Designing the Slide-Ring Polymer Network with both Good Mechanical and Damping Properties via Molecular Dynamics Simulation

Abstract

:1. Introduction

2. Simulation and Method

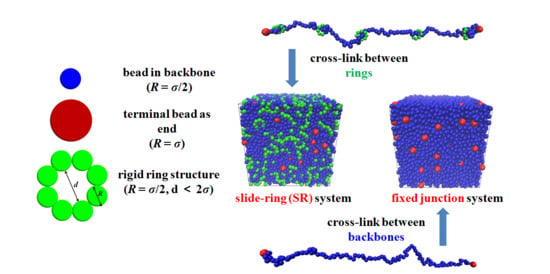

2.1. Model and Force Field

2.2. Equilibrium Simulation

2.3. Non-Equilibrium Simulation

3. Results and Discussion

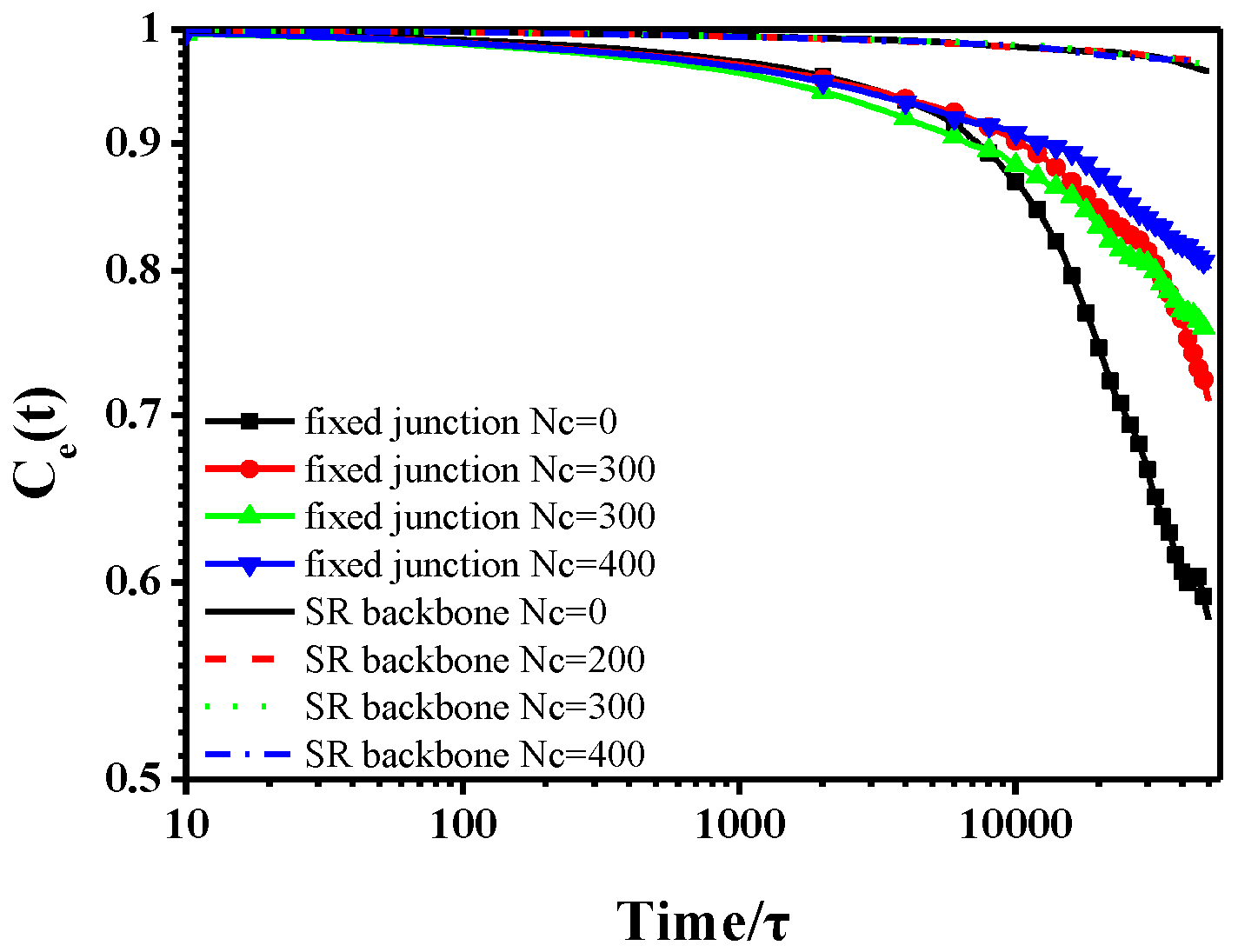

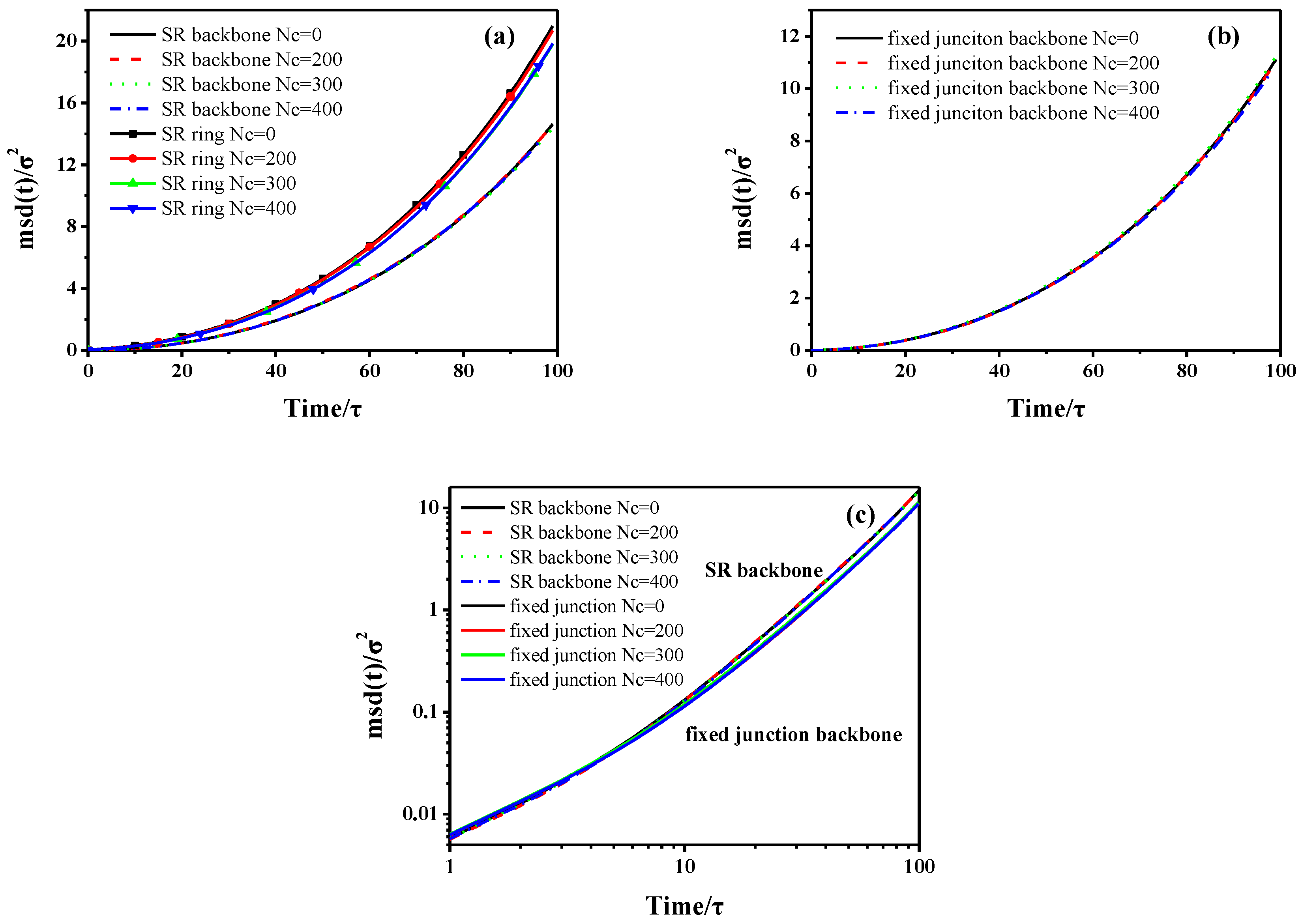

3.1 Dynamic Properties

