Maleic Anhydride-Grafted Isotactic Polybutene-1 and Modified Polyamide 6

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Purification of iPB-g-MAH

2.3. Characterizations

3. Results

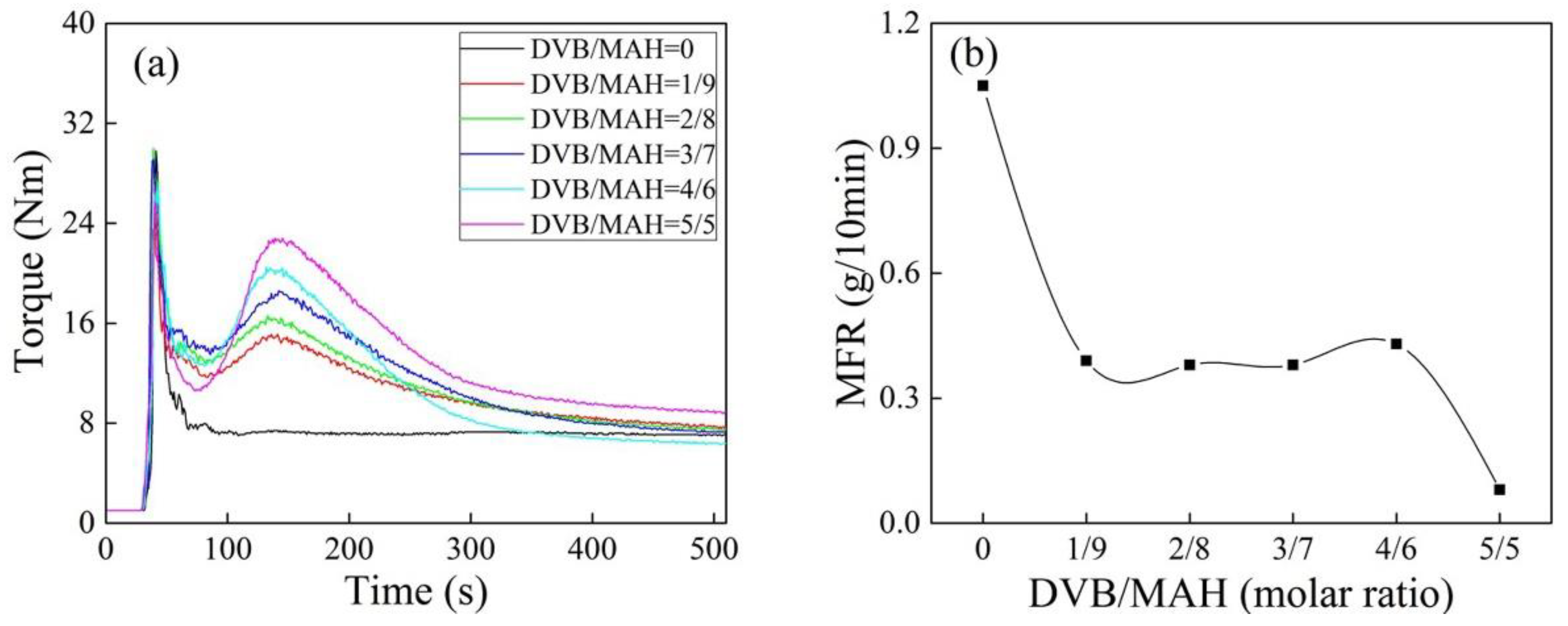

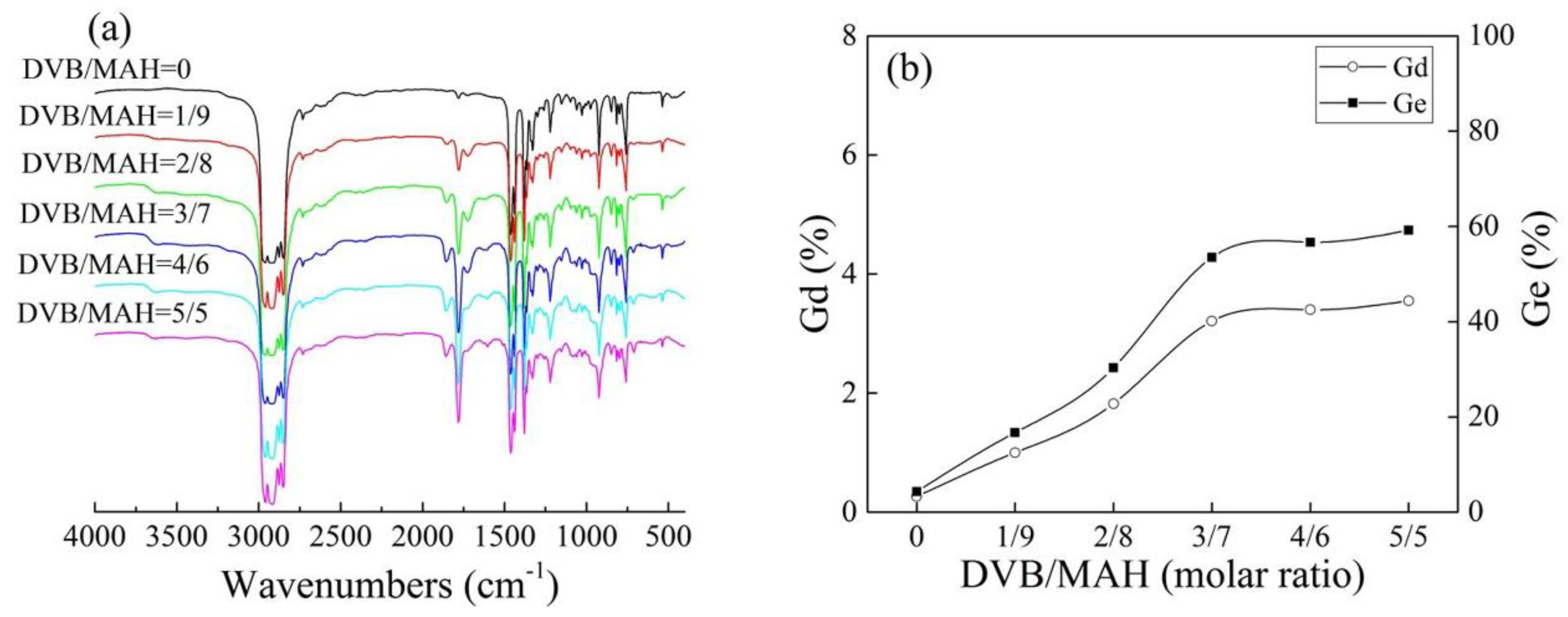

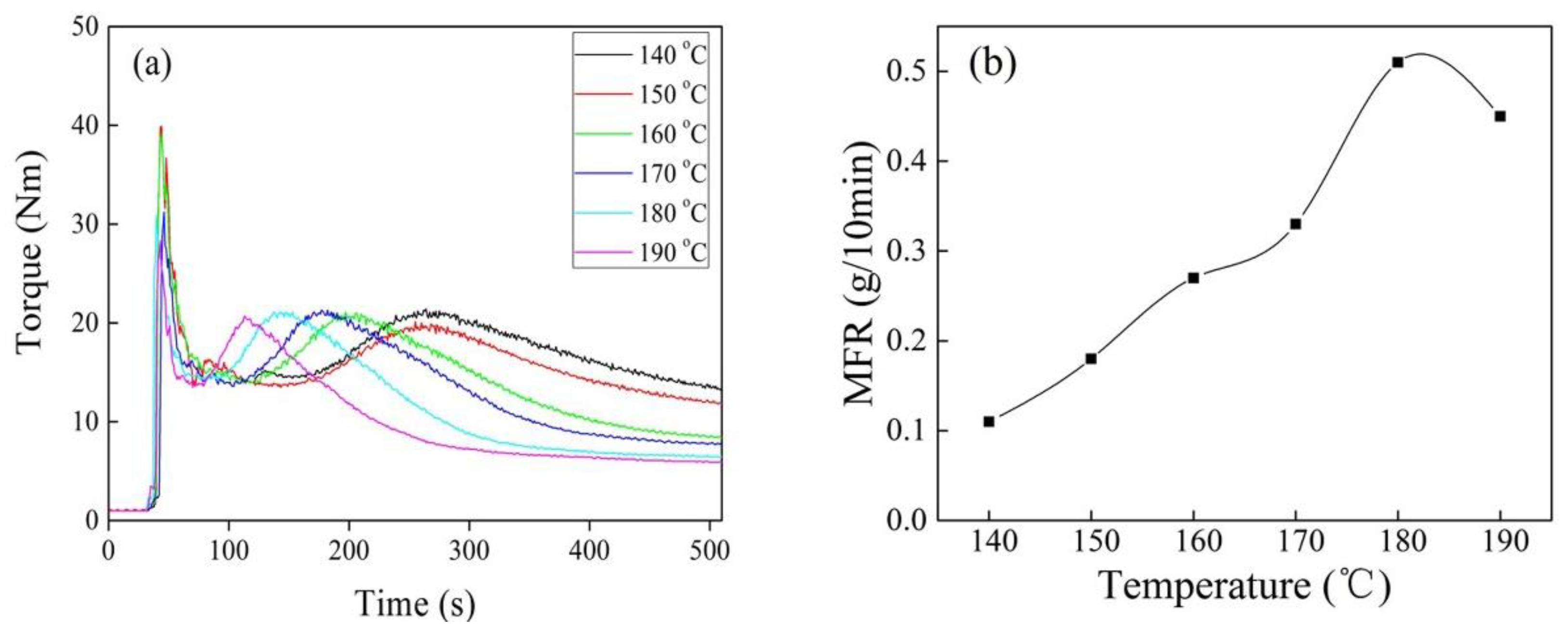

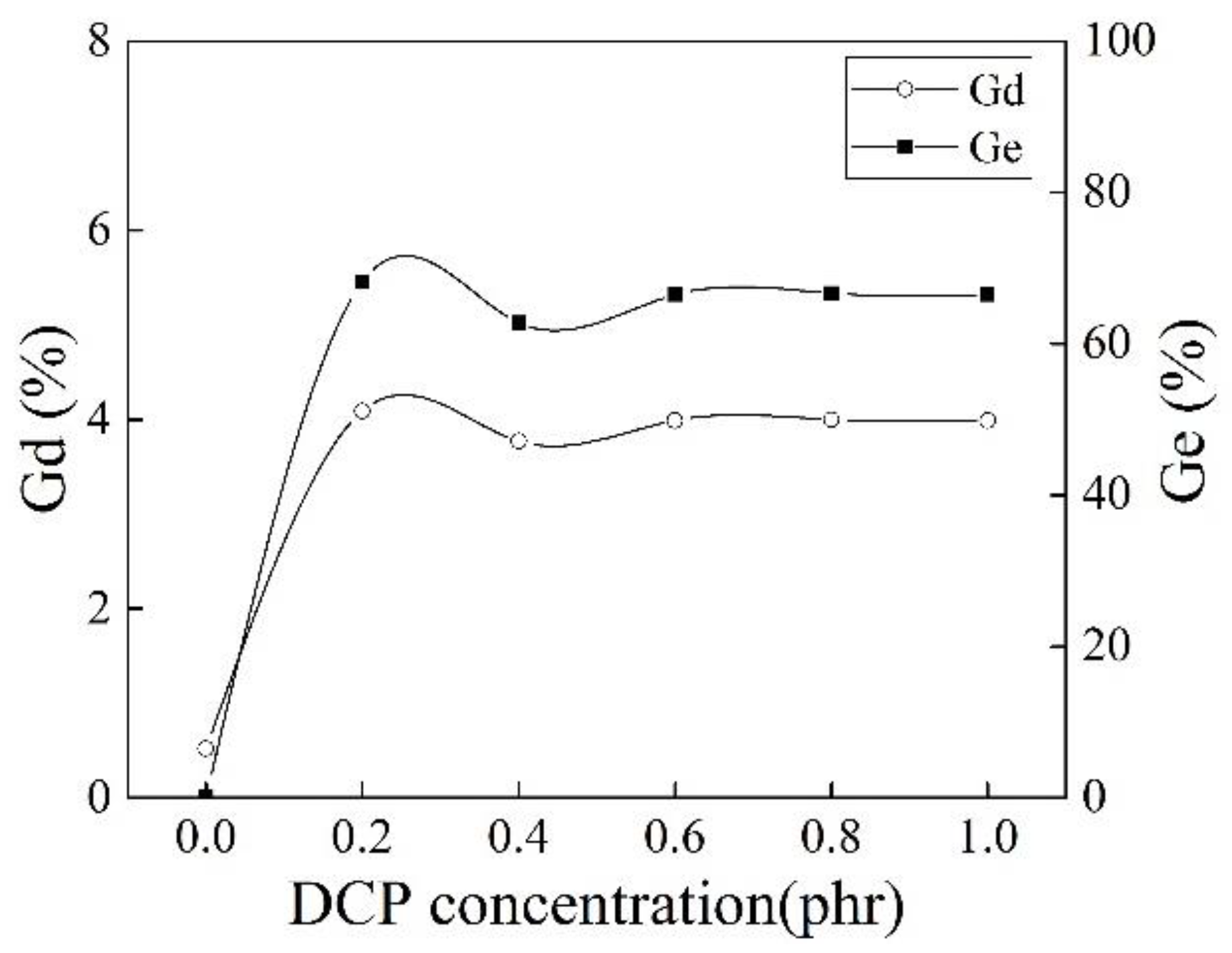

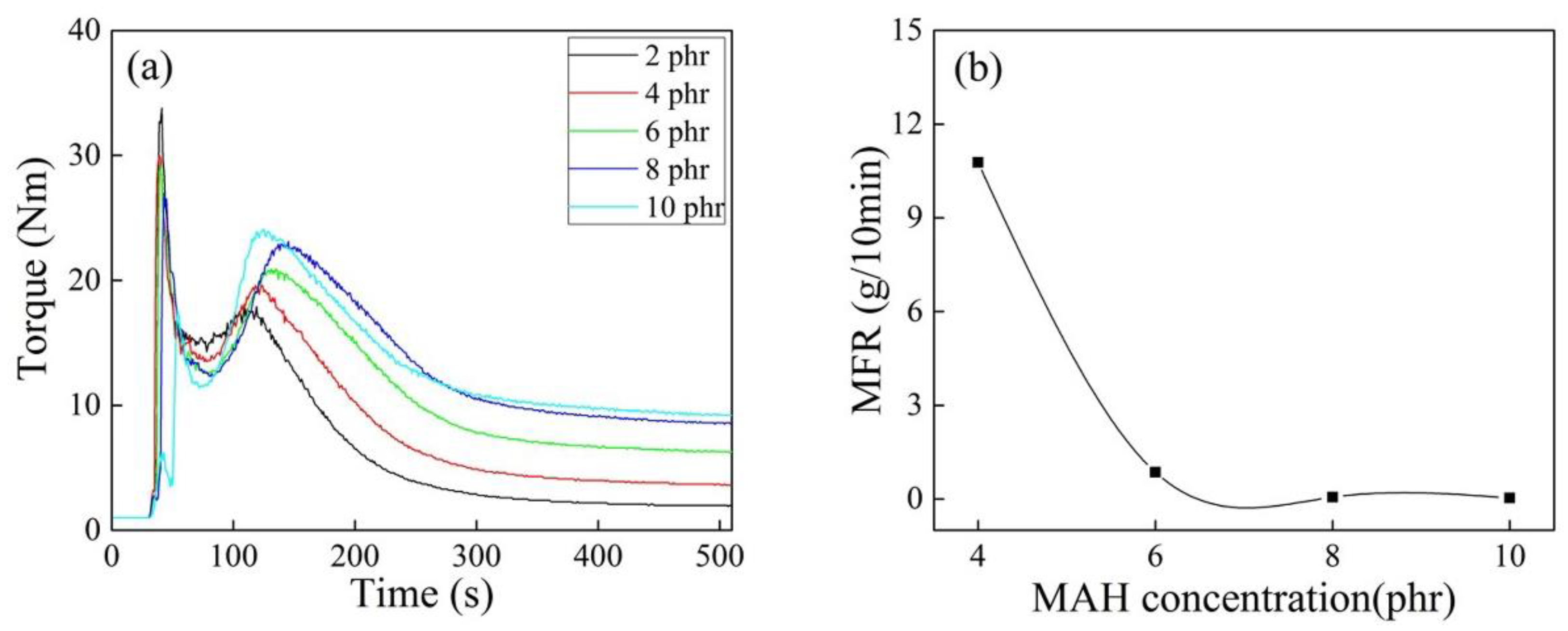

3.1. The Grafting Reaction of DVB/MAH onto iPB-1

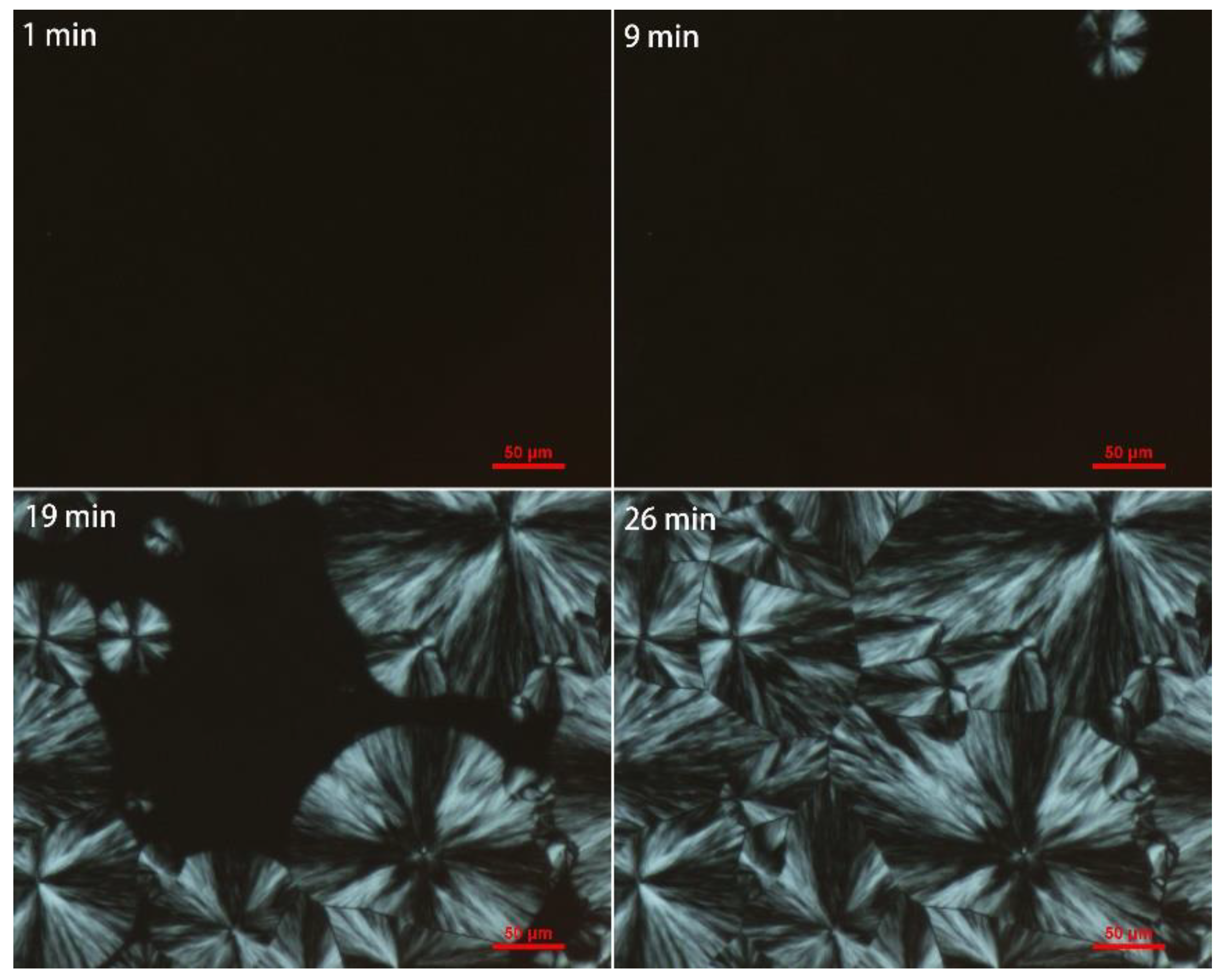

