3.2. Analysis of the Thickness after Thermoforming

The thickness distribution in thermoformed trays is dependent on a variety of processing parameters, such as sheet temperature, mold temperature, heating time, thermoforming pressure, evacuation rate, plug temperature, plug speed,

etc. [

2,

7,

8,

9,

12,

14,

21]. To obtain commercially acceptable trays, processing parameters for each material were optimized based on stability and visual criteria of the formed trays. After evaluation by the industrial partners, series of test samples for each tray type were produced for detailed thickness and OTR measurements, and chemical characterization.

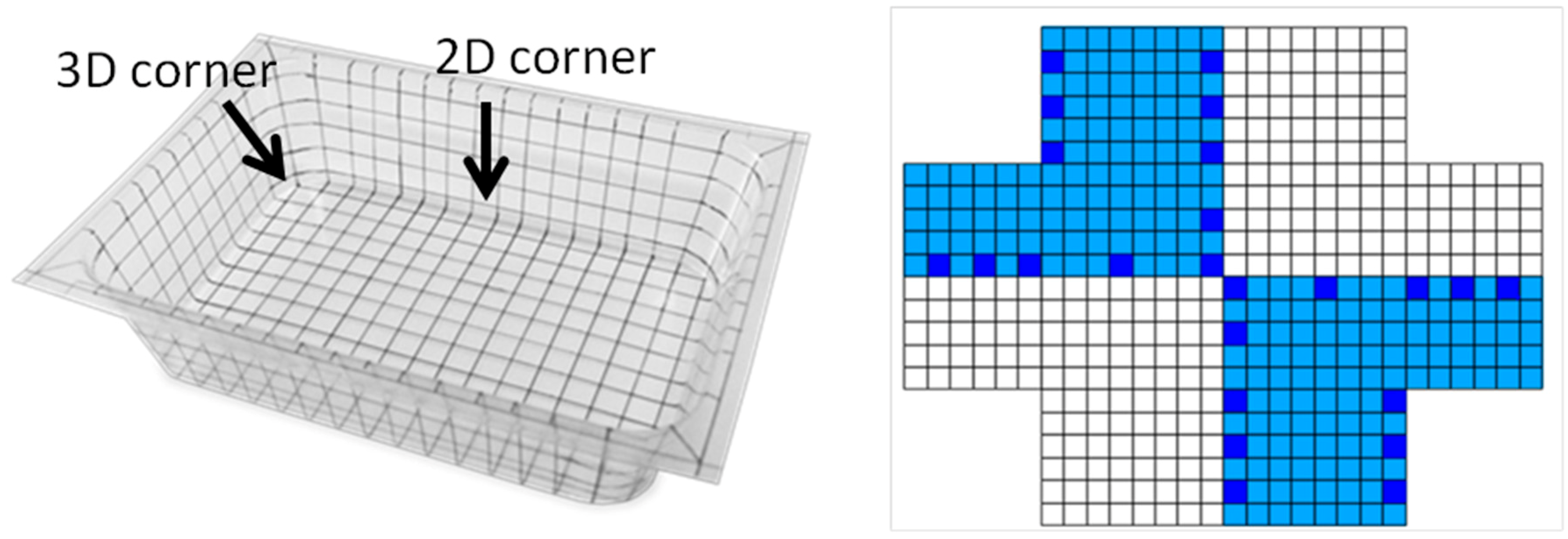

Three thermoformed trays of each tray type were provided with a grid of squares of ~1 cm

2. The percentage thinning in all squares of one 50-mm tray (thick variant of each material) was measured according to Equation 1 and visualized as shown in

Figure 2,

Figure 3,

Figure 4 and

Figure 5 (472 squares in a 50-mm tray). Since the visual presentation of these data showed sufficient symmetry, the thickness of the squares in all other tray types was measured in two diagonal opposing quadrants (197, 236, and 287 squares in the 25-, 50- and 75-mm trays, respectively), and the data were mirrored (

Figure 1). To evaluate this method on its reproducibility, 24 strategic locations in the 50-mm trays were selected (

Figure 1, dark squares) and the thickness was measured in triplicate on trays thermoformed on two or three different production times. Analogously, 17 and 29 strategic locations were selected in the 25- and 75-mm trays, respectively. The standard deviation of the thinning% in all selected locations was between 1% and 5%, indicating that the thickness measurements were representative for all trays of the same design. Only the trays produced from flexible PA films showed more deviation, probably due to local shrinkage (standard deviation of 2%–13%).

