Evaluation of Thin Copper Wire and Lead-Free Solder Joint Strength by Pullout Tests and Wire Surface Observation

Abstract

:1. Introduction

2. Experimental Procedures

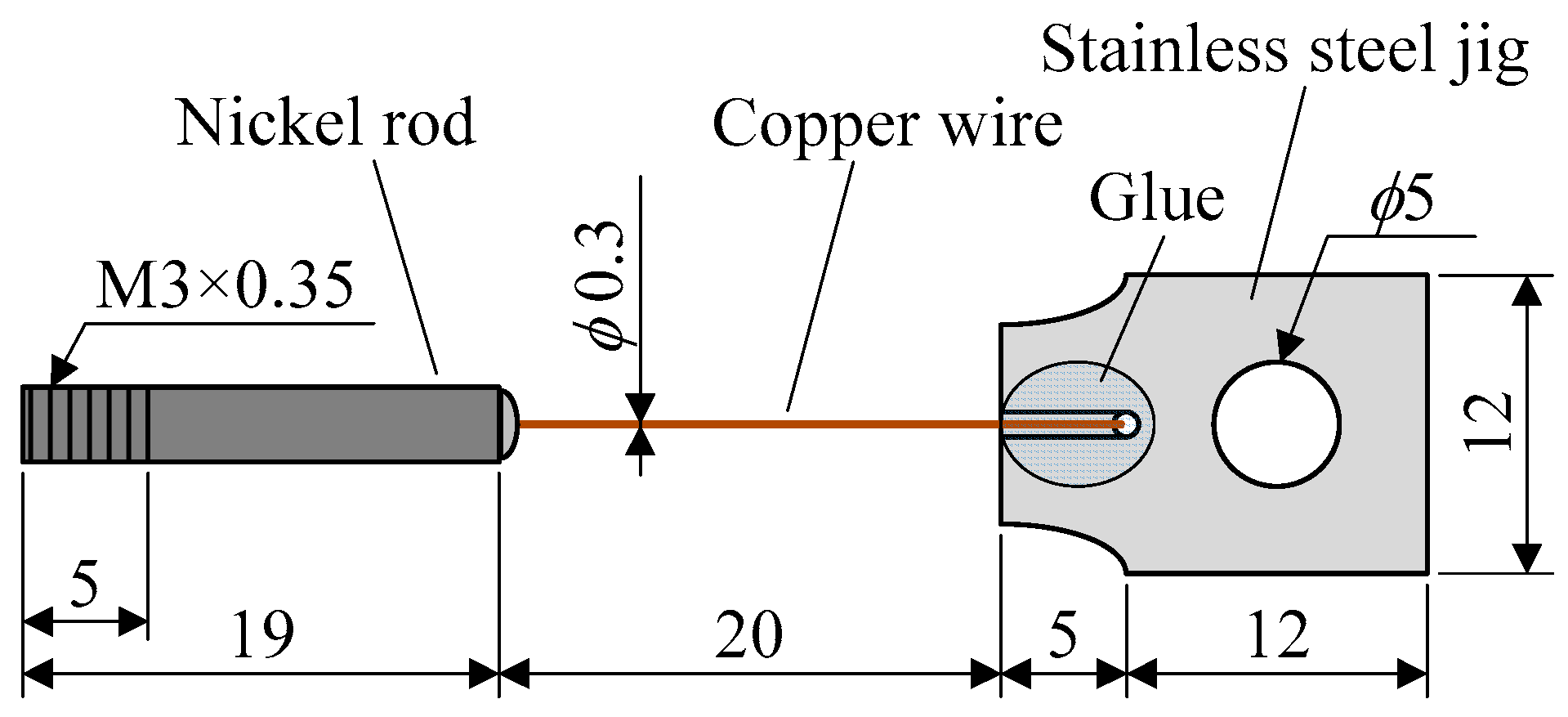

2.1. Solder Joint Specimen

- One end of the copper wire was mechanically polished using emery papers #800 and #1200 and an ultrasonic cleaning was performed by isopropanol.

- The other (unpolished) end of the copper wire was glued to the stainless-steel jig by cyanoacrylate-based instantaneous adhesive, and held together for more than one day to ensure complete hardening.

- A small piece of lead-free solder was cut and heated at the tip of a soldering iron to melt it into a spheroidal shape. Lead-free solder HS-304 (Sn-3Ag-0.5Cu) manufactured by Hozan tool industrial Co., Ltd., Osaka, Japan was used.

