Preparation and Characterization of Novel PVC/Silica–Lignin Composites

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Methods

| Sample | Filler type | Filler content (wt %) |

|---|---|---|

| PVC | - | 0 |

| PVC/S1 | silica | 2.5 |

| PVC/S2 | 5 | |

| PVC/S3 | 7.5 | |

| PVC/L1 | lignin | 2.5 |

| PVC/L2 | 5 | |

| PVC/L3 | 7.5 | |

| PVC/L4 | 10 | |

| PVC/H1 | silica–lignin hybrid | 2.5 |

| PVC/H2 | 5 | |

| PVC/H3 | 7.5 | |

| PVC/H4 | 10 |

2.2. Physicochemical Characteristics of Silica–Lignin Filler

2.3. Processing Methods and Properties

2.3.1. Preparation of PVC Composites

2.3.2. Processing Properties

2.3.3. Mechanical Properties

2.3.4. Thermal Properties

2.3.5. Structure Assessment

3. Results and Discussion

3.1. Characteristics of Silica–Lignin Filler

| Stage | Mass loss (%) | Temperature range (°C) | Cause/reason |

|---|---|---|---|

| 1 | 4 | 30–220 | Desorption of physically bound water from the surface of the product. |

| 2 | 6 | 220–650 | Thermal decomposition of lignin macromolecule. |

| 3 | 2 | 650–1000 | Fragmentation, combined with the degradation of the compound. |

