4.1. Samples Characterization

In order to understand the effect of different processing on structures, the first step of this study was a crystallographic characterization. It was performed by wide angle X-ray diffraction (WAXD) and small angle X-ray scattering (SAXS) on samples in the dry state. In

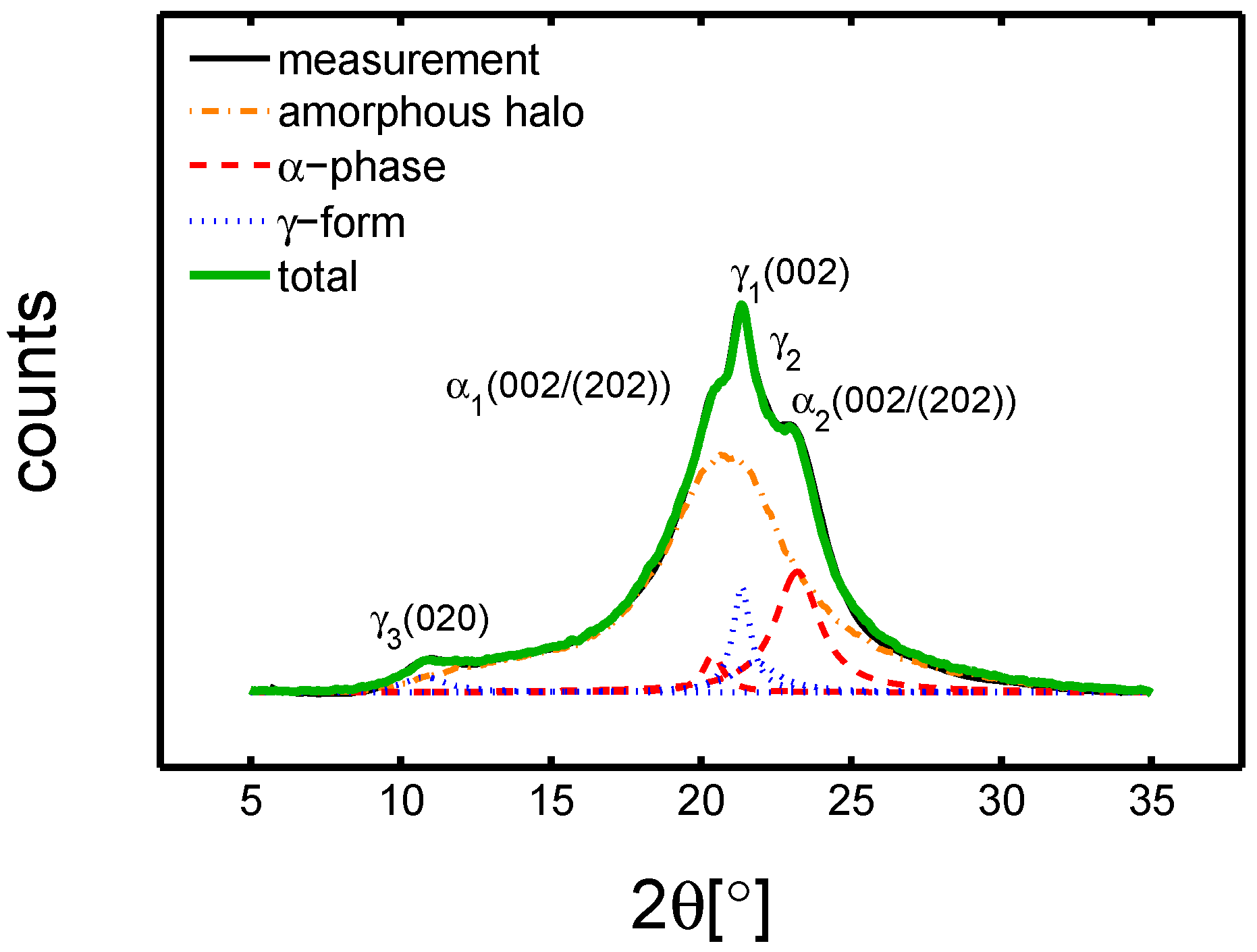

Figure 2a,b, the integrated WAXD patterns and the results of deconvolution analysis are shown, respectively.

In

Figure 2a, the integrated patterns show that the samples

-I and

-I have crystallized in the

-form, which is recognizable by the characteristic central peak at around 2

21°and the secondary peak at 2

10°; the obtained crystallinity is around 30% and by deconvolution it is possible to state that, only in the case of