- The solder ball was put on the upper surface of the nickel rod standing in the vertical direction, and was heated on the hot plate. Soldering flux RM-5 manufactured by Nihon Superior Co., Ltd., Suita, Japan, was glued to the upper surface of the nickel rod before the heating.

- When the melting of the solder was confirmed, one end of the copper wire opposite to the jig side was inserted into the melted solder, and naturally cooled to room temperature for about an hour.

2.2. Pullout Test

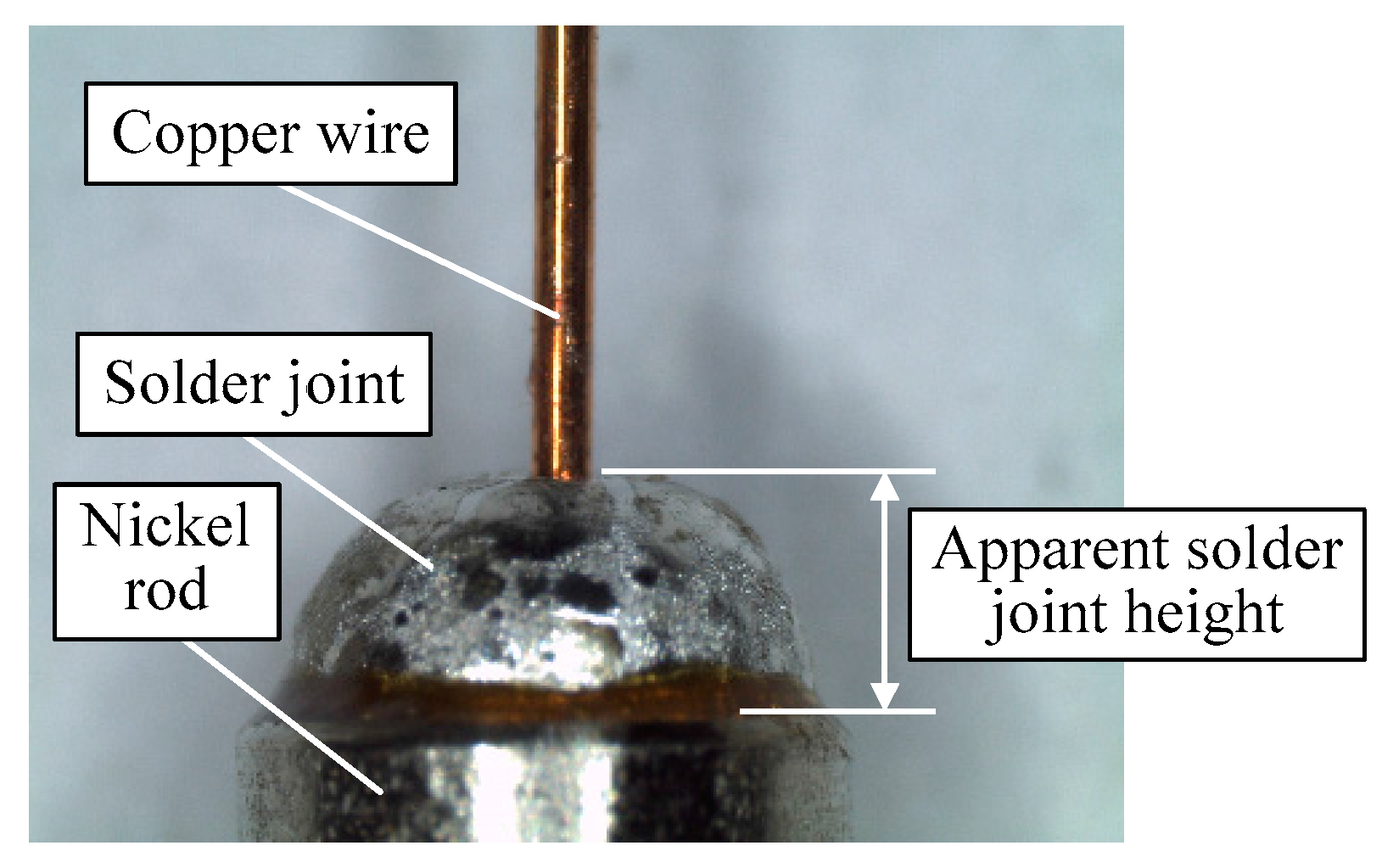

2.3. Apparent Height of Solder Joint and Actual Bond Length

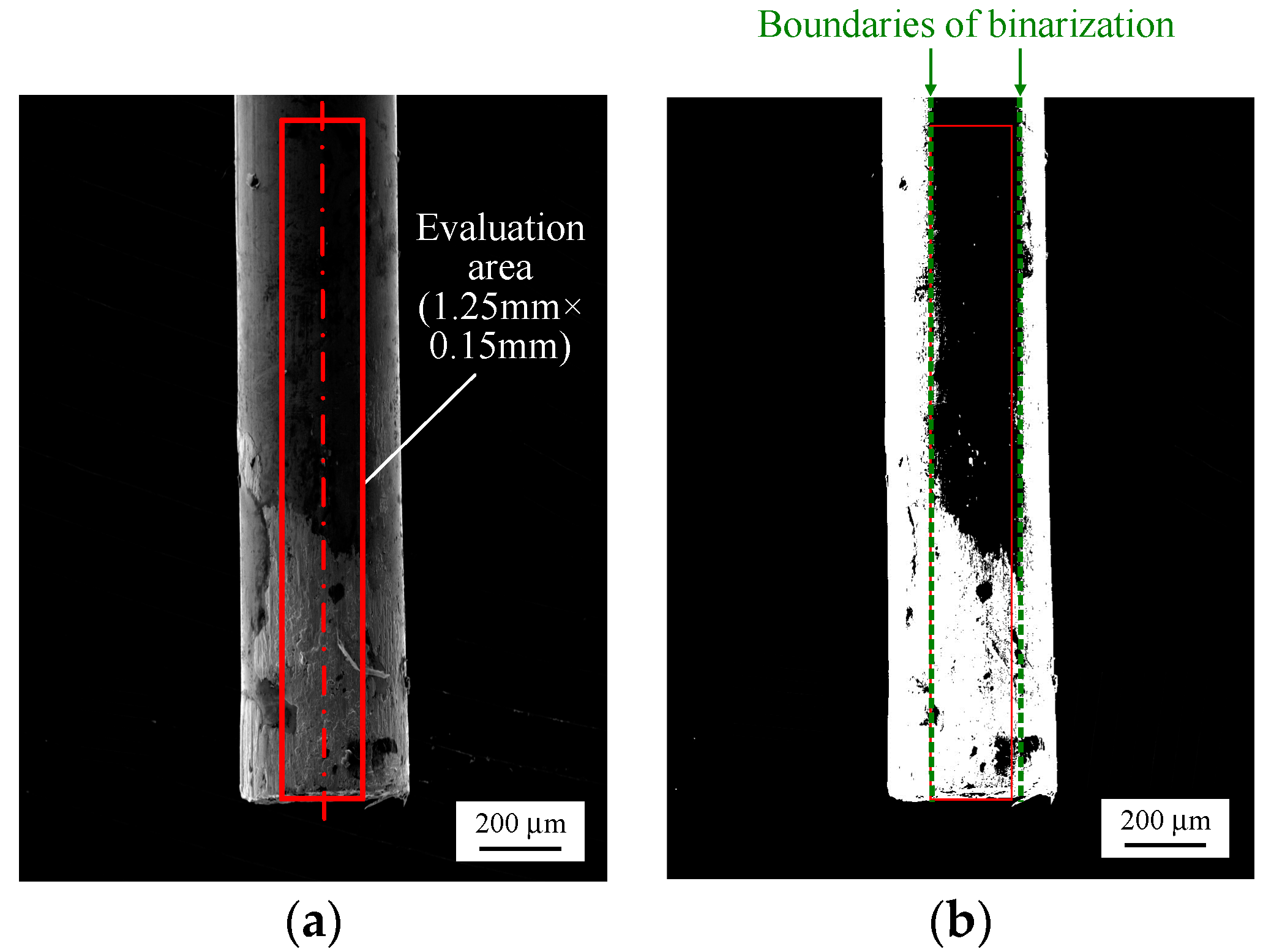

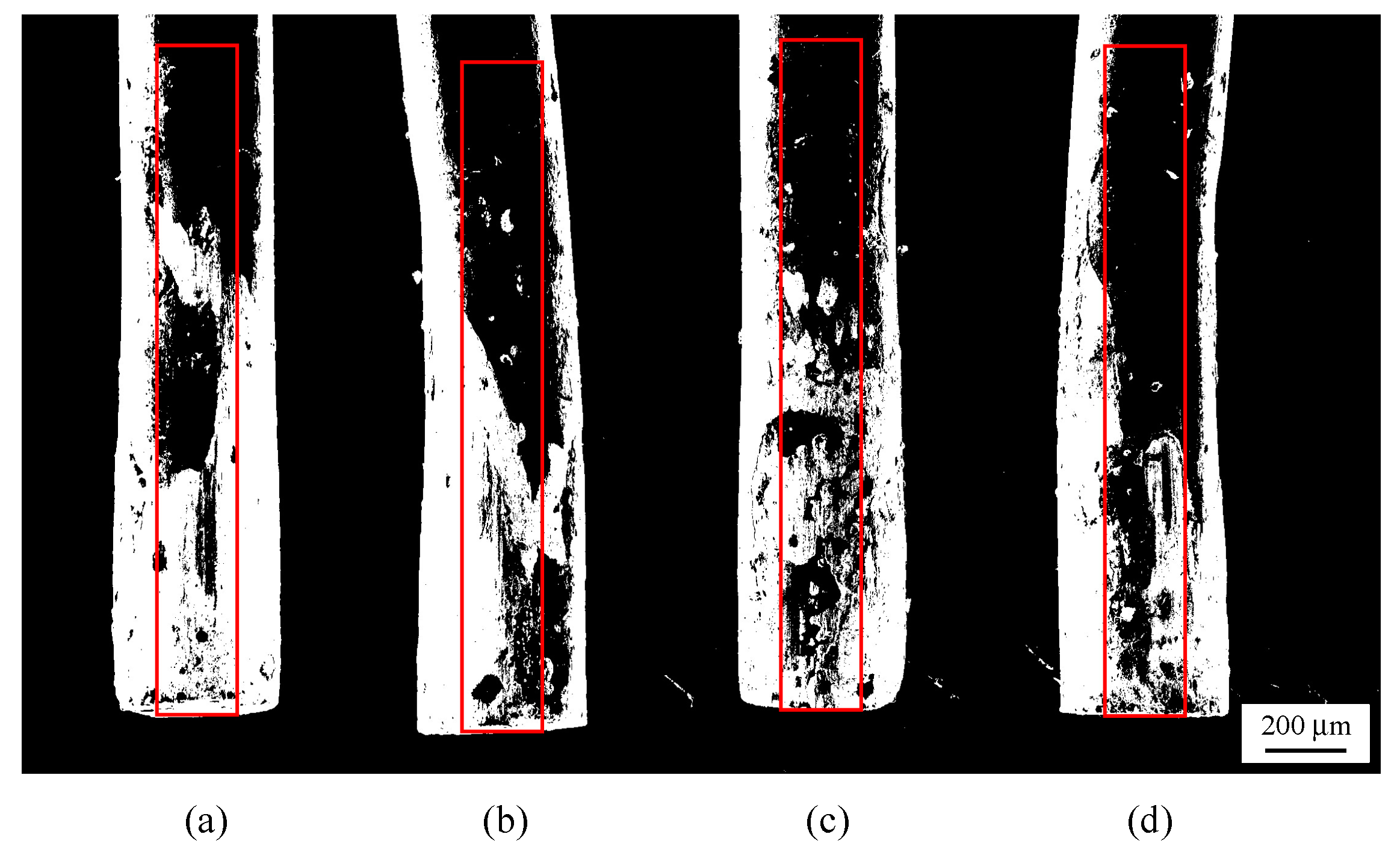

- The observation of the copper wire surface was carried out in four orthogonal directions by a scanning electron microscope (SEM, Hitachi, S-3500N, Tokyo, Japan). An evaluation area of 1.25 mm × 0.15 mm (1100 × 132 pixels), shown by a red rectangle in Figure 3a, was set on the surface of the copper wire. Its location was determined so that the center line and the bottom side coincided with those of the copper wire, respectively. The observation of the copper wire surface was also performed by the optical microscope, and it was confirmed that the brighter areas observed by SEM corresponded to the remaining silver solder.

- As seen in Figure 3a, the actual bonded area is brighter than the other area. On the other hand, when focusing on the upper portion of the copper wire where there is no bonded area, the peripheral area along the edge of copper wire is brighter than the central area. Considering these characteristics of the SEM image, the threshold of binarization was determined as follows. Two parallel green broken lines in Figure 3b show the boundaries of binarization at a certain threshold. The boundaries move to the right and left according to the level of threshold. In this study, the binarization threshold was determined so that two parallel lines are situated on or outside the evaluation area. Taking the threshold value, only the bonded area becomes white in the evaluation area.

