Prediction of the Tensile Response of Carbon Black Filled Rubber Blends by Artificial Neural Network

Abstract

:1. Introduction

2. Materials and Methods

2.1. ANN Structure and Architecture

2.2. Training, Validation, and Testing of ANN

3. Results

3.1. Results of Tensile Tests

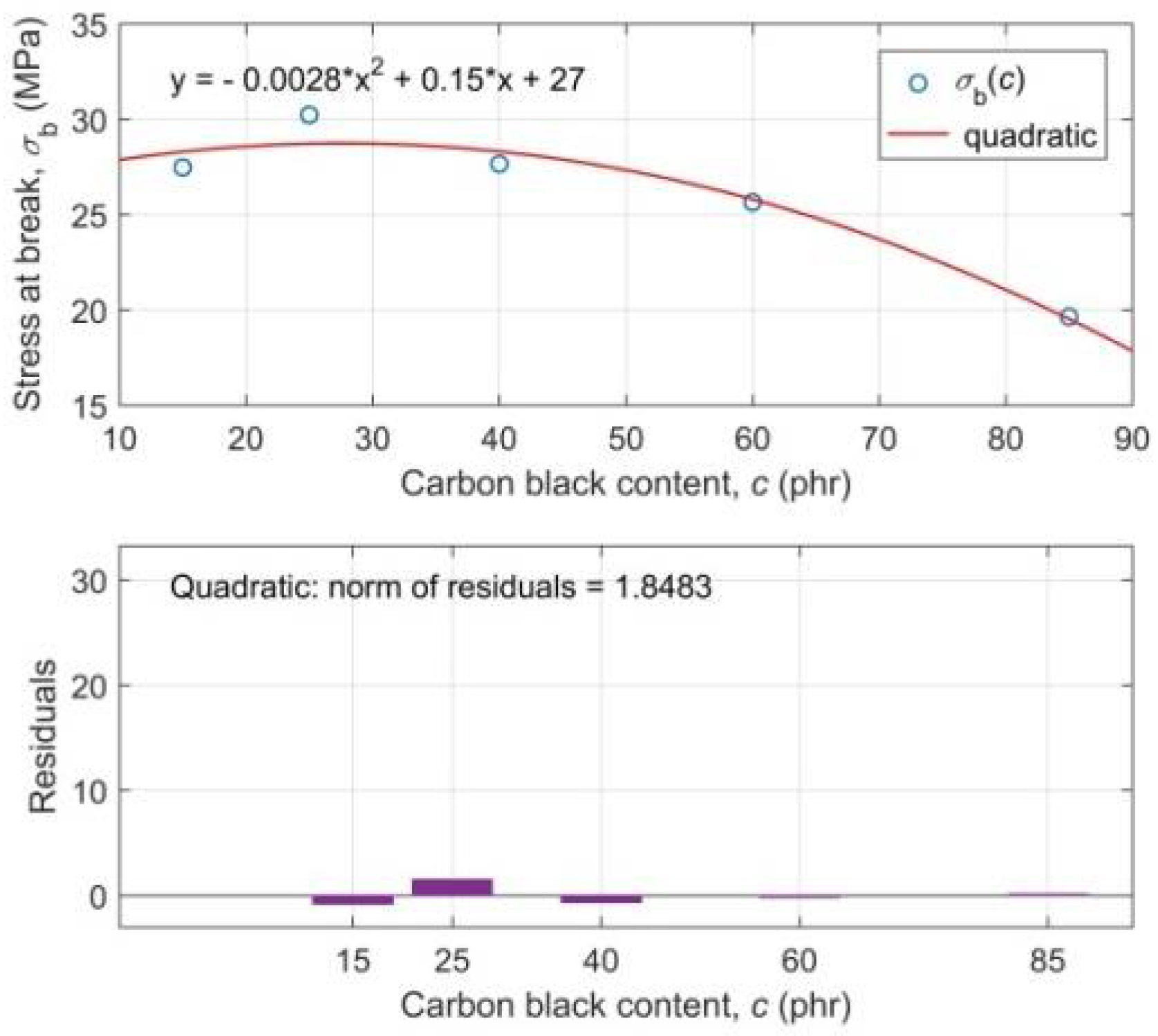

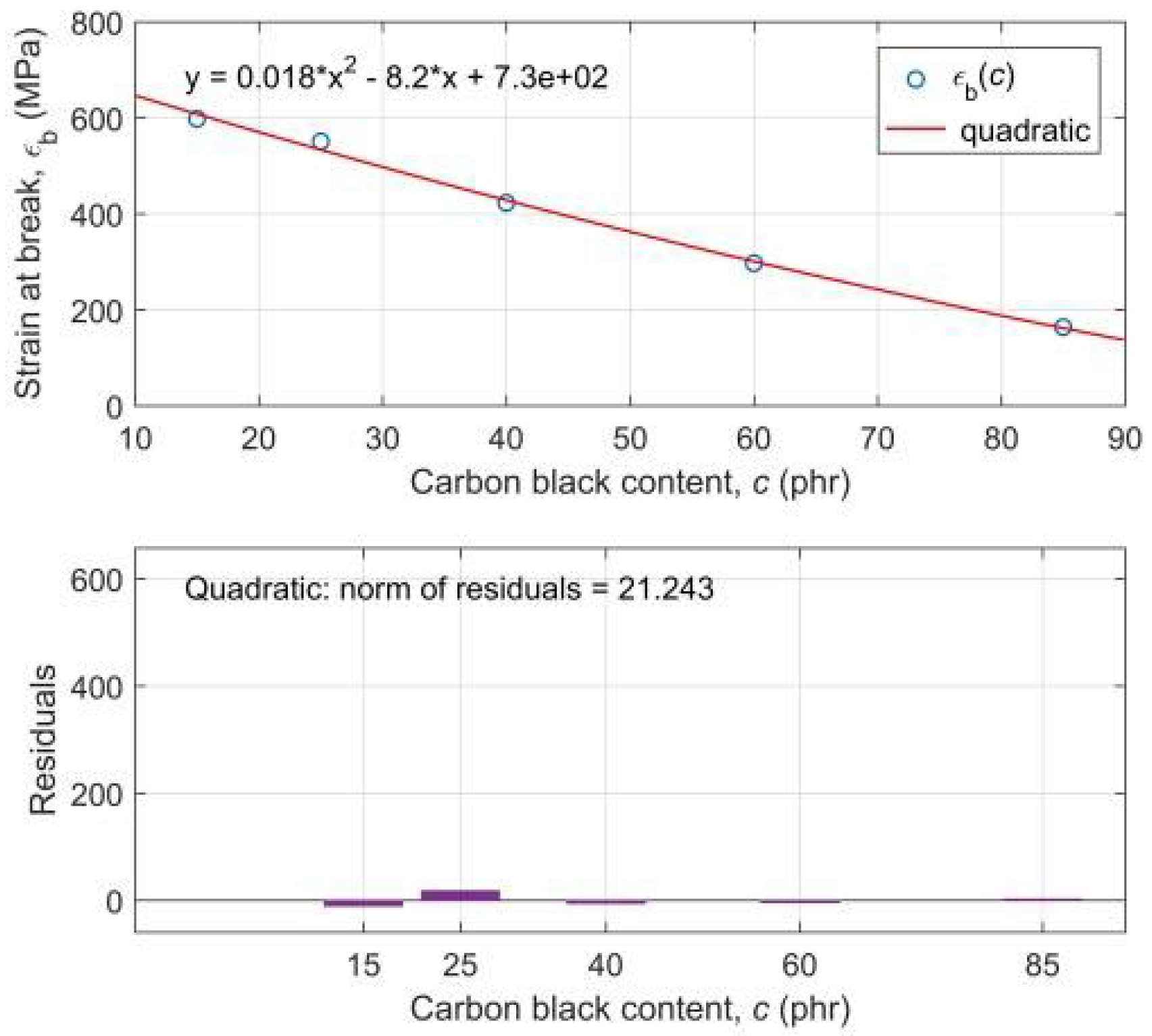

3.2. Pre-Processing of Experimental Data

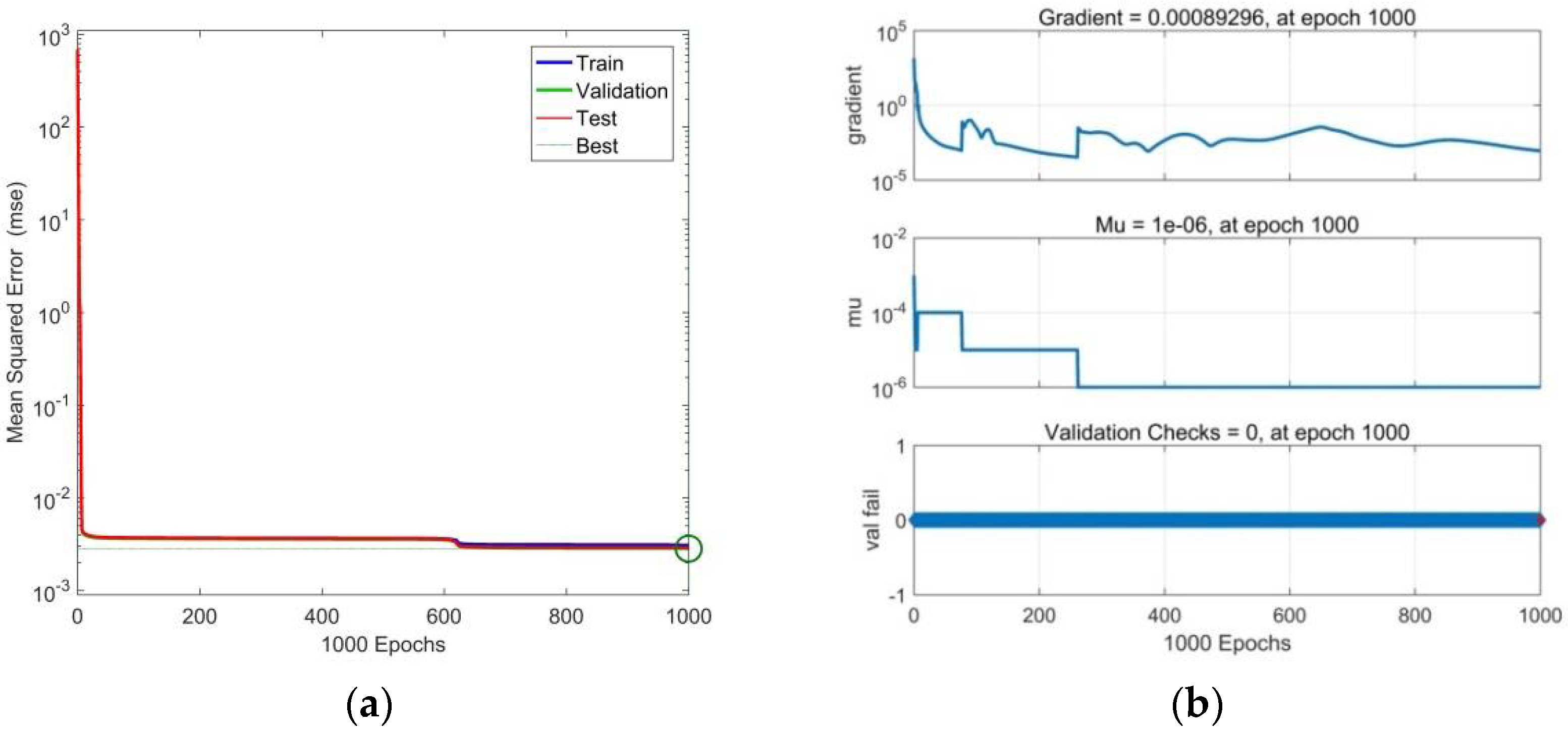

3.3. Optimization of the ANN Model

