Material Evaluation and Process Optimization of CNT-Coated Polymer Powders for Selective Laser Sintering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Material Characterization and Numerical Evaluation

2.3. Selective Laser Sintering

3. Results and Discussion

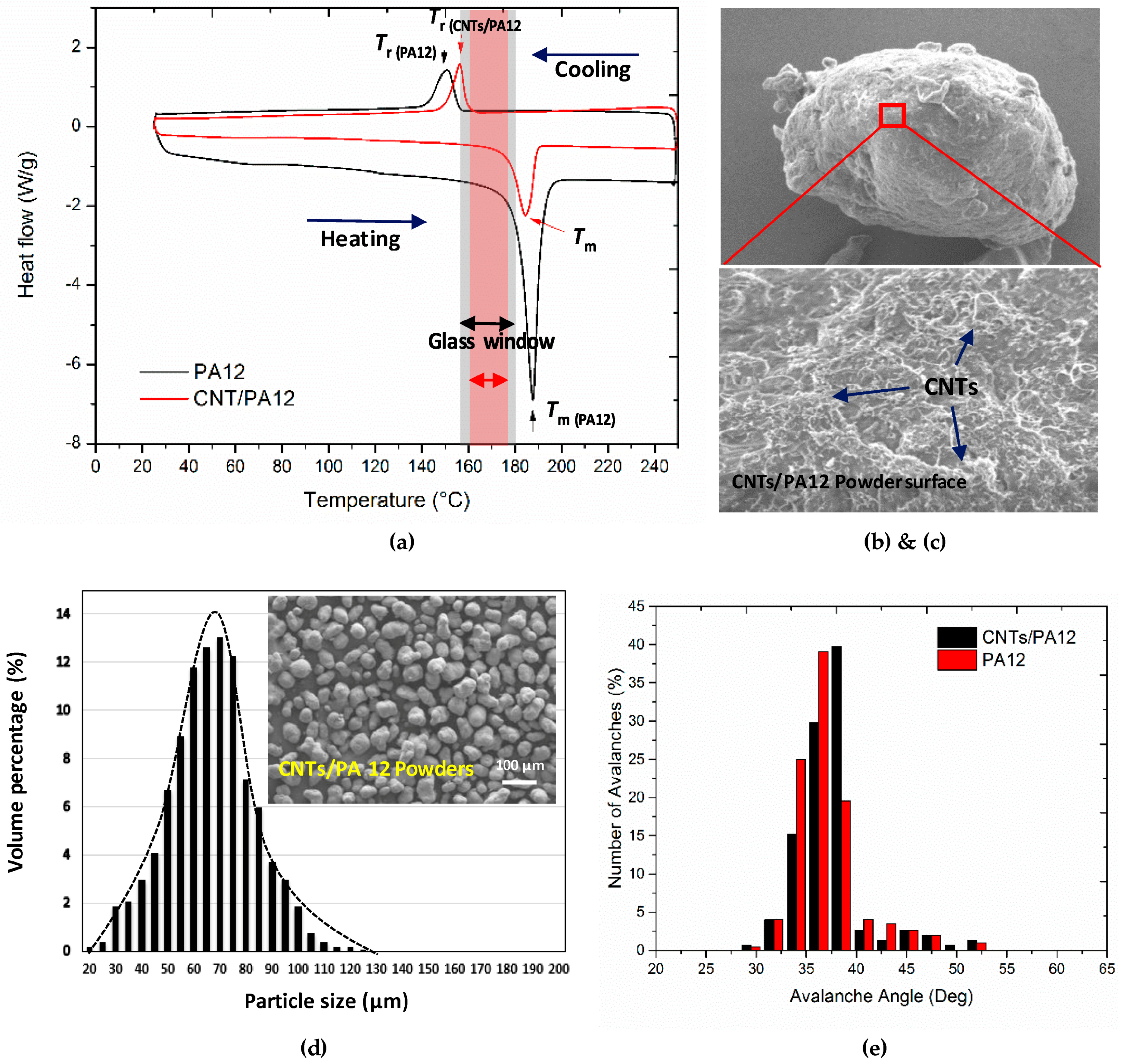

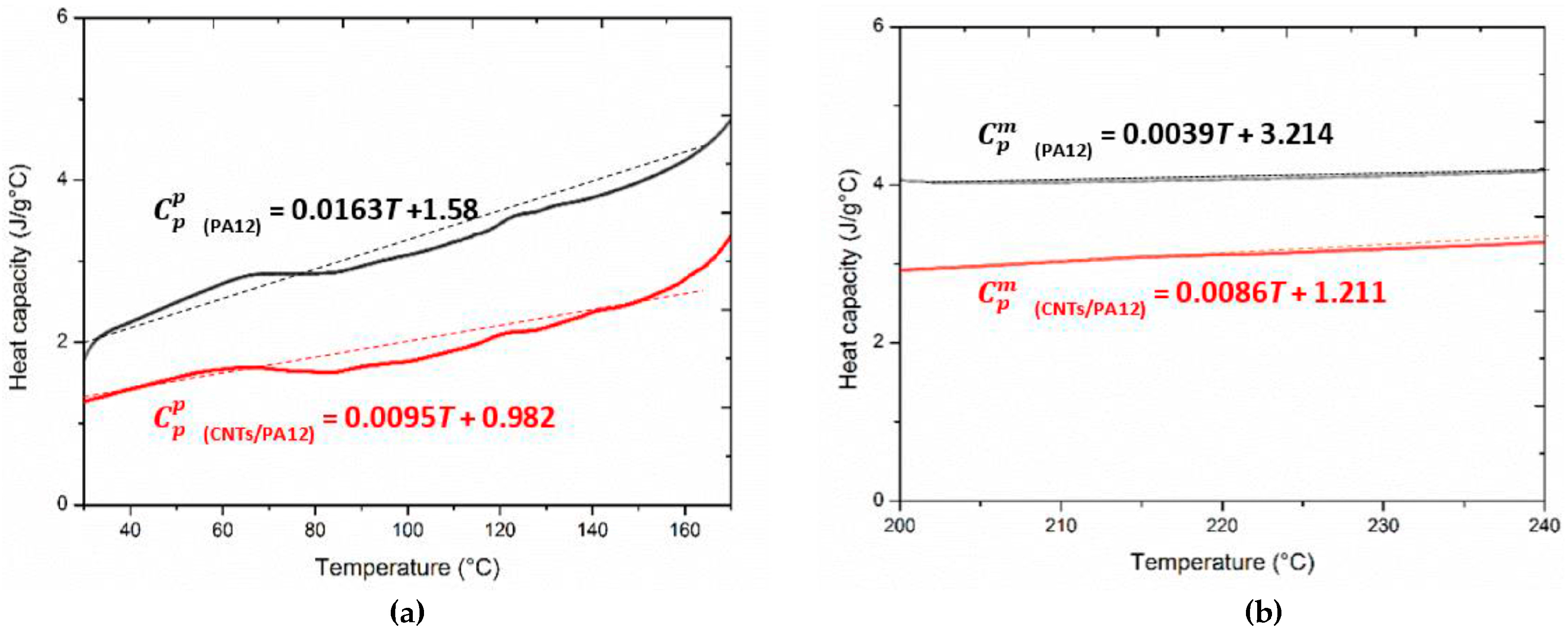

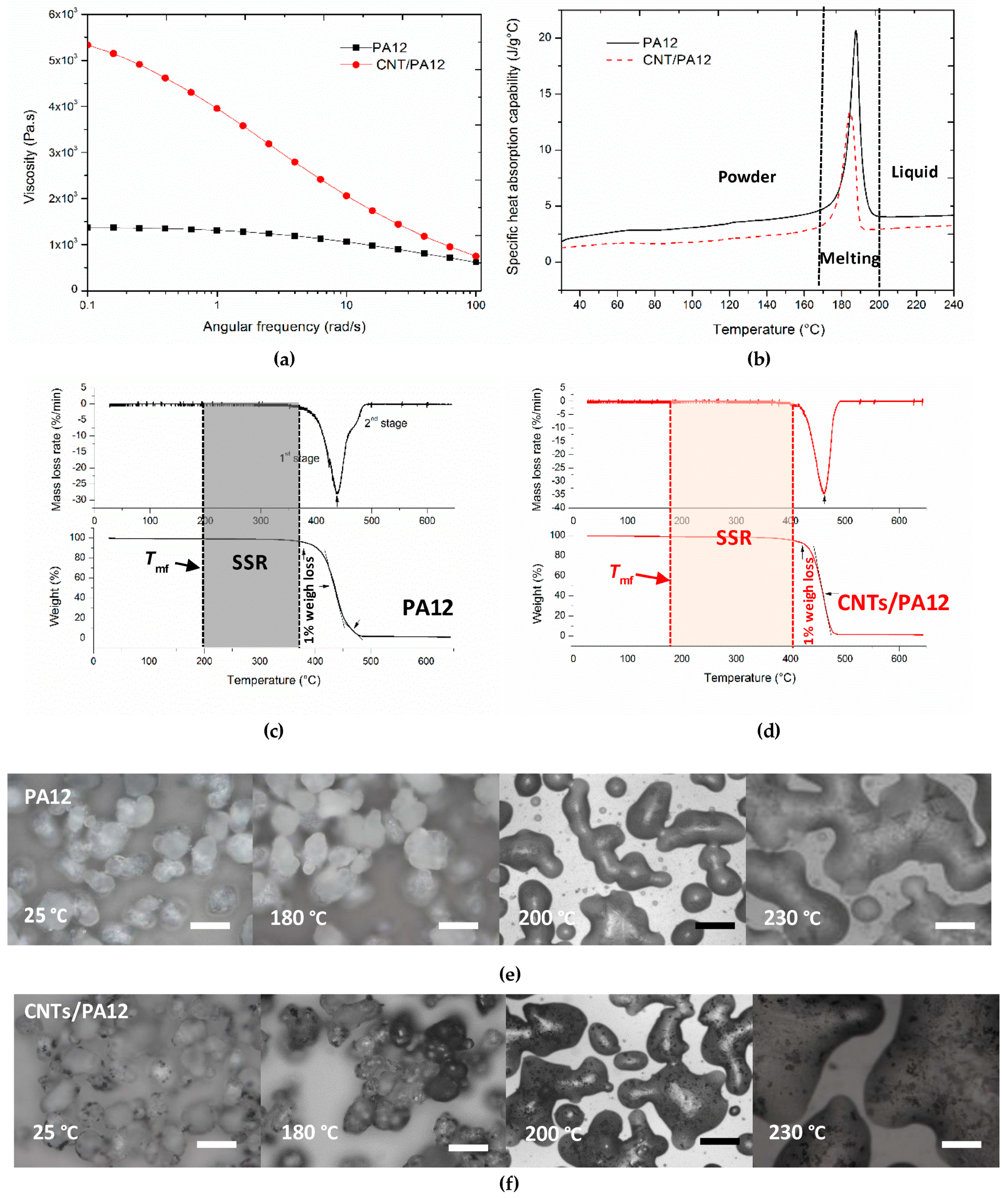

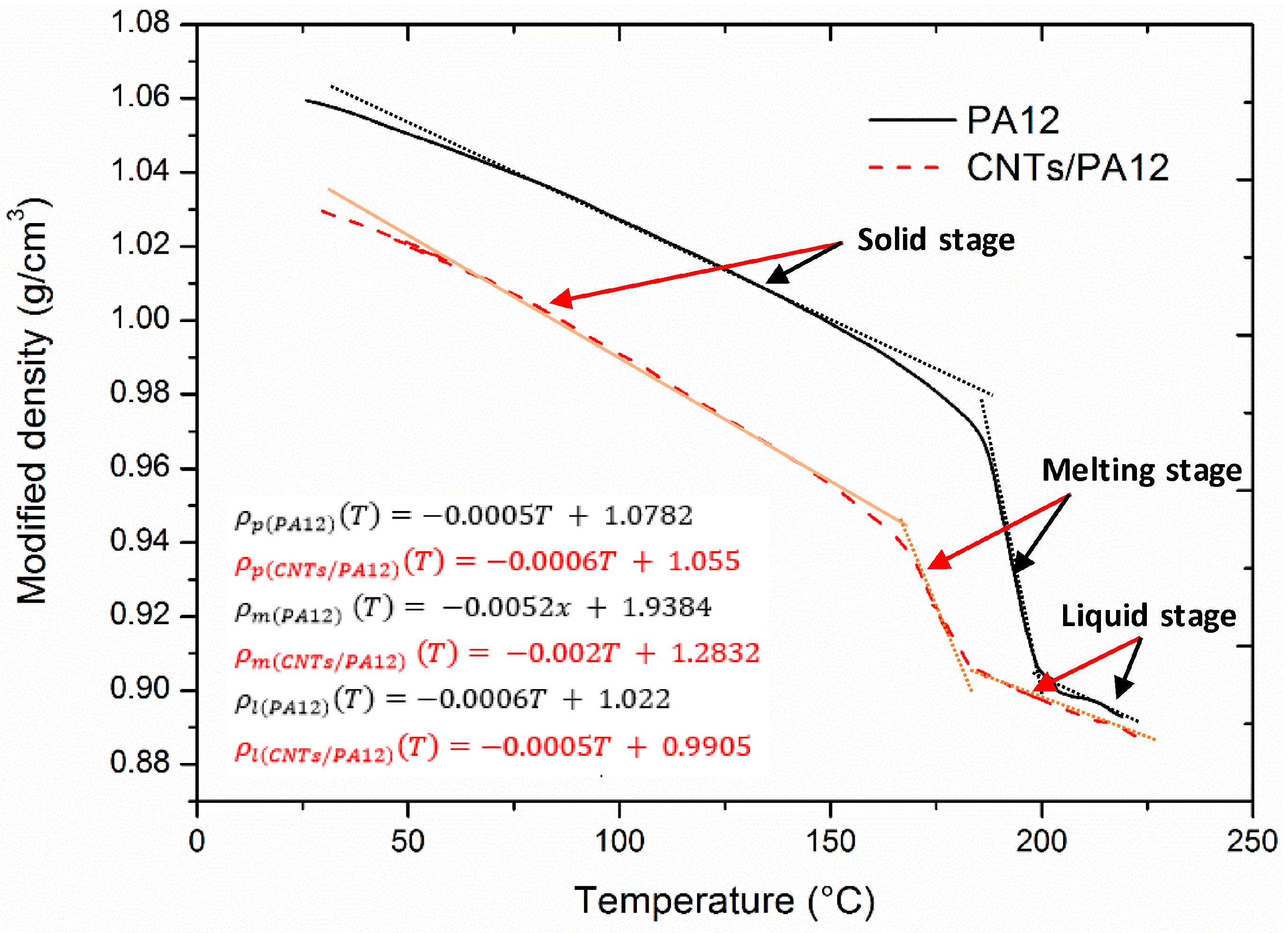

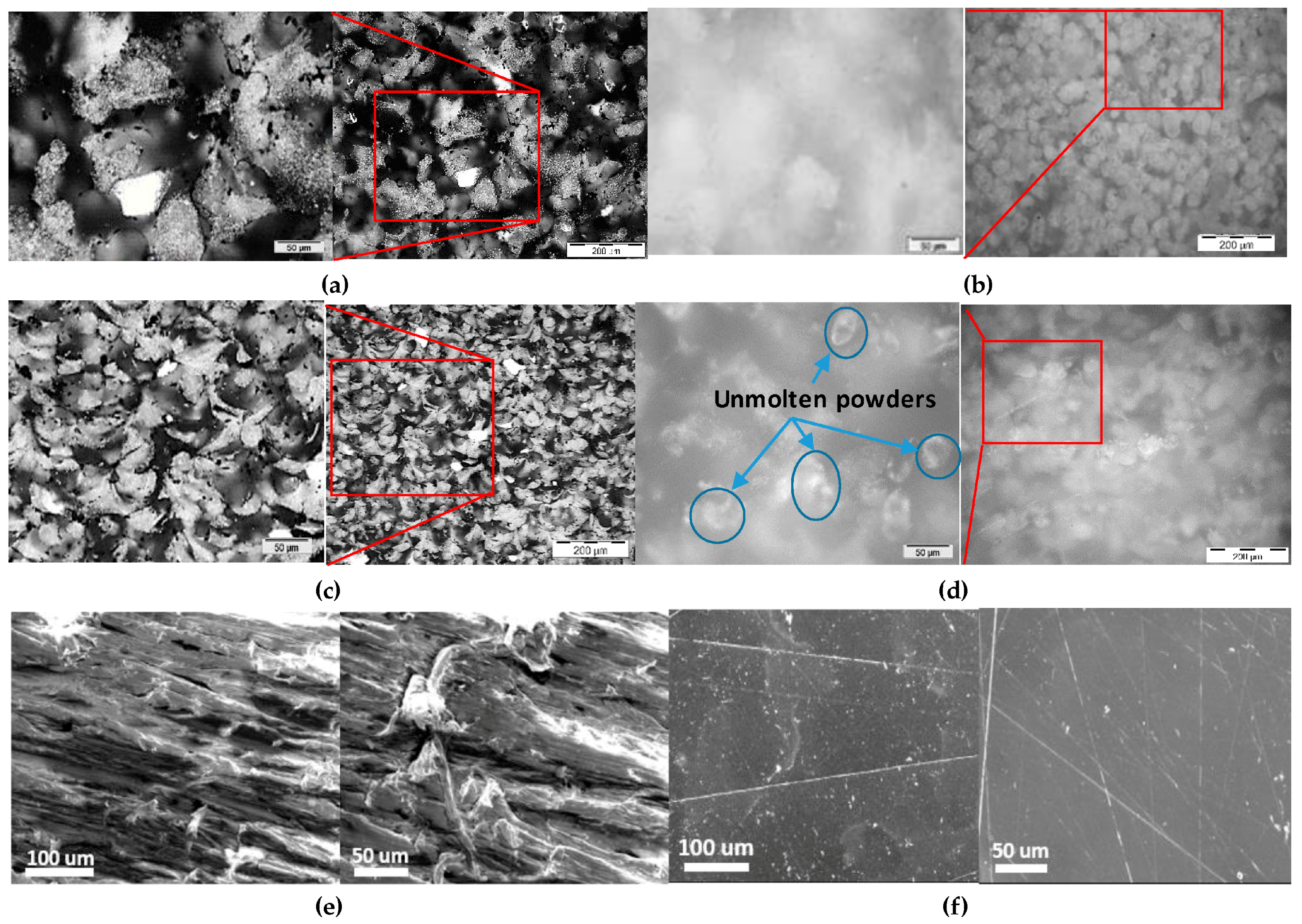

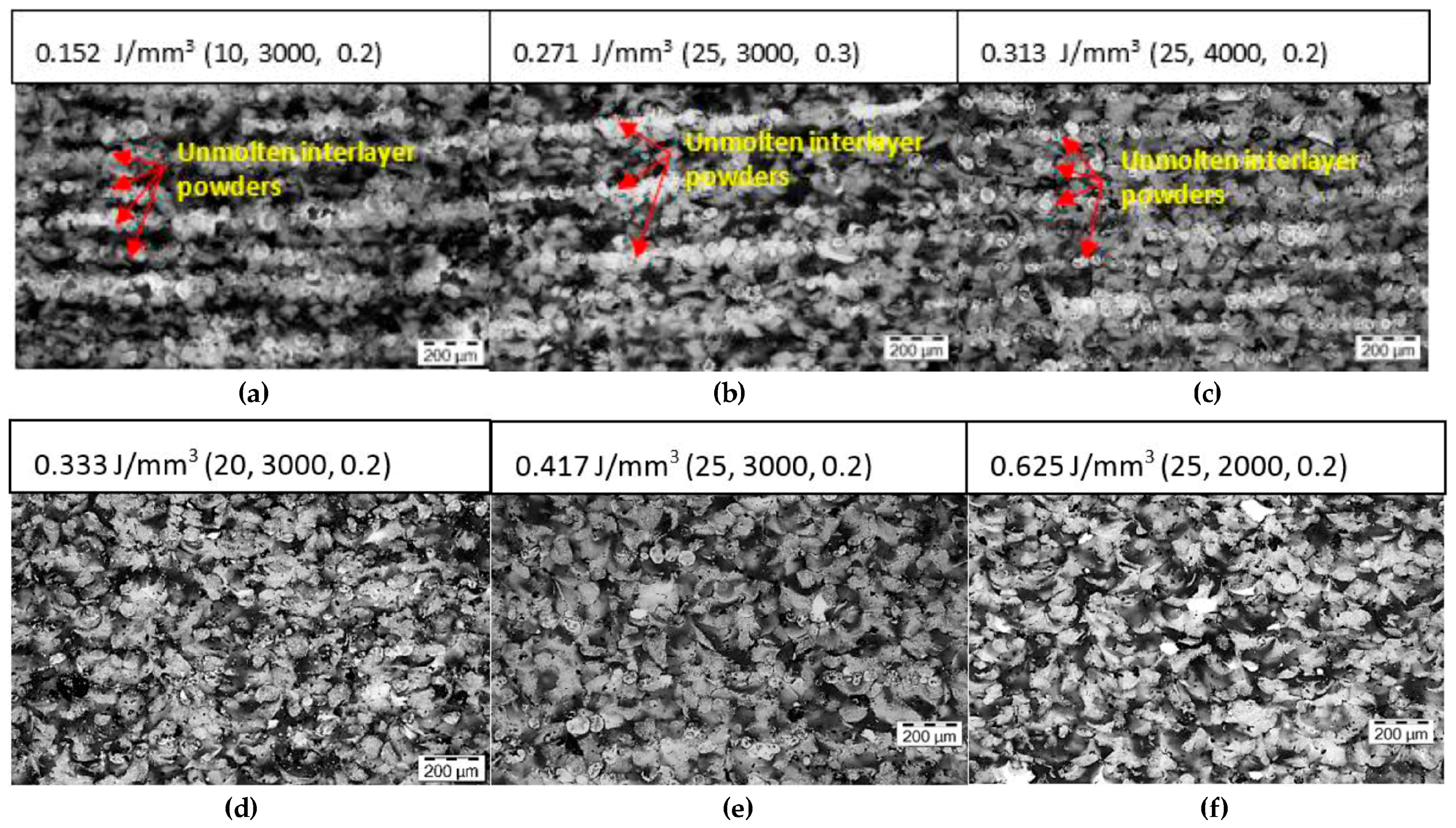

