Enhancement of Heat Dissipation by Laser Micro Structuring for LED Module

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

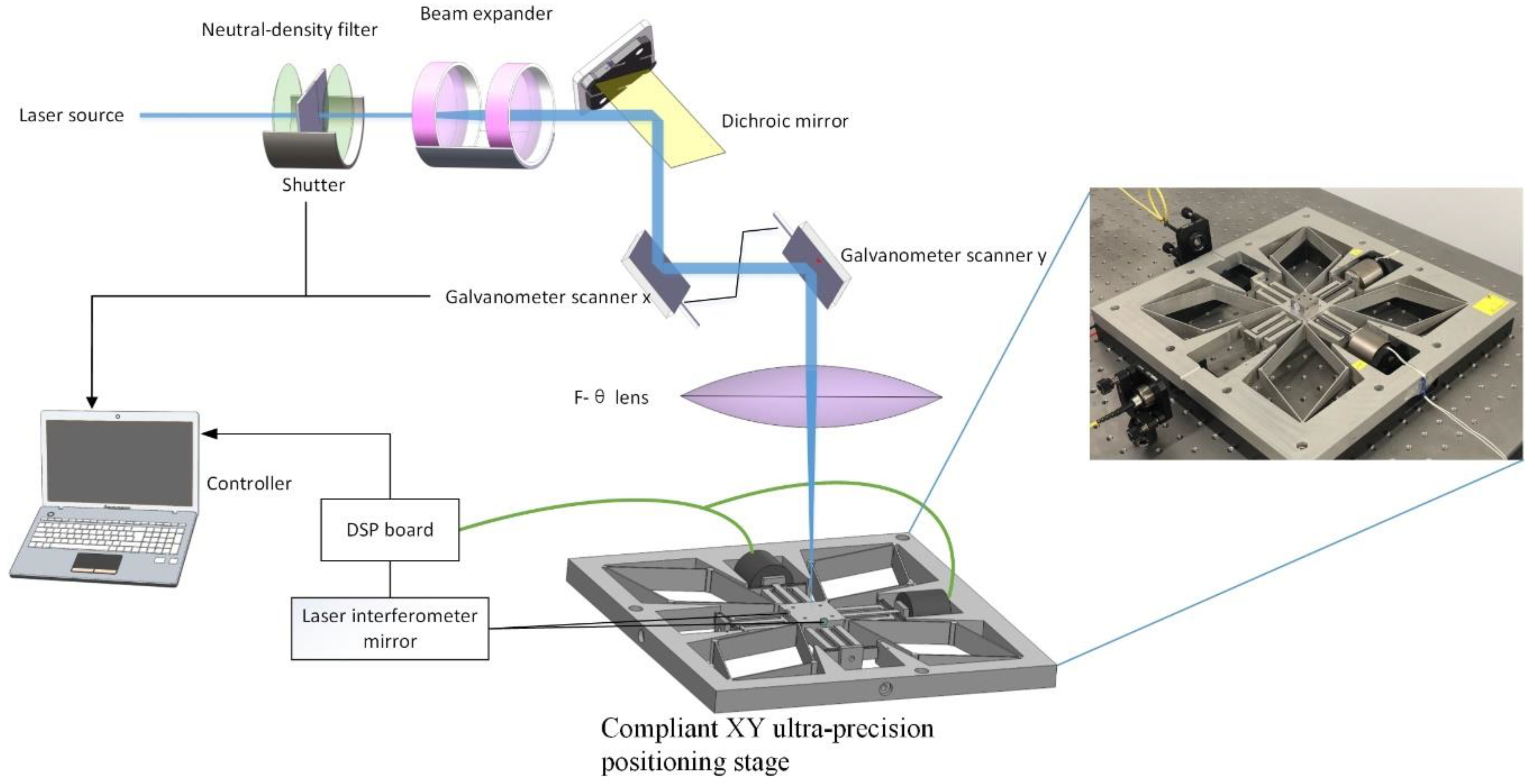

2.2. Laser Surface Texturing

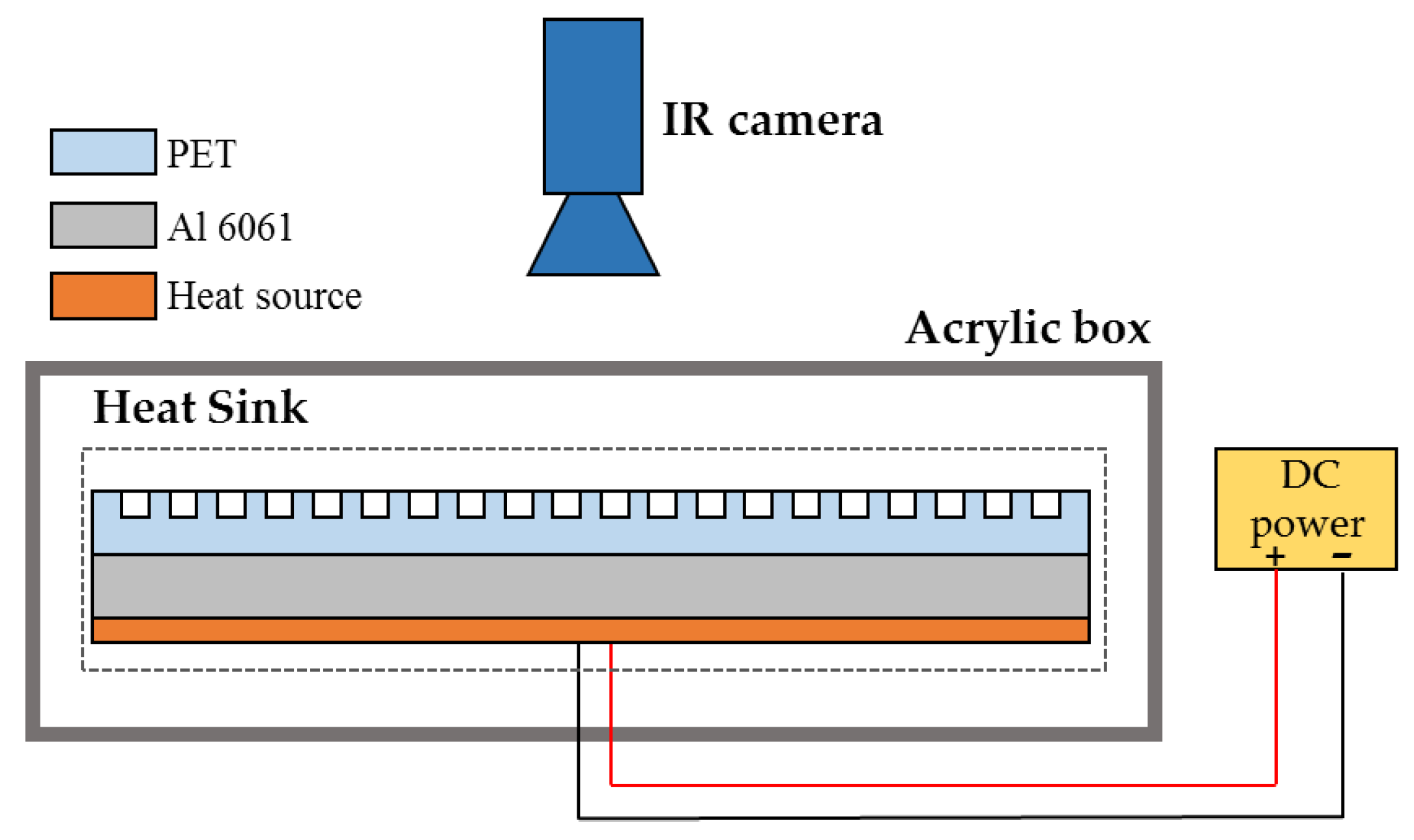

2.3. Experimental Setup

2.4. Numerical Models and Governing Equations

- (1)

- The solid materials are isotropic;

- (2)

- The heat transfer at each surface exposed to the air is governed by natural convection;

- (3)

- The contact thermal resistance between contact areas is neglected;

- (4)

- The bottom of heat source is adiabatic.

