Green Binder Based on Enzymatically Polymerized Eucalypt Kraft Lignin for Fiberboard Manufacturing: A Preliminary Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Lignin

2.2. Laccase Enzyme

2.3. Wood Fibers

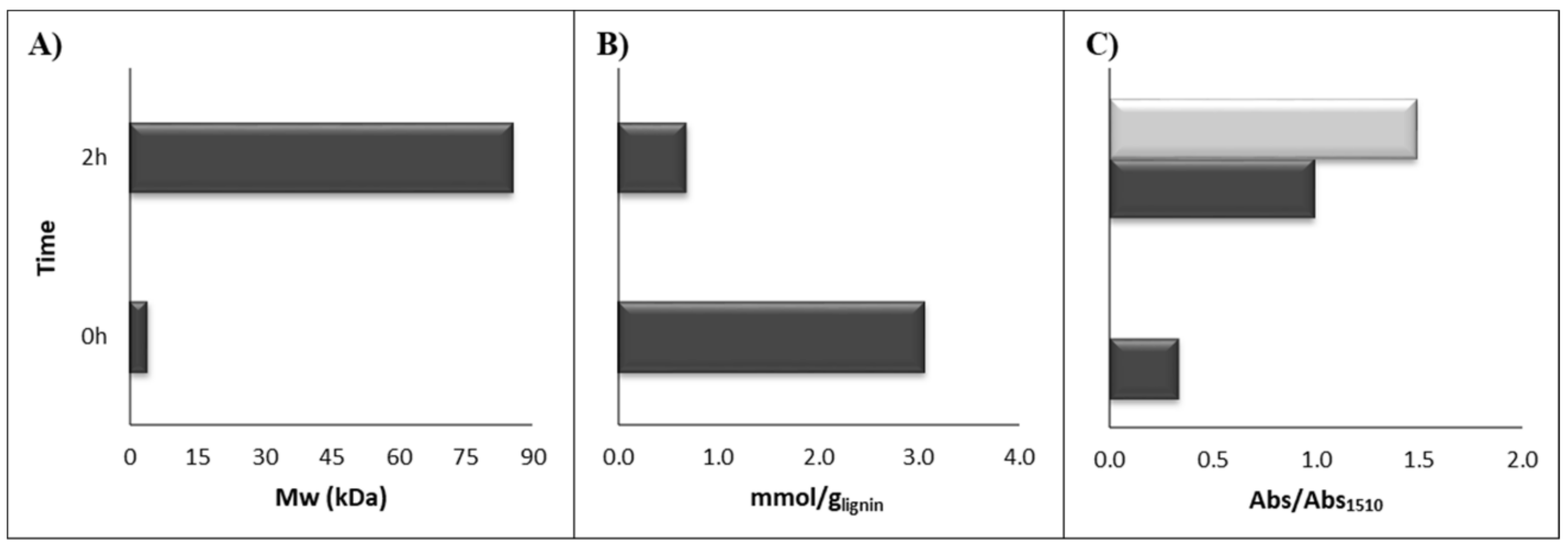

2.4. KL Enzymatic Polymerization

2.5. KL Characterization

2.5.1. Determination of Phenolic Content

2.5.2. Fourier Transform Infrared Spectroscopy (FTIR)

2.5.3. Molecular Weight Distribution

2.5.4. Nuclear Magnetic Resonance (NMR)

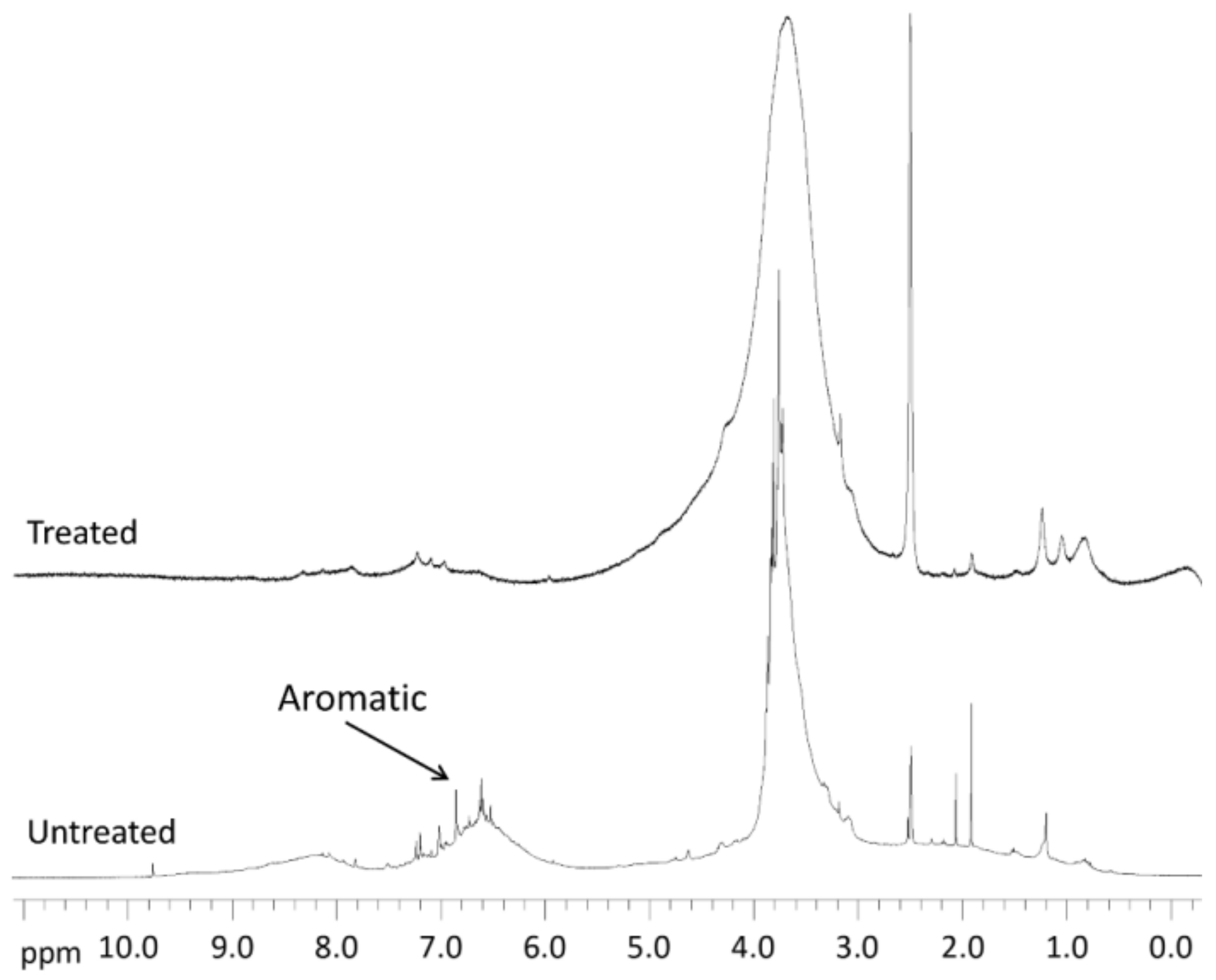

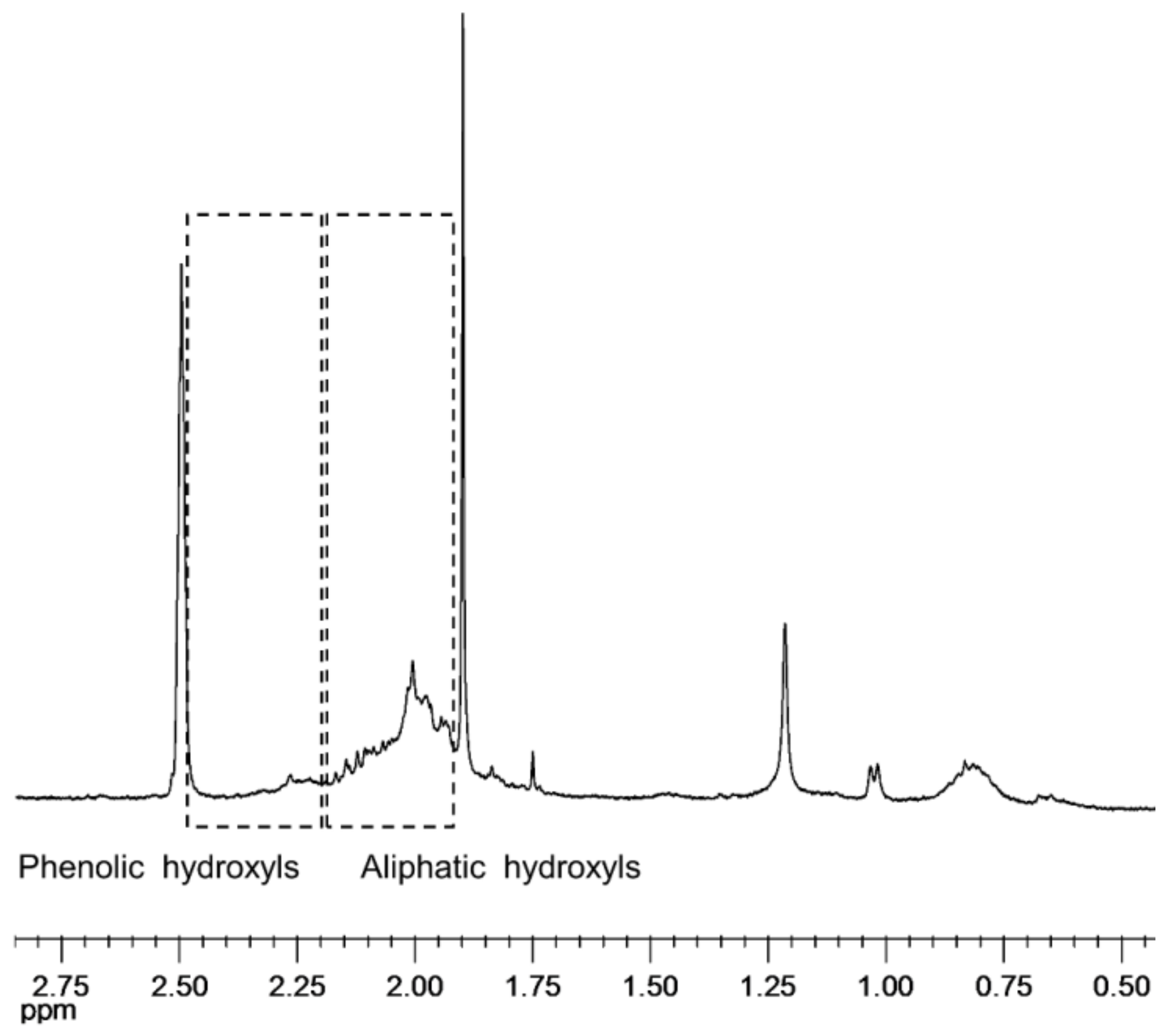

1H NMR

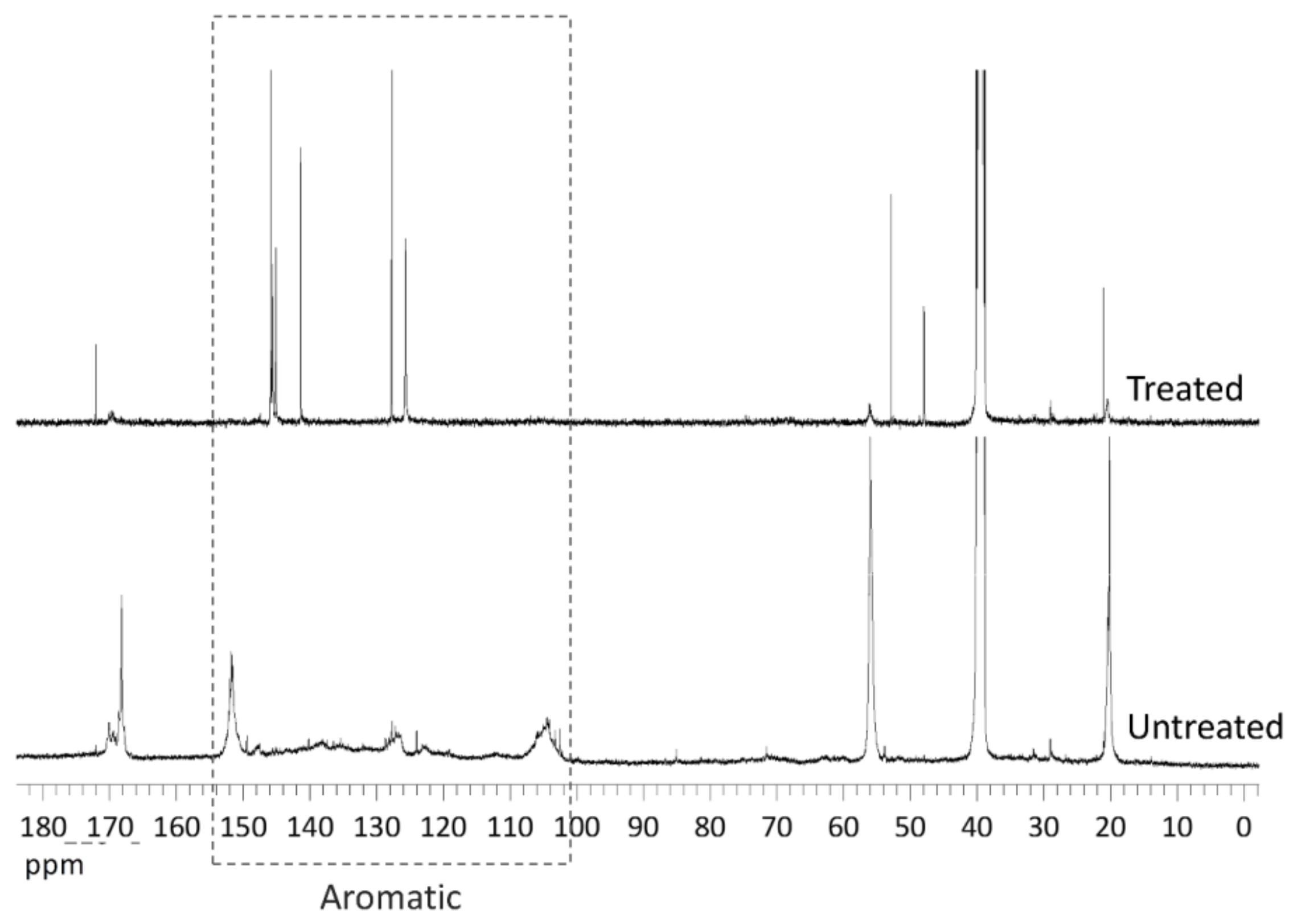

13C NMR

HSQC

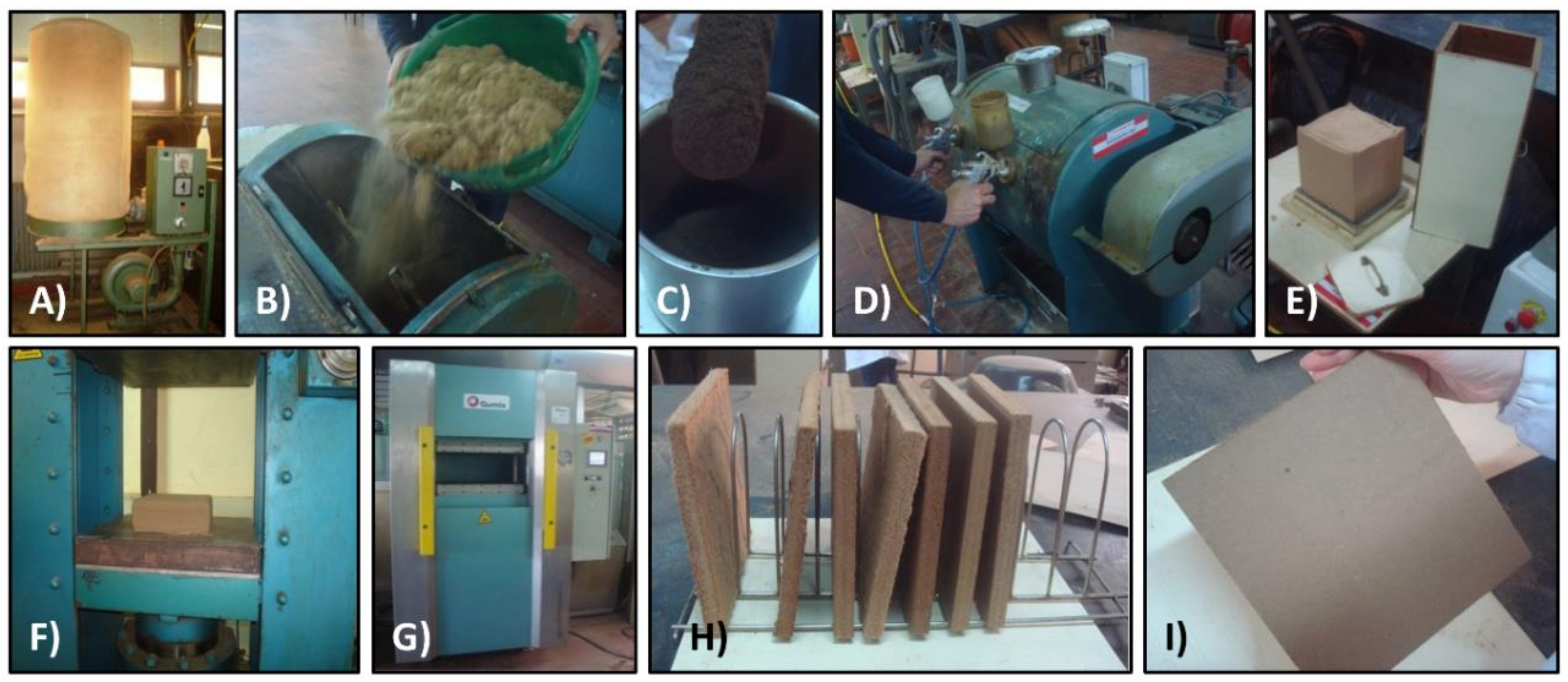

2.6. Medium-Density Fiberboards Production

2.6.1. Enzymatic Fiber Pre-Treatments

2.6.2. MDF Preparation

