Thermal Aging Effects on the Mechanical Behavior of Glass-Fiber-Reinforced Polyphenylene Sulfide Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermal Aging Treatments

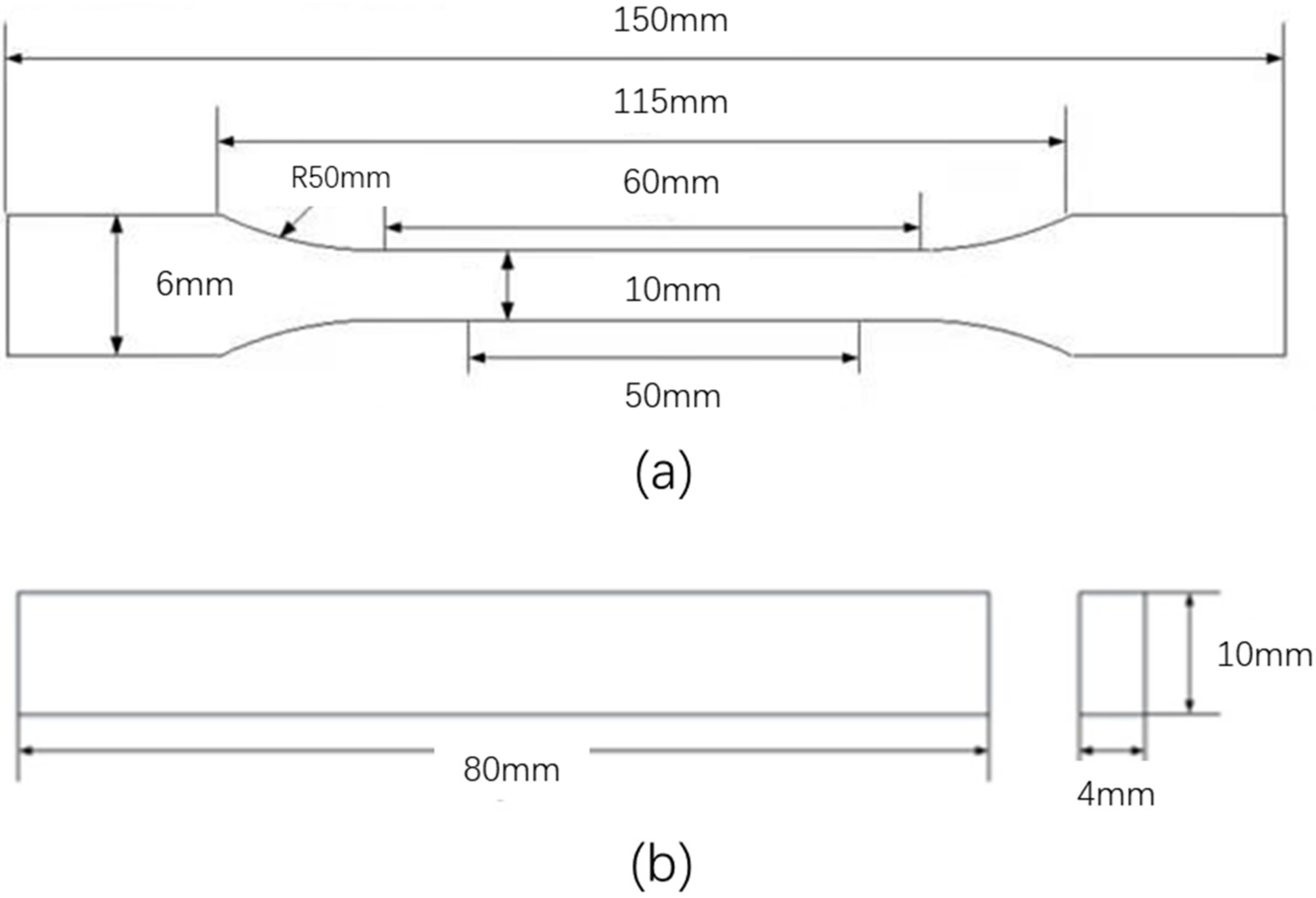

2.3. Mechanical Testing

2.4. Fracture Surface Analysis

2.5. Color Characterization

3. Results and Discussion

