Stress Relaxation Properties and Microscopic Deformation Structure in Bending of the C7025 and C7035 Alloy

Abstract

:1. Introduction

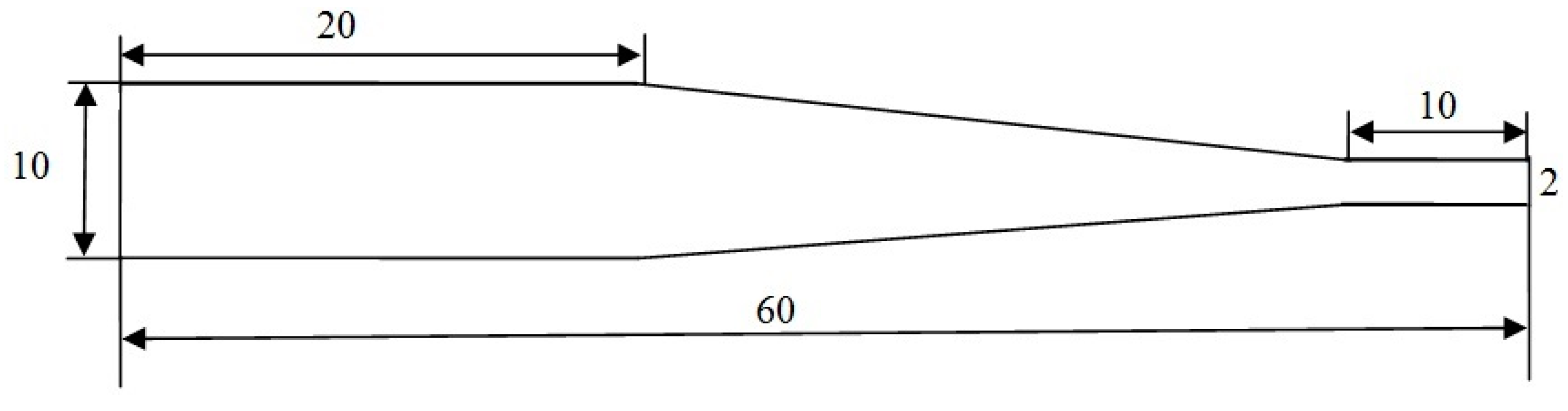

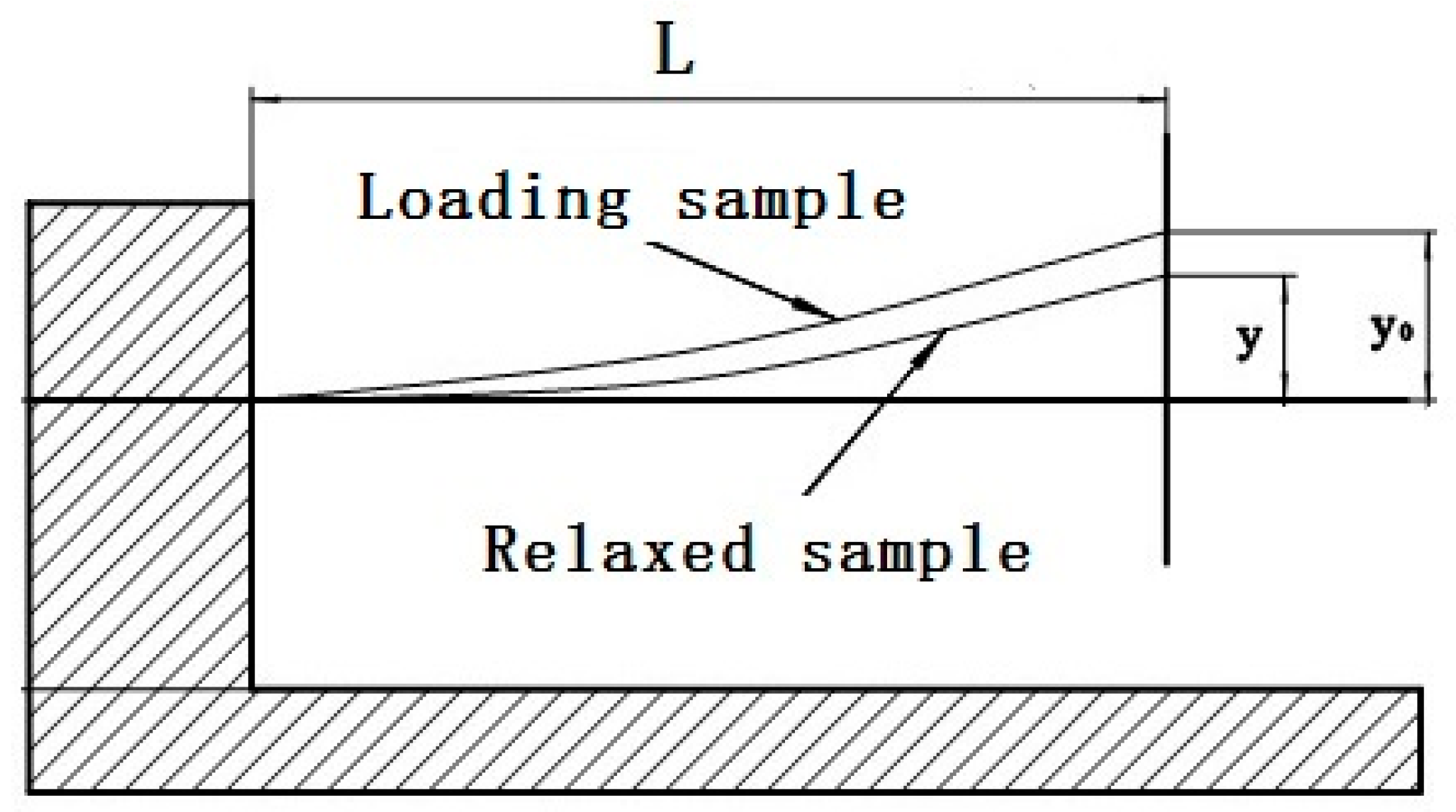

2. Experimental Section

3. Calculation

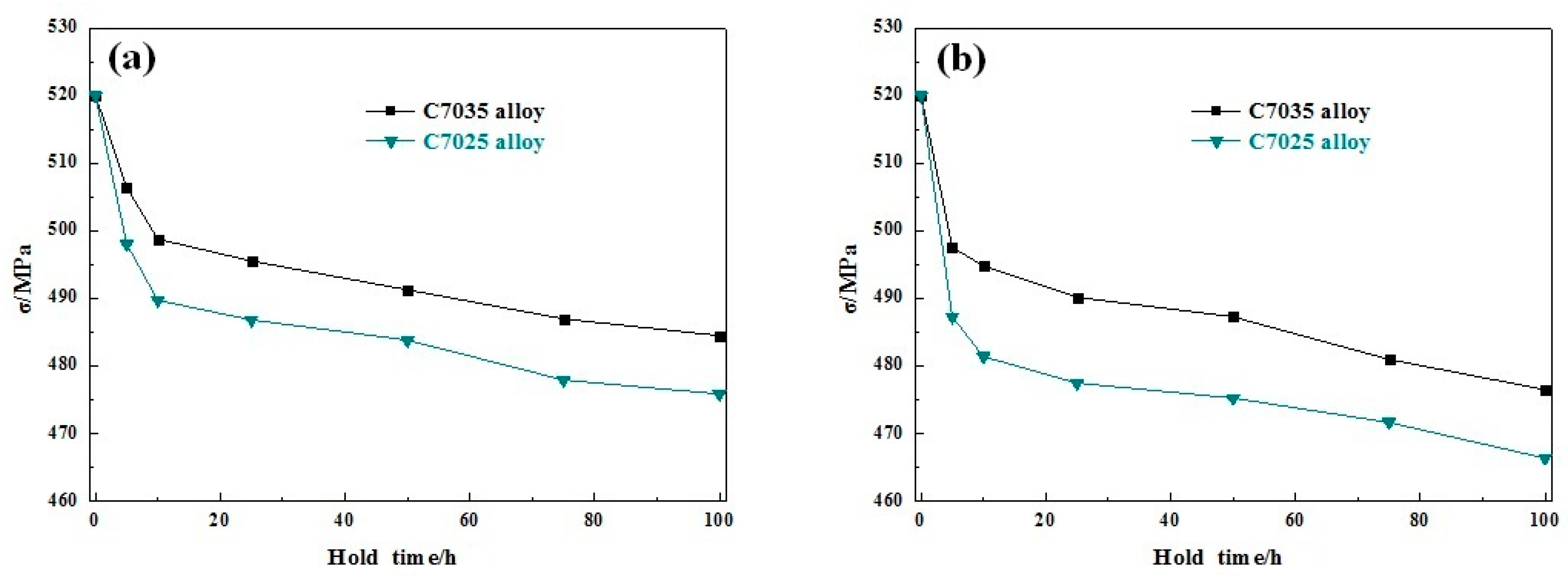

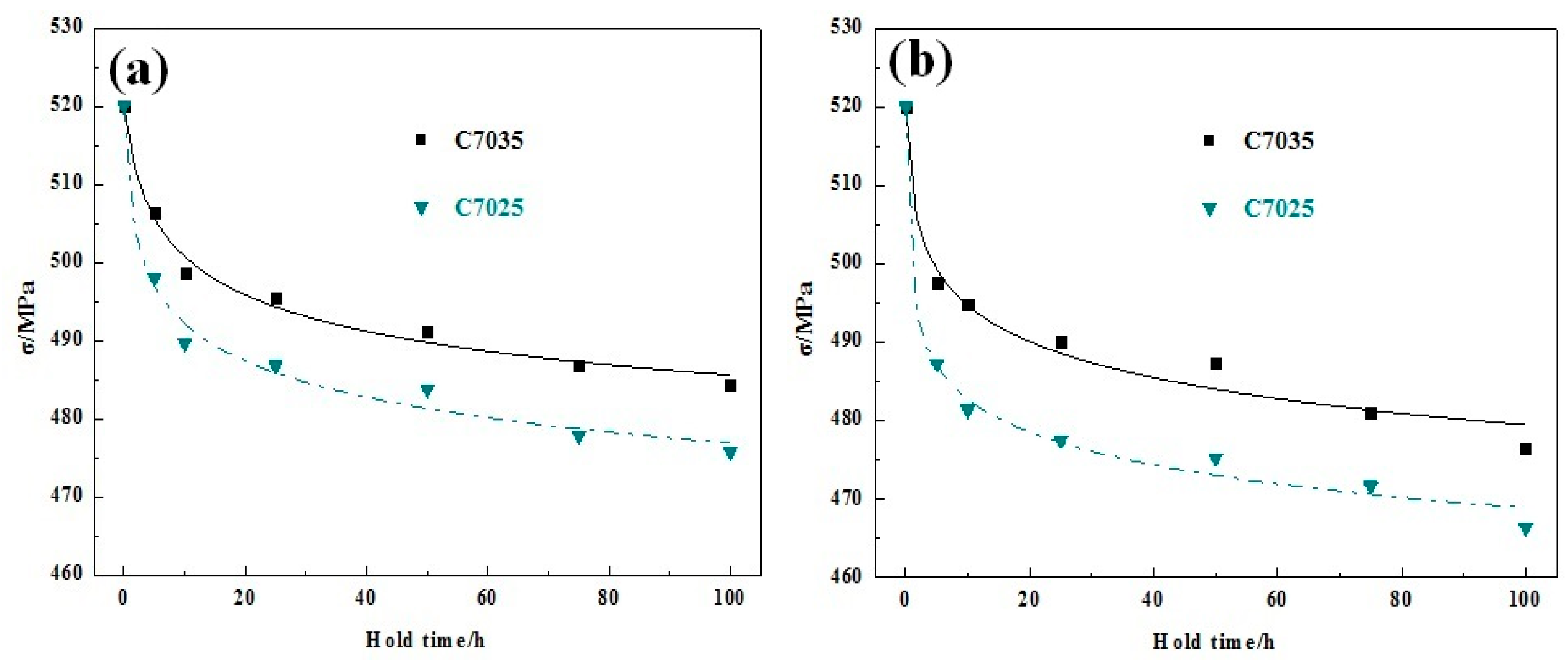