2.5. Analysis and Characterization

3. Results and Discussion

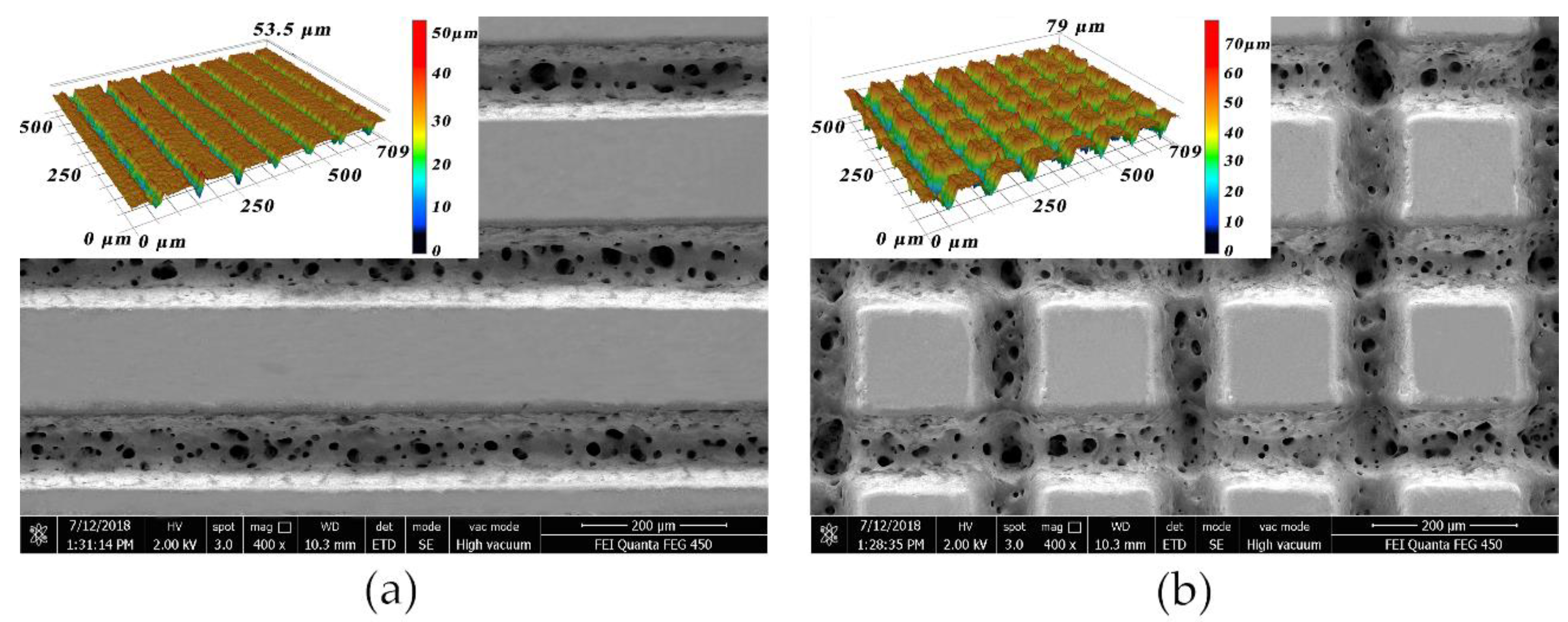

3.1. Surface Morphology

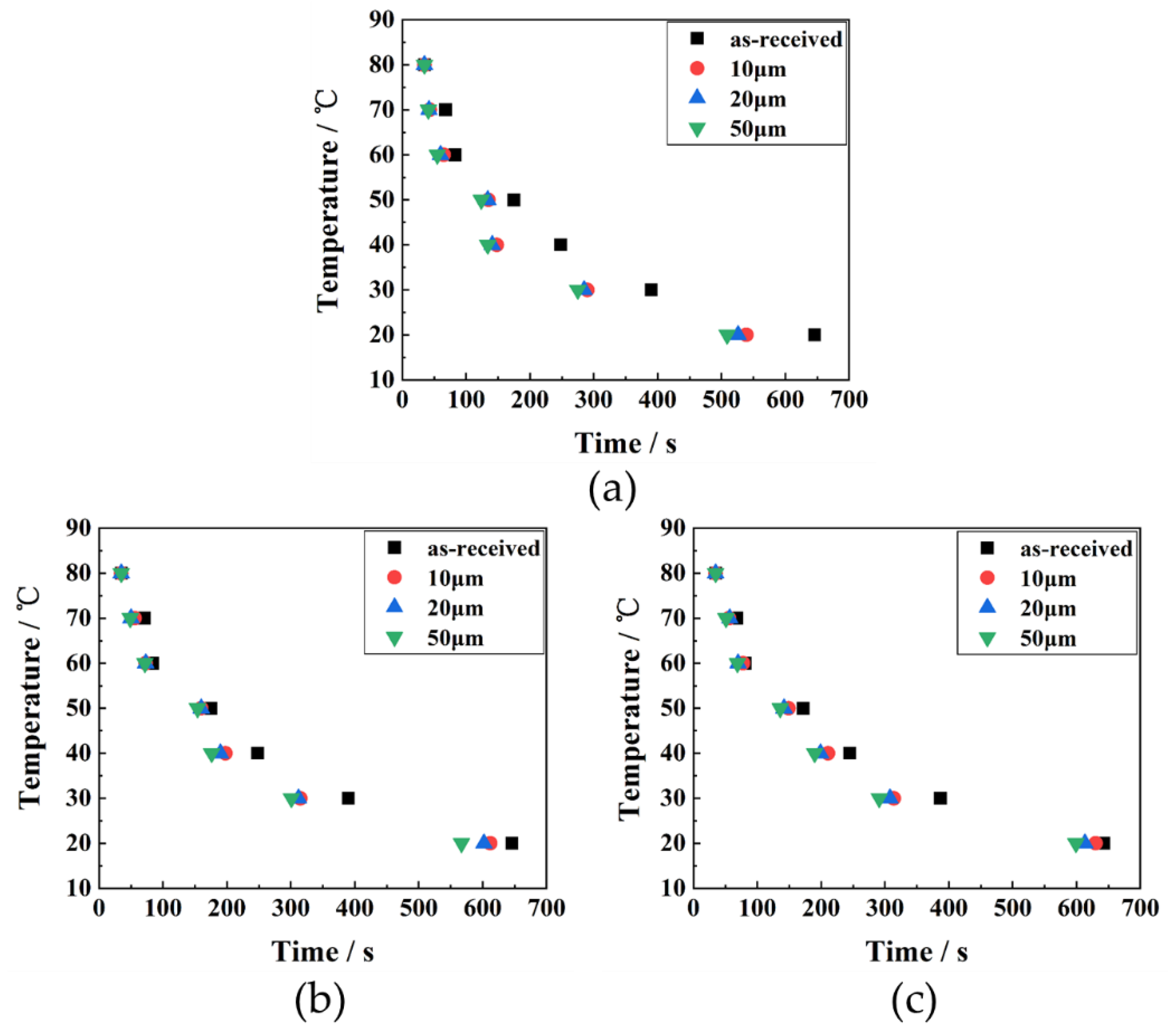

3.2. Dependence of the Heat Dissipation Performance on the Textured PET Heat Sink

3.3. Cooling Performance of LED Chip with Textured PET Heat Sink

4. Conclusions

- Smaller texture spacing and larger texture depth were shown to be beneficial to reduce thermal resistance, resulting in increase of dissipation efficiency.

