K0.5Na0.5NbO3-SrTiO3/PVDF Polymer Composite Film with Low Remnant Polarization and High Discharge Energy Storage Density

Abstract

:1. Introduction

2. Materials and Methods

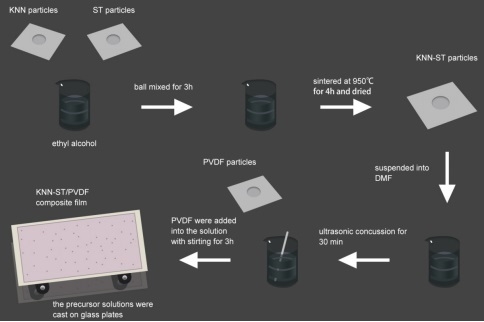

2.1. KNN-ST Fillers Preparation

2.2. KNN-ST/PVDF Polymer Composites Films Preparation

2.3. Characterization

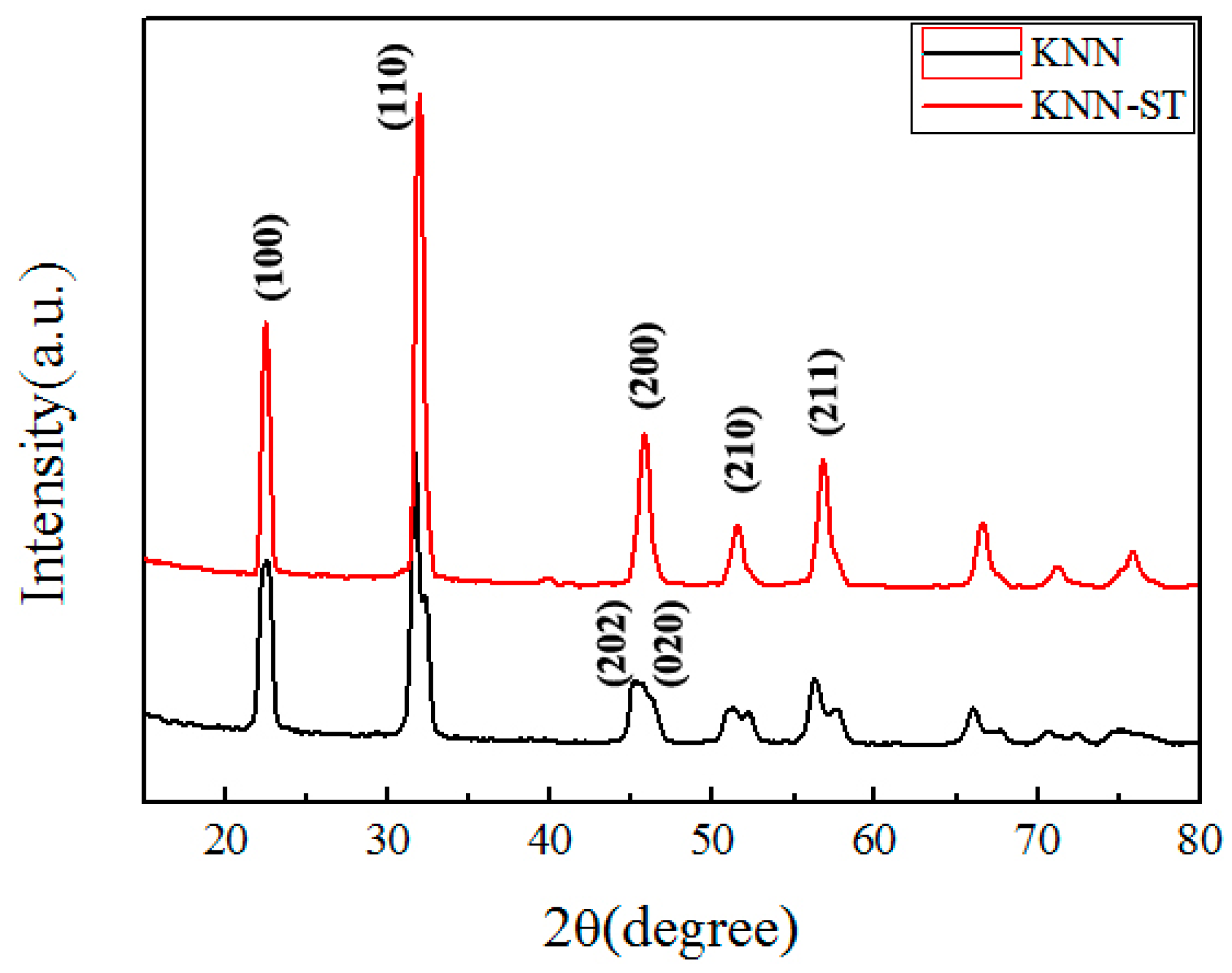

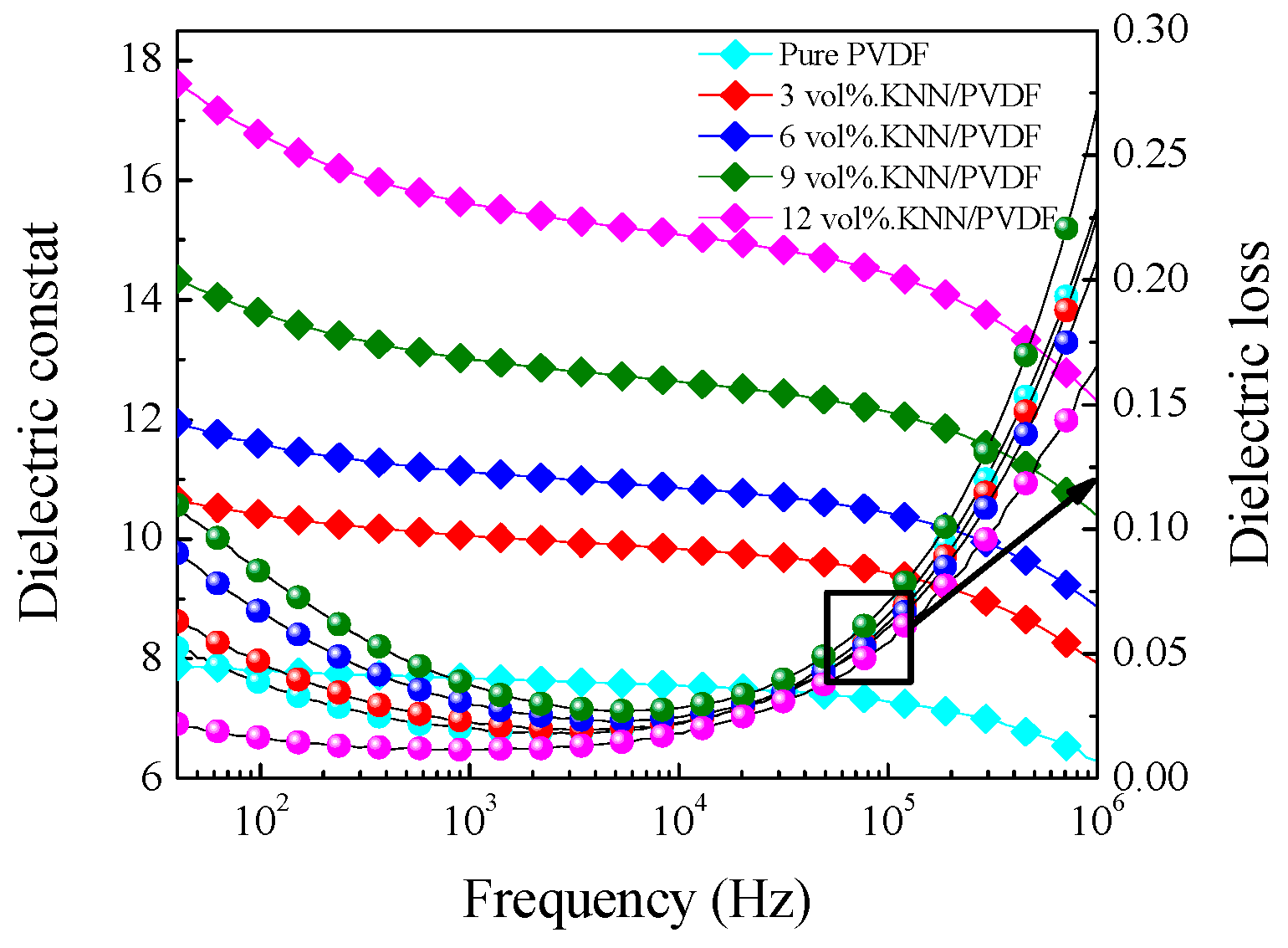

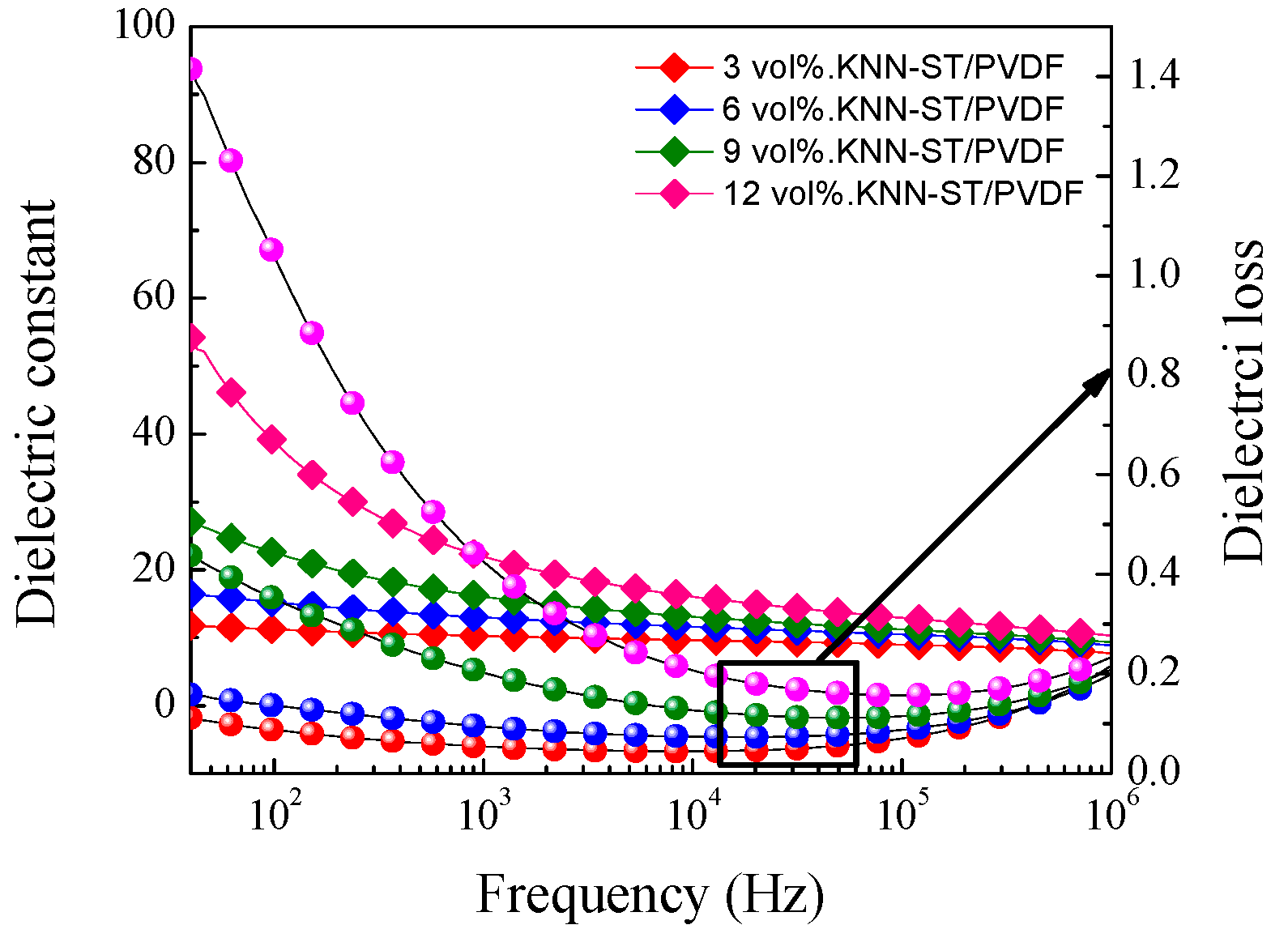

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Guo, D.; Cai, K.; Wang, Y. A distinct mutual phase transition in a new PVDF based lead-free composite film with enhanced dielectric and energy storage performance and low loss. J. Mater. Chem. C 2017, 5, 2531–2541. [Google Scholar] [CrossRef]