-II, a small fraction of

-phase is obtained, as shown in

Figure 2b. The samples

-I,

-II and

-III showed the two characteristic peaks of

-phase, at about 2

20°and 2

24°; the obtained crystallinity is around 40% in the case of

-III and

-I, while a slightly lower crystallinity (about 35%) is obtained for

-II. These three

-samples have crystallized in pure

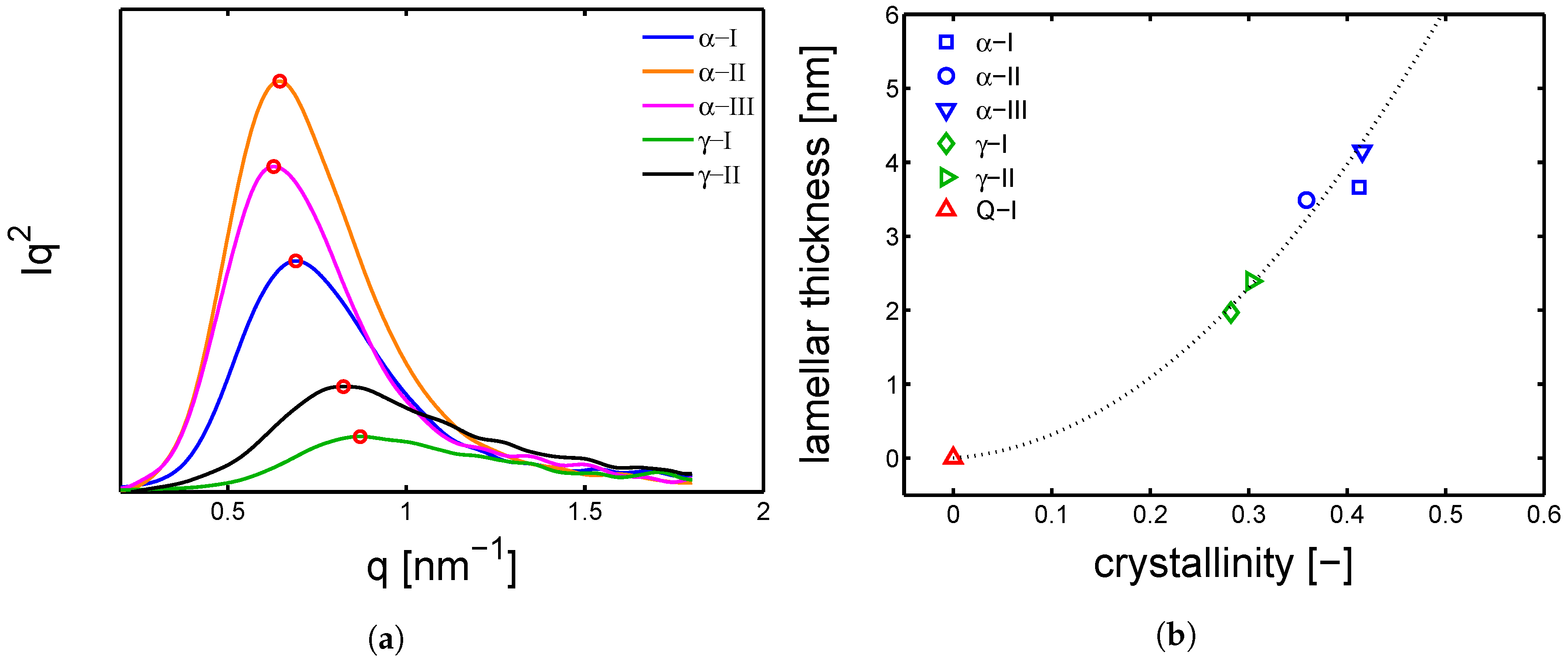

-phase. To estimate the average lamellar thickness, small angle X-ray were performed on the dry samples. Examples of SAXS pattern are given in

Figure 3a; accordingly to the procedure described in

Section 3.5, the average lamellar thickness is estimated and plotted as a function of crystallinity (see

Figure 3b).

In

Figure 3a, the integrated patterns are reported, the peak position (red markers) is translated to the long period by Equation (

8). The relationship between

and crystallinity is given in

Figure 3b; the average lamellar thickness increases for increasing crystallinity with an asymptotic-like trend. It is remarked that, as stated in [

32], crystallization of

-mesophase at high under-cooling leads to the formation of non-lamellar morphology. Therefore, the values of

for the

-samples should be intended as crystal thickness rather than lamellar thickness.

4.2. Mechanical Properties

Next, the study can proceed with the investigation of the mechanical properties. This is initially done by tensile test at different temperatures, applying a range of strain rates (from s−1 up to s−1) and the samples were kept in dry conditions. As a starting point for the mechanical properties’ investigation, only three cases will be investigated: -I for the polymorph , -I for the polymorph and Q-I for the complete amorphous material.

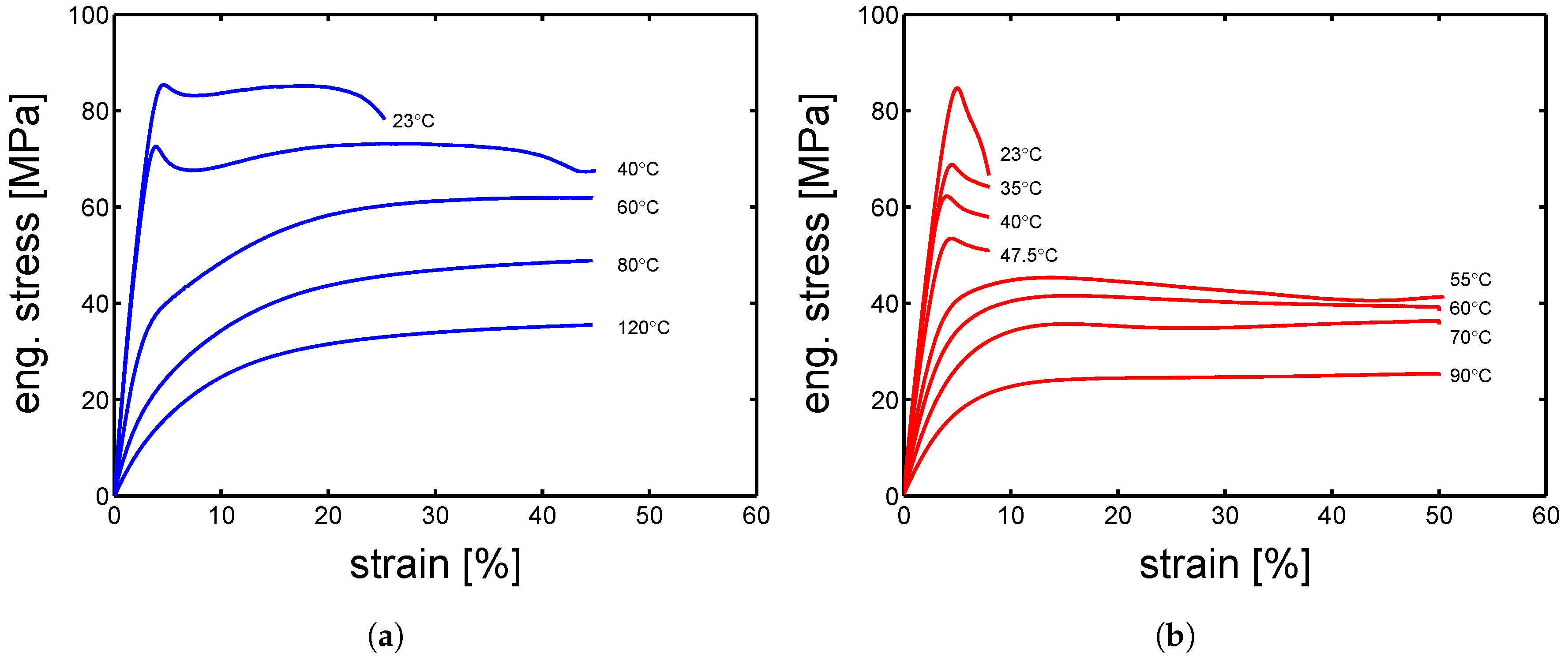

As expected, the stress–strain response increases as the strain rate increases for both

-I and

-I; while it decreases as temperature increases (see

Figure 4a,b). In the case of

-I at 23 °C, the stress–strain response shows a very clear double yielding (see

Figure 4a). This occurs because the amorphous and crystalline domains yield at different strains; indeed, the yield at low strain range (about 5–10%) is regarded as the contribution of amorphous domains, and the yield at higher strain range (about 15–35%) is considered to be the contributions of crystalline regions. This effect can be simply proven by observing the effect of temperature (for a fixed strain rate) on the stress–strain response: the first yield, well visible at room temperature, tend to disappear as temperature increases and clearly disappear when the temperature is above

(see

Figure 4a green lines)—notwithstanding, also at temperatures higher than

, the double yielding would occur if very high strain rates were applied. The double yielding is less visible in the case of

-I, which is likely due to a smaller contribution of the crystalline fraction, as demonstrated by the lower value of crystallinity estimated for

-I (≈30%) compared with the one of

-I (≈40%). In order to study the yield kinetics, the yield stress is plotted as a function of the applied strain rate for different temperatures.

