Knowing the chemical composition of polymeric matrices obtained via radical polymerization is very important, as it influences all the properties of the material, yet in some cases it can be challenging to obtain, due to the random nature of the process. Previously we have used a combination of monomer conversions, determined by

1H NMR, and chemical yields to estimate the chemical nature of different acrylamide-based nanogels obtained by high dilution radical polymerization (HDRP) [

6]. In this work, we sought to study how key parameters such as monomer structure, initiator content, total monomer concentration, and temperature can influence the chemical composition and morphology of covalently crosslinked nanogels obtained by HDRP. In order to minimize the number of variables, we chose to carry out all polymerizations in DMSO, to ensure good solubility of all the monomers used, while AIBN was used as the initiator.

Figure 1 shows the structures of all the monomers used in this study.

3.1. Two-Monomer Nanogels

The first part of the work focused on a series of nanogels based on NIPAM crosslinked with MBA. Small-scale (1–3 mL) polymerizations were performed in deuterated DMSO to determine the monomer conversions by

1H NMR analyses of initial and final polymerization solutions. When carrying out NMR-based conversion studies, the quantitative measurements require the use of an internal standard. In the first set of experiments (80 mol % NIPAM and 20 mol % MBA), 2-ethylnaphthalene was used as internal standard and was added either to the pre-polymerization mixture or after polymerization, as described in the experimental section. Both approaches resulted in analogous results, suggesting that the presence of the internal standard in the reaction mixture does not affect the monomer conversions (

Table S1). Furthermore, reproducibility studies of the method for calculating monomer conversions by

1H NMR revealed an inter-assay variability below 1% (

Table S1).

The rates of polymerization are dependent on individual monomer reactivities, which can vary significantly with small changes in their chemical structure. A simple homopolymerization experiment carried out at 70 °C for 12 h (C

M = 1%, AIBN = 1%) resulted in 80% conversion for NIPAM, while the crosslinker MBA was quantitatively converted under the same conditions (

Table S3). In copolymerizations, rates are not only dependent on individual intrinsic reactivities of each monomer but also on the presence of other monomers and their relative concentrations in the mixture. When 20 mol % MBA was copolymerized for 24 h with 80 mol % NIPAM under the same conditions, MBA conversion was quantitative, whereas NIPAM conversion reached 87% (

N7,

Figure 2a and

Table S2), resulting in 89% total monomer conversion. This suggests that the real crosslinker content for

N7 is slightly higher than in the starting solution, resulting in a matrix that is more rigid.

We first focused on screening different reaction conditions for the NIPAM crosslinked with MBA (20 mol %) system, to evaluate the effect of three parameters: 1) initial AIBN concentration (1, 5, and 10 mol %), 2) lower reaction temperature (60 °C), and 3) reaction time (24 and 48 h). The monomer conversions resulting from this screening are summarized in

Figure 2 and

Table S2. The data on monomer conversions were evaluated together with the chemical yields after isolation of the nanogels. The half-life of the initiator, AIBN, in DMSO increases from 3.9 to 15.9 h when the reaction temperature decreases from 70 to 60 °C [

30,

31]. We thus aimed to evaluate the impact of a slower initiation reaction on final monomer conversions. For polymerizations at 70 °C, the monomer conversions reached a maximum after 24 h, while for reactions at 60 °C, 48 h were required to reach similar conversion values. Increasing the concentration of initiator used had a larger impact on conversions. At 60 °C, an increase in AIBN initial concentration from 1 to 5% resulted in an increase in NIPAM conversion of 20% at 24 h (

N1–

N3) and of 10% at 48 h (

N4–

N6). Similar trends were observed for an analogous set of experiments at 70 °C (

N7–

N12), albeit the effect is less pronounced since all conversions with 1% AIBN were already above 85%. Regarding the concentration of AIBN, it is interesting to observe that, although a higher concentration of initiator resulted in higher monomer conversions, there was a remarkable effect on the chemical yield, which dropped from 85 to 62%, as shown in

Figure 2c. This is due to the formation of larger quantities of low M

r polymer chains, due to a higher concentration of radicals at any time in the mixture, which were then lost during purification of the nanogels via dialysis, using membranes with a molecular weight cut-off of 3500 Da.