- Chandrasekhar, M.; Kumar, P. Synthesis and characterizations of SrTiO3modified BNT-KNN ceramics for energy storage applications. J. Electroceram. 2017, 38, 111–118. [Google Scholar] [CrossRef]

- Chen, J.; Yu, X.; Yang, F.; Fan, Y.; Jiang, Y.; Zhou, Y.; Duan, Z. Enhanced energy density of polymer composites filled with BaTiO3@Ag nanofibers for pulse power application. J. Mater. Sci. Mater. Electron. 2017, 28, 8043–8050. [Google Scholar] [CrossRef]

- Chi, Q.; Ma, T.; Zhang, Y.; Cui, Y.; Zhang, C.; Lin, J.; Wang, X.; Lei, Q. Significantly enhanced energy storage density for poly(vinylidene fluoride) composites by induced PDA-coated 0.5Ba(Zr0.2Ti0.8)O3–0.5(Ba0.7Ca0.3)TiO3nanofibers. J. Mater. Chem. A 2017, 5, 16757–16766. [Google Scholar] [CrossRef]

- Chi, Q.; Sun, J.; Zhang, C.; Liu, G.; Lin, J.; Wang, Y.; Wang, X.; Lei, Q. Enhanced dielectric performance of amorphous calcium copper titanate/polyimide hybrid film. J. Mater. Chem. C 2014, 2, 172–177. [Google Scholar] [CrossRef]

- He, D.; Wang, Y.; Song, S.; Liu, S.; Luo, Y.; Deng, Y. Polymer-based nanocomposites employing Bi2S3@SiO2nanorods for high dielectric performance: Understanding the role of interfacial polarization in semiconductor-insulator core-shell nanostructure. Compos. Sci. Technol. 2017, 151, 25–33. [Google Scholar] [CrossRef]

- Yao, L.; Pan, Z.; Zhai, J.; Zhang, G.; Liu, Z.; Liu, Y. High-energy-density with polymer nanocomposites containing of SrTiO3nanofibers for capacitor application. Compos. A Appl. Sci. 2018, 109, 48–54. [Google Scholar] [CrossRef]

- Ponraj, B.; Bhimireddi, R.; Varma, K.B.R. Effect of nano- and micron-sized K0.5Na0.5NbO3 fillers on the dielectric and piezoelectric properties of PVDF composites. J. Adv. Ceram. 2016, 5, 308–320. [Google Scholar] [CrossRef]

- Qu, B.; Du, H.; Yang, Z. Lead-free relaxor ferroelectric ceramics with high optical transparency and energy storage ability. J. Mater Chem. C 2016, 4, 1795–1803. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Sun, N.; Zhang, Q.; Zhang, L.; Hao, X.; Chou, X. Effects of Fe3+ doping on electrical properties and energy-storage performances of the (Na0.85K0.15)0.5Bi0.5TiO3 thick films prepared by sol-gel method. J. Alloys Compd. 2017, 727, 596–602. [Google Scholar] [CrossRef]

- Puli, V.S.; Ejaz, M.; Elupula, R.; Kothakonda, M.; Adireddy, S.; Katiyar, R.S.; Grayson, S.M.; Chrisey, D.B. Core-shell like structured barium zirconium titanate-barium calcium titanate–poly(methyl methacrylate) nanocomposites for dielectric energy storage capacitors. Polymer 2016, 105, 35–42. [Google Scholar] [CrossRef]

- Chen, G.; Zhang, P.; Pan, L.; Qi, L.; Yu, F.; Gao, C. Flexible nonvolatile resistive memory devices based on SrTiO3nanosheets and polyvinylpyrrolidone composites. J. Mater. Chem. C 2017, 5, 9799–9805. [Google Scholar] [CrossRef]