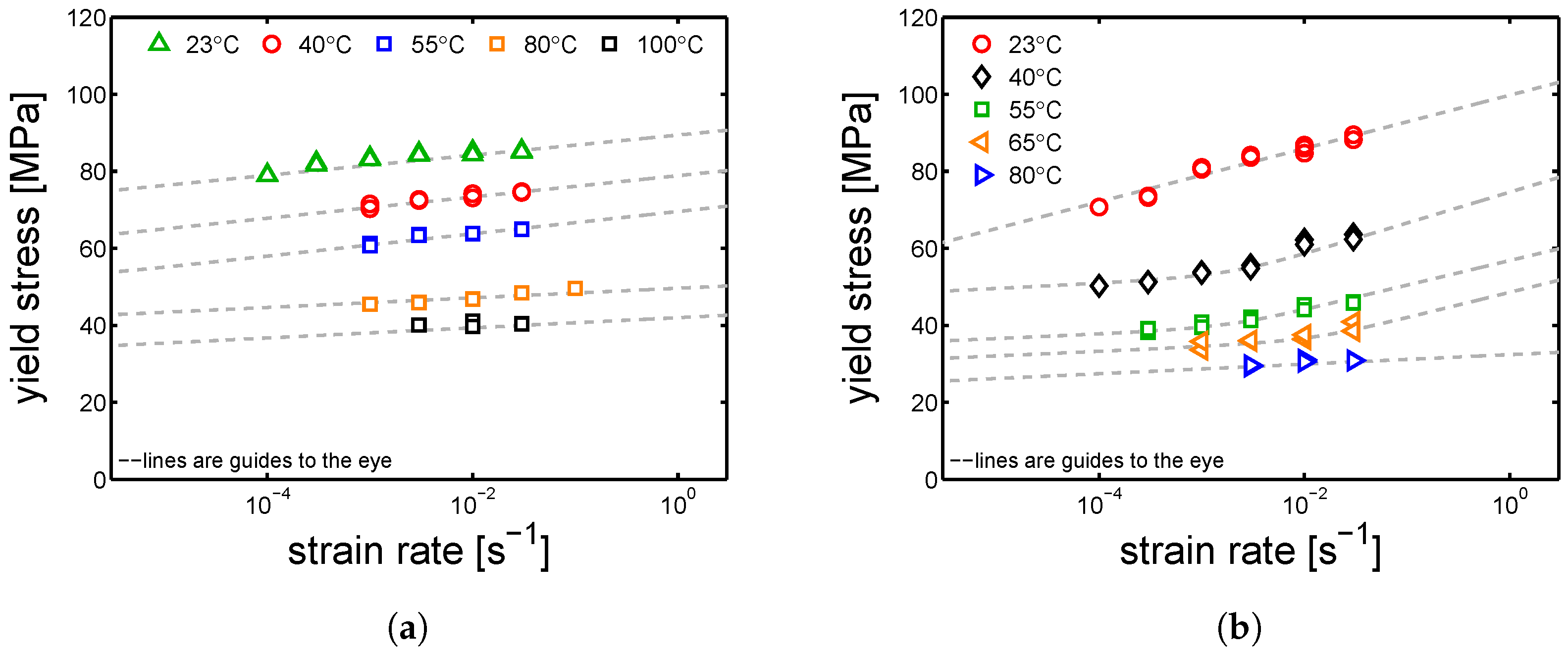

In

Figure 5a,b, the yield kinetics are shown; in both

-I and

-I cases, two different strain rate dependences are observed, as mentioned in

Section 2. A steep slope is observed at low temperatures and (or) high strain rates, while a rather flat one is displayed at high temperatures and (or) low strain rates. In