3.4. Analysis of the ANN Model

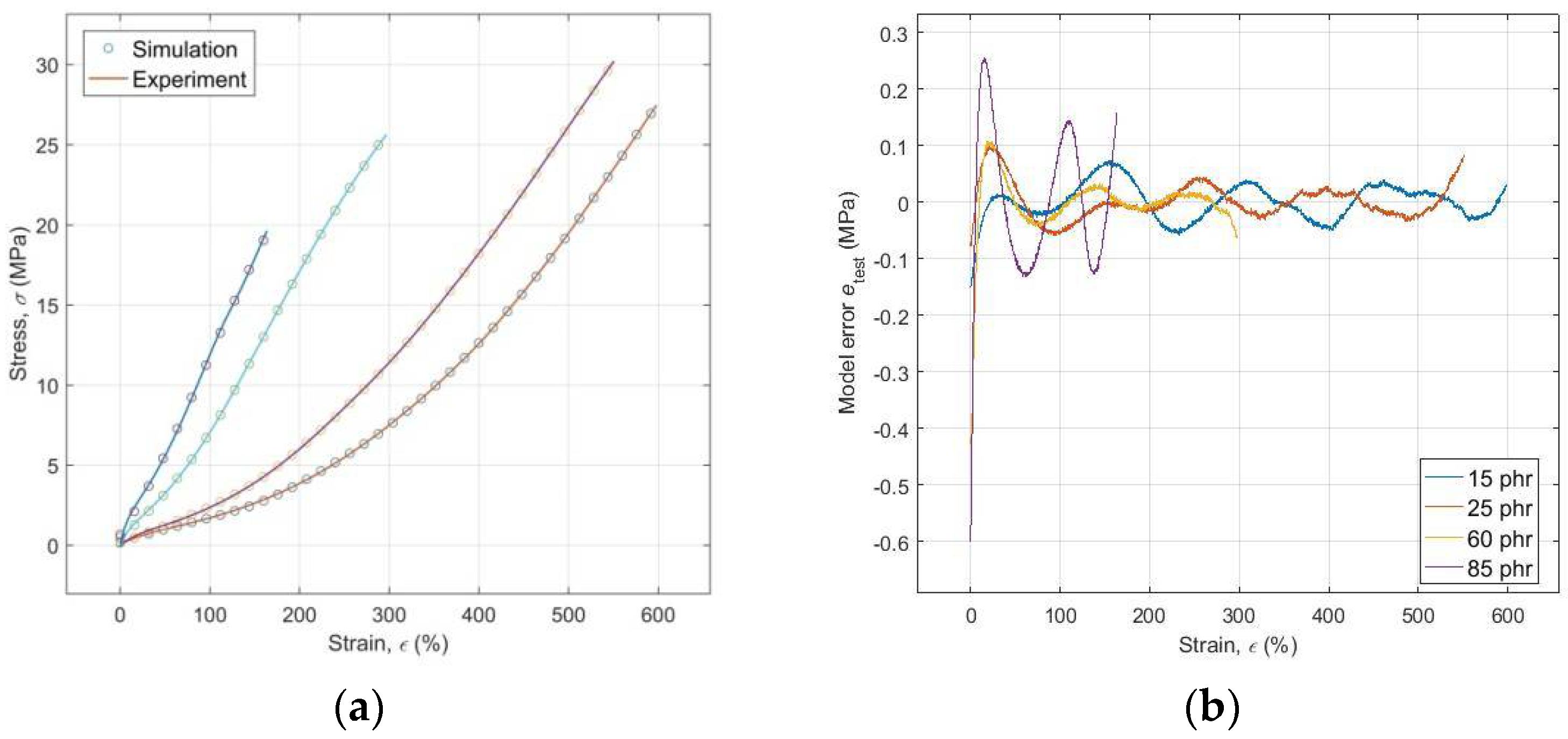

3.5. Generalization Capabilities of the ANN Model

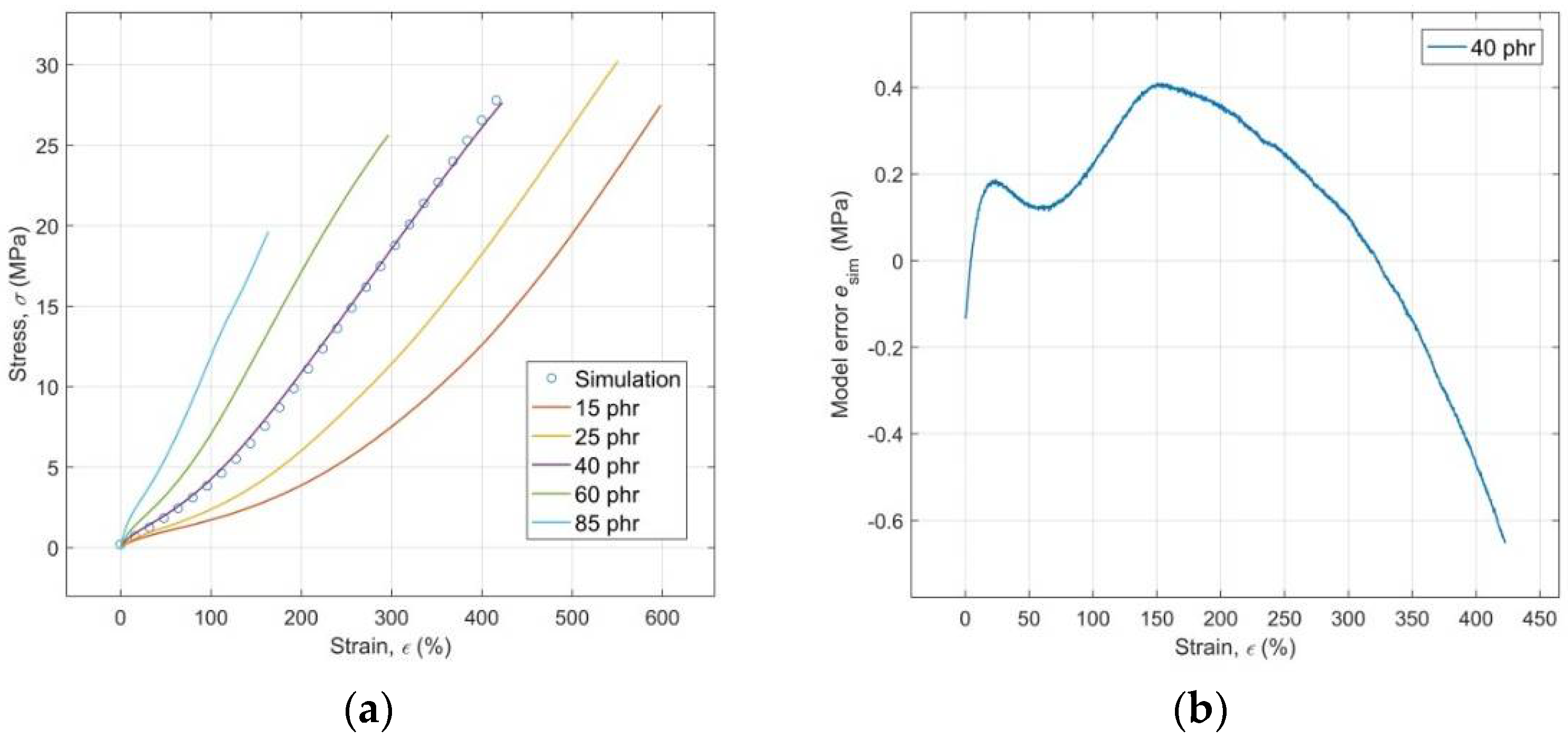

3.6. Simulation of the ANN Model Based on Modeled Inputs

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Krmela, J. Tire Casings and Their Material Characteristics for Computational Modelling, 1st ed.; Printing House the Managers of Quality and Production Association: Czestochowa, Poland, 2017; ISBN 978-83-63978-62-4. [Google Scholar]