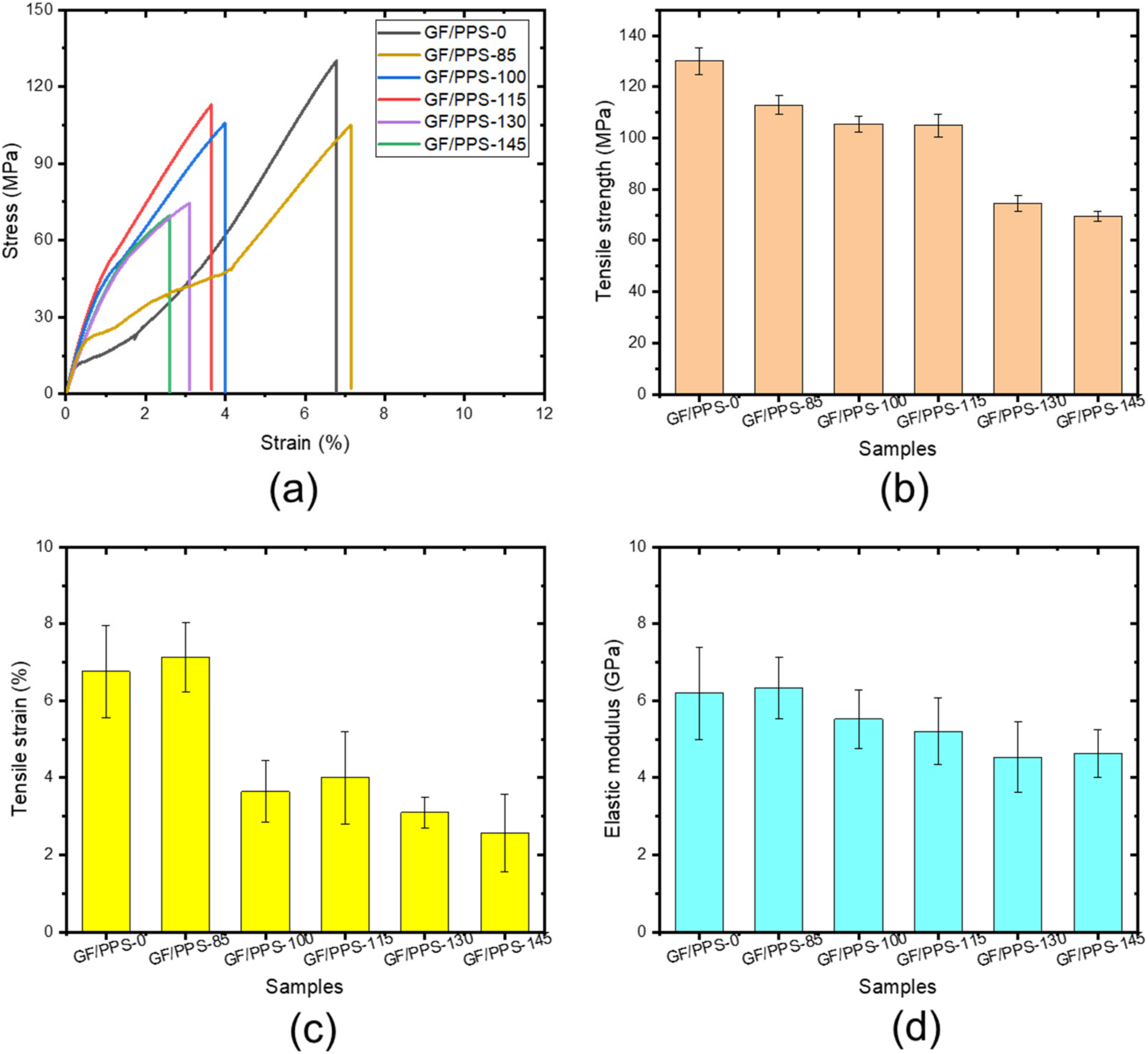

3.1. Tensile Properties

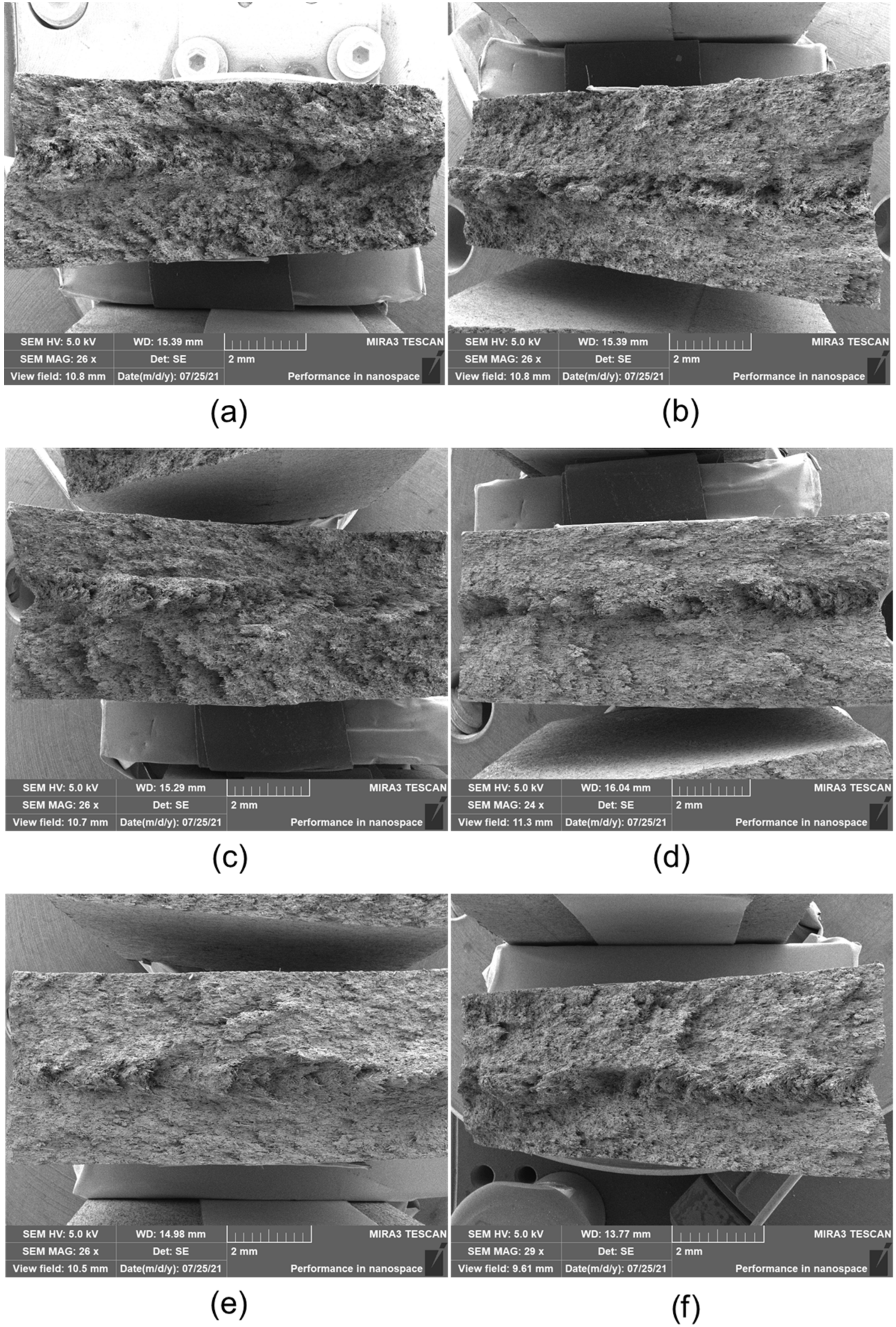

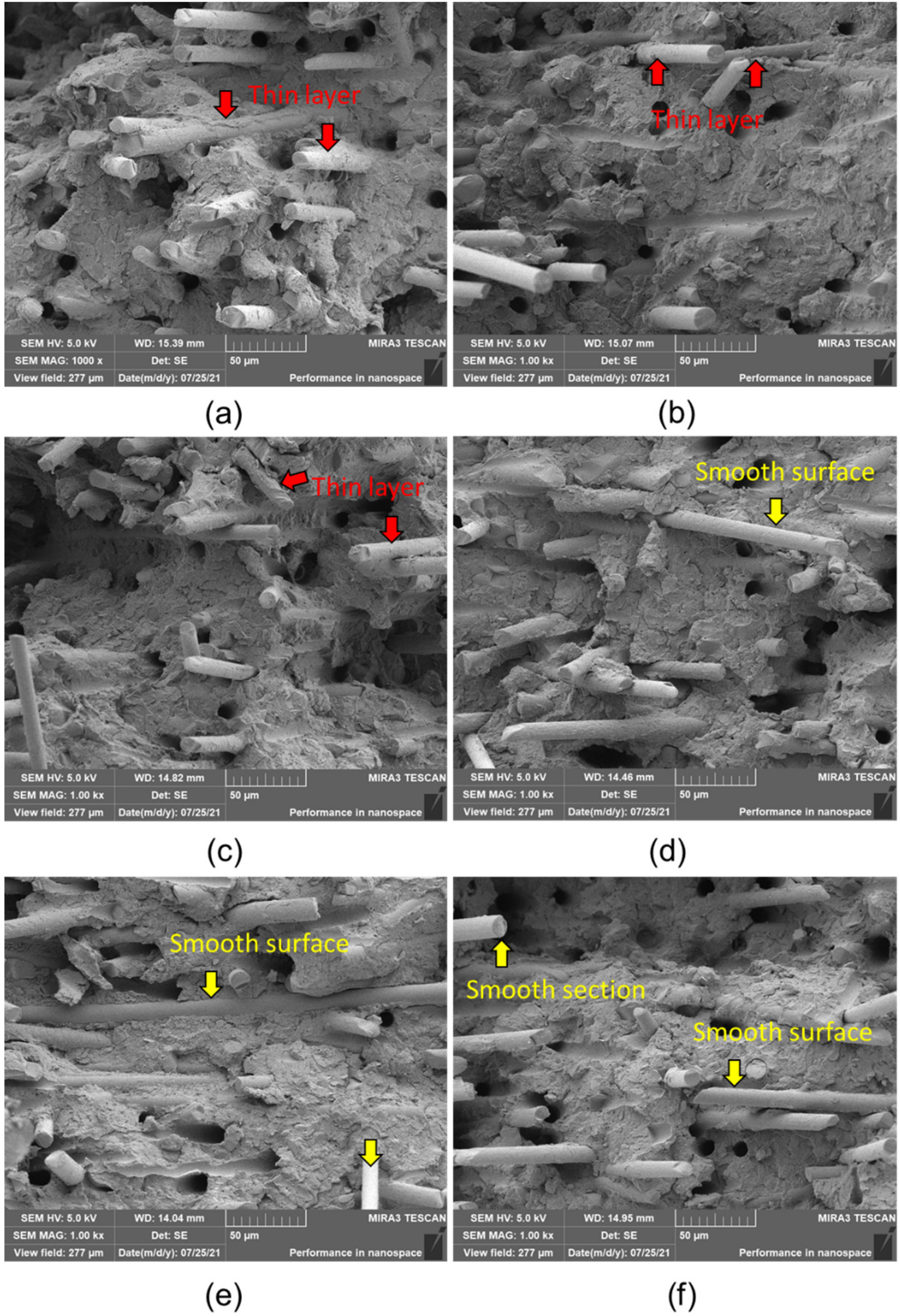

3.2. Failure Analysis

3.3. Flexural Properties

3.4. Color Difference

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yonggang, Y.; Yubao, L.; Zheng, Y.; Yi, Z.; Jie, W.; Xia, C.; Yongrong, C. Synthesis and properties of a copolymer of poly(l,4-phenylene sulfide)–poly(2,4-phenylene sulfide acid) and its nano-apatite reinforced composite. Eur. Polym. J. 2003, 39, 411–416. [Google Scholar] [CrossRef]

- Caramaro, L.; Chabert, B.; Chauchard, J.; Vu-Khanh, T. Morphology and mechanical performance of polyphenylenesulfide carbon fiber composite. Polym. Eng. Sci. 1991, 31, 1279–1285. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, G.; Liu, B.; Wang, X.; Long, S.; Yang, J. Effect of aminated polyphenylene sulfide on the mechanical properties of short carbon fiber reinforced polyphenylene sulfide composites. Compos. Sci. Technol. 2014, 98, 57–63. [Google Scholar] [CrossRef]