2.6.3. Medium-Density Fiberboard Properties

3. Results and Discussion

3.1. Kraft Lignin Enzymatic Polymerization and Characterization

3.2. MDF Manufacture

3.2.1. One-Component System

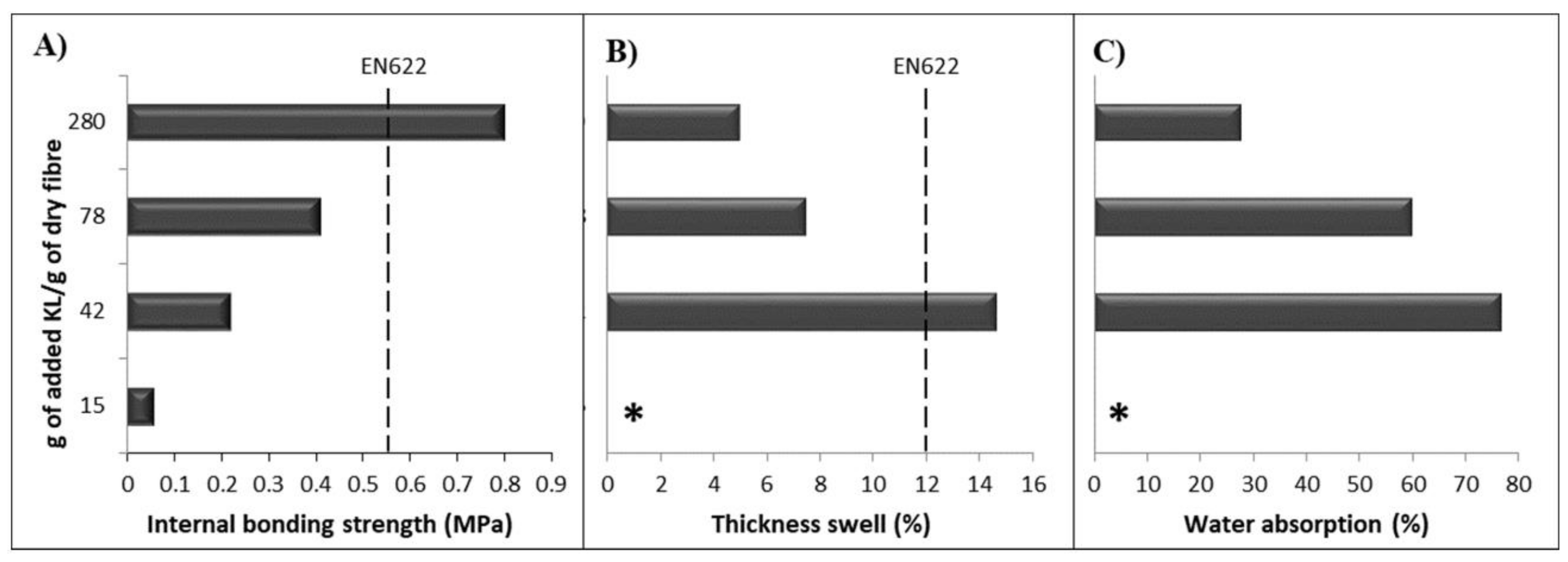

3.2.2. Two-Component System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kalami, S.; Arefmanesh, M.; Master, E.; Nejad, M. Replacing 100% of phenol in phenolic adhesive formulations with lignin. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Li, X.; Luo, J.; Gao, Q.; Li, J. “Green” bio-thermoset resins derived from soy protein isolate and condensed tannins. Ind. Crop. Prod. 2017, 108, 363–370. [Google Scholar] [CrossRef]

- Zhang, W.; Ma, Y.; Wang, C.; Li, S.; Zhang, M.; Chu, F. Preparation and properties of lignin–phenol–formaldehyde resins based on different biorefinery residues of agricultural biomass. Ind. Crop. Prod. 2013, 43, 326–333. [Google Scholar] [CrossRef]