- Ward, I.M.; Sweeney, J. Mechanical Properties of Solid Polymers, 3rd ed.; Wiley: Chichester, UK, 2013; ISBN 978-1-444-31950-7. [Google Scholar]

- Drobny, G.J. Handbook of Thermoplastic Elastomers, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 9780323221368. [Google Scholar]

- Pandian, J.J.; Govindan, T. Comparative Studies on the Mechanical Properties of Natural Rubber and Natural Rubber Carbon Black Composites. IJETCSE 2015, 13, 48–52. [Google Scholar]

- Vineetkumat, J. Carbon Black Filler Reinforcement of Elastomers; Queen Mary University of London: London, UK, 2008. [Google Scholar]

- Rothert, H.; Kaliske, M. Constitutive approach to rate-independent properties of filled elastomers. Int. J. Solids Struct. 1998, 35, 2057–2071. [Google Scholar]

- Kucherskii, A.M. Hysteresis losses in carbon-black-filled rubbers under small and large elongations. Polym. Test. 2005, 24, 733–738. [Google Scholar] [CrossRef]

- Tomita, Y.; Azuma, K.; Naito, M. Strain-rate-dependent deformation behavior of carbon-black-filled rubber under monotonic and cyclic straining. Int. J. Mech. Sci. 2008, 340, 856–868. [Google Scholar] [CrossRef]

- Xiang, K.L.; Xiang, P.Y.; Wu, Y.P. Prediction of the fatigue life of natural rubber composites by artificial neural network approaches. Mater. Des. 2014, 57, 180–185. [Google Scholar] [CrossRef]

- Kamal, M.M.; Clarke, J.; Ahmad, M.A. Comparison of properties of natural rubber compounds with various fillers. J. Rubber Res. 2009, 12, 27–44. [Google Scholar]