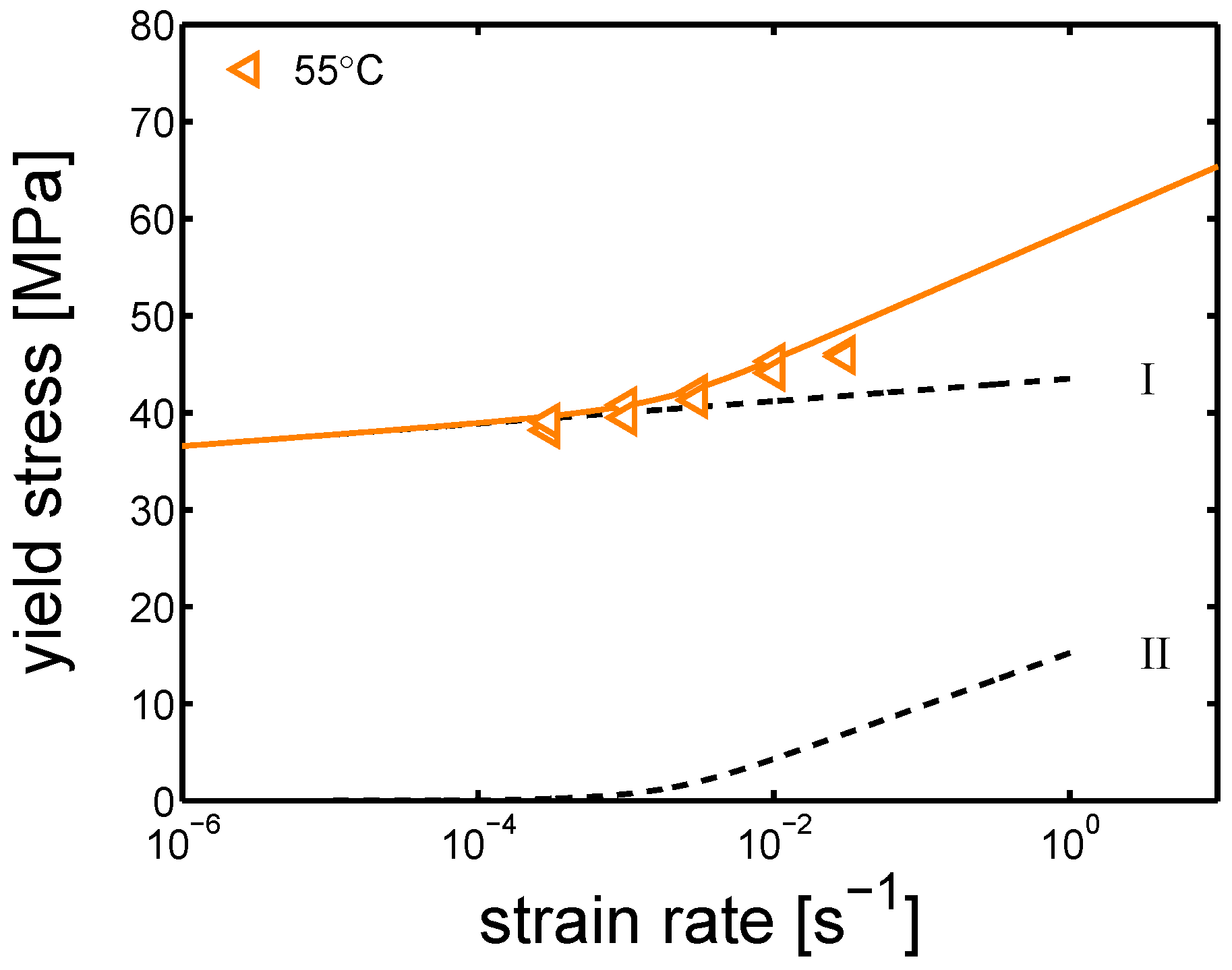

Figure 6, a schematic decomposition of the two processes is proposed.

In order to describe the yield kinetics obtained experimentally, Equation (

1) is used and the parameters in

Table 2 and

Table 3 were employed.

In

Figure 7a,b, it is shown that the model can describe well the results at different temperatures for both

-I and

-I. Moreover, it is remarkable that the activation energy and activation volume employed for process I are the same for both

-I and

-I. The parameters of process II do not match between the two different polymorphs; a plausible reason could be found introducing the concept of amorphous constraint. Looking at the mobility scenario in a semi-crystalline polymer, it is known that the crystalline regions have the lowest mobility, whereas the amorphous region should have the highest mobility. However, an elevated presence of crystalline regions may constrain the amorphous regions, with a consequent decrease of mobility. Thus, a difference in crystallinity may affect also the state (mobility) of the amorphous regions.

4.3. Influence of Temperature

To obtain a large overview about the effect of temperature on the yield stress, several tensile tests were performed at

s

−1 and several temperatures were tested (see

Figure 8). Observing the results in

Figure 8a, it is possible to notice a clear double yielding behavior at temperature lower than

, while increasing the testing temperature, the first yield (at low strains) tends to disappear. The

-I samples show a predominantly crystalline contribution to yield, this is due to a high crystallinity index and a relatively high lamella thickness.

Figure 8b shows a very different picture; at low temperature, yield takes place at low strains (≈5%) and it moves to about 15% strain when the temperature is increased above 50 °C. Comparing the strain at yield for both

-I and

-I samples, we observed a very similar strain for the yield related to the amorphous domains (about 5%), whereas the contribution of the crystalline domains takes place at quite a different strain range, ≈15% for

-I and about 30% for

-I.

Figure 9 shows that

-I,

-I and Q-I samples have three very different temperature dependencies. For the green markers, related to Q-I samples, no description (solid line) is provided. In fact, looking at the trend of yield stress as a function of temperature, three regions are found: (i) at low temperature, yield stress decreases drastically as temperature increases; (ii) at about 50 °C, the yield stress reaches a minimum; (iii) after which the material starts cold crystallizing and the yield stress increases and reaches a plateau up to 120°. The Q-I stress–strain behavior variation is due to an evolution of the material morphology, which is time- and temperature-dependent. For this reason, the Q-I samples will be taken out of this study. As far as the blue and red markers (

-I and

-I, respectively) is concerned, they show very similar yield stress at 23 °C, but, as temperature increases,

-I yield stress decrease more rapidly than

-I. In these two cases, the model is applied: in the case of

-I, the experimental results are matching the description; in the case of

-I, the description matches the experimental results up to 90 °C. After this temperature, the experimental yield stress flattens. As already explained in [

24], an evolution of crystallinity and/or lamellar thickness takes place at high temperatures; this phenomenon, called “annealing”, is a time- temperature-activated process, it is governed by an enhancement of mobility that results in either cold crystallization and (or) lamellar thickening (perfectioning). Hence, higher crystallinity and (or) lamellar thickness results in an increase of yield stress, as shown in

Figure 9. This effect is not observed in the case of

-I samples. It is hypothesized that “annealing” does not occur in

-I because of the already very high crystallinity and lamellar thickness obtained during processing.

The Ree–Eyring equation is applied with satisfactory results on the dry samples for both the two polymorphs, and two sets of parameters have been defined for the

-phase and

-form, respectively; next, the influence of relative humidity and other thermal histories are investigated (see

Table 1).

4.4. Influence of Humidity

As explained in

Section 3.3, the samples were exposed to humid environments (relative humidity ranging from 35 to 75%) for a period long enough to allow the complete saturation. All the samples were conditioned at room temperature (23 °C). The absorbed water fraction was calculated by the following:

where

is the weight of the sample before conditioning and

is the weight at the time

.