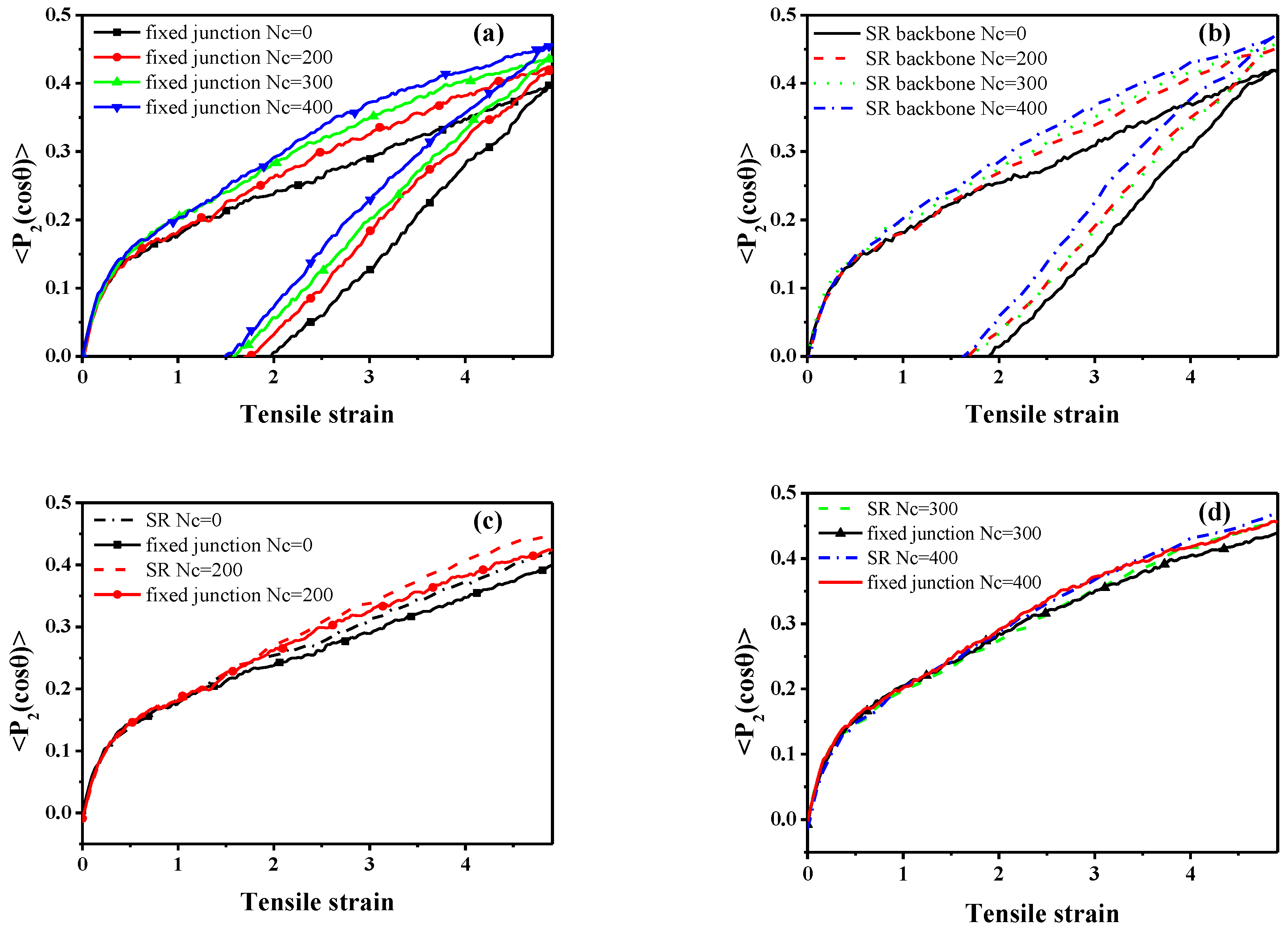

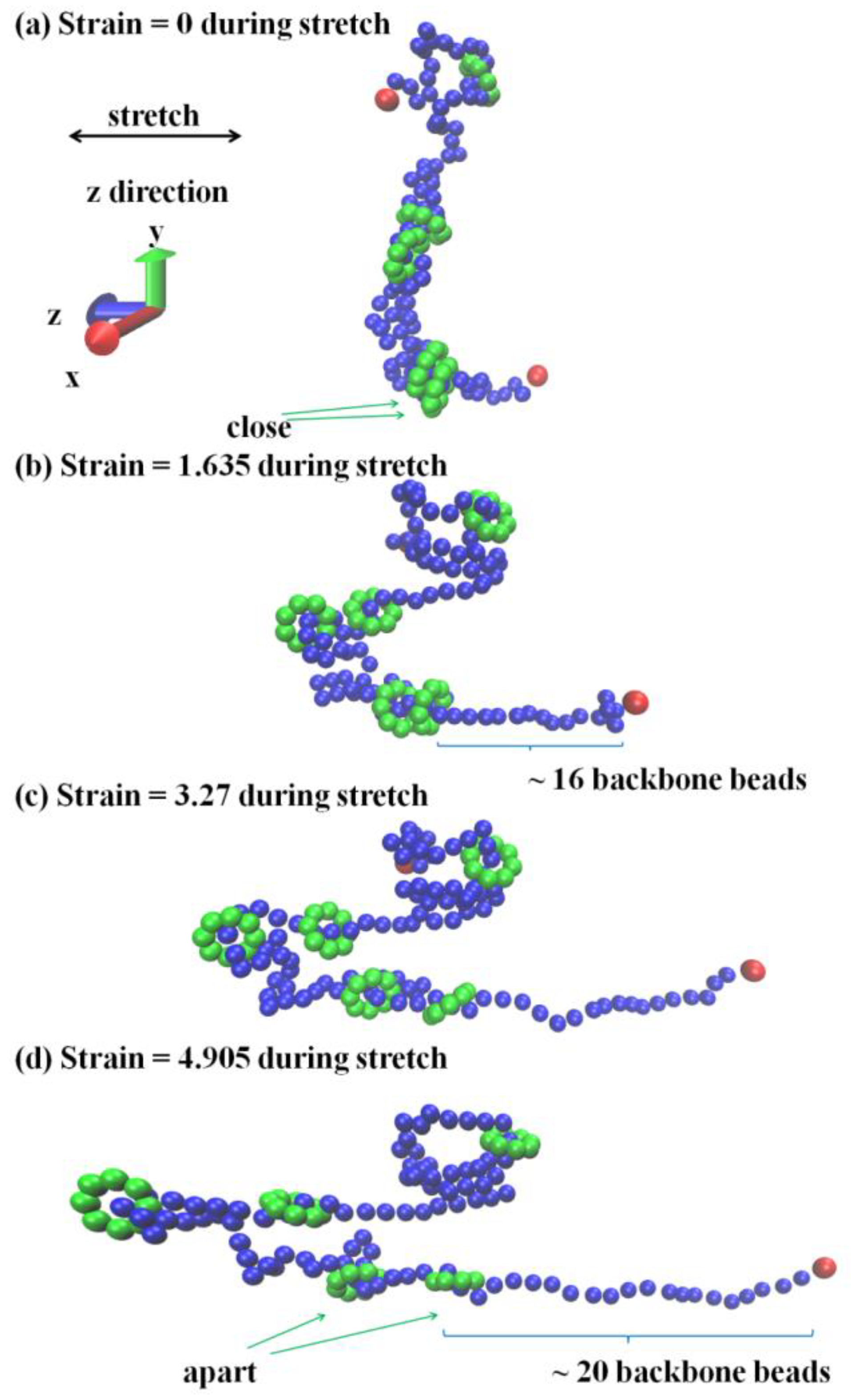

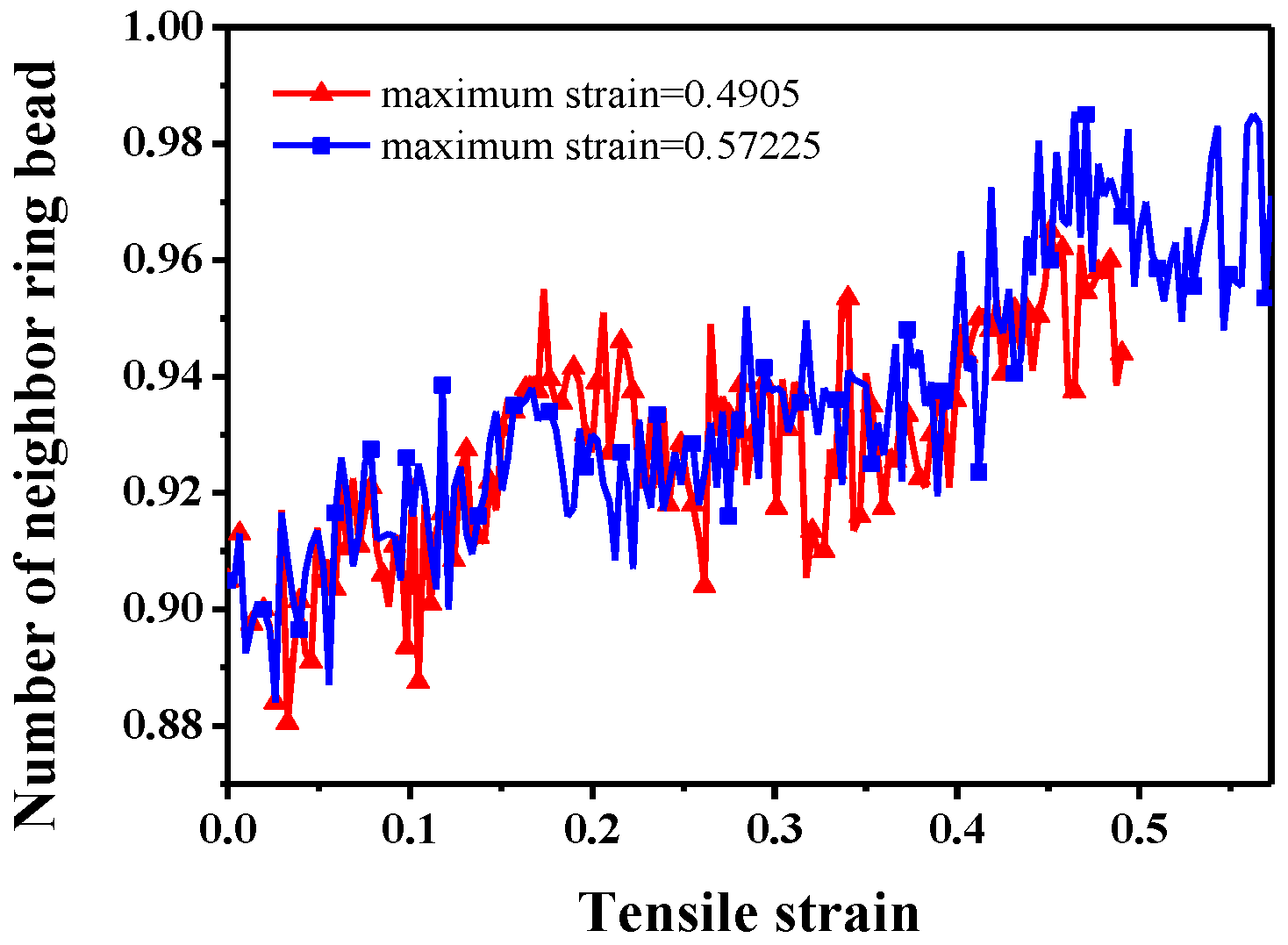

3.2. Stretch-Recovery Behavior

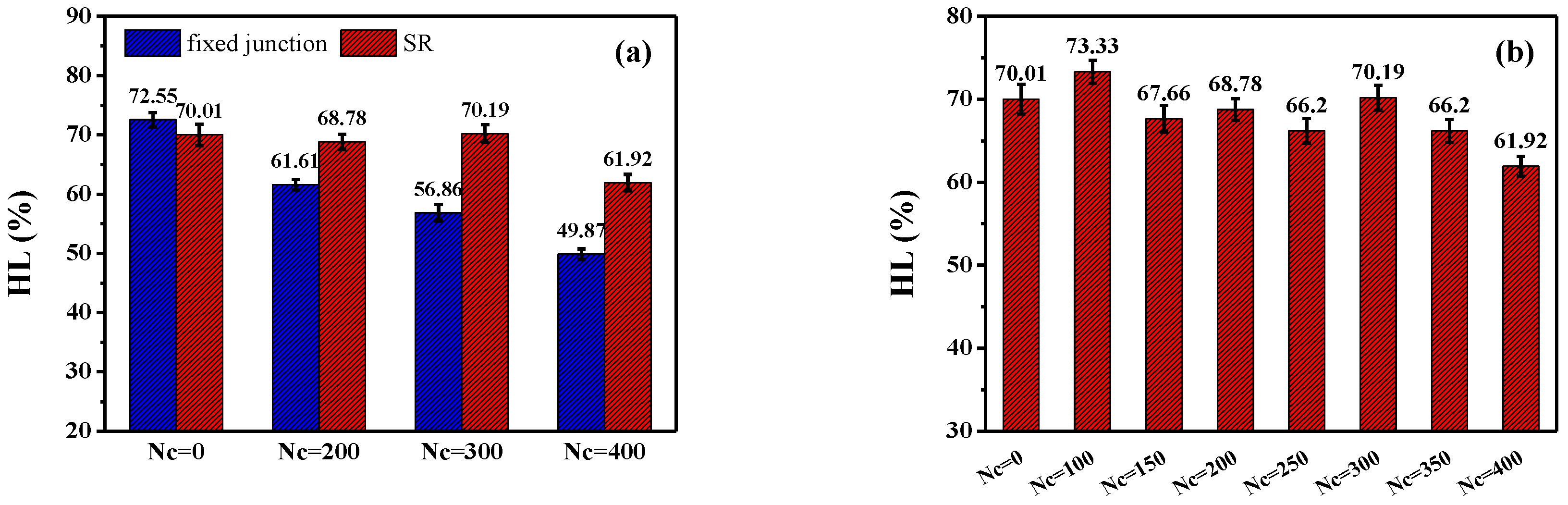

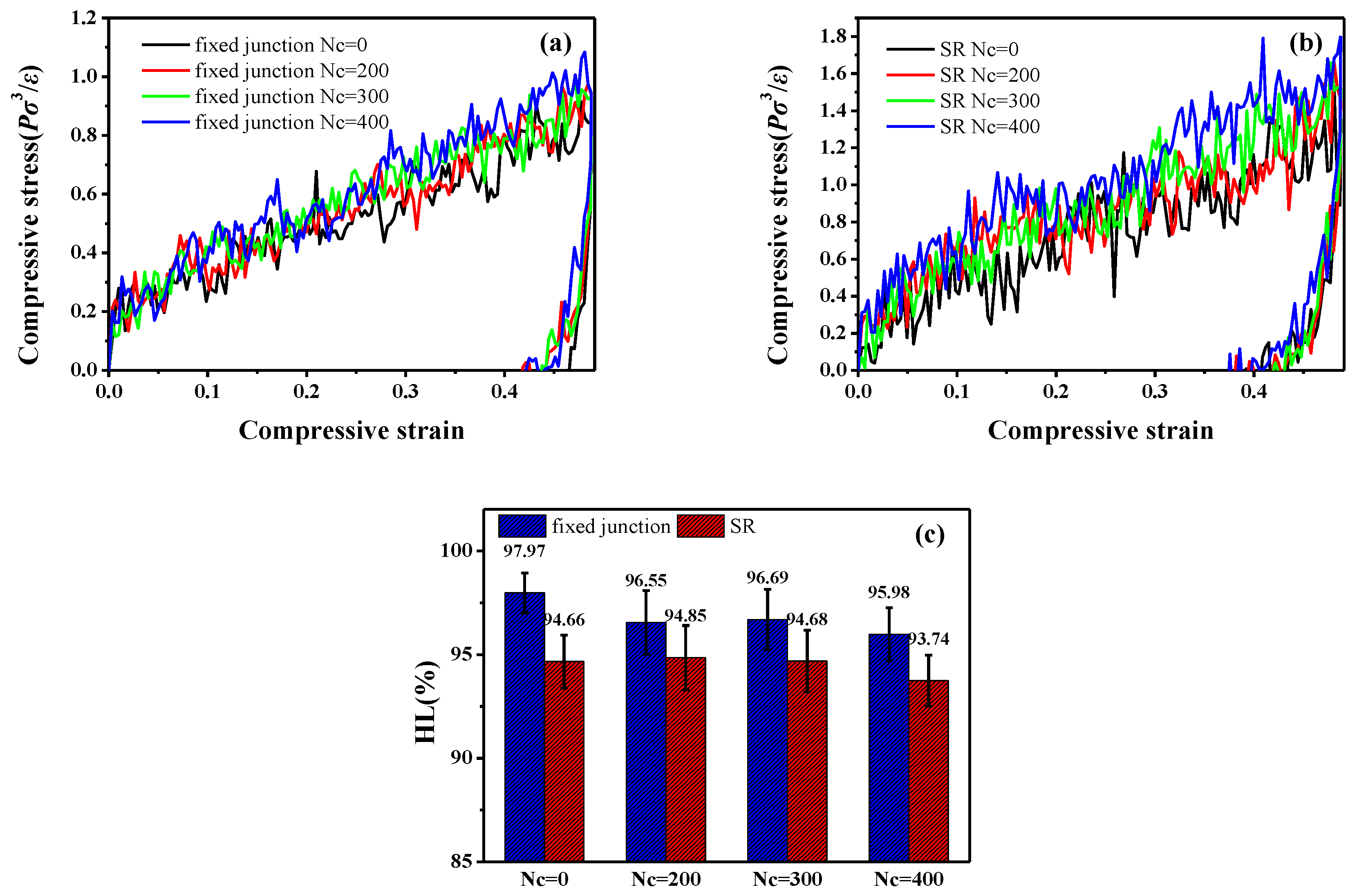

3.3. Compression-Recovery Behavior

4. Conclusions

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| length parameter | |

| Well depth in LJ interaction | |

| reduced time | |

