Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MFCs

2.3. Characterization

2.3.1. Structural Characterization

2.3.2. Mechanical Characterization

3. Results and Discussion

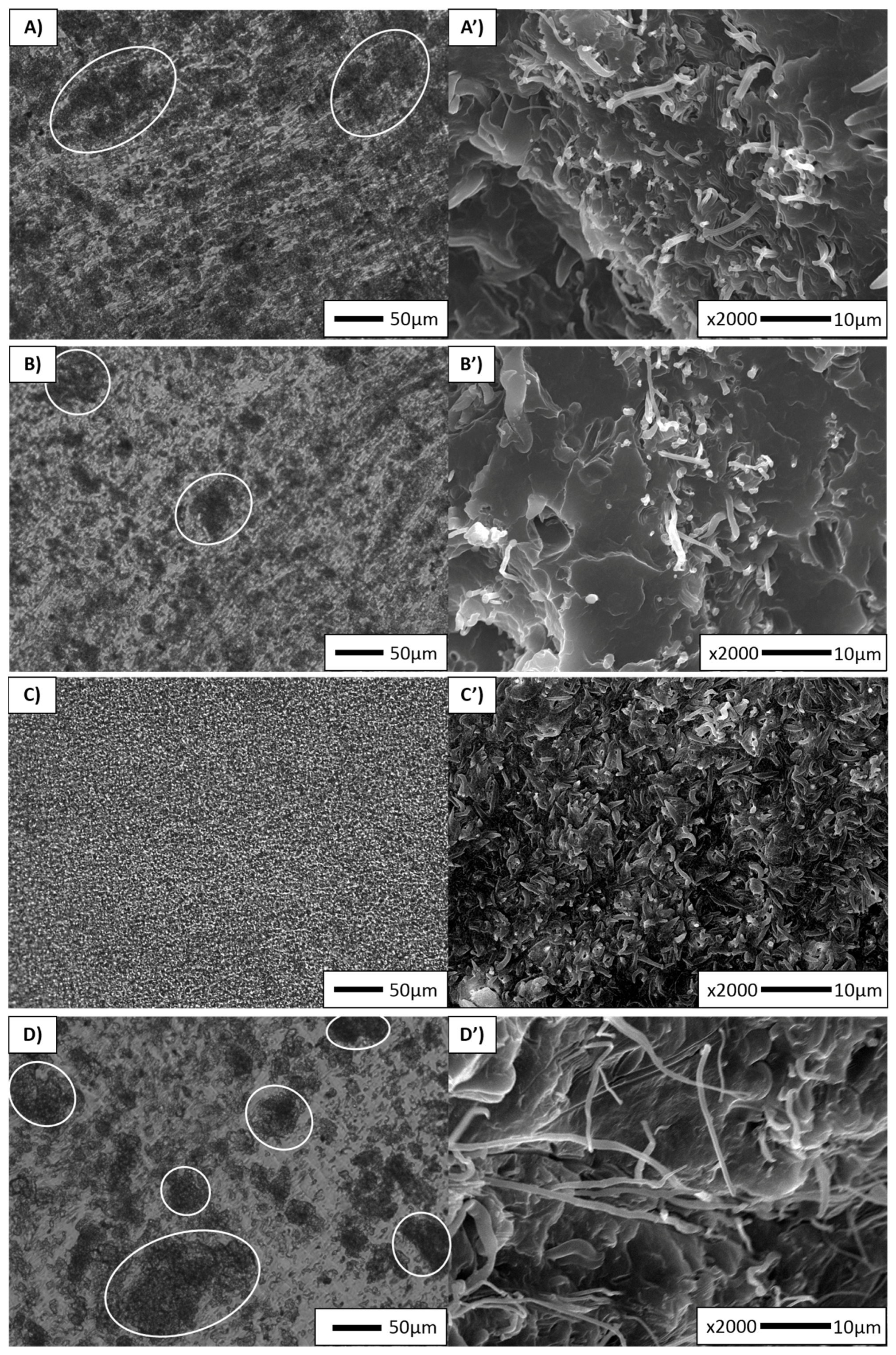

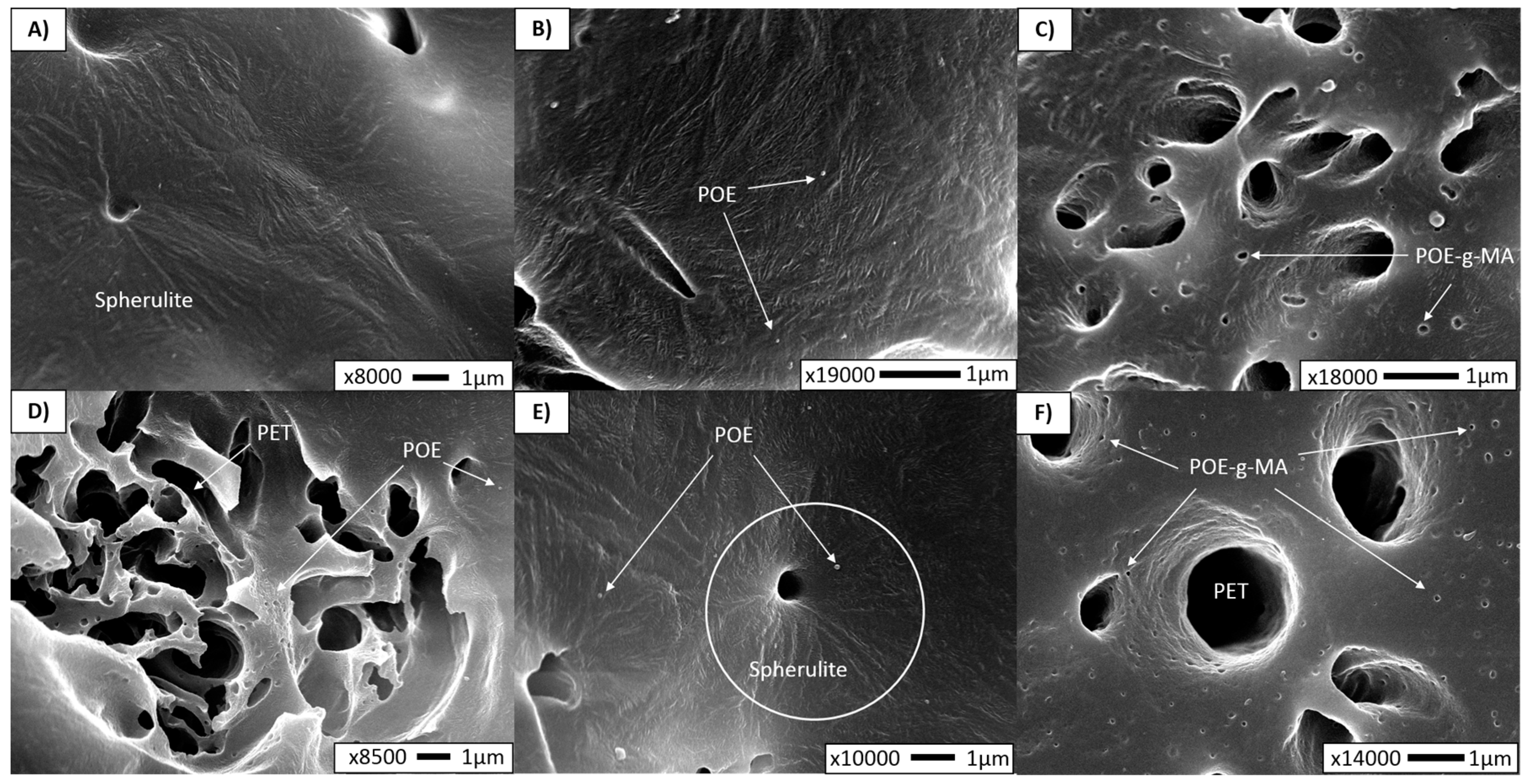

3.1. Morphology Development

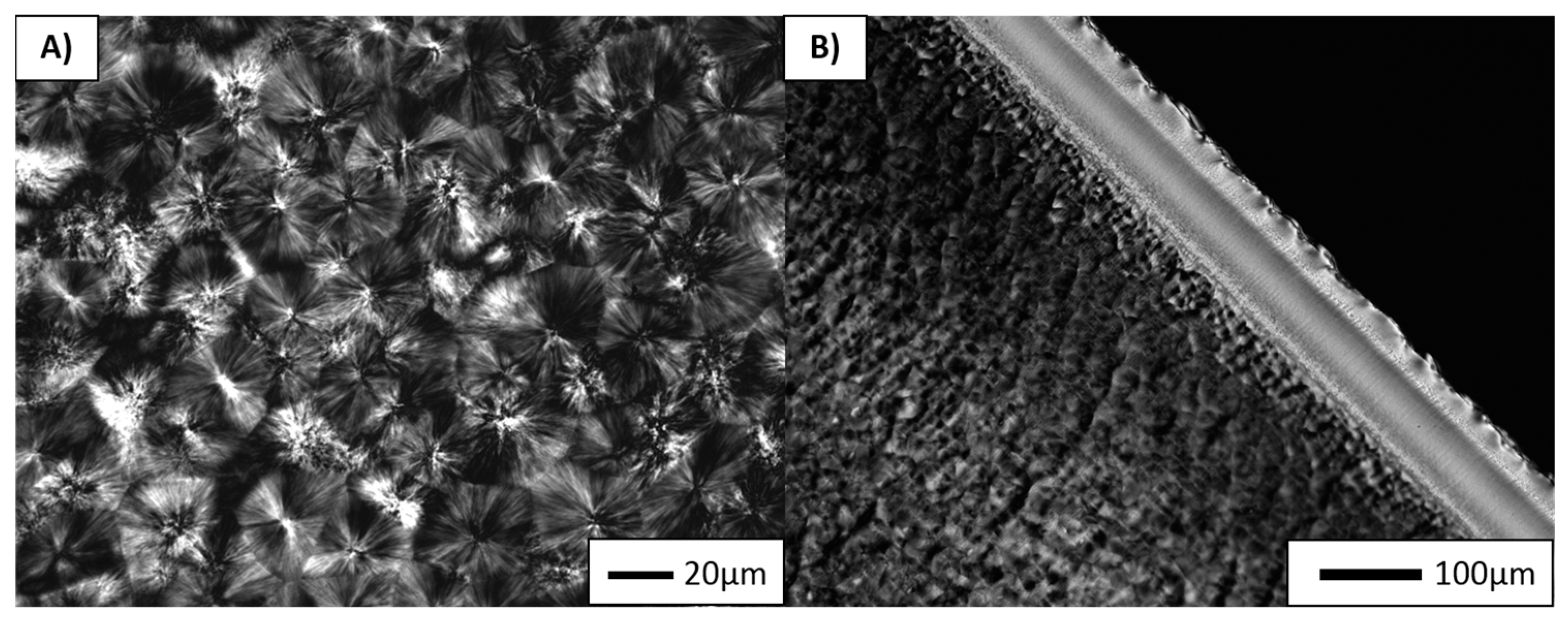

3.2. Development of Crystalline Morphologies

3.3. Crystallinity Development

4. Mechanical Properties

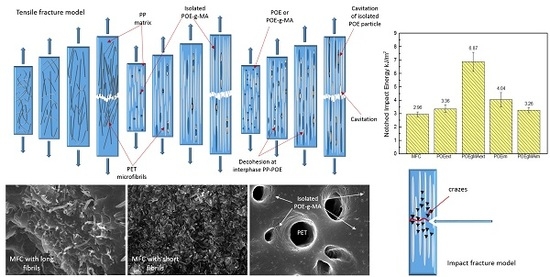