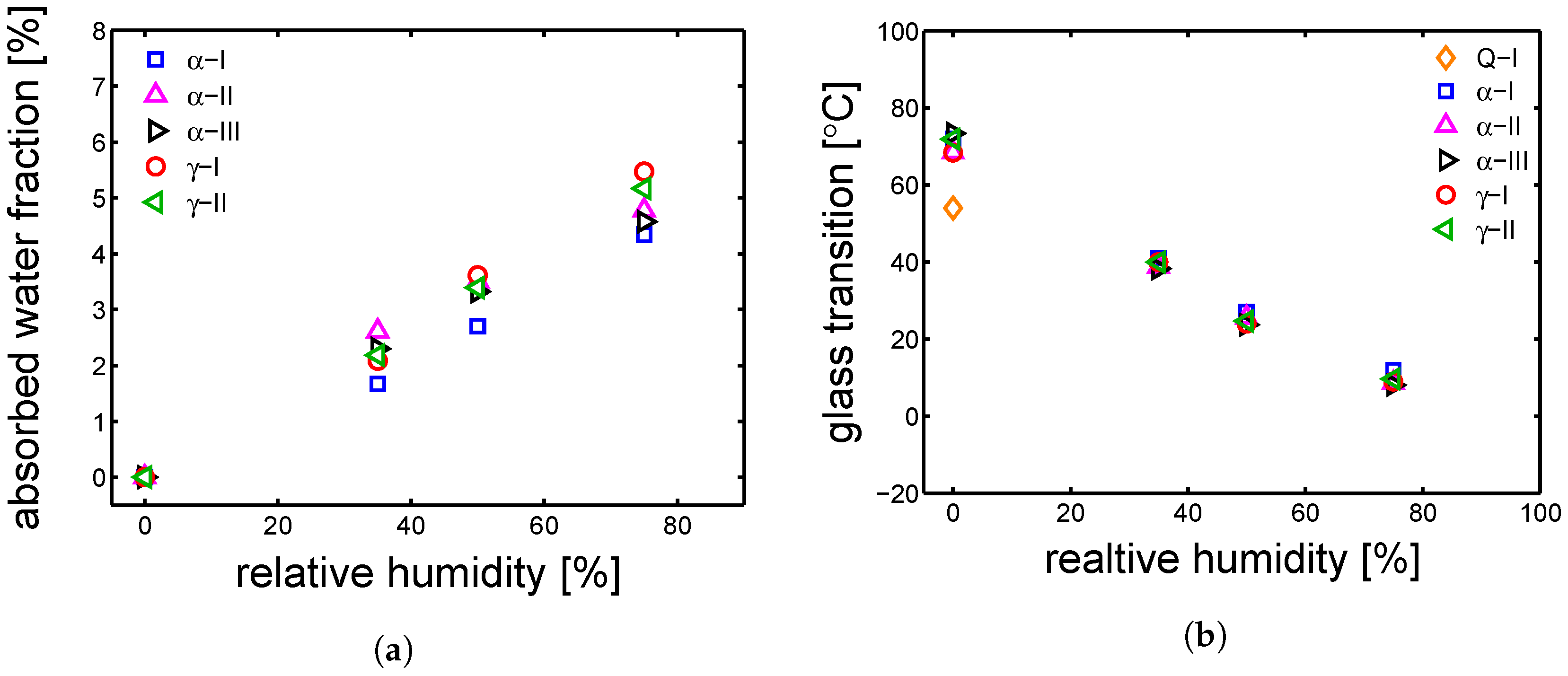

The absorbed water fraction is plotted as a function of relative humidity (HR%) (see

Figure 10a). The saturation level is different between the the samples because of a difference in crystallinity; as mentioned in

Section 1, water can be absorbed only by the amorphous regions (because of their mobility state). In

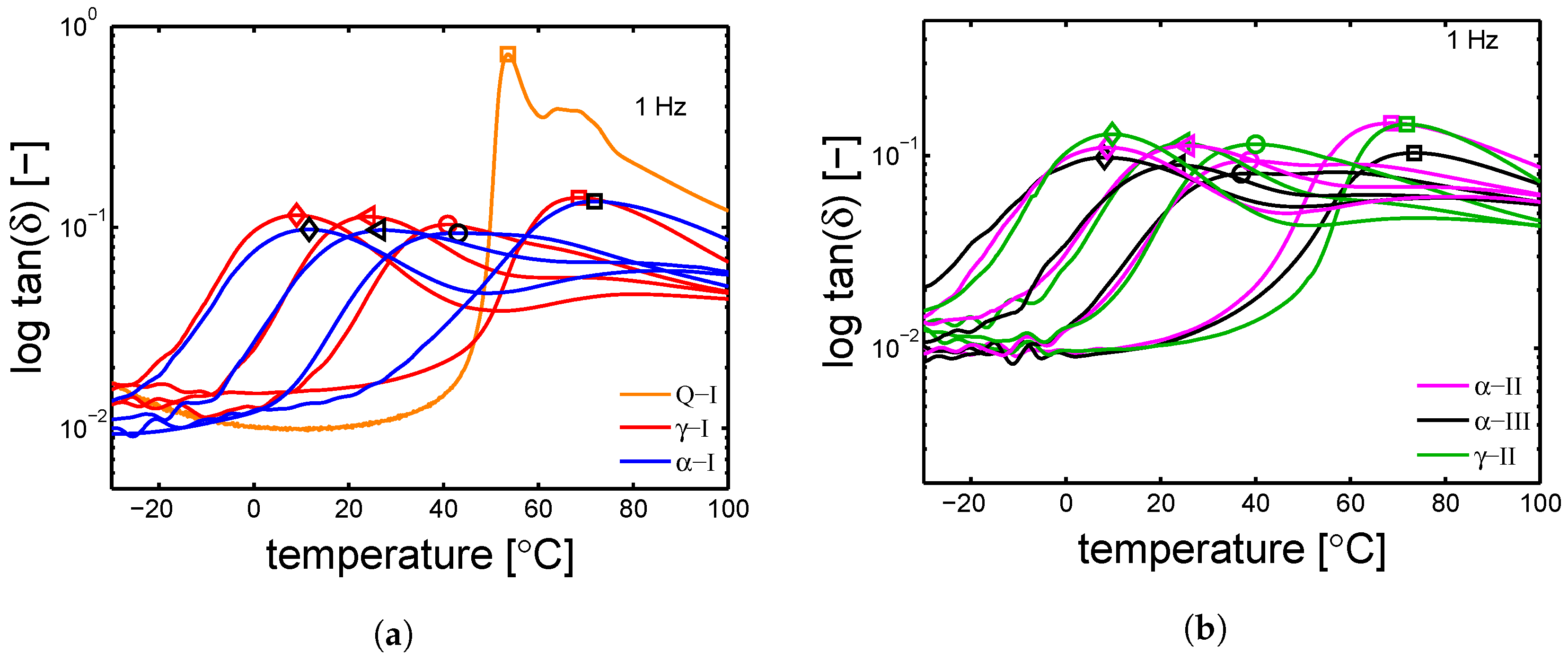

Figure 10b, the measured glass transition temperatures are plotted as functions of the relative humidity; a monotonic decrease of glass transition temperature is found by increasing the RH%. The results of the thermal-mechanical characterization, performed by DMTA, are shown in

Figure 11a,b. The details about this technique are given in

Section 3.6.

Figure 11a shows the results of DMTA for the samples Q-I,

-I and

-I after conditioning at different RH%; the markers are the defined

s. The Q-I is presented only in a dry condition because, upon conditioning, it crystallizes and therefore it changes its state drastically.

