Effect of Rubber Nanoparticle Agglomeration on Properties of Thermoplastic Vulcanizates during Dynamic Vulcanization

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Dynamic Vulcanization of EPDM/PP System

2.3. Compression Molding of the Samples

2.4. Characterizations

2.4.1. Degree of Crosslinking of Rubber Phase

2.4.2. Morphology

2.4.3. Crystallinity and Crystal Structures by Wide-Angle X-ray Diffraction (WAXD)

2.4.4. Tensile Properties

2.4.5. Rheological Behavior

3. Results and discussion

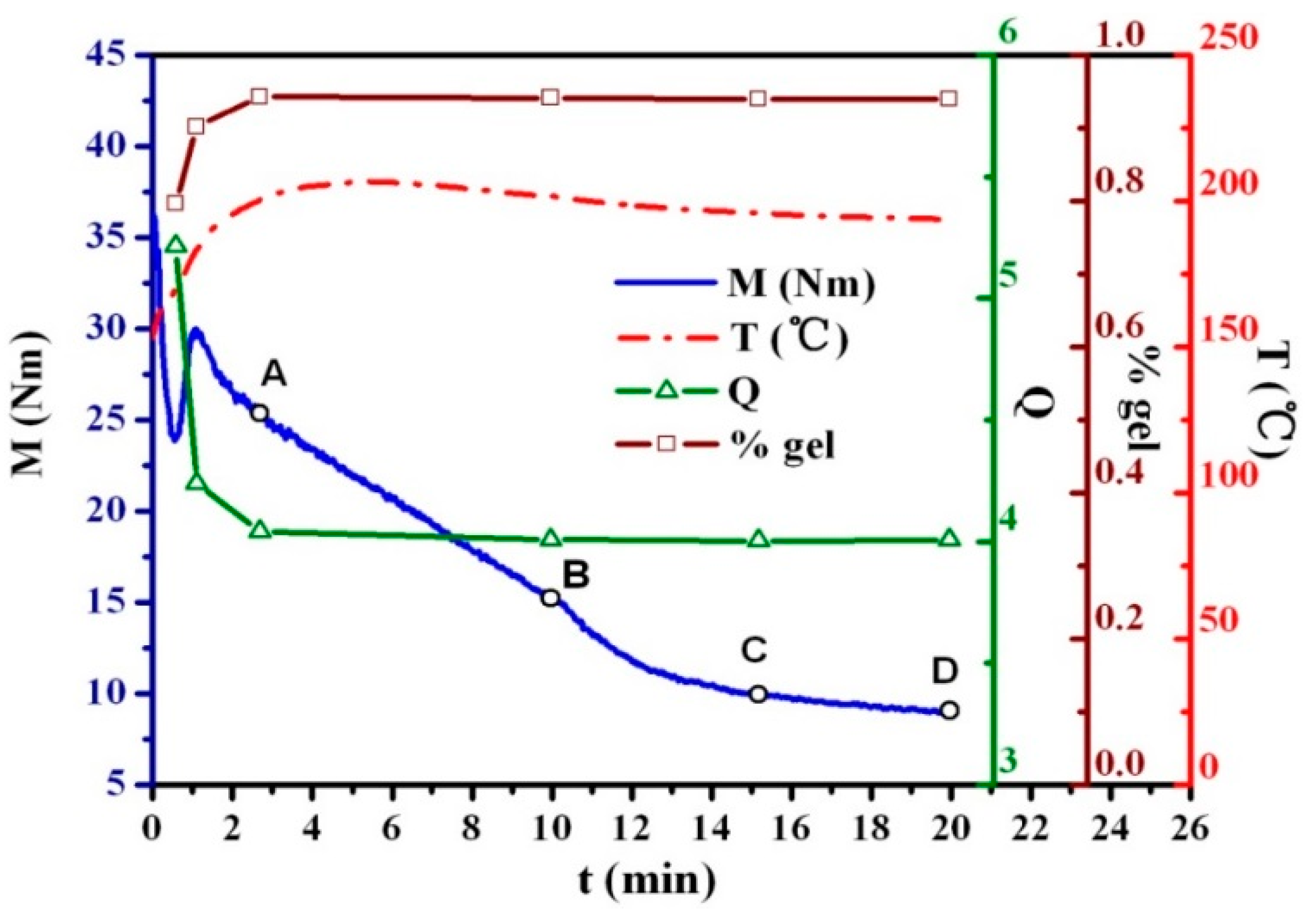

3.1. Evolution of Degree of Crosslinking of TPVs during DV

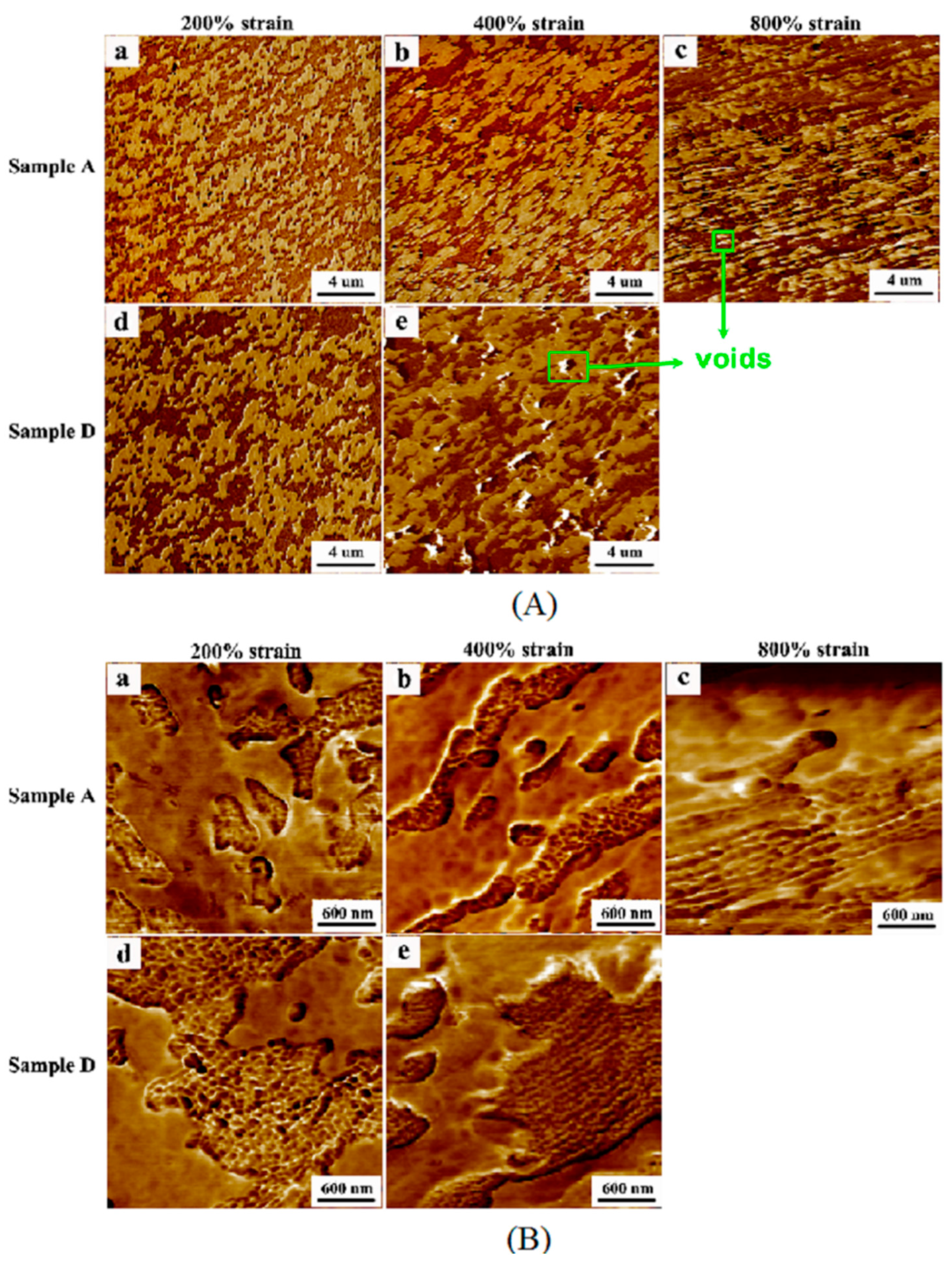

3.2. Evolution of Size of Rubber Agglomerates during DV

3.3. Evolution of Crystal Structure of PP

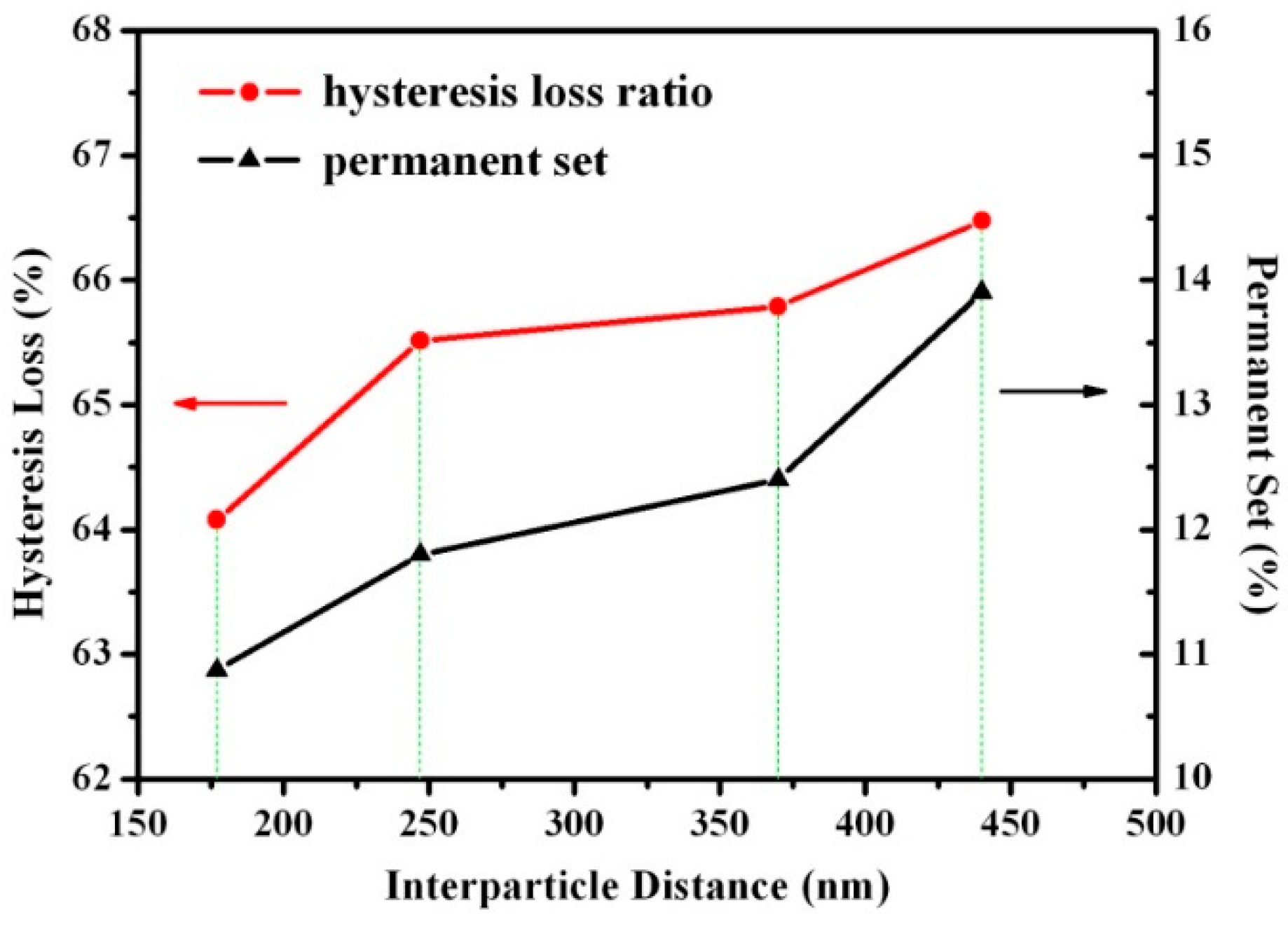

3.4. Effect of Rubber Nanoparticle Agglomerationon Elasticity of TPV

3.5. Effect of Rubber Nanoparticle Agglomeration on Melt Processability

3.6. Effect of Rubber Nanoparticle Agglomeration on Tensile Properties

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Antunes, C.F.; Machado, A.V.; Duin, M.V. Morphology development and phase inversion during dynamic vulcanisation of EPDM/PP blends. Eur. Polym. J. 2011, 47, 1447–1459. [Google Scholar] [CrossRef]

- Duin, M.V. Recent developments for EPDM-based thermoplastic vulcanisates. Macromolecules 2006, 233, 11–16. [Google Scholar]