- Felby, C.; Hassingboe, J.; Lund, M. Pilot-scale production of fiberboards made by laccase oxidized wood fibers: Board properties and evidence for cross-linking of lignin. Enzyme Microb. Technol. 2002, 31, 736–741. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, A.; Xue, L. A review of preparation of binderless fiberboards and its self-bonding mechanism. Wood Sci. Technol. 2015, 49, 661–679. [Google Scholar] [CrossRef]

- Álvarez, C.; Rojano, B.; Almaza, O.; Rojas, O.J.; Gañán, P. Self-Bonding Boards From Plantain Fiber Bundles After Enzymatic Treatment: Adhesion Improvement of Lignocellulosic Products by Enzymatic Pre-Treatment. J. Polym. Environ. 2011, 19, 182–188. [Google Scholar] [CrossRef]

- Widsten, P.; Kandelbauer, A. Adhesion improvement of lignocellulosic products by enzymatic pre-treatment. Biotechnol. Adv. 2008, 26, 379–386. [Google Scholar] [CrossRef] [PubMed]

- Pye, E. Kendall Industrial Lignin Production and Applications. In Biorefineries-Industrial Processes and Products; Wiley Online Books; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008; pp. 165–200. ISBN 978-3-527-31027-2. [Google Scholar]

- Felby, C.; Pedersen, L.S.; Nielsen, B.R. Enhanced auto adhesion of wood fibers using phenol oxidases. Holzforschung 1997, 51, 281–286. [Google Scholar] [CrossRef]

- Kharazipour, A.; Schindel, K.; Hüttermann, A. Enzymatic Activation of Wood Fibers for Wood Composite Production. In Enzyme Applications in Fiber Processing; ACS Symposium Series; American Chemical Society: Washington DC, USA, 1998; Volume 687, pp. 99–115. ISBN 0-8412-3547-3. [Google Scholar]

- Gouveia, S.; Fernández-Costas, C.; Sanromán, M.A.; Moldes, D. Polymerisation of Kraft lignin from black liquors by laccase from Myceliophthora thermophila: Effect of operational conditions and black liquor origin. Bioresour. Technol. 2013, 131, 288–294. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, S.; Fernández-Costas, C.; Sanromán, M.A.; Moldes, D. Enzymatic polymerisation and effect of fractionation of dissolved lignin from Eucalyptus globulus Kraft liquor. Bioresour. Technol. 2012, 121, 131–138. [Google Scholar] [CrossRef] [PubMed]

- Dashtban, M.; Schraft, H.; Syed, T.A.; Qin, W. Fungal biodegradation and enzymatic modification of lignin. Int. J. Biochem. Mol. Biol. 2010, 1, 36–50. [Google Scholar] [PubMed]