4. Results

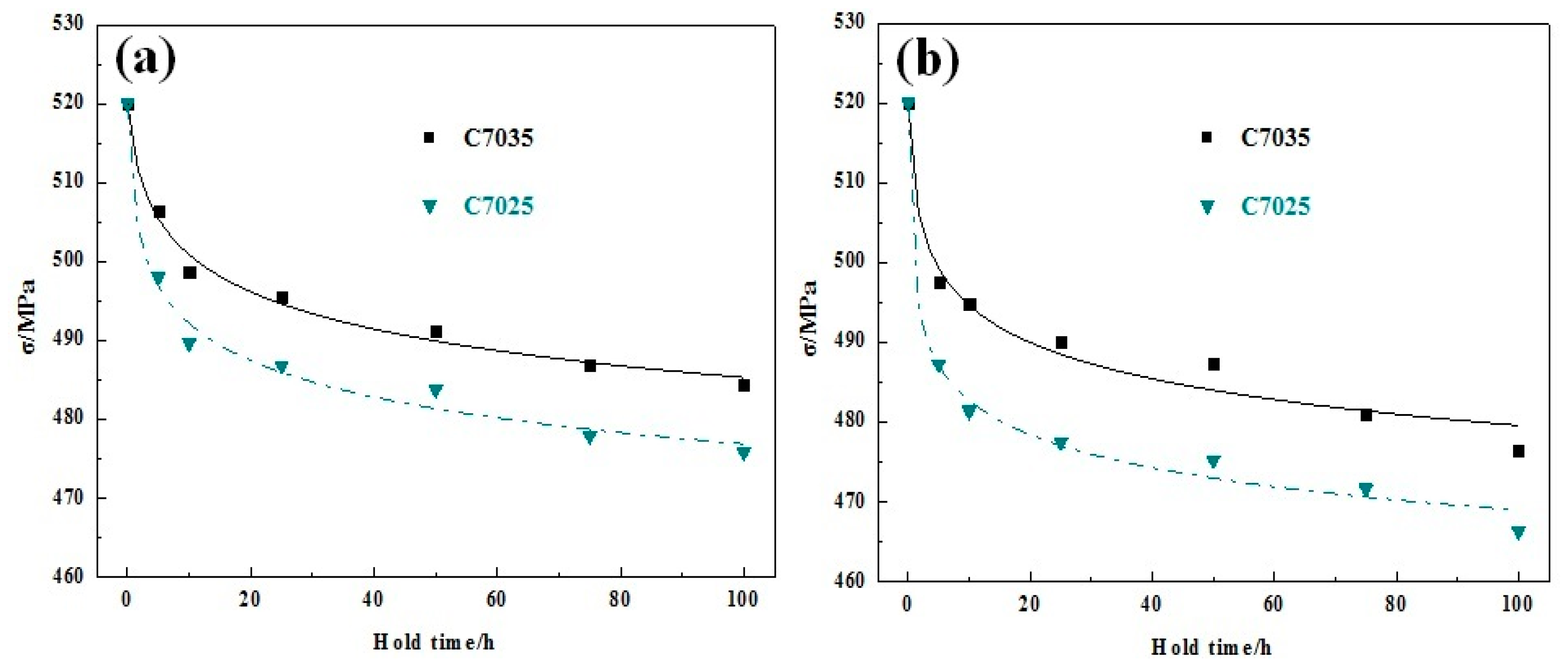

4.1. Dynamic Equation of Stress Relaxation

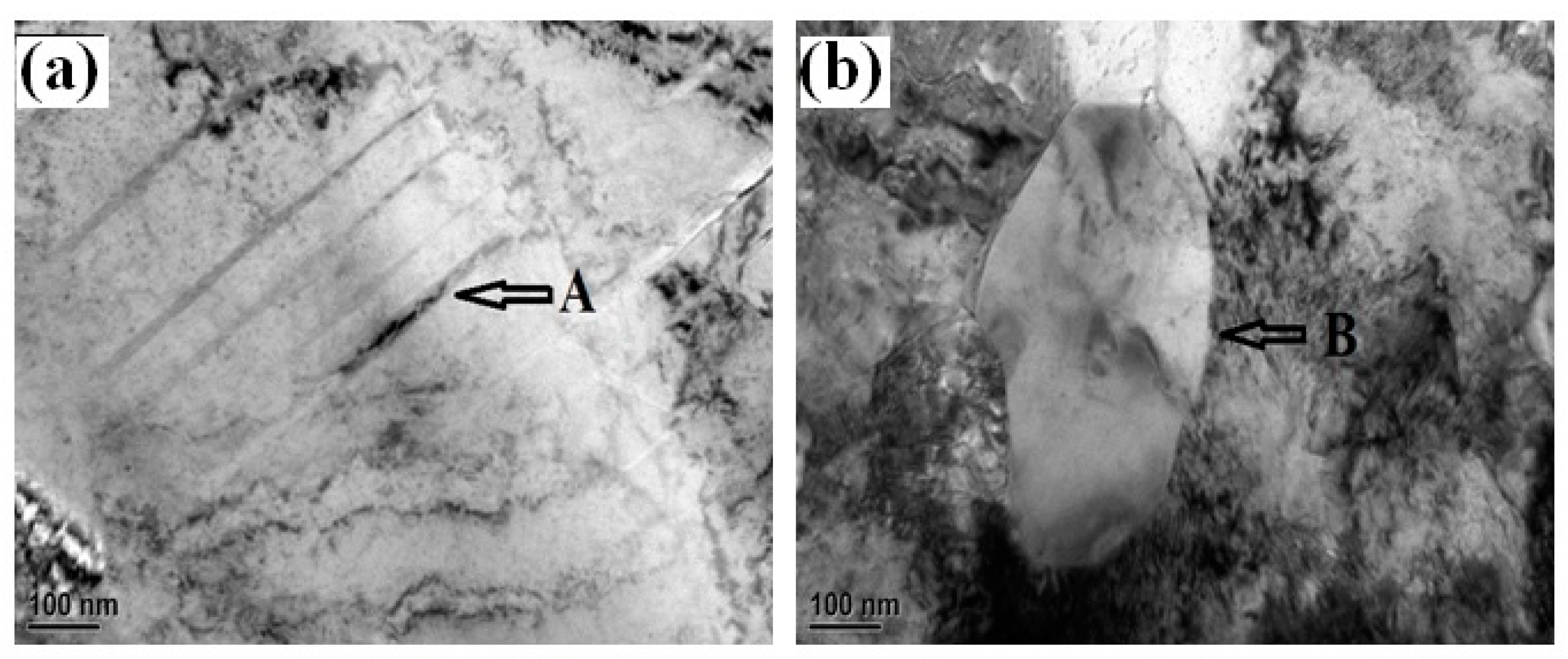

4.2. Transmission Electron Microscopy Analysis of Relaxed Specimens

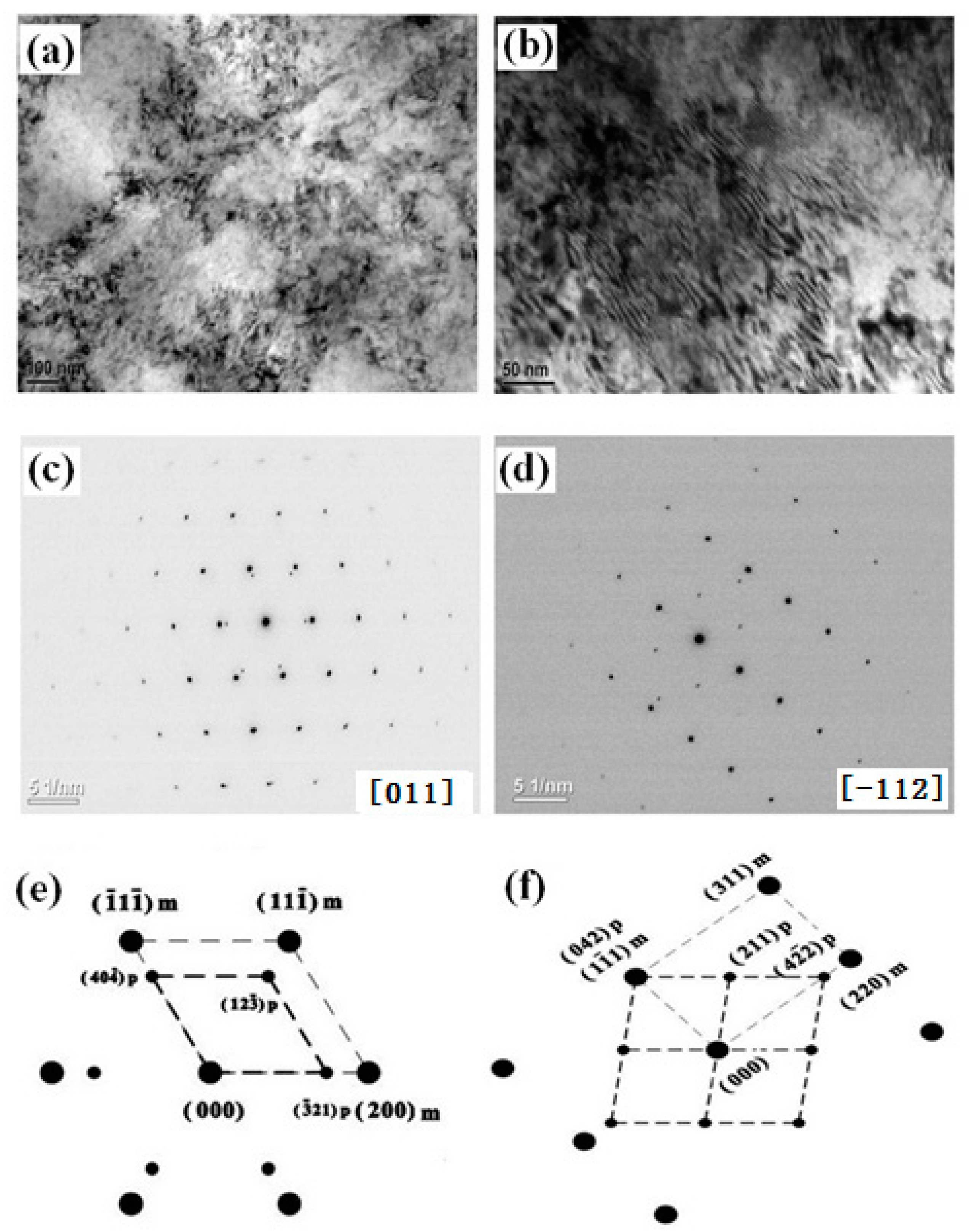

4.2.1. Before Stress Relaxation

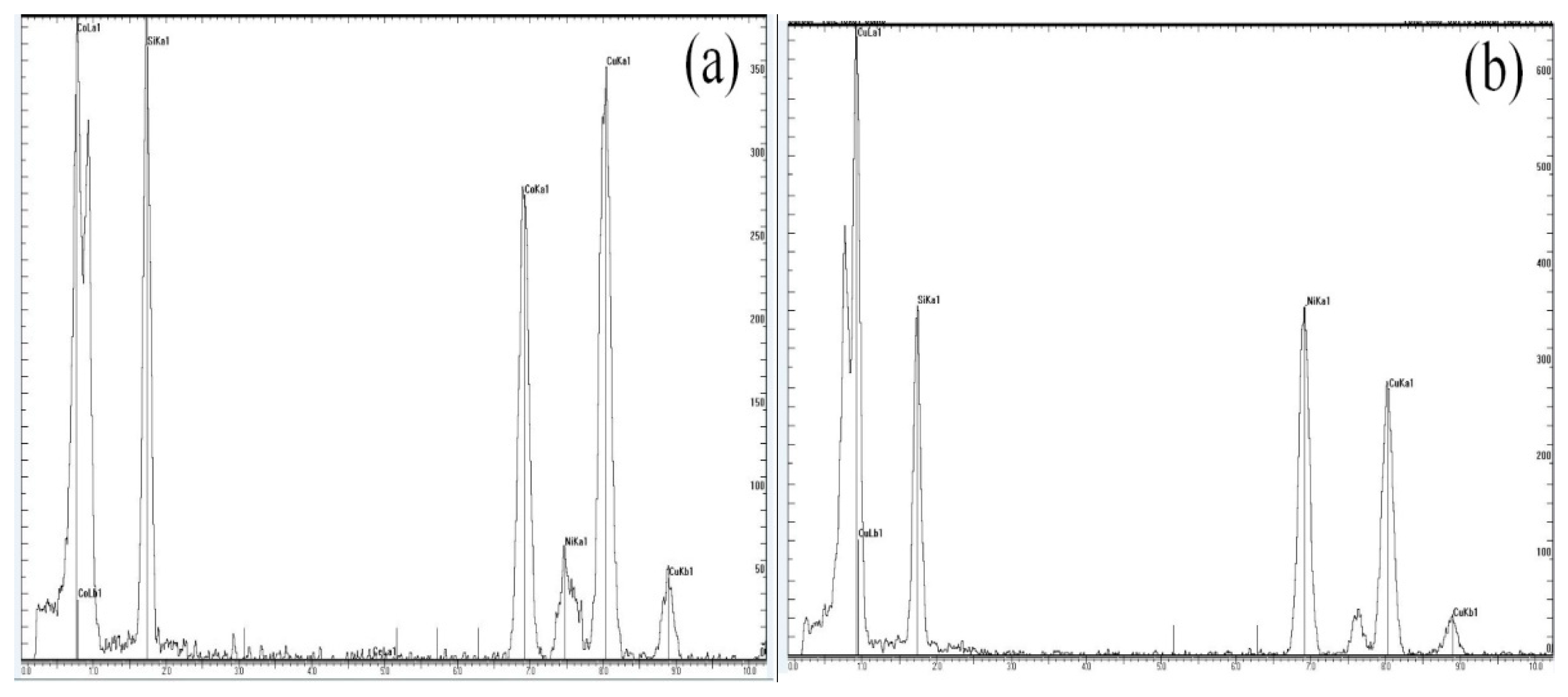