| reduced temperature | |

| reduced density | |

| reduced pressure | |

| reduced energy | |

| reduced volume | reduced volume |

References

- Dai, L.; Zhang, L.; Wang, B.; Yang, B.; Khan, I.; Khan, A.; Ni, Y. Multifunctional self-assembling hydrogel from guar gum. Chem. Eng. J. 2017, 330, 1044–1051. [Google Scholar] [CrossRef]

- Jung, Y.-S.; Park, W.; Park, H.; Lee, D.-K.; Na, K. Thermo-sensitive injectable hydrogel based on the physical mixing of hyaluronic acid and pluronic f-127 for sustained nsaid delivery. Carbohydr. Polym. 2017, 156, 403–408. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Yuk, H.; Zhang, T.; Parada, G.A.; Koo, H.; Yu, C.; Zhao, X. Stretchable hydrogel electronics and devices. Adv. Mater. 2016, 28, 4497–4505. [Google Scholar] [CrossRef] [PubMed]

- Maulvi, F.A.; Lakdawala, D.H.; Shaikh, A.A.; Desai, A.R.; Choksi, H.H.; Vaidya, R.J.; Ranch, K.M.; Koli, A.R.; Vyas, B.A.; Shah, D.O. In vitro and in vivo evaluation of novel implantation technology in hydrogel contact lenses for controlled drug delivery. J. Control. Release 2016, 226, 47–56. [Google Scholar] [CrossRef] [PubMed]

- Peppas, N.A.; Hilt, J.Z.; Khademhosseini, A.; Langer, R. Hydrogels in biology and medicine: From molecular principles to bionanotechnology. Adv. Mater. 2006, 18, 1345–1360. [Google Scholar] [CrossRef]