Next, the impact of the total monomer concentration (C

M) was investigated (

Figure 2d,e). Polymerizations were conducted with AIBN concentrations ranging from 1 to 10%, at 60 or 70 °C for 24 h and with C

M = 1 or 2%. As expected, monomer conversions increased when the total monomer concentration was doubled, with the effect being particularly noticeable at 1% AIBN, where the increase in monomer concentration results in a 10% increase of the total monomer conversion. These results show that experimental conditions have a very significant effect on the chemical composition of the final polymer matrix and therefore will also influence the various morphological aspects, such as particle size. To evaluate this, the hydrodynamic diameters (

dh) of NIPAM-MBA (20 mol %) nanogels polymerized for 24 h under different conditions of temperature, total monomer concentration, and percentage of initiator were obtained via dynamic light scattering (DLS) measurements (

Figure 2f,

Table S2). When a 1% total monomer concentration was used, all nanogels (

N1–

N3 and

N7–

N9) showed very similar diameters, within the range of 5–10 nm, suggesting that neither the polymerization temperature nor the AIBN concentration used have an influencing effect. However, when C

M was doubled to 2% (

N13–

N18), the particle size slightly increased (16–26 nm), possibly due to an increased degree of intermolecular crosslinking given the higher monomer concentration [

32]. A larger particle size can lead to a less stable colloidal solution [

33], as confirmed by the VPTT values obtained for nanogels

N13–

N18 via UV-vis measurements (

Table S2). VPTT values for nanogels prepared at higher C

M (2%), with larger particle size, were found to be at least 1 °C lower than those prepared at C

M = 1% (

N1–

N3 and

N7–

N9). These data highlight the importance of understanding the actual composition of the polymeric matrices and demonstrate that even small changes can impact the morphology and behavior of the nanoparticles.

As a result of this initial screening, the optimized parameters for the synthesis of NIPAM-based nanogels crosslinked with 20 mol % of MBA were identified as C

M = 1% and AIBN = 1%, polymerizing at 70 °C for 24 h. These conditions were then used to evaluate the impact of crosslinker content on monomer conversions (

Table 1). NIPAM nanogels

N19 and

N20 (5 and 10 mol % MBA) showed that an increased MBA content led to higher NIPAM conversions and hence higher total monomer conversions. Within the low crosslinker content range (5–20 mol %) particle size did not change: very similar values were measured (4–9 nm) for

N7,

N19, and

N20. The VPPT values however, showed some variations, consistent with previously reported data [

6].

Within the two-monomer system, we also investigated how subtle changes in monomer structure could affect the degree of incorporation into the polymer matrix.

N-

n-propylacrylamide (NPAM) is a constitutional isomer of NIPAM, also with thermoresponsive characteristics (

Figure 1). We have used this monomer for the development of a dual responsive nanogel [

6]. Despite the small difference in structure, NPAM displays lower reactivity than NIPAM: under analogous homopolymerization conditions, NPAM reacted to 60% conversion compared to 80% obtained for NIPAM (12 h, C

M 1%, AIBN = 1%, 70 °C,

Table S2). In the copolymerization of NPAM with MBA, however, the effect was less pronounced. The lower reactivity of NPAM did decrease the total monomer conversion obtained for NPAM nanogels crosslinked with 5 mol % MBA (

N21) when compared with the NIPAM-based counterpart (

N19) but only by 4% (

Table 1). This effect was supressed when higher amounts of the highly reactive MBA were added to the polymerization mixtures (

N22 and

N23). The impact on particle size and VPTT values was found to be similar to that of the NIPAM-based nanogels (

Table 2 and

Table S4).

3.2. Three-Monomer System: Chemical Composition of pH and Temperature-Responsive Nanogels

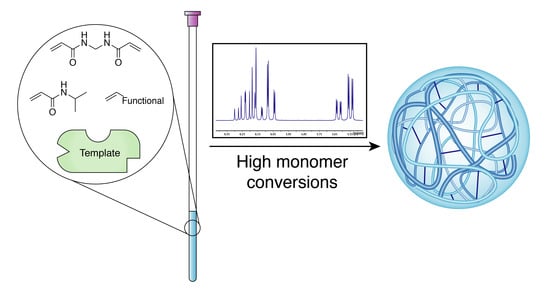

The development of nanogels for specific applications often requires an additional comonomer (functional monomer), whose structure provides the matrix with a particular function. The presence of this additional monomer may influence the reaction kinetics of the three-monomer system and thus the final chemical composition of the resulting material. Optimization of the reaction conditions to ensure maximum functional monomer and crosslinker incorporation is a critical step prior to evaluating the properties of the nanogels.

We recently reported the synthesis and characterization of a thermo- and pH-responsive nanogel [

6], based on PNPAM crosslinked with 10 mol % MBA and including a proline-based monomer (A–Pr–OH, 2.5 mol %) as the functional monomer. Using this preparation, we probed the effect of adding a third component on monomer conversions and nanogel composition. The pH-responsive functional monomer A–Pr–OH was copolymerized with MBA as the crosslinker and NIPAM or NPAM as backbone monomers. In our studies, A–Pr–OH displayed very similar reactivity to that of MBA, both under homopolymerization conditions (

Table S3) and in copolymerizations (

Table 1), with incorporations reaching 98% in most cases. The high reactivity of A–Pr–OH promoted higher NIPAM and MBA conversions in nanogels

N24–

N26, containing 5–20 mol % of MBA, but did not affect the conversions of NPAM-based nanogels (

N27–

N29). The high monomer conversions obtained for nanogels

N24–

N29, polymerized under the optimized conditions, provided evidence of consistency between initial monomer ratios and final polymer composition. The data obtained suggests that in this system the introduction of a third component in the polymerization solution did not negatively impact monomer conversions and the final composition of the matrix; however, this needs to be evaluated each time, as it greatly depends on the monomer structure.

