The Influence of the Initial Treatment of Oak Wood on Increasing the Durability of Exterior Transparent Coating Systems

Abstract

:1. Introduction

2. Materials and Methods

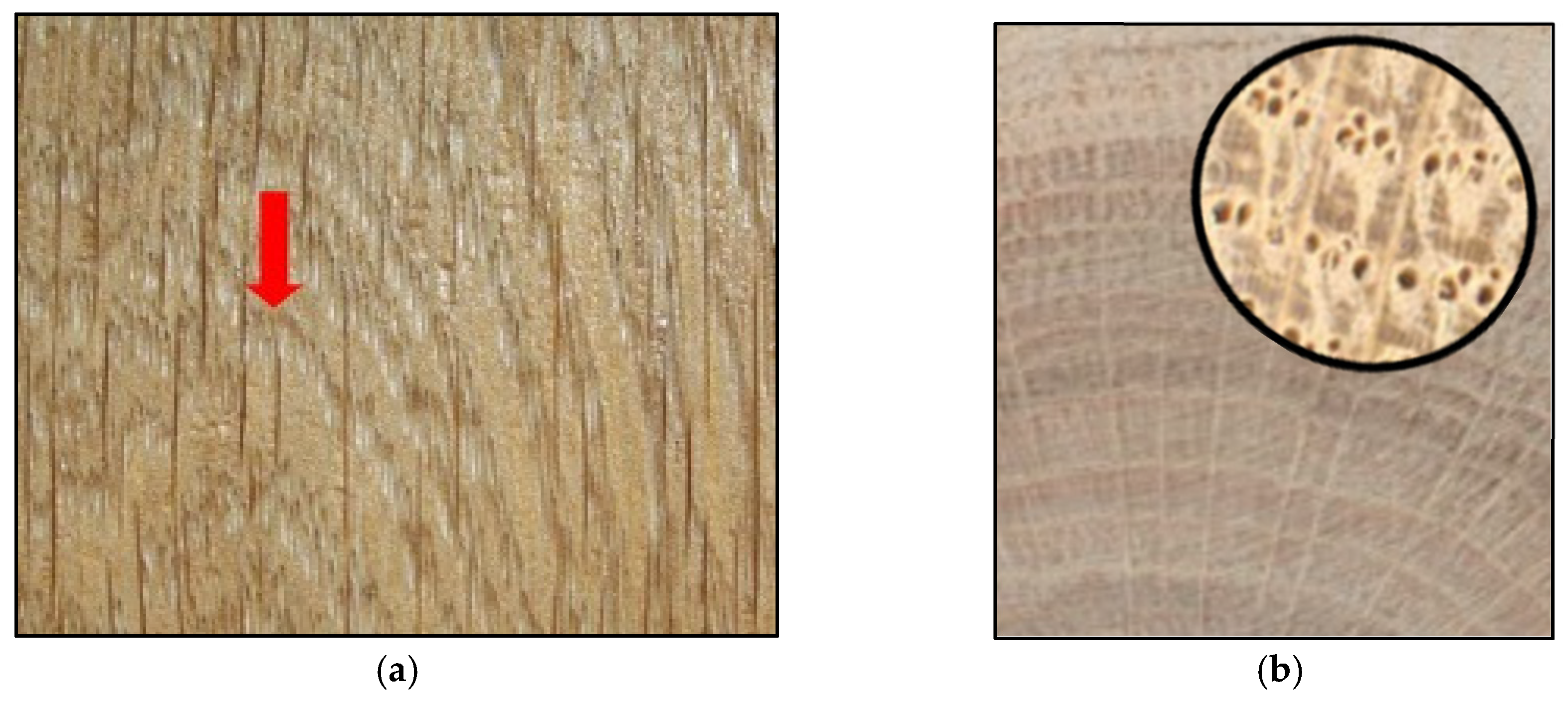

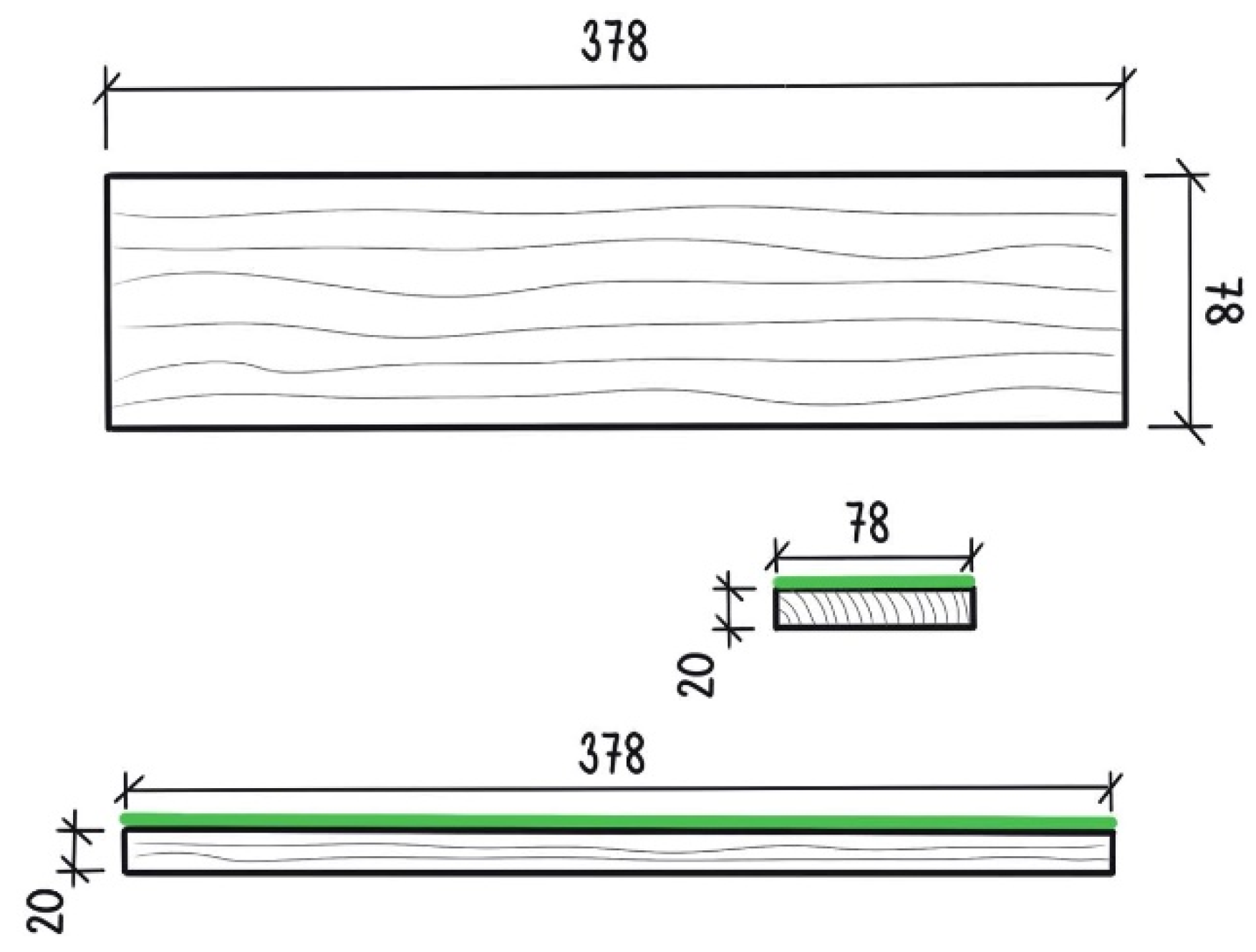

2.1. Wood Samples, Treatment, and Exposure

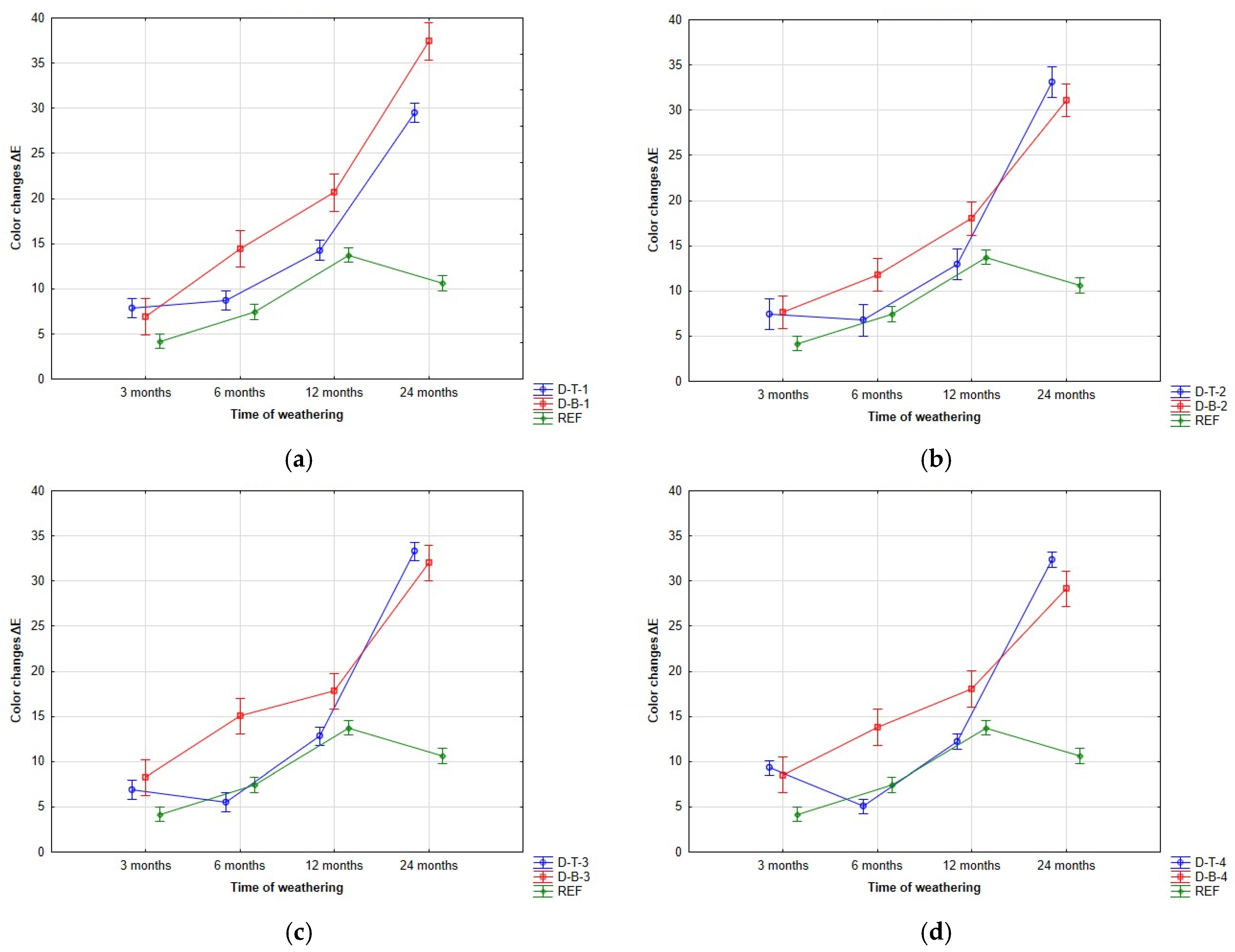

2.2. Changes in Color Determination

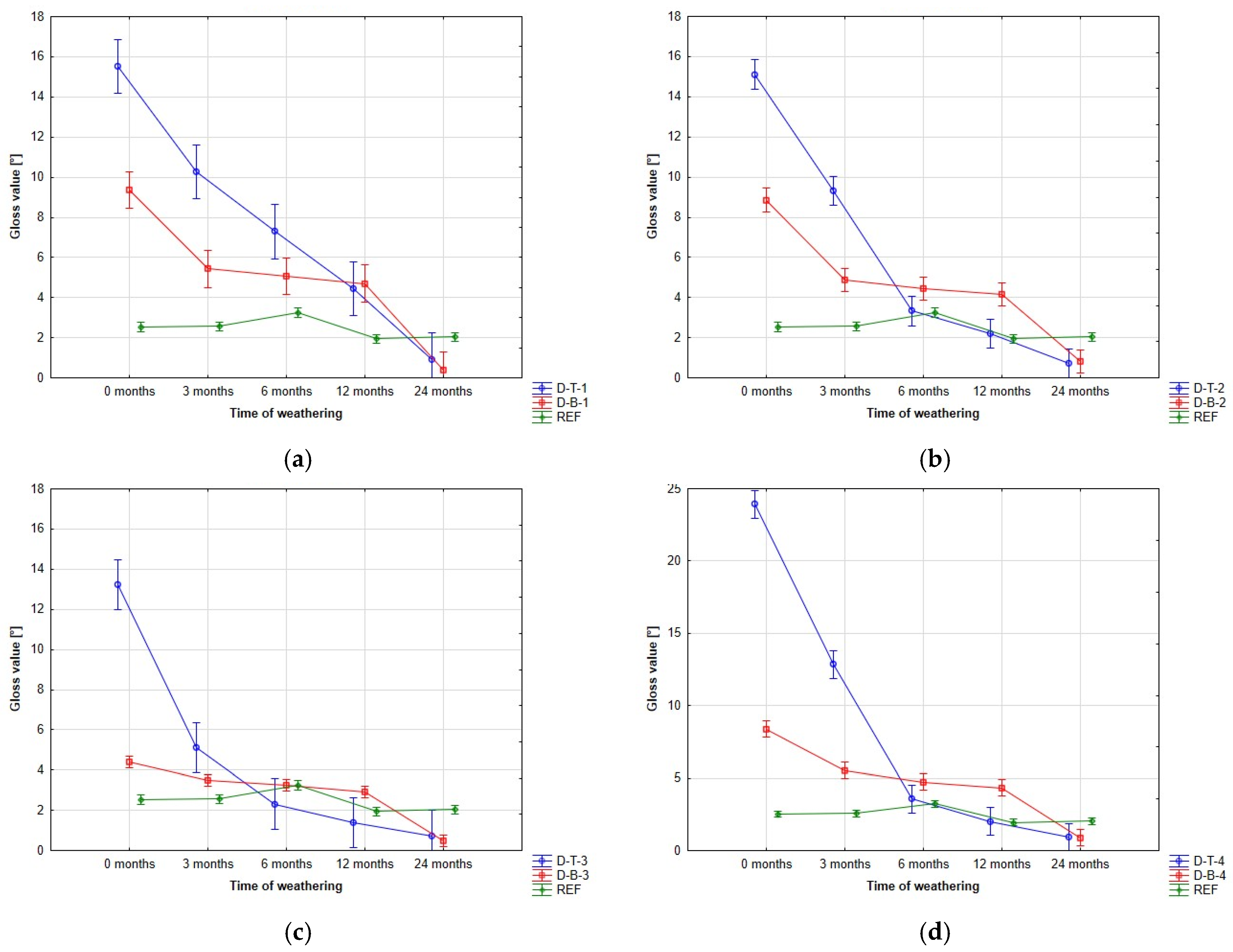

2.3. Changes in Gloss Determination

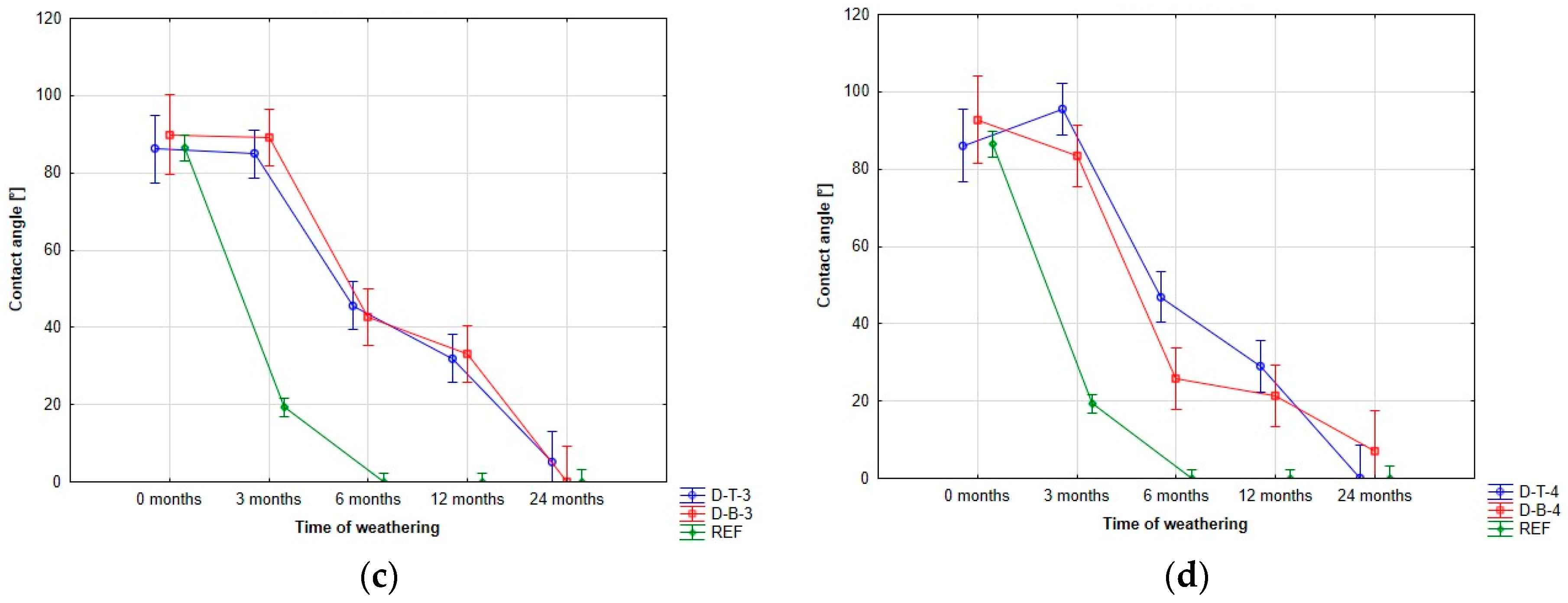

2.4. Changes in Hydrophobicity Determination and Surface Free Energy

- γS—surface free energy of a solid material,

- γL—surface energy of a liquid,

- γSL—surface energy at the interface of solid material and liquid,