- Hu, P.; Jia, Z.; Shen, Z.; Wang, P.; Liu, X. High dielectric constant and energy density induced by the tunable TiO2 interfacial buffer layer in PVDF nanocomposite contained with core–shell structured TiO2 @BaTiO3 nanoparticles. Appl. Surf. Sci. 2018, 441, 824–831. [Google Scholar] [CrossRef]

- Chen, G.; Lin, J.; Wang, X.; Yang, W.; Li, D.; Ding, W.; Li, H.; Lei, Q. Three-layer structure design for enhancing the energy efficiency and breakdown strength of KTa0.5Nb0.5O3/polyimide nanocomposite films with high thermal stability. J. Mater. Sci. Mater. Electron. 2017, 28, 13861–13868. [Google Scholar] [CrossRef]

- Ji, H.; Ren, W.; Wang, L.; Shi, P.; Chen, X.; Wu, X.; Yao, X. Enhanced Structures and Electrical Properties of Lead-Free K0.5Na0.5NbO3-Bi0.5Na0.5TiO3 0-3 Composite Ferroelectric Thick Films. J. Am. Ceram. Soc. 2011, 94, 3425–3430. [Google Scholar] [CrossRef]

- Yang, H.; Yan, F.; Lin, Y.; Wang, T. Improvement of dielectric and energy storage properties in SrTiO3-based lead-free ceramics. J. Alloys Compd. 2017, 728, 780–787. [Google Scholar] [CrossRef]

- Wang, J.; Liu, S.; Wang, J.; Hao, H.; Zhao, L.; Zhai, J. Improving dielectric properties and energy storage performance of poly(vinylidene fluoride) nanocomposite by surface-modified SrTiO3 nanoparticles. J. Alloys Compd. 2017, 726, 587–592. [Google Scholar] [CrossRef]

- Liu, S.; Zhai, J. Improving the dielectric constant and energy density of poly(vinylidene fluoride) composites induced by surface-modified SrTiO3nanofibers by polyvinylpyrrolidone. J. Mater. Chem. A 2015, 3, 1511–1517. [Google Scholar] [CrossRef]

- Tang, H.X.; Sodano, H.A. High energy density nanocomposite capacitors using non-ferroelectric nanowires. Appl. Phys. Lett. 2013, 102, 063901. [Google Scholar] [CrossRef]

- Tang, H.X.; Sodano, H.A. Ultra high energy density nanocomposite capacitors with fast discharge using Ba0.2Sr0.8TiO3nanowires. Nano Lett. 2013, 13, 1373–1379. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, X.; Sun, R.; Luo, H. Crystal growth and electric properties of lead-free NBT-BT at compositions near the morphotropic phase boundary. Phys. Status Solidi A 2011, 208, 1012–1020. [Google Scholar] [CrossRef]

- Jin, L.; Li, F.; Zhang, S.; Green, D.J. Decoding the Fingerprint of Ferroelectric Loops: Comprehension of the Material Properties and Structures. J. Am. Ceram. Soc. 2014, 97, 1–27. [Google Scholar] [CrossRef]

- Jo, W.; Schaab, S.; Sapper, E.; Schmitt, L.A.; Kleebe, H.-J.; Bell, A.J.; Rödel, J. On the phase identity and its thermal evolution of lead free (Bi1/2Na1/2)TiO3-6 mol% BaTiO3. J. Appl. Phys. 2011, 110, 074106. [Google Scholar] [CrossRef]

- Xiao, D.Q.; Lin, D.M.; Zhu, J.G.; Yu, P. Investigation on the design and synthesis of new systems of BNT-based lead-free piezoelectric ceramics. J. Electroceram. 2006, 16, 271–275. [Google Scholar] [CrossRef]

- Liu, D.; Pallon, L.K.H.; Pourrahimi, A.M.; Zhang, P.; Diaz, Z.; Holler, M.; Schneider, K.; Olsson, R.T.; Hedenqvist, M.S.; Yu, S.; et al. Cavitation in strained polyethylene/aluminium oxide nanocomposites. Eur. Polym. J. 2017, 87, 255–265. [Google Scholar] [CrossRef]