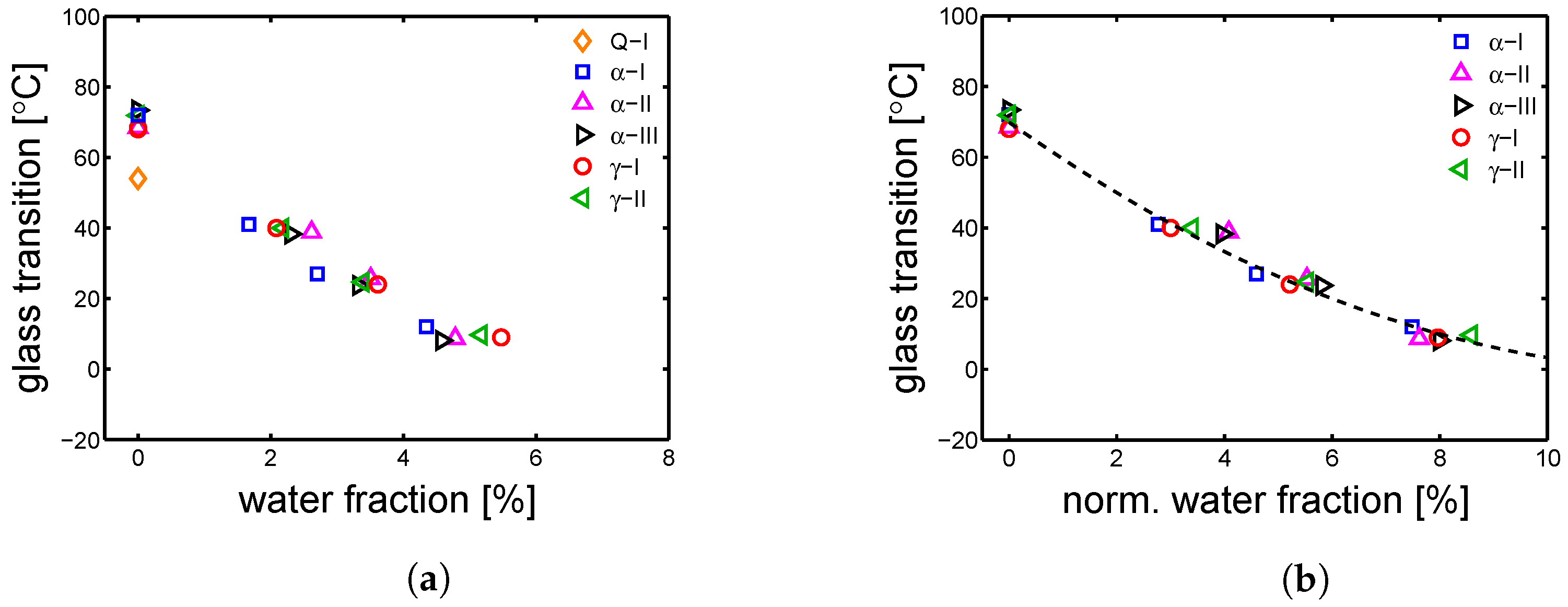

Figure 12a shows the glass transition temperatures as functions of absorbed water fractions. At RH 0% (dry condition), all the investigated samples show a maximum in glass transition temperature; increasing the absorbed water fraction, a monotonic decrease of

is recorded. This is due to the plasticizing effect described in

Section 1. Moreover, relying on the fact that only the amorphous region can absorb water, the glass transition temperature can be plotted as a function of normalized water fraction. The normalization is applied as follows:

where

is the crystallinity by WAXD and W% is the water fraction estimated experimentally (see Equation (

11)). The results are shown in

Figure 12b. As proposed,

follows a unique trend if plotted against a normalized water fraction. All of the

are reported in

Table 4.

As already mentioned in

Section 1, the glass transition can drop at temperatures even below room temperature. In this case, the polymer chains acquire the sufficient mobility needed to cold crystallize and (or) thickening the pre-existing crystals. The crystallinity can be plotted as a function of relative humidity for different samples as shown in

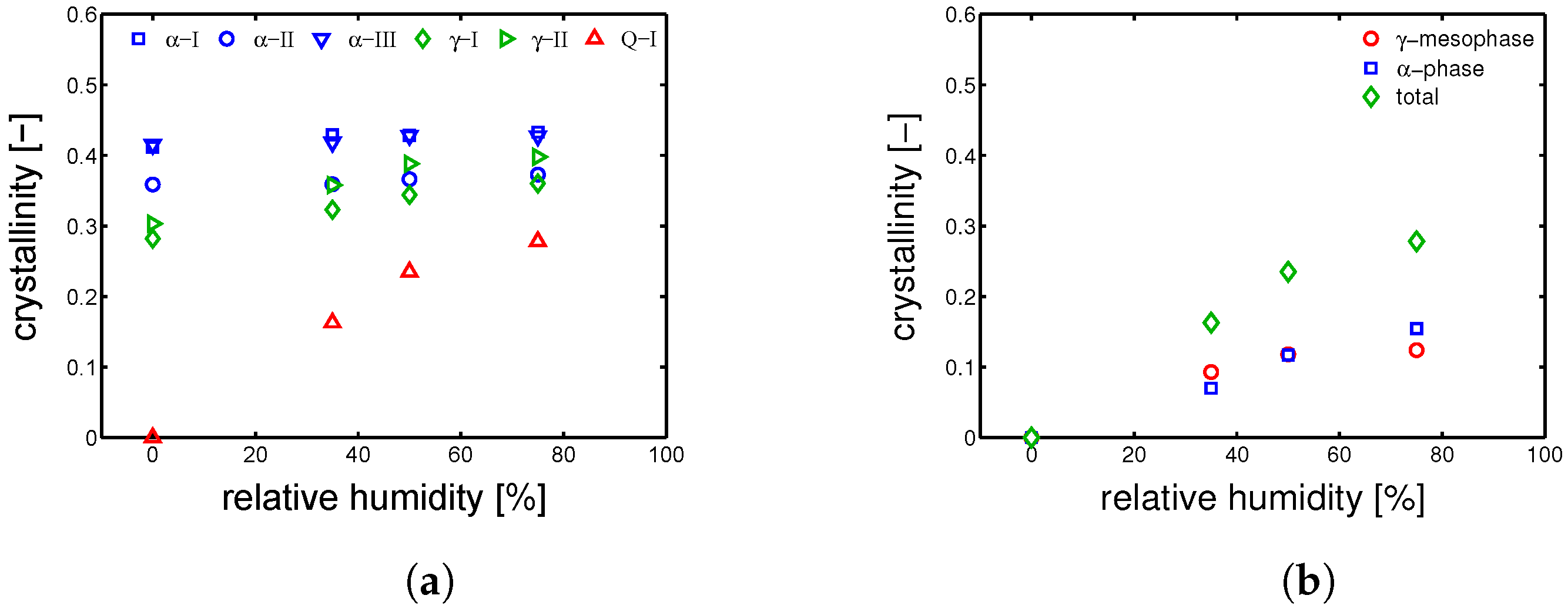

Figure 13a.