- Liang, B.; Ji, J.M.; Hong, X.D. Study on mechanical properties of EPDM/HPVC prepared by dynamic vulcanization. Adv. Mater. Res. 2011, 299–300, 751–754. [Google Scholar] [CrossRef]

- Georgeb, S.; Ramamurthyb, K.; Anandb, J.S.; Groeninckxc, G.; Varughesed, K.T. Rheological behaviour of thermoplastic elastomers from polypropylene/acrylonitrile–butadiene rubber blends: Effect of blend ratio, reactive compatibilization and dynamic vulcanization. Polymer 1999, 40, 4325–4344. [Google Scholar] [CrossRef]

- Babu, R.R.; Naskar, K. Recent developments on thermoplastic elastomers by dynamic vulcanization. Adv. Polym. Sci. 2010, 239, 219–247. [Google Scholar]

- Naderi, G.; Lafleur, P.G.; Dubois, C. Microstructure-properties correlations in dynamically vulcanized nanocomposite thermoplastic elastomers based on PP/EPDM. Polym. Eng. Sci. 2007, 47, 207–217. [Google Scholar] [CrossRef]

- Naskar, K.; Babu, R.R. Thermoplastic elastomers (TPEs) and thermoplastic vulcanizates (TPVs). Encycl. Polym. Nanomater. 2015. [Google Scholar] [CrossRef]

- l’Abee Roy, M.A.; Martin, V.D. The rubber particle size to control the properties-processing balance of thermoplastic/cross-linked elastomer blends. Soft Matter 2010, 6, 1758. [Google Scholar] [CrossRef]

- Wu, H.; Ning, N.; Zhang, L.; Ting, H.; Tian, M. New understanding of microstructure formation of the rubber phase in thermoplastic vulcanizates (TPV). Soft Matter 2014, 10, 1816–1822. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Ning, N.; Zhang, L.; Ting, H.; Tian, M. New understanding of morphology evolution of thermoplastic vulcanizate (TPV) during dynamic vulcanization. ACS Sustain. Chem. Eng. 2014, 3, 26–32. [Google Scholar] [CrossRef]

- Mitra, S.; Ghanbari-Siahkali, A.; Kingshott, P.; Rehmeier, H.K.; Abildgaard, H.; Almdal, K. Chemical degradation of crosslinked ethylene-propylene-diene rubber in an acidic environment. Part I. Effect on accelerated sulphur crosslinks. Polym. Degrad. Stabil. 2006, 91, 69–80. [Google Scholar] [CrossRef]

- Vennemann, N.; Bökamp, K.; Bröker, D. Crosslink density of peroxide cured TPV. Macromol. Symp. 2006, 245, 641–650. [Google Scholar] [CrossRef]

- Legrand, D. Domain formation in block copolymers. J. Polym. Sci. Part B: Polym. Phys. 1970, 8, 195–198. [Google Scholar] [CrossRef]

- Coran, A.Y.; Patel, R. Thermoplastic rubber blends comprising crystalline polyolefin, vulcanized mono-olefin rubber and vulcanized nitrile rubber. US Patents 4409365, 11 October 1983. [Google Scholar]

- Liu, J.; Lu, Y.; Tian, M.; Zhang, L. Thermoplastic elastomeric (TPE) materials and their use in outdoor electrical insulation. Rev. Adv. Mater. Sci. 2011, 29, 15–30. [Google Scholar]

- Gallot, B.R. Preparation and study of block copolymers with ordered structures. In Structure and Properties of Polymers; Springer: Orleans, France, 1978; pp. 85–156. [Google Scholar]

- Tian, M.; Li, T.; Zhang, L.; Tian, H.; Wu, Y.; Ning, N. Interfacial crystallization and its mechanism in in situ dynamically vulcanized iPP/POE blends. Polymer 2014, 55, 3068–3074. [Google Scholar] [CrossRef]

- Oderkerk, D.; Goderis, B.; Hellemans, L.; Groeninckx, G. Micromechanical Deformation and recovery processes of nylon-6/rubber thermoplastic vulcanizates as studied by atomic force microscopy and transmission electron microscopy. Macromolecules 2002, 35, 6623–6629. [Google Scholar] [CrossRef]

- Legge, N.R. Thermoplastic elastomers. Rubber Chem. Technol. 1987, 60, 83–117. [Google Scholar] [CrossRef]

- Coran, A.; Patel, R. Rubber-thermoplastic compositions. Part VII. Chlorinated polyethylene rubber-nylon compositions. Rubber Chem. Technol. 1983, 56, 210–225. [Google Scholar] [CrossRef]