3.1. Evaluation of CNTs/PA12 for SLS Compared with PA12

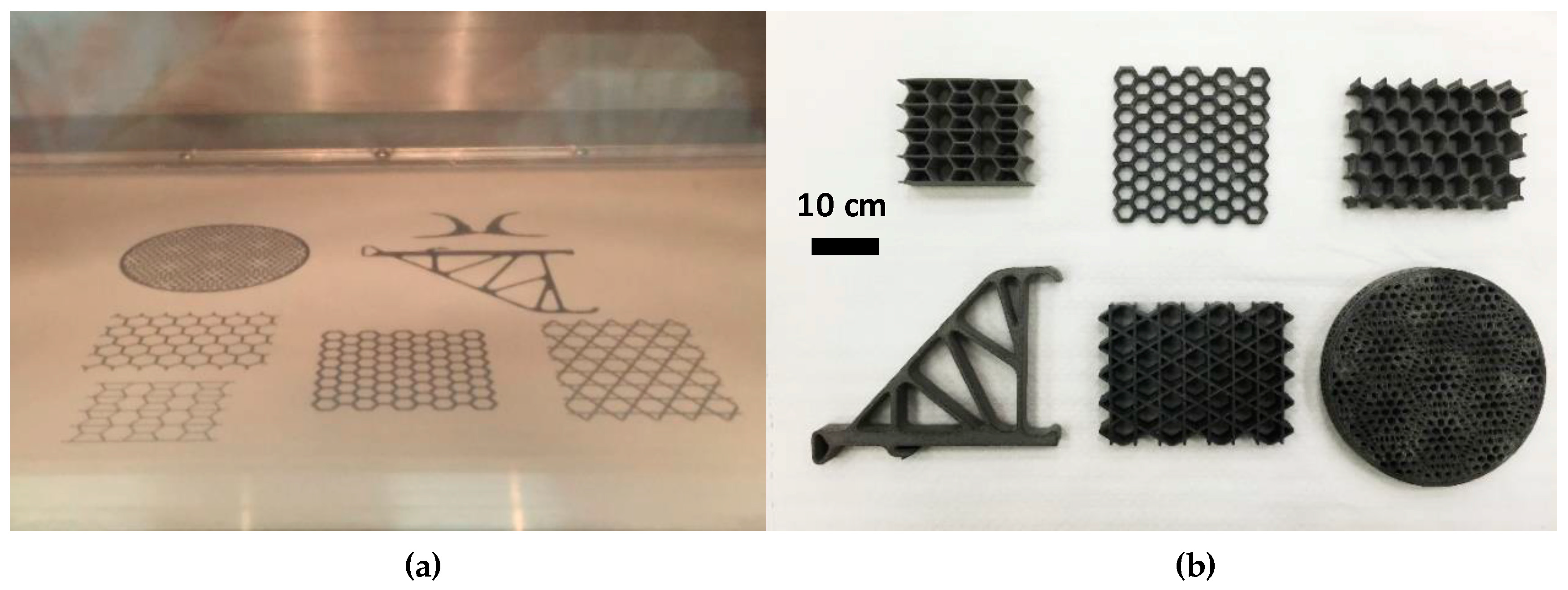

3.2. Enhancements of CNTs in PA12 Matrix

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications; World Scientific Publishing Company Pte Limited: Singapore, 2014. [Google Scholar]

- Aliakbari, M. Additive Manufacturing: State-of-the-Art, Capabilities, and Sample Applications with Cost Analysis. Master’s Thesis, KTH School of Industrial Engineering and Management, Stockholm, Sweden, June 2012. [Google Scholar]