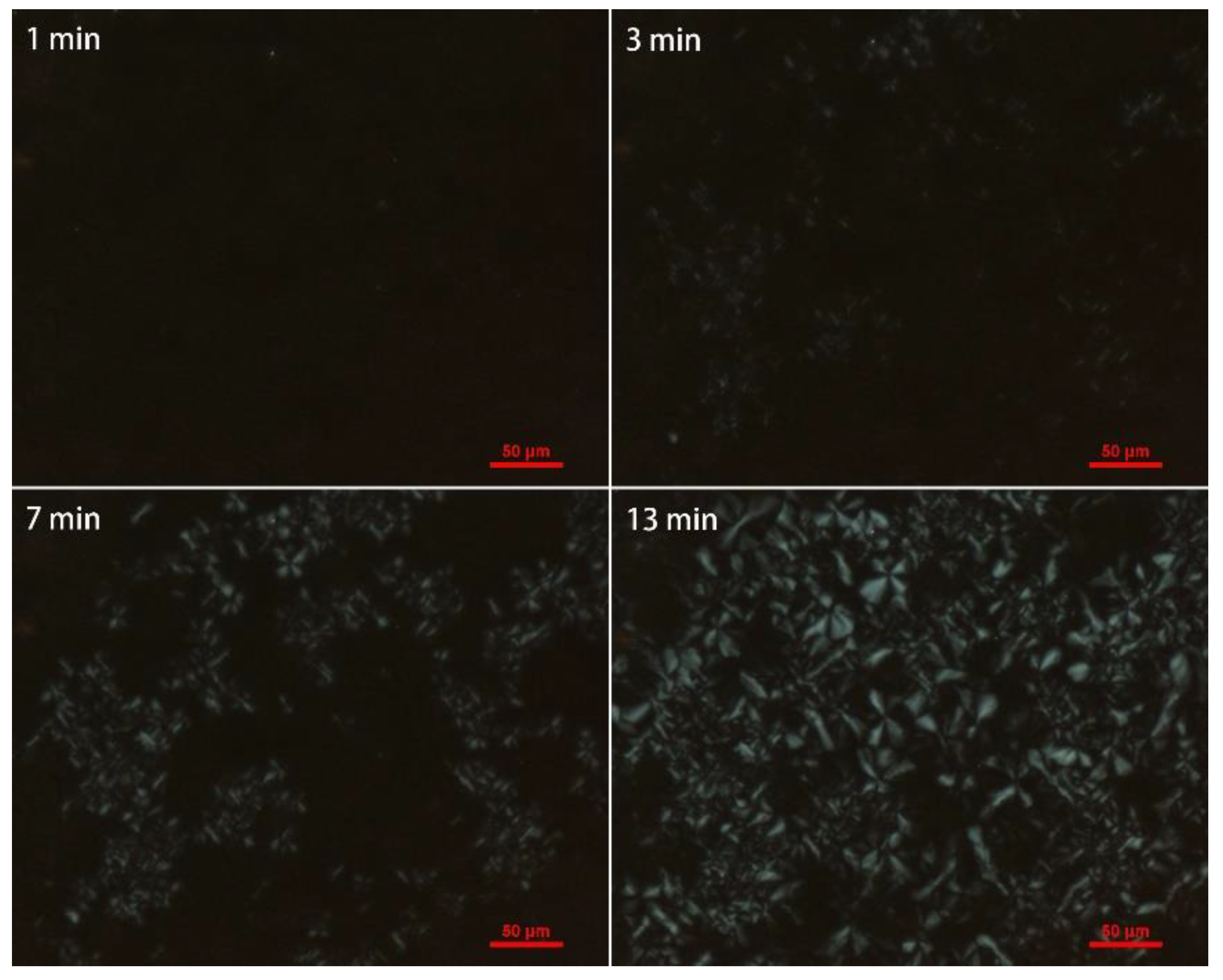

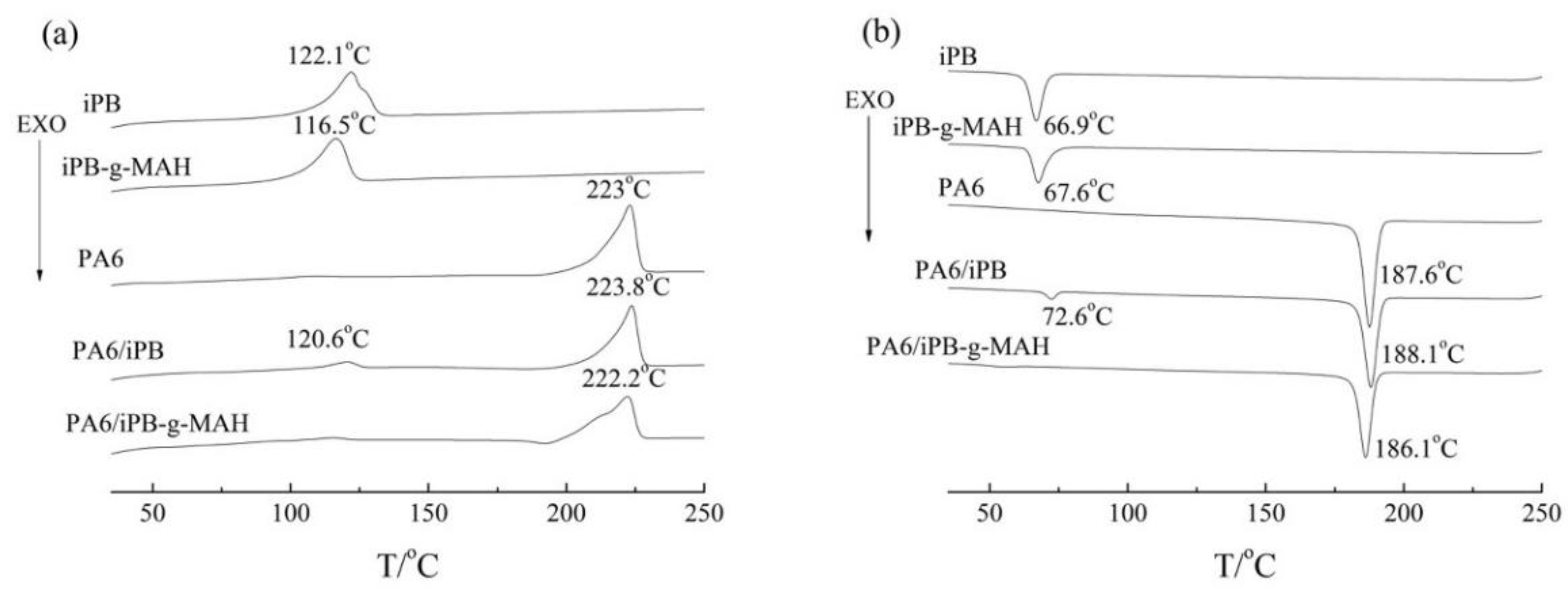

3.2. Surface Properties and Crystallization Properties of iPB-1 and Its Grafts

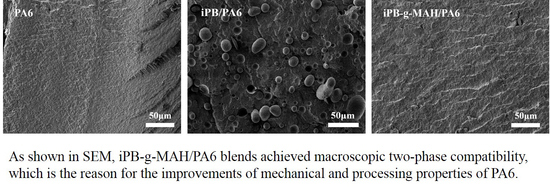

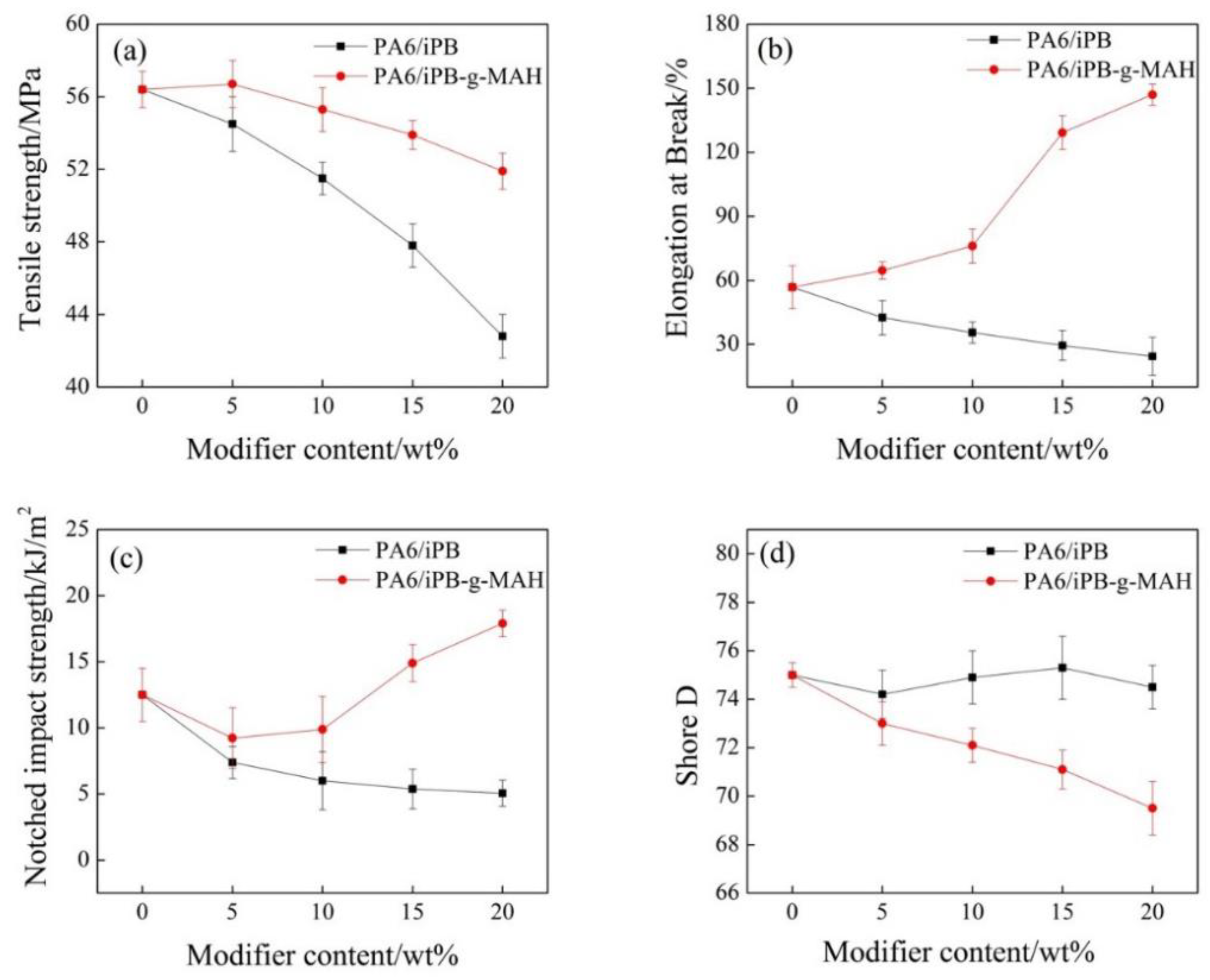

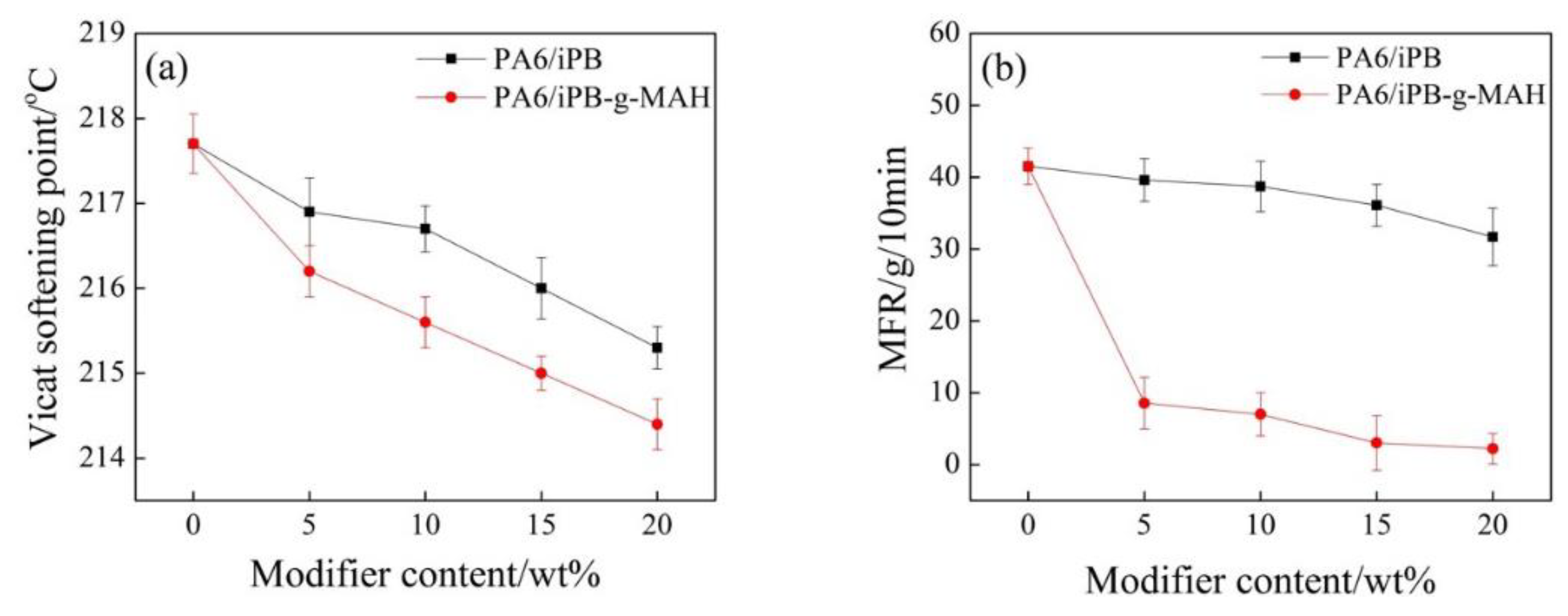

3.3. iPB-g-MAH Modified PA6

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Abedi, S.; Sharifi-Sanjani, N. Preparation of high isotactic polybutene-1. J. Appl. Polym. Sci. 2015, 78, 2533–2539. [Google Scholar] [CrossRef]