- θ—wetting angle [44].

2.5. Visual Evaluation and Microscopic Analyses

2.6. Statistical Analyses

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Požgaj, A.; Chovanec, D.; Kurjatko, S.; Babiak, M. Štruktúra a Vlastnosti Dreva, 1st ed.; Príroda: Bratislava, Slovakia, 1993; p. 485. ISBN 80-07-00600-1. [Google Scholar]

- Čabalová, I.; Výbohová, E.; Igaz, R.; Kristak, L.; Kačík, F.; Antov, P.; Papadopoulos, A.N. Effect of oxidizing thermal modification on the chemical properties and thermal conductivity of Norway spruce (Picea abies L.) wood. Wood Mater. Sci. Eng. 2022, 17, 366–375. [Google Scholar] [CrossRef]

- Nutsch, W. Příručka pro Truhláře, 2nd ed.; Europa-Sobotáles: Praha, Czech Republic, 2006; ISBN 80-86706-14-1. [Google Scholar]

- Rowell, R.M. Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 978-1-4398-5380-1. [Google Scholar]

- Wagenführ, R. Holzatlas, 6th ed.; Fachbuchverlag: Leipzig, Germany, 2007; p. 816. ISBN 3-446-40649-2. [Google Scholar]

- Dawson, B.S.W.; Singh, A.P.; Kroese, H.W.; Schwitzer, M.A.; Gallagher, S.; Riddiough, S.J.; Wu, S. Enhancing exterior performance of clear coatings through photostabilization of wood. Part 2: Coating and weathering performance. J. Coat. Technol. Res. 2008, 5, 207–219. [Google Scholar] [CrossRef]

- Pánek, M.; Dvořák, O.; Oberhofnerová, E.; Šimůnková, K.; Zeidler, A. Effectiveness of Two Different Hydrophobic Topcoats for Increasing of Durability of Exterior Coating Systems on Oak Wood. Coatings 2019, 9, 280. [Google Scholar] [CrossRef] [Green Version]