- Jha, V.; Hon, A.A.; Thomas, A.G; Busfield, T.J. Modelling of the effect of on the stiffness of rubbers. J. Appl. Polym. Sci. 2007, 107, 2572–2577. [Google Scholar] [CrossRef]

- Gil-Negrete, N.; Alonso, A. Constitutive Models for Rubber VIII; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9781138000728. [Google Scholar]

- Boyce, M.C.; Arruda, E.M. Constitutive models of rubber elasticity: A review. Rubber Chem. Technol. 2000, 73, 504–523. [Google Scholar] [CrossRef]

- El Kadi, H. Modeling the mechanical behavior of fiber-reinforced polymeric composite materials using artificial neural networks—A review. Compos. Struct. 2006, 73, 1–23. [Google Scholar] [CrossRef]

- Lion, A. A constitutive model for carbon black filled rubber: Experimental investigations and mathematical representation. Contin. Mech. Thermdyn. 1996, 8, 153–169. [Google Scholar] [CrossRef]

- Bergstorm, J.S.; Boyce, M.C. Constitutive modelling of the large strain time dependemt behaviour of elastomers. J. Mech. Phys. Solids 1998, 46, 931–954. [Google Scholar] [CrossRef]

- Guo, Z.; Sluys, L.J. Constitutive modelling of hyperelastic rubber-like materials. Heron 2008, 43, 109–132. [Google Scholar]

- Zéhil, G.P.; Gavin, H.P. Unified constitutive modeling of rubber-like materials under diverse loading conditions. Int. J. Eng. Sci. 2016, 62, 90–105. [Google Scholar] [CrossRef]

- Ali, A.; Hosseini, M.; Sahari, B.B. A Review of Constitutive Models for Rubber-Like Materials. Am. J. Eng. Appl. Sci. 2010, 3, 232–239. [Google Scholar] [CrossRef]

- Dargazany, R.; Itskov, M. A network evolution model for the anisotropic mullins effect in carbon black filled rubbers. Int. J. Solids Struct. 2009, 46, 2967–2977. [Google Scholar] [CrossRef]

- Liang, G.; Chandrashekhara, K. Neural network based constitutive model for elastomeric foams. Eng. Struct. 2008, 39, 2002–2011. [Google Scholar] [CrossRef]

- Fausett, N. Fundamentals of Neural Networks: Architectures, Algorithms and Applications; Prentice Hall: Upper Saddle River, NJ, USA, 1993; ISBN 978-0-13334-186-7. [Google Scholar]

- Aliev, R.; Bonfig, K.; Aliew, F. Soft Computing; Verlag Technic: Berlin, Germany, 2000. [Google Scholar]

- Shanmuganathan, S.; Samarasinghe, S. Artificial Neural Network Modelling; Springer: Berlin, Germany, 2016. [Google Scholar]

- David, J.; Sally, L. Advances in Computer Science, Intelligent System and Environment; Springer: Berlin, Germany, 2011; ISBN 9783642237553. [Google Scholar]

- Du, K.L.; Swamy, M.N.S. Neural Networks and Statistical Learning; Springer: New York, NY, USA, 2013; ISBN 978-1-4471-5570-6. [Google Scholar]

- Auer, P.; Burgsteiner, H.; Maass, W.A. A learning rule for very simple universal approximators consisting of a single layer of perceptrons. Neural Netw. 2008, 21, 786–795. [Google Scholar] [CrossRef] [PubMed]

- Kotsiantis, S.B. Supervised Machine Learning: A Review of Classification Techniques. Informatica 2007, 31, 249–268. [Google Scholar]

- Hagan, M.T.; Menhaj, M. Training feed-forward networks with the Marquardt algorithm. IEEE Trans. Neural Netw. 1994, 5, 989–999. [Google Scholar] [CrossRef] [PubMed]

- Mohri, M.; Rostamizadeh, A.; Talwalkar, A. Foundations of Machine Learning; MIT Press: Cambridge, MA, USA, 2012; ISBN 978-0-262-01825-8. [Google Scholar]

- Zhang, Z.; Friedrich, K. Artificial neural networks applied to polymer composites: A review. Compos. Sci. Technol. 2003, 63, 2029–2044. [Google Scholar] [CrossRef]