- Li, H.; Lv, G.-Y.; Zhang, G.; Ren, H.-H.; Fan, X.-X.; Yan, Y.-G. Synthesis and characterization of novel poly(phenylene sulfide) containing a chromophore in the main chain. Polym. Int. 2014, 63, 1707–1714. [Google Scholar] [CrossRef]

- Zwettler, N.; Engbæk, J.S.; Lundsgaard, R.; Paranowska, I.; Nielsen, T.E.; Clyens, S.; Christiansen, J.; Andersen, M. Chemical surface functionalization of bulk poly (p-phenylene sulfide) yields a stable sulfonic acid catalyst. React. Funct. Polym. 2015, 88, 47–54. [Google Scholar] [CrossRef]

- Zhang, R.-C.; Xu, Y.; Lu, A.; Cheng, K.; Huang, Y.; Li, Z.-M. Shear-induced crystallization of poly(phenylene sulfide). Polymer 2008, 49, 2604–2613. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Díez-Vicente, A.L. High-Performance Aminated Poly(phenylene sulfide)/ZnO Nanocomposites for Medical Applications. ACS Appl. Mater. Interfaces 2014, 6, 10132–10145. [Google Scholar] [CrossRef] [Green Version]

- Bergeret, A.; Pires, I.; Foulc, M.P.; Abadie, B.; Ferry, L.; Crespy, A. The Hygrothermal Behaviour of Glass-fibre-reinforced Thermoplastic Composites: A Prediction of the Composite Lifetime. Polym. Test. 2001, 20, 753–763. [Google Scholar] [CrossRef]

- Jiang, Z.; Gyurova, L.A.; Schlarb, A.K.; Friedrich, K.; Zhang, Z. Study on friction and wear behavior of polyphenylene sulfide composites reinforced by short carbon fibers and sub-micro TiO2 particles. Compos. Sci. Technol. 2008, 68, 734–742. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Xiao, M.; Wang, S.; Ge, X.; Meng, Y. Preparation and properties of electrically conductive PPS/expanded graphite nanocomposites. Compos. Sci. Technol. 2007, 67, 2528–2534. [Google Scholar] [CrossRef]

- Liu, B.; Liu, Z.; Wang, X.; Zhang, G.; Long, S.; Yang, J. Interfacial shear strength of carbon fiber reinforced polyphenylene sulfide measured by the microbond test. Polym. Test. 2013, 32, 724–730. [Google Scholar] [CrossRef]

- Yang, C.; Han, N.; Wang, W.; Zhang, W.; Han, C.; Cui, Z.; Zhang, X. Fabrication of a PPS Microporous Membrane for Efficient Water-in-Oil Emulsion Separation. Langmuir 2018, 34, 10580–10590. [Google Scholar] [CrossRef] [PubMed]

- Fan, T.; Li, Z.; Cheng, B.; Li, J. Preparation, characterization of PPS micro-porous membranes and their excellent performance in vacuum membrane distillation. J. Membr. Sci. 2018, 556, 107–117. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Su, K.; Fan, T.; Cao, L. Mussel-inspired modification of PPS membrane to separate and remove the dyes from the wastewater. Chem. Eng. J. 2018, 341, 371–382. [Google Scholar] [CrossRef]

- Jiang, T.; Geng, C.; Zhou, H.; Lu, A. Rheological and mechanical properties of polyphenylene sulfide reinforced with round and rectangle cross-section glass fibers. High Perform. Polym. 2016, 29, 849–856. [Google Scholar] [CrossRef]

- Li, J.; Qiao, Y.; Li, D.; Zhang, S.; Liu, P. Improving interfacial and mechanical properties of glass fabric/polyphenylene sulfide composites via grafting multi-walled carbon nanotubes. RSC Adv. 2019, 9, 32634–32643. [Google Scholar] [CrossRef] [Green Version]

- Yasuda, H.; Chiba, Y.; Ishikawa, M. Effect of the glass fiber length on the mechanical properties of long glass fiber reinforced polyphenylene sulfide. J. Polym. Eng. 2011, 31, 427–434. [Google Scholar] [CrossRef]

- Liang, J.-Z. Crystallization of glass fiber-reinforced poly(p-phenylene sulfide) nanocomposites. Polym. Int. 2011, 61, 511–515. [Google Scholar] [CrossRef]

