Polarization Properties and Polarization Depth Profiles of (Cd:Zn)S/P(VDF-TrFE) Composite Films in Dependence of Optical Excitation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Electrical, Ferroelectric and Pyroelectric Properties

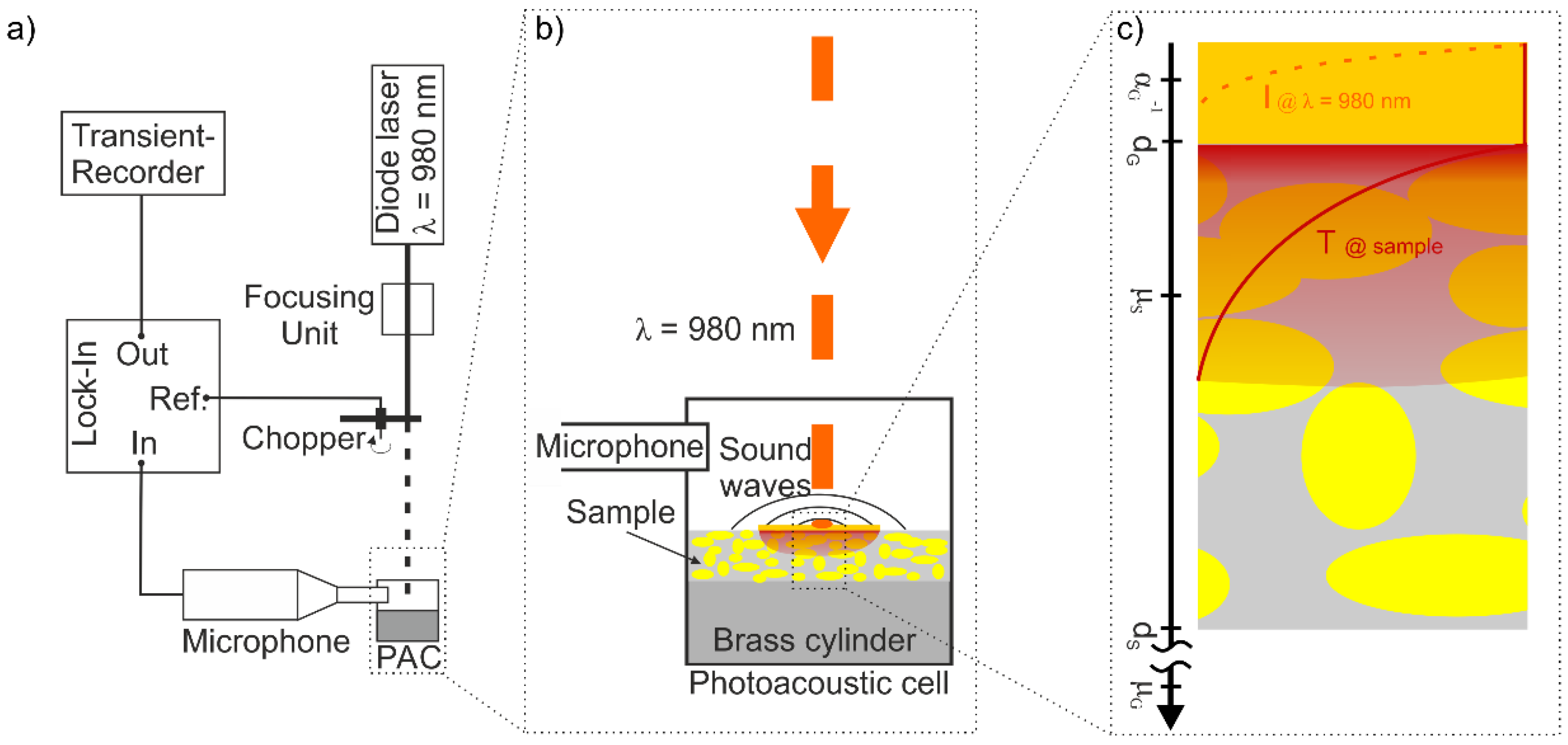

2.3. Characterization of the Pyroelectric Depth Profile