- Leonowicz, A.; Cho, N.; Luterek, J.; Wilkolazka, A.; Wojtas-Wasilewska, M.; Matuszewska, A.; Hofrichter, M.; Wesenberg, D.; Rogalski, J. Fungal laccase: Properties and activity on lignin. J. Basic Microbiol. 2001, 41, 185–227. [Google Scholar] [CrossRef]

- Hofrichter, M. Review: Lignin conversion by manganese peroxidase (MnP). Enzyme Microb. Technol. 2002, 30, 454–466. [Google Scholar] [CrossRef]

- Wong, D.W.S. Structure and action mechanism of ligninolytic enzymes. Appl. Biochem. Biotechnol. 2009, 157, 174–209. [Google Scholar] [CrossRef] [PubMed]

- Felby, C.; Thygesen, L.G.; Sanadi, A.; Barsberg, S. Native lignin for bonding of fiber boards--evaluation of bonding mechanisms in boards made from laccase-treated fibers of beech (Fagus sylvatica). Ind. Crop. Prod. 2004, 20, 181–189. [Google Scholar] [CrossRef]

- Areskogh, D.; Li, J.; Gellerstedt, G.; Henriksson, G. Investigation of the molecular weight increase of commercial lignosulfonates by laccase catalysis. Biomacromolecules 2010, 11, 904–910. [Google Scholar] [CrossRef] [PubMed]

- Faix, O. Fourier transform infrared spectroscopy. In Methods in Lignin Chemistry; Springer-Verlag: Berlin/Heidelberg, Germany, 1992; pp. 83–109. ISBN 3-540-50295-5. [Google Scholar]

- El Mansouri, N.-E.; Salvadó, J. Analytical methods for determining functional groups in various technical lignins. Ind. Crop. Prod. 2007, 26, 116–124. [Google Scholar] [CrossRef]

- European Standards EN 319:1993. Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; European Commission: Brussels, Belgium, 1993. [Google Scholar]

- Huber, D.; Pellis, A.; Daxbacher, A.; Nyanhongo, G.S.; Guebitz, G.M. Polymerization of Various Lignins via Immobilized Myceliophthora thermophila Laccase (MtL). Polymers 2016, 8, 280. [Google Scholar] [CrossRef]

- Ortner, A.; Huber, D.; Haske-Cornelius, O.; Weber, H.K.; Hofer, K.; Bauer, W.; Nyanhongo, G.S.; Guebitz, G.M. Laccase mediated oxidation of industrial lignins: Is oxygen limiting? Process Biochem. 2015, 50, 1277–1283. [Google Scholar] [CrossRef]

- Fernández-Costas, C.; Gouveia, S.; Sanromán, M.A.; Moldes, D. Structural characterization of Kraft lignins from different spent cooking liquors by 1D and 2D Nuclear Magnetic Resonance spectroscopy. Biomass Bioenergy 2014, 63, 156–166. [Google Scholar] [CrossRef]

- Capanema, E.A.; Balakshin, M.Y.; Kadla, J.F. A comprehensive approach for quantitative lignin characterization by NMR spectroscopy. J. Agric. Food Chem. 2004, 52, 1850–1860. [Google Scholar] [CrossRef] [PubMed]

- Maniet, G.; Schmetz, Q.; Jacquet, N.; Temmerman, M.; Gofflot, S.; Richel, A. Effect of steam explosion treatment on chemical composition and characteristic of organosolv fescue lignin. Ind. Crop. Prod. 2017, 99, 79–85. [Google Scholar] [CrossRef]

- Nugroho Prasetyo, E.; Kudanga, T.; Østergaard, L.; Rencoret, J.; Gutiérrez, A.; del Río, J.C.; Ignacio Santos, J.; Nieto, L.; Jiménez-Barbero, J.; Martínez, A.T.; et al. Polymerization of lignosulfonates by the laccase-HBT (1-hydroxybenzotriazole) system improves dispersibility. Bioresour. Technol. 2010, 101, 5054–5062. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Areskogh, D.; Li, J.; Nousiainen, P.; Gellerstedt, G.; Sipilä, J.; Henriksson, G. Oxidative polymerisation of models for phenolic lignin end-groups by laccase. Holzforschung 2010, 64, 21–34. [Google Scholar] [CrossRef]

- Back, E.L.; Salmen, N.L. Glass transitions of wood components hold implications for molding and pulping processes. Tappi 1982, 65, 107–110. [Google Scholar]

- Widsten, P.; Laine, J.E.; Qvintus-Leino, P.; Tuominen, S. Effect of high-temperature defibration on the chemical structure of hardwood. Holzforschung 2002, 56, 51–59. [Google Scholar] [CrossRef]

- Widsten, P.; Laine, J.E.; Qvintus-Leino, P.; Tuominen, S. Effect of high-temperature fiberization on the chemical structure of softwood. J. Wood Chem. Technol. 2001, 21, 227–245. [Google Scholar] [CrossRef]

- Müller, C.; Kües, U.; Schöpper, C.; Kharazipour, A. Natural Binders. In Wood Production, Wood Technology, and Biotechnological Impacts; Universitätsverlag Göttingen: Göttingen, Germany, 2007; pp. 433–467. ISBN 978-3-940344-11-3. [Google Scholar]