Figure 13a shows that hydration has an actual effect on the crystallographic properties of PA6. In details, the crystallinity of Q-I samples rapidly increases for increasing relative humidity,

-samples show a modest increase of crystallinity and

-samples show a rather constant crystallinity. In order to investigate the process of “cold crystallization” taking place in the Q-I samples, the deconvolution analysis of the WAXD patterns was performed; results are shown in

Figure 13b. The samples Q-I, starting from a completely amorphous material, are exposed to three different relative humidities, always at room temperature. The lowest RH% (35%) leads to crystallization of

-form and

-phase with a balance slightly shifted towards the

-form; at 50 RH%, the total

increases and the balance

-

is perfectly even; at the highest investigated relative humidity (75%), the crystallinity increases even further and the balance

-

is slightly shifted towards the

-phase. In the case of

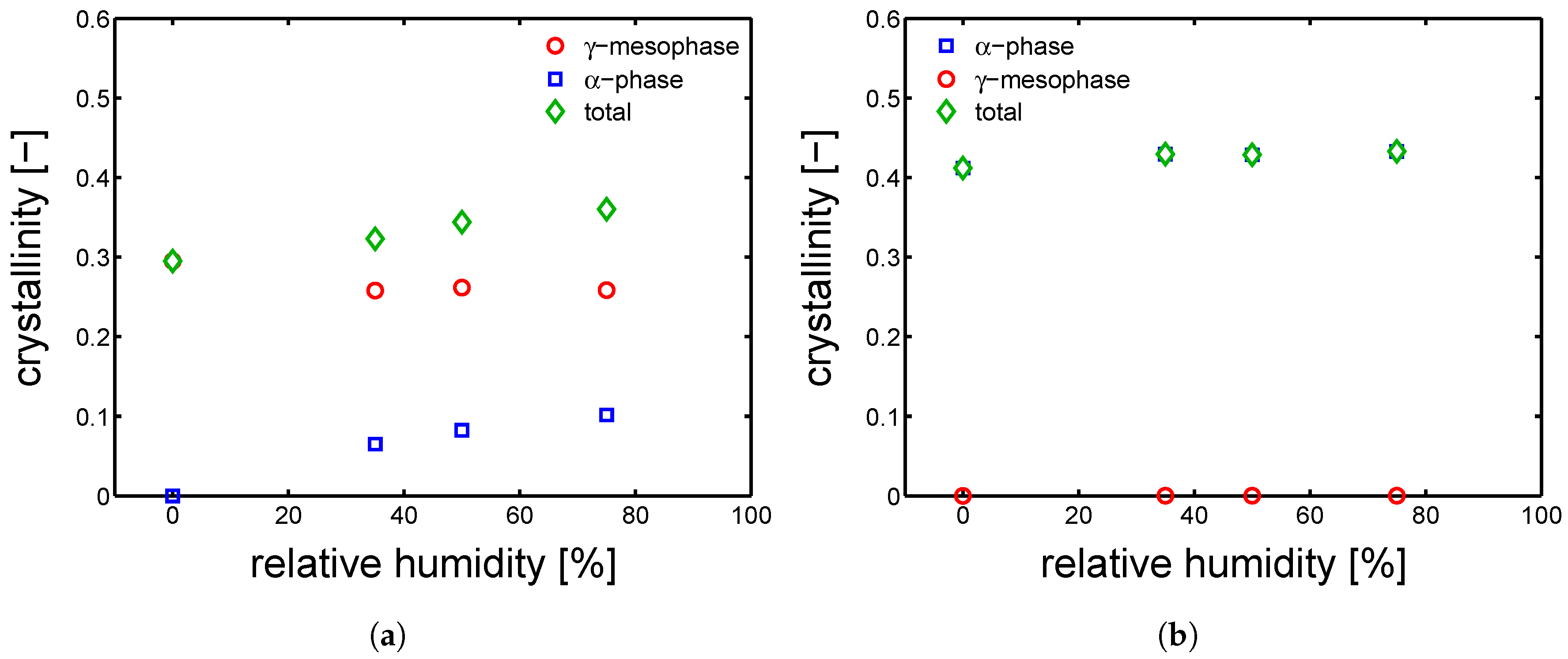

-samples, the starting material is already semi-crystalline with a rather high crystalline index, thus secondary crystallization, phase transition and (or) lamellar perfectioning (thickening) are expected. In

Figure 14a, the results of deconvolution analysis for

-I are shown. The

increases along the whole range of relative humidity, in particular a slight decrease of

-form and a substantial increase of

-phase is detected. This effect can be related to a partial transformation

to

, followed by a secondary crystallization of

-phase. In the case of

-I (see

Figure 14b), the deconvolution reveals that no transformation takes place and only the crystallinity seems to increase a little (probably within an experimental error).

In order to capture the lamellar thickness evolution upon hydration, SAXS experiments were performed (as explained in

Section 3.5). In

Figure 15a, the results of lamellar thickness are proposed as a function of relative humidity. A similar trend to

versus RH% are found. The lamellar thickness of Q-I samples increase quickly with relative humidity; in addition, the

of

-samples increases although less rapidly than the amorphous samples, while the

-samples lamellar thickness are rather steady. These results can be plotted more intuitively as a function of the “apparent temperature”. In

Figure 15b, the

are plotted as a function of

, in this way, the increase of

due to hydration can be easily regarded to a “cold crystallization” or “annealing” process, in which the samples are heated from the glassy state to a temperature above

.

Following this, the samples were tested by tensile test at different relative humidities and a range of strain rates (

s

−1 up to

s

−1). As it was done for yield kinetics in dry conditions, the aim is to also describe the results of test at different relative humidities by the Ree–Eyring equation (see

Section 2, Equation (

3)) employing the two set of parameters defined for the

-phase and

-form (see

Table 2 and

Table 3). Firstly, the model is applied to the samples

-I and

-I (the results are shown in

Figure 16a,b).

It is shown that Equation (

3) describes the experimental results obtained at different conditions for two polymorphs of PA6. As shown in

Table 2 and

Table 3, the parameters employed for the

and

polymorph differ mainly in the rate factors and the process II (inter-lamellar deformation). In

Figure 17a,b, the yield kinetics of

-II,

-III and

-II are shown, respectively. In order to describe these experimental results, the set of parameters used for

-I was employed for

-II and

-III, whereas the set used for

-I was employed

-II; in both cases, only the rate factors had to be changed. The parameters employed for these cases are listed in

Table 5,

Table 6 and

Table 7.