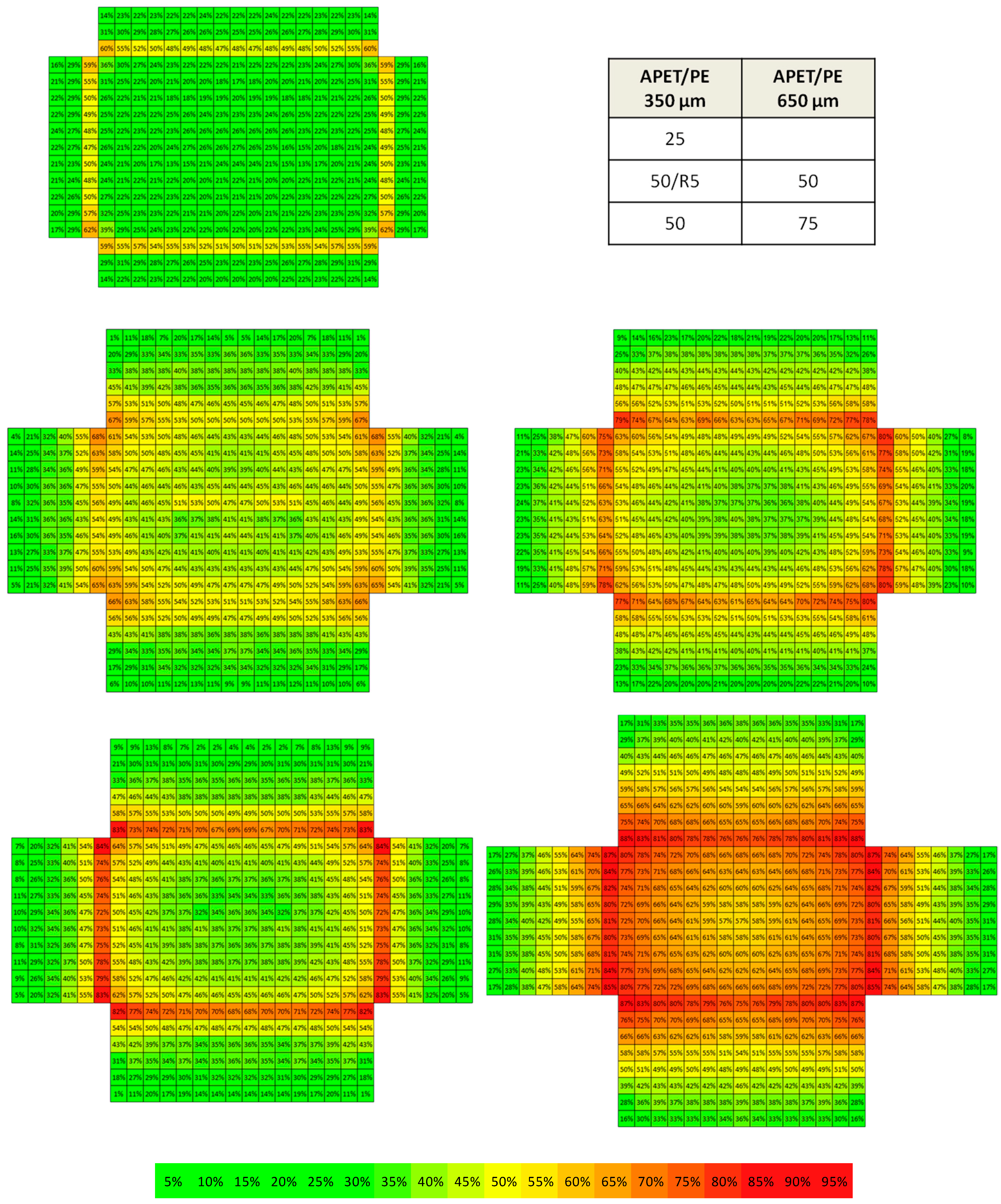

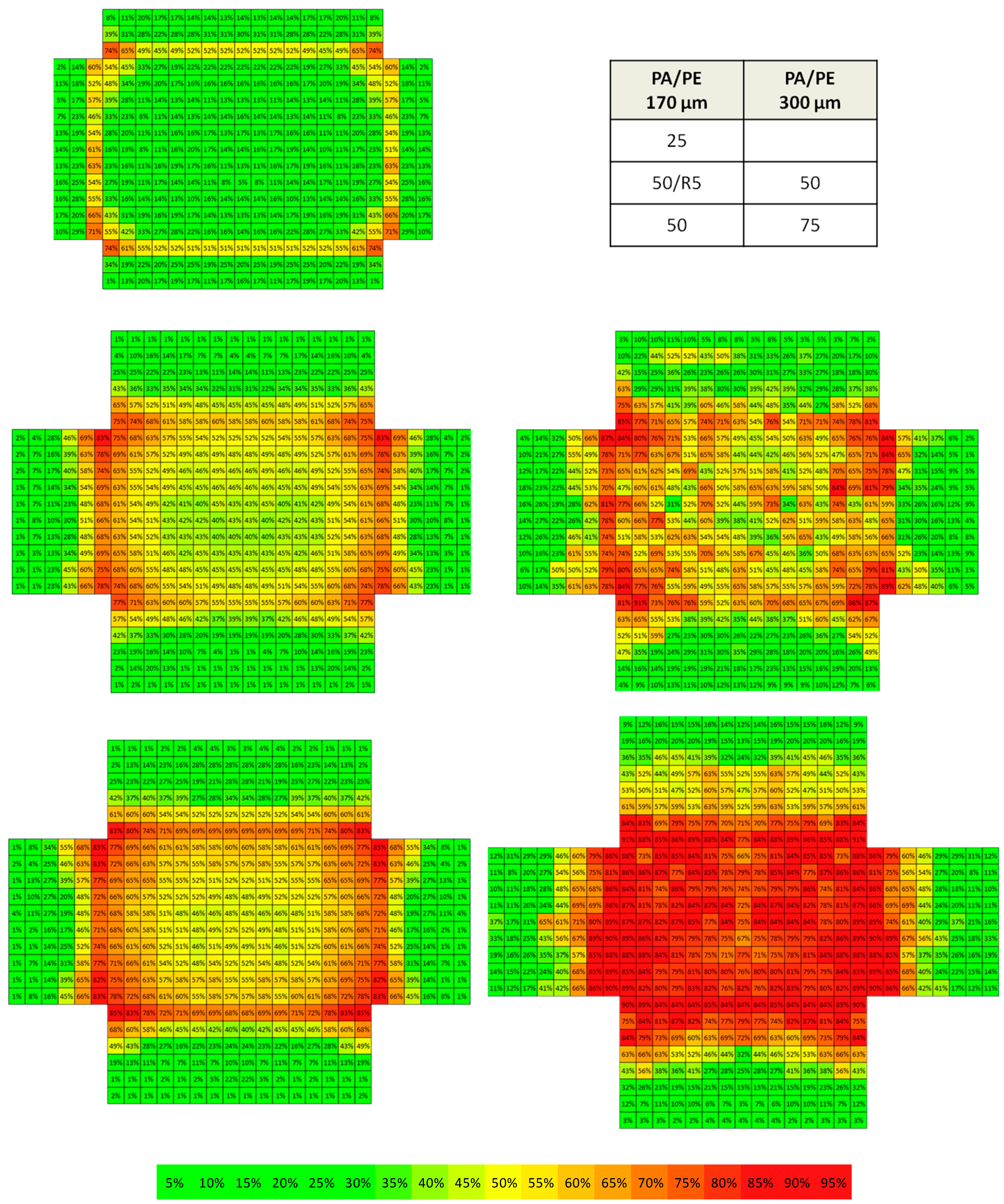

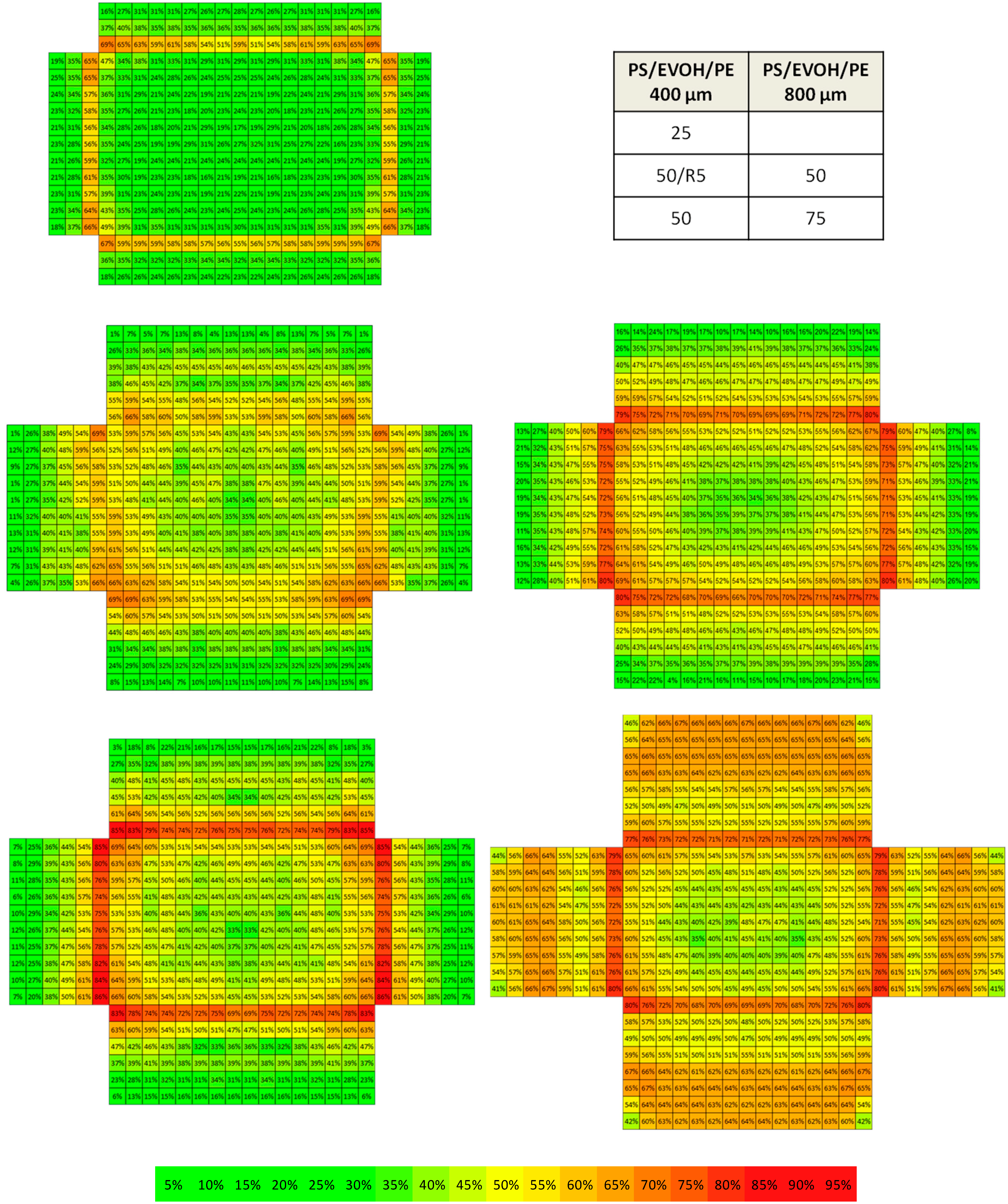

According to this method, the percentage thinning of each material in the bottom, the walls, and the corners as a consequence of the thermoforming processes was visualized.

Figure 2,

Figure 3,

Figure 4 and

Figure 5 show the results in all tray types thermoformed from the PP, APET/PE, PA/PE, and PS/EVOH/PE sheets, respectively. The initial target thickness of the thin and thicker sheets is shown in

Figure 2,

Figure 3,

Figure 4 and

Figure 5; the measured thickness is shown in

Table 1. From these figures, it is clear that the impact on material thinning was increasingly observed in the 25-mm tray, the 50-mm tray with round corners (radius 5), and the 50-mm tray of each material. Furthermore, material thinning in all thin variants was most pronounced in the 3D and the 2D corners in the bottom. In addition, deep drawing of the thicker variants to 50 and 75 mm analogously showed an increasing thinning effect proportional to the depth. However, the locations in the tray that were most affected by the thermoforming process were strongly dependent on the test material, e.g., in the 75-mm trays of PP, the walls were clearly more affected, whereas in the PA/PE trays particularly the bottom was severely thinned. The material distribution in the 75-mm PS/EVOH/PE tray looks more uniform over the walls, corners, and bottom, whereas the pattern in the 75-mm APET/PE tray rather shows an extrapolation of the pattern of the 25- and 50-mm trays. A possible explanation for these differences might be related to the use (or not) of the plug in combination with each test material. Since the plug material is cooler than the softened sheet, the sheet that contacts the plug is chilled and will not stretch as much as the sheet that is free from the plug [

2,

8,

22].