- The number of white pixels corresponding to the bonded area was counted and converted to the actual area in mm2. The actual bond length was evaluated by dividing the bonded area by the width of the evaluation area, 0.15 mm, which represents the average height of the bonded area.

- The above steps 1 to 3 were repeated in four orthogonal directions and the values were averaged.

3. Experimental Results

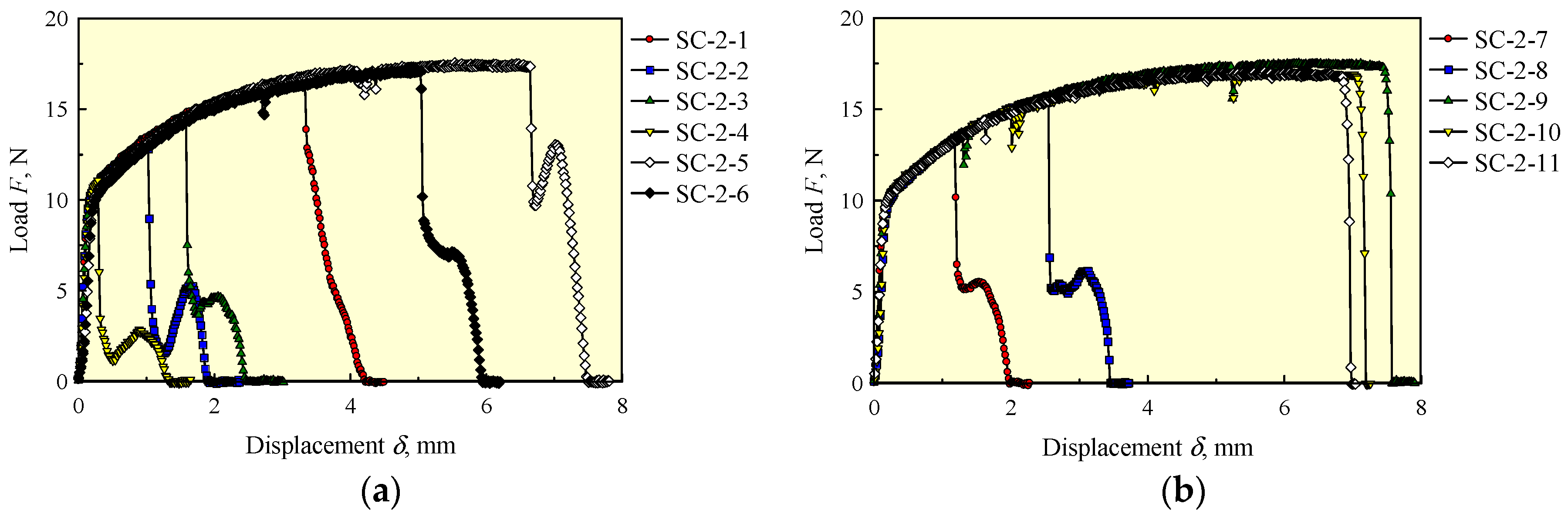

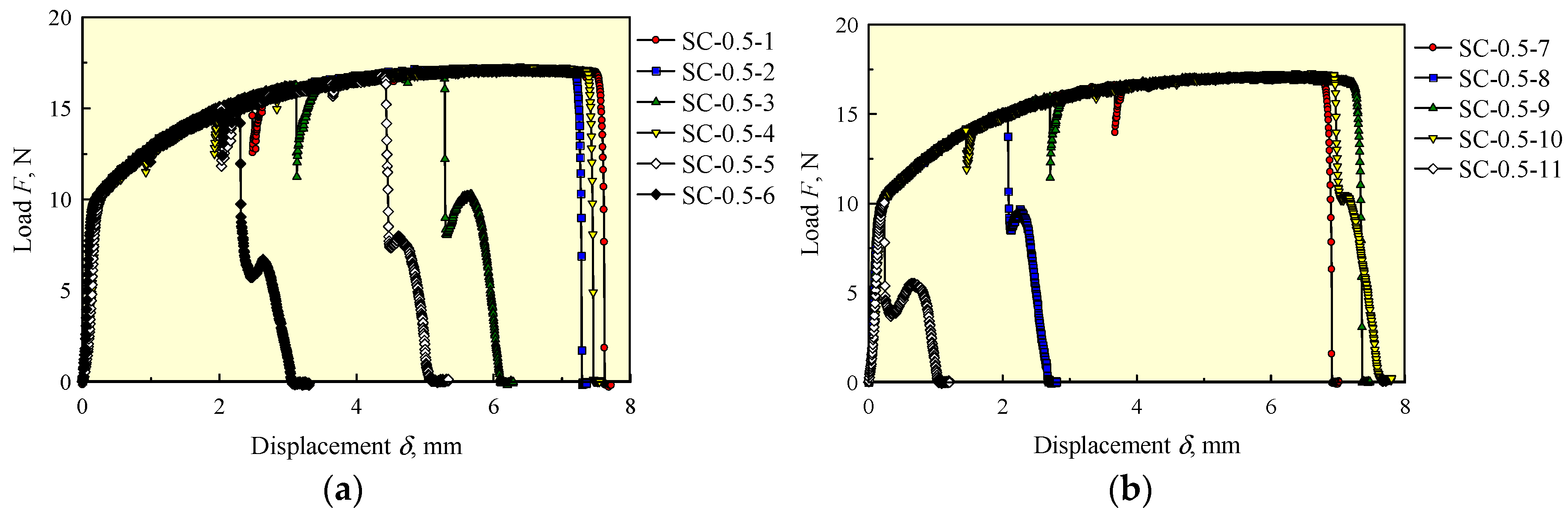

3.1. Load-Displacement Diagram