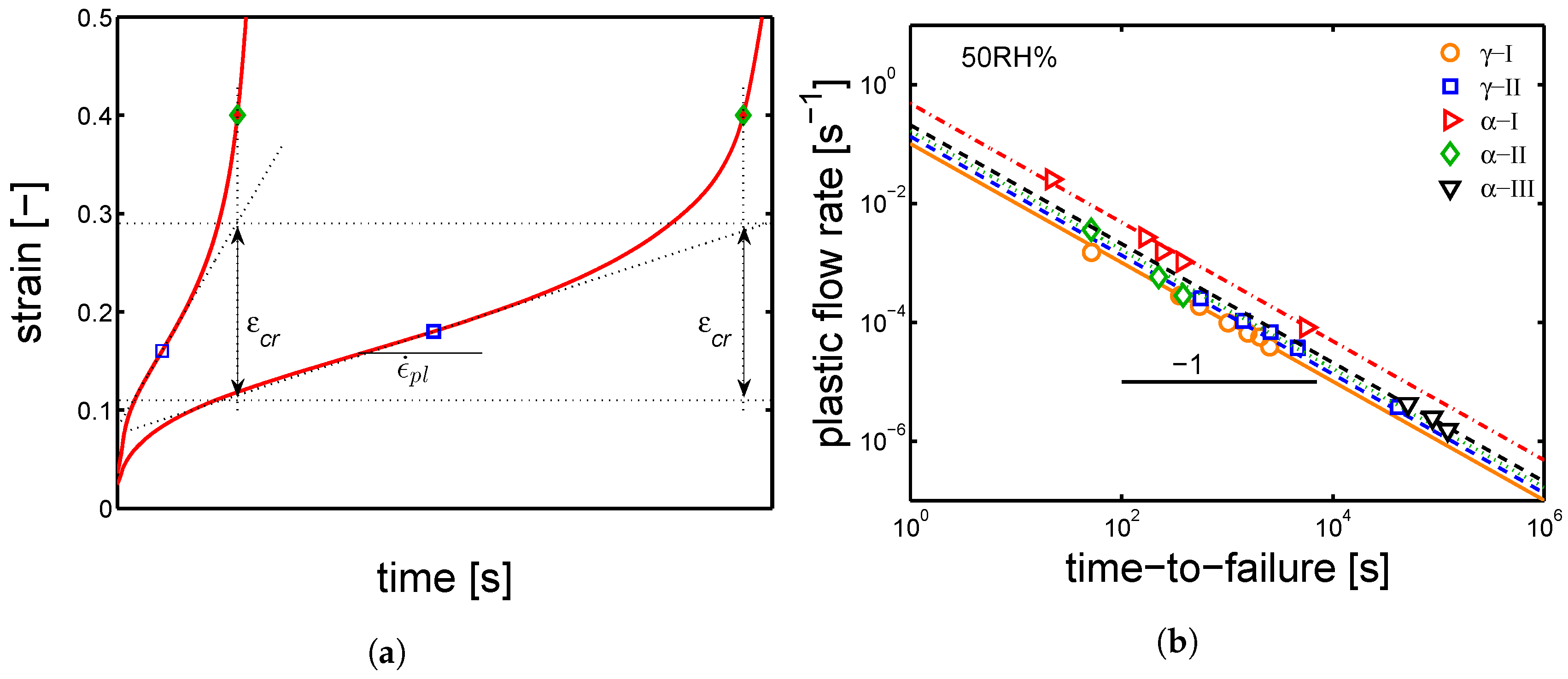

4.5. Time-to-Failure

Next, the influence of relative humidity on the PA6 lifetime was investigated. Several creep tests were performed at 23 °C and relative humidity ranging from 35% to 75%. All of the five sample series were tested at different applied loads. Subsequently, the

is estimated by the use of the Sherby–Dorn plot [

33]; where the strain rate is plotted as a function of strain, and the

is defined as the minimum of the obtained curve. Finally, all the

are plotted as functions of the corresponding time-to-failure, as shown in

Figure 18b. As mentioned in

Section 2, the data plotted in a log–log graph show a slope of −1.

By extrapolating to

= 1 s, the results shown in

Figure 18b, the

is estimated. Eventually, to describe the time-to-failure results obtained for the different samples series, the

obtained by the Ree–Eyring equation (Equation (

3)) modified to include the influence of relative humidity are combined with the

in Equation (

5). In

Figure 19a,b, the applied loads are plotted as functions of the time-to-failure. The lines are the results of Equation (

5) and they are related to samples conditioned at different relative humidities (range from 35–75%) and 23 °C. The lines have the same stress dependence as the ones shown in

Figure 16a,b but the slopes have opposite signs.

Figure 19a,b shows that a satisfactory prediction of time-to-failure is achieved for samples

-I and

-I employing the set of parameters reported in

Table 2 and

Table 3 for samples

-I and

-I, respectively. By the use of the parameters listed in

Table 5,

Table 6 and

Table 7, also samples

-II,

-III and

-II are described by Equation (

5); the results are shown in

Figure 20a,b.

4.6. Structure–Properties Relations

For all the investigated PA6 samples, the temperature, relative humidity and stress dependent deformation kinetics were captured by the Ree–Eyring theory. To apply this theory, the characteristic parameters were defined, namely the activation volume (

), the activation energy (

) and the rate factors (

). As explained in

Section 4.2, PA6 shows two strain rate dependences that are related to two deformation mechanisms: an intra-lamellar deformation mechanism (also called process I) and an inter-lamellar mechanism (also called process II). As shown in Equation (

1), each process needs one set of parameters.

The analysis has led to the conclusion that: (i) for process I, identical activation volume and activation energy can be used for all of the sample type, a part for the quenched samples whose structures, as explained in

Section 4.3, are very dependent on temperature and relative humidity; (ii) for process II,

and

are different for the two different polymorphs, i.e.,

-phase and

-mesophase; (iii) the rate factors were varied for each samples series, for both process I and process II. About the different

and

determined for the two crystallographic phases in the case of process II, the author can only hypothesize that the reason might be in the different constriction level of the amorphous phase. In fact, as proposed in a previous study [

24], process II is associated to the deformation of the amorphous phase. About the rate factors (

and

), a rather clear correlation between the lamellar thickness (

) was found (see

Figure 21a,b).

Figure 21a shows the relation between the rate factor I and the lamellar thickness; plotting the logarithm of

as functions of lamellar thickness for both

and

samples, a linear trend is found. In the case of

, two trends are found: one related to the

-samples and one for the

-samples (see

Figure 21b). Remember that also the

and the

are different for process II, therefore there is no reason to expect that the trend of

for

matches the one for

samples. This relation between the rate factors and the lamellar thickness was also proposed by other authors in the case of i-PP (isotactic polypropylene) [

7,

8]. The funding shown in

Figure 21a,b are crucial for the prediction of the deformation kinetics and time-to-failure of PA6 processed with different histories. It is important to remark that, in the case of “real-life” applications, products are designed to work upon loads largely below the yield stress, hardly in dry conditions and often at high temperatures. Thus, the most frequent failure mode would be governed by intra-lamellar deformation, i.e., process I; consequently, the prediction would be governed by a

and

, which are not dependent on the crystallographic phase.