2.4. Photo-Acoustic Characterization of the Thermal Properties

3. Results

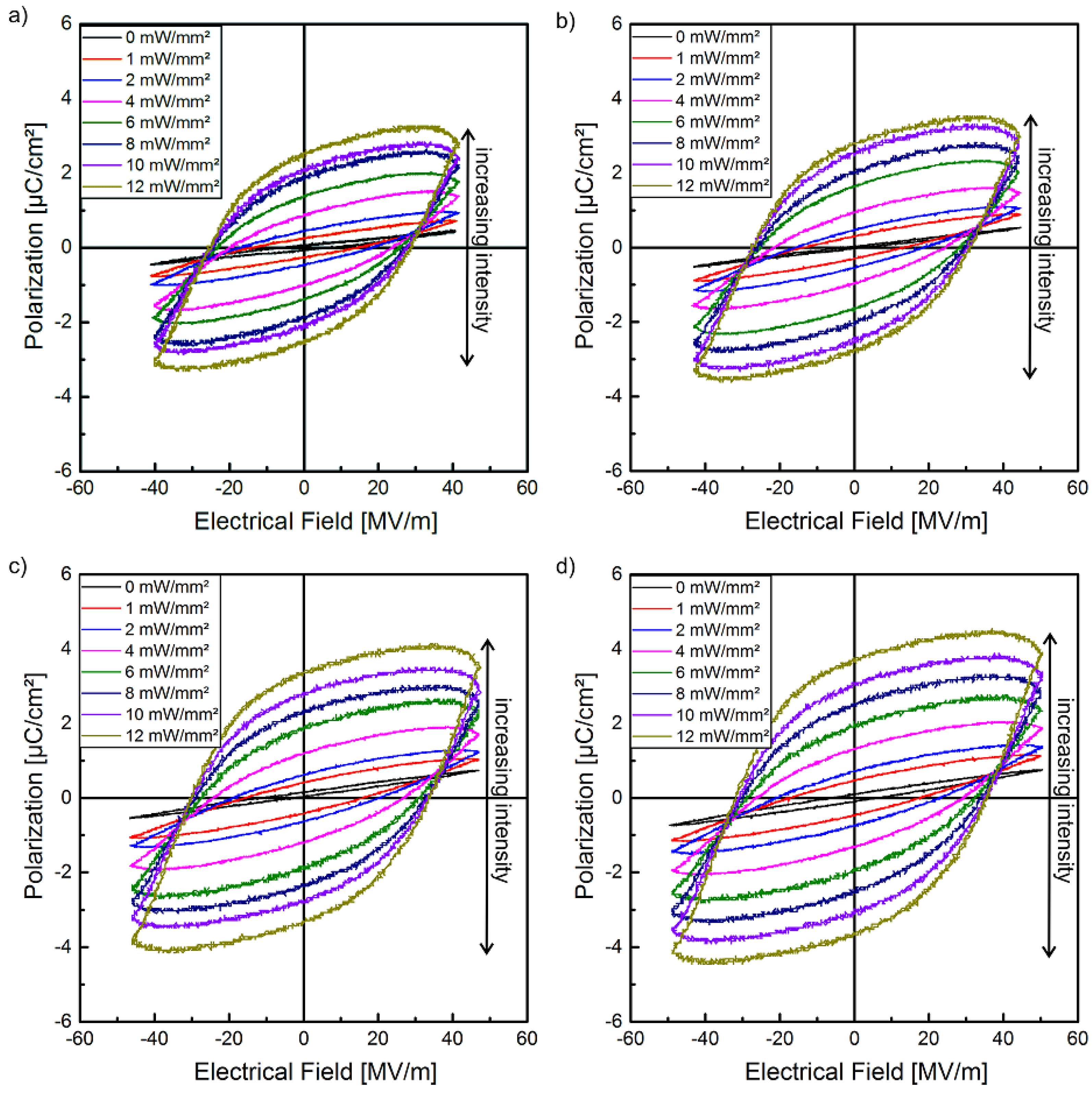

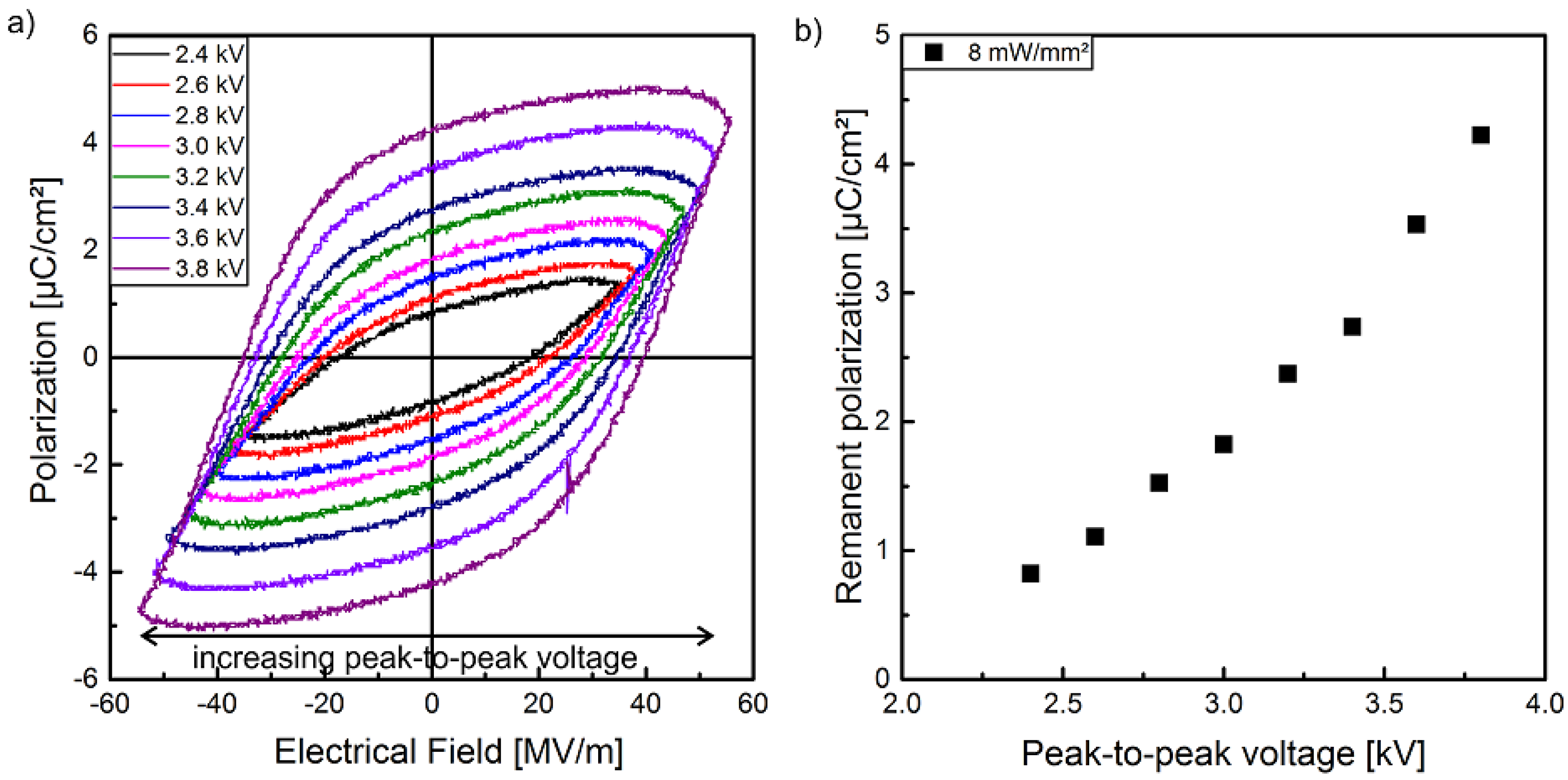

3.1. Electrical and Ferroelectric Properties

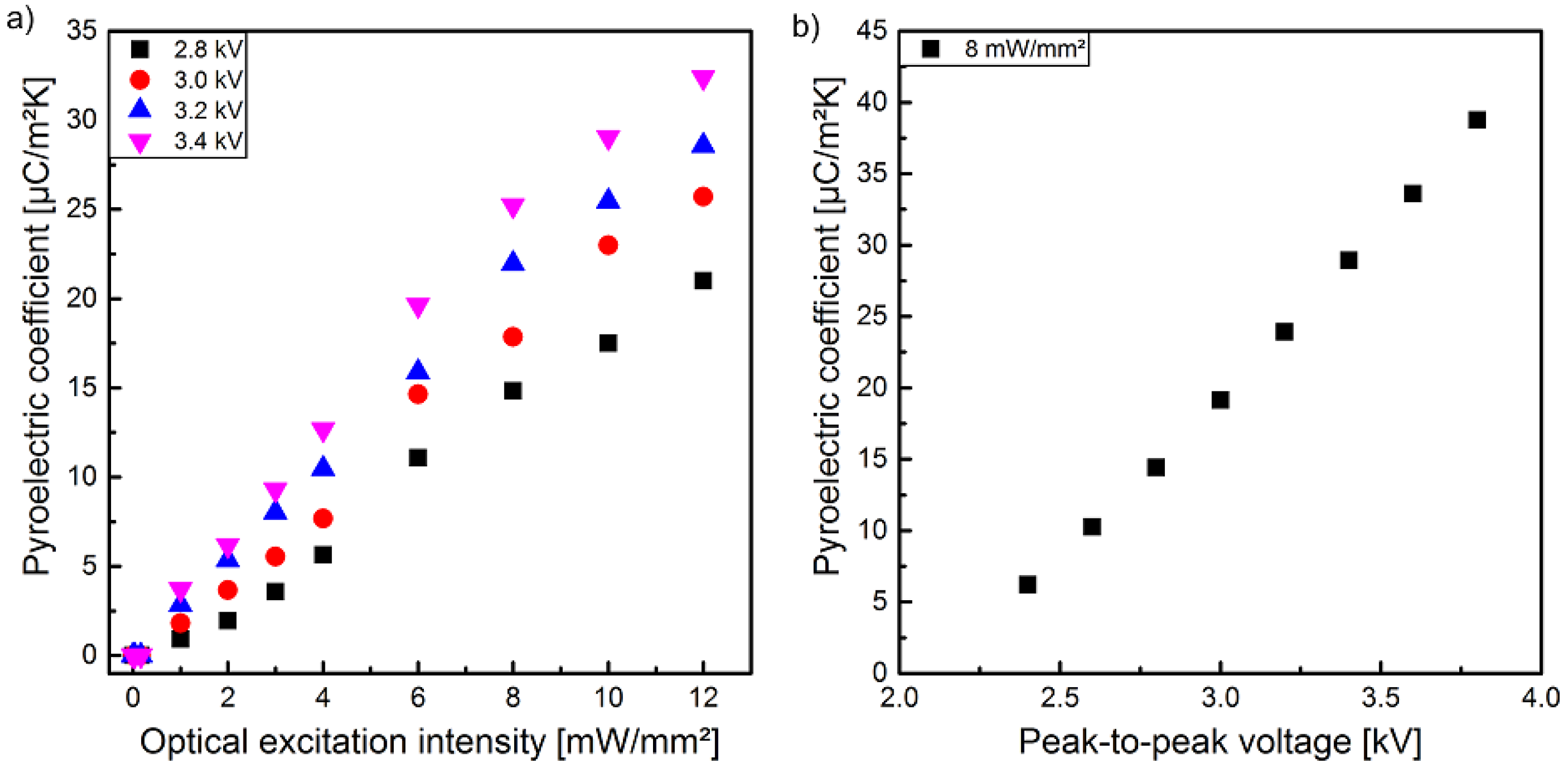

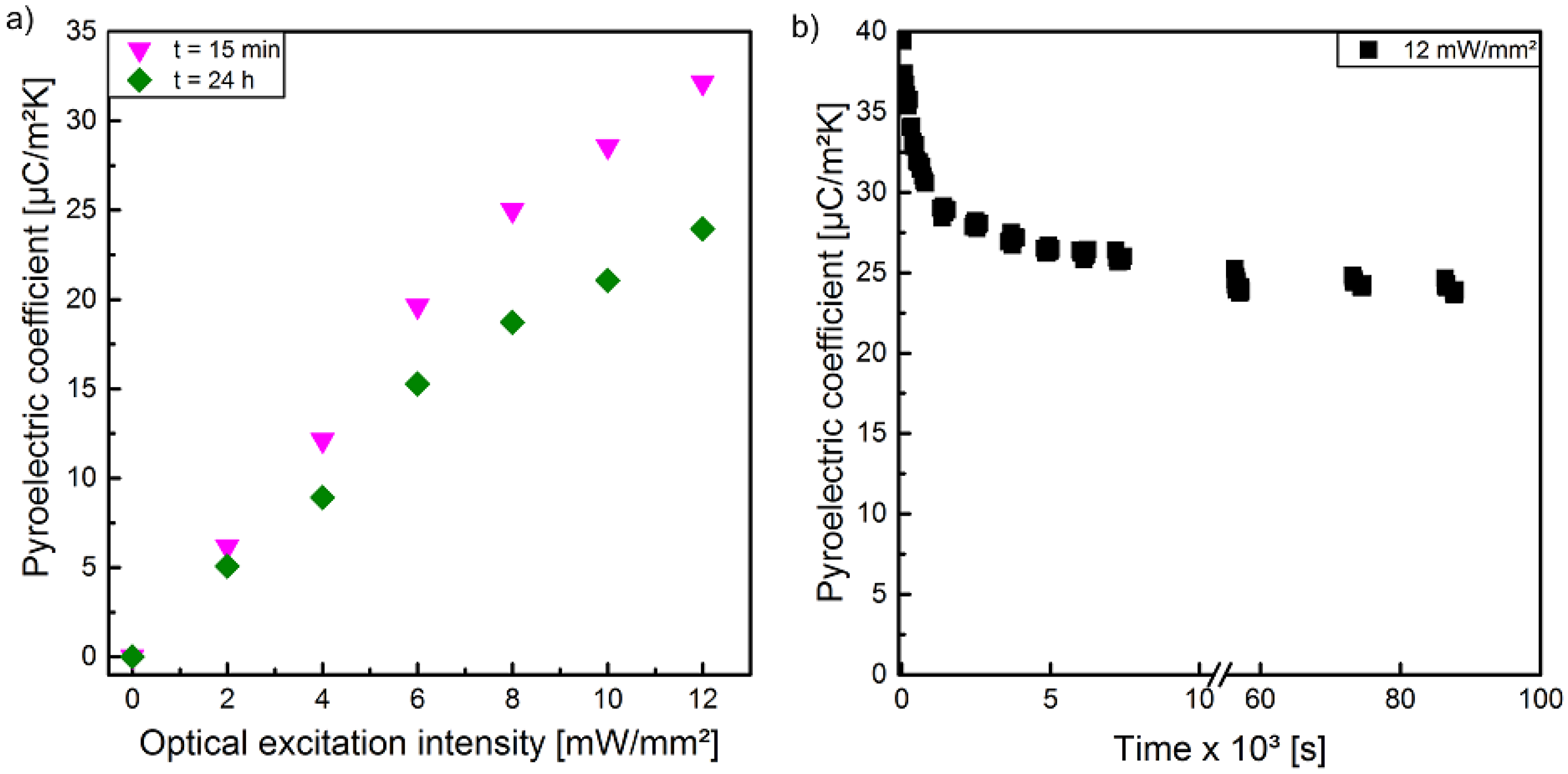