- Yuk, H.; Lin, S.; Ma, C.; Takaffoli, M.; Fang, N.X.; Zhao, X. Hydraulic hydrogel actuators and robots optically and sonically camouflaged in water. Nat. Commun. 2017, 8, 14230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yashin, V.V.; Balazs, A.C. Pattern formation and shape changes in self-oscillating polymer gels. Science 2006, 314, 798–801. [Google Scholar] [CrossRef] [PubMed]

- Cho, W.R.; Wu, J.H.; Shim, B.S.; Kuan, W.F.; Mastroianni, S.E.; Young, W.S.; Kuo, C.C.; Epps, T.H.; Martin, D.C. Synthesis and characterization of bicontinuous cubic poly(3,4-ethylene dioxythiophene) gyroid (pedot gyr) gels. Phys. Chem. Phys. Chem. 2015, 17, 5115–5123. [Google Scholar] [CrossRef] [PubMed]

- Veschgini, M.; Habe, T.; Mielke, S.; Inoue, S.; Liu, X.H.; Krafft, M.P.; Tanaka, M. Existence of two-dimensional physical gels even at zero surface pressure at the air/water interface: Rheology of self-assembled domains of small molecules. Angew. Chem. 2017, 59, 12603–12607. [Google Scholar] [CrossRef] [PubMed]

- Flory, P.J. Principles of Polymer Chemistry; Cornell University Press: New York, NY, USA, 1953. [Google Scholar]

- Wilson, A.J. Non-covalent polymer assembly using arrays of hydrogen-bonds. Soft Matter 2007, 3, 409–425. [Google Scholar] [CrossRef]

- Fukao, K.; Nonoyama, T.; Kiyama, R.; Furusawa, K.; Kurokawa, T.; Nakajima, T.; Gong, J.P. Anisotropic growth of hydroxyapatite in stretched double network hydrogel. ACS Nano 2017, 11, 12103–12110. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.Y.; Liu, J.; Shen, J.X.; Cao, D.P.; Zhang, L.Q. Molecular dynamics simulation of the rupture mechanism in nanorod filled polymer nanocomposites. Phys. Chem. Chem. Phys. 2014, 16, 18483–18492. [Google Scholar] [CrossRef] [PubMed]

- Ito, K. Slide-ring materials using topological supramolecular architecture. Curr. Opin. Solid State Mater. Sci. 2010, 14, 28–34. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, D.; Yang, J.; Nishi, T.; Ito, K.; Zhao, X.; Zhang, L. Novel slide-ring material/natural rubber composites with high damping property. Sci. Rep. 2016, 6, 22810. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Niu, K.; Xu, Y.; Peng, Z.; Jia, L.; Hui, D.; Zhang, L. Morphology and performance of nr/nbr/enr ternary rubber composites. Compos. Part B Eng. 2016, 107, 106–112. [Google Scholar] [CrossRef]

- Howell, I.R.; Li, C.; Colella, N.S.; Ito, K.; Watkins, J.J. Strain-tunable one dimensional photonic crystals based on zirconium dioxide/slide-ring elastomer nanocomposites for mechanochromic sensing. ACS Appl. Mater. Interfaces 2015, 7, 3641–3646. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Ge, F.; Tian, M.; Ning, N.; Zhang, L.; Zhao, C.; Ito, K.; Nishi, T.; Wang, H.; Luan, Y. Dielectric elastomer actuator with excellent electromechanical performance using slide-ring materials/barium titanate composites. J. Mater. Chem. A 2015, 3, 9468–9479. [Google Scholar] [CrossRef]

- Harada, A.; Li, J.; Kamachi, M. The molecular necklace: A rotaxane containing many threaded α-cyclodextrins. Nature 1992, 356, 325–327. [Google Scholar] [CrossRef]

- Okumura, Y. Topological gel: A third kind of gel consisting of linear polymer chains and figure-of-eight cross-links. Kobunshi Ronbunshu 2005, 62, 380–389. [Google Scholar] [CrossRef]

- Murayama, H.; Bin Imran, A.; Nagano, S.; Seki, T.; Kidowaki, M.; Ito, K.; Takeoka, Y. Chromic slide-ring gel based on reflection from photonic bandgap. Macromolecules 2008, 41, 1808–1814. [Google Scholar] [CrossRef]

- Karino, T.; Okumura, Y.; Ito, K.; Shibayama, M. Sans studies on spatial inhomogeneities of slide-ring gels. Macromolecules 2004, 37, 6177–6182. [Google Scholar] [CrossRef]

- Ito, K. Novel cross-linking concept of polymer network: Synthesis, structure, and properties of slide-ring gels with freely movable junctions. Polym. J. 2007, 39, 489–499. [Google Scholar] [CrossRef]

- Kato, K.; Yasuda, T.; Ito, K. Peculiar elasticity and strain hardening attributable to counteracting entropy of chain and ring in slide-ring gels. Polymer 2014, 55, 2614–2619. [Google Scholar] [CrossRef]

- Kato, K.; Ito, K. Polymer networks characterized by slidable crosslinks and the asynchronous dynamics of interlocked components. React. Funct. Polym. 2013, 73, 405–412. [Google Scholar] [CrossRef]

- Ito, K. Novel entropic elasticity of polymeric materials: Why is slide-ring gel so soft? Polym. J. 2011, 44, 38–41. [Google Scholar] [CrossRef]

- Bando, A.; Kasahara, R.; Kayashima, K.; Okumura, Y.; Kato, K.; Sakai, Y.; Yokoyama, H.; Shinohara, Y.; Amemiya, Y.; Ito, K. Volume phase transitions of slide-ring gels. Polymers 2016, 8, 217. [Google Scholar] [CrossRef]