- Pal, V.; Dwivedi, R.K.; Thakur, O.P. Effect of neodymium substitution on structural and ferroelectric properties of BNT ceramics. Mater. Res. Bull. 2014, 51, 189–196. [Google Scholar] [CrossRef]

- Puli, V.S.; Pradhan, D.K.; Riggs, B.C.; Chrisey, D.B.; Katiyar, R.S. Investigations on structure, ferroelectric, piezoelectric and energy storage properties of barium calcium titanate (BCT) ceramics. J. Alloys Compd. 2014, 584, 369–373. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, Y.; Li, Z.; Fan, P.; Ma, W.; Xie, B. High discharged energy density of polymer nanocomposites containing paraelectric SrTiO3 nanowires for flexible energy storage device. J. Alloys Compd. 2018, 744, 116–123. [Google Scholar] [CrossRef]

- Pourrahimi, A.M.; Olsson, R.T.; Hedenqvist, M.S. The role of interfaces in polyethylene/metal-Oxide nanocomposites for ultrahigh-voltage insulating materials. Adv. Mater. 2017, 30, 1703624. [Google Scholar] [CrossRef]

- Shalu, S.; Kar, P.; Krupka, J.; DasguptaGhosh, B. Synthesis, characterization, thermal, dynamic mechanical, and dielectric studies of Ba0.7Sr0.3TiO3/polystyrene composites. Polym. Compos. 2018, 39, E1714–E1724. [Google Scholar]

- Luo, S.; Yu, S.; Sun, R.; Wong, C.-P. Nano Ag-deposited BaTiO3hybrid particles as fillers for polymeric dielectric composites: Toward high dielectric constant and suppressed loss. Appl. Mater. Interface 2014, 6, 176–182. [Google Scholar] [CrossRef]

- Luo, B.; Wang, X.; Wang, Y.; Li, L. Fabrication, characterization, properties and theoretical analysis of ceramic/PVDF composite flexible films with high dielectric constant and low dielectric loss. J. Mater. Chem. A 2014, 2, 510–519. [Google Scholar] [CrossRef]

- Chen, G.; Lin, X.; Li, J.; Fisher, J.G.; Zhang, Y.; Huang, S.; Cheng, X. Enhanced dielectric properties and discharged energy density of composite films using submicron PZT particles. Ceram. Int. 2018, 44, 15331–15337. [Google Scholar] [CrossRef]

- Hu, P.; Shen, Y.; Guan, Y.; Zhang, X.; Lin, Y.; Zhang, Q.; Nan, C.-W. Topological-Structure Modulated Polymer Nanocomposites Exhibiting Highly Enhanced Dielectric Strength and Energy Density. Adv. Funct. Mater. 2014, 24, 3172–3178. [Google Scholar] [CrossRef]

- Pan, Z.; Liu, B.; Zhai, J.; Yao, L.; Yang, K.; Shen, B. NaNbO3 two-dimensional platelets induced highly energy storage density in trilayered architecture composites. Nano Energy 2017, 40, 587–595. [Google Scholar] [CrossRef]

- Prateek; Thakur, V.K.; Gupta, R.K. Recent Progress on Ferroelectric Polymer-Based Nanocomposites for High Energy Density Capacitors: Synthesis, Dielectric Properties, and Future Aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar] [CrossRef]

- Song, Y.; Shen, Y.; Liu, H.; Lin, Y.; Li, M.; Nan, C.-W. Improving the dielectric constants and breakdown strength of polymer composites: Effects of the shape of the BaTiO3nanoinclusions, surface modification and polymer matrix. J. Mater. Chem. 2012, 22, 16491. [Google Scholar] [CrossRef]

- Zhu, L. Exploring Strategies for High Dielectric Constant and Low Loss Polymer Dielectrics. J. Phys. Chem. Lett. 2014, 5, 3677–3687. [Google Scholar] [CrossRef]

- Song, Z.; Liu, H.; Zhang, S.; Wang, Z.; Shi, Y.; Hao, H.; Cao, M.; Yao, Z.; Yu, Z. Effect of grain size on the energy storage properties of (Ba0.4Sr0.6)TiO3paraelectric ceramics. J. Eur. Ceram. Soc. 2014, 34, 1209–1217. [Google Scholar] [CrossRef]