The average thickness ± standard deviation of all the trays is shown in

Table 3. From these data, it can be deduced that the thinning pattern of the PP/EVOH/PP, APET/PE/EVOH/PE, and (PE/)PA/EVOH/PA/PE trays was quite similar to the patterns of the PP, APET/PE, and PA/PE trays shown in

Figure 2,

Figure 3 and

Figure 4, respectively (therefore these patterns are not shown).

Table 3.

Average thickness ± standard deviation of all sheets and trays expressed in µm.

Table 3.

Average thickness ± standard deviation of all sheets and trays expressed in µm.

| Average thickness (µm) | d0 a | d25 b | d50/R5 c | d50 c | d0 a | d50 d | d75 e |

|---|

| PP | 403 ± 3 | 280 ± 59 | 240 ± 81 | 233 ± 82 | 801 ± 5 | 434 ± 113 | 353 ± 152 |

| PP/EVOH/PP | 404 ± 4 | 282 ± 56 | 229 ± 73 | 226 ± 85 | 789 ± 3 | 437 ± 136 | 354 ± 158 |

| APET/PE | 338 ± 4 | 245 ± 38 | 200 ± 46 | 197 ± 58 | 648 ± 8 | 353 ± 92 | 292 ± 104 |

| APET/PE/EVOH/PE | 369 ± 3 | 277 ± 48 | 213 ± 56 | 218 ± 66 | - | - | - |

| PA/PE | 166 ± 2 | 125 ± 27 | 102 ± 39 | 95 ± 43 | 293 ± 5 | 160 ± 66 | 140 ± 83 |

| PE/PA/EVOH/PA/PE | 164 ± 3 | 121 ± 26 | 93 ± 39 | 90 ± 39 | 291 ± 3 | 165 ± 64 | 133 ± 70 |

| PS/EVOH/PE | 413 ± 3 | 279 ± 55 | 236 ± 62 | 223 ± 73 | 817 ± 3 | 430 ± 124 | 347 ± 73 |

Figure 2.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) PP sheets.

Figure 2.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) PP sheets.

Figure 3.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) APET/PE sheets.

Figure 3.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) APET/PE sheets.

Figure 4.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) PA/PE sheets.

Figure 4.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) PA/PE sheets.

Figure 5.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) PS/EVOH/PE sheets.

Figure 5.

Visual representation of percentage thinning in 25-, 50/R5-, 50-, and 75-trays of the thin (left) and thicker (right) PS/EVOH/PE sheets.

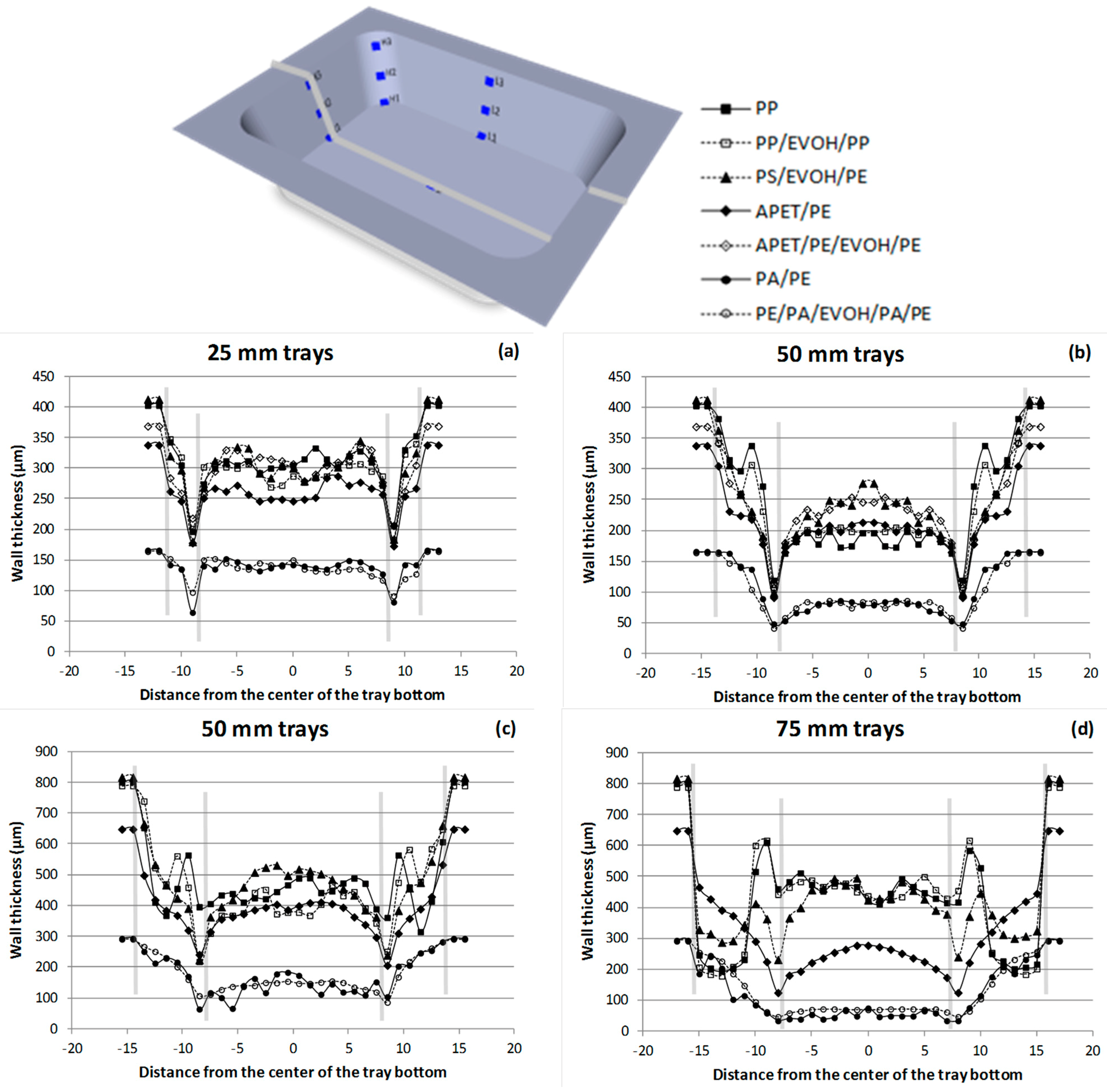

To give a better insight into the absolute wall thickness of the formed trays, the measured wall thickness distribution was also plotted as a profile from the left piece of unconverted sheet over the middle of the short sidewall, through the center of the bottom, over the other short sidewall to the right piece of unconverted sheet of the 25- and 50-mm trays of the thin sheet materials (

Figure 6a,b) and the 50- and 75-mm trays of the thicker sheet materials (

Figure 6c,d), respectively. Again, the profiles of the thin sheet materials clearly show that the edges are more thinned than the walls and the bottom. In addition, in the case of the 50-mm APET/PE trays, no difference in wall thickness distribution was observed after thermoforming trays with or without the aid of the plug (data not shown). The thicker sheet materials show more variation in wall thickness distribution, which might be related to the material characteristics and the parameters that were selected for the plug-assisted thermoforming process. In the case of the PP materials, the plug was optimized with rounded corners to obtain high-quality trays. For the PA materials, no plug was used, since this is generally not done in industrial processes. These results can add to further optimization of the thermoforming process.

Figure 6.

Wall thickness distribution (µm) along a cross-section through the short side walls of the 25-mm (a) and 50-mm (b) trays and the thicker 50-mm (c) and 75-mm (d) trays. Distance from the center of the tray bottom is expressed in centimeter.

Figure 6.

Wall thickness distribution (µm) along a cross-section through the short side walls of the 25-mm (a) and 50-mm (b) trays and the thicker 50-mm (c) and 75-mm (d) trays. Distance from the center of the tray bottom is expressed in centimeter.