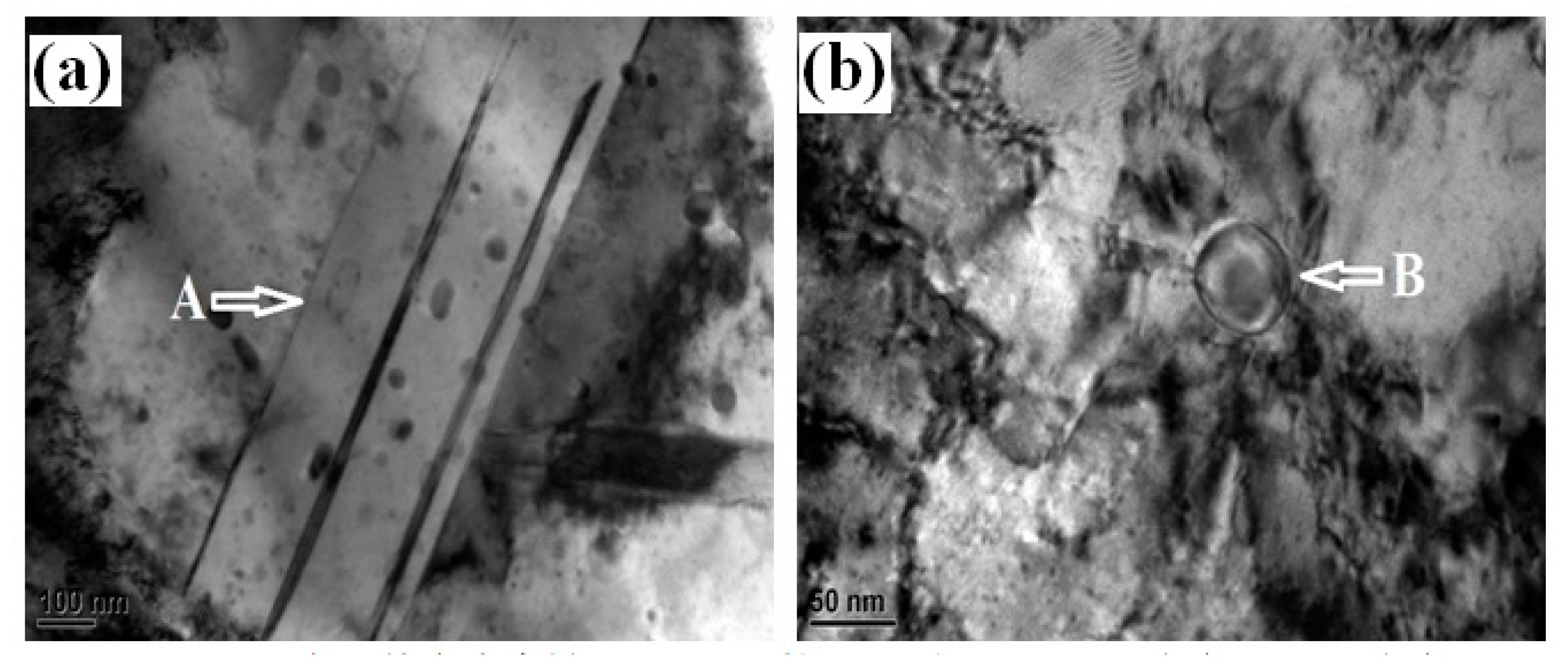

4.2.2. After Stress Relaxation

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Suzuki, S.; Shibutani, N.; Mimura, K.; Isshiki, M.; Waseda, Y. Improvement in strength and electrical conductivity of Cu–Ni–Si alloys by aging and cold rolling. J. Alloys Compd. 2006, 417, 116–120. [Google Scholar] [CrossRef]