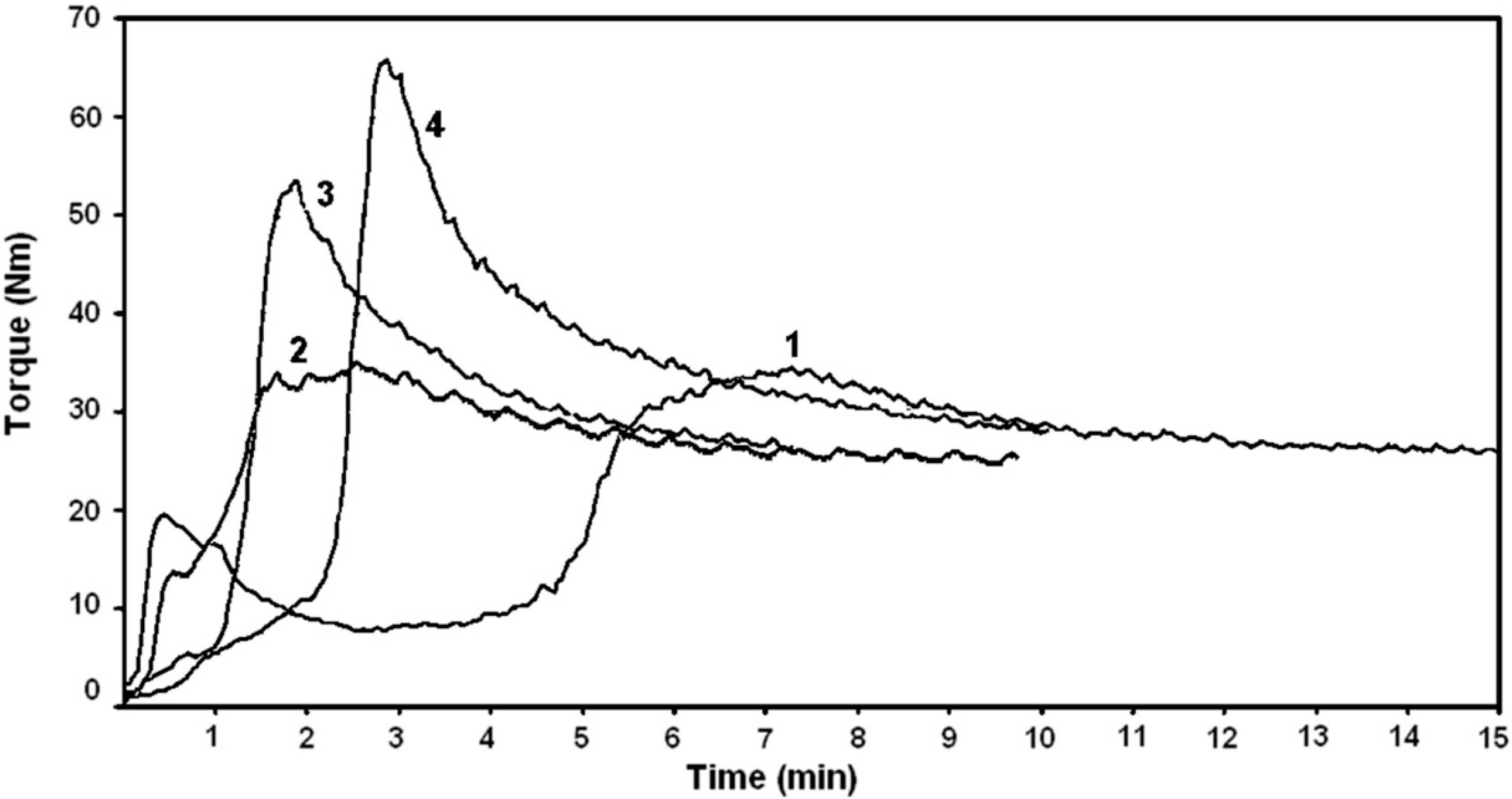

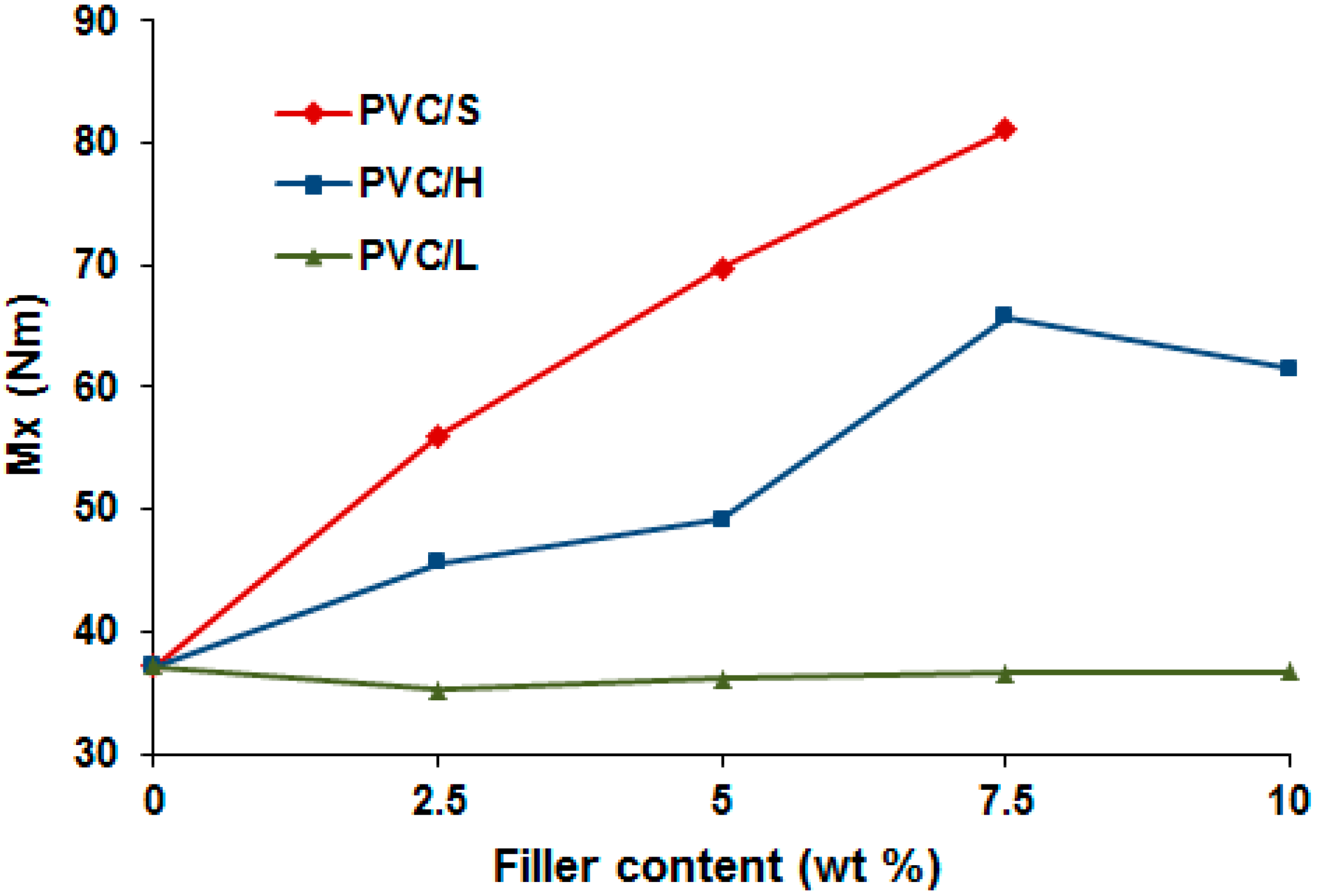

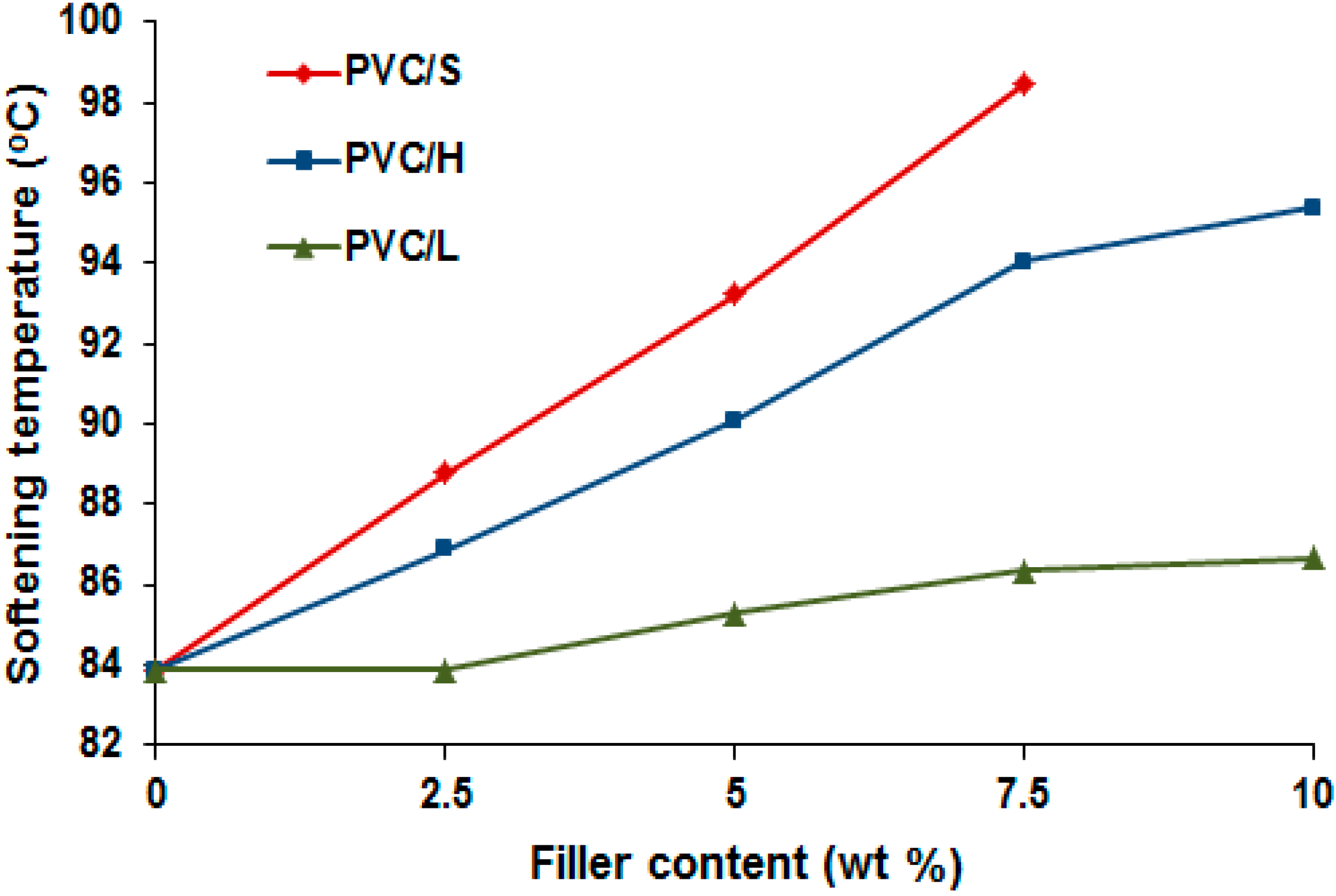

3.2. Processing Properties

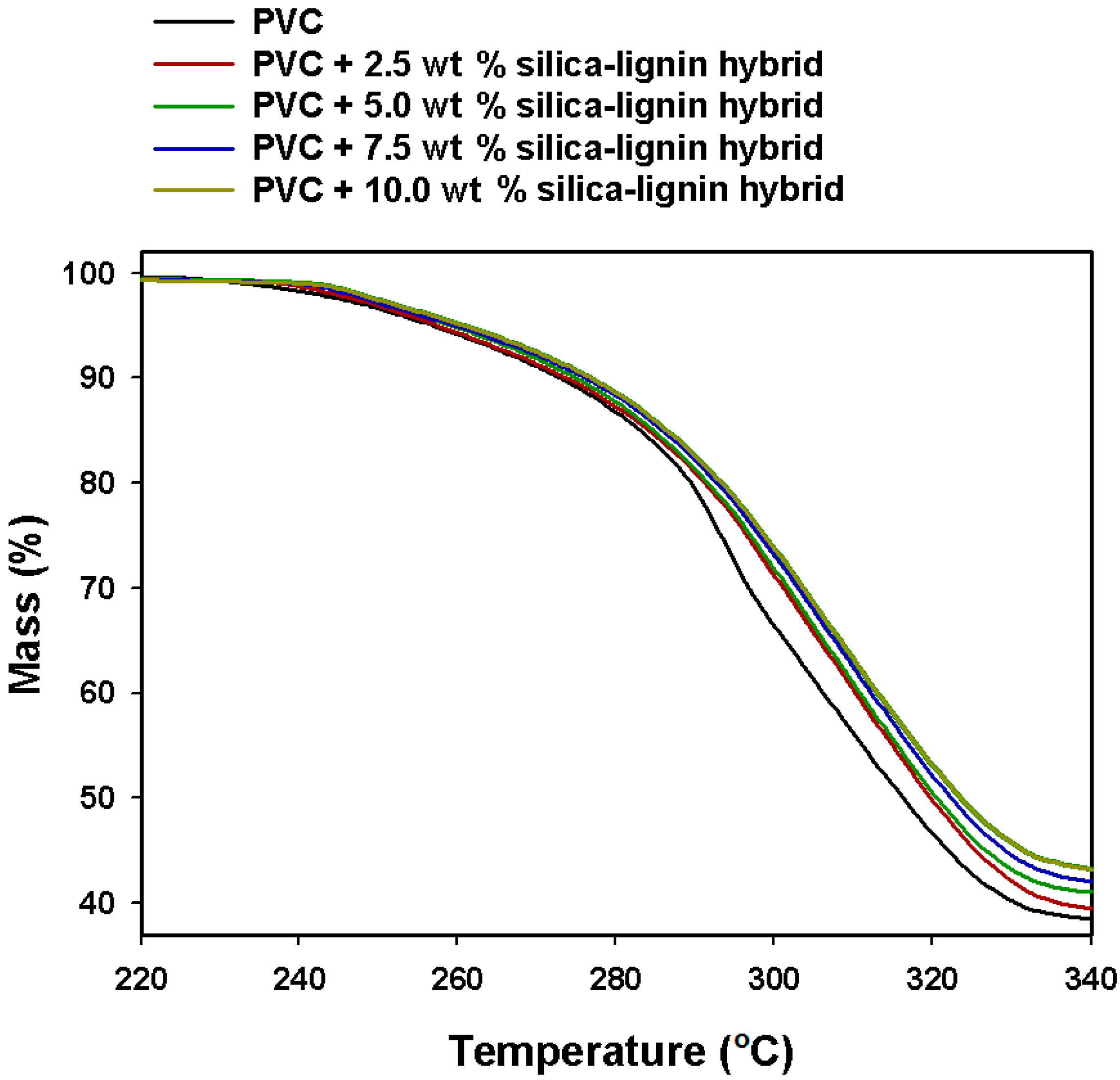

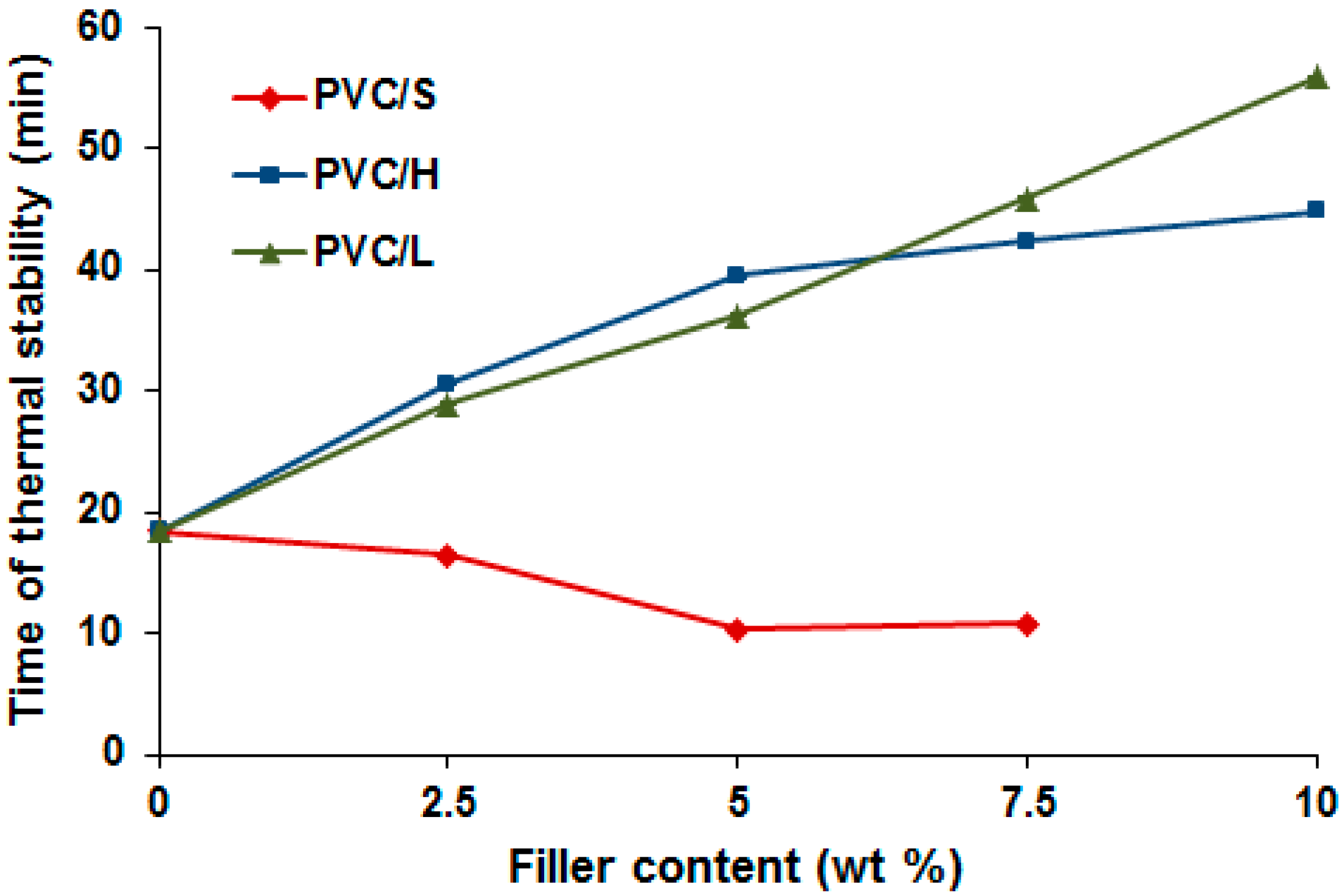

3.3. Thermal Properties

| Sample | Temperature value of weight loss (°C) | ||