- Euring, M.; Rühl, M.; Ritter, N.; Kües, U.; Kharazipour, A. Laccase mediator systems for eco-friendly production of medium-density fiberboard (MDF) on a pilot scale: Physicochemical analysis of the reaction mechanism. Biotechnol. J. 2011, 6, 1253–1261. [Google Scholar] [CrossRef] [PubMed]

- Nasir, M.; Gupta, A.; Beg, M.D.H.; Chua, G.K.; Kumar, A. Fabrication of medium density fibreboard from enzyme treated rubber wood (Hevea brasiliensis) fibre and modified organosolv lignin. Int. J. Adhes. Adhes. 2013, 44, 99–104. [Google Scholar] [CrossRef]

- Kirsch, A.; Ostendorf, K.; Kharazipour, A.; Euring, M. Phenolics as mediators to accelerate the enzymatically initialized oxidation of laccase-mediator-systems for the production of medium density fiberboards. BioResources 2016, 11, 7091–7101. [Google Scholar] [CrossRef]

- Euring, M.; Kirsch, A.; Schneider, P.; Kharazipour, A. Lignin-Laccase-Mediator-Systems (LLMS) for the Production of Binderless Medium Density Fiberboards (MDF). J. Mater. Sci. Res. 2016, 5, 7. [Google Scholar] [CrossRef]

- Bouajila, J.; Limare, A.; Joly, C.; Dole, P. Lignin plasticization to improve binderless fiberboard mechanical properties. Polym. Eng. Sci. 2005, 45, 809–816. [Google Scholar] [CrossRef]

- Moya, R.; Saastamoinen, P.; Hernández, M.; Suurnäkki, A.; Arias, E.; Mattinen, M.-L. Reactivity of bacterial and fungal laccases with lignin under alkaline conditions. Bioresour. Technol. 2011, 102, 10006–10012. [Google Scholar] [CrossRef] [PubMed]

- Van de Pas, D.; Hickson, A.; Donaldson, L.; Lloyd-Jones, G.; Tamminen, T.; Fernyhough, A.; Mattinen, M.-L. Characterization of fractionated lignins polymerized by fungal laccases. BioResources 2011, 6, 1105–1121. [Google Scholar]

- Rathke, J.; Sinn, G.; Konnerth, J.; Müller, U. Strain measurements within fiber boards. Part i: Inhomogeneous strain distribution within medium density fiberboards (MDF) loaded perpendicularly to the plane of the board. Materials 2012, 5, 1115–1124. [Google Scholar] [CrossRef] [PubMed]

- Lora, J. Industrial commercial lignins: Sources, properties and applications. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008; pp. 225–241. ISBN 978-0-08-045316-3. [Google Scholar]

- Lund, M.; Eriksson, M.; Felby, C. Reactivity of a fungal laccase towards lignin in softwood kraft pulp. Holzforschung 2003, 57, 21–26. [Google Scholar] [CrossRef]

- American National Standard Institute ANSI A.208.2-2002. Medium Density Fiberboard (MDF) for Interior Application; American National Standard Institute: Washington DC, USA, 2002. [Google Scholar]

- European Standards EN 622-5:2010. Fibreboards Specifications. Part 5: Requirements for Dry Process Boards (MDF); European Commission: Brussels, Belgium, 2010. [Google Scholar]

| Treatment | One-Component System | Two-Component System | |||||||

|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | T9 | |

| Dry fiber (g) | 520 | 520 | 520 | 520 | 520 | 421 | 421 | 325 | 145 |

| KL (% w/w dry fiber) | 0 | 0 | 0 | 15 | 15 | 42 | 42 | 78 | 280 |

| Water added (% w/w dry fiber) | 12 | 12 | 12 | ||||||

| Enzyme dosage (U·g−1 dry fiber) | 0 | 29 | 29 | ||||||

| Enzyme dosage (U·g−1 KL) | 0 | 190 | 0 | 190 | 190 | 190 | |||

| Moisture content after blending (%) | 12 | 12 | 12 | 11 | 11 | 11 | 20 | 26 | 36 |

| Incubation time at 70°C (h) | 2 | 24 | 2 | 2 | 2 | 2 | |||

| Moisture content before pressing (%) | 11 | 11 | 11 | 10 | 10 | 10 | 12 | 13 | 15 |

| Fixed experimental conditions | |||||||||

| Wood fiber origin | Eucalyptus globulus (100%) | ||||||||

| KL origin | Eucalyptus globulus (100%) | ||||||||

| Target board density | 650–700 kg·m−3 | ||||||||

| Cold pressing time | 120 s | ||||||||

| Cold press plate position (H) | 30 mm | ||||||||

| Hot pressing temperature | 200 °C | ||||||||

| Hot press plate position (H) | 22 mm | 18.5 mm | 16.7 mm | ||||||

| Hot pressing times | 232 s | 124 s | 124 s | ||||||

| Final board size (W × L × H) | 250 mm × 250 mm × 16.7 mm | ||||||||

| Fiber | Incubation Conditions | Pressing Conditions | Scale | Board Properties | Reference | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laccase | T (°C) | Time (h) | pH | Enzyme Dosage (U·g−1 Fiber) | Press Factor (s/mm) | T (°C) | Density (kg·m−3) | MOE (GPa) | MOR (MPa) | IB (MPa) | WA (%) | TS (%) | ||||