- Karino, T.; Okumura, Y.; Zhao, C.M.; Kataoka, T.; Ito, K.; Shibayama, M. Sans studies on deformation mechanism of slide-ring gel. Macromolecules 2005, 38, 6161–6167. [Google Scholar] [CrossRef]

- Koga, T.; Tanaka, F. Elastic properties of polymer networks with sliding junctions. Eur. Phys. J. E 2005, 17, 225–229. [Google Scholar] [CrossRef] [PubMed]

- Sevick, E.M.; Williams, D.R.M. Piston-rotaxanes as molecular shock absorbers. Langmuir 2010, 26, 5864–5868. [Google Scholar] [CrossRef] [PubMed]

- Habasaki, J.; Ishikawa, M. Molecular dynamics study of coagulation in silica-nanocolloid-water-nacl systems based on the atomistic model. Phys. Chem. Chem. Phys. 2014, 16, 24000–24017. [Google Scholar] [CrossRef] [PubMed]

- Qian, Y.D.; Xu, X.Q.; Wang, Q.; Wu, P.; Zhang, H.; Cai, C.X. Electrochemical probing of the solution ph-induced structural alterations around the heme group in myoglobin. Phys. Chem. Chem. Phys. 2013, 15, 16941–16948. [Google Scholar] [CrossRef] [PubMed]

- Frankland, S.J.V.; Harik, V.M.; Odegard, G.M.; Brenner, D.W.; Gates, T.S. The stress-strain behavior of polymer-nanotube composites from molecular dynamics simulation. Compos. Sci. Technol. 2003, 63, 1655–1661. [Google Scholar] [CrossRef]

- Shen, J.; Liu, J.; Li, H.; Gao, Y.; Li, X.; Wu, Y.; Zhang, L. Molecular dynamics simulations of the structural, mechanical and visco-elastic properties of polymer nanocomposites filled with grafted nanoparticles. Phys. Chem. Chem. Phys. 2015, 17, 7196–7207. [Google Scholar] [CrossRef] [PubMed]

- Vemparala, S.; Karki, B.B.; Kalia, R.K.; Nakano, A.; Vashishta, P. Large-scale molecular dynamics simulations of alkanethiol self-assembled monolayers. J. Chem. Phys. 2004, 121, 4323–4330. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Lu, Y.-L.; Tian, M.; Li, F.; Shen, J.; Gao, Y.; Zhang, L. The interesting influence of nanosprings on the viscoelasticity of elastomeric polymer materials: Simulation and experiment. Adv. Funct. Mater. 2013, 23, 1156–1163. [Google Scholar] [CrossRef]

- Pavlov, A.S.; Khalatur, P.G. Filler reinforcement in cross-linked elastomer nanocomposites: Insights from fully atomistic molecular dynamics simulation. Soft Matter 2016, 12, 5402–5419. [Google Scholar] [CrossRef] [PubMed]

- Xu, D.D.; Huang, J.C.; Zhao, D.; Ding, B.B.; Zhang, L.; Cai, J. High-flexibility, high-toughness double-cross-linked chitin hydrogels by sequential chemical and physical cross-linkings (vol 28, pg 5844, 2016). Adv. Mater. 2016, 28, 9667. [Google Scholar] [CrossRef] [PubMed]

- Tonpheng, B.; Yu, J.C.; Andersson, O. Effects of cross-links, pressure and temperature on the thermal properties and glass transition behaviour of polybutadiene. Phys. Chem. Chem. Phys. 2011, 13, 15047–15054. [Google Scholar] [CrossRef] [PubMed]

- Kremer, K.; Grest, G.S. Dynamics of entangled linear polymer melts: A molecular-dynamics simulation. J. Chem. Phys. 1990, 92, 5057–5086. [Google Scholar] [CrossRef]

- Zheng, Z.; Shen, J.; Liu, J.; Wu, Y.; Zhang, L.; Wang, W. Tuning the visco-elasticity of elastomeric polymer materials via flexible nanoparticles: Insights from molecular dynamics simulation. Rsc Adv. 2016, 6, 28666–28678. [Google Scholar] [CrossRef]

- Allen, M.P.; Tildesley, D.J. Computer Simulation of Liquids; Oxford University Press: New York, NY, USA, 1987. [Google Scholar]

- Hagita, K.; Morita, H.; Doi, M.; Takano, H. Coarse-grained molecular dynamics simulation of filled polymer nanocomposites under uniaxial elongation. Macromolecules 2016, 49, 1972–1983. [Google Scholar] [CrossRef]

- Hou, G.; Tao, W.; Liu, J.; Gao, Y.; Zhang, L.; Li, Y. Tailoring the dispersion of nanoparticles and the mechanical behavior of polymer nanocomposites by designing the chain architecture. Phys. Chem. Chem. Phys. 2017, 19, 32024–32037. [Google Scholar] [CrossRef] [PubMed]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Shen, J.; Liu, J.; Gao, Y.; Li, X.; Zhang, L. Elucidating and tuning the strain-induced non-linear behavior of polymer nanocomposites: A detailed molecular dynamics simulation study. Soft Matter 2014, 10, 5099–5113. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, Z.; Zhang, Z.; Shen, J.; Chen, Y.; Zheng, Z.; Zhang, L.; Lyulin, A.V. Self-assembly of block copolymer chains to promote the dispersion of nanoparticles in polymer nanocomposites. J. Phys. Chem. B 2017, 121, 9311–9318. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Hou, G.; Zheng, Z.; Wang, L.; Liu, J.; Wu, Y.; Zhang, L.; Lyulin, A.V. Designing polymer nanocomposites with a semi-interpenetrating or interpenetrating network structure: Toward enhanced mechanical properties. Phys. Chem. Chem. Phys. 2017, 19, 15808–15820. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Cao, D.; Zhang, L. Molecular dynamics study on nanoparticle diffusion in polymer melts: A test of the stokes—Einstein law. J. Phys. Chem. C 2008, 112, 6653–6661. [Google Scholar] [CrossRef]