- Monzen, R.; Watanabe, C. Microstructure and mechanical properties of Cu-Ni-Si alloys. Mater. Sci. Eng. A 2008, 482, 117–123. [Google Scholar] [CrossRef]

- Izawa, K.; Ozawa, A.; Kita, K.; Watanabe, C.; Monzen, R.J. Influence of Co on strength and microstructure of Cu-Ni-Co-Si alloy. Soc. Mater. Sci. Jan. 2014, 63, 401–408. [Google Scholar] [CrossRef]

- Xiao, X.P.; Yi, Z.Y.; Chen, T.T.; Liu, R.Q.; Wang, H. Suppressing spinodal decomposition by adding Co into Cu-Ni-Si alloy. J. Alloys Compd. 2016, 660, 178–183. [Google Scholar] [CrossRef]

- Wang, Q.S.; Xie, G.L.; Mi, X.J.; Xiong, B.Q.; Xiao, X.P. The precipitation and strengthening mechanism of Cu-Ni-Si-Co alloy. Chin. Mater. Conf. 2012, 749, 294–298. [Google Scholar] [CrossRef]

- Chen, J.F.; Jiang, J.T.; Zhen, L. Stress relaxation behavior of an Al-Zn-Mg-Cu alloy in simulated age-forming process. J. Mater. Process. Technol. 2014, 214, 775–783. [Google Scholar] [CrossRef]

- Xu, X.X.; San, X.Y.; Gong, Y.L. Studies on strength and ductility of Cu-Zn alloys by stress relaxation. Mater. Des. 2013, 47, 295–299. [Google Scholar]

- Chandler, H.D. A comparison between steady state creep and stress relaxation in copper. Mater. Sci. Eng. A 2010, 527, 6219–6223. [Google Scholar] [CrossRef]

- Parikin, Stress Relaxation Testing; ASTM: West Conshohocken, PA, USA, 1979; pp. 48–53.