|---|---|---|---|

| 1% | 5% | 50% | |

| PVC | 233 | 257 | 316 |

| PVC/S1 | 228 | 255 | 317 |

| PVC/S2 | 225 | 256 | 316 |

| PVC/S3 | 224 | 255 | 317 |

| PVC/L1 | 237 | 257 | 320 |

| PVC/L2 | 239 | 259 | 319 |

| PVC/L3 | 236 | 260 | 321 |

| PVC/L4 | 237 | 260 | 322 |

| PVC/H1 | 238 | 257 | 319 |

| PVC/H2 | 241 | 259 | 321 |

| PVC/H3 | 240 | 260 | 322 |

| PVC/H4 | 240 | 261 | 323 |

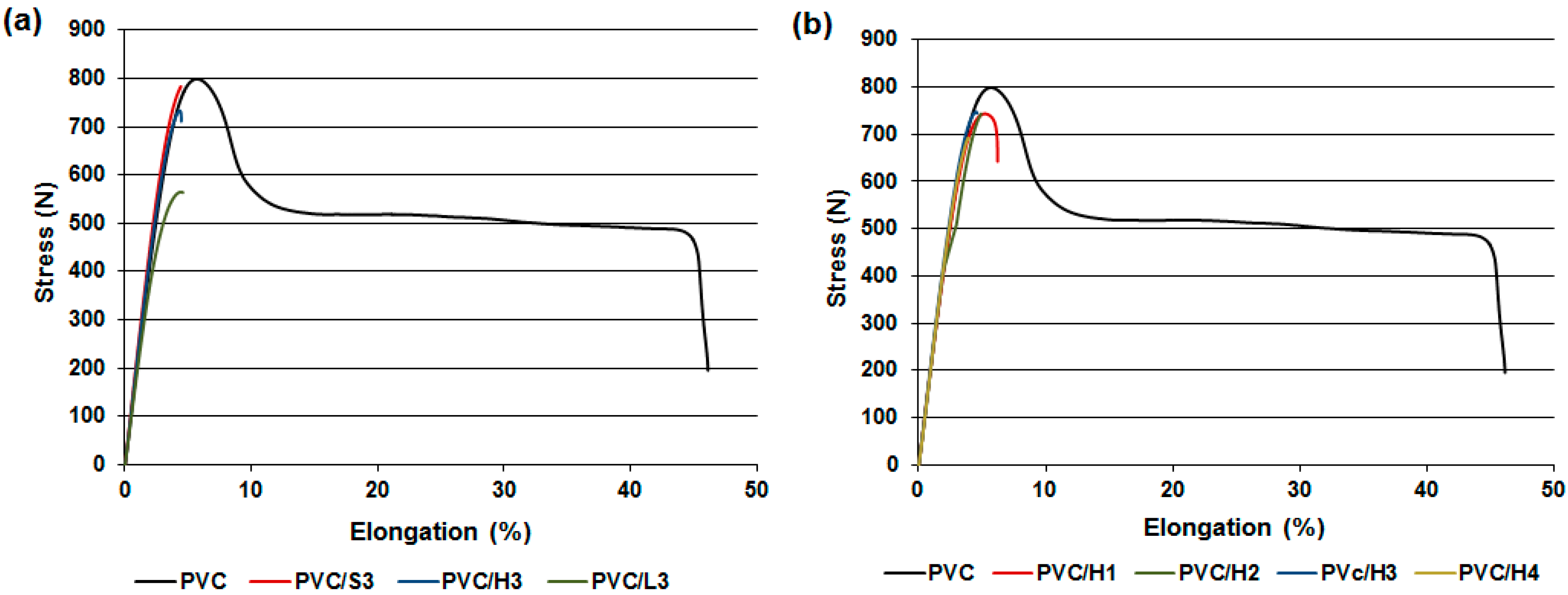

3.4. Mechanical Properties

| Sample | Young modulus E (MPa) | Yield point δY (MPa) | Tensile strength δM (MPa) | Elongation at break (%) |

