Static-Aligned Piezoelectric Poly (Vinylidene Fluoride) Electrospun Nanofibers/MWCNT Composite Membrane: Facile Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nanofiber Formation

2.3. Electric Field and Orientation Analysis

2.4. Characterizations Procedures

3. Results and Discussions

3.1. Fields Distribution Analysis

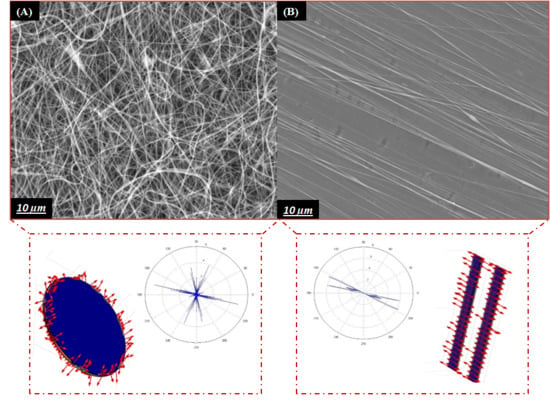

3.2. Orientation Analysis

3.3. Physical Analysis

3.4. Piezoelectric Characterization

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Baytekin, B.; Baytekin, H.T.; Grzybowski, B.A. Retrieving and converting energy from polymers: Deployable technologies and emerging concepts. Energy Environ. Sci. 2013, 6, 3467–3482. [Google Scholar] [CrossRef]

- Karan, S.K.; Mandal, D.; Khatua, B.B. Self-powered flexible Fe-doped RGO/PVDF nanocomposite: An excellent material for a piezoelectric energy harvester. Nanoscale 2015, 7, 10655–10666. [Google Scholar] [CrossRef] [PubMed]

- Sirohi, J.; Chopra, I. Fundamental understanding of piezoelectric strain sensors. J. Intell. Mater. Syst. Struct. 2000, 11, 246–257. [Google Scholar] [CrossRef]

- Xue, J.; Wu, L.; Hu, N.; Qiu, J.; Chang, C.; Atobe, S.; Atobe, S.; Fukunaga, H.; Watanabe, T.; Liu, Y.L.; et al. Evaluation of piezoelectric property of reduced graphene oxide (rGO)–poly (vinylidene fluoride) nanocomposites. Nanoscale 2012, 4, 7250–7255. [Google Scholar]

- Lei, T.; Yu, L.; Zheng, G.; Wang, L.; Wu, D.; Sun, D. Electrospinning-induced preferred dipole orientation in PVDF fibers. J. Mater. Sci. 2015, 50, 4342–4347. [Google Scholar] [CrossRef]

- Carponcin, D.; Dantras, E.; Dandurand, J.; Aridon, G.; Levallois, F.; Cadiergues, L.; Lacabanne, C. Electrical and Piezoelectric Behavior of Polyamide/PZT/CNT Multifunctional Nanocomposites. Adv. Eng. Mater. 2014, 16, 1018–1025. [Google Scholar] [CrossRef]

- Esterly, D.M. Manufacturing of Poly (vinylidene fluoride) and Evaluation of its Mechanical Properties. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Washington, VA, USA, 2002. [Google Scholar]

- Zampetti, E.; Bearzotti, A.; Macagnano, A. Flexible piezoelectric transducer based on electrospun PVDF nanofibers for sensing applications. Procedia Eng. 2014, 87, 1509–1512. [Google Scholar] [CrossRef]

- Sengupta, D.; Kottapalli, A.G.P.; Chen, S.H.; Miao, J.M.; Kwok, C.Y.; Triantafyllou, M.S.; Warkiani, M.E.; Asadnia, M. Characterization of single polyvinylidene fluoride (PVDF) nanofiber for flow sensing applications. AIP Adv. 2017, 7, 105205. [Google Scholar] [CrossRef]

