The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blending and Filament Processing

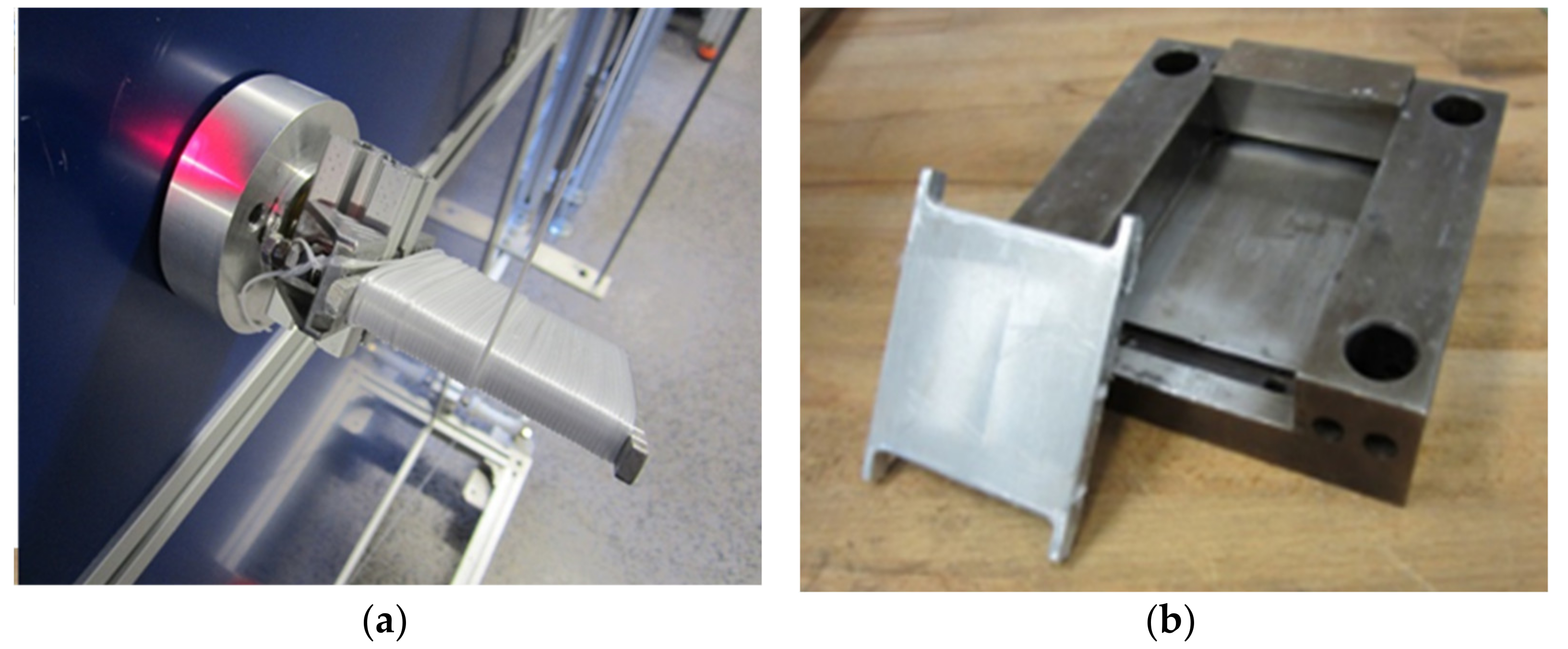

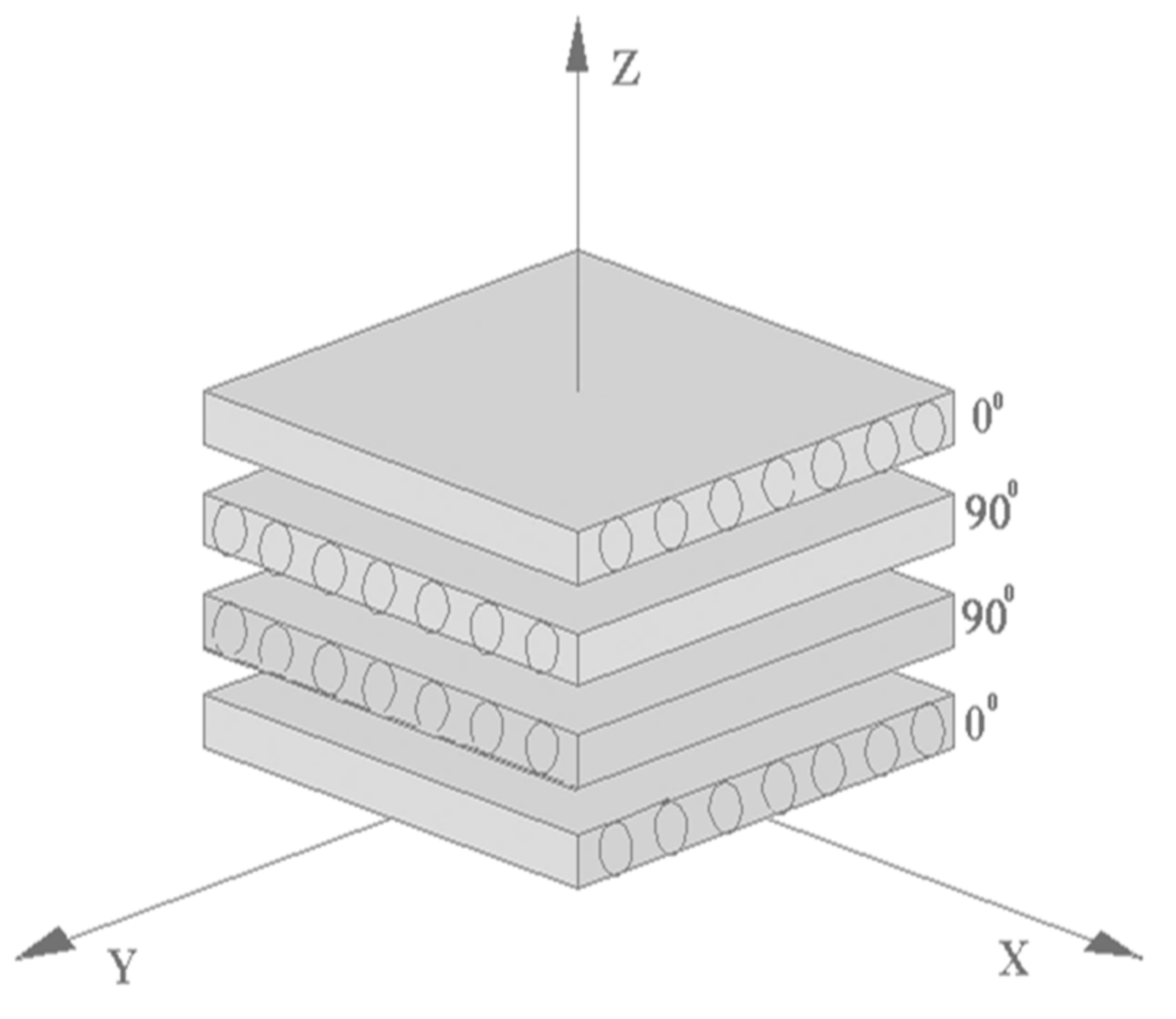