|---|---|---|---|---|

| PVC | 1,530 ± 62.2 | 57.1 ± 1.2 | 57.1 ± 1.2 | 52.4 ± 8.3 |

| PVC/S1 | 1,650 ± 33.4 | 59.3 ± 1.5 | 59.3 ± 1.5 | 7.2 ± 1.1 |

| PVC/S2 | 1,710 ± 48.1 | - | 60.2 ± 2.1 | 5.4 ± 1.2 |

| PVC/S3 | 1,720 ± 81.6 | - | 57.6 ± 1.8 | 4.3 ± 0.5 |

| PVC/L1 | 1,600 ± 55.5 | 53.5 ± 0.9 | 53.5 ± 0.9 | 8.8 ± 1.8 |

| PVC/L2 | 1,580 ± 38.7 | 50.3 ± 0.7 | 50.3 ± 0.7 | 6.5 ± 0.9 |

| PVC/L3 | 1,570 ± 113.4 | 44.7 ± 3.7 | 44.7 ± 3.7 | 5.3 ± 1.2 |

| PVC/L4 | 1,590 ± 135.3 | - | 39.5 ± 2.3 | 3.9 ± 0.6 |

| PVC/H1 | 1,630 ± 44.1 | 57.1 ± 1.3 | 57.1 ± 1.3 | 7.8 ± 1.7 |

| PVC/H2 | 1,690 ± 56.8 | - | 54.8 ± 1.3 | 4.8 ± 0.9 |

| PVC/H3 | 1,670 ± 45.3 | - | 55.9 ± 1.1 | 4.5 ± 0.3 |

| PVC/H4 | 1,630 ± 117.0 | - | 50.9 ± 2.4 | 3.7 ± 0.3 |

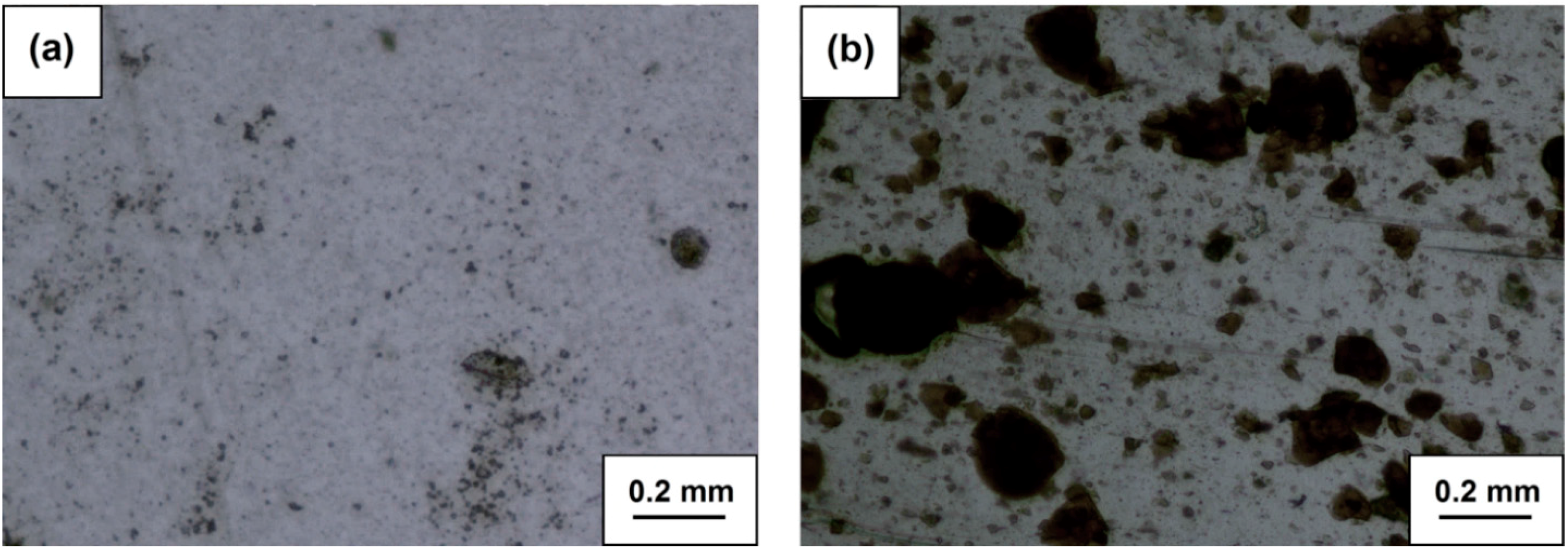

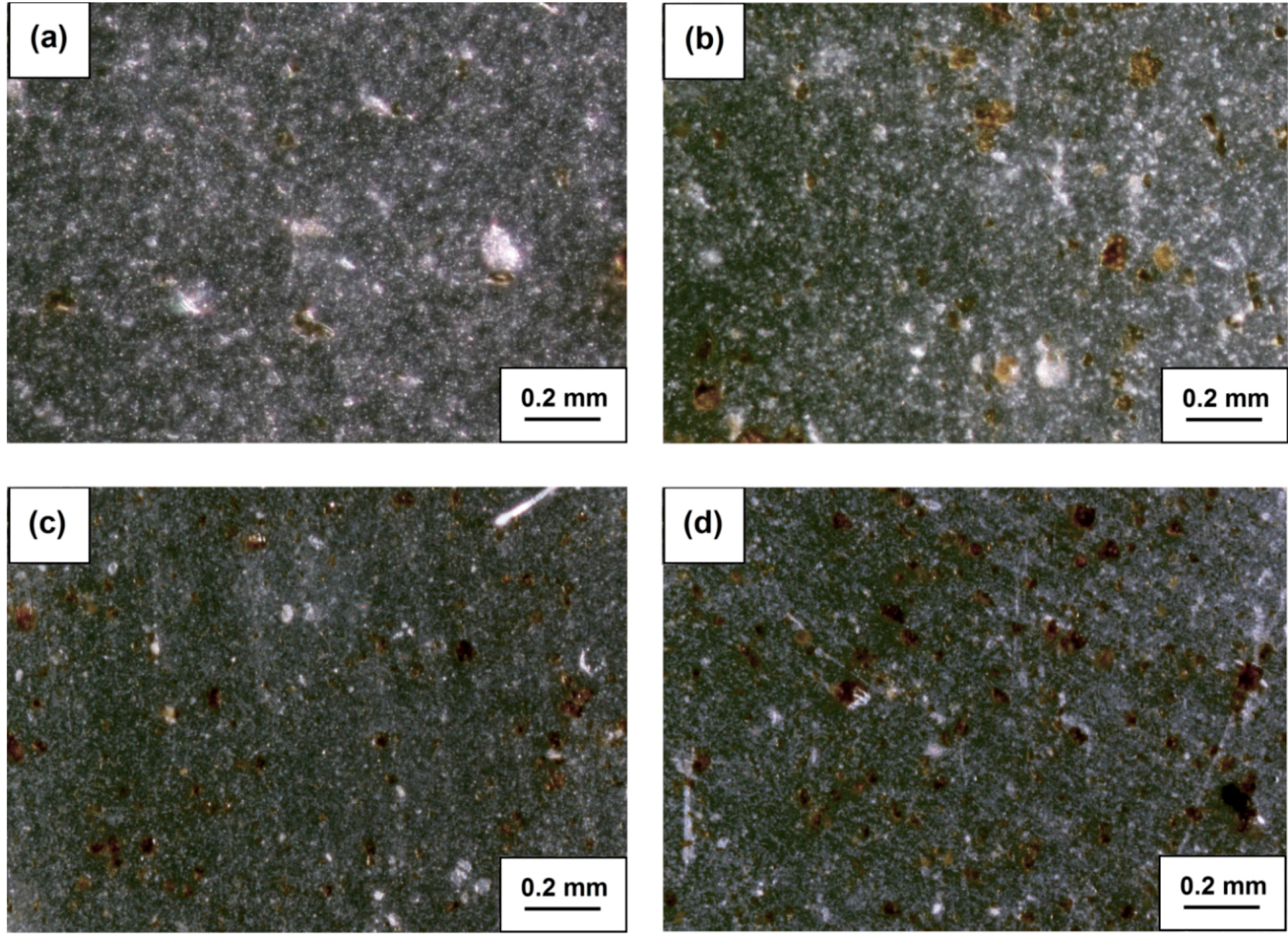

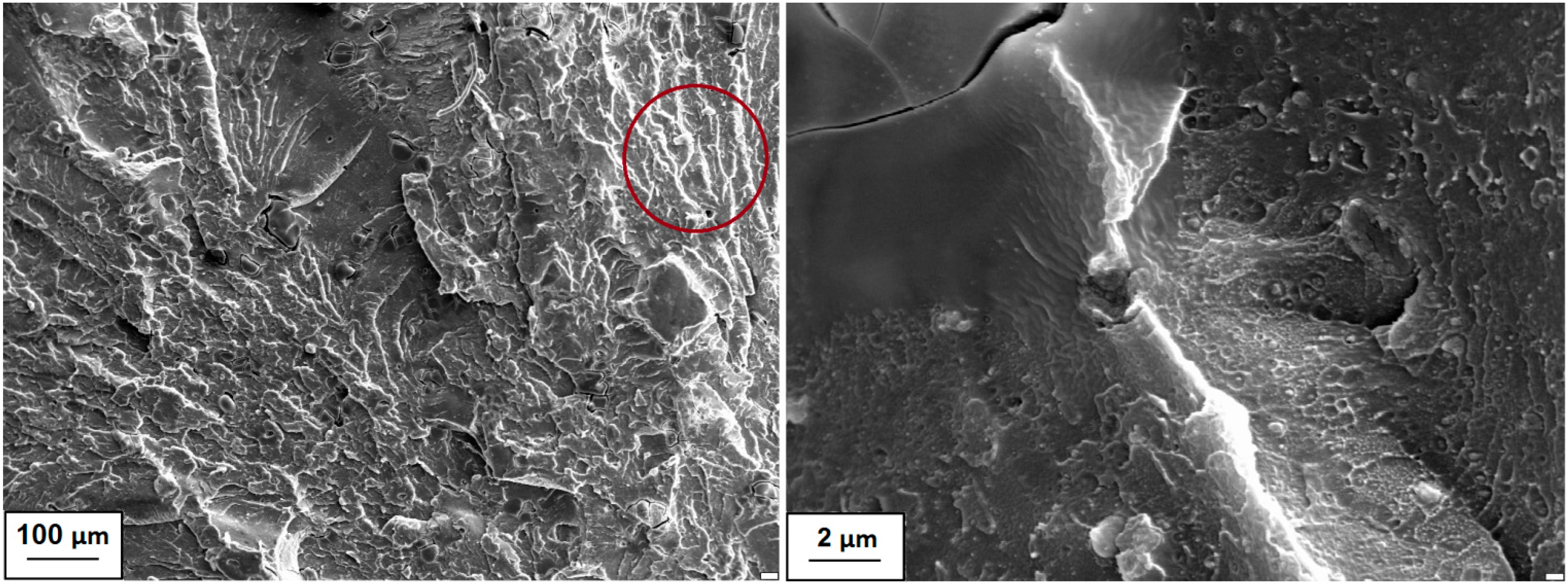

3.5. Microscopic Observations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yang, S.Y.; Liu, L.; Jia, Z.X.; Fu, W.W.; Jia, D.M.; Luo, Y.F. Study on the structure-properties relationship of natural rubber/SiO2 composites modified by a novel multi-functional rubber agent. eXPRESS Polym. Lett. 2014, 8, 425–435. [Google Scholar] [CrossRef]

- Estevez, M.; Rodriguez, R.J.; Vargas, S.; Guerra, J.A.; Brostow, W.; Lobland, H.E.H. Scratch and abrasion properties of polyurethane-based micro- and nano-hybrids obturation materials. J. Nanosci. Nanotechnol. 2013, 13, 4446–4455. [Google Scholar] [CrossRef] [PubMed]

- Bolbukh, Y.; Kuzema, P.; Tertykh, V.A.; Laguta, I. Thermal degradation of polyethylene containing antioxidant and hydrophilic/hydrophobic silica. J. Therm. Anal. Calorim. 2008, 94, 727–736. [Google Scholar] [CrossRef]

- Zhou, T.H.; Ruan, W.H.; Mai, Y.L.; Rong, M.Z.; Zhang, M.Q. Performance improvement of nano-silica/polypropylene composites through in-situ cross-linking approach. Compos. Sci. Technol. 2008, 68, 2858–2863. [Google Scholar] [CrossRef]

- Zhang, W.H.; Fan, X.D.; Tian, W.; Fan, W.W. Polystyrene/nano-SiO2 composite microspheres fabricated by Pickering emulsion polymerization: Preparation, mechanisms and thermal properties. eXPRESS Polym. Lett. 2012, 6, 532–542. [Google Scholar] [CrossRef] [Green Version]