- Pánek, M.; Oberhofnerová, E.; Hýsek, Š.; Šedivka, P.; Zeidler, A. Colour Stabilization of Oak, Spruce, Larch and Douglas Fir Heartwood Treated with Mixtures of Nanoparticle Dispersions and UV-Stabilizers after Exposure to UV and VIS-Radiation. Materials 2018, 11, 1653. [Google Scholar] [CrossRef] [Green Version]

- EN 350; Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Material. European Committee for Standardization: Brussels, Belgium, 2019.

- Kubovský, I.; Oberhofnerová, E.; Kačík, F.; Pánek, M. Surface Changes of Selected Hardwoods Due to Weather Conditions. Forests 2018, 9, 557. [Google Scholar] [CrossRef] [Green Version]

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, accelerated, and simulated weathering of wood: A Review. Bioresources 2020, 15, 9998–10062. [Google Scholar] [CrossRef]

- Sivrikaya, H.; Tesařová, D.; Jeřábková, E.; Can, A. Color change and emission of volatile organic compounds from Scots pine exposed to heat and vacuum-heat treatment. J. Build. Eng. 2019, 26, 100918. [Google Scholar] [CrossRef]

- de Meijer, M. Review on the durability of exterior wood coatings with reduced VOC-content. Prog. Org. Coat. 2001, 43, 217–225. [Google Scholar] [CrossRef]

- Evans, P.D.; Haase, J.G.; Seman, A.S.B.; Kiguchi, M. The Search for Durable Exterior Clear Coatings for Wood. Coatings 2015, 5, 830–864. [Google Scholar] [CrossRef] [Green Version]

