CrossRef]

- Cai, X.; Riedl, B.; Ait-Kadi, A. Cellulose fiber/poly (ethylene-co-methacrylic acid) composites with ionic interphase. Compos. Part A: Appl. Sci. Manuf. 2003, 34, 1075–1084. [Google Scholar] [CrossRef]

- Canche-Escamilla, G.; Rodriguez-Laviada, J.; Cauich-Cupul, J.; Mendizabal, E.; Puig, J.; Herrera-Franco, P. Flexural, impact and compressive properties of a rigid-thermoplastic matrix/cellulose fiber reinforced composites. Compos. Part A: Appl. Sci. Manuf. 2002, 33, 539–549. [Google Scholar] [CrossRef]

- Samyn, P. Wetting and hydrophobic modification of cellulose surfaces for paper applications. J. Mater. Sci. 2013, 48, 6455–6498. [Google Scholar] [CrossRef]

- Antova, G.; Vasvasova, P.; Zlatanov, M. Studies upon the synthesis of cellulose stearate under microwave heating. Carbohydr. Polym. 2004, 57, 131–134. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, W.-T.; Wang, X.-L.; Li, B.; Wang, Y.-Z. Green synthesis of a novel biodegradable copolymer base on cellulose and poly (p-dioxanone) in ionic liquid. Carbohydr. Polym. 2009, 76, 139–144. [Google Scholar] [CrossRef]

- Liu, Z.-T.; Fan, X.; Wu, J.; Zhang, L.; Song, L.; Gao, Z.; Dong, W.; Xiong, H.; Peng, Y.; Tang, S. A green route to prepare cellulose acetate particle from ramie fiber. React. Funct. Polym. 2007, 67, 104–112. [Google Scholar] [CrossRef]

- Heo, Y.H.; Jeon, S.-C.; Fisher, J.G.; Choi, S.-Y.; Hur, K.-H.; Kang, S.-J.L. Effect of step free energy on delayed abnormal grain growth in a liquid phase-sintered batio 3 model system. J. Eur. Ceram. Soc. 2011, 31, 755–762. [Google Scholar] [CrossRef]

- Yang, X.Y.; Huang, C.; Guo, H.J.; Xiong, L.; Luo, J.; Wang, B.; Lin, X.Q.; Chen, X.F.; Chen, X.D. Bacterial cellulose production from the litchi extract by Gluconacetobacter xylinus. Prep. Biochem. Biotechnol. 2016, 46, 39–43. [Google Scholar] [CrossRef] [PubMed]

- Trejo-o'reilly, J.-A.; Cavaille, J.-Y.; Gandini, A. The surface chemical modification of cellulosic fibres in view of their use in composite materials. Cellulose 1997, 4, 305–320. [Google Scholar] [CrossRef]

- Mähner, C.; Lechner, M.D.; Nordmeier, E. Synthesis and characterisation of dextran and pullulan sulphate. Carbohydr. Res. 2001, 331, 203–208. [Google Scholar] [CrossRef]

- Watanabe, S.; Hayashi, J.; Akahori, T. Molecular chain conformation and crystallite structure of cellulose. I. Fine structure of rayon fibers. J. Polym. Sci.: Polym. Chem. Ed. 1974, 12, 1065–1087. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.; Modak, J.M.; Chanda, M. Mechanical properties of wood–fiber reinforced polypropylene composites: Effect of a novel compatibilizer with isocyanate functional group. Compos. Part A: Appl. Sci. Manuf. 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Bledzki, A.; Gassan, J. Composites reinforced with cellulose based fibres. Progr. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Felix, J.M.; Gatenholm, P. The nature of adhesion in composites of modified cellulose fibers and polypropylene. J. Appl. Polym. Sci. 1991, 42, 609–620. [Google Scholar] [CrossRef]

- Haward, R.; Bucknall, C. The provision of toughness in one and two phase polymers. Pure Appl. Chem. 1976, 46, 227–238. [Google Scholar] [CrossRef]

- Jang, B.; Uhlmann, D.; Vander Sande, J. Ductile–brittle transition in polymers. J. Appl. Polym. Sci. 1984, 29, 3409–3420. [Google Scholar] [CrossRef]

- Wu, S. Impact fracture mechanisms in polymer blends: Rubber-toughened nylon. J. Polym. Sci.: Polym. Phys. Ed. 1983, 21, 699–716. [Google Scholar] [CrossRef]

- Hristov, V.; Lach, R.; Grellmann, W. Impact fracture behavior of modified polypropylene/wood fiber composites. Polym. Test. 2004, 23, 581–589. [Google Scholar] [CrossRef]

- Supaphol, P.; Harnsiri, W.; Junkasem, J. Effects of calcium carbonate and its purity on crystallization and melting behavior, mechanical properties, and processability of syndiotactic polypropylene. J. Appl. Polym. Sci. 2004, 92, 201–212. [Google Scholar] [CrossRef]

- Zuiderduin, W.; Westzaan, C.; Huetink, J.; Gaymans, R. Toughening of polypropylene with calcium carbonate particles. Polymer 2003, 44, 261–275. [Google Scholar] [CrossRef]

- Gent, A. Detachment of an elastic matrix from a rigid spherical inclusion. J. Mater. Sci. 1980, 15, 2884–2888. [Google Scholar] [CrossRef]

- Needleman, A. A continuum model for void nucleation by inclusion debonding. J. Appl. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Gent, A.; Park, B. Failure processes in elastomers at or near a rigid spherical inclusion. J. Mater. Sci. 1984, 19, 1947–1956. [Google Scholar] [CrossRef]

| Sample | Isotactic Polypropylene (iPP) (wt %) | Bacterial Cellulose (BC) (wt %) | Cellulose Octoate (CO) (wt %) |

|---|---|---|---|

| iPP | 100 | – | – |

| iPP + 1% BC | 100 | 1 | – |

| iPP + 2% BC | 100 | 2 | – |

| iPP + 3% BC | 100 | 3 | – |

| iPP + 5% BC | 100 | 5 | – |

| iPP + 10% BC | 100 | 10 | – |

| iPP + 1% CO | 100 | – | 1 |

| iPP + 2% CO | 100 | – | 2 |

| iPP + 3% CO | 100 | – | 3 |

| iPP + 5% CO | 100 | – | 5 |

| iPP + 10% CO | 100 | – | 10 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Yang, D.; Zhang, H.-r.; Huang, C.; Xiong, L.; Luo, J.; Chen, X.-d. Preparation of Esterified Bacterial Cellulose for Improved Mechanical Properties and the Microstructure of Isotactic Polypropylene/Bacterial Cellulose Composites. Polymers 2016, 8, 129. https://doi.org/10.3390/polym8040129

Wang B, Yang D, Zhang H-r, Huang C, Xiong L, Luo J, Chen X-d. Preparation of Esterified Bacterial Cellulose for Improved Mechanical Properties and the Microstructure of Isotactic Polypropylene/Bacterial Cellulose Composites. Polymers. 2016; 8(4):129. https://doi.org/10.3390/polym8040129

Chicago/Turabian StyleWang, Bo, Dan Yang, Hai-rong Zhang, Chao Huang, Lian Xiong, Jun Luo, and Xin-de Chen. 2016. "Preparation of Esterified Bacterial Cellulose for Improved Mechanical Properties and the Microstructure of Isotactic Polypropylene/Bacterial Cellulose Composites" Polymers 8, no. 4: 129. https://doi.org/10.3390/polym8040129