- Wang, X.; Sun, F.; Yin, G.; Wang, Y.; Liu, B.; Dong, M. Tactile-Sensing Based on Flexible PVDF Nanofibers via Electrospinning: A Review. Sensors 2018, 18, 330. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Zhou, W.; Ma, D.; Ma, Q.; Bridges, D.; Ma, Y.; Hu, A. Electrospinning of nanofibers and their applications for energy devices. J. Nanomater. 2015, 16, 122. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R.; Kyratzis, I.L.; Truong, Y.B.; Arnold, L. Recent advances in nanofibre fabrication techniques. Text. Res. J. 2012, 82, 129–147. [Google Scholar] [CrossRef]

- Oktay, B.; Kayaman-Apohan, N.; Erdem-Kuruca, S. Fabrication of nanofiber mats from electrospinning of functionalized polymers. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Orlando, FL, USA, 19–21 January 2018. [Google Scholar]

- Dai, Y.; Liu, W.; Formo, E.; Sun, Y.; Xia, Y. Ceramic nanofibers fabricated by electrospinning and their applications in catalysis, environmental science, and energy technology. Polym. Adv. Technol. 2011, 22, 326–338. [Google Scholar] [CrossRef]

- Bognitzki, M.; Czado, W.; Frese, T.; Schaper, A.; Hellwig, M.; Steinhart, M.; Greiner, A.; Wendorff, J.H. Nanostructured fibers via electrospinning. Adv. Mater. 2001, 13, 70–72. [Google Scholar] [CrossRef]

- Fang, J.; Wang, X.; Lin, T. Electrical power generator from randomly oriented electrospun poly (vinylidene fluoride) nanofibre membranes. J. Mater. Chem. 2011, 21, 11088–11091. [Google Scholar] [CrossRef]

- Yiin-Kuen, F.; Hsi-Chun, H.; Bo-Sheng, W.; Shan-Chien, L. All-fiber transparent piezoelectric harvester with a cooperatively enhanced structure. Nanotechnology 2016, 27, 435403. [Google Scholar]

- Wu, C.-M.; Chou, M.-H.; Zeng, W.-Y. Piezoelectric Response of Aligned Electrospun Polyvinylidene Fluoride/Carbon Nanotube Nanofibrous Membranes. Nanomaterials 2018, 8, 420. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.-M.; Zhang, Y.-Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Katta, P.; Alessandro, M.; Ramsier, R.; Chase, G. Continuous electrospinning of aligned polymer nanofibers onto a wire drum collector. Nano Lett. 2004, 4, 2215–2218. [Google Scholar] [CrossRef]

- Tanase, M.; Bauer, L.A.; Hultgren, A.; Silevitch, D.M.; Sun, L.; Reich, D.H.; Searson, P.C.; Meyer, G.J. Magnetic alignment of fluorescent nanowires. Nano Lett. 2001, 1, 155–158. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Xia, Y.; Yang, H. Magnetic-field-assisted electrospinning of aligned straight and wavy polymeric nanofibers. Adv. Mater. 2010, 22, 2454–2457. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Wang, Y.; Xia, Y. Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays. Nano Lett. 2003, 3, 1167–1171. [Google Scholar] [CrossRef]

- Ruan, L.; Yao, X.; Chang, Y.; Zhou, L.; Qin, G.; Zhang, X. Properties and Applications of the β Phase Poly (vinylidene fluoride). Polymers 2018, 10, 228. [Google Scholar] [CrossRef]

- Hadimani, R.L.; Bayramol, D.V.; Sion, N.; Shah, T.; Qian, L.; Shi, S.; Siores, E. Continuous production of piezoelectric PVDF fibre for e-textile applications. Smart Mater. Struct. 2013, 22, 075017. [Google Scholar] [CrossRef] [Green Version]

- Jain, A.; Sharma, A.K.; Jain, A. Dielectric and piezoelectric properties of PVDF/PZT composites: A review. Polym. Eng. Sci. 2015, 55, 1589–1616. [Google Scholar] [CrossRef] [Green Version]

- Yildirim, Y.A.; Toprak, A.; Tigli, O. Piezoelectric Membrane Actuators for Micropump Applications Using PVDF-TrFE. J. Microelectromech. Syst. 2018, 27, 86–94. [Google Scholar] [CrossRef]