- Al-Sagheer, F.A.; Ahmad, Z. PVC-silica hybrids: Effect of sol–gel conditions on the morphology of silica particles and thermal mechanical properties of the hybrids. J. Sol–Gel Sci. Technol. 2012, 61, 229–235. [Google Scholar] [CrossRef]

- Bolbukh, Y.; Tertykh, V.A.; Klonos, P.; Pissis, P. DSC study of polyhydroxyethyl-methacrylate filled with modified silicas. J. Therm. Anal. Calorim. 2012, 108, 1111–1119. [Google Scholar] [CrossRef]

- Brostow, W.; Datashvili, T.; Hackenberg, K.P. Synthesis and characterization of poly(methyl acrylate)+SiO2 hybrids. E-Polymers 2008, 8, 1–13. [Google Scholar] [CrossRef]

- Jesionowski, T.; Bula, K.; Janiszewski, J.; Jurga, J. The influence of filler modification on its aggregation and dispersion behaviour in silica PBT composite. Compos. Interface 2003, 10, 225–242. [Google Scholar] [CrossRef]

- Maciejewska, M.; Zaborski, M. Effect of ionic liquids on the dispersion of zinc oxide and silica nanoparticles, vulcanization behavior and properties of NBR composites. eXPRESS Polym. Lett. 2014, 8, 932–940. [Google Scholar] [CrossRef]

- Pietrasik, J.; Gaca, M.; Zaborski, M.; Okrasa, L.; Boiteux, G.; Gain, O. Studies of molecular dynamics of carboxylated acrylonitrile-butadiene rubber composites containing in situ synthesized silica particles. Eur. Polym. J. 2009, 45, 3317–3325. [Google Scholar] [CrossRef]

- Brostow, W.; Chonkaew, W.; Datashvili, T.; Menard, K.P. Tribological properties of epoxy+silica hybrid materials. J. Nanosci. Nanotechnol. 2009, 9, 1916–1922. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Błędzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 229, 9–26. [Google Scholar] [CrossRef]

- Tomaszewska, J.; Zajchowski, S. Study on the mechanical properties and structure of the compounds of PE/PVC recyclates filled with wood flour. Polimery 2013, 58, 106–113. [Google Scholar] [CrossRef]

- Jiang, H.; Kamdem, D.P. Development of poly(vinyl chloride)/wood composites. A literature review. J. Vinyl Addit. Technol. 2004, 10, 59–69. [Google Scholar] [CrossRef]

- Khan, R.A.; Sharmin, N.; Khan, M.A.; Das, A.K.; Dey, K.; Saha, S.; Islam, T.; Islam, R.; Nigar, F.; Sarker, B.; et al. Comparative studies of mechanical and interfacial properties between jute fiber/PVC and e-glass fiber/PVC composites. Polym. Plast. Technol. Eng. 2011, 50, 153–159. [Google Scholar] [CrossRef]

