Heat Dissipation in Epoxy/Amine-Based Gradient Composites with Alumina Particles: A Critical Evaluation of Thermal Conductivity Measurements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instrumentation

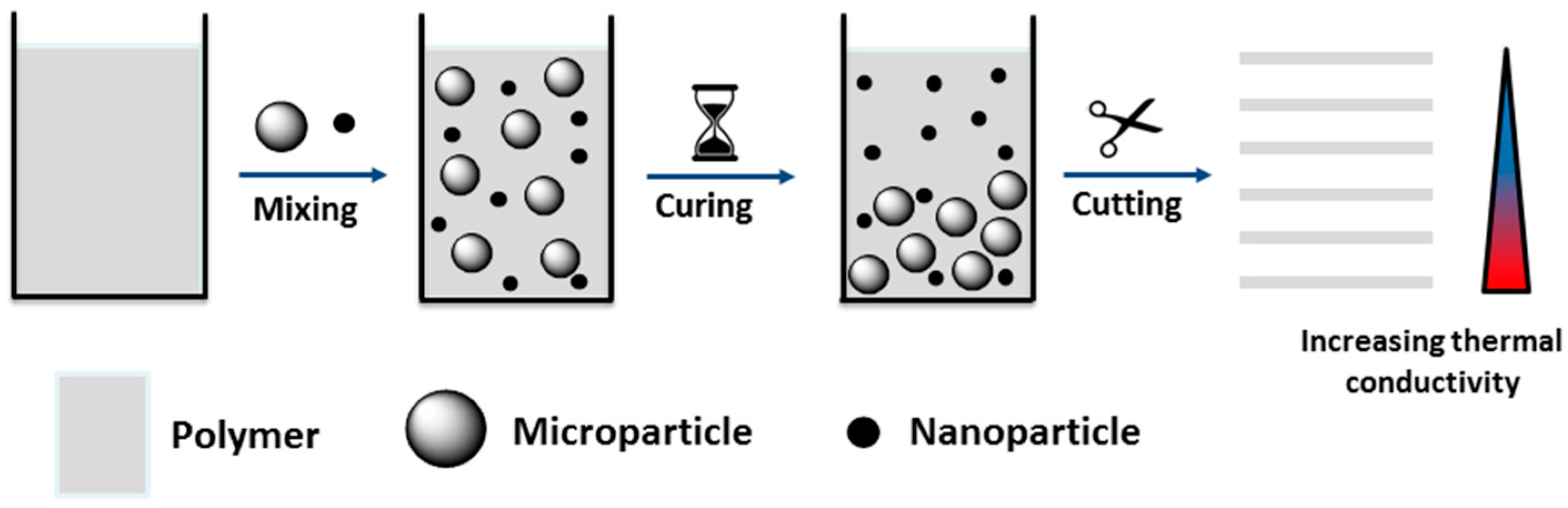

2.3. Preparation of the Gradient Epoxy-Amine-Based Composite

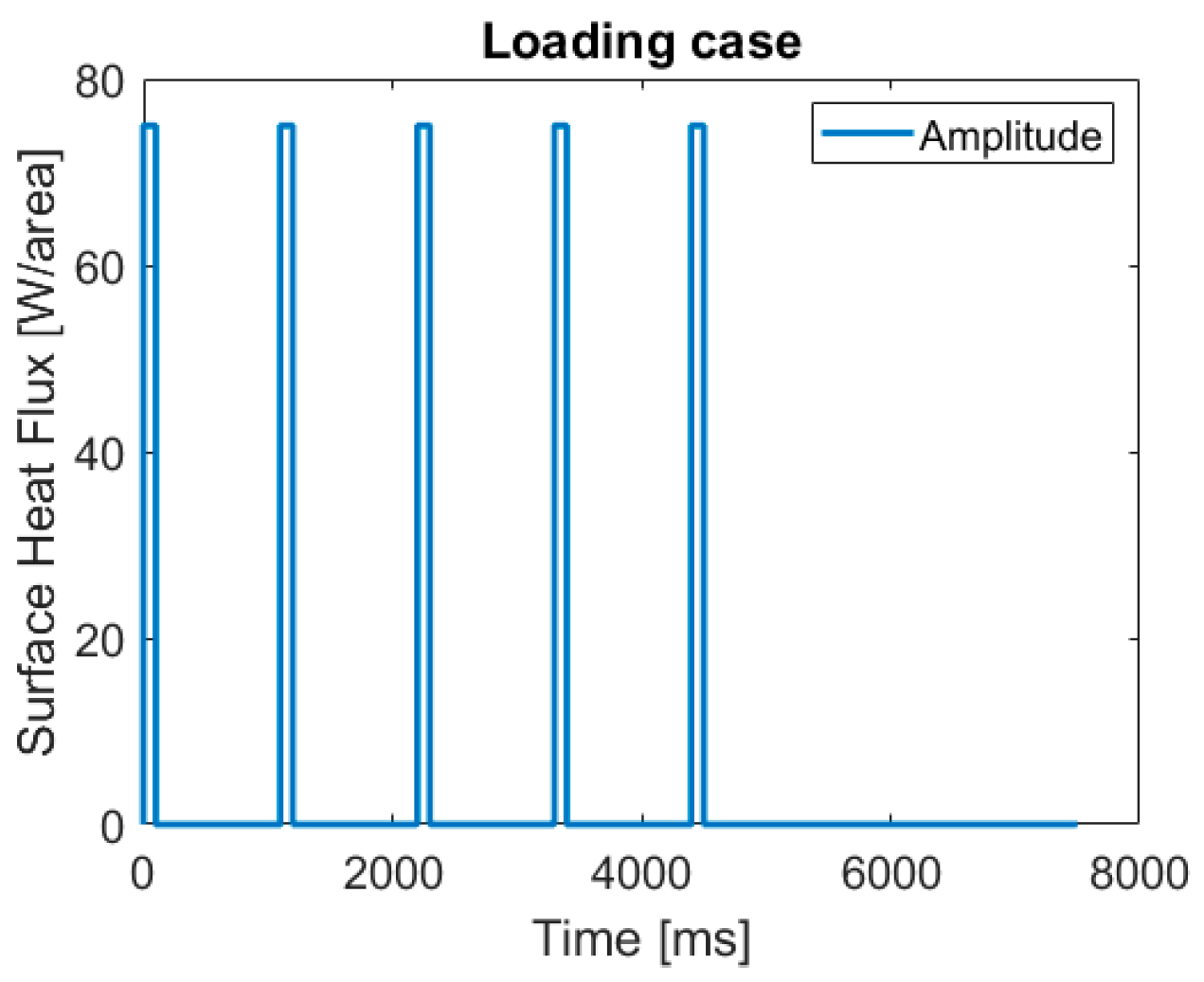