3.2. Pyroelectric Properties

3.3. Thermal Properties and Pyroelectric Depth Profile

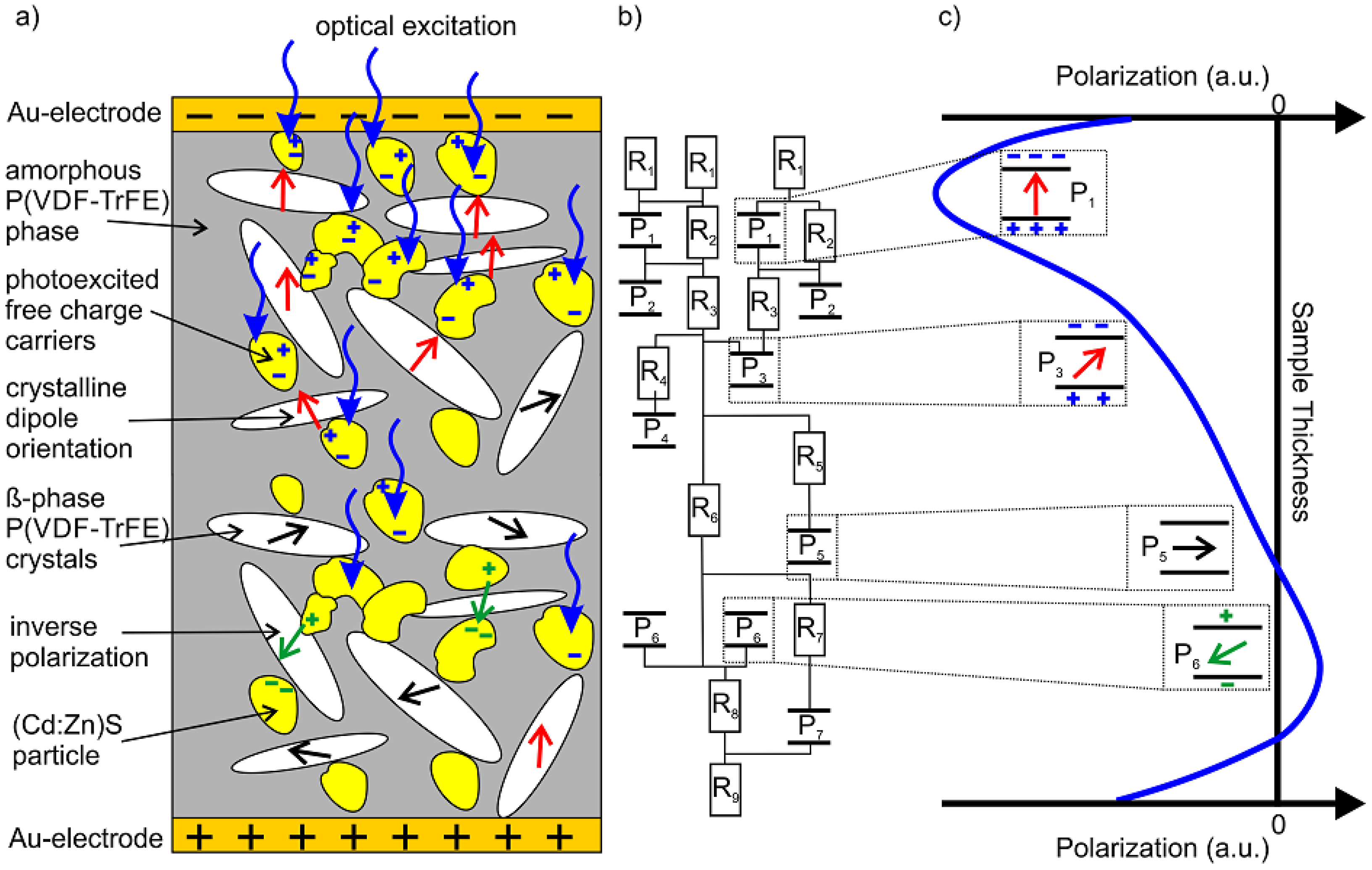

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Li, B.; Xu, C.; Zhang, F.; Zheng, J.; Xu, C. Self-polarized piezoelectric thin films: Preparation, formation mechanism and application. J. Mater. Chem. C 2015, 3, 8926–8931. [Google Scholar] [CrossRef]

- Li, M.; Katsouras, I.; Piliego, C.; Glasser, G.; Lieberwirth, I.; Blom, P.W.; de Leeuw, D.M. Controlling the microstructure of poly(vinylidene-fluoride)(PVDF) thin films for microelectronics. J. Mater. Chem. C 2013, 1, 7695–7702. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Q. Ferroelectric polymers and their energy-related applications. Macromol. Chem. Phys. 2016, 217, 1228–1244. [Google Scholar] [CrossRef]

- Shirinov, A.; Schomburg, W. Pressure sensor from a PVDF film. Sens. Actuators A Phys. 2008, 142, 48–55. [Google Scholar] [CrossRef]