- Sheng, K.; Qian, S.; Wang, H. Influence of potassium permanganate pretreatment on mechanical properties and thermal behavior of moso bamboo particles reinforced PVC composites. Polym. Compos. 2014, 35, 1460–1465. [Google Scholar] [CrossRef]

- Djidjelli, H.; Boukerrou, A.; Founas, R.; Rabouhi, A.; Kaci, M.; Ferenc, J.; Martinez-Vega, J.B.; Benachour, D. Preparation and characterization of poly(vinyl chloride)/virgin and treated sisal fiber composites. J. Appl. Polym. Sci. 2007, 103, 3630–3636. [Google Scholar] [CrossRef]

- Kamel, S. Preparation and properties of composites made from rice straw and poly(vinyl chloride) (PVC). Polym. Adv. Technol. 2004, 15, 612–616. [Google Scholar] [CrossRef]

- Markarian, J. Wood-plastic composites: Current trends in materials and processing. Plast. Addit. Compound. 2005, 7, 20–26. [Google Scholar] [CrossRef]

- Chaochanchaikul, K.; Rosarpitak, V.; Sombatsompop, N. Photodegradation profiles of PVC compound and wood/PVC composites under UV weathering. eXPRESS Polym. Lett. 2013, 7, 146–160. [Google Scholar] [CrossRef] [Green Version]

- Shah, B.L.; Matuana, L.M. Novel coupling agents for PVC/wood-flour composite. J. Vinyl Addit. Technol. 2005, 11, 160–165. [Google Scholar] [CrossRef]

- Wirawan, R.; Zainudin, E.S.; Sapuan, S.M. Mechanical properties of natural fibre reinforced PVC composites: A review. Sains Malaysiana 2009, 38, 531–535. [Google Scholar]

- Maldas, D.; Kokta, B.; Daneault, C. Composites of polyvinyl chloride–wood fibers: IV. Effect of the nature of fibers. J. Vinyl Addit. Technol. 1989, 11, 90–99. [Google Scholar] [CrossRef]

- Mengeloglu, F.; Matuana, L.; King, J. Effects of impact modifiers on the properties of rigid PVC/wood-fiber composites. J. Vinyl Addit. Technol. 2000, 6, 153–157. [Google Scholar] [CrossRef]

- Kokta, B.V.; Maldas, D.; Daneault, C.; Beland, P. Composites of poly(vinyl chloride) and wood fibers. Part II: Effect of chemical treatment. Polym. Compos. 1990, 11, 84–89. [Google Scholar] [CrossRef]

- Kociszewski, M.; Gozdecki, C.; Wilczyński, A.; Zajchowski, S.; Mirowski, J. Effect of industrial wood particle size on mechanical properties of wood-polyvinyl chloride composites. Eur. J. Wood Wood Prod. 2012, 70, 113–118. [Google Scholar] [CrossRef]

- Ping, Q.W.; Xiao, J.; Zhao, J. The preparation and property of organic solvent lignin and PVC composite materials. Adv. Mater. Res. 2011, 236–238, 1195–1198. [Google Scholar] [CrossRef]

- Feldman, D.; Banu, D. Contribution to the study of rigid PVC polyblends with different lignins. J. Appl. Polym. Sci. 1997, 66, 1731–1744. [Google Scholar] [CrossRef]

- Saheb, D.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Liu, F.; Xu, K.; Chen, M.; Cao, D. Thermal stability of PVC–lignin blends miscibilized by poly(ethyl acrylate-co-acrylic acid). CIESC J. 2012, 63, 3324–3329. [Google Scholar]

- Elashmawi, I.S.; Hakeem, N.A.; Marei, L.K.; Hanna, F.F. Structure and performance of ZnO/PVC nanocomposites. Phys. B Condens. Matt. 2011, 405, 4163–4169. [Google Scholar] [CrossRef]

- Abu-Abdeen, M. Static and dynamic mechanical properties of poly(vinyl chloride) loaded with aluminum oxide nanopowder. Mater. Des. 2012, 33, 523–528. [Google Scholar] [CrossRef]

- Xie, X.L.; Liu, Q.X.; Li, R.K.Y.; Zhou, X.P.; Zhang, Q.X.; Yu, Z.Z.; Mai, Y.W. Rheological and mechanical properties of PVC/CaCO3 nanocomposites prepared by in situ polymerization. Polymer 2004, 45, 6665–6673. [Google Scholar] [CrossRef]

- Xiong, Ch.; Lu, S.; Wang, D.; Dong, L.; Jiang, D.D.; Wang, Q. Microporous polyvinyl chloride: Novel reactor for PVC/CaCO3 nanocomposites. Nanotechnology 2005, 16, 1787–1792. [Google Scholar] [CrossRef]

- Broza, G.; Piszczek, K.; Schulte, K.; Sterzyński, T. Nanocomposites of poly(vinyl chloride) with carbon nanotubes (CNT). Compos. Sci. Technol. 2007, 67, 890–894. [Google Scholar] [CrossRef]

- Sterzyński, T.; Tomaszewska, J.; Piszczek, K.; Skórczewska, K. The influence of carbon nanotubes on the PVC glass transition temperature. Compos. Sci. Technol. 2010, 70, 966–969. [Google Scholar] [CrossRef]

- Xu, B.; Zhou, Z.F.; Ge, M.L.; Pan, W.P. Glass polyvinyl chloride/montmorillonite nanocomposites: Transition temperature and mechanical properties. J. Therm. Anal. Calorim. 2004, 78, 91–100. [Google Scholar] [CrossRef]

- Sterky, K.; Jacobsen, H.; Jakubowicz, I.; Yarahmadi, N.; Hjertberg, T. Influence of processing technique on morphology and mechanical properties of PVC nanocomposites. Eur. Polym. J. 2010, 46, 1203–1209. [Google Scholar] [CrossRef]

- Gilbert, M.; Haghighat, S.; Chua, S.K.; Yeng, N.S. Development of PVC/silica hybrids using PVC plastisols. Macromol. Symp. 2006, 233, 198–202. [Google Scholar] [CrossRef]

- Ulutan, S.; Balköse, D. Diffusivity, solubility and permeability of water vapor in flexible PVC/silica composite membranes. J. Membrane Sci. 1996, 115, 217–224. [Google Scholar] [CrossRef]

- Conradi, M.; Zorko, M.; Jerman, I.; Orel, B.; Verpoest, I. Mechanical properties of high density packed silica/poly(vinyl chloride) composites. Polym. Eng. Sci. 2013, 53, 1448–1453. [Google Scholar] [CrossRef]