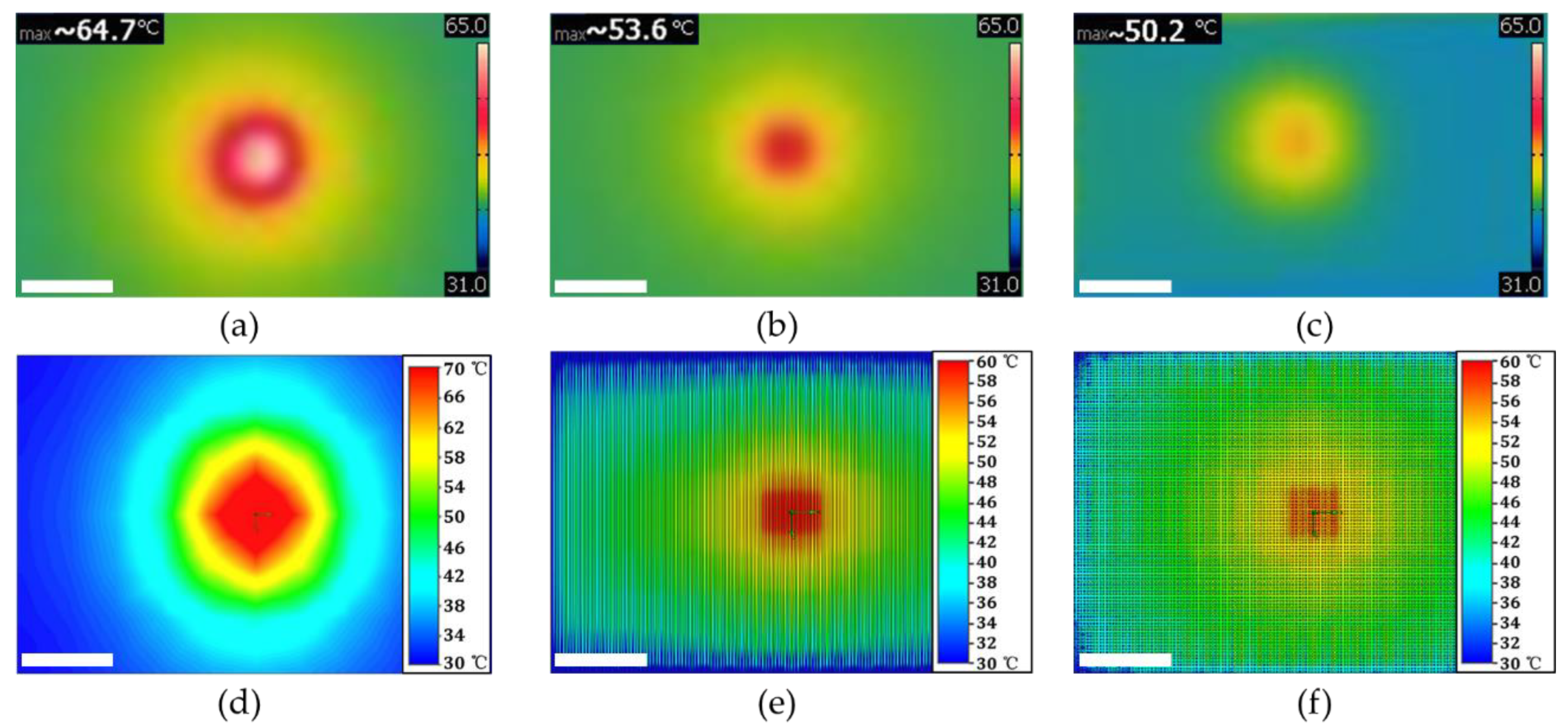

- Micro-grid with a depth of 50 μm and a spacing of 100 μm enhances the effectiveness by 25% and reduces cooling time by 27.8%. This is mainly due to the combined effects of large surface area, low thermal resistance and natural convection reinforcement.