- Li, Y.L.; Han, Y.J.; Yu, S.C. Stress relaxation properties and microstructure of Cu-Be alloys. Trans. Nonferrous Met. Soc. China 1993, 3, 62–65. [Google Scholar]

- Xiao, L.; Bai, J.L. Stress relaxation properties and microscopic deformation structure of H68 and QSn6.5-0.1 copper alloys at 353 K. Mater. Sci. Eng. A 1998, 244, 250–256. [Google Scholar] [CrossRef]

- Kula, E.; Weiss, V. Residual stress and stress relaxation; Plenum Press: New York, NY, USA, 1981; pp. 140–148. [Google Scholar]

- Orowan, E. Fracture and Strength of Solids [Metals]. Rep. Prog. Phys. 1948, 12, 185–232. [Google Scholar] [CrossRef]

- Johnston, W.J.; Gilman, J.J.J. Dislocation velocities, dislocation densities, and plastic flow in Lithium fluoride crystals. Appl. Phys. 1959, 30, 129–144. [Google Scholar] [CrossRef]

- Li, J.C.M. Dislocation dynamics in deformation and recovery. Can. J. Phys. 1967, 45, 493–509. [Google Scholar] [CrossRef]

- Virtanen, P.; Tiainen, T. Stress relaxation behavior in bending of high strength copper alloys in the Cu-Ni-Sn system. Mater. Sci. Eng. A 1997, 238, 407–420. [Google Scholar] [CrossRef]

- Povolo, F.; Tinivella, R. Stress relaxation in bending of type AISI 304 and A-286 steels at 773K. J. Mater. Sci. 1984, 19, 1851–1862. [Google Scholar] [CrossRef]

- Lee, D.H.; Nam, S.W.; Choe, S.J. Effect of microstructure and relaxation behavior on the high temperature low cycle fatigue of near-a-Ti-1100. Mater. Sci. Eng. A 2000, 291, 60–67. [Google Scholar] [CrossRef]

- Povarov, I.A. Stress relaxation in structural titanium alloys. Met. Sci. Heat Treat. 1982, 22, 433–452. [Google Scholar] [CrossRef]

- Mori, T. Diffusional relaxation around a second phase particle. Acta Metall. 1980, 28, 319–321. [Google Scholar] [CrossRef]

- Onaka, S. Kinetics of Stress relaxation caused by the combination of interfacial sliding and diffusiong: Two-dimensional analysis. Acta Mater. 1998, 46, 3821–3830. [Google Scholar] [CrossRef]

| Alloy | Nickel | Silicon | Cobalt | Copper |

|---|---|---|---|---|

| C7025 | 2.6 | 0.6 | 0 | Balance |

| C7035 | 1.4 | 0.6 | 1.2 | Balance |

| Alloy | Tensile Strength σb (MPa) | Yield Strength σs (MPa) | Elongation δ (%) |

|---|---|---|---|

| C7025 | 756 ± 20 | 535 ± 10 | 5~7 |

| C7035 | 838 ± 20 | 584 ± 10 | 5~7 |

| Alloy | Temperature | Dynamic Equation | Variance | Correlation Coefficient |

|---|---|---|---|---|

| C7035 | 298 K | σ* = 449.96 + 75.75 × (t + 1.61)−0.16 | 3.19 | 0.989 |

| 393 K | σ* = 108.98 + 401.91 × (t + 0.28)−0.02 | 8.71 | 0.978 | |

| C7025 | 298 K | σ* = 367.44 + 142.56 × (t + 0.31)−0.06 | 5.31 | 0.988 |

| 393 K | σ* = 63.18 + 433.9 × (t + 0.03)−0.02 | 5.02 | 0.992 | |

| C7035 | 298 K | σ* = [1.23 × 10−6 + 4.47 × 10−8 × (t + 0.95)]−0.46 | 2.89 | 0.991 |

| 393 K | σ* = [8.27 × 10−7 + 2.82 × 10−8 × (t + 0.36)]−0.45 | 8.28 | 0.979 | |

| C7025 | 298 K | σ* = [1.31 × 10−6 + 4.42 × 10−8 × (t + 0.28)]−0.46 | 5.30 | 0.988 |

| 393 K | σ* = [8.54 × 10−7 + 2.68 × 10−8 × (t + 0.05)]−0.45 | 4.86 | 0.992 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, X.; Xu, H.; Huang, J.; Wang, J.; Zhang, J. Stress Relaxation Properties and Microscopic Deformation Structure in Bending of the C7025 and C7035 Alloy. Crystals 2018, 8, 324. https://doi.org/10.3390/cryst8080324

Xiao X, Xu H, Huang J, Wang J, Zhang J. Stress Relaxation Properties and Microscopic Deformation Structure in Bending of the C7025 and C7035 Alloy. Crystals. 2018; 8(8):324. https://doi.org/10.3390/cryst8080324

Chicago/Turabian StyleXiao, Xiangpeng, Hai Xu, Jian Huang, Junfeng Wang, and Jianbo Zhang. 2018. "Stress Relaxation Properties and Microscopic Deformation Structure in Bending of the C7025 and C7035 Alloy" Crystals 8, no. 8: 324. https://doi.org/10.3390/cryst8080324