2.3. Composite Processing

2.4. Mechanical Characterization

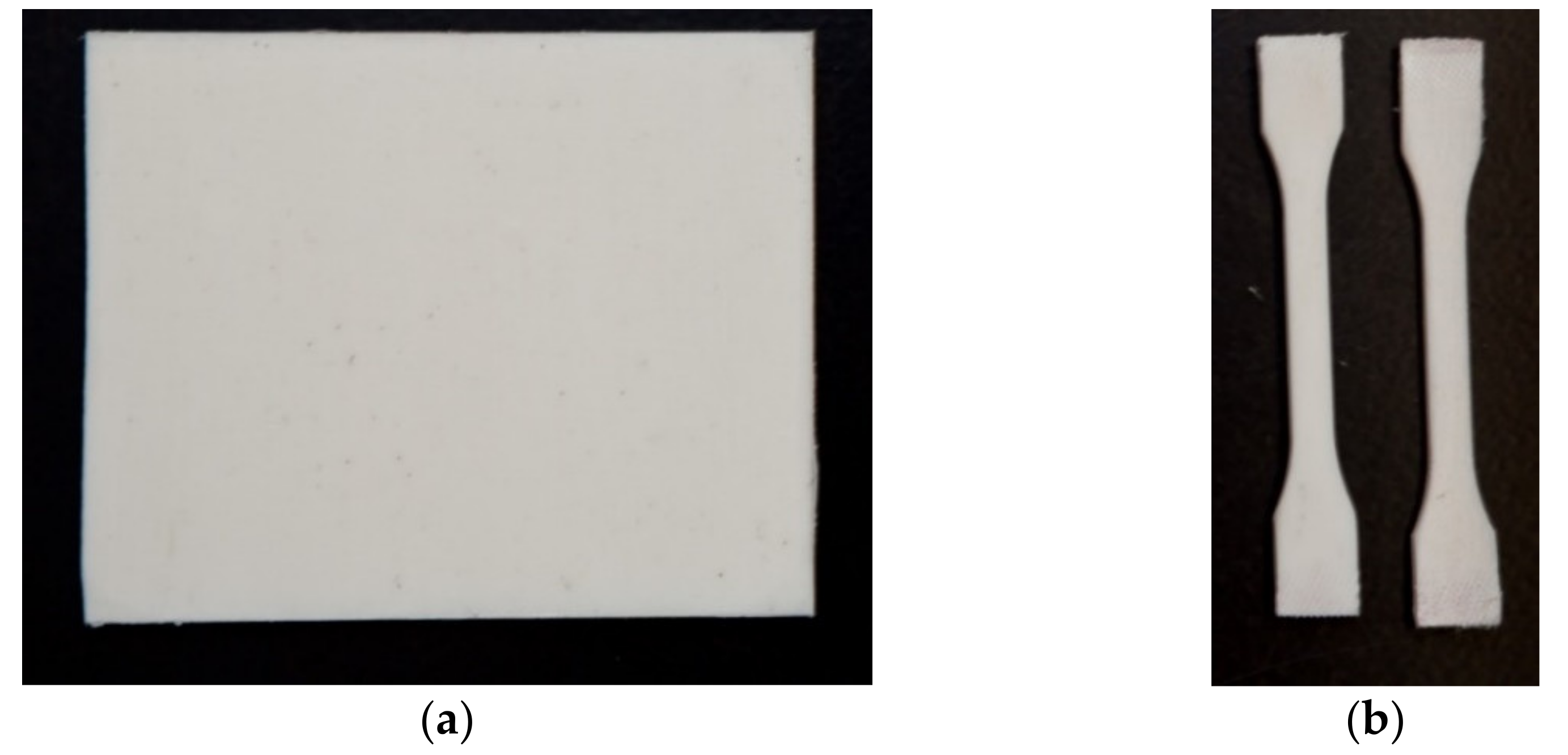

2.4.1. Tensile Test