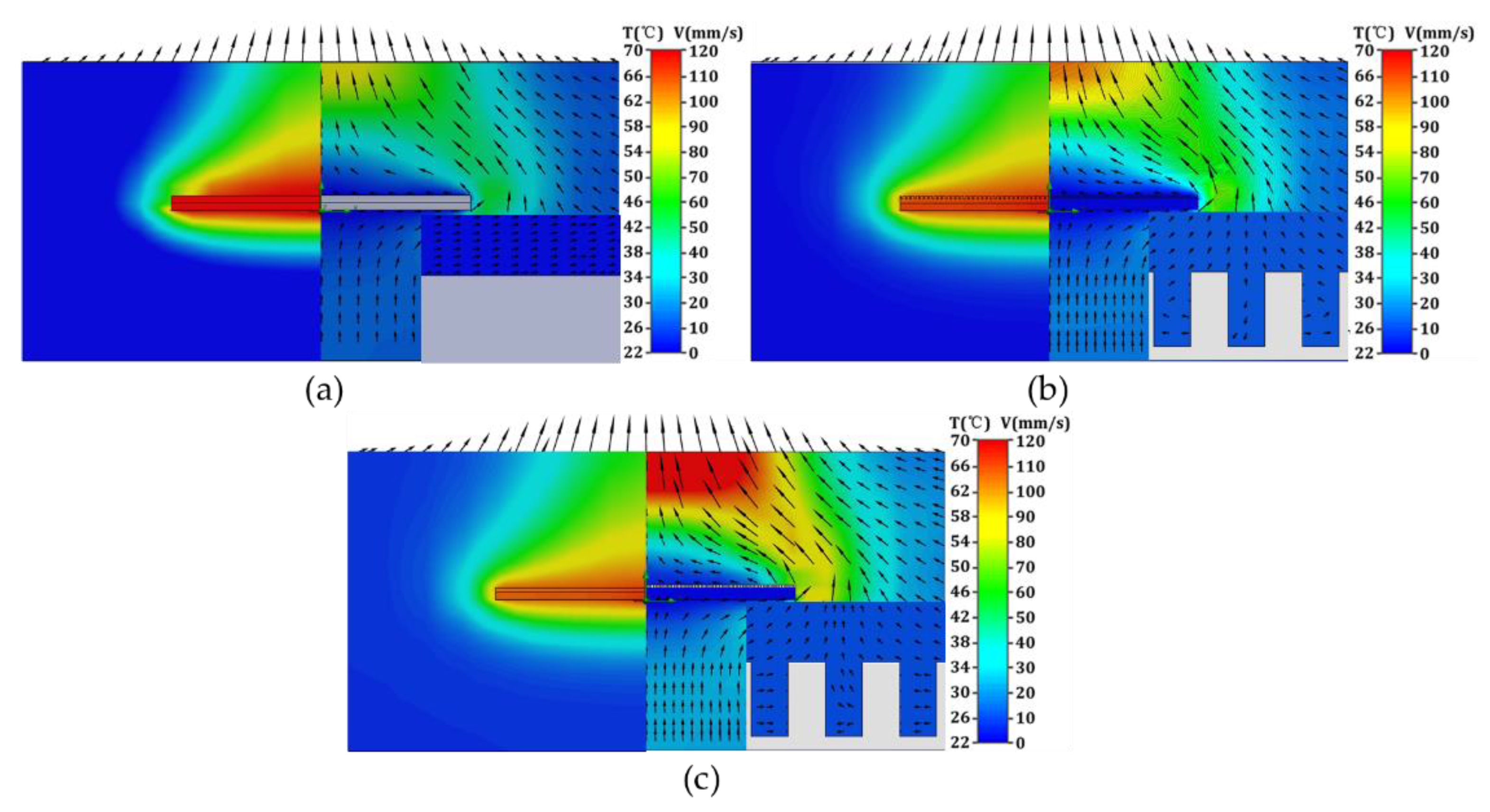

- FEA results show that the heat cooling devices with textured PET can significantly improve air velocity distribution and a more effective heat transfer to the air, resulting in the enhanced heat dissipation performance.