- Jeamtrakull, S.; Kositchaiyong, A.; Markpin, T.; Rosarpitak, V.; Sombatsompop, N. Effects of wood constituents and content, and glass fiber reinforcement on wear behavior of wood/PVC composites. Compos. B Eng. 2012, 43, 2721–2729. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, K.; Zhu, F.; Xue, P.; Jia, M. Properties of poly(vinyl chloride)/wood flour/montmorillonite composites: Effects of coupling agents and layered silicate. Polym. Degrad. Stabil. 2006, 91, 2874–2883. [Google Scholar] [CrossRef]

- Deka, B.K.; Maji, T.K. Study on the properties of nanocomposite based on high density polyethylene, polypropylene, polyvinyl chloride and wood. Compos. A Appl. Sci. Manufactur. 2011, 42, 686–693. [Google Scholar] [CrossRef]

- Yim, H.; Kim, D.S. Physical properties of PVC/aminosilane-treated wood flour/organoclay composites. Polym. Adv. Technol. 2011, 23, 1441–1445. [Google Scholar] [CrossRef]

- Faruk, O.; Matuana, L.M. Reinforcement of rigid PVC/wood–flour composites with multi-walled carbon nanotubes. J. Vinyl Addit. Technol. 2008, 14, 60–64. [Google Scholar] [CrossRef]

- Feldman, D.; Banu, D.; Lora, J.; El-Raghi, S. Rigid poly(vinyl chloride)-organosolv lignin blends for applications in building. J. Appl. Polym. Sci. 1996, 61, 2119–2128. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Nowacka, M.; Milczarek, G.; Jesionowski, T. Physicochemical and electrokinetic properties of silica/lignin biocomposites. Carbohydr. Polym. 2013, 94, 345–355. [Google Scholar]

- Klapiszewski, Ł.; Królak, M.; Jesionowski, T. Silica synthesis by the sol-gel method and its use in the preparation of multifunctional biocomposites. Cent. Eur. J. Chem. 2014, 12, 173–184. [Google Scholar]

- Bula, K.; Klapiszewski, Ł.; Jesionowski, T. A novel functional silica/lignin hybrid material as a potential bio-based polypropylene filler. Polym. Compos. 2015, 36, 913–922. [Google Scholar] [CrossRef]

- Tomaszewska, J.; Sterzyński, T.; Piszczek, K. The influence of the chamber temperature in the Brabender measuring mixer on the state of equilibrium of the torque of rigid poly(vinyl chloride). Polimery 2008, 53, 678–680. [Google Scholar]

- Tomaszewska, J.; Sterzyński, T.; Piszczek, K. Rigid poly(vinyl chloride) gelation in a Brabender measuring mixer. III. Transformation in the torque maximum. J. Appl. Polym. Sci. 2007, 106, 3158–3164. [Google Scholar] [CrossRef]

- Ari, G.A.; Aydin, I. A study on fusion and rheological behaviors of PVC/SiO2 microcomposites and nanocomposites: The effects of SiO2 particle size. Polym. Eng. Sci. 2011, 51, 1574–1579. [Google Scholar] [CrossRef]

- Chen, C.H.; Li, H.C.; Teng, C.C.; Yang, C.H. Fusion, electrical conductivity, thermal and mechanical properties of rigid poly(vinyl chloride) (PVC)/carbon black (CB) composites. J. Appl. Polym. Sci. 2006, 99, 2167–2173. [Google Scholar] [CrossRef]

- Tomaszewska, J.; Sterzyński, T.; Zajchowski, S. Thermal and structural effects of poly(vinyl chloride)/(wood flour) compound gelation in the Brabender mixer. J. Vinyl Addit. Technol. 2011, 17, 239–244. [Google Scholar] [CrossRef]

- Shimpi, N.G.; Verma, J.; Mishra, S. Preparation, characterization and properties of poly(vinyl chloride)/CaSO4 nanocomposites. Polym. Plast. Technol. Eng. 2009, 48, 997–1001. [Google Scholar] [CrossRef]

- Chrissafis, K.; Bikiaris, D. Can nanoparticles really enhance thermal stability of polymers? Part I: An overview on thermal decomposition of addition polymers. Themochim. Acta 2011, 523, 1–24. [Google Scholar] [CrossRef]

- Folarin, O.M.; Sadiku, E.R. Thermal stabilizers for poly(vinyl chloride): A review. Int. J. Phys. Sci. 2011, 6, 4323–4330. [Google Scholar]

- McNeill, I.C.; Memetea, L.; Cole, W.J. A study of the products of PVC thermal degradation. Polym. Degrad. Stabil. 1995, 49, 181–191. [Google Scholar] [CrossRef]

- Mohamed, N.A.; Sabaa, M.W. Thermal degradation behavior of poly(vinyl chloride)–poly(vinyl butyral) blends. Eur. Polym. J. 1999, 35, 1731–1737. [Google Scholar] [CrossRef]

- Poerschmann, J.; Weiner, B.; Woszidlo, S.; Koehler, R.; Kopinke, F.D. Hydrothermal carbonization of poly(vinyl chloride). Chemosphere 2015, 119, 682–689. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Tian, M.; Guo, S. A study on the morphology and mechanical properties of PVC/nano–SiO2 composites. J. Macromol. Sci. B 2006, 45, 709–725. [Google Scholar] [CrossRef]

- Jabbari, M.; Åkesson, D.; Skrifvars, M.; Taherzadeh, M.J. Novel lightweight and highly thermally insulative silica aerogel-doped poly(vinyl chloride)-coated fabric composite. J. Reinf. Plast. Compos. 2015. [Google Scholar] [CrossRef]

- Czegeny, Z.; Jakab, E.; Bozi, J.; Blazso, M. Pyrolysis of wood–PVC mixtures. Formation of chloromethane from lignocellulosic materials in the presence of PVC. J. Anal. Appl. Pyrol. 2015, 113, 123–132. [Google Scholar] [CrossRef] [Green Version]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klapiszewski, Ł.; Pawlak, F.; Tomaszewska, J.; Jesionowski, T. Preparation and Characterization of Novel PVC/Silica–Lignin Composites. Polymers 2015, 7, 1767-1788. https://doi.org/10.3390/polym7091482

Klapiszewski Ł, Pawlak F, Tomaszewska J, Jesionowski T. Preparation and Characterization of Novel PVC/Silica–Lignin Composites. Polymers. 2015; 7(9):1767-1788. https://doi.org/10.3390/polym7091482

Chicago/Turabian StyleKlapiszewski, Łukasz, Franciszek Pawlak, Jolanta Tomaszewska, and Teofil Jesionowski. 2015. "Preparation and Characterization of Novel PVC/Silica–Lignin Composites" Polymers 7, no. 9: 1767-1788. https://doi.org/10.3390/polym7091482