2.4. Simulation Model

3. Results

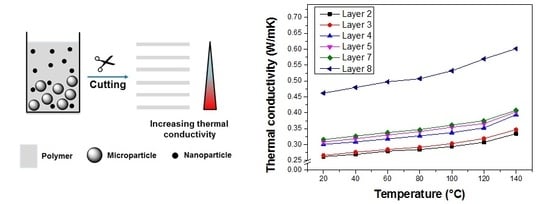

3.1. Concept and Preparation of the Gradient Composites

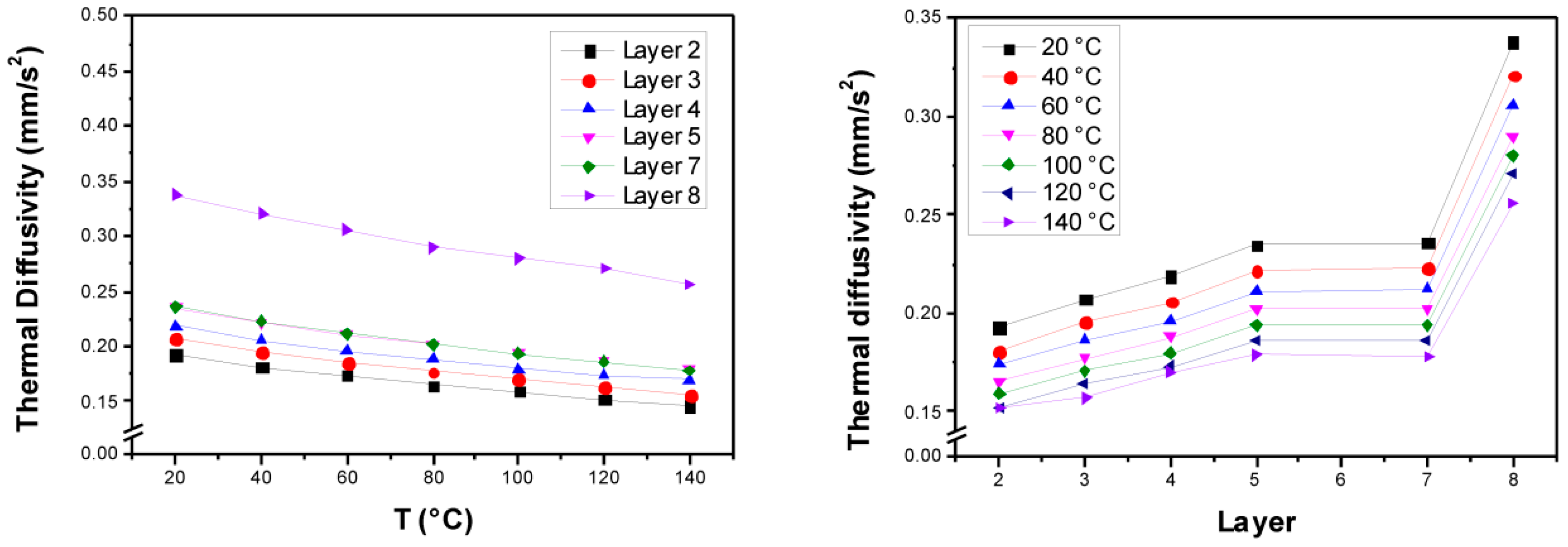

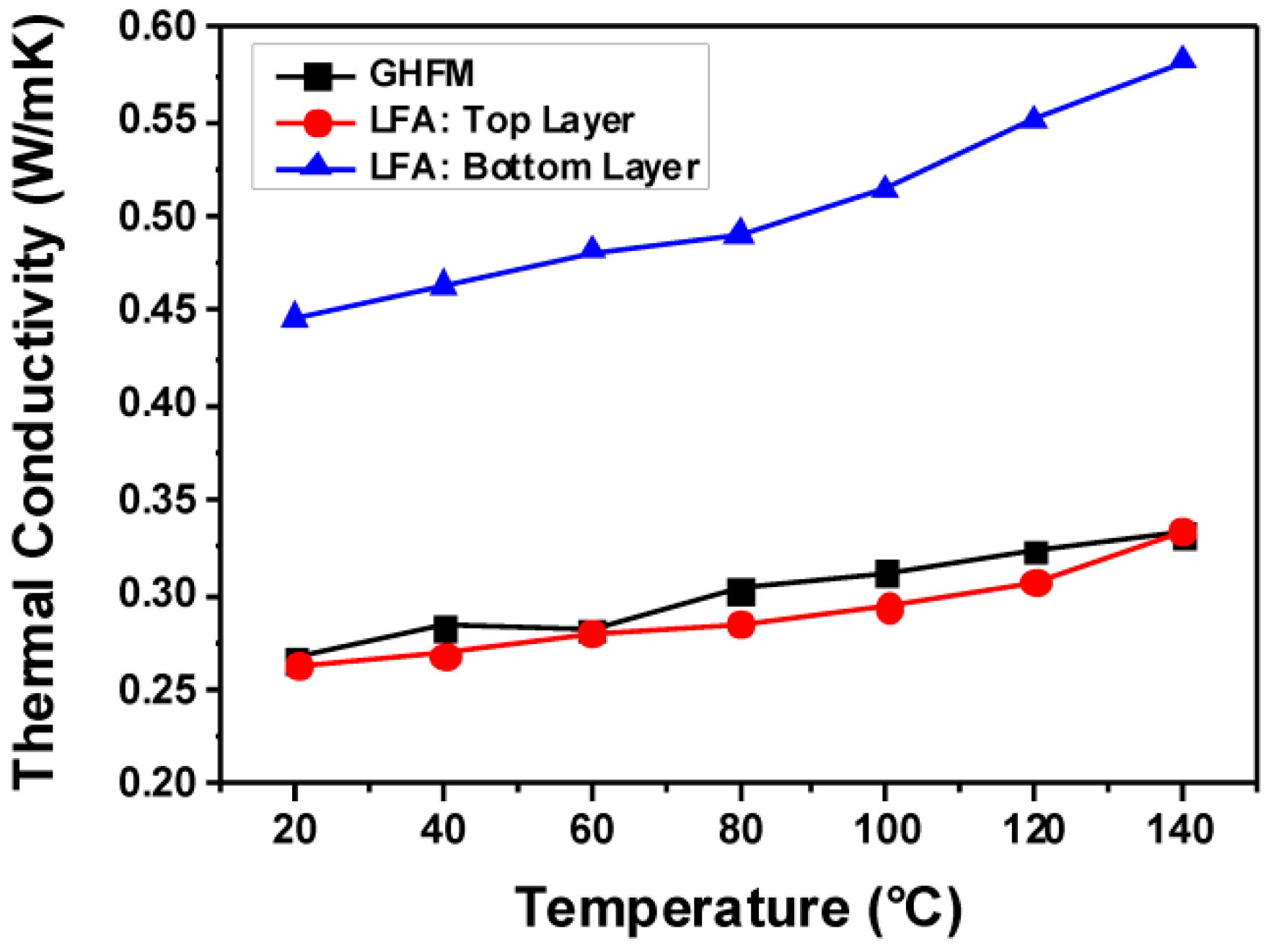

3.2. Measurement of the Thermal Conductivity

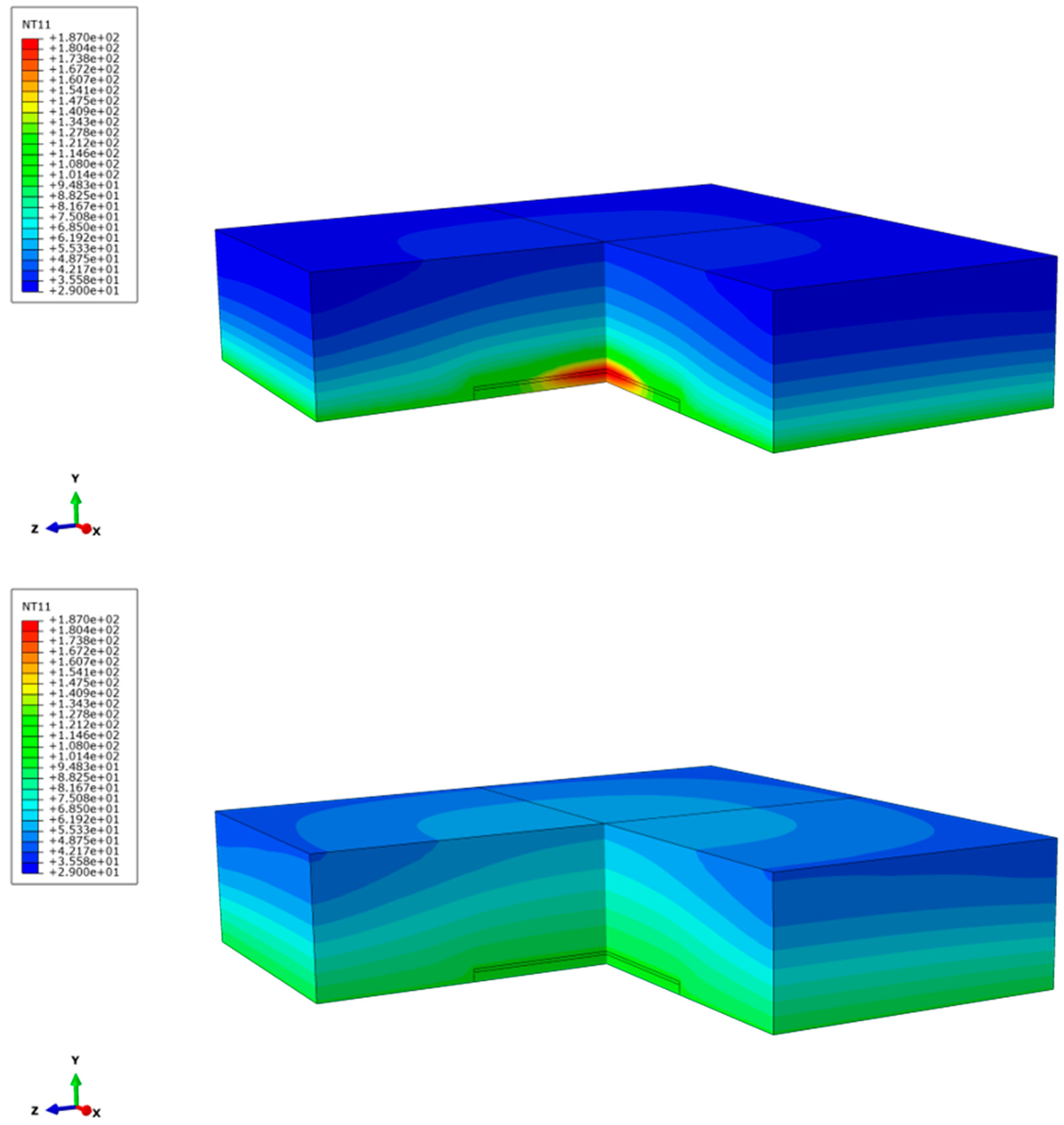

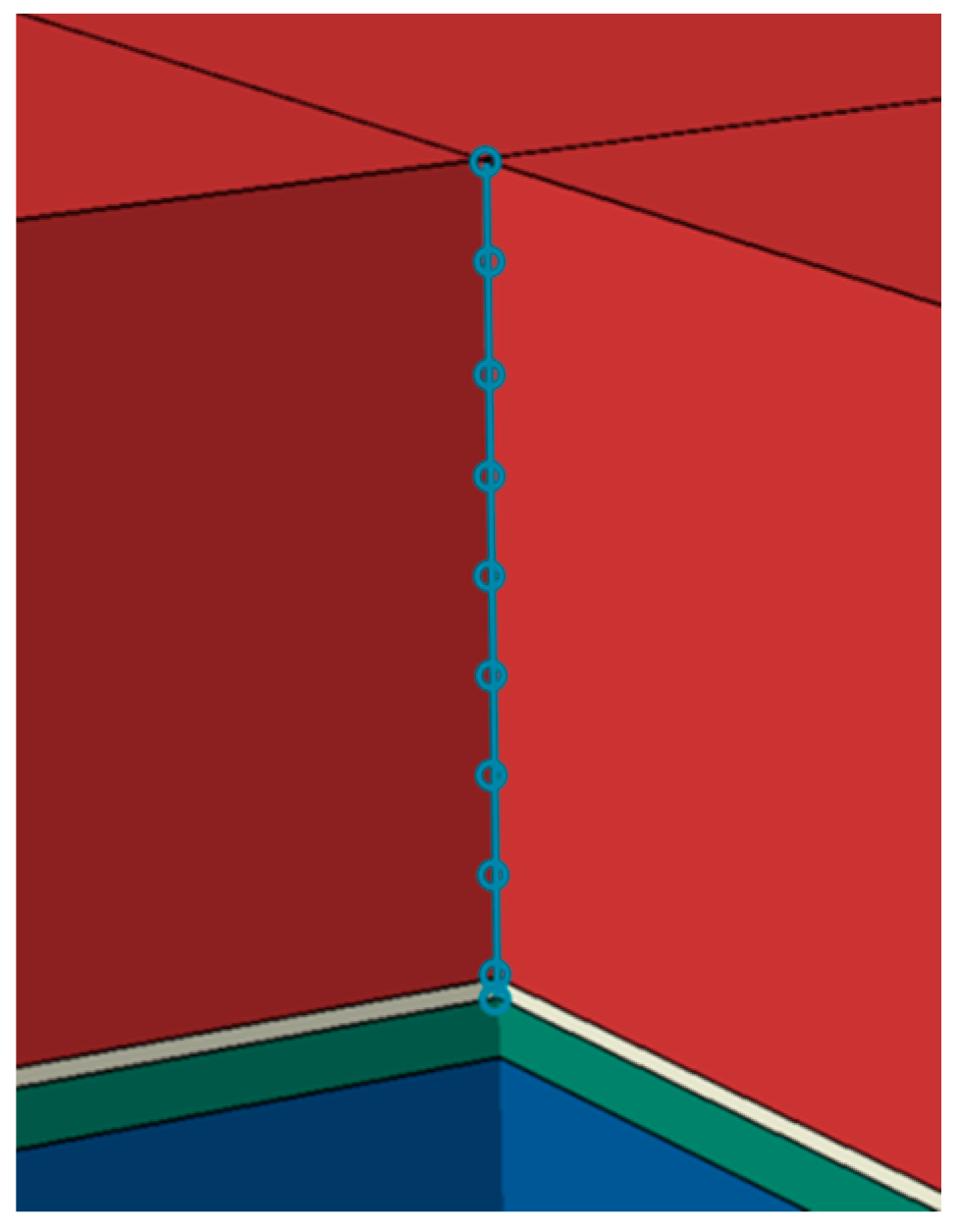