2.4.2. Impact/Falling Weight Test

3. Results and Discussion

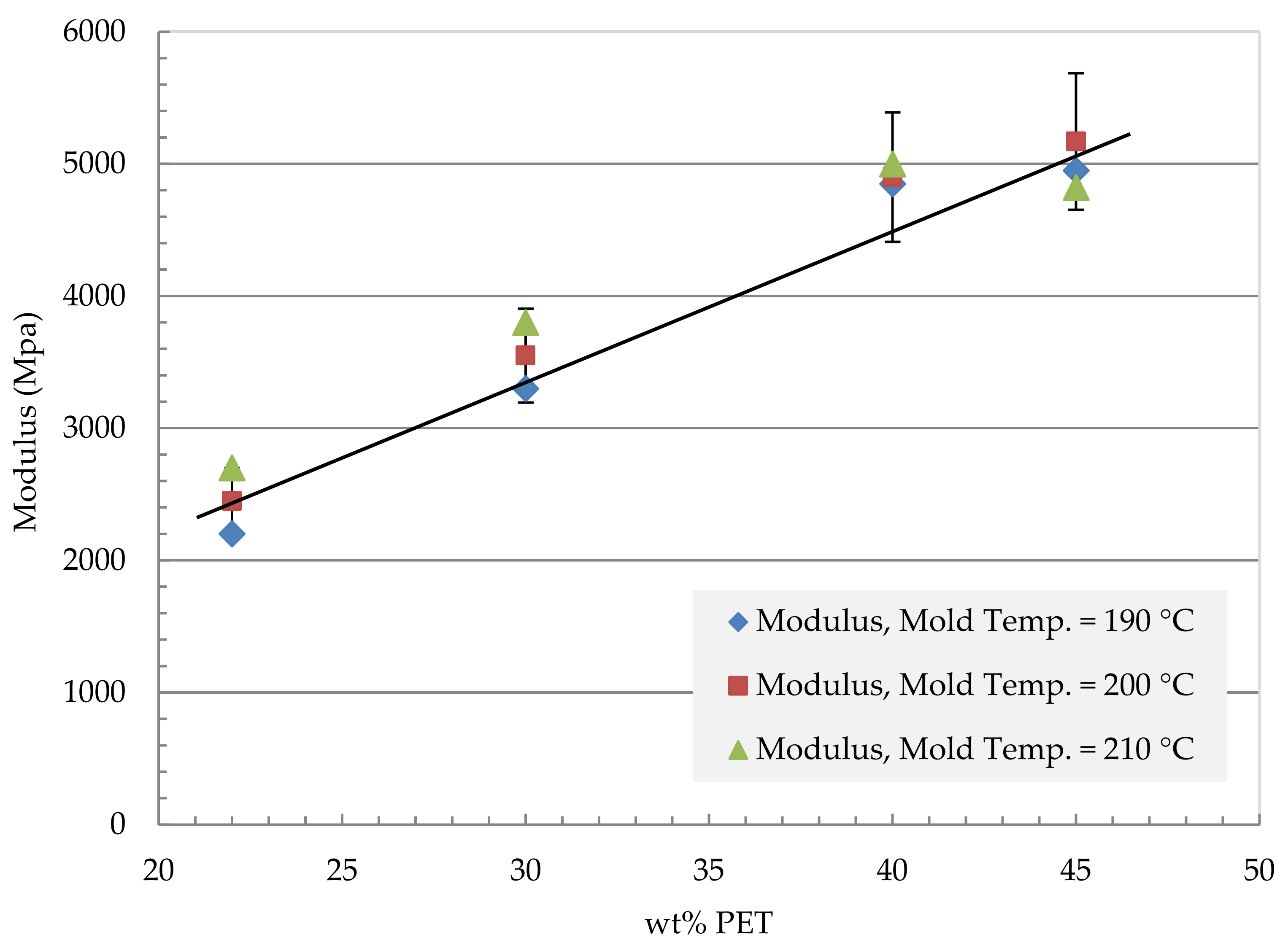

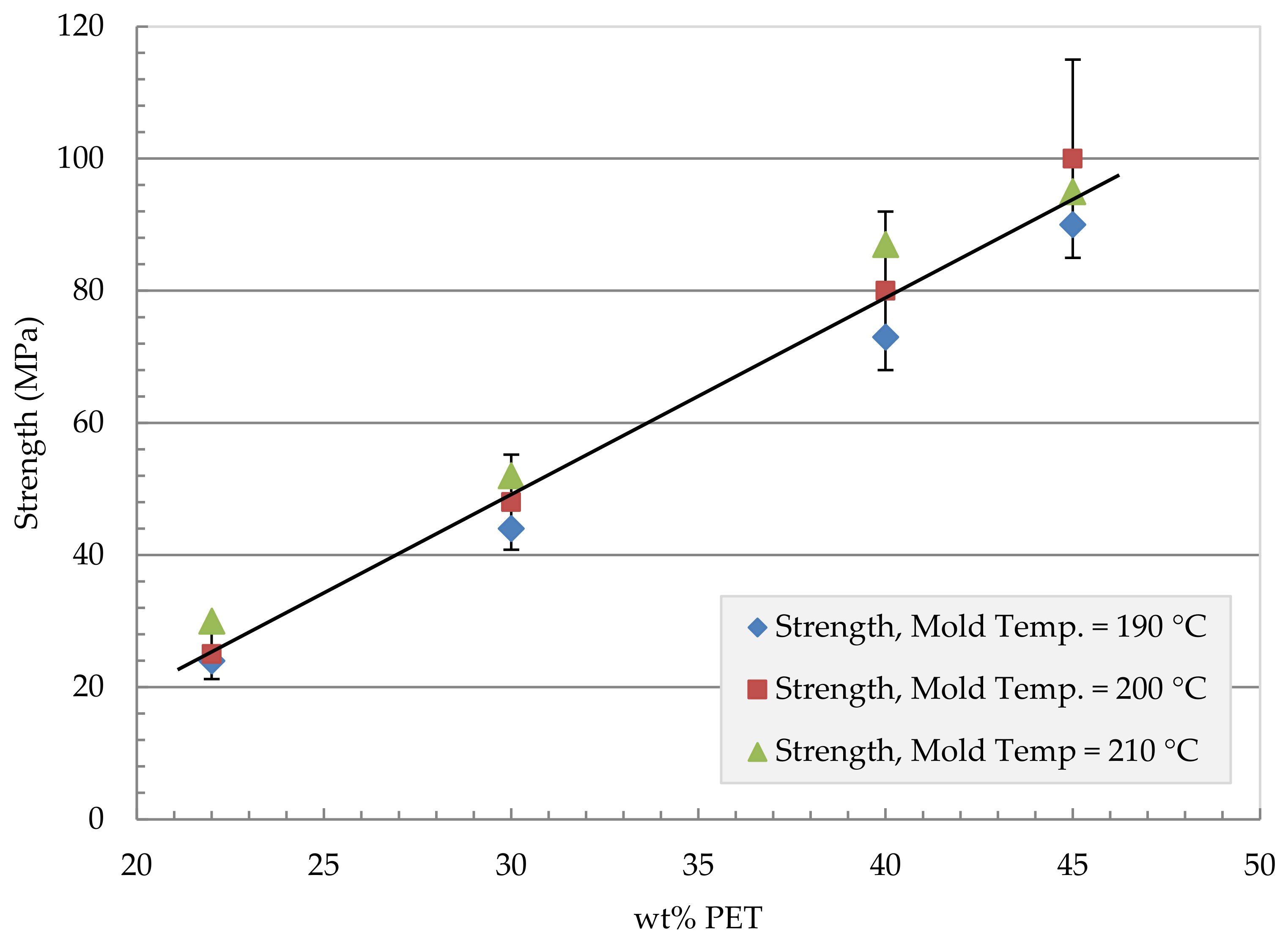

3.1. Tensile Test