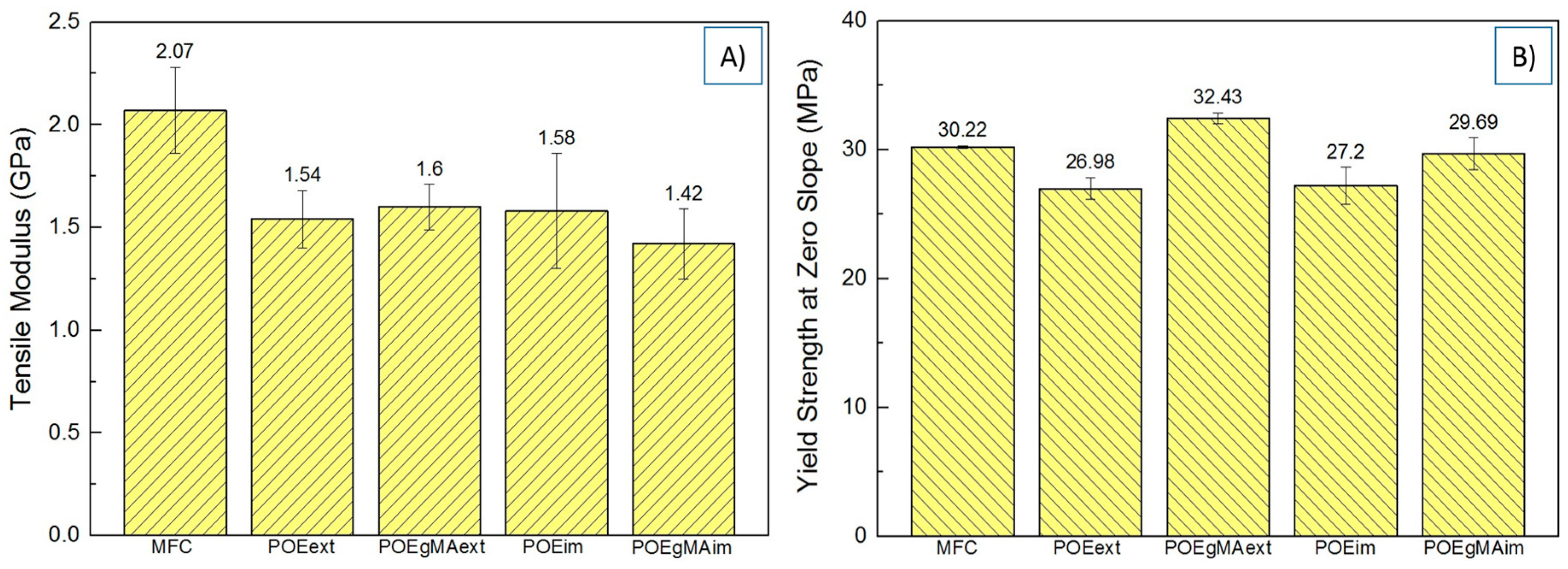

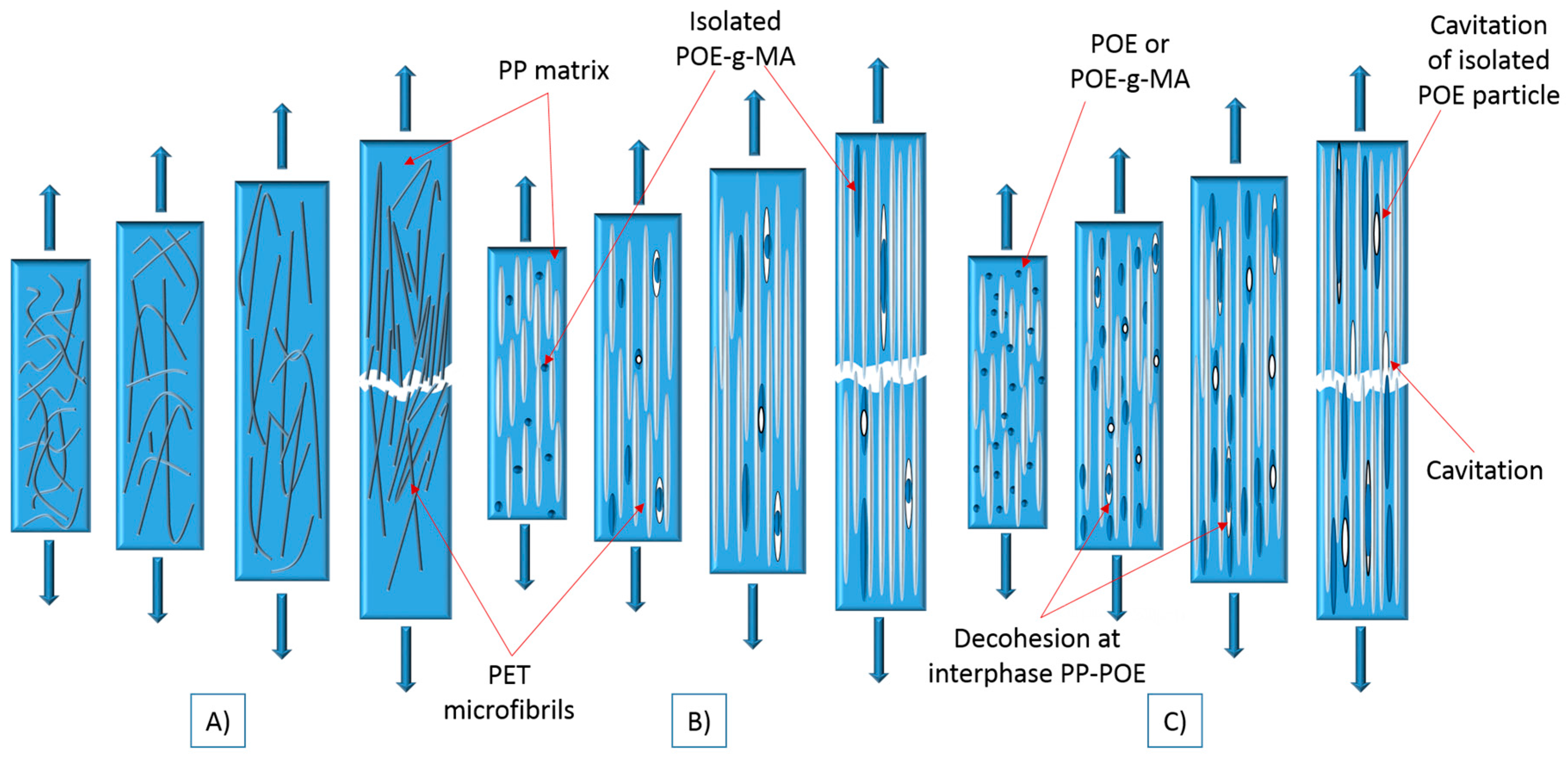

4.1. Tensile Behaviour

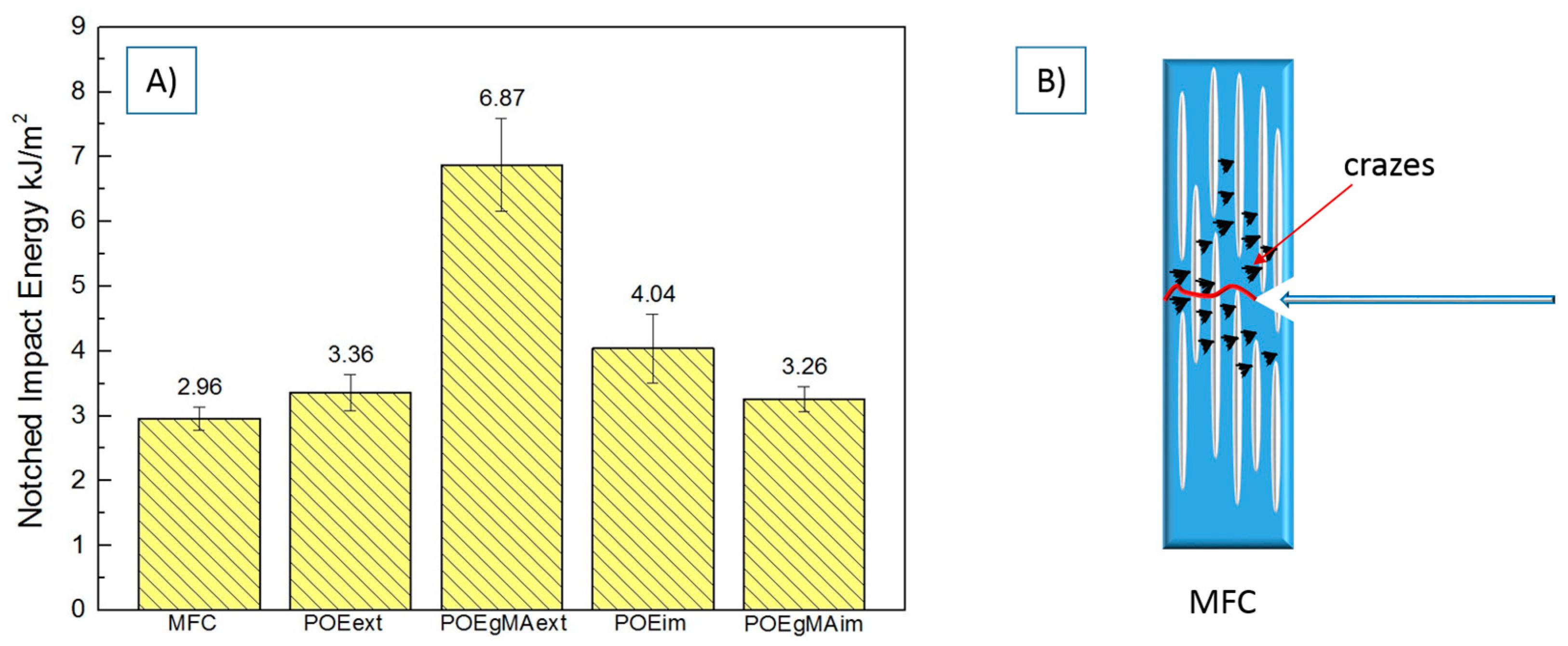

4.2. Impact Behaviour

4.3. Comparison to Non-Fibrillated Blends

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fu, S.-Y.; Lauke, B.; Mäder, E.; Yue, C.-Y.; Hu, X. Tensile properties of short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Bao, S.; Liang, G.; Tjong, S. Part II: Polymer-Polymer Composites with Premade Fibrous Reinforcement: Fracture Behavior of Short Carbon Fiber Reinforced Polymer Composites. In Synthetic Polymer–Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2012; pp. 117–143. [Google Scholar]

- McCardle, R.; Bhattacharyya, D.; Fakirov, S. Effect of Reinforcement Orientation on the Mechanical Properties of Microfibrillar PP/PET and PET Single-Polymer Composites. Macromol. Mater. Eng. 2012, 297, 711–723. [Google Scholar] [CrossRef]

- Fakirov, S. The Concept of Micro-or Nanofibrils Reinforced Polymer-Polymer Composites; Carl Hanser Verlag: Munich, Germany, 2012. [Google Scholar]

- Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. The Effect of Injection Molding Temperature on the Morphology and Mechanical Properties of PP/PET Blends and Microfibrillar Composites. Polymers 2016, 8, 355. [Google Scholar] [CrossRef] [Green Version]

- Yi, X.; Xu, L.; Wang, Y.-L.; Zhong, G.-J.; Ji, X.; Li, Z.-M. Morphology and properties of isotactic polypropylene/poly(ethylene terephthalate) in situ microfibrillar reinforced blends: Influence of viscosity ratio. Eur. Polym. J. 2010, 46, 719–730. [Google Scholar] [CrossRef]

- Chiu, H.-T.; Hsiao, Y.-K. Compatibilization of poly(ethylene terephthalate)/polypropylene blends with maleic anhydride grafted polyethylene-octene elastomer. J. Polym. Res. 2006, 13, 153–160. [Google Scholar] [CrossRef]