- Freeman, J.A.; Skapura, D.M. Neural Networks: Algorithms, Applications, and Programming Techniques; Addison-Wesley: Reading, MA, USA, 1991; ISBN 978-0201513769. [Google Scholar]

- Lagaros, N.D.; Papadrakikis, M. Learning improvement of neural networks used in structural optimization. Adv. Eng. Softw. 2004, 35, 9–25. [Google Scholar] [CrossRef]

- Rutkowski, L. Generalized regression neural networks in time-varying environment. In New Soft Computing Techniques for System Modeling, Pattern Classification and Image Processing. Studies in Fuzziness and Soft Computing, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2004; Volume 143, pp. 73–134. [Google Scholar]

- Demirhan, E.; Kandemirli, F.; Kandemirli, M.; Kovalishyn, V. Investigation of the physical and rheological properties of SBR-1712 rubber compounds by neural network approaches. Mater. Des. 2007, 28, 1737–1741. [Google Scholar] [CrossRef]

- Kopal, I.; Harničárová, M.; Valíček, J.; Kušnerová, M. Modelling the temperature dependence of dynamic mechanical properties and visco-elastic behavior of thermoplastic polyurethane using artificial neural network. Polymers 2017, 9, 519. [Google Scholar] [CrossRef]

- Fernandez-Martinez, R.; Hernandez, R.; Ibarretxe, J.; Jimbert, P.; Iturrondobeitia, M.; Guraya-Díez, T. Modeling of the Mechanical Properties of Carbon Black Reinforced Rubber Blends by Machine Learning Techniques. Appl. Mech. Mater. 2014, 627, 97–100. [Google Scholar] [CrossRef]

- Wang, B.; Ma, J.H.; Wu, J.P. Application of artificial neural network in prediction of abrasion of rubber composites. Mater. Des. 2013, 49, 802–807. [Google Scholar] [CrossRef]

- Ružiak, I.; Koštial, P.; Jančíková, Z.; Gajtanska, M.; Krišťák, Ľ.; Kopal, I.; Polakovič, P. Artificial Neural Networks Prediction of Rubber Mechanical Properties in Aged and Nonaged State. In Improved Performance of Materials; Öchsner, A., Altenbach, H., Eds.; Springer: Berlin, Germany, 2018; Volume 72, pp. 27–35. [Google Scholar]

- Karaağaç, B.; Inal, M.; Deniz, V. Artificial neural network approach for predicting optimum cure time of rubber compounds. Mater. Des. 2009, 30, 1685–1690. [Google Scholar] [CrossRef]

- Yang, X.; Behroozi, M.; Olatunbosun, O.A. A Neural Network Approach to Predicting Car Tyre Micro-Scale and Macro-Scale Behaviour. J. Intell. Learn. Syst. Appl. 2014, 6, 11–20. [Google Scholar] [CrossRef]

- Trebar, M.; Susteric, Z.; Lotric, U. Predicting mechanical properties of elastomers with neural networks. Polymer 2007, 48, 5340–5347. [Google Scholar] [CrossRef]

- Zhang, Z.; Klein, P.; Friedrich, K. Dynamic mechanical properties of PTFE based short carbon fibre reinforced composites: Experiment and artificial neural network prediction. Compos. Sci. Technol. 2002, 62, 1001–1009. [Google Scholar] [CrossRef]

- Nematollahi, M.; Jalali-Arani, A.; Golzar, K. Organoclay maleated natural rubber nanocomposite. Prediction of abrasion and mechanical properties by artificial neural network and adaptive neuro-fuzzy inference. Appl. Clay Sci. 2014, 97–98, 187–199. [Google Scholar] [CrossRef]

- Beale, M.H.; Hagan, M.T.; Demuth, H.B. Neural Network Toolbox™ User’s Guide; The MathWorks, Inc.: Natick, MA, USA, 2017. [Google Scholar]

- Bowden, G.J.; Maier, H.R.; Dandy, G.C. Optimal division of data for neural network models in water resources applications. Water Resour. Res. 2002, 38, 2-1–2-11. [Google Scholar] [CrossRef]

- Bennett, Ch.; Stewart, R.A.; Beal, C.D. ANN-based residential water end-use demand forecasting model. Expert Syst. Appl. 2013, 40, 1014–1023. [Google Scholar] [CrossRef] [Green Version]