- Compared to the LED chip with as-received PET substrate, the LED chip with optimized laser-textured PET led to the temperature reduction by 22.4%.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Alabastri, A.; Malerba, M.; Calandrini, E.; Manjavacas, A.; De Angelis, F.; Toma, A.; Proietti Zaccaria, R. Controlling the heat dissipation in temperature-Matched plasmonic nanostructures. Nano Lett. 2017, 17, 5472–5480. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Lee, J.; Kim, J.; Choi, C.-H.; Chung, W. Enhancement of heat dissipation of led module with cupric-Oxide composite coating on aluminum-Alloy heat sink. Energy Convers. Manag. 2015, 106, 958–963. [Google Scholar] [CrossRef]

- Moore, A.L.; Shi, L. Emerging challenges and materials for thermal management of electronics. Mater. Today 2014, 17, 163–174. [Google Scholar] [CrossRef]

- Pop, E. Energy dissipation and transport in nanoscale devices. Nano Res. 2010, 3, 147–169. [Google Scholar] [CrossRef] [Green Version]

- James, J.-A.; Thomas, V.M.; Pandit, A.; Li, D.; Crittenden, J.C. Water, air emissions and cost impacts of air-Cooled microturbines for combined cooling, heating and power systems: A case study in the atlanta region. Engineering 2016, 2, 470–480. [Google Scholar] [CrossRef]

- Jiang, S.; Liu, C.; Fan, S. Efficient natural-Convective heat transfer properties of carbon nanotube sheets and their roles on the thermal dissipation. ACS Appl. Mater. Interfaces 2014, 6, 3075–3080. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Jiang, S.; Yao, W.; Liu, C. Enhancement of natural convection by carbon nanotube films covered microchannel-Surface for passive electronic cooling devices. ACS Appl. Mater. Interfaces 2016, 8, 31202–31211. [Google Scholar] [CrossRef] [PubMed]

- Yan, Z.; Liu, G.; Khan, J.M.; Balandin, A.A. Graphene quilts for thermal management of high-Power gan transistors. Nat. Commun. 2012, 3, 827. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Shimazu, J.; Fukaminato, T.; Ogata, T.; Kurihara, S. Thermal conductivity of graphene oxide-Enhanced polyvinyl alcohol composites depending on molecular interaction. Polymer 2017, 129, 201–206. [Google Scholar] [CrossRef]

- Tu, H.; Ye, L. Thermal conductive ps/graphite composites. Polym. Adv. Technol. 2009, 20, 21–27. [Google Scholar] [CrossRef]

- Yi, P.; Awang, R.A.; Rowe, W.S.; Kalantar-Zadeh, K.; Khoshmanesh, K. Pdms nanocomposites for heat transfer enhancement in microfluidic platforms. Lab Chip 2014, 14, 3419–3426. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W. Thermal and dielectric properties of the aln particles reinforced linear low-Density polyethylene composites. Thermochim. Acta 2011, 512, 183–188. [Google Scholar] [CrossRef]

- Kordas, K.; Tóth, G.; Moilanen, P.; Kumpumäki, M.; Vähäkangas, J.; Uusimäki, A.; Vajtai, R.; Ajayan, P. Chip cooling with integrated carbon nanotube microfin architectures. Appl. Phys. Lett. 2007, 90, 123105. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Zhang, Y.J.; Wu, D.M.; Zhuang, J.; Dang, K.F. Optimal Design of Micro Plastic Heat Radiator; Key Engineering Materials; Trans Tech Publications: Zürich, Switzerland, 2012; Volume 503, pp. 67–70. [Google Scholar]

- Lee, P.-S.; Garimella, S.V.; Liu, D. Investigation of heat transfer in rectangular microchannels. Int. J. Heat Mass Transf. 2005, 48, 1688–1704. [Google Scholar] [CrossRef] [Green Version]

- Yu, S.-H.; Lee, K.-S.; Yook, S.-J. Optimum design of a radial heat sink under natural convection. Int. J. Heat Mass Transf. 2011, 54, 2499–2505. [Google Scholar] [CrossRef]