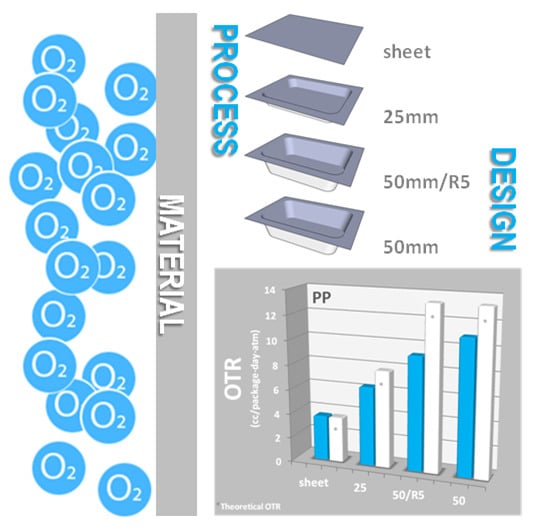

3.3. Oxygen Transmission Rate of Sheets versus Trays

In order to investigate how the material distribution before and after thermoforming relates to the oxygen barrier properties, the OTR of all sheets and trays was measured under the same conditions. In this study 50% RH outside and 90% RH inside the tray was chosen because of the relevance for a lot of potential food products. All tests were performed at standard lab conditions (23 °C). It should be remarked that a lot of food products are stored at 4 °C. Since the permeation and diffusion process is strongly temperature controlled, an Arrhenius model should be applied, from which the OTR can be extrapolated to other temperatures [

23].

Since the OTR of sheets and trays was measured at oxygen pressure gradients of 0%–99.9% and 0%–20.9%, respectively, OTR values are expressed in [cc/m2·day·atm] for the sheets and in [cc/package·day·0.209·atm] for the trays. The latter were recalculated into [cc/package·day·atm]. In order to compare the OTR of sheets versus formed trays, the data were recalculated into the same units, by dividing the OTR of the tray by its surface area. Surface areas of trays with a depth of 25, 50, and 75 mm were respectively, 0.0361, 0.0471, and 0.0574 m2. The exact surface area of the sheet (A0) that is thermoformed into a tray was 0.0247 m2.

3.3.1. Measured OTR

Table 4 shows the OTR of all tested materials. The PP sheets showed the lowest oxygen barrier properties (149.2 and 65.70 cc/m

2·day·atm); the OTR of the APET/PE and PA/PE sheets ranged between 14.3 and 4.70 cc/m

2·day·atm, depending on the respective sheet thickness; and the OTR of the multilayer sheets containing EVOH ranged from 0.48 to 1.7 cc/m

2·day·atm. These results are in accordance with permeability data found in the literature, summarized by Vandewijngaarden

et al. [

24]. Furthermore, all EVOH-containing sheets showed OTR values below 2 cc/m

2·day·atm, the limit value required for packaging applications of shelf-stable food [

20]. The higher OTR of the PE/PA/EVOH/PA/PE multilayer can be explained by the EVOH type containing 38 mol% ethylene, exhibiting poorer barrier properties as compared to the 32 mol% ethylene types [

19,

25].

Table 4.

Mean OTR ± standard deviation (n = 2–3) of tested sheets and trays, expressed in cc/m2·day·atm.

Table 4.

Mean OTR ± standard deviation (n = 2–3) of tested sheets and trays, expressed in cc/m2·day·atm.

| Test materials | d0 | OTRsheet | OTR25 | OTR50/R5 | OTR50 | OTR75 |

|---|

| PP | 403 µm | 149.2 ± 0.5 | 179 ± 10 | 197 ± 3 | 234 ± 10 | - |

| PP | 801 µm | 65.70 ± 0.05 | - | 88 ± 2 | 90 ± 2 | 129 ± 5 |

| APET/PE | 338 µm | 10.1 ± 0.6 | 14 ± 2 | 18.5 ± 0.1 | 21 ± 2 | - |

| APET/PE | 648 µm | 4.70 ± 0.04 | - | - | 9.3 ± 0.2 | 13.6 ± 0.3 |

| PA/PE | 166 µm | 14.3 ± 0.3 | 20.95 ± 0.08 | - | 26.47 ± 0.05 | - |

| PA/PE | 293 µm | 8.2 ± 0.7 | - | - | 21.3 ± 0.6 | 29.5 ± 0.3 |

| PP/EVOH/PP | 404 µm | 0.93 ± 0.01 | 1.87 ± 0.02 | 3.42 ± 0.04 | 3.2 ± 0.2 | - |

| PP/EVOH/PP | 789 µm | 0.52 ± 0.05 | - | - | 1.4 ± 0.2 | 2.32 ± 0.08 |

| APET/PE/EVOH/PE | 369 µm | 1.5 ± 0.2 | 2.4 ± 0.5 | - | 2.5 ± 0.1 | - |

| PS/EVOH/PE | 413 µm | 0.9 ± 0.2 | 1.5 ± 0.2 | - | 2.0 ± 0.2 | - |

| PS/EVOH/PE | 817 µm | 0.48 ± 0.03 | - | - | 1.22 ± 0.02 | 1.18 ± 0.09 |

| PA/EVOH/PA/PE | 164 µm | 0.69 ± 0.01 | 1.16 ± 0.02 | - | 1.22 ± 0.03 | - |

| PE/PA/EVOH/PA/PE | 291 µm | 1.7 ± 0.1 | - | - | 2.8 ± 0.1 | 3.57 ± 0.07 |

The OTR results of the EVOH multilayer sheets with PP, PS, and APET were proportional to the thickness of the respective EVOH layers (

Table 1). However, since EVOH resins are hygroscopic and readily absorb moisture depending on the ambient temperature and relative humidity, the oxygen barrier properties of EVOH are adversely affected by the amount of moisture absorbed [

20]. This might explain the small variation observed with the PA/EVOH/PA/PE sheet containing only 8 µm EVOH and performing better than slightly thicker EVOH layers. In a study of Kuraray, the humidity and OTR of middle layer EVOH (EVAL™) in various sandwich structures was determined. These results indicate that the barrier properties of EVAL™ resin layers can be optimized if a film with high moisture transmission rate such as PA is employed on the outside (65% RH) and LDPE on the inside when packaging high-moisture products (100% RH). According to this study, gas barrier properties are better as compared to low moisture transmission rate materials such as PP on the outside in analogous conditions [

25]. Furthermore, care must be taken to determine the OTR, since it can take a long time before the EVOH-containing multilayer reaches equilibrium, especially when sandwiched between two low moisture transmission rate materials. In this respect, the measured OTR of the PP/EVOH/PP sheet at RH of 50% inside and 90% outside of the film could be a slight overestimation of the actual barrier properties [

25].