- Yuan, Y.; Reece, T.J.; Sharma, P.; Poddar, S.; Ducharme, S.; Gruverman, A.; Yang, Y.; Huang, J. Efficiency enhancement in organic solar cells with ferroelectric polymers. Nat. Mater. 2011, 10, 296–302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhu, L. Exploring strategies for high dielectric constant and low loss polymer dielectrics. J. Phys. Chem. Lett. 2014, 5, 3677–3687. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yang, B.; Liu, J.; Zhu, Y.; Yang, C.; He, Q. A flexible triboelectric-piezoelectric hybrid nanogenerator based on P(VDF-TrFE) nanofibers and PDMS/MWCNT for wearable devices. Sci. Rep. 2016, 6, 36409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Von Münch, W.; Nägele, M.; Rinner, M.; Wöhl, G.; Ploss, B.; Ruppel, W. P(VDF/TrFE) copolymer films for the fabrication of pyroelectric arrays. Sens. Actuators A Phys. 1993, 37, 365–369. [Google Scholar] [CrossRef]

- Ploss, B.; Lehmann, P.; Schopf, H.; Lessle, T.; Bauer, S.; Thiemann, U. Integrated pyroelectric detector arrays with the sensor material PVDF. Ferroelectrics 1990, 109, 223–228. [Google Scholar] [CrossRef]

- Lovinger, A.J.; Furukawa, T.; Davis, G.; Broadhurst, M. Crystallographic changes characterizing the Curie transition in three ferroelectric copolymers of vinylidene fluoride and trifluoroethylene: 1. As-crystallized samples. Polymer 1983, 24, 1225–1232. [Google Scholar] [CrossRef]

- Bargain, F.; Panine, P.; Dos Santos, F.D.; Tence-Girault, S. From solvent-cast to annealed and poled poly (VDF-co-TrFE) films: New insights on the defective ferroelectric phase. Polymer 2016, 105, 144–156. [Google Scholar] [CrossRef]

- Furukawa, T. Structure and functional properties of ferroelectric polymers. Adv. Colloid Interface Sci. 1997, 71, 183–208. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Metta, G.; Valle, M.; Adami, A.; Lorenzelli, L. Piezoelectric oxide semiconductor field effect transistor touch sensing devices. Appl. Phys. Lett. 2009, 95, 034105. [Google Scholar] [CrossRef]

- Oh, S.R.; Wong, T.C.; Tan, C.Y.; Yao, K.; Tay, F.E.-H. Fabrication of piezoelectric polymer multilayers on flexible substrates for energy harvesting. Smart Mater. Struct. 2013, 23, 015013. [Google Scholar] [CrossRef]

- Rendl, C.; Kim, D.; Fanello, S.; Parzer, P.; Rhemann, C.; Taylor, J.; Zirkl, M.; Scheipl, G.; Rothl, T.; Haller, M.; et al. Flexsense: A transparent self-sensing deformable surface. In Proceedings of the 27th Annual ACM Symposium on User Interface Software and Technology, Honolulu, HI, USA, 5–8 October 2014; pp. 129–138. [Google Scholar]

- Graz, I.; Krause, M.; Bauer-Gogonea, S.; Bauer, S.; Lacour, S.P.; Ploss, B.; Zirkl, M.; Stadlober, B.; Wagner, S. Flexible active-matrix cells with selectively poled bifunctional polymer-ceramic nanocomposite for pressure and temperature sensing skin. J. Appl. Phys. 2009, 106, 034503. [Google Scholar] [CrossRef]

- Ploss, B.; Ploss, B.; Shin, F.G.; Chan, H.L.; Choy, C. Pyroelectric activity of ferroelectric PT/PVDF-TrFE. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 517–522. [Google Scholar] [CrossRef] [Green Version]

- Martins, P.; Lasheras, A.; Gutierrez, J.; Barandiaran, J.; Orue, I.; Lanceros-Mendez, S. Optimizing piezoelectric and magnetoelectric responses on CoFe2O4/P(VDF-TrFE) nanocomposites. J. Phys. D Appl. Phys. 2011, 44, 495303. [Google Scholar] [CrossRef]

- Paik, H.; Choi, Y.-Y.; Hong, S.; No, K. Effect of Ag nanoparticle concentration on the electrical and ferroelectric properties of Ag/P(VDF-TrFE) composite films. Sci. Rep. 2015, 5, 13209. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tsutsumi, N.; Kosugi, R.; Kinashi, K.; Sakai, W. Nature of the enhancement in ferroelectric properties by gold nanoparticles in vinylidene fluoride and trifluoroethylene copolymer. ACS Appl. Mater. Interfaces 2016, 8, 16816–16822. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.X.; Dai, J.Y.; So, L.C.; Sun, C.L.; Lo, C.Y.; Or, S.W.; Chan, H.L.W. The effect of magnetic nanoparticles on the morphology, ferroelectric, and magnetoelectric behaviors of CFO/P(VDF-TrFE) 0–3 nanocomposites. J. Appl. Phys. 2009, 105, 054102. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.; Liu, Z.; Wang, F.; Yan, K. Influence of shell thickness on the dielectric properties of composites filled with Ag@SiO2 nanoparticles. RSC Adv. 2016, 6, 64634–64639. [Google Scholar] [CrossRef]