- Natta, G.; Pino, P.; Corradini, P.; Corradini, F.; Danusso, F.; Mantica, E.; Mazzanti, G.; Moraglio, G. Crystalline high polymers of α-olefins. J. Am. Chem. Soc. 1955, 77, 1708–1710. [Google Scholar] [CrossRef]

- Wang, B.; Nie, K.; Xue, X.R.; Lin, F.H.; Li, X.Y.; Xue, Y.B.; Luo, J. Preparation of Maleic Anhydride Grafted Polybutene and Its Application in Isotactic Polybutene-1/Microcrystalline Cellulose Composites. Polymers 2018, 10, 393. [Google Scholar] [CrossRef]

- Su, F.; Li, X.; Zhou, W.; Chen, W.; Li, H.; Cong, Y.; Hong, Z.; Qi, Z.; Li, L. Accelerating crystal–crystal transition in poly(1-butene) with two-step crystallization: An in-situ microscopic infrared imaging and microbeam X-ray diffraction study. Polymer 2013, 54, 3408–3416. [Google Scholar] [CrossRef]

- Azzurri, F.; Flores, A.; Alfonso, C. Polymorphism of isotactic polybutene-1 as revealed by microindentation hardness. Part II: Correlations to microstructure. Polymer 2003, 44, 1641–1645. [Google Scholar] [CrossRef]