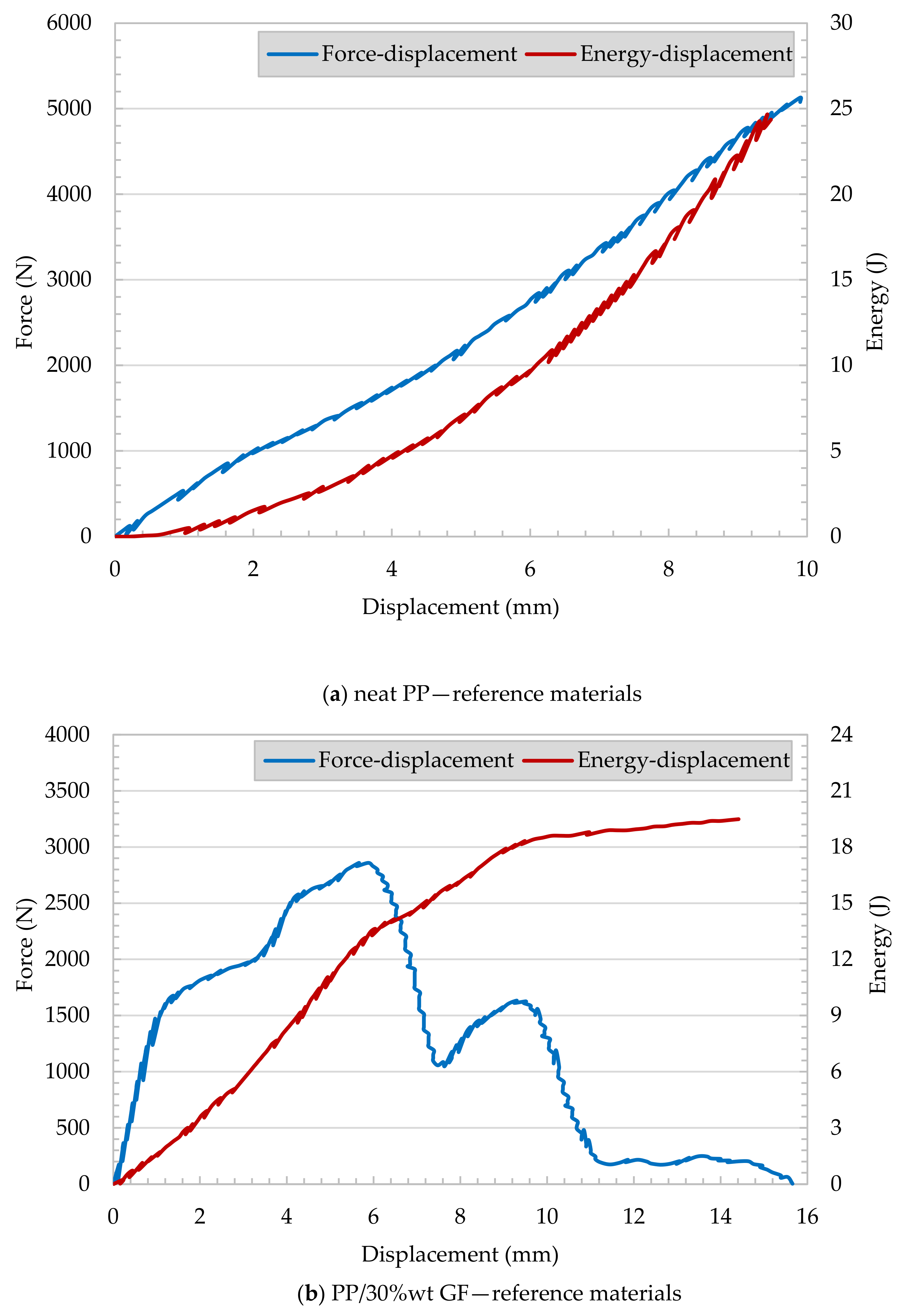

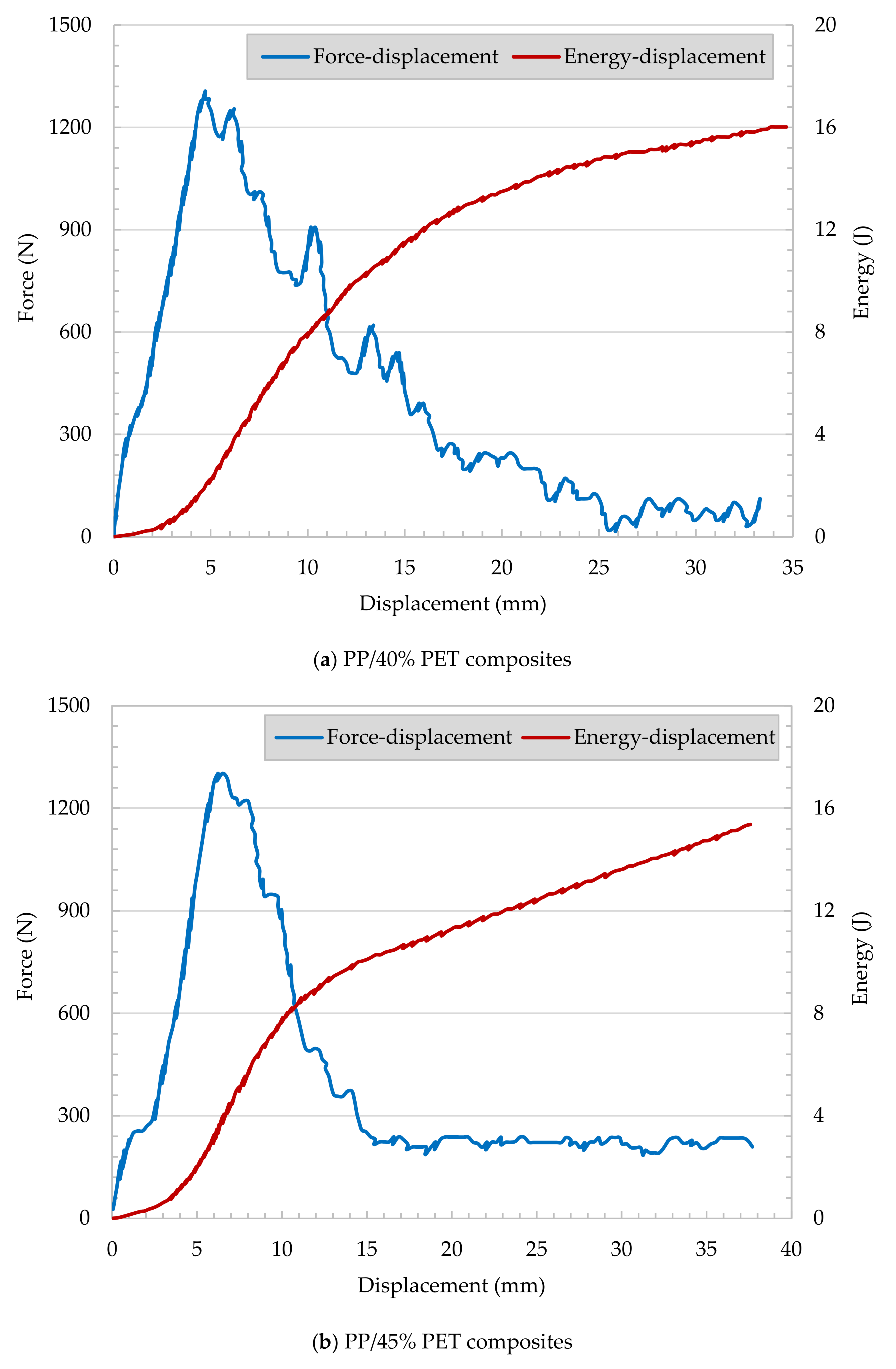

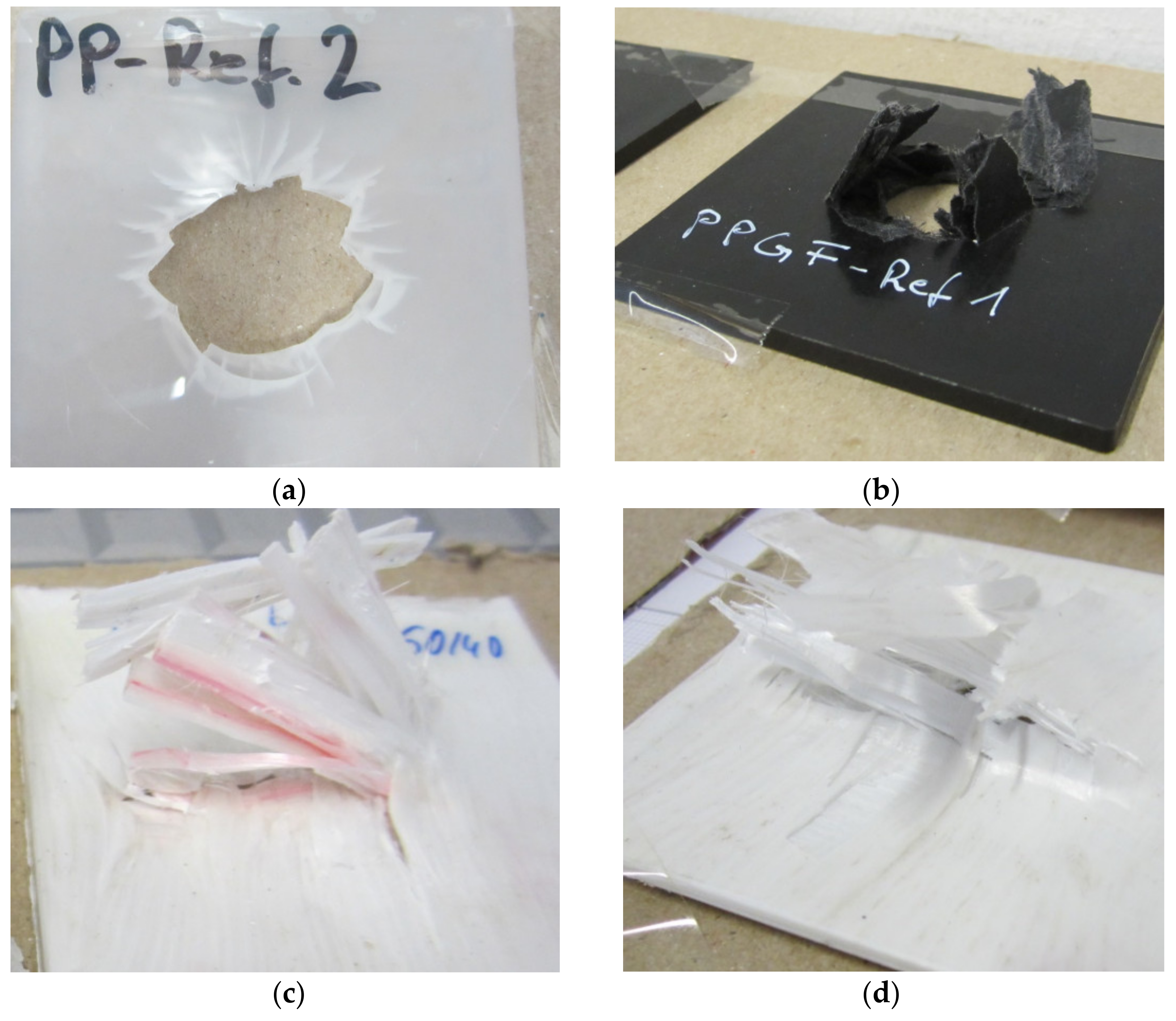

3.2. Impact/Falling Weight Test

3.2.1. Sample Preparation

3.2.2. Impact/Falling Weight Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Directive 2000/53/EC of the European Parliament and of the Council. 2000. Available online: http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:2000L0053:20050701:EN:PDF (accessed on 7 January 2005).