- ASTM F2792. Standard Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2010.

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Wen, S.F.; Yan, C.Z.; Wei, Q.S.; Zhang, L.C.; Zhao, X.; Zhu, W.; Shi, Y.S. Investigation and development of large-scale equipment and high performance materials for powder bed laser fusion additive manufacturing. Virtual Phys. Prototyp. 2014, 9, 213–223. [Google Scholar] [CrossRef]

- Papadakis, L.; Loizou, A.; Risse, J.; Bremen, S.; Schrage, J. A computational reduction model for appraising structural effects in selective laser melting manufacturing. Virtual Phys. Prototyp. 2014, 9, 17–25. [Google Scholar] [CrossRef]

- Wu, W.; Tor, S.B.; Chua, C.K.; Leong, K.F.; Merchant, A. Investigation on processing of ASTM A131 Eh36 high tensile strength steel using selective laser melting. Virtual Phys. Prototyp. 2015, 10, 187–193. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual Phys. Prototyp. 2015, 10, 67–76. [Google Scholar] [CrossRef]

- Park, S.; Lim, T.; Yang, D.-Y.; Kim, R.; Lee, K.-S. Improvement of spatial resolution in nano-stereolithography using radical quencher. Macromol. Res. 2006, 14, 559–564. [Google Scholar] [CrossRef]

- Jariwala, A.S.; Ding, F.; Boddapati, A.; Breedveld, V.; Grover, M.A.; Henderson, C.L.; Rosen, D.W. Modeling effects of oxygen inhibition in mask-based stereolithography. Rapid Prototyp. J. 2011, 17, 168–175. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, G.S. An experimental and theoretical investigation of surface roughness of poly-jet printed parts. Virtual Phys. Prototyp. 2015, 10, 23–34. [Google Scholar] [CrossRef]

- Versavaud, S.; Régnier, G.; Gouadec, G.; Vincent, M. Influence of injection molding on the electrical properties of polyamide 12 filled with multi-walled carbon nanotubes. Polymer 2014, 55, 6811–6818. [Google Scholar] [CrossRef] [Green Version]

- Zhu, W.; Yan, C.; Shi, Y.; Wen, S.; Liu, J.; Shi, Y. Investigation into mechanical and microstructural properties of polypropylene manufactured by selective laser sintering in comparison with injection molding counterparts. Mater. Des. 2015, 82, 37–45. [Google Scholar] [CrossRef]