- Alfadhel, K.; Al-Mulla, A.; Al-Busairi, B. Development and characterization of novel polybutylene nanocomposites. J. Compos. Mater. 2016, 51, 95–108. [Google Scholar] [CrossRef]

- Shieh, Y.T.; Lee, M.S.; Chen, S.A. Crystallization behavior, crystal transformation, and morphology of polypropylene/polybutene-1 blends. Polymer 2001, 42, 4439–4448. [Google Scholar] [CrossRef]

- Cavallo, D.; Gardella, L.; Portale, G.; Muller, A.J.; Alfonso, G.C. Kinetics of cross-nucleation in isotactic poly(1-butene). Macromolecules 2014, 47, 870–873. [Google Scholar] [CrossRef]

- Ji, Y.; Su, F.; Cui, K. Mixing Assisted Direct Formation of Isotactic Poly(1-butene) Form I’ Crystals from Blend Melt of Isotactic Poly(1-butene)/Polypropylene. Macromolecules 2016, 49, 266–270. [Google Scholar] [CrossRef]

- Cavallo, D.; Gardella, L.; Portale, G.; Muller, A.J.; Alfonso, G.C. On cross- and self-nucleation in seeded crystallization of isotactic poly (1-butene). Polymer 2013, 54, 4637–4644. [Google Scholar] [CrossRef]

- Bettini, S.H.P.; Filho, A.C.R. Styrene-assisted grafting of maleic anhydride onto polypropylene by reactive processing. J. Appl. Polym. Sci. 2010, 107, 1430–1438. [Google Scholar] [CrossRef]

- Lei, C.; Chen, D.; Bo, W.; Xu, Y.; Li, S.; Huang, W. Melt-grafting mechanism study of maleic anhydride onto polypropylene with 1-decene as the second monomer. J. Appl. Polym. Sci. 2011, 121, 3724–3732. [Google Scholar] [CrossRef]