- Mazda Develops Automatic Bumper Recycling Process. 2009. Available online: http://green.autoblog.com/2009/03/23/mazdadevelops-automatic-bumper-recycling-process (accessed on 23 March 2009).

- Mishra, R.K.; Verma, K.; Chaudhary, R.G.; Lambat, T.; Joseph, K. An efficient fabrication of polypropylene hybrid nanocomposites using carbon nanotubes and PET fibrils. Mater. Today Proc. 2020, 29, 794–800. [Google Scholar] [CrossRef]

- Narula, C.K.; Allison, J.E.; Bauer, D.R.; Gandhi, H.S. Materials Chemistry Issues Related to Advanced Materials Applications in the Automotive Industry. Chem. Mater. 1996, 8, 984–1003. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S. Microfibrillar Reinforcement of Polymer Blends. Polymer 1992, 33, 877–880. [Google Scholar] [CrossRef]

- Mehta, A.; Isayev, A. Rheology, morphology, and mechanical characteristics of poly(etherether keton)-liquid crystalline polymer. Polym. Eng. Sci. 1991, 31, 971–980. [Google Scholar] [CrossRef]

- Tjong, S.C.; Liu, S.L.; Li, R.K.Y. Structure and mechanical properties of the extruded blends of a liquid crystalline polymer with polypropylene. J. Mater. Sci. 1995, 30, 353–360. [Google Scholar] [CrossRef]

- Tjong, S.C.; Liu, S.L.; Li, R.K.Y. Mechanical properties of injection moulded blend of polypropylene with thermotropic liquid crystalline polymer. J. Mater. Sci. 1996, 31, 479–484. [Google Scholar] [CrossRef]

- Varga, L.J.; Bárány, T. Development of Polypropylene-Based Single-Polymer Composites with Blends of Amorphous Poly-Alpha-Olefin and Random Polypropylene Copolymer. Polymers 2020, 12, 1429. [Google Scholar] [CrossRef]

- Kim, T.K.; Kim, B.K.; Lee, S.Y.; Cho, Y.L.; Kim, M.S.; Jeong, H.M. Thermoplastic polyurethane elastomer/thermoplastic polyolefin elastomer blends compatibilized with a polyolefinic segment in TPU. Macromol. Res. 2010, 18, 177–184. [Google Scholar] [CrossRef]

- Li, J.-L.; Wang, X.-F.; Yang, C.-J.; Yang, J.-H.J.; Wang, Y.; Ahang, J.-H. Toughening modification of polycarbonate/poly(butylene terephthalate) blends achieved by simultaneous addition of elastomer particles and carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2016, 90, 200–210. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Friedrich, K. Effect of Blend Composition on the Structure-Properties Relationship of Nanostructured Polymer Composites from Polycondensate/Polyolefin Blends. Int. J. Polym. Mater. 2004, 53, 211–228. [Google Scholar]

- Pilipović, A.; Ilinčić, P.; Petruša, J.; Domitran, Z. Influence of Polymer Composites and Memory Foam on Energy Absorption in Vehicle Application. Polymers 2020, 12, 1222. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmed, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Ramasubbu, R.; Madasamy, S. Fabrication of Automobile Component Using Hybrid Natural Fiber Reinforced Polymer Composite. J. Nat. Fibers 2020. [Google Scholar] [CrossRef]

- El Hajj, N.; Seif, S.; Zgheib, N. Recycling of poly(propylene)-based car bumpers as carrier resin for short glass fiber composites. J. Mater. Cycles Waste Manag. 2021, 23, 288–300. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Shields, R.J. Nanofibril reinforced composites from polymer blends. Colloids Surf. A Physicochem. Eng. Asp. 2008, 313–314, 2–8. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Bechtold, G.; Friedrich, K. Structure-property relationships of injection—And compression-molded microfibrillar-reinforced PET/PA-6 composites. Adv. Polym. Technol. 2000, 19, 249–259. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Krasteva, B.; Friedrich, K.; Covas, J.; Cunha, A. Recycling of poly(ethylene terephthalate) as polymer-polymer composites. Polym. Eng. Sci. 2002, 42, 826–835. [Google Scholar] [CrossRef]

- Nakagaito, A.; Fujimura, A.; Sasaki, T.; Hama, Y.; Yano, H. Production of microfibrillated cellulose (MFC)-reinforced polylactic acid (PLA) nanocomposites from sheets obtained by a papermaking-like process. Compos. Sci. Technol. 2009, 69, 1293–1297. [Google Scholar] [CrossRef]

- Evstatiev, M.; Simeonova, S.; Friedrich, K.; Pei, X.-O.; Formanek, P. MFC-structured biodegradable poly(l-lactide)/poly(butylene adipate-co-terephatalate) blends with improved mechanical and barrier properties. J. Mater. Sci. 2013, 48, 6312–6330. [Google Scholar] [CrossRef]

- Friedrich, K.; Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Ishii, M.; Harrass, M. Microfibrillar reinforced composites from PET/PP blends: Processing, morphology and mechanical properties. Compos. Sci. Technol. 2005, 65, 107–116. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. Relationship between the Processing, Structure, and Properties of Microfibrillar Composites. Adv. Mater. 2020, 32, 2003938. [Google Scholar] [CrossRef] [PubMed]