- Song, K.; Zhang, Y.; Meng, J.; Green, E.; Tajaddod, N.; Li, H.; Minus, M.L. Structural polymer-based carbon nanotube composite fibers: Understanding the processing–structure–performance relationship. Materials 2013, 6, 2543. [Google Scholar] [CrossRef]

- Meyer, K.R.; Hornung, K.H.; Feldmann, R.; Smigerski, H.J. Method for Polytropically Precipitating Polyamide Powder Coating Compositions Where the Polyamides Have at Least 10 Aliphatically Bound Carbon Atoms Per Carbonamide Group. U.S. Patent 4,334,056 A, 8 June 1982. [Google Scholar]

- Zhang, Y.; Song, K.; Meng, J.; Minus, M.L. Tailoring polyacrylonitrile interfacial morphological structure by crystallization in the presence of single-wall carbon nanotubes. ACS Appl. Mater. Interfaces 2013, 5, 807–814. [Google Scholar] [CrossRef] [PubMed]

- Bai, J.; Yuan, S.; Chow, W.; Chua, C.K.; Zhou, K.; Wei, J. Effect of surface orientation on the tribological properties of laser sintered polyamide 12. Polym. Test. 2015, 48, 111–114. [Google Scholar] [CrossRef]

- Bai, J.M.; Goodridge, R.D.; Hague, R.J.M.; Song, M. Improving the mechanical properties of laser-sintered polyamide 12 through incorporation of carbon nanotubes. Polym. Eng. Sci. 2013, 53, 1937–1946. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.; Yuan, S.; Zhou, K.; Chua, C.; Wei, J. Thermal influence of CNT on the polyamide 12 nanocomposite for selective laser sintering. Molecules 2015, 20, 19041. [Google Scholar] [CrossRef] [PubMed]

- Berretta, S.; Evans, K.E.; Ghita, O. Predicting processing parameters in high temperature laser sintering (HT-LS) from powder properties. Mater. Des. 2016, 105, 301–314. [Google Scholar] [CrossRef]

- Verbelen, L.; Dadbakhsh, S.; Van den Eynde, M.; Kruth, J.-P.; Goderis, B.; Van Puyvelde, P. Characterization of polyamide powders for determination of laser sintering processability. Eur. Polym. J. 2016, 75, 163–174. [Google Scholar] [CrossRef]

- Vasquez, M.; Haworth, B.; Hopkinson, N. Methods for quantifying the stable sintering region in laser sintered polyamide-12. Polym. Eng. Sci. 2013, 53, 1230–1240. [Google Scholar] [CrossRef] [Green Version]

- Cai, D.; Jin, J.; Song, M. Process. U.S. Patents 20,100,267,902 A1, 21 October 2010. [Google Scholar]

- Yuan, S.; Bai, J.; Chua, C.K.; Zhou, K.; Jun, W. Highly enhanced thermal conductivity of thermoplastic nanocomposites with a low mass fraction of MWCNTs by a facilitated latex approach. Compos. Part A Appl. Sci. Manuf. 2016, 90, 699–710. [Google Scholar] [CrossRef]

- Scholten, H.; Christoph, W. Use of a Nylon-12 for Selective Laser Sintering. U.S. Patent 6,245,281 B1, 12 June 2001. [Google Scholar]

- Danley, R.L. New heat flux DSC measurement technique. Thermochim. Acta 2003, 395, 201–208. [Google Scholar] [CrossRef]

- Peyre, P.; Rouchausse, Y.; Defauchy, D.; Régnier, G. Experimental and numerical analysis of the selective laser sintering (SLS) of PA12 and PEKK semi-crystalline polymers. J. Mater. Process. Technol. 2015, 225, 326–336. [Google Scholar] [CrossRef]

- Bai, J.; Goodridge, R.D.; Hague, R.J.M.; Song, M.; Okamoto, M. Influence of carbon nanotubes on the rheology and dynamic mechanical properties of polyamide-12 for laser sintering. Polym. Test. 2014, 36, 95–100. [Google Scholar] [CrossRef] [Green Version]

- Ristić, M.M.; Milosević, S. Frenkel’s theory of sintering. Sci. Sinter. 2006, 38, 7–11. [Google Scholar] [CrossRef]

- Grewell, D.; Rooney, P.; Kagan, V.A. Relationship between optical properties and optimized processing parameters for through-transmission laser welding of thermoplastics. J. Reinf. Plast. Compos. 2004, 23, 239–247. [Google Scholar] [CrossRef]

- Salmoria, G.V.; Paggi, R.A.; Lago, A.; Beal, V.E. Microstructural and mechanical characterization of PA12/MWCNTs nanocomposite manufactured by selective laser sintering. Polym. Test. 2011, 30, 611–615. [Google Scholar] [CrossRef]

- Chung, H.; Das, S. Processing and properties of glass bead particulate-filled functionally graded Nylon-11 composites produced by selective laser sintering. Mater. Sci. Eng. A 2006, 437, 226–234. [Google Scholar] [CrossRef]