- Kremer, K.; Grest, G.S.; Carmesin, I. Crossover from rouse to reptation dynamics: A molecular-dynamics simulation. Phys. Rev. Lett. 1988, 61, 566–569. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Srivastava, D.; Cho, K. Thermal expansion and diffusion coefficients of carbon nanotube-polymer composites. Nano Lett. 2002, 2, 647–650. [Google Scholar] [CrossRef]

- Batchelor, G.K. An Introduction to Fluid Dynamics; Cambridge University Press: Cambrige, UK, 1990; p. 635. [Google Scholar]

- Riggleman, R.A.; Lee, H.-N.; Ediger, M.D.; De Pablo, J.J. Free volume and finite-size effects in a polymer glass under stress. Phys. Rev. Lett. 2007, 99, 215501. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Shen, J.; Gao, Y.; Zhou, H.; Wu, Y.; Zhang, L. Detailed simulation of the role of functionalized polymer chains on the structural, dynamic and mechanical properties of polymer nanocomposites. Soft Matter 2014, 10, 8971–8984. [Google Scholar] [CrossRef] [PubMed]

- Murat, M.; Grest, G.S. Structure of a grafted polymer brush: A molecular dynamics simulation. Macromolecules 1989, 22, 4054–4059. [Google Scholar] [CrossRef]

- Vilgis, T.A.; Heinrich, G. Dynamics of heterogeneous polymer networks. Phys. Rev. E 1994, 49, 2167. [Google Scholar] [CrossRef]

- Lin, P.-H.; Khare, R. Local chain dynamics and dynamic heterogeneity in cross-linked epoxy in the vicinity of glass transition. Macromolecules 2010, 43, 6505–6510. [Google Scholar] [CrossRef]

- Kenkare, N.R.; Smith, S.W.; Hall, C.K.; Khan, S.A. Discontinuous molecular dynamics studies of end-linked polymer networks. Macromolecules 1998, 31, 5861–5879. [Google Scholar] [CrossRef]

- Oh, H.; Green, P.F. Polymer chain dynamics and glass transition in athermal polymer/nanoparticle mixtures. Nat. Mater. 2009, 8, 139–143. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Kröger, M.; Liu, W.K. Nanoparticle geometrical effect on structure, dynamics and anisotropic viscosity of polyethylene nanocomposites. Macromolecules 2012, 45, 2099–2112. [Google Scholar] [CrossRef]

- Rubinstein, M.; Colby, R.H. Polymer Physics; Oxford University Press: New York, NY, USA, 2003; Volume 23. [Google Scholar]

- Zhong, X.J.; Liu, Z.P.; Cao, D.P. Improved classical united-atom force field for imidazolium-based ionic liquids: Tetrafluoroborate, hexafluorophosphate, methylsulfate, trifluoromethylsulfonate, acetate, trifluoroacetate, and bis(trifluoromethylsulfonyl)amide. J. Phys. Chem. B 2011, 115, 10027–10040. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Gao, Y.G.; Cao, D.P.; Zhang, L.Q.; Guo, Z.H. Nanoparticle dispersion and aggregation in polymer nanocomposites: Insights from molecular dynamics simulation. Langmuir 2011, 27, 7926–7933. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wu, Y.; Shen, J.; Gao, Y.; Zhang, L.; Cao, D. Polymer-nanoparticle interfacial behavior revisited: A molecular dynamics study. Phys. Chem. Chem. Phys. 2011, 13, 13058–13069. [Google Scholar] [CrossRef] [PubMed]

| Non-Bonding Pair | |||||

|---|---|---|---|---|---|

| backbone | backbone | 1.0 | 1.0 | 0 | 2.5 |

| backbone | end | 5.0 | 1.0 | 0.5 | 2.24 |

| backbone | ring | 1.0 | 1.0 | 0 | 2.24 |

| end | end | 1.0 | 1.0 | 1.0 | 1.12 |

| end | ring | 1.0 | 1.0 | 0.5 | 1.12 |

| ring | ring | 1.0 | 1.0 | 0 | 1.12 |

| Bond Stretching | ||

|---|---|---|

| backbone–backbone | 100 | 1.0 |

| cross-linking bond inter-backbone | 100 | 1.0 |

| backbone–end | 180 | 1.5 |

| cross-linking bond inter-ring | 100 | 1.0 |

| Permanent Set after Stretch-Recovery Deformation | ||

|---|---|---|

| Fixed Junction | SR | |

| 0 | 3.10 | 3.01 |

| 200 | 2.61 | 3.01 |

| 300 | 2.42 | 2.97 |

| 400 | 2.29 | 2.65 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Hou, G.; Shen, J.; Liu, J.; Gao, Y.; Zhao, X.; Zhang, L. Designing the Slide-Ring Polymer Network with both Good Mechanical and Damping Properties via Molecular Dynamics Simulation. Polymers 2018, 10, 964. https://doi.org/10.3390/polym10090964

Zhang Z, Hou G, Shen J, Liu J, Gao Y, Zhao X, Zhang L. Designing the Slide-Ring Polymer Network with both Good Mechanical and Damping Properties via Molecular Dynamics Simulation. Polymers. 2018; 10(9):964. https://doi.org/10.3390/polym10090964

Chicago/Turabian StyleZhang, Zhiyu, Guanyi Hou, Jianxiang Shen, Jun Liu, Yangyang Gao, Xiuying Zhao, and Liqun Zhang. 2018. "Designing the Slide-Ring Polymer Network with both Good Mechanical and Damping Properties via Molecular Dynamics Simulation" Polymers 10, no. 9: 964. https://doi.org/10.3390/polym10090964