3.3. Three-Monomer Polymers in Combination with a Template Molecule

Particular applications, such as sensing, use nanogels in conjunction with a templating approach, where a non-polymerizable species (template) is added to the polymerization mixture to create specific binding sites within the polymer matrix. The presence of this template can impact the polymerization kinetics in different ways, e.g., by forming a complex with the functional monomer, which may alter its reactivity, or by radical scavenging. Thus, the effect of the template on monomer reactivities needs to be carefully examined, although this is often overlooked [

24].

To study how a template molecule can impact polymerization rates we used nanogels developed for the therapeutic drug monitoring of imatinib, a chemotherapeutic agent used in the treatment of chronic myelogenous leukaemia and gastro-intestinal stromal tumors [

34,

35]. For effective templating of the nanogel, 2-acrylamido-2-methyl-1-propanesulfonic acid (AMPS,

Figure 1) was used as the functional monomer. AMPS (20 mol %) was initially polymerized without template in combination with NIPAM (20 mol %) and MBA (60 mol %), under the optimized conditions (C

M 1%, AIBN = 1%, 70 °C, 24 h).

1H NMR data confirmed quantitative incorporation of MBA and high conversion of NIPAM (>90%), but a lower conversion (70%) was observed for AMPS (

N30,

Figure 3a). Increasing the initial concentration of AIBN to 3 or 5% resulted in an increased AMPS conversion but only by a maximum of 8% (

N36,

Figure 3c). These results suggest that AMPS has a lower reactivity and is the least reactive of the monomers reported here. It is also evident from the homopolymerization of AMPS that the reactivity of this monomer is lower, with a conversion of 36% being achieved after 12 h when using 1% AIBN and C

M = 1%, at 70 °C in DMSO (

Table S3). As a result of this lower reactivity, the AMPS content in the final polymer is still lower than in the feed composition for the optimized formulation

N36 (16 vs. 20%).

Imatinib is available in two forms: the free base and the mesylate salt. Any possible changes in the polymerization kinetics due to the presence of either compound was evaluated by

1H NMR (

Figure 3,

Table S5). In all cases, AMPS conversions decreased in the presence of the template, with imatinib free base (

N32,

N35, and

N38) appearing to have a more noticeable effect than imatinib mesylate (

N31,

N34, and

N37). This is consistent with the observed decrease in AMPS reactivity (14% conversion) under homopolymerization conditions in the presence of imatinib free base. We ruled out a radical quenching effect by the template, as no degradation of imatinib was observed when heated to 70 °C for 24 h in the presence of AIBN in DMSO (

Figure S4). We thus hypothesize that the observed effect of the template is due to the interaction between AMPS and imatinib, resulting in an altered AMPS reactivity to different degrees depending on the use of the free base or the mesylate salt. It is also interesting to note the negative effect on NIPAM conversions when imatinib mesylate is used, possibly due to the presence of the counterion. The results obtained for this system suggest that the presence of a fourth non-polymerizable component in the polymerization mixture has an impact on monomer conversions, resulting in a lower functional monomer content than in the non-templated nanogel. This is particularly relevant and should be investigated carefully when comparisons are drawn between templated and non-templated polymers, such as in the case of molecular-imprinted polymers.

The Effect of Introducing a Vinyl Monomer

Often polymerizations require the use of monomers with different polymerizable groups, so we also investigated the effect of these changes on conversion rates. For this purpose, we selected a formulation of nanogels templated with caffeine, containing MBA as the crosslinker, acrylamide (AM) as the backbone monomer, and 4-vinyl-1H-imidazole (4VI,

Figure 1), containing a vinyl group as the polymerizable unit, as the functional monomer. Initially, polymerizations were attempted using 4VI (10 mol %), AM (40 mol %), and MBA (50 mol %), under our standard conditions, 70 °C, 24 h, AIBN = 1%, and C

M = 0.5 and 1%, but no significant amount of polymer could be isolated. Under homopolymerization conditions (

Figure 4a), AM displayed similar reactivity to the acrylamide-based monomers NIPAM and NPAM, while 4VI reacted considerably less, which still did not explain the very low yields. We hypothesized a radical quenching effect by 4VI and thus increased AIBN initial concentration to 2 and 5%, using both C

M = 0.5 and 1% (

N41–

N44,

Figure 4b). The data demonstrate that the increase in AIBN concentration leads to higher monomer conversions, while the higher C

M maximized chemical yields. In the preparation of

N44 (5% AIBN and 1% C

M), monomer conversions above 80% and an 80% chemical yield were achieved.