- Wackerly, D.D.; Mendenhall, W.; Scheaffer, L.R. Mathematical Statistics with Applications, 7th ed.; Thomson Brooks/Cole: Belmont, CA, USA, 2008; ISBN 978-0495110811. [Google Scholar]

- Zhang, T.; Yu, B. Boosting with Early Stopping: Convergence and Consistency. Ann. Stat. 2005, 33, 1538–1579. [Google Scholar] [CrossRef]

- Sifaoui, A.; Abdelkrim, A.; Benrejeb, M. On the Use of Neural Network as a Universal Approximator. Int. J. Sci. Tech. Control Comput. Eng. 2008, 2, 386–399. [Google Scholar]

- Croeze, A.; Pittman, L.; Reynolds, W. Nonlinear Least-Squares Problems with the Gauss-Newton and Levenberg-Marquardt Methods; University of Mississippi: Oxford, UK, 2012. [Google Scholar]

- Menczel, D.J.; Prime, B.R. Thermal Analysis of Polymers; John Wiley: Hoboken, NJ, USA, 2009; ISBN 9780470423837. [Google Scholar]

- Simon, L. An Introduction to Multivariable Mathematics; Morgan & Claypool: St. Louis, CA, USA, 2008. [Google Scholar]

- Shi, F.; Wang, X.C.; Yu, L.; Li, Y. MATLAB 30 Case Analysis of MATLAB Neural Network; Beijing University Press: Beijing, China, 2009. [Google Scholar]

- Ward, I.M.; Sweeney, J. An Introduction to the Mechanical Properties of Solid Polymers, 2nd ed.; Wiley: Chichester, UK, 2004. [Google Scholar]

- Paliwal, M.; Kumar, U.A. Neural networks and statistical techniques: A review of applications. Expert Syst. Appl. 2009, 36, 2–17. [Google Scholar] [CrossRef]

- Bessa, M.A.; Bostanabad, R.; Liu, Z.; Hu, A.; Apley, D.W.; Brinson, C.; Chen, W.; Liu, W.K. A framework for data-driven analysis of materials under uncertainty: Countering the curse of dimensionality. Comput. Methods Appl. Mech. Eng. 2017, 320, 633–667. [Google Scholar] [CrossRef]

- Basem, F.J.; Mourada, A.I.; Alnaqbia, A.H. Prediction of the Mechanical Properties of PE/PP Blends Using Artificial Neural Networks. Procedia Eng. 2011, 10, 2713–2718. [Google Scholar]

- Zhang, Y.; Ge, S.; Tang, B.; Koga, T.; Rafailovich, M.; Sokolov, J.; Peiffer, D.G.; Li, Z.; Dias, A.J.; McElrath, K.O.; et al. Effect of carbon black and silica fillers in elastomer blends. Macromolecules 2001, 34, 7056–7065. [Google Scholar] [CrossRef]

- Le, B.A.; Yvonnet, J.; He, Q.C. Computational homogenization of nonlinear elastic materials using neural networks. Int. J. Numer. Meth. Eng. 2015, 104, 1061–1084. [Google Scholar] [CrossRef]

| Errorx | 12 phr | 25 phr | 40 phr | 60 phr | 85 phr |

|---|---|---|---|---|---|

| εb (%) | 0.33 | 5.92 | 0.67 | 0.97 | 2.38 |

| σb (%) | 0.44 | 8.82 | 1.57 | 1.08 | 3.04 |

| M100 (%) | 0.52 | 2.36 | 5.45 | 0.35 | 0.85 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kopal, I.; Labaj, I.; Harničárová, M.; Valíček, J.; Hrubý, D. Prediction of the Tensile Response of Carbon Black Filled Rubber Blends by Artificial Neural Network. Polymers 2018, 10, 644. https://doi.org/10.3390/polym10060644

Kopal I, Labaj I, Harničárová M, Valíček J, Hrubý D. Prediction of the Tensile Response of Carbon Black Filled Rubber Blends by Artificial Neural Network. Polymers. 2018; 10(6):644. https://doi.org/10.3390/polym10060644

Chicago/Turabian StyleKopal, Ivan, Ivan Labaj, Marta Harničárová, Jan Valíček, and Dušan Hrubý. 2018. "Prediction of the Tensile Response of Carbon Black Filled Rubber Blends by Artificial Neural Network" Polymers 10, no. 6: 644. https://doi.org/10.3390/polym10060644