- Zeidler, A.; Borůvka, V.; Černý, J.; Baláš, M. Douglas-fir outperforms most commercial European softwoods. Ind. Crop. Prod. 2022, 181, 114828. [Google Scholar] [CrossRef]

- Bockel, S.; Mayer, I.; Konnerth, J.; Harling, S.; Niemz, P.; Swaboda, C.; Beyer, M.; Bieri, N.; Weiland, G.; Pichelin, F. The role of wood extractives in structural hardwood bonding and their influence on different adhesive systems. Int. J. Adhes. Adhes. 2019, 91, 43–53. [Google Scholar] [CrossRef]

- Tondi, G.; Schnabel, T.; Wieland, S.; Petutschnigg, A. Surface properties of tannin treated wood during natural and artificial weathering. Int. Wood Prod. J. 2013, 4, 150–157. [Google Scholar] [CrossRef]

- Tomak, E.D.; Gonultas, O. The Wood Preservative Potentials of Valonia, Chestnut, Tara and Sulphited Oak Tannins. J. Wood Chem. Technol. 2018, 38, 183–197. [Google Scholar] [CrossRef]

- Sjökvist, T. Coated Norway Spruce: Influence of Wood Characteristics on Water Sorption and Coating Durability. Doctoral Dissertation, Linnaeus University Press, Växjö, Sweden, 2019. [Google Scholar]

- Sandberg, D. Additives in wood products—Today and future development. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Springer: Singapore, 2016; pp. 105–172. [Google Scholar] [CrossRef] [Green Version]

- Reinprecht, L.; Tiňo, R.; Šomšák, M. The Impact of Fungicides, Plasma, UV-Additives and Weathering on the Adhesion Strength of Acrylic and Alkyd Coatings to the Norway Spruce Wood. Coatings 2020, 10, 1111. [Google Scholar] [CrossRef]

- Rao, F.; Zhang, Y.; Bao, M.; Zhang, Z.; Bao, Y.; Li, N.; Chen, Y.; Yu, W. Photostabilizing Efficiency of Acrylic-based Bamboo Exterior Coatings Combining Benzotriazole and Zinc Oxide Nanoparticles. Coatings 2019, 9, 533. [Google Scholar] [CrossRef] [Green Version]

- Hýsek, Š.; Żółtowska, S. Novel Lignin–Beeswax adhesive for production of composites from beech and spruce particles. J. Clean. Prod. 2022, 362, 132460. [Google Scholar] [CrossRef]

- Hýsek, Š.; Fidan, H.; Pánek, M.; Böhm, M.; Trgala, K. Water permeability of exterior wood coatings: Waterborne acrylate dispersions for windows. J. Green Build. 2018, 13, 1–16. [Google Scholar] [CrossRef]

- Pánek, M.; Reinprecht, L. Colour stability and surface defects of naturally aged wood treated with transparent paints for exterior constructions. Wood Res. 2014, 59, 421–430. [Google Scholar]

- Nikafshar, S.; McCracken, J.; Dunne, K.; Nejad, M. Improving UV-Stability of epoxy coating using encapsulated halloysite nanotubes with organic UV-Stabilizers and lignin. Prog. Org. Coat. 2021, 151, 105843. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, H.; Li, K.; Yang, Z. Comparison on the Aging of Woods Exposed to Natural Sunlight and Artificial Xenon Light. Polymers 2019, 11, 709. [Google Scholar] [CrossRef] [Green Version]

- Kržišnik, D.; Lesar, B.; Thaler, N.; Humar, M. Influence of Natural and Artificial Weathering on the Colour Change of Different Wood and Wood-Based Materials. Forests 2018, 9, 488. [Google Scholar] [CrossRef] [Green Version]

- Cogulet, A.; Blanchet, P.; Landry, V. The Multifactorial Aspect of Wood Weathering: A Review Based on a Holistic Approach of wood Degradation Protected by Clear Coating. BioResources 2018, 13, 2116–2138. [Google Scholar] [CrossRef] [Green Version]

- Hanifah, N.P.; Martha, R.; Rahayu, I.S.; Darmawan, W.; George, B.; Gérardin, P. Surface characterization and paint bonding quality on chemically and thermally modified short rotation teak wood. Int. Wood Prod. J. 2022, 14, 13–20. [Google Scholar] [CrossRef]

- Jankowska, A.; Zbiec, M.; Kozakiewicz, P.; Koczan, G.; Olenska, S.; Beer, P. The wettability and surface free energy of sawn, sliced and sanded European oak wood. Maderas. Ciencia y Tecnología 2018, 20, 443–454. [Google Scholar] [CrossRef] [Green Version]