We further explored the effect of 4VI in a series of copolymerizations with fixed crosslinker MBA content (20 mol %) and varying percentages of 4VI, AM, and NIPAM. Individual and total monomer conversions determined by

1H NMR (

Table 2), using the optimized conditions for the system (70 °C, 24 h, C

M = 1%, and AIBN = 5%), demonstrate that, when 4VI is present in large quantities, such as in

N46, its quenching effect significantly impacts the overall reaction: even with 5% AIBN, MBA conversion is limited to 31% and results in a total monomer conversion as low as 36%. When 4VI is added in a lower concentration (10 mol %) to NIPAM (

N47) and AM (

N48) formulations, the high AIBN percentage (5%) suppresses the inhibition effect more efficiently, resulting in quantitative conversions for 4VI and higher conversions for the backbone monomers (53–60%) and the crosslinker (73–83%). However, these are still lower than conversions obtained in the absence of the vinyl monomer in

N8 and

N45: 91% (NIPAM), 87% (AM), and >96% (MBA). In agreement with the homopolymerization studies, AM showed a similar reactivity to NIPAM in two-monomer (

N8 and

N46) and three-monomer (

N47 and

N48) systems, which allowed us to infer that the change in the chemical structure of the backbone monomer did not have a significant impact on monomer conversions.

The data demonstrate that, regarding monomers with different polymerizable groups, additional studies are required to evaluate their effect on monomer conversions. Any particular quenching factor may require adjustment of the experimental conditions, including the percentages of the individual monomers in the feeding mixture. Interestingly with this specific preparation, when caffeine was added to the polymerization mixture as a template molecule, monomer conversions were not affected. Conversion values for polymerizations in the presence of caffeine (1 mol equivalent with respect to the concentration of 4VI) were analogous to the values obtained for polymerization in its absence (

Table S6). The different outcome compared to the previous example with imatinib again highlights the need for more in-depth studies and optimization of radical polymerizations, before conclusions regarding the structure of the polymers and their behaviors can be drawn.

3.4. Kinetic Study of Selected Two- and Three-Monomer systems

To further probe the impact of monomer reactivity on the polymers chemical structure, kinetic studies were conducted for selected formulations. The monomer conversion was monitored over time for nanogels

N7 (80 mol % NIPAM and 20 mol % MBA),

N26 and

N29 (2.5 mol % A–Pr–OH, 77.5 mol % NIPAM or NPAM and 20 mol % MBA),

N36 (AMPS formulation with 5% AIBN) and

N44 (4VI formulation with 5% AIBN and C

M 1%). The data obtained also provide information on how the nanogel composition varies with time. The key kinetic profiles for

N29,

N36, and

N44 are shown in

Figure 5, while additional ones are presented in the ESI (

Figures S16–S18). A stacked plot of the NMR spectra recorded for the kinetic study of polymerization

N44 is shown in

Figure 6 as a representative example. The decrease in intensity with time of the peaks at 6.58 ppm (4VI), 6.07 ppm (AM), and 5.63 ppm (MBA) confirm the decrease in concentration of polymerizable units in the solution.

The kinetic profile for the two-monomer system

N7 confirms the faster kinetics of MBA compared to NIPAM (

Figure S16), which results in nanoparticles with a more crosslinked core [

33,

36]. The profiles for nanogels

N26 and

N29 display a similar behavior but with a higher reactivity of A–Pr–OH, resulting in the functional monomer being completely incorporated in the first 2 h of polymerization (

Figure 5d and

Figure S17). The AMPS formulation (

N36,

Figure 5b) exhibited fast kinetics for both MBA and NIPAM as a result of higher MBA concentration (60 mol %) and AIBN concentration (5%). After 30 min, total monomer conversion had already reached 67% (57% NIPAM and 81% MBA), while AMPS had only reached 37% conversion. Thus, the nanogel is expected to have a higher degree of crosslinking in the core with a higher proportion of the functional monomer AMPS found on the nanogel outer layer (

Figure 5e). Interestingly, the kinetic profile of

N44 (

Figure 5c) showed a very fast polymerization for the functional unit 4VI, which reached 90% conversion in 4 h, compared to 27% and 12% for AM and MBA, respectively. As shown in

Figure 5f, this results in polymer chains being initially enriched in 4VI (up to the first 4 h of reaction) and becoming more enriched in AM as polymerization continues after that time. The results suggest that the particles of nanogel

N44 are more homogeneously crosslinked than the nanogels discussed above, with the functional monomer mainly located in the core of the structure.