- Moini Jazani, O.; Khoramabadi, M.A.; Salehi, M.M.; Riazi, H.; Soltanokottabi, F. Effective parameters on the phase morphology and mechanical properties of PP/PET/SEBS ternary polymer blends. J. Part. Sci. Technol. 2015, 1, 39–48. [Google Scholar]

- Jayanarayanan, K.; Thomas, S.; Joseph, K. Effect of compatibilizer on the morphology development, static and dynamic mechanical properties of polymer-polymer composites from LDPE and PET. Int. J. Plast. Technol. 2015, 19, 84–105. [Google Scholar] [CrossRef]

- Heino, M.; Kirjava, J.; Hietaoja, P. Compatibilization of polyethylene terephthalate/polypropylene blends with styrene–ethylene/butylene–styrene (SEBS) block copolymers. J. Appl. Polym. Sci. 1997, 65, 241–249. [Google Scholar] [CrossRef]

- Asgari, M.; Masoomi, M. Thermal and impact study of PP/PET fibre composites compatibilized with glycidyl methacrylate and maleic anhydride. Compos. Part B Eng. 2012, 43, 1164–1170. [Google Scholar] [CrossRef]

- Zhang, X.; Li, B.; Wang, K.; Zhang, Q.; Fu, Q. The effect of interfacial adhesion on the impact strength of immiscible PP/PETG blends compatibilized with triblock copolymers. Polymer 2009, 50, 4737–4744. [Google Scholar] [CrossRef]

- Pang, Y.; Jia, D.; Hu, H.; Hourston, D.; Song, M. Effects of a compatibilizing agent on the morphology, interface and mechanical behaviour of polypropylene/poly(ethylene terephthalate) blends. Polymer 2000, 41, 357–365. [Google Scholar] [CrossRef]

- Entezam, M.; Khonakdar, H.A.; Yousefi, A.A.; Jafari, S.H.; Wagenknecht, U.; Heinrich, G.; Kretzschmar, B. Influence of interfacial activity and micelle formation on rheological behavior and microstructure of reactively compatibilized PP/PET blends. Macromol. Mater. Eng. 2012, 297, 312–328. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Lin, R.; Fuchs, C.; Friedrich, K. Contribution of coalescence to microfibril formation in polymer blends during cold drawing. J. Macromol. Sci. Part B Phys. 2007, 46, 183–194. [Google Scholar] [CrossRef]

- Friedrich, K.; Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Ishii, M.; Harrass, M. Microfibrillar reinforced composites from PET/PP blends: Processing, morphology and mechanical properties. Compos. Sci. Technol. 2005, 65, 107–116. [Google Scholar] [CrossRef]

- Schrauwen, B.B. Deformation and Failure of Semi-Crystalline Polymers: Influence of Micro and Molecular Structure. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, January 2003. [Google Scholar]

- Perkins, W.G. Polymer toughness and impact resistance. Polym. Eng. Sci. 1999, 39, 2445–2460. [Google Scholar] [CrossRef]

- Zhao, Z.; Yang, Q.; Kong, M.; Tang, D.; Chen, Q.; Liu, Y.; Lou, F.; Huang, Y.; Liao, X. Unusual hierarchical structures of micro-injection molded isotactic polypropylene in presence of an in situ microfibrillar network and a β-nucleating agent. RSC Adv. 2015, 5, 43571–43580. [Google Scholar] [CrossRef]

- Harel, H.; Marom, G. On crystalline interfaces in composite materials. Acta Polym. 1998, 49, 583–587. [Google Scholar] [CrossRef]

- Quan, H.; Li, Z.-M.; Yang, M.-B.; Huang, R. On transcrystallinity in semi-crystalline polymer composites. Compos. Sci. Technol. 2005, 65, 999–1021. [Google Scholar] [CrossRef]

- Yalcin, B.; Cakmak, M. Superstructural hierarchy developed in coupled high shear/high thermal gradient conditions of injection molding in nylon 6 nanocomposites. Polymer 2004, 45, 2691–2710. [Google Scholar] [CrossRef]

- Meeten, G. Refraction and extinction of polymers. In Optical Properties of Polymers; Elsevier Applied Science Publishers Ltd.: Amsterdam, The Netherlands, 1986; pp. 1–62. [Google Scholar]

- Jayanarayanan, K.; Bhagawan, S.; Thomas, S.; Joseph, K. Morphology development and non isothermal crystallization behaviour of drawn blends and microfibrillar composites from PP and PET. Polym. Bull. 2008, 60, 525–532. [Google Scholar] [CrossRef]

- Xu, J.; Ye, H.; Zhang, S.; Guo, B. Organization of Twisting Lamellar Crystals in Birefringent Banded Polymer Spherulites: A Mini-Review. Crystals 2017, 7, 241. [Google Scholar] [CrossRef]