- Lohr, C.; Beck, B.; Henning, F.; Weidenmann, K.A.; Elsner, P. Mechanical properties of foamed long glass fiber reinforced polyphenylene sulfide integral sandwich structures manufactured by direct thermoplastic foam injection molding. Compos. Struct. 2019, 220, 371–385. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Q.; Heng, Z.; Zou, H.; Chen, Y.; Liang, M. Improved mechanical properties of graphene oxide/short carbon fiber–polyphenylene sulfide composites. Polym. Compos. 2019, 40, 3866–3876. [Google Scholar] [CrossRef]

- Sliwa, F.; El Bounia, N.-E.; Charrier, F.; Marin, G.; Malet, F. Mechanical and interfacial properties of wood and bio-based thermoplastic composite. Compos. Sci. Technol. 2012, 72, 1733–1740. [Google Scholar] [CrossRef]

- Idrisi, A.; Mourad, A.-H.; Sherif, M. Impact of Prolonged Exposure of Eleven Years to Hot Seawater on the Degradation of a Thermoset Composite. Polymers 2021, 13, 2154. [Google Scholar] [CrossRef] [PubMed]

- Micota, D.; Isaincu, A.; Marşavina, L. Experimental testing of two short-fiber reinforced composites: PPA-GF33 and PPS-GF40. Mater. Des. Process. Commun. 2021, 3, e264. [Google Scholar] [CrossRef]

- Shingankuli, V.L.; Jog, J.P.; Nadkarni, V.M. Thermal and crystallization behavior of engineering polyblends. I. Glass reinforced polyphenylene sulfide with polyethylene terephthalate. J. Appl. Polym. Sci. 1988, 36, 335–351. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, Y.; Min, M.; Gao, Y.; Yu, X.; Lu, A.; Lu, Z. Isothermal crystallization of pure and glass fiber reinforced poly(phenylene sulfide) composites. Polym. Compos. 2009, 30, 460–466. [Google Scholar] [CrossRef]

- Wang, W.; Wu, X.; Ding, C.; Huang, X.; Ye, N.; Yu, Q.; Mai, K. Thermal aging performance of glass fiber/polyphenylene sulfide composites in high temperature. J. Appl. Polym. Sci. 2021, 138, 50948. [Google Scholar] [CrossRef]

- Zuo, P.; Fitoussi, J.; Shirinbayan, M.; Bakir, F.; Tcharkhtchi, A. Thermal aging effects on overall mechanical behavior of short glass fiber-reinforced polyphenylene sulfide composites. Polym. Eng. Sci. 2018, 59, 765–772. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Effect of thermal aging on crystallization behaviors and dynamic mechanical properties of glass fiber reinforced polyphenylene sulfide (PPS/GF) composites. J. Polym. Res. 2020, 27, 77. [Google Scholar] [CrossRef]

- Scobbo, J.J.; Hwang, C.R. Annealing effects in poly(phenylene sulfide) as observed by dynamic mechanical analysis. Polym. Eng. Sci. 1994, 34, 1744–1749. [Google Scholar] [CrossRef]

- Pantelakis, S.G.; Katsiropoulos, C.V.; Lefebure, P. Effect of thermal treatment on the tensile and in-plane shear behavior of carbon fiber-reinforced poly(phenylene sulfide) composite specimens. J. Appl. Polym. Sci. 2007, 107, 3190–3199. [Google Scholar] [CrossRef]

- Perng, L. Thermal decomposition characteristics of poly(phenylene sulfide) by stepwise Py-GC/MS and TG/MS techniques. Polym. Degrad. Stab. 2000, 69, 323–332. [Google Scholar] [CrossRef]

- Cao, J.; Chen, L. Effect of thermal cycling on carbon fiber-reinforced PPS composites. Polym. Compos. 2005, 26, 713–716. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Fitoussi, J.; Shirinbayan, M.; Bakir, F. Multiscale thermal study of virgin and aged polyphenylene sulfide reinforced by glass fiber. J. Appl. Polym. Sci. 2020, 137, e49031. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Multiscale physicochemical characterization of a short glass fiber-reinforced polyphenylene sulfide composite under aging and its thermo-oxidative mechanism. Polym. Adv. Technol. 2018, 30, 584–597. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Xu, T.; Lu, A.; Zhang, Q.; Tan, H.; Fu, Q. Preparation and properties of poly (p-phenylene sulfide)/multiwall carbon nanotube composites obtained by melt compounding. Compos. Sci. Technol. 2009, 69, 147–153. [Google Scholar] [CrossRef]