- Fakirov, S.; Kamo, H.; Evstatiev, M.; Friedrich, K. Microfibrillar Reinforced Composites from PET/LDPE Blend: Morphology and Mechanical properties. J. Macromol. Sci. Part B Phys. 2004, 43, 775–789. [Google Scholar] [CrossRef]

- Kuzmanovi, M.; Delva, L.; Mi, D.; Martins, C.I.; Cardon, L.; Ragaert, K. Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA. Polymers 2018, 10, 291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Machiels, A.G.C.; Dam, J.V.; Boer, A.P.D.; Norder, B. Stability of blends of thermoplastic liquid crystalline polymers with thermoplastic polymers. Polym. Eng. Sci. 1997, 37, 1512–1525. [Google Scholar] [CrossRef]

- Friedrich, K.; Ueda, E.; Kamo, H.; Evstatiev, M.; Fakirov, S. Direct Electron Microscopic Observation of Transcrystalline Layers in Microfibrillar Reinforced Polymer-Polymer Composites. J. Mater. Sci. 2002, 37, 4299–4306. [Google Scholar] [CrossRef]

- Krumova, M.; Michler, G.H.; Evstatiev, M.; Friedrich, K.; Stribeck, N.; Fakirov, S. Transcrystallisation with reorientation of polypropylene in drawn PET/PP and PA66/PP blends. Part 2. Electron microscopic observations on the PET/PP blend. In Scattering Methods and the Properties of Polymer Materials; Stribeck, N., Smarsly, B., Eds.; Progress in Colloid and Polymer Science 130; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Almajid, A.; Walter, R.; Kroos, T.; Junaidi, H.; Gurka, M.; Abdelrazek Khalil, K. Development of Polypropylene/Polyethylene Terephthalate Microfibrillar Composites Filament to Support Waste Management. Polymers 2021, 13, 233. [Google Scholar] [CrossRef]

- Hartikainen, J.; Lindner, M.; Harmia, T.; Friedrich, K. Mechanical properties of polypropylene composites reinforced with long glass fibres and mineral fillers. Plast. Rubber Compos. 2004, 33, 77–84. [Google Scholar] [CrossRef]

- Mi, D.; Wang, Y.; Kuzmanovic, M.; Delva, L.; Jiang, Y.; Cardon, L.; Zhang, J.; Ragaert, K. Effects of Phase Morphology on Mechanical Properties: Oriented/Unoriented PP Crystal Combination with Spherical/Microfibrillar PET Phase. Polymers 2019, 11, 248. [Google Scholar] [CrossRef] [Green Version]

- Krumova, M.; Flores, A.; Baltá Calleja, F.; Fakirov, S. Elastic properties of oriented polymers, blends and reinforced composites using the microindentation technique. Colloid Polym. Sci. 2002, 280, 591–598. [Google Scholar] [CrossRef]

| Polymer Type | Polymer Grade | Manufacturer | Density (g/cm3) | MFR (dg/min) | Intrinsic Viscosity (dL/g) | |

|---|---|---|---|---|---|---|

| Bulk | Crystalline | |||||

| PET | BC111 | Sabic | 0.838 | 1.39 | - | 0.74–0.78 |

| PP | 500P | Sabic | - | 0.905 | 3 | - |

| % PET | Densityg/cm3 | Thickness(mm) | Fmax (N) | Standard Deviation, Fmax | Displ. at Fmax (mm) | Standard Deviation, Disp. | Energy at Fmax (J/mm) | Etot (J/mm) | Specific Etot (J/g) | Ductility Index (DI) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.905 | 3.9 | 5440 | ±200 | 11.3 | ±1.3 | 8.4 | 8.52 | 0.23 | 0.02 |

| 40 | 1.1 | 4.07 | 1449 | ±50 | 7.0 | ±0.5 | 2.42 | 6.59 | 0.147 | 0.61 |

| 45 | 1.12 | 3.08 | 1309 | ±40 | 6.3 | ±0.4 | 2.49 | 7.76 | 0.223 | 0.67 |

| 30 wt% GF | 1.15 | 4.0 | 3388 | ±120 | 5.2 | ±0.27 | 4.58 | 9.07 | 0.197 | 0.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almajid, A.; Walter, R.; Kroos, T.; Junaedi, H.; Gurka, M.; Khalil, K.A. The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties. Polymers 2021, 13, 1296. https://doi.org/10.3390/polym13081296

Almajid A, Walter R, Kroos T, Junaedi H, Gurka M, Khalil KA. The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties. Polymers. 2021; 13(8):1296. https://doi.org/10.3390/polym13081296

Chicago/Turabian StyleAlmajid, Abdulhakim, Rolf Walter, Tim Kroos, Harri Junaedi, Martin Gurka, and Khalil Abdelrazek Khalil. 2021. "The Multiple Uses of Polypropylene/Polyethylene Terephthalate Microfibrillar Composite Structures to Support Waste Management—Composite Processing and Properties" Polymers 13, no. 8: 1296. https://doi.org/10.3390/polym13081296