- Merker, R.L.; Scott, M.J. Preparation and properties of poly(tetramethyl-p-silphenylene-siloxane). J. Polym. Sci. Part A: General Papers 1964, 2, 15–29. [Google Scholar] [CrossRef]

- Mary, C.B.; Socrate, S.; Kear, K.; Yeh, O. Micromechanisms of deformation and recovery in thermoplastic vulcanizates. J. Mech. Phys. Solids 2001, 49, 1323–1342. [Google Scholar]

- Mary, C.B.; Kear, K.; Socrate, S.; Shaw, K. Vulcanization: conventional and dynamic. Rubber Chem. Technol. 1995, 68, 351–375. [Google Scholar]

- Rajeev, R.; De, S. Thermoplastic elastomers based on waste rubber and plastics. Rubber Chem. Technol. 2004, 77, 569–578. [Google Scholar] [CrossRef]

- Brydson, J.A. Thermoplastic Elastomers: Properties and Applications; RAPRA Technology Ltd.: Shropshire, UK, 1995. [Google Scholar]

- Goharpey, F.; Nazockdast, H.; Katbab, A. Relationship between the rheology and morphology of dynamically vulcanized thermoplastic elastomers based on EPDM/PP. Polym. Eng. Sci. 2005, 45, 84–94. [Google Scholar] [CrossRef]

- Antunes, C.; Machado, A.; van Duin, M. Degradation of the rubber network during dynamic vulcanization of EPDM/PP blends using phenolic resol. Rubber Chem. Technol. 2009, 8, 492–505. [Google Scholar] [CrossRef]

- Corte, L.; Leibler, L. A model for toughening of semicrystalline polymers. Macromolecules 2007, 40, 5606–5611. [Google Scholar] [CrossRef]

- Junior, D.; Nei, S.; Forte, M.M.; Riegel, I.C. Thermal and rheological behavior of reactive blends from metallocene olefin elastomers and polypropylene. Polymer 2012, 22, 213–219. [Google Scholar]

| Number | dn (µm) | dv (µm) | PDI | IDpoly (µm) |

|---|---|---|---|---|

| Sample A | 0.53 ± 0.11 | 0.70 | 1.31 | 0.12 |

| Sample B | 0.72 ± 0.25 | 0.91 | 1.26 | 0.16 |

| Sample C | 1.46 ± 0.24 | 1.58 | 1.08 | 0.31 |

| Sample D | 1.96 ± 0.22 | 2.09 | 1.06 | 0.41 |

| Number | Xc (%) | Xα (%) | Xβ (%) |

|---|---|---|---|

| Sample A | 42.4 ± 1.3 | 37.7 | 4.7 |

| Sample B | 43.6 ± 0.9 | 41.5 | 2.1 |

| Sample C | 42.7 ± 1.2 | 41.8 | 0.9 |

| Sample D | 42.3 ± 2.1 | 41.5 | 0.8 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Tian, M.; Zhang, L.; Tian, H.; Wu, Y.; Ning, N.; Hu, G.-H. Effect of Rubber Nanoparticle Agglomeration on Properties of Thermoplastic Vulcanizates during Dynamic Vulcanization. Polymers 2016, 8, 127. https://doi.org/10.3390/polym8040127

Wu H, Tian M, Zhang L, Tian H, Wu Y, Ning N, Hu G-H. Effect of Rubber Nanoparticle Agglomeration on Properties of Thermoplastic Vulcanizates during Dynamic Vulcanization. Polymers. 2016; 8(4):127. https://doi.org/10.3390/polym8040127

Chicago/Turabian StyleWu, Hanguang, Ming Tian, Liqun Zhang, Hongchi Tian, Youping Wu, Nanying Ning, and Guo-Hua Hu. 2016. "Effect of Rubber Nanoparticle Agglomeration on Properties of Thermoplastic Vulcanizates during Dynamic Vulcanization" Polymers 8, no. 4: 127. https://doi.org/10.3390/polym8040127

APA StyleWu, H., Tian, M., Zhang, L., Tian, H., Wu, Y., Ning, N., & Hu, G.-H. (2016). Effect of Rubber Nanoparticle Agglomeration on Properties of Thermoplastic Vulcanizates during Dynamic Vulcanization. Polymers, 8(4), 127. https://doi.org/10.3390/polym8040127