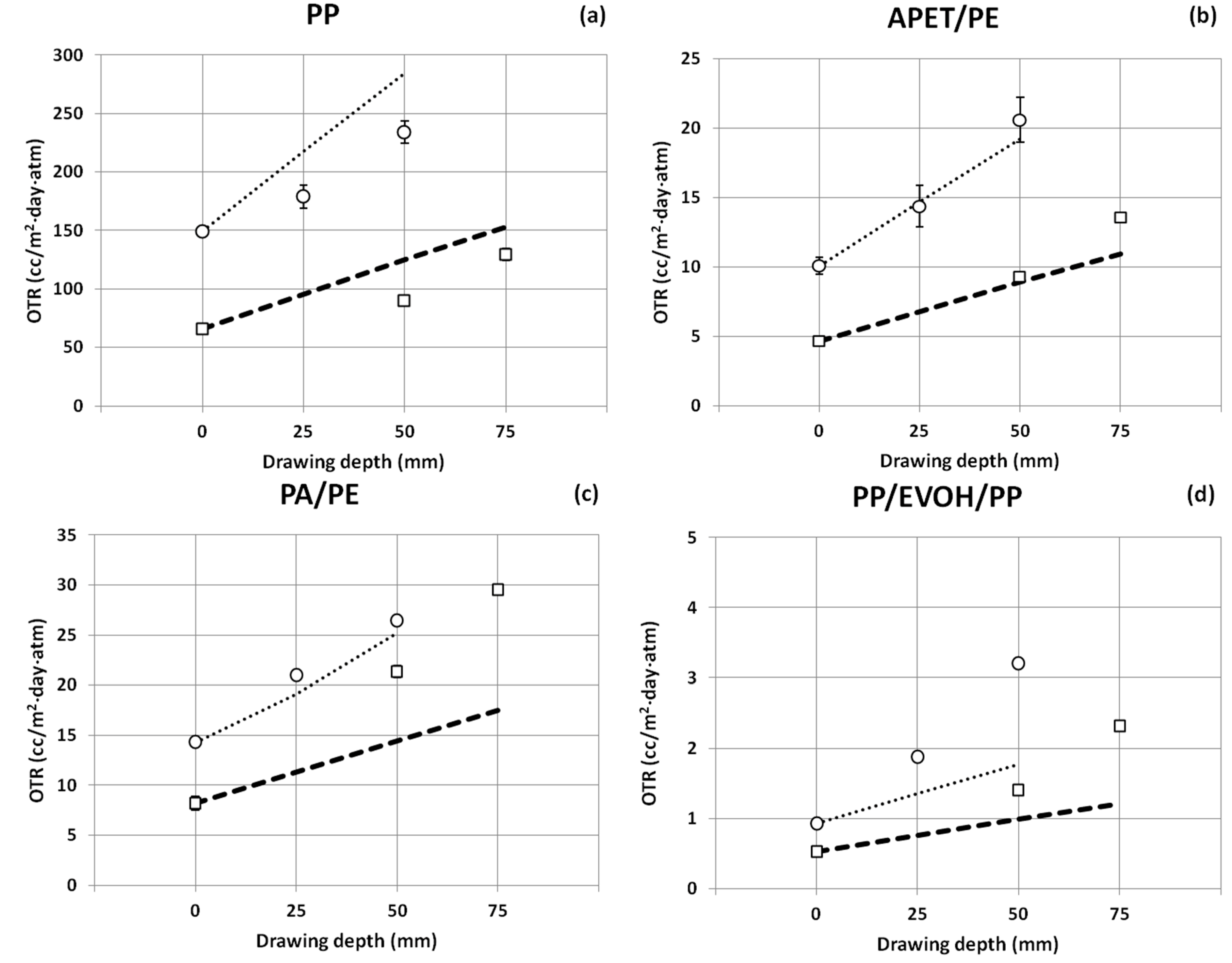

In

Table 4 and

Figure 7, the OTR is shown as a function of the drawing depth for each material. The OTR at drawing depth 0 mm corresponds to OTR

sheet. In all cases the OTR of the trays increased with enhanced deep drawn depth. From these figures, one can clearly see the impact of using a thinner or thicker sheet material on the OTR of the tray, which can be of major importance from an economical and environmental point of view.

3.3.2. Theoretical OTR

It would also be interesting to predict the OTR of the trays based on the thickness and OTR of the sheet. This kind of calculation can be done based on the fact that the OTR is proportional to the area and inversely proportional to the thickness. The OTR of the tray was calculated according to Equation (2), with OTR

0 and

d0 the measured OTR in [cc/m

2·day·atm] and thickness of the unconverted sheet, respectively; and

Ai and

di, the partial tray area and corresponding measured thickness, which are summed over the overall tray:

The calculated OTR of the tray, OTR

tray, is then expressed in [cc/package.day.atm]. Under the assumption of a constant volume of the sheet during thermoforming, one could calculate the theoretical thickness of the tray according to Equation (3), with

A0 the area of the unconverted sheet;

Atray, the area of the tray; and

dtray the theoretical thickness of the tray:

The theoretical OTR of the trays can thus be calculated according to Equation (2), with

n = 1;

Ai the area of the tray,

Atray; and

di the theoretical thickness,

dtray, according to Equation (3) [

5].

Equation (5) was used to predict the normalized OTR values of the 25-mm, 50-mm, and 75-mm trays in

Figure 7. These results are shown by the thin and thicker dashed lines for the respective sheet variants in all the graphs. Although this simplified calculation only considers the ratio of the sheet

versus tray surface area, it seems to be quite a good approximation for materials, such as APET/PE (

Figure 7b) and most EVOH multilayers. However, deviations of the measured data (○ and □) from the dashed line can be caused by various factors, such as uneven thinning (as shown in

Figure 2,

Figure 3,

Figure 4 and

Figure 5), reorientation, or crystallization effects. In the case of monolayer PP, the measured OTR of the trays was far better than the predicted values (

Figure 7a). In contrast, the predicted values of flexible PA/PE were rather an overestimate of the barrier properties as compared to the measured results (

Figure 7c). In the case of the EVOH-containing multilayers, there was a variable deviation from the predicted values (

Figure 7d–g).

Figure 7.

Measured and theoretical OTR in cc/m2·day·atm as function of the deep drawn depth for (a) PP; (b) APET/PE; (c) PA/PE; (d) PP/EVOH/PP; (e) APET/PE/EVOH/PE; (f) PS/EVOH/PE; and (g) (PE/)PA/EVOH/PA/PE materials. Symbols ○ and □ represent the measured OTR of the thin and thicker sheet variant of each material, respectively. Dashed lines (····· and ---) represent the theoretical OTR based on Equation (5) for the thin and thicker sheet variants, respectively.

Figure 7.

Measured and theoretical OTR in cc/m2·day·atm as function of the deep drawn depth for (a) PP; (b) APET/PE; (c) PA/PE; (d) PP/EVOH/PP; (e) APET/PE/EVOH/PE; (f) PS/EVOH/PE; and (g) (PE/)PA/EVOH/PA/PE materials. Symbols ○ and □ represent the measured OTR of the thin and thicker sheet variant of each material, respectively. Dashed lines (····· and ---) represent the theoretical OTR based on Equation (5) for the thin and thicker sheet variants, respectively.

3.4. Effect of (Re)Crystallization

The increase in OTR with increasing drawing depth is mainly the result of a reduction in material thickness. However, this negative effect can be countered by reorientation and (re)crystallization during thermoforming, which might improve the OTR [

10]. The crystallinity of the polymer is a key parameter, since the permeant must seek out amorphous zones in order to penetrate a material. Therefore, a lower degree of crystallinity yields greater permeability. Increased molecular orientation reduces permeability, in effect making the path to permeate more difficult [

26].

By normalizing the OTR data for relative sample thickness, the permeability coefficients (PO

2) expressed in [cc·mm/m

2·day·atm] are useful to observe effects in addition to thinning or increase of the surface area. Equation (6) was applied, with

n the number of layers; OTR the O

2 transmission rate of the multilayer in cc·mm/m

2·day·atm;

di the thickness of

ith layer in mm; and PO

2(

i) the permeability coefficient of

ith layer in cc·mm/m

2·day·atm [

27]:

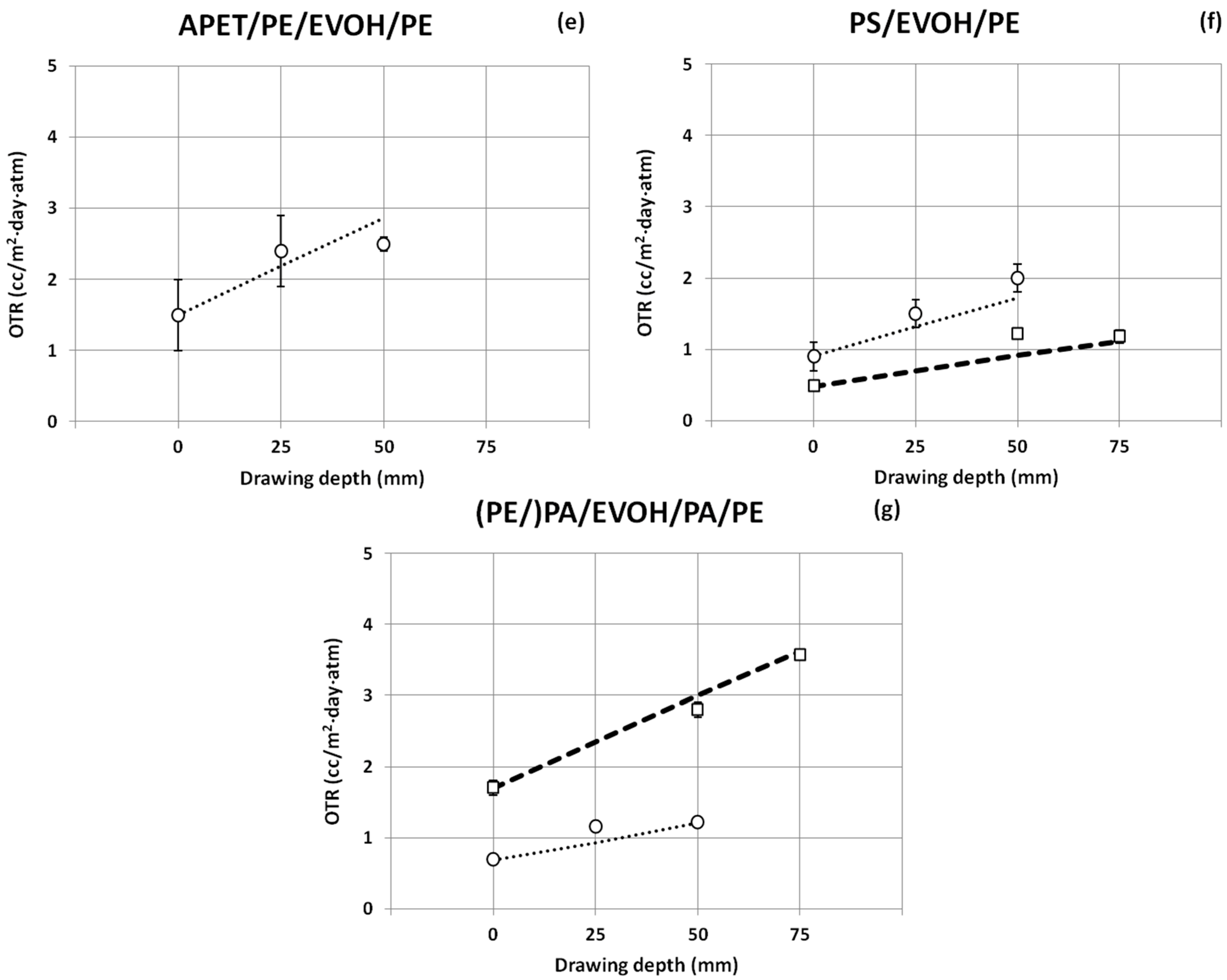

In

Figure 8, the PO

2 of the PP (

a), APET (

b), and PA (

c) layers are shown as a function of the deep drawn depth. These values were calculated from the OTR of the PP, APET/PE, and PA/PE sheets and trays, and the average thickness of the PP, APET, and PA layers, respectively, assuming that the contribution of PE to the oxygen barrier is negligible as compared to APET and PA [

24].

Figure 8.

Permeability coefficients of PP (a), APET (b), and PA layers (c) in sheets and trays, expressed in cc·mm/m2·day·atm as a function of the deep drawn depth. Connected symbols ○ and □ represent the PO2 of the thin and thicker sheet variant of each material, respectively.

Figure 8.

Permeability coefficients of PP (a), APET (b), and PA layers (c) in sheets and trays, expressed in cc·mm/m2·day·atm as a function of the deep drawn depth. Connected symbols ○ and □ represent the PO2 of the thin and thicker sheet variant of each material, respectively.

In the case of PP, the permeability coefficients of the trays were lower as compared to the sheet material (

Figure 8a). This implies that the barrier properties had improved as a consequence of the thermoforming process. DSC analyses were performed on samples from the thin PP sheet and its 50-mm tray to explain the OTR results. The melt enthalpy (Δ

Hm) of PP was significantly increased in three locations of the tray (97 ± 4 J/g in a 3D corner; 101 ± 2 J/g in a 2D corner; and 101 ± 4 J/g in a side wall) as compared to the sheet material (85 ± 1 J/g;

p < 0.01). The degree of crystallinity of PP (

Xc) was increased from 41.3% ± 0.6% in the unconverted sheet, to 47% ± 2%, 49% ± 1%, and 49% ± 2% in the respective corners and wall of the tray. These results might explain why the measured OTR values in

Figure 7a were better than the predicted values, since the latter only take into account material thinning. Obviously, the impact of the material thinning during thermoforming is anticipated by orientation and (re)crystallization of the PP chains, resulting in a better oxygen barrier than might be expected from the simplified theoretical thickness model [

10].

APET’s PO

2 was unchanged for the 25-mm and 50-mm trays, as compared to the thin and thick sheets, respectively. However, thermoforming to a deeper extent negatively affected APET’s PO

2 in both the thin and thicker material variants (

Figure 8b). A DSC analysis was run on the 50-mm thin tray to measure the polymer’s crystallinity. The Δ

Hm of APET was only slightly increased in a 3D corner (40 ± 1 J/g) as compared to the sheet (36 ± 1 J/g) (

p < 0.05), and no significant differences were observed in the 2D corner or wall. Based on the OTR results in

Figure 7b, no positive effect of crystallization was expected; APET’s

Xc was 25.7% ± 0.8% in the unconverted sheet

versus 28.5% ± 0.9% in the 3D corner, 26% ± 3% in a 2D corner, and 27% ± 1% in a thinned wall of the tray.

In the case of the thin PA/PE variant, PO

2 remained rather equal (

Figure 8c). The DSC analysis showed an increased Δ

Hm of PA in a 3D corner (26.9 ± 3.5 J/g,

p < 0.05) and a 2D corner (25.0 ± 3.8 J/g,

p > 0.05) of the 50-mm tray as compared to the Δ

Hm of the sheet (19.0 ± 2.3 J/g). PA’s

Xc was slightly increased from 8% ± 1% in the sheet to 12% ± 2% and 11% ± 2% in a 3D and 2D corner, respectively. In contrast, the barrier properties of the thick PA/PE variant got worse during thermoforming (

Figure 8c). No significant effects were observed on the Δ

Hm of PA in either a 3D corner (18.6 ± 1.2 J/g) or a 2D corner (18.8 ± 0.1 J/g) of the 50-mm tray, as compared to the Δ

Hm of the sheet (18.9 ± 0.3 J/g). Deviation from the theoretical OTR values might be further explained by unequal thinning (

Figure 4) and shrinkage after thermoforming.

3.5. EVOH Multilayer Materials

It is more difficult to explain the observed differences between the measured and predicted OTR values of the EVOH-containing multilayers in

Figure 7. The EVOH gas barrier properties are dependent on various factors, such as the thickness of the EVOH layer, which varies throughout the tray, but also on the RH inside and outside the package, and the thickness and water vapor transmission rate of the constituent layers [

19,

28,

29]. Furthermore, EVOH copolymers are semi-crystalline and the crystallinity, orientation, chain stiffness, free volume, and cohesive energy density of the polymer influence the barrier properties as well [

28,

30]. The crystallinity of EVOH might be affected by parameters of the thermoforming process, e.g., the thermoforming temperatures of the respective multilayers are different, as shown in

Table 2. The effect on gain or loss of crystallinity of EVOH requires further in-depth study by other techniques, as the melt enthalpy of this polymer was too small to obtain accurate results from the DSC profiles.

In addition, all samples were measured at a RH of 50% outside and 90% inside the trays. It is known that water molecules absorbed by EVOH at a high RH can interact with the hydroxyl groups in the EVOH matrix and weaken the hydrogen bonds between the polymer molecules. This plasticizing effect can impair the barrier properties of hydrophilic polymers [

19]. Therefore, the barrier properties of the PP/EVOH/PP, APET/PE/EVOH/PE, PS/EVOH/PE, and (PE/)PA/EVOH/PA/PE multilayers are also dependent on the thickness and water vapor transmission rate of the sandwich layers [

19,

29]. The presence of small molecules such as water in the polymer matrix may change the way oxygen is sorbed and diffused in a polymer. Hernandez has discussed different interaction mechanisms of water and oxygen within PA polymers, including self-association of water molecules and oxygen/water molecular competition [

31].

In order to acquire deeper insight into the OTR of the EVOH multilayers, microscopic thickness measurements of the individual layers were performed in strategic locations such as the long (L) and short (K) side wall, a 3D corner (H), and the bottom (B) of all tray types (

Figure 9). The portion of EVOH as compared to the actual total thickness in each location was expressed as percentage EVOH. The average EVOH% in the respective locations of three trays was compared to the initial EVOH% in the sheets. These results indicated that the EVOH layer, in general, was reduced proportionally with the global thickness (EVOH% remained about the same). Nonetheless, the EVOH layers in locations close to the bottom (L

1, K

1, and H

1) were the most reduced during thermoforming.

Table 5 shows the minimum and maximum EVOH% that were measured in the respective locations shown in

Figure 9.

Table 5.

Minimum and maximum portion of EVOH in the layer distribution in locations Ki, Li, Hi, and Bi of the trays as compared to the average EVOH% in the respective sheet materials.

Table 5.

Minimum and maximum portion of EVOH in the layer distribution in locations Ki, Li, Hi, and Bi of the trays as compared to the average EVOH% in the respective sheet materials.

| Multilayer | sheet | tray25 a | tray50 b | sheet | tray50 b | tray75 c |

|---|

| PP/EVOH/PP | 3.2% | 1.5%–3.2% | 1.8%–3.5% | 3.0% | 1.9%–3.7% | 2.0%–4.4% |

| PS/EVOH/PE | 2.9% | 1.9%–3.5% | 2.1%–3.4% | 3.1% | 1.8%–3.3% | 1.8%–3.5% |

| APET/PE/EVOH/PE | 2.7% | 1.8%–4.1% | 1.5%–3.0% | - | - | - |

| PE/PA/EVOH/PA/PE | 4.9% | 3.8%–5.6% | 3.6%–5.4% | 4.1% | 3.4%–4.9% | 3.1%–4.3% |

Figure 9.

Locations in 25- (a), 50- (b), and 75-mm (c) trays that were analyzed microscopically for individual layer thickness. Locations L, K, H, and B were selected in the long side wall, short side wall, corner, and bottom, respectively.

Figure 9.

Locations in 25- (a), 50- (b), and 75-mm (c) trays that were analyzed microscopically for individual layer thickness. Locations L, K, H, and B were selected in the long side wall, short side wall, corner, and bottom, respectively.

In addition, the absolute values of the average EVOH layer thickness in the most critical locations are shown in

Table 6. In this study, the minimum thickness of the EVOH layer was 1.5 µm ± 0.2 µm (H

1); 1.4 µm ± 0.3 µm (H

1); 2.5 µm ± 0.3 µm (K

1); and 1.1 ± 0.1 µm (H

1) in the 50-mm trays of the thin variants of PP/EVOH/PP; APET/PE/EVOH/PE; PS/EVOH/PE; and PA/EVOH/PA/PE, respectively.

In the thicker variants, EVOH was also most reduced in locations L

1, K

1, and H

1 (

Table 6), except for the 75-mm PP/EVOH/PP tray, where locations L

3, K

3, H

1, and H

3 (5.7 ± 0.7 µm, 6.5 ± 1.2 µm, 4.5 ± 0.6 µm, and 5.5 ± 0.6 µm, respectively) showed the thinnest EVOH layers, which could be expected from

Figure 2. These results give a quantitative impression of the impact of the thermoforming process on the EVOH layer thickness.

Table 6.

EVOH layer thickness in the most critical locations of the tray versus sheet material in µm.

Table 6.

EVOH layer thickness in the most critical locations of the tray versus sheet material in µm.

| Multilayer | Tray type | Sheet a | L1 b | K1 b | H1 b |

|---|

| PP/EVOH/PP | tray25 | 13 ± 1 | 3.2 ± 0.7 | 4.1 ± 0.6 | 2.7 ± 0.8 |

| tray50 | 13 ± 1 | 2.4 ± 0.2 | 2.4 ± 0.5 | 1.5 ± 0.2 |

| PS/EVOH/PE | tray25 | 12 ± 2 | 3.5 ± 0.6 | 4.7 ± 0.3 | 3.8 ± 0.7 |

| tray50 | 12 ± 2 | 2.6 ± 0.3 | 2.5 ± 0.3 | 2.9 ± 0.5 |

| APET/PE/EVOH/PE | tray25 | 10 ± 1 | 3.1 ± 0.5 | 4.4 ± 0.4 | 2.4 ± 0.7 |

| tray50 | 10 ± 1 | 2.2 ± 0.4 | 1.6 ± 0.2 | 1.4 ± 0.3 |

| PA/EVOH/PA/PE | tray25 | 8 ± 1 | 3.0 ± 0.3 | 3.8 ± 0.5 | 2.8 ± 0.2 |

| tray50 | 8 ± 1 | 2.4 ± 0.2 | 2.3 ± 0.2 | 1.1 ± 0.1 |

| PP/EVOH/PP | tray50 | 24 ± 2 | 8.8 ± 1.1 | 5.3 ± 1.5 | 3.3 ± 0.4 |

| tray75 | 24 ± 2 | 10.5 ± 1.4 | 11.5 ± 2.1 | 4.5 ± 0.6 |

| tray75 | 24 ± 2 | 5.7 ± 0.7 (L3) | 6.5 ± 1.2 (K3) | 5.5 ± 0.6 (H3) |

| PS/EVOH/PE | tray50 | 24 ± 3 | 5.0 ± 0.6 | 5.9 ± 2.1 | 3.3 ± 0.7 |

| tray75 | 24 ± 3 | 4.9 ± 1.1 | 5.8 ± 0.7 | 3.9 ± 0.1 |

| PE/PA/EVOH/PA/PE | tray50 | 12 ± 1 | 4.8 ± 0.3 | 3.9 ± 0.7 | 2.6 ± 0.6 |

| tray75 | 12 ± 1 | 2.2 ± 0.2 | 1.9 ± 0.2 | 1.3 ± 0.2 |

In summary, the presence of an EVOH layer (~3%) in the PP variants resulted in OTR values that were 160, 96, and 73 times better than the OTR values of the thin PP monolayer sheet and the 25- and 50-mm trays, respectively. In the case of the thicker PP variants, the OTR values of the PP/EVOH/PP sheet, 50-, and 75-mm trays were improved with a factor of 126, 64, and 56, respectively, as compared to the monolayer PP samples. As discussed in

Section 3.3.1, the measured oxygen barrier of the PP/EVOH/PP sheets might be an overestimation. In addition, the OTR of the PA/EVOH/PA/PE sheet and the 25- and 50-mm trays (~4.9% EVOH) was 21, 18, and 22 times better than the respective sheet and trays without an EVOH layer, and the OTR of the APET/PE/EVOH/PE sheet and 25- and 50-mm trays (2.7% EVOH) was 7, 6, and 8 times better than the respective sheet and trays without an EVOH layer. Furthermore, the importance of considering the mol% ethylene in the EVOH grade was shown in the OTR of the PE/PA/EVOH/PA/PE sheet and the 50- and 75-mm trays (4.1% of 38 mol% ethylene EVOH), which were improved by a factor of only 5, 8, and 8 as compared to the samples without EVOH.

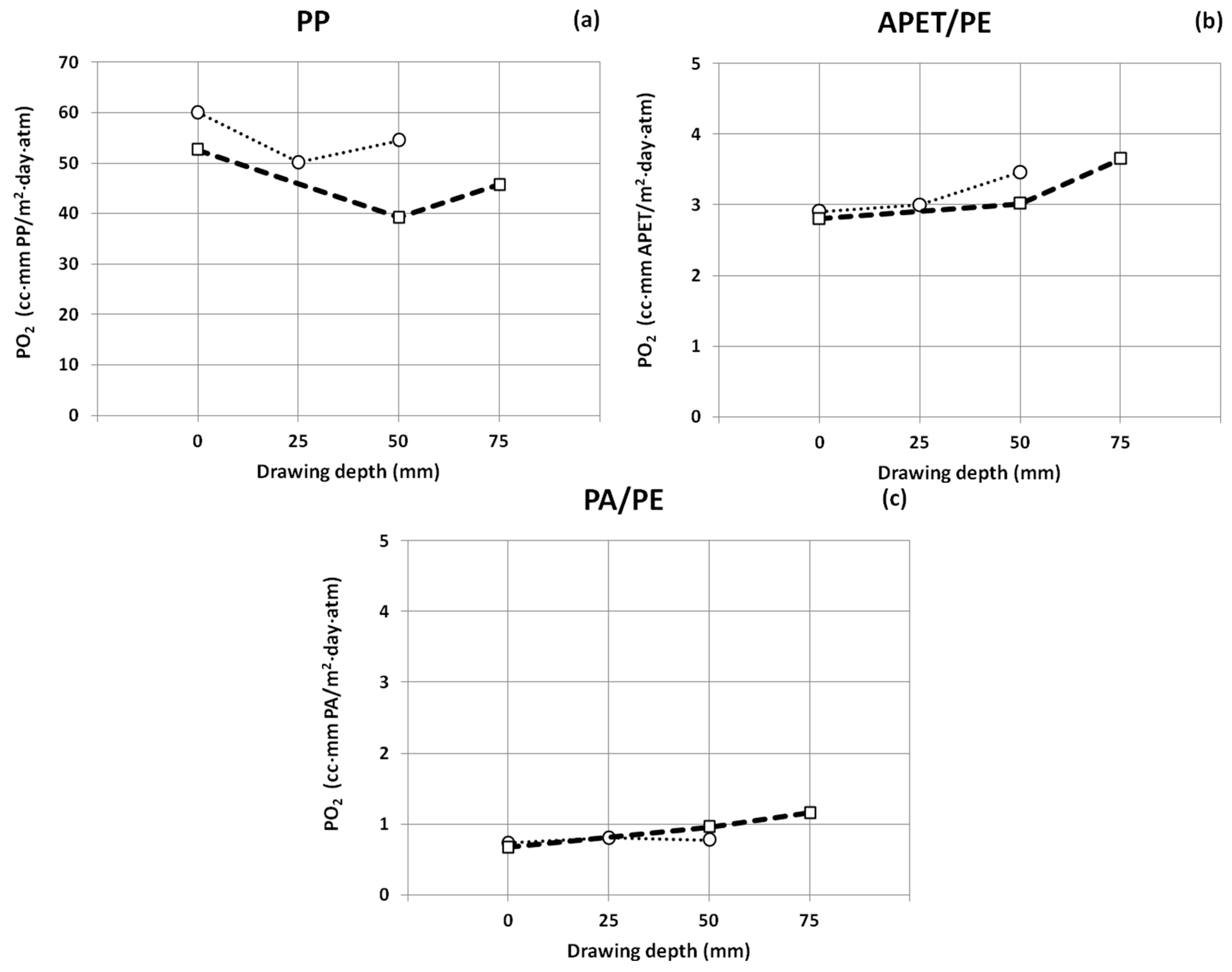

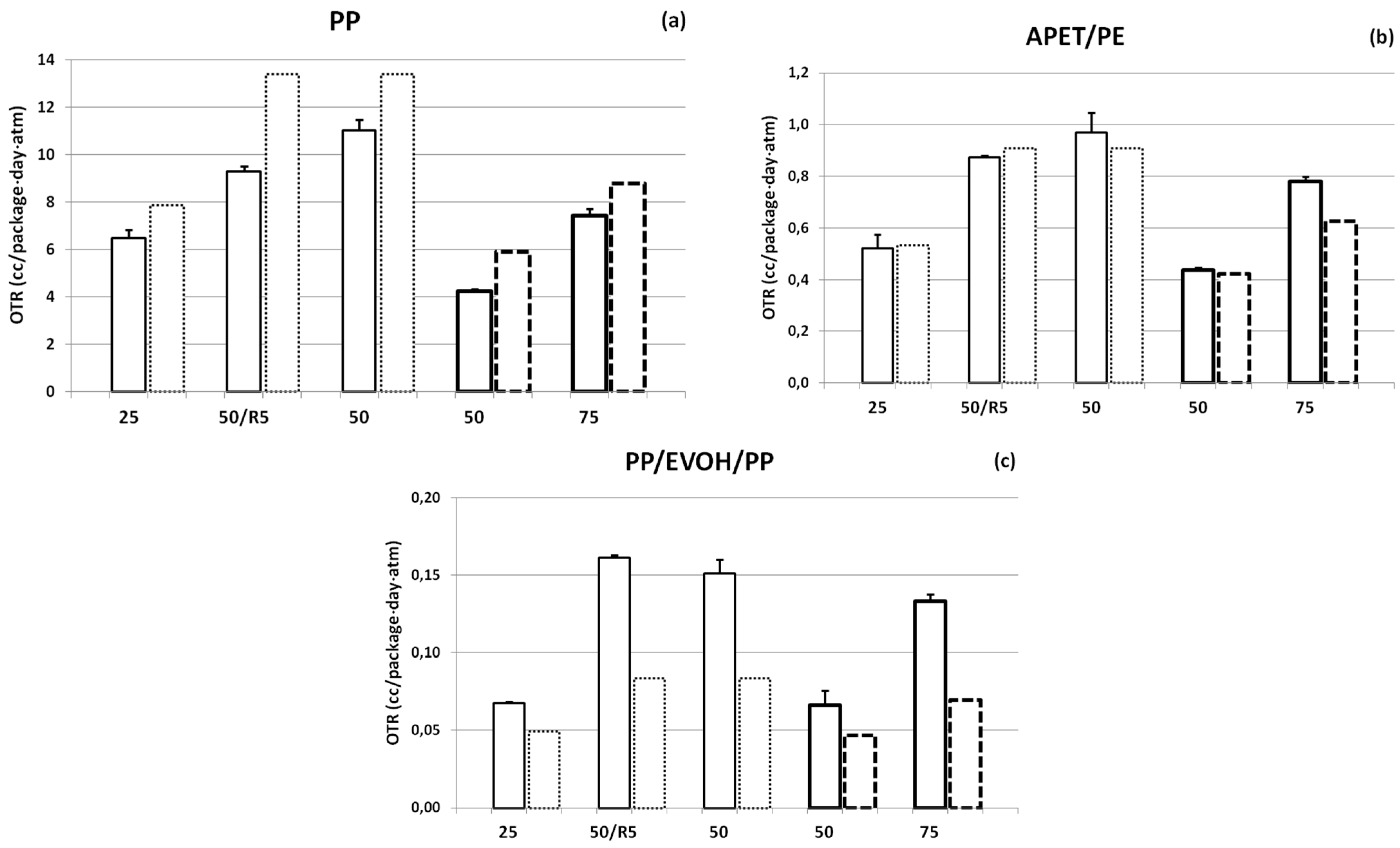

3.6. Impact of Tray Design on the OTR

So far, the effect of increased exposed area of the thermoformed trays is eliminated from the previous expressions of the OTR data. With regard to the application of a tray as a food packaging, it is important to consider the exposed area and express the OTR of the trays in [cc/package·day·atm].

Figure 10 shows the OTR data of the 25-, 50-/R5, 50-, and 75-mm trays of PP, APET/PE, and PP/EVOH/PP expressed in [cc/package·day·atm]. These figures clearly demonstrate the impact of the thickness of the sheet material, as well as the impact of the deep drawing depth and the effect of round corners, on the final OTR of the thermoformed trays. The uneven thinning of PP (shown in

Figure 2), which was increasingly observed in the 25-, 50/R5- and 50-mm trays, clearly corresponds to an enhanced OTR − from 6.5 ± 0.4 to 9.3 ± 0.2 and 11.0 ± 0.5 cc/package·day·atm in the respective trays (

Figure 10a). The same phenomenon was observed for the APET/PE materials, showing OTR values of 0.5 ± 0.1, 0.87 ± 0.01, and 1.0 ± 0.1 cc/package·day·atm, respectively (

Figure 10b). These results indicate that modifying the mold design to form trays with round corners has a beneficial effect on the final OTR of the tray [

32,

33].

In contrast, no significant effect of round corners was observed for PP/EVOH/PP multilayers (

Figure 10c). Furthermore, since the OTR of the 25- and 50-mm trays of APET/PE/EVOH/PE and PA/EVOH/PA/PE were in close proximity (

Table 4), no significant effect was expected from a tray design with round corners either.

Figure 10.

OTR results expressed in cc/package·day·atm. Bars in thin and thick lines represent the measured OTR of the trays from the thin and thicker (a) PP; (b) APET/PE; and (c) PP/EVOH/PP material variants, respectively; bars in thin and thicker dotted lines (····and ---) represent the theoretical OTR based on Equation (4) for the thin and thicker sheet variants, respectively.

Figure 10.

OTR results expressed in cc/package·day·atm. Bars in thin and thick lines represent the measured OTR of the trays from the thin and thicker (a) PP; (b) APET/PE; and (c) PP/EVOH/PP material variants, respectively; bars in thin and thicker dotted lines (····and ---) represent the theoretical OTR based on Equation (4) for the thin and thicker sheet variants, respectively.

3.7. Simulation of the Oxygen Level in the Packaging

In practice it will be important to estimate the barrier properties in terms of the shelf life of a food product in specific storage conditions or the time when a specific percentage of oxygen will be present in the package at a specific storage temperature. The O

2 concentration in the packaging is determined by the residual O

2 after packaging, the respiration or consumption of O

2 by the product, and by the O

2 ingress during the shelf life (OTR) [

34,

35]. The simulation software PredOxyPack

® is a practical tool to predict the oxygen ingress for different packaging configurations, materials, and time–temperature profiles [

36]. In this way, realistic estimations can be made for the circumstances to which food is exposed during its preservation including cold chain conditions [

37].

Using the OTR data obtained in this study combined with the following settings of simulation: (i) an impermeable seal film; (ii) tray filled with 50% headspace; (iii) a residual level of 0.5% O2 after filling; and (iv) a time temperature profile of 20 months at 21 °C—the O2 evolution in the package was calculated for the different EVOH-trays. After 20 months, the O2 concentration under the simulation conditions would be 3.5% and 3.7% for the 50 and 50/R5 PP/EVOH/PP trays, respectively; and 2.9%, 2.3%, and 1.8% for the thin 50-mm APET/PE/EVOH/PE, PS/EVOH/PE, and PA/EVOH/PA/PE trays, respectively. In addition, the O2 concentration under the same simulation conditions would be 3.7%, 3.0%, 2.5%, and 2.2% for the 25-mm APET/PE/EVOH/PE, PP/EVOH/PP, PS/EVOH/PE, and PA/EVOH/PA/PE trays, respectively.