- Zou, Y.; Han, L.; Yuan, G.; Liu, B.; Zhao, X.; Tian, B.; Wang, J.; Sun, S.; Sun, J.; Meng, X. Enhanced ferroelectric and dielectric properties of the P(VDF-TrFE)/Ag nanoparticles composite thin films. J. Mater. Sci. Mater. Electron. 2014, 25, 3461–3465. [Google Scholar] [CrossRef]

- Mahdi, R.; Gan, W.; Majid, W.A.; Mukri, N.I.; Furukawa, T. Ferroelectric polarization and pyroelectric activity of functionalized P(VDF-TrFE) thin film lead free nanocomposites. Polymer 2018, 141, 184–193. [Google Scholar] [CrossRef]

- Ploss, B.; Shin, F. A general formula for the effective pyroelectric coefficient of composites. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 1170–1176. [Google Scholar] [CrossRef]

- Ploss, B. Improving the pyroelectric coefficient of ceramic/polymer composite by doping the polymer matrix. Ferroelectrics 2006, 338, 145–151. [Google Scholar] [CrossRef]

- Ploss, B.; Krause, M. Optimized pyroelectric 0–3 composites of PZT particles in doped polyurethane, Applications of Ferroelectrics. In Proceedings of the Sixteenth IEEE International Symposium on the Applications of Ferroelectrics, ISAF 2007, Nara, Japan, 27–31 May 2007; pp. 818–820. [Google Scholar]

- Engel, S.; Smykalla, D.; Ploss, B.; Gräf, S.; Müller, F.A. Effect of (Cd:Zn) s particle concentration and photoexcitation on the electrical and ferroelectric properties of (Cd:Zn) S/P(VDF-TrFE) composite films. Polymers 2017, 9, 650. [Google Scholar] [CrossRef]

- Lang, S.B. Laser intensity modulation method (LIMM): Experimental techniques, theory and solution of the integral equation. Ferroelectrics 1991, 118, 343–361. [Google Scholar] [CrossRef]

- Ploss, B.; Emmerich, R.; Bauer, S. Thermal wave probing of pyroelectric distributions in the surface region of ferroelectric materials: A new method for the analysis. J. Appl. Phys. 1992, 72, 5363–5370. [Google Scholar] [CrossRef]

- Tajitsu, Y.; Ogura, H.; Chiba, A.; Furukawa, T. Investigation of switching characteristics of vinylidene fluoride/trifluoroethylene copolymers in relation to their structures. Jpn. J. Appl. Phys. 1987, 26, 554. [Google Scholar] [CrossRef]

- Garn, L.E.; Sharp, E.J. Use of low-frequency sinusoidal temperature waves to separate pyroelectric currents from nonpyroelectric currents. Part I. Theory. J. Appl. Phys. 1982, 53, 8974–8979. [Google Scholar] [CrossRef]

- Sharp, E.J.; Garn, L.E. Use of low-frequency sinusoidal temperature waves to separate pyroelectric currents from nonpyroelectric currents. Part II. Experiment. J. Appl. Phys. 1982, 53, 8980–8987. [Google Scholar] [CrossRef]

- Bauer, S.; Ploss, B. A method for the measurement of the thermal, dielectric, and pyroelectric properties of thin pyroelectric films and their applications for integrated heat sensors. J. Appl. Phys. 1990, 68, 6361–6367. [Google Scholar] [CrossRef]

- Lang, S.B.; Das-Gupta, D. A new technique for determination of the spatial distribution of polarization in polymer electrets. Ferroelectrics 1984, 60, 23–36. [Google Scholar] [CrossRef]

- Smiles, S. Chemische Konstitution und Physikalische Eigenschaften; Springer: Berlin, Germany, 2013. [Google Scholar]

- Cline, C.F.; Dunegan, H.L.; Henderson, G.W. Elastic constants of hexagonal BeO, ZnS, and CdSe. J. Appl. Phys. 1967, 38, 1944–1948. [Google Scholar] [CrossRef]

- Abrikosov, N.K. Semiconducting II–VI, IV–VI, and V–VI Compounds; Springer: Berlin, Germany, 2013. [Google Scholar]

- Wong, Y.; Hui, N.; Ong, E.; Chan, H.; Choy, C. Specific heat and thermal diffusivity of vinylidene fluoride/trifluoroethylene copolymers. J. Appl. Polym. Sci. 2003, 89, 3160–3166. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Tocho, J.O.; Cussó, F. Photoacoustic determination of the luminescent quantum efficiency of Yb3+ ions in lithium niobate. Appl. Opt. 1998, 37, 7096–7099. [Google Scholar] [CrossRef] [PubMed]

- Engel, S.; Wenisch, C.; Müller, F.; Gräf, S. A new photoacoustic method based on the modulation of the light induced absorption coefficient. Meas. Sci. Technol. 2016, 27, 045202. [Google Scholar] [CrossRef] [Green Version]

- Nikolić, P.; Todorović, D. Photoacoustic and electroacoustic properties of semiconductors. Prog. Quantum Electron. 1989, 13, 107–189. [Google Scholar] [CrossRef]