- Ji, S.H.; Cho, J.H.; Jeong, Y.H.; Paik, J.-H.; Do Yun, J.; Yun, J.S. Flexible lead-free piezoelectric nanofiber composites based on BNT-ST and PVDF for frequency sensor applications. Sens. Actuators A 2016, 247, 316–322. [Google Scholar] [CrossRef]

- Wu, D.; Huang, S.; Xiao, Z.; Yu, L.; Wang, L.; Sun, D.; Lin, L. Piezoelectric properties of PVDF nanofibers via non-uniform field electrospinning. In Proceedings of the International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Taipei, Taiwan, 27–31 October 2014; pp. 285–289. [Google Scholar]

- Hosoda, K.; Tada, Y.; Asada, M. Anthropomorphic robotic soft fingertip with randomly distributed receptors. Robot. Autom. Syst. 2006, 54, 104–109. [Google Scholar] [CrossRef]

- Erdem, E.; Böttcher, R.; Semmelhack, H.-C.; Gläsel, H.-J.; Hartmann, E.; Hirsch, D. Preparation of lead titanate ultrafine powders from combined polymerisation and pyrolysis route. J. Mater. Sci. 2003, 38, 3211–3217. [Google Scholar] [CrossRef]

- Barocas, V. Image-Based-Fiber-Orientation-and-Alignment-Calculator, Technology No. 20170064. Available online: http://license.umn.edu/technologies/20170064_image-based-fiber-orientation-and-alignment-calculator (accessed on 6 October 2018).

- Sander, E.A.; Barocas, V.H. Comparison of 2D fiber network orientation measurement methods. J. Biomed. Mater. Res. Part A 2009, 88, 322–331. [Google Scholar] [CrossRef] [PubMed]

| Collector | Two-bar Collector | Conventional Collector | ||

|---|---|---|---|---|

| Ω | 0.8627 | −0.3069 | 0.4797 | −0.0351 |

| −0.3069 | 0.1373 | −0.0351 | 0.5203 | |

| λ1,λ2 | 0.0249, 0.9751 | 0.4595, 0.5405 | ||

| α | 0.9745 | 0.1500 | ||

| Collector | PVDF/0.1%CNTs | PVDF/0.3%CNTs | ||

|---|---|---|---|---|

| Ω | 0.4131 | −0.0369 | 0.3983 | −0.0070 |

| −0.0369 | 0.5869 | −0.0070 | 0.6017 | |

| λ1,λ2 | 0.4056, 0.5944 | 0.3981, 0.6019 | ||

| A | 0.3178 | 0.3386 | ||

| Collector | PVDF/0.1%CNTs | PVDF/0.3%CNTs | ||

|---|---|---|---|---|

| Ω | 0.3375 | 0.1946 | 0.6719 | −0.1969 |

| 0.1946 | 0.6625 | −0.1969 | 0.3281 | |

| λ1,λ2 | 0.2465, 0.7535 | 0.2386, 0.7614 | ||

| A | 0.6729 | 0.6866 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shehata, N.; Elnabawy, E.; Abdelkader, M.; Hassanin, A.H.; Salah, M.; Nair, R.; Ahmad Bhat, S. Static-Aligned Piezoelectric Poly (Vinylidene Fluoride) Electrospun Nanofibers/MWCNT Composite Membrane: Facile Method. Polymers 2018, 10, 965. https://doi.org/10.3390/polym10090965

Shehata N, Elnabawy E, Abdelkader M, Hassanin AH, Salah M, Nair R, Ahmad Bhat S. Static-Aligned Piezoelectric Poly (Vinylidene Fluoride) Electrospun Nanofibers/MWCNT Composite Membrane: Facile Method. Polymers. 2018; 10(9):965. https://doi.org/10.3390/polym10090965

Chicago/Turabian StyleShehata, Nader, Eman Elnabawy, Mohamed Abdelkader, Ahmed H. Hassanin, Mohamed Salah, Remya Nair, and Sameer Ahmad Bhat. 2018. "Static-Aligned Piezoelectric Poly (Vinylidene Fluoride) Electrospun Nanofibers/MWCNT Composite Membrane: Facile Method" Polymers 10, no. 9: 965. https://doi.org/10.3390/polym10090965