- Micheli, L.; Reddy, K.; Mallick, T.K. General correlations among geometry, orientation and thermal performance of natural convective micro-Finned heat sinks. Int. J. Heat Mass Transf. 2015, 91, 711–724. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, J.; Li, W.; Zhang, N. Effect of surface microstructure on microchannel heat transfer performance. J. Heat Transf. 2011, 133, 124501. [Google Scholar] [CrossRef]

- Sun, J.; Zhuang, J.; Jiang, H.; Huang, Y.; Zheng, X.; Liu, Y.; Wu, D. Thermal dissipation performance of metal-Polymer composite heat exchanger with v-Shape microgrooves: A numerical and experimental study. Appl. Therm. Eng. 2017, 121, 492–500. [Google Scholar] [CrossRef]

- Hung, T.-C.; Yan, W.-M.; Li, W.-P. Analysis of heat transfer characteristics of double-Layered microchannel heat sink. Int. J. Heat Mass Transf. 2012, 55, 3090–3099. [Google Scholar] [CrossRef]

- Kim, J.-S.; Park, B.; Lee, J. Natural convection heat transfer around microfin arrays. Exp. Heat Transf. 2008, 21, 55–72. [Google Scholar] [CrossRef]

- Zhuang, J.; Huang, C.; Zhou, G.; Liu, Z.; Xu, H.; Wu, D.; Fan, Y.; Zhang, Y. Influence of factors on heat dissipation performance of composite metal-Polymer heat exchanger with rectangular microstructure. Appl. Therm. Eng. 2016, 102, 1473–1480. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, P.; Yan, P.; Guan, Y. A beam flexure-Based nanopositioning stage supporting laser direct-Write nanofabrication. Sci. China Phys. Mech. Astron. 2016, 59, 684211. [Google Scholar] [CrossRef]

- Jiang, H.; Zhuang, J.; Liu, Y.; Zhao, Z.; Wu, D. Quantitative analysis of factors influencing heat dissipation in a metal-Plastic composite heat radiator with a hemispherical microstructure array. Math. Probl. Eng. 2015, 2015, 195813. [Google Scholar] [CrossRef]

- Baset, F.; Villafranca, A.; Guay, J.-M.; Bhardwaj, R. Femtosecond laser induced porosity in poly-Methyl methacrylate. Appl. Surf. Sci. 2013, 282, 729–734. [Google Scholar] [CrossRef]

- Krüger, J.; Martin, S.; Mädebach, H.; Urech, L.; Lippert, T.; Wokaun, A.; Kautek, W. Femto and nanosecond laser treatment of doped polymethylmethacrylate. Appl. Surf. Sci. 2005, 247, 406–411. [Google Scholar] [CrossRef]

- Efthimiopoulos, T.; Kiagias, H.; Christoulakis, S.; Merlemis, N. Bubble creation and collapse during excimer laser ablation of weak absorbing polymers. Appl. Surf. Sci. 2008, 254, 5626–5630. [Google Scholar] [CrossRef]

- Lösekrug, B.; Meschede, A.; Krebs, H.-U. Pulsed laser deposition of smooth poly (methyl methacrylate) films at 248 nm. Appl. Surf. Sci. 2007, 254, 1312–1315. [Google Scholar] [CrossRef]

- Harms, T.M.; Kazmierczak, M.J.; Gerner, F.M. Developing convective heat transfer in deep rectangular microchannels. Int. J. Heat Fluid Flow 1999, 20, 149–157. [Google Scholar] [CrossRef]

- Yu, Z.-Q.; Feng, Y.-L.; Zhou, W.-J.; Jin, Y.; Li, M.-J.; Li, Z.-Y.; Tao, W.-Q. Study on flow and heat transfer characteristics of composite porous material and its performance analysis by fsp and edep. Appl. Energy 2013, 112, 1367–1375. [Google Scholar] [CrossRef]

- Lu, T.J. Heat transfer efficiency of metal honeycombs. Int. J. Heat Mass Transf. 1999, 42, 2031–2040. [Google Scholar] [CrossRef]

- Ehsan, M.M.; Guan, Z.; Klimenko, A.Y. A comprehensive review on heat transfer and pressure drop characteristics and correlations with supercritical CO2 under heating and cooling applications. Renew. Sustain. Energy Rev. 2018, 92, 658–675. [Google Scholar] [CrossRef]

- Kruse, C.M.; Anderson, T.; Wilson, C.; Zuhlke, C.; Alexander, D.; Gogos, G.; Ndao, S. Enhanced pool-Boiling heat transfer and critical heat flux on femtosecond laser processed stainless steel surfaces. Int. J. Heat Mass Transf. 2015, 82, 109–116. [Google Scholar] [CrossRef]