- Brunn, J. Photoakustische Untersuchungen Mit Einem Fourier-Spektralphotometer; Universitätsverlag Aachen: Aachen, Germany, 1987. [Google Scholar]

- Rosencwaig, A.; Gersho, A. Theory of the photoacoustic effect with solids. J. Appl. Phys. 1976, 47, 64–69. [Google Scholar] [CrossRef]

- Axelevitch, A.; Apter, B.; Golan, G. Simulation and experimental investigation of optical transparency in gold island films. Opt. Express 2013, 21, 4126–4138. [Google Scholar] [CrossRef] [PubMed]

- Hodgman, C.D.; Weast, R.; Selby, S. Handbook of Physics and Chemistry; Chemical Rubber Publishing Co.: Cleveland, OH, USA, 1955; p. 1162. [Google Scholar]

- Tye, R. Thermal Conductivity; Academic: London, UK, 1969; Volume 2. [Google Scholar]

- Kuhn, S.; Tiegel, M.; Herrmann, A.; Rüssel, C.; Engel, S.; Wenisch, C.; Gräf, S.; Müller, F.A.; Körner, J.; Seifert, R. Photo-acoustic spectroscopy and quantum efficiency of Yb3+ doped alumino silicate glasses. J. Appl. Phys. 2015, 118, 103104. [Google Scholar] [CrossRef]

- Guan, F.; Wang, J.; Pan, J.; Wang, Q.; Zhu, L. Effects of polymorphism and crystallite size on dipole reorientation in poly(vinylidene fluoride) and its random copolymers. Macromolecules 2010, 43, 6739–6748. [Google Scholar] [CrossRef]

- Hu, E.-T.; Guo, S.; Gu, T.; Zang, K.-Y.; Yao, Y.; Wang, Z.-Y.; Yu, K.-H.; Wei, W.; Zheng, Y.-X.; Wang, S.-Y. Enhancement of solar absorption by a surface-roughened metal–dielectric film structure. Jpn. J. Appl. Phys. 2017, 56, 112301. [Google Scholar] [CrossRef]

- Li, Y.; Tjong, S. Nonlinear current–voltage characteristics in polymer nanocomposites. In Physical Properties and Applications of Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2010; pp. 862–890. [Google Scholar]

- Das, S.C.; Majumdar, A.; Shahee, A.; Lalla, N.P.; Shripathi, T.; Hippler, R. Low cost ferroelectric loop study set up with new and simple compensation circuit: Operated at variable frequencies. Ferroelectr. Lett. Sect. 2011, 38, 78–85. [Google Scholar] [CrossRef]

- Sessler, G. Electrets-Introduction; Springer: New York, NY, USA, 1987. [Google Scholar]

- Holdik, K.; Eisenmenger, W. Charge and polarization dynamics in polymer films, Electrets (ISE 5). In Proceedings of the IEEE 5th International Symposium on Electrets, Heidelberg, Germany, 4–6 September 1985; pp. 553–558. [Google Scholar]

- Sessler, G.M.; Das-Gupta, D.K.; DeReggi, A.S.; Eisenmenger, W.; Furukawa, T.; Giacometti, J.A.; Gerhard-Multhaupt, R. Piezo-and pyroelectricity in electrets, caused by charges, dipoles or both. IEEE Trans. Electr. Insul. 1992, 27, 872–897. [Google Scholar]

- Eberle, G.; Bihler, E.; Eisenmenger, W. Polarization dynamics of VDF-TrFE copolymers. IEEE Trans. Electr. Insul. 1991, 26, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Wübbenhorst, M.; Petzsche, T. Messung der räumlichen polarisationsverteilung in poly(vinylidenfluorid) mittels der laser-intensitäts-modulations-methode. Acta Polym. 1988, 39, 201–206. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, M.-H.; Zhu, Z.-X.; Wang, K.; Zhou, J.-S.; Yao, F.-Z.; Li, J.-F. Poling engineering of (K,Na) NbO3-based lead-free piezoceramics with orthorhombic–tetragonal coexisting phases. J. Mater. Chem. C 2017, 5, 549–556. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Engel, S.; Smykalla, D.; Ploss, B.; Gräf, S.; Müller, F.A. Polarization Properties and Polarization Depth Profiles of (Cd:Zn)S/P(VDF-TrFE) Composite Films in Dependence of Optical Excitation. Polymers 2018, 10, 1205. https://doi.org/10.3390/polym10111205

Engel S, Smykalla D, Ploss B, Gräf S, Müller FA. Polarization Properties and Polarization Depth Profiles of (Cd:Zn)S/P(VDF-TrFE) Composite Films in Dependence of Optical Excitation. Polymers. 2018; 10(11):1205. https://doi.org/10.3390/polym10111205

Chicago/Turabian StyleEngel, Sebastian, David Smykalla, Bernd Ploss, Stephan Gräf, and Frank A. Müller. 2018. "Polarization Properties and Polarization Depth Profiles of (Cd:Zn)S/P(VDF-TrFE) Composite Films in Dependence of Optical Excitation" Polymers 10, no. 11: 1205. https://doi.org/10.3390/polym10111205