- Tong, S.; Ma, B.; Narayanan, M.; Liu, S.; Koritala, R.; Balachandran, U.; Shi, D. Lead lanthanum zirconatetitanate ceramic thin films for energy storage. ACS Appl. Mater. Interface 2013, 5, 1474–1480. [Google Scholar] [CrossRef]

- Yang, K.; Huang, X.; Zhu, M.; Xie, L.; Tanaka, T.; Jiang, P. Combining RAFT polymerization and thiol-ene click reaction for core-shell structured polymer@BaTiO3nanodielectrics with high dielectric constant, low dielectric loss, and high energy storage capability. ACS Appl. Mater. Interface 2014, 6, 1812–1822. [Google Scholar] [CrossRef]

- Ye, J.; Liu, Y.; Lu, Y.; Ding, J.; Ma, C.; Qian, H.; Yu, Z. Enhanced energy-storage properties of SrTiO3 doped (Bi1/2Na1/2)TiO3–(Bi1/2K1/2)TiO3 lead-free antiferroelectricceramics. J. Mater. Sci. Mater. Electron. 2014, 25, 4632–4637. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, J.; Zhou, C.; Yuan, C.; Li, Q.; Chen, G.; Wang, H.; Yang, L. High energy storage properties and dielectric behavior of (Bi0.5Na0.5)0.94Ba0.06Ti1−x(Al0.5Nb0.5)xO3 lead-free ferroelectric ceramics. Ceram. Int. 2016, 42, 2221–2226. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, J.; Yu, Y.; Jiang, W.; Zhang, Z. Enhancing breakdown strength and energy storage performance of PVDF-based nanocomposites by adding exfoliated boron nitride. Appl. Surf. Sci. 2018, 440, 1150–1158. [Google Scholar] [CrossRef]