- Wang, X.; Yang, K.; Zhang, P. Evaluation of the aging coefficient and the aging lifetime of carbon black-filled styrene-isoprene-butadiene rubber after thermal-oxidative aging. Compos. Sci. Technol. 2022, 220, 109258. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, F.; Su, Z.; Xie, T. Effect of Radiation-Induced Cross-Linking on Thermal Aging Properties of Ethylene-Tetrafluoroethylene for Aircraft Cable Materials. Materials 2021, 14, 257. [Google Scholar] [CrossRef]

- Lee, S.; Kim, D.-H.; Park, J.-H.; Park, M.; Joh, H.-I.; Ku, B.-C. Effect of Curing Poly(p-Phenylene Sulfide) on Thermal Properties and Crystalline Morphologies. Adv. Chem. Eng. Sci. 2013, 3, 145–149. [Google Scholar] [CrossRef] [Green Version]

- Gleadall, A. Mechanical Properties of Biodegradable Polymers for Medical Applications, Modelling Degradation of Bioresorbable Polymeric Medical Devices. In Woodhead Publishing Series in Biomaterials, Modelling Degradation of Bioresorbable Polymeric Medical Devices; Pan, J., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 163–199. [Google Scholar] [CrossRef]

- Patel, J.P.; Deshmukh, S.; Zhao, C.; Wamuo, O.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. An analysis of the role of nonreactive plasticizers in the crosslinking reactions of a rigid resin. J. Polym. Sci. Part B Polym. Phys. 2016, 55, 206–213. [Google Scholar] [CrossRef]

- Patel, J.P.; Xiang, Z.G.; Hsu, S.L.; Schoch, A.B.; Carleen, S.A.; Matsumoto, D. Path to achieving molecular dispersion in a dense reactive mixture. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1519–1526. [Google Scholar] [CrossRef]

| Samples | L | a | b | ΔE | Gray | G60 |

|---|---|---|---|---|---|---|

| GF/PPS-0 | 81.56 | 0.48 | 13.12 | 0 | 202 ± 2 | 56.6 ± 3.3 |

| GF/PPS-85 | 82.81 | 0.48 | 9.21 | 4.11 ± 0.23 | 206 ± 4 | 8.4 ± 1.3 |

| GF/PPS-100 | 82.92 | 0.39 | 10.30 | 3.13 ± 0.28 | 206 ± 5 | 5.7 ± 1.2 |

| GF/PPS-115 | 82.68 | 0.43 | 10.72 | 2.65 ± 0.31 | 205 ± 3 | 5.3 ± 1.5 |

| GF/PPS-130 | 82.44 | 0.84 | 11.56 | 1.83 ± 0.22 | 204 ± 3 | 4.6 ± 1.2 |

| GF/PPS-145 | 83.19 | 0.40 | 12.54 | 1.74 ± 0.27 | 207 ± 2 | 4.4 ± 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J.; Song, Y.; Xu, Z.; Nie, Y.; Lan, Z. Thermal Aging Effects on the Mechanical Behavior of Glass-Fiber-Reinforced Polyphenylene Sulfide Composites. Polymers 2022, 14, 1275. https://doi.org/10.3390/polym14071275

Deng J, Song Y, Xu Z, Nie Y, Lan Z. Thermal Aging Effects on the Mechanical Behavior of Glass-Fiber-Reinforced Polyphenylene Sulfide Composites. Polymers. 2022; 14(7):1275. https://doi.org/10.3390/polym14071275

Chicago/Turabian StyleDeng, Jiangang, You Song, Zhuolin Xu, Yu Nie, and Zhenbo Lan. 2022. "Thermal Aging Effects on the Mechanical Behavior of Glass-Fiber-Reinforced Polyphenylene Sulfide Composites" Polymers 14, no. 7: 1275. https://doi.org/10.3390/polym14071275