- Zhang, S.; Lin, W.; Zhu, L.; Wong, C.P.; Bucknall, D.G. γ-Form Transcrystals of Poly propylene) Induced by Individual Carbon Nanotubes. Macromol. Chem. Phys. 2010, 211, 1348–1354. [Google Scholar] [CrossRef]

- Jayanarayanan, K.; Thomas, S.; Joseph, K. In situ microfibrillar blends and composites of polypropylene and poly(ethylene terephthalate): Morphology and thermal properties. J. Polym. Res. 2011, 18, 1–11. [Google Scholar] [CrossRef]

- Marcinčin, A. Modification of fiber-forming polymers by additives. Prog. Polym. Sci. 2002, 27, 853–913. [Google Scholar] [CrossRef]

- Friedrich, K.; Ueda, E.; Kamo, H.; Evstatiev, M.; Krasteva, B.; Fakirov, S. Direct electron microscopic observation of transcrystalline layers in microfibrillar reinforced polymer-polymer composites. J. Mater. Sci. 2002, 37, 4299–4305. [Google Scholar] [CrossRef]

- Li, Z.M.; Li, L.B.; Shen, K.Z.; Yang, W.; Huang, R.; Yang, M.B. Transcrystalline morphology of an in situ microfibrillar poly(ethylene terephthalate)/poly(propylene) blend fabricated through a slit extrusion hot stretching-quenching process. Macromol. Commun. 2004, 25, 553–558. [Google Scholar] [CrossRef]

- Denchev, Z.; Dencheva, N. Preparation, mechanical properties and structural characterization of microfibrillar composites based on polyethylene/polyamide blends. In Synthetic Polymer-Polymer Composites; Hanser: Munich, Germany, 2012; pp. 465–524. [Google Scholar]

- Xu, L.; Zhong, G.-J.; Ji, X.; Li, Z.-M. Crystallization behavior and morphology of one-step reaction compatibilized microfibrillar reinforced isotactic polypropylene/poly(ethylene terephthalate)(iPP/PET) blends. Chin. J. Polym. Sci. 2011, 29, 540–551. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Kallo, A.; Szafner, A.; Bodor, G.; Senyei, Z. Morphological study on the effect of elastomeric impact modifiers in polypropylene systems. Polymer 1979, 20, 37–43. [Google Scholar] [CrossRef]

- Martuscelli, E.; Silvestre, C.; Abate, G. Morphology, crystallization and melting behaviour of films of isotactic polypropylene blended with ethylene-propylene copolymers and polyisobutylene. Polymer 1982, 23, 229–237. [Google Scholar] [CrossRef]

- Danesi, S.; Porter, R.S. Blends of isotactic polypropylene and ethylene-propylene rubbers: Rheology, morphology and mechanics. Polymer 1978, 19, 448–457. [Google Scholar] [CrossRef]

- Chen, Y.; Zhong, G.; Li, Z. Microfibril Reinforced Polymer-Polymer Composites via Hot Stretching: Preparation, Structure and Properties; Hanser: Munich, Germany, 2012. [Google Scholar]

- G’Sell, C.; Bai, S.-L.; Hiver, J.-M. Polypropylene/polyamide 6/polyethylene–octene elastomer blends. Part 2: Volume dilatation during plastic deformation under uniaxial tension. Polymer 2004, 45, 5785–5792. [Google Scholar] [CrossRef]

- Shi, D.; Liu, E.; Tan, T.; Shi, H.; Jiang, T.; Yang, Y.; Luan, S.; Yin, J.; Mai, Y.-W.; Li, R.K. Core/shell rubber toughened polyamide 6: An effective way to get good balance between toughness and yield strength. RSC Adv. 2013, 3, 21563–21569. [Google Scholar] [CrossRef]

- Argon, A.; Cohen, R. Toughenability of polymers. Polymer 2003, 44, 6013–6032. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Bechtold, G.; Friedrich, K. Structure-property relationships of injection-and compression-molded microfibrillar-reinforced PET/PA-6 composites. Adv. Polym. Technol. 2000, 19, 249–259. [Google Scholar] [CrossRef]

- Redakcji, O. Plastic deformation and cavitation in semicrystalline polymers studied by X-ray methods. Polimery 2014, 59, 533. [Google Scholar] [CrossRef]

- Meijer, H.E.; Govaert, L.E. Mechanical performance of polymer systems: The relation between structure and properties. Prog. Polym. Sci. 2005, 30, 915–938. [Google Scholar] [CrossRef]

- Galeski, A. Strength and toughness of crystalline polymer systems. Prog. Polym. Sci. 2003, 28, 1643–1699. [Google Scholar] [CrossRef]