3.3. Modelling & Simulation of the Thermal Dissipation Behavior

4. Summary, Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Coombs, C.F., Jr. Printed Circuits Handbook, 6th ed.; McGraw-Hill: New York, NY, USA, 2008; ISBN 978-0071467346. [Google Scholar]

- Liu, S.; Liu, Y. Modeling and Simulation for Microelectronic Packaging Assembly: Manufacturing, Reliability, and Testing, 1st ed.; John Wiley & Sons (Asia) Pte Ltd.: Singapore, 2011; ISBN 978-0-470-82780-2. [Google Scholar]

- Tanaka, Y.; Chen, G.; Zhao, Y.; Davies, A.E.; Vaughan, A.S.; Takada, T. Effect of additives on morphology and space charge accumulation in low density polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 148–154. [Google Scholar] [CrossRef]

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of Polymer Composites Used in High-Voltage Applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef]

- Bernardoni, M.; Cova, P.; Delmonte, N.; Menozzi, R. Heat management for power converters in sealed enclosures. A numerical study. Microelectron. Reliab. 2009, 49, 1293–1298. [Google Scholar] [CrossRef]

- Sokolov, A.; Liu, C.; Mohn, F. Reliability assessment of SiC power module stack based on thermo-structural analysis. In Proceedings of the 19th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), Toulouse, France, 15–18 April 2018. [Google Scholar]

- Benda, V. Progress in power semiconductor devices. Microelectron. Reliab. 2012, 52, 461–462. [Google Scholar] [CrossRef]