| Fagus sylvatica | Control | Heat deactivated | 20 | 1.0 | 5 | 0 | 100 | 200 | Lab. | 850 | 3.42 | 25.3 | 0.91 | 143 | 45 | [9] |

| Treated | Trametes versicolor | 3.5 | 895 | 4.02 | 41.7 | 1.57 | 72 | 19 | ||||||||

| Fagus sylvatica | Control | Untreated | 50 | 0.5 | 7 | 0 | 25 | 200 | Pilot | 820 | (b) | (b) | 0.33 | 224 | 146 | [4] |

| Treated | M. thermophila | 6 | 858 | 3.70 | 40.1 | 0.82 | 109 | 69 | ||||||||

| 24 | 868 | 3.95 | 46.0 | 0.93 | 92 | 46 | ||||||||||

| Leaf sheath from commercial plants | Control | Untreated | 30 | 1.0 | 6 | 0 | 160 | 200 | Lab. | 1100 | 1.3 | 13.3 | - | 268.3 | 218.8 | [6] |

| Treated | Aspergillus oryzae | 6 | 1100 | 13.3 | 17.5 | - | 82.4 | 67.5 | ||||||||

| 12 | 1100 | 268.3 | 18.6 | - | 79.7 | 31.4 | ||||||||||

| 24 | 1100 | 218.8 | 18.7 | - | 80.5 | 30.1 | ||||||||||

| P. sylvestris (90%) P. radiata (10%) | Control | Heat deactivated | ≤120 | ≈0.5 | 6 | 0 | 22 | 200 | Pilot | 800 | - | ≈10 | ≈0.1 | - | ≈122 | [33] |

| Treated | Trametes villosa | 100 | 800 | - | ≈20 | ≈0.38 | - | ≈62 | ||||||||

| Havea brasiliensis | Control | - | 25 | 1.0 | 5 | - | 40 | 200 | Lab. | - | - | - | - | - | - | [34] |

| Treated | Trametes villosa | 9 | 750 | 3.6 | 9.3 | 0.67 | - | - | ||||||||

| Spruce. (80%) Fir (20%) | Control | Buffer + wax | ≤165 | ≈0.5 | 6 | 100 | 60 | 200 | Pilot | 850 | - | 19 | <0.1 | - | 32 | [35] |

| Treated | Trametes villosa + wax | 3.5 | 850 | - | 37 | 0.32 | - | 20 | ||||||||

| Spruce. (80%) Fir (20%) | Control | Buffer | - | - | 6 | 100 | 12 | 190 | Pilot | 750 | - | 12 | <0.1 | - | 100 | [36] |

| Treated | Trametes villosa | - | 20 | 0.42 | - | 50 | ||||||||||

| Treatment | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| One-Component System | Two-Component System | ||||||||

| T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | T9 | |

| Treatment | |||||||||

| KL (% w/w dry fiber) | 0 | 0 | 0 | 15 | 15 | 42 | 42 | 78 | 280 |

| Enzyme dose (U·g−1fiber) | 0 | 29 | 29 | ||||||

| Enzyme dose (U·g−1 KL) | 0 | 190 | 0 | 190 | 190 | 190 | |||

| Incubation time (h) | 2 | 24 | 2 | 2 | 2 | 2 | |||

| Board properties | |||||||||

| Density (kg·m−3) | 661 | 670 | 633 | 697 | 705 | 698 | 688 | 785 | 831 |

| IB (MPa) | <0.01 | <0.01 | <0.01 | <0.01 | 0.06 | 0.04 | 0.22 | 0.41 | 0.80 |

| WA (%) | D | D | D | D | D | 134.7 | 76.8 | 60.0 | 27.8 |

| TS (%) | D | D | D | D | D | 55.2 | 14.6 | 7.5 | 5.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gouveia, S.; Otero, L.A.; Fernández-Costas, C.; Filgueira, D.; Sanromán, Á.; Moldes, D. Green Binder Based on Enzymatically Polymerized Eucalypt Kraft Lignin for Fiberboard Manufacturing: A Preliminary Study. Polymers 2018, 10, 642. https://doi.org/10.3390/polym10060642

Gouveia S, Otero LA, Fernández-Costas C, Filgueira D, Sanromán Á, Moldes D. Green Binder Based on Enzymatically Polymerized Eucalypt Kraft Lignin for Fiberboard Manufacturing: A Preliminary Study. Polymers. 2018; 10(6):642. https://doi.org/10.3390/polym10060642

Chicago/Turabian StyleGouveia, Susana, Luis Alberto Otero, Carmen Fernández-Costas, Daniel Filgueira, Ángeles Sanromán, and Diego Moldes. 2018. "Green Binder Based on Enzymatically Polymerized Eucalypt Kraft Lignin for Fiberboard Manufacturing: A Preliminary Study" Polymers 10, no. 6: 642. https://doi.org/10.3390/polym10060642