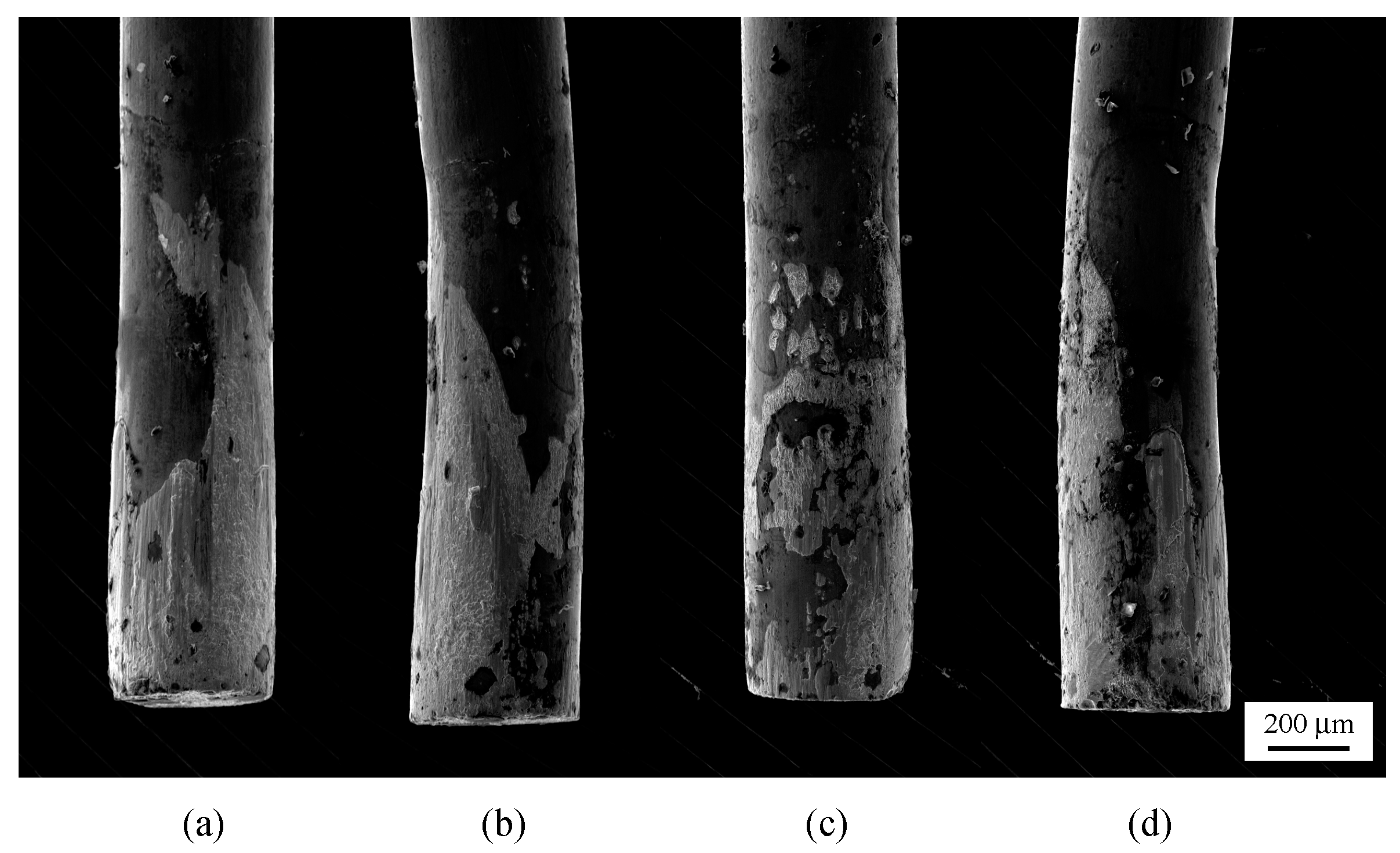

3.2. Surface of the Copper Wire

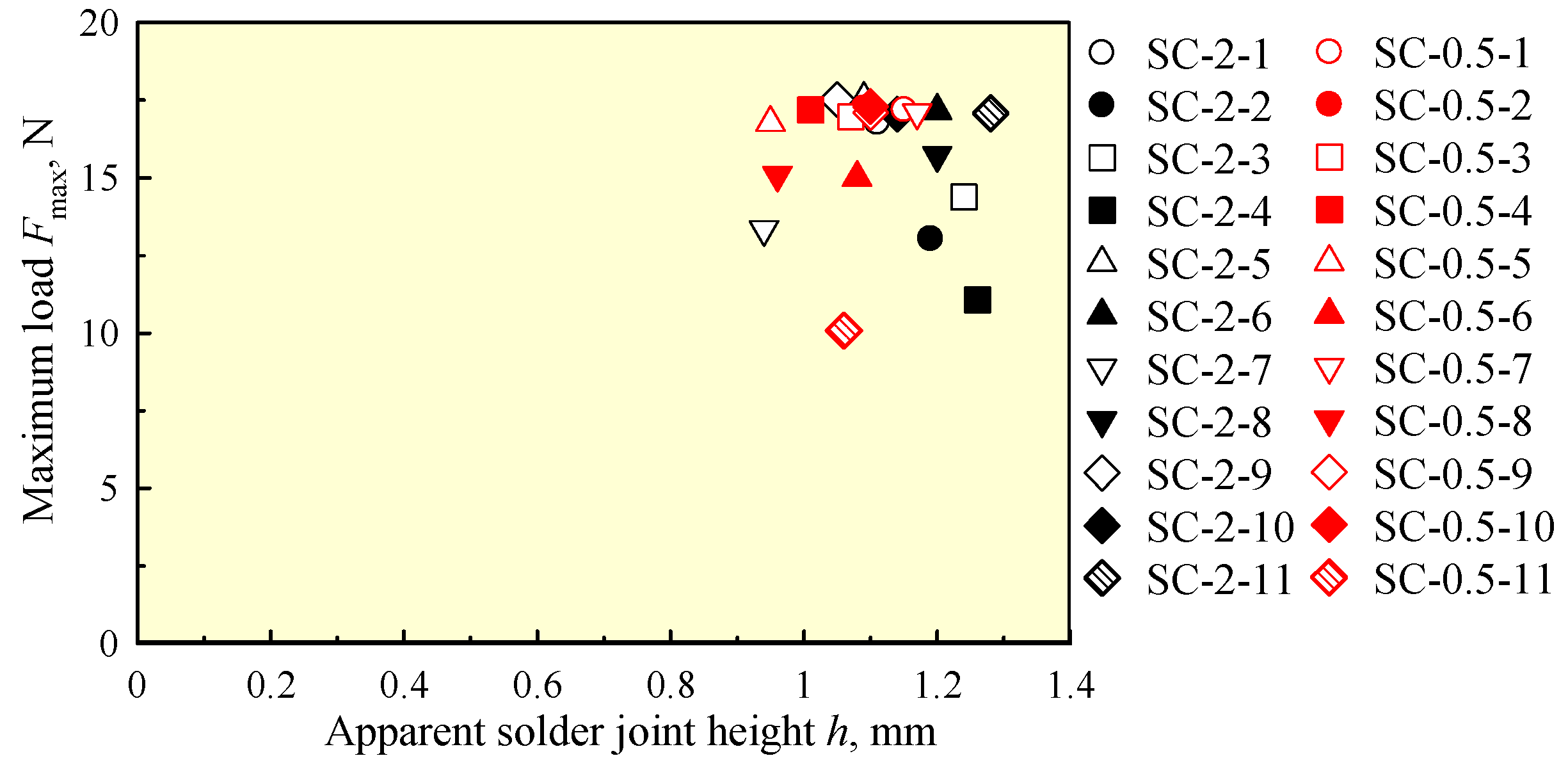

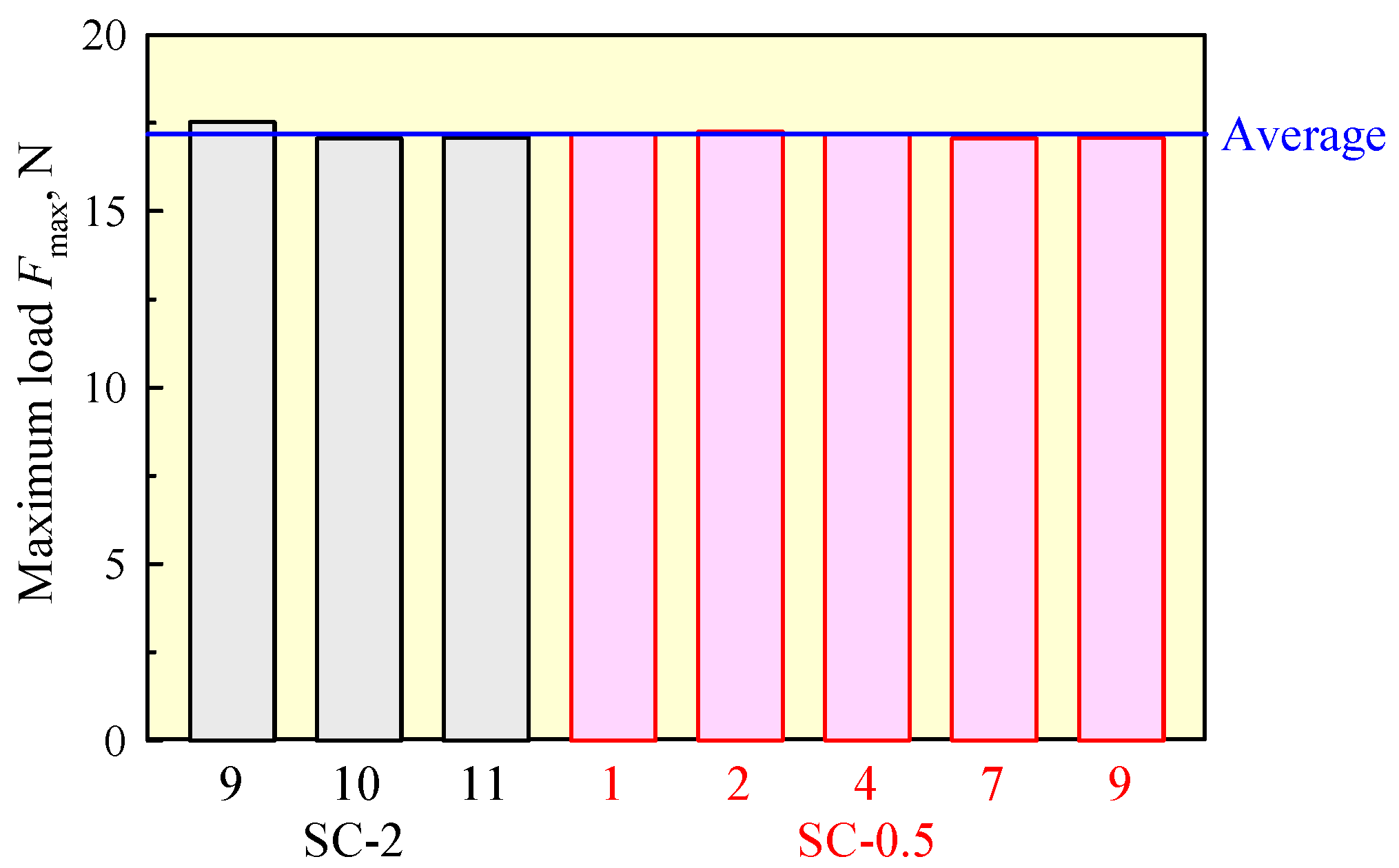