- Shi, D.; Yang, J.; Yao, Z. Functionalization of isotactic polypropylene with maleic anhydride by reactive extrusion: Mechanism of melt grafting. Polymer 2001, 42, 5549–5557. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, Y.; Yao, W.; Huang, B. Styrene-assisted melt-free radical grafting of glycidyl methacrylate onto isotactic poly(1-butene). Polym. Eng. Sci. 2011, 51, 1669–1674. [Google Scholar] [CrossRef]

- Zhao, Y.; Du, Y.; Han, L.; Liu, Z.; Chen, J. Study on DTBP initiated MAH onto polybutene-1 with melt-grafting. J. Polym. Eng. 2012, 32, 567–574. [Google Scholar] [CrossRef]

- Zhao, Y.; Han, L.; Li, D.; Xu, W. The mechanism of grafting of maleic anhydride onto isotactic polybutene-1 assisted by comonomers. Colloid Polym. Sci. 2017, 295, 463–469. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Y.; Yao, W.; Huang, B. Styrene-assisted grafting of maleic anhydride onto isotactic polybutene-1. Polym. Eng. Sci. 2011, 51, 2483–2489. [Google Scholar] [CrossRef]

- Han, L. Study on Preparation, Grafting Mechanism and Crystallization Properties of Maleic Anhydride /Comonomer Grafting Isotactic Polybutene-1. Master Thesis, Qingdao University of Science and Technology, Qingdao, China, 2014. [Google Scholar]

- Xie, X.; Chen, N.; Guo, B.; Li, S. Study of multi-monomer melt-grafting onto polypropylene in an extruder. Polym. Int. 2000, 49, 1677–1683. [Google Scholar] [CrossRef]

- Thompson, M.R.; Tzoganakis, C.; Rempel, G.L. Terminal functionalization of polypropylene via the Alder Ene reaction. Polymer 1998, 39, 327–334. [Google Scholar] [CrossRef]

- Burton, E.L.; Woodhead, M.; Coates, P.; Gough, T. Reactive grafting of glycidyl methacrylate onto polypropylene. J. Appl. Polym. Sci. 2010, 117, 2707–2714. [Google Scholar] [CrossRef]

- Flores-Gallardo, S.G.; Sanchez, S.; Devalle, L.F. Polypropylene/polypropylene-grafted acrylic acid blends for multilayer films: Preparation and characterization. J. Appl. Polym. Sci. 2015, 79, 1497–1505. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Wan, D.; Xing, H.P.; Zhang, Z.J.; Tan, H.Y.; Wang, L.; Zheng, J.; An, Y.J.; Tang, T. A new grafting monomer for synthesizing long chain branched polypropylene through melt radical reaction. Polymer 2012, 53, 121–129. [Google Scholar] [CrossRef]

- Yi, S.; Xu, S.; Fang, Y.; Wang, H.; Wang, Q. Effects of Matrix Modification on the Mechanical Properties of Wood–Polypropylene Composites. Polymers 2017, 9, 712. [Google Scholar] [CrossRef]

- Li, Y.; Xie, X.M.; Guo, B.H. Study on styrene-assisted melt free-radical grafting of maleic anhydride onto polypropylene. Polymer 2001, 42, 3419–3425. [Google Scholar] [CrossRef]

| Reaction Temperature (°C) | DCP Concentration (phr) | MAH Concentration (phr) | Comonomers Concentration (phr) | Gd (%) | Ge (%) | |

|---|---|---|---|---|---|---|

| iPB-g-MAH | 180 | 0.6 | 6 | 0 | 0.26 | 4.3 |

| iPB-g-MAH-co-DVB | 180 | 0.6 | 6 | 4 | 3.4 | 56.7 |

| iPB-g-MAH-co-St | 180 | 0.6 | 6 | 6 | 1.62 | 27 |

| MAH | St | DVB | |

|---|---|---|---|

| Q | 0.23 | 1 | 3.350 |

| e | 2.25 | −0.8 | −1.770 |

| Samples | Degree of Crystallinity |

|---|---|

| PA6 | 39.7% |

| PA6/iPB | 33.4% |

| PA6/iPB-g-MAH | 27.8% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Ma, C.; Cheng, S.; Xu, W.; Du, Y.; Bao, Y.; Xiao, Z. Maleic Anhydride-Grafted Isotactic Polybutene-1 and Modified Polyamide 6. Polymers 2018, 10, 872. https://doi.org/10.3390/polym10080872

Zhao Y, Ma C, Cheng S, Xu W, Du Y, Bao Y, Xiao Z. Maleic Anhydride-Grafted Isotactic Polybutene-1 and Modified Polyamide 6. Polymers. 2018; 10(8):872. https://doi.org/10.3390/polym10080872

Chicago/Turabian StyleZhao, Yongxian, Chen Ma, Shijie Cheng, Wei Xu, Yuejuan Du, Yansong Bao, and Zuojie Xiao. 2018. "Maleic Anhydride-Grafted Isotactic Polybutene-1 and Modified Polyamide 6" Polymers 10, no. 8: 872. https://doi.org/10.3390/polym10080872

APA StyleZhao, Y., Ma, C., Cheng, S., Xu, W., Du, Y., Bao, Y., & Xiao, Z. (2018). Maleic Anhydride-Grafted Isotactic Polybutene-1 and Modified Polyamide 6. Polymers, 10(8), 872. https://doi.org/10.3390/polym10080872