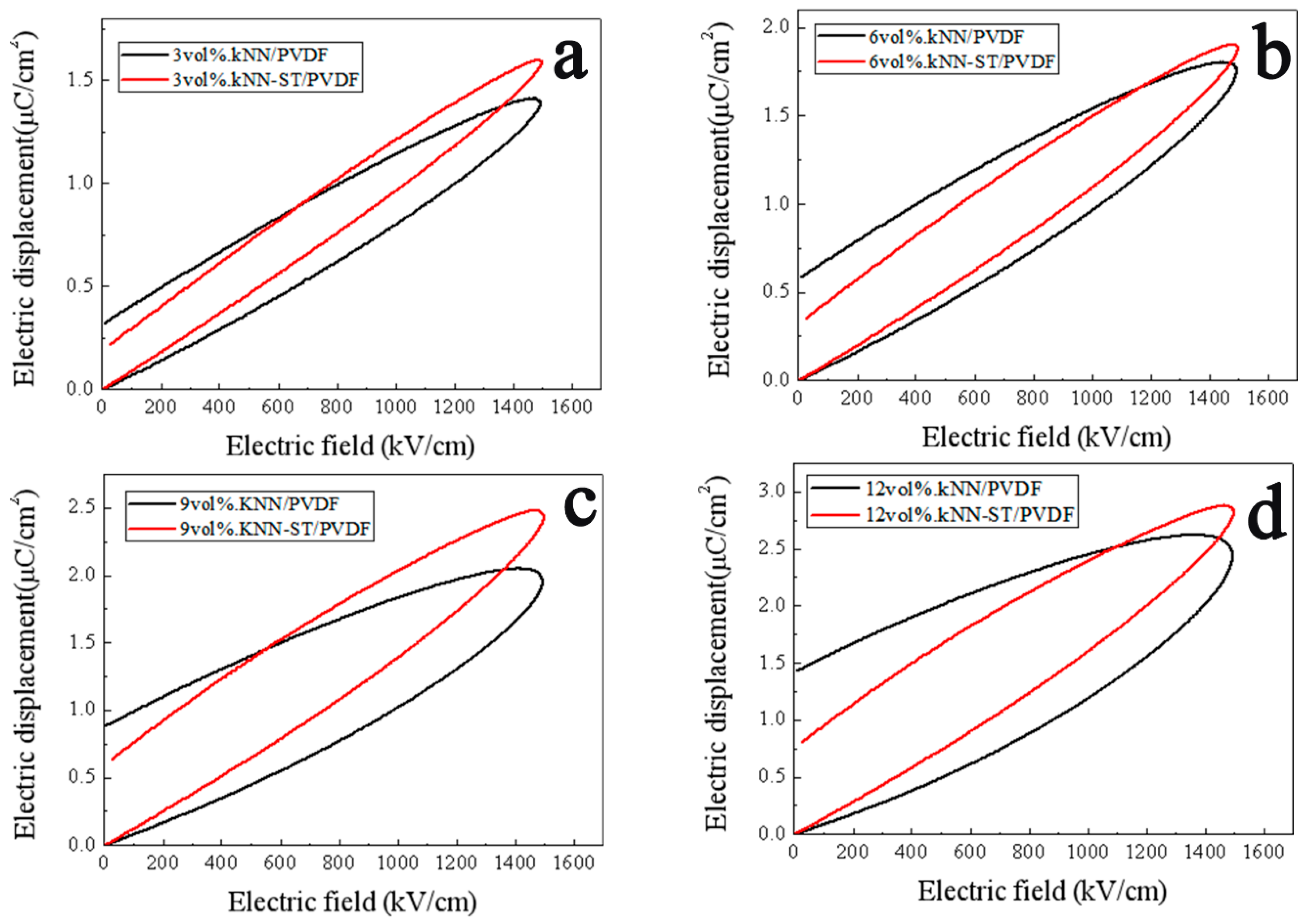

| Pure PVDF | εr | tanδ | Pr(μC/cm2) | Wrec(J/cm3) | η (%) | Eb(kV/cm) |

|---|---|---|---|---|---|---|

| 8 | 0.012 | 0.31 | 0.55 | 57.99 | 301.58 | |

| KNN vol% | εr | tanδ | Pr(μC/cm2) | Wrec(J/cm3) | η (%) | Eb(kV/cm) |

| 3 | 10 | 0.019 | 0.32 | 0.72 | 59.67 | 282.58 |

| 6 | 12 | 0.022 | 0.58 | 0.77 | 50.34 | 243.75 |

| 9 | 14 | 0.029 | 0.88 | 0.70 | 36.65 | 207.57 |

| 12 | 17 | 0.037 | 1.42 | 0.66 | 29.02 | 173.85 |

| KNN-ST vol% | εr | tanδ | Pr(μC/cm2) | Wrec(J/cm3) | η (%) | Eb(kV/cm) |

| 3 | 11 | 0.053 | 0.22 | 0.98 | 74.68 | 304.44 |

| 6 | 15 | 0.094 | 0.35 | 1.06 | 66.02 | 263.64 |

| 9 | 22 | 0.201 | 0.64 | 1.22 | 56.94 | 218.01 |

| 12 | 38 | 0.419 | 0.80 | 1.34 | 53.87 | 183.83 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Wang, L.; Liu, X.; Yang, W.; Lin, J.; Chen, G.; Yang, X. K0.5Na0.5NbO3-SrTiO3/PVDF Polymer Composite Film with Low Remnant Polarization and High Discharge Energy Storage Density. Polymers 2019, 11, 310. https://doi.org/10.3390/polym11020310

Chen C, Wang L, Liu X, Yang W, Lin J, Chen G, Yang X. K0.5Na0.5NbO3-SrTiO3/PVDF Polymer Composite Film with Low Remnant Polarization and High Discharge Energy Storage Density. Polymers. 2019; 11(2):310. https://doi.org/10.3390/polym11020310

Chicago/Turabian StyleChen, Chuntian, Lei Wang, Xinmei Liu, Wenlong Yang, Jiaqi Lin, Gaoru Chen, and Xinrui Yang. 2019. "K0.5Na0.5NbO3-SrTiO3/PVDF Polymer Composite Film with Low Remnant Polarization and High Discharge Energy Storage Density" Polymers 11, no. 2: 310. https://doi.org/10.3390/polym11020310