- Reinprecht, L.; Mamoňová, M.; Pánek, M.; Kačík, F. The impact of natural and artificial weathering on the visual, colour and structural changes of seven tropical woods. Eur. J. Wood Wood Prod. 2018, 76, 175–190. [Google Scholar] [CrossRef]

- Šimůnková, K.; Hýsek, Š.; Reinprecht, L.; Šobotník, J.; Lišková, T.; Pánek, M. Lavender oil as eco-friendly alternative to protect wood against termites without negative effect on wood properties. Sci. Rep. 2022, 12, 1909. [Google Scholar] [CrossRef] [PubMed]

- Marais, B.N.; Brischke, C.; Militz, H. Wood durability in terrestrial and aquatic environments–A review of biotic and abiotic influence factors. Wood Mater. Sci. Eng. 2022, 17, 82–105. [Google Scholar] [CrossRef]

- Ugovšek, A.; Šubic, B.; Starman, J.; Rep, G.; Humar, M.; Lesar, B.; Thaler, N.; Brischke, C.; Meyer-Veltrup, L.; Jones, D.; et al. Short-term performance of wooden windows and facade elements made of thermally modified and non-modified Norway spruce in different natural environments. Wood Mater. Sci. Eng. 2019, 14, 42–47. [Google Scholar] [CrossRef]

- Žigon, J.; Pavlič, M.; Kibleur, P.; Van Den Bulcke, J.; Petrič, M.; Van Acker, J.; Dahle, S. Treatment of wood with atmospheric plasma discharge: Study of the treatment process, dynamic wettability and interactions with a waterborne coating. Holzforschung 2020, 75, 603–613. [Google Scholar] [CrossRef]

- Kúdela, J.; Sikora, A.; Gondáš, L. Wood Surface Finishing with Transparent Lacquers Intended for Indoor Use, and the Colour Resistance of These Surfaces during Accelerated Aging. Polymers 2023, 15, 747. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Li, L.; Cao, Y.; Wang, Q.; Guo, C. Preparation and flame retardancy of castor oil based UV-cured flame retardant coating containing P/Si/S on wood surface. Ind. Crop. Prod. 2019, 130, 562–570. [Google Scholar] [CrossRef]

- Żółtowska, S.; Mitterpach, J.; Šedivka, P.; Jeroušek, L.; Pánek, M. Outdoor efficacy of additional hydrophobic treatment of weathered wood by siloxane. Constr. Build. Mater. 2022, 360, 129134. [Google Scholar] [CrossRef]

- Meteorologic Data 3.3.2023 Dostupná z. Available online: http://meteostanice.agrobiologie.cz (accessed on 18 April 2023).

- Tolvaj, L.; Faix, O. Artificial Ageing of Wood Monitored by DRIFT Spectroscopy and CIE L*a*b* Color Measurements. 1. Effect of UV Light. Holzforschung 1995, 49, 397–404. [Google Scholar] [CrossRef]

- EN 927-3; Paints and Varnishes. Coating Materials and Coating Systems for Exterior Wood. Part 3: Natural Weathering Test. European Committee for Standardization: Brussels, Belgium, 2019.

- EN ISO 2813; Paints and Varnishes. Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees. European Committee for Standardization: Brussels, Belgium, 2014.

- Bertolin, C.; de Ferri, L.; Strojecki, M. Application of the Guggenheim, Anderson, de Boer (GAB) equation to sealing treatments on pine wood. Procedia Struct. Integr. 2020, 26, 147–154. [Google Scholar] [CrossRef]

- Seo, K.; Kim, M. Re-derivation of young’s equation, Wenzel equation, and Cassie-Baxter equation based on energy minimization. In Surface Energy; InTechOpen: London, UK, 2015. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.-G.; Bao, H.; Deng, W.; Li, Y. Iron-Catalyzed Carboiodination of Alkynes. Synthesis 2018, 50, 2974–2980. [Google Scholar] [CrossRef] [Green Version]

- Pavlič, M.; Petrič, M.; Žigon, J. Interactions of Coating and Wood Flooring Surface System Properties. Coatings 2021, 11, 91. [Google Scholar] [CrossRef]