- Wang, J.; Wu, H.; Guo, S. Realizing simultaneous reinforcement and toughening in polypropylene based on polypropylene/elastomer via control of the crystalline structure and dispersed phase morphology. RSC Adv. 2016, 6, 1313–1323. [Google Scholar] [CrossRef]

| Material | PP/PET wt % | CA wt % |

|---|---|---|

| MFC | 80/20 | 0 |

| POEEXT | 75.2/18.8 | 6 EXT |

| POE-g-MAEXT | 75.2/18.8 | 6 EXT |

| POEIM | 75.2/18.8 | 6 IM |

| POE-g-MAIM | 75.2/18.8 | 6 IM |

| Material | Spherulite Size (µm) | Fibril Diameter (µm) |

|---|---|---|

| PP MFC | 22.3 ± 0.8 8.9 ± 0.4 | - 0.6 ± 0.2 |

| POEEXT | 5.5 ± 0.7 | 0.8 ± 0.3 |

| POE-g-MAEXT | 4.2 ± 0.3 | 0.5 ± 0.1 |

| POEIM | 7.2 ± 0.4 | 0.7 ± 0.3 |

| POE-g-MAIM | 7.6 ± 0.4 | 0.6 ± 0.2 |

| Material | TmPP (°C) | TcPP (°C) | Tconset (°C) | Tcendset (°C) | αcPP (%) |

|---|---|---|---|---|---|

| PP MFC | 171.5 ± 0.2 170.2 ± 0.8 | 118.8 ± 0.1 122.8 ± 0.7 | 122.5 ± 1.2 127.2 ± 0.2 | 108.1 ± 1.4 112.8 ± 0.4 | 47.05 ± 0.8 47.35 ± 2.2 |

| POEEXT | 170.1 ± 0.4 | 123.1 ± 0.6 | 127.1 ± 0.2 | 113.2 ± 0.1 | 48.40 ± 0.5 |

| POE-g-MAEXT | 170.1 ± 0.4 | 118.1 ± 0.6 | 121.5 ± 0.2 | 109.3 ± 0.9 | 50.01 ± 1.9 |

| POEIM | 169.3 ± 0.9 | 122.9 ± 0.4 | 127.1 ± 0.2 | 113.2 ± 0.3 | 51.65 ± 2.9 |

| POE-g-MAIM | 170.1 ± 1.2 | 116.4 ± 0.6 | 123.0 ± 0.1 | 108.3 ± 0.5 | 49.44 ± 2.8 |

| Material | Strain at Yield (%) | Strain at Break (%) |

|---|---|---|

| MFC | 3.74 ± 0.9 | 5.29 ± 0.9 |

| POEEXT | 6.84 ± 0.2 | 10.69 ± 1.7 |

| POE-g-MAEXT POEIM POE-g-MAIM | 11.90 ± 0.3 6.52 ± 1.1 8.91 ± 1.4 | 190.37 ± 162.8 9.70 ± 2.3 11.42 ± 2.4 |

| Material | Tensile Modulus GPa | Yield Strength MPa | Strain at Break % | Impact Strength kJ/m2 |

|---|---|---|---|---|

| PP IMB | 1.47 ± 0.1 1.72 ± 0.1 | 17.3 ± 1.2 24.8 ± 0.4 | >500 4.78 ± 0.5 | 1.45 ± 0.2 2.06 ± 0.4 |

| IMBPOEext | 1.58 ± 0.1 | 27.59 ± 0.7 | 10.43 ± 2.6 | 3.04 ± 0.5 |

| IMBPOE-g-MAext POE-g-MAEXT MFC | 1.21 ± 0.1 1.60 ± 0.1 2.07 ± 0.2 | 29.54 ± 0.1 32.43 ± 0.4 30.22 ± 0.1 | 10.48 ± 4.8 190.32 ± 162.8 5.29 ± 0.9 | 6.55 ± 1.9 6.87 ± 0.7 2.96 ± 0.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuzmanović, M.; Delva, L.; Mi, D.; Martins, C.I.; Cardon, L.; Ragaert, K. Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA. Polymers 2018, 10, 291. https://doi.org/10.3390/polym10030291

Kuzmanović M, Delva L, Mi D, Martins CI, Cardon L, Ragaert K. Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA. Polymers. 2018; 10(3):291. https://doi.org/10.3390/polym10030291

Chicago/Turabian StyleKuzmanović, Maja, Laurens Delva, Dashan Mi, Carla Isabel Martins, Ludwig Cardon, and Kim Ragaert. 2018. "Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA" Polymers 10, no. 3: 291. https://doi.org/10.3390/polym10030291

APA StyleKuzmanović, M., Delva, L., Mi, D., Martins, C. I., Cardon, L., & Ragaert, K. (2018). Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA. Polymers, 10(3), 291. https://doi.org/10.3390/polym10030291