- Yang, D.; Kengen, M.; Peels, W.; Heyes, D.; van Driel, W.D. Reliability modeling on a MOSFET power package based on embedded die technology. Microelectron. Reliab. 2010, 50, 923–927. [Google Scholar] [CrossRef]

- Pfost, M.; Boianceanu, C.; Lohmeyer, H.; Stecher, M. Electrothermal Simulation of Self-Heating in DMOS Transistors up to Thermal Runaway. IEEE Trans. Electron. Devices 2013, 60, 699–707. [Google Scholar] [CrossRef]

- Boettcher, L.; Karaszkiewicz, S.; Manessis, D.; Ostmann, A. Embedding of Power Semiconductors for Innovative Packages and Modules. In Proceedings of the SMTA International 2014 Proceedings, Rosemont, IL, USA, 28 September–2 October 2014; pp. 222–228, ISBN 978-1-63439-399-7. [Google Scholar]

- Bolton, W.; Higgins, R.A. Materials for Engineers and Technicians, 5th ed.; Elsevier: Oxford, UK, 2010; ISBN 978-1856177696. [Google Scholar]

- Eibel, A.; Marx, P.; Jin, H.; Tsekmes, I.-A.; Mühlbacher, I.; Smit, J.J.; Kern, W.; Wiesbrock, F. Enhancement of the Insulation Properties of Poly(2-oxazoline)-co-Polyester Networks by the Addition of Nanofillers. Macromol. Rapid Commun. 2018, 39. [Google Scholar] [CrossRef] [PubMed]

- Reading, M.; Vaughan, A.S.; Lewin, P.L. An investigation into improving the breakdown strength and thermal conduction of an epoxy system using boron nitride. In Proceedings of the 2011 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Cancun, Mexico, 16–19 October 2011. [Google Scholar]

- Marx, P.; Wanner, A.J.; Zhang, Z.; Jin, H.; Tsekmes, I.A.; Smit, J.J.; Kern, W.; Wiesbrock, F. Effect of Interfacial Polarization and Water Absorption on the Dielectric Properties of Epoxy-Nanocomposites. Polymers 2017, 9, 195. [Google Scholar] [CrossRef]

- Kidalov, S.V.; Shakhov, F.M. Thermal Conductivity of Diamond Composites. Materials 2009, 2, 2467–2495. [Google Scholar] [CrossRef] [Green Version]

- Weng, Q.H.; Wang, X.B.; Wang, X.; Bando, Y.; Golberg, D. Functionalized hexagonal boron nitride nanomaterials: Emerging properties and applications. Chem. Soc. Rev. 2016, 45, 3989–4012. [Google Scholar] [CrossRef] [PubMed]

- Franco Júnior, A.; Shanafield, D.J. Thermal conductivity of polycrystalline aluminum nitride (AlN) ceramics. Cerâmica 2004, 50, 247–253. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 84th ed.; CRC Press: Boca Raton, FL, USA, 2003; ISBN 978-0-8493048-4-2. [Google Scholar]

- Dahmen, W.; Reusken, A. Numerik für Ingenieure und Naturwissenschaftler, 1st ed.; Springer: Berlin, Germany, 2008; ISBN 978-3540764922. [Google Scholar]

- Eck, C.; Garcke, H.; Knabner, P. Mathematische Modellierung, 3rd ed.; Springer: Berlin, Germany, 2017; ISBN 978-3662543344. [Google Scholar]

- Dassault Systèmes: Simulia User Assistance 2017; Abaqus Documentation: Providence, RI, USA, 2017.