- Mahmoud, S.; Al-Dadah, R.; Aspinwall, D.; Soo, S.; Hemida, H. Effect of micro fin geometry on natural convection heat transfer of horizontal microstructures. Appl. Therm. Eng. 2011, 31, 627–633. [Google Scholar] [CrossRef]

- Harahap, F.; McManus, H. Natural convection heat transfer from horizontal rectangular fin arrays. J. Heat Transf. 1967, 89, 32–38. [Google Scholar] [CrossRef]

- Shen, Q.; Sun, D.; Xu, Y.; Jin, T.; Zhao, X. Orientation effects on natural convection heat dissipation of rectangular fin heat sinks mounted on leds. Int. J. Heat Mass Transf. 2014, 75, 462–469. [Google Scholar] [CrossRef]

- Cheng, S.; Chou, P.-C.; Chieng, W.-H.; Chang, E.Y. Enhanced lateral heat dissipation packaging structure for gan hemts on si substrate. Appl. Therm. Eng. 2013, 51, 20–24. [Google Scholar] [CrossRef]

- Yuan, C.; Li, L.; Duan, B.; Xie, B.; Zhu, Y.; Luo, X. Locally reinforced polymer-Based composites for efficient heat dissipation of local heat source. Int. J. Therm. Sci. 2016, 102, 102–209. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Specifc Heat (J/g⋅K) | Termal Conductivity (W/m⋅K) | Types of Thermal Conductivity | Melting Temperature (K) |

|---|---|---|---|---|---|

| Air | 1.21 | 1.01 | 0.03 | Isotropic | - |

| Al6061 | 2688.90 | 0.90 | 237 | Isotropic | 855 |

| PET | 1.35 | 1.28 | 0.28 | Isotropic | 520 |

| Thermal Conductivity (W/m⋅K) | Thickness (um) | Radiant Emissivity (ε) | ||||

|---|---|---|---|---|---|---|

| λ1 | λ1 | λ1 | δ1 | δ2 | δ3 | ε |

| 381 | 237 | 0.28 | 50 | 100 | 100 | 0.7 |

| Specimen | Depth (μm) | Spacing (μm) | Total Cooling Time (s) | Heat Transfer Coefficient (Wm−2K) | Texture Effectiveness |

|---|---|---|---|---|---|

| As-received | / | / | 593 | 11.51 | 1 |

| 100 | 499 | 9.62 | 1.02 | ||

| 10 | 200 | 564 | 10.1 | 1.02 | |

| 250 | 589 | 10.51 | 1.01 | ||

| 100 | 489 | 8.91 | 1.10 | ||

| Micro-groove | 20 | 200 | 553 | 9.71 | 1.09 |

| 250 | 578 | 10.12 | 1.04 | ||

| 100 | 475 | 7.81 | 1.19 | ||

| 50 | 200 | 517 | 8.12 | 1.18 | |

| 250 | 559 | 9.18 | 1.13 | ||

| 100 | 464 | 9.93 | 1.05 | ||

| 10 | 200 | 531 | 10.01 | 1.04 | |

| 250 | 553 | 10.32 | 1.03 | ||

| 100 | 446 | 9.41 | 1.16 | ||

| Micro-groove | 20 | 200 | 492 | 9.64 | 1.15 |

| 250 | 534 | 9.82 | 1.13 | ||

| 100 | 428 | 7.14 | 1.25 | ||

| 50 | 200 | 461 | 7.30 | 1.20 | |

| 250 | 517 | 8.12 | 1.16 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, L.; Zhang, Z.; Guan, Y.; Zheng, H. Enhancement of Heat Dissipation by Laser Micro Structuring for LED Module. Polymers 2018, 10, 886. https://doi.org/10.3390/polym10080886

Lu L, Zhang Z, Guan Y, Zheng H. Enhancement of Heat Dissipation by Laser Micro Structuring for LED Module. Polymers. 2018; 10(8):886. https://doi.org/10.3390/polym10080886

Chicago/Turabian StyleLu, Libin, Zhen Zhang, Yingchun Guan, and Hongyu Zheng. 2018. "Enhancement of Heat Dissipation by Laser Micro Structuring for LED Module" Polymers 10, no. 8: 886. https://doi.org/10.3390/polym10080886

APA StyleLu, L., Zhang, Z., Guan, Y., & Zheng, H. (2018). Enhancement of Heat Dissipation by Laser Micro Structuring for LED Module. Polymers, 10(8), 886. https://doi.org/10.3390/polym10080886