- Lee, G. Selective Laser Sintering of Calcium Phosphate Materials for Orthopedic Implants. Ph.D. Thesis, University of Texas, Austin, TX, USA, 1997. [Google Scholar]

- Tan, W.S.; Chua, C.K.; Chong, T.H.; Fane, A.G.; Jia, A. 3D printing by selective laser sintering of polypropylene feed channel spacers for spiral wound membrane modules for the water industry. Virtual Phys. Prototyp. 2016, 11, 151–158. [Google Scholar] [CrossRef]

- Francis, V.; Jain, P.K. Experimental investigations on fused deposition modelling of polymer-layered silicate nanocomposite. Virtual Phys. Prototyp. 2016, 11, 109–121. [Google Scholar] [CrossRef]

| Process parameter | Value |

|---|---|

| Laser power p, (W) | 40 |

| Scanning speed s, (mm/s) | 4000 |

| Hatching spacing h, (mm) | 0.3 |

| Bed temperature Tb, (°C) | 174 |

| Chamber temperature Tc, (°C) | 130 |

| Layer thickness L, (μm) | 100 |

| Laser beam diameter d, (mm) | 0.42 |

| Set | Fixed parameters | Controlled parameters | |||||

|---|---|---|---|---|---|---|---|

| 1 | s: 3000 (mm/s), h: 0.2 (mm) | p (W) | 10 | 15 | 20 | 25 | 30 |

| 2 | p: 25 (W), h: 0.2 (mm) | s (mm/s) | 2000 | 2500 | 3000 | 3500 | 4000 |

| 3 | p: 25 (W), s: 3000 (mm/s) | h (mm) | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 |

| Parameters | PA12 | CNTs/PA12 |

|---|---|---|

| Powder specific heat , (J/g·°C) | Figure 3a | Figure 3a |

| Melt specific heat , (J/g·°C) | Figure 3b | Figure 3b |

| Melting peak Tm, (°C) | 187.66 | 184.46 |

| Enthalpy of melting ∆Hm, (J/g) | 107.2 | 90.85 |

| Recrystallization peak Tr, (°C) | 150.90 | 156.22 |

| Enthalpy of recrystallization ∆Hr, (J/g) | 50.04 | 46.11 |

| Modified density , (g/cm3) | Figure 5 | Figure 5 |

| Packing fraction | 0.445 | 0.44 |

| Thermal conductivity Kp, (W/mK) | 0.12 (±0.04) | 0.25 (±0.08) |

| Onset melting temperature Tms, (°C) | 180.93 | 177.21 |

| Onset recrystallization temperature Trs, (°C) | 155.70 | 159.22 |

| Glass window width (GW), (°C) | 25.23 | 17.99 |

| Stable sintering region (SSR), (°C) | 198–360 | 187–402 |

| Melt viscosity at 0.1 rad/s,, (Pa·s) | 1.4 × 103 | 5.4 × 103 |

| Material features | PA12 | CNTs/PA12 |

|---|---|---|

| Mass energy for melt Emm, (J/g) | 189.51 | 167.07 |

| Volume energy for melt Emv, (J/mm3) | 0.072 | 0.064 |

| Mass energy before decomposition Edm, (J/g) | 688.96 | 767.52 |

| Volume energy before decomposition Edv, (J/mm3) | 0.555 | 0.606 |

| Thermal conductivity Ko, (W/mK) | 0.15 (±0.05) | 0.45 (±0.09) |

| Properties | Tensile modulus (MPa) | Tensile strength (MPa) | Elongation at break (%) | Toughness (MJ/mm3) |

|---|---|---|---|---|

| PA12 | 1291 (±12.1) | 44 (±1.3) | 24 (±0.8) | 10.18 (±0.9) |

| CNTs/PA12 | 1301 (±14.5) | 58 (±2.4) | 33 (±2.4) | 18.86 (±1.8) |

| Enhancement (%) | 0.8 | 31.8 | 37.5 | 84.9 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, S.; Bai, J.; Chua, C.K.; Wei, J.; Zhou, K. Material Evaluation and Process Optimization of CNT-Coated Polymer Powders for Selective Laser Sintering. Polymers 2016, 8, 370. https://doi.org/10.3390/polym8100370

Yuan S, Bai J, Chua CK, Wei J, Zhou K. Material Evaluation and Process Optimization of CNT-Coated Polymer Powders for Selective Laser Sintering. Polymers. 2016; 8(10):370. https://doi.org/10.3390/polym8100370

Chicago/Turabian StyleYuan, Shangqin, Jiaming Bai, Chee Kai Chua, Jun Wei, and Kun Zhou. 2016. "Material Evaluation and Process Optimization of CNT-Coated Polymer Powders for Selective Laser Sintering" Polymers 8, no. 10: 370. https://doi.org/10.3390/polym8100370