- Durand, C.; Klinger, M.; Coutellier, D.; Naceur, H. Power Cycling Reliability of Power Module: A Survey. IEEE Trans. Device Mater. Reliab. 2016, 16, 80–97. [Google Scholar] [CrossRef]

- Chiozzi, D.; Bernardoni, M.; Delmonte, N.; Cova, P. A simple 1-D finite elements approach to model the effect of PCB in electronic assemblies. Microelectron. Reliab. 2016, 58, 126–132. [Google Scholar] [CrossRef]

- Lutz, J.; Schlangenotto, H.; Scheuermann, U.; De Doncker, R. Semiconductor Power Devices: Physics, Characteristics, Reliability, 1st ed.; Springer: Berlin, Germany, 2011; ISBN 978-3-642-11124-2. [Google Scholar]

- Parker, W.J.; Jenkins, R.J.; Butler, C.P. Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity. J. Appl. Phys. 1961, 32, 1679–1684. [Google Scholar] [CrossRef]

- Schulz, B.; Hoffmann, M. Thermophysical properties of the system Al2O3-MgO. High Temp. High Press. 2002, 34, 203–212. [Google Scholar] [CrossRef]

- Swier, S.; van Assche, G.; van Mele, B. Reaction Kinetics Modeling and Thermal Properties of Epoxy–Amines as Measured by Modulated-Temperature DSC. I. Linear Step-Growth Polymerization of DGEBA and Aniline. J. Appl. Polym. Sci. 2004, 91, 2798–2813. [Google Scholar] [CrossRef]

- ISO 8301:1991. Thermal Insulation-Determination of Steady-State Thermal Resistance and Related Properties-Heat Flow Meter Apparatus; International Organization for Standardization: Geneva, Switzerland, 1991. [Google Scholar]

- ASTM E1530-11. Standard Test Method for Evaluating the Resistance to Thermal Transmission of Materials by the Guarded Heat Flow Meter Technique; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Yoon, S.; Macphee, D.E.; Imbabi, M.S. Estimation of the thermal properties of hardened cement paste on the basis of guarded heat flow meter measurements. Thermochim. Acta 2014, 588, 1–10. [Google Scholar] [CrossRef]

| Layer | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|

| Copper (layer 1) | 9.5 | 9.5 | 1 |

| Silicon | 4.5 | 4.5 | 0.15 |

| Copper (layer 2) | 4.5 | 4.5 | 0.05 |

| Epoxy | 9.5 | 9.5 | 2.2 |

| Epoxy layers | 0.3125 | 0.3125 | 0.25 |

| Material | Temperature (°C) | |||

|---|---|---|---|---|

| Copper | 25 | 4.0 × 10−1 | 8.93 × 10−3 | 3.85 × 102 |

| Silicon | 25 | 1.670 × 10−1 | 2.329 × 10−3 | 5.769 × 102 |

| 400 | 5.257 × 10−2 | 2.329 × 10−3 | 8.741 × 102 |

| Height Position (mm) | Layer (#) | Density ρ (g·cm−3) |

|---|---|---|

| 1.592 | 2 | 1.364 |

| 2.767 | 3 | 1.376 |

| 3.856 | 4 | 1.364 |

| 4.961 | 5 | 1.367 |

| 7.177 | 7 | 1.368 |

| 8.448 | 8 | 1.372 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morak, M.; Marx, P.; Gschwandl, M.; Fuchs, P.F.; Pfost, M.; Wiesbrock, F. Heat Dissipation in Epoxy/Amine-Based Gradient Composites with Alumina Particles: A Critical Evaluation of Thermal Conductivity Measurements. Polymers 2018, 10, 1131. https://doi.org/10.3390/polym10101131

Morak M, Marx P, Gschwandl M, Fuchs PF, Pfost M, Wiesbrock F. Heat Dissipation in Epoxy/Amine-Based Gradient Composites with Alumina Particles: A Critical Evaluation of Thermal Conductivity Measurements. Polymers. 2018; 10(10):1131. https://doi.org/10.3390/polym10101131

Chicago/Turabian StyleMorak, Matthias, Philipp Marx, Mario Gschwandl, Peter Filipp Fuchs, Martin Pfost, and Frank Wiesbrock. 2018. "Heat Dissipation in Epoxy/Amine-Based Gradient Composites with Alumina Particles: A Critical Evaluation of Thermal Conductivity Measurements" Polymers 10, no. 10: 1131. https://doi.org/10.3390/polym10101131