- Oberhofnerová, E.; Šimůnková, K.; Dvořák, O.; Štěrbová, I.; Hiziroglu, S.; Šedivka, P.; Pánek, M. Comparison of Exterior Coatings Applied to Oak Wood as a Function of Natural and Artificial Weathering Exposure. Coatings 2019, 9, 864. [Google Scholar] [CrossRef] [Green Version]

| Wood | Code | Modification | Code | First Layer | Company | Second Layer | Company | Coating System Number | Number of Sample |

|---|---|---|---|---|---|---|---|---|---|

| Oak | D | Sealed pores | T | Rhenodecor Trans TIX | (DOMAŽLICE, CZECH REPUBLIC) Rhenocoll© | Protector−Plus | Adler© | 1 | 1, 2, 3 |

| Rhenocryl FK 47 High Solid | Rhenocoll© | Protector–Plus | Adler© | 2 | 1, 2, 3 | ||||

| Aquawood Ligno + Base | Adler© | Aquawood Ligno + Top | Adler© | 3 | 1, 2, 3 | ||||

| Lignofix | Stachema© | Lignofix | Stachema© | 4 | 1, 2, 3 | ||||

| Oak | D | Unsealed pores | B | Rhenodecor Trans TIX | Rhenocoll© | Protector–Plus | Adler© | 1 | 1, 2, 3 |

| Rhenocryl FK 47 High Solid | Rhenocoll© | Protector–Plus | Adler© | 2 | 1, 2, 3 | ||||

| Aquawood Ligno + Base | Adler© | Aquawood Ligno + Top | Adler© | 3 | 1, 2, 3 | ||||

| Lignofix | Stachema© | Lignofix | Stachema© | 4 | 1, 2, 3 | ||||

| Oak | D | Reference | REF | Natural wood without coating | 1, 2 | ||||

| Year | Average Daily Temperature (°C) | Maximum Temperature (°C) | Average Relative Air Humidity (%) | Total Precipitation (mm) | Daily Incident Solar Energy (kJ/m2) | Maximum Solar Energy (kJ/m2) |

|---|---|---|---|---|---|---|

| 2021 | 8.92 | 33.9 | 72.38 | 568.93 | 10,416.25 | 28,424 |

| 2022 | 10.34 | 37.7 | 68.98 | 472.81 | 11,534.65 | 29,648 |

| 0.2 > ΔE | Invisible difference |

| 0.2 < ΔE < 2 | Little difference |

| 2 < ΔE < 3 | Color change visible with a high-quality filter |

| 3 < ΔE < 6 | Color change visible with a medium-quality filter |

| 6 < ΔE < 12 | High color changes |

| ΔE > 12 | Different color |

| Time of Weathering (Months) | |||||

|---|---|---|---|---|---|

| 0 | 3 | 6 | 12 | 24 | |

| B-1 |  |  |  |  |  |

| T-1 |  |  |  |  |  |

| B-2 |  |  |  |  |  |

| T-2 |  |  |  |  |  |

| B-3 |  |  |  |  |  |

| T-3 |  |  |  |  |  |

| B-4 |  |  |  |  |  |

| T-4 |  |  |  |  |  |

| Natural Oak—Reference | 12 Months | 24 Months | ||

|---|---|---|---|---|

| Unmodified | Modified | Unmodified | Modified | |

|  |  |  |  |

| Modified Surface | Unmodified Surface | |

|---|---|---|

| Total free surface energy (mN/m) | 42.42 ± 6.85 | 47.12 ± 10.97 |

| Dispersion component (mN/m) | 37.48 ± 2.66 | 37.67 ± 2.84 |

| Polar component (mN/m) | 4.94 ± 4.19 | 9.45 ± 8.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvořák, O.; Kvietková, M.S.; Šimůnková, K.; Machanec, O.; Pánek, M.; Pastierovič, F.; Lin, C.-F.; Jones, D. The Influence of the Initial Treatment of Oak Wood on Increasing the Durability of Exterior Transparent Coating Systems. Polymers 2023, 15, 3251. https://doi.org/10.3390/polym15153251

Dvořák O, Kvietková MS, Šimůnková K, Machanec O, Pánek M, Pastierovič F, Lin C-F, Jones D. The Influence of the Initial Treatment of Oak Wood on Increasing the Durability of Exterior Transparent Coating Systems. Polymers. 2023; 15(15):3251. https://doi.org/10.3390/polym15153251

Chicago/Turabian StyleDvořák, Ondřej, Monika Sarvašová Kvietková, Kristýna Šimůnková, Ondřej Machanec, Miloš Pánek, Filip Pastierovič, Chia-Feng Lin, and Dennis Jones. 2023. "The Influence of the Initial Treatment of Oak Wood on Increasing the Durability of Exterior Transparent Coating Systems" Polymers 15, no. 15: 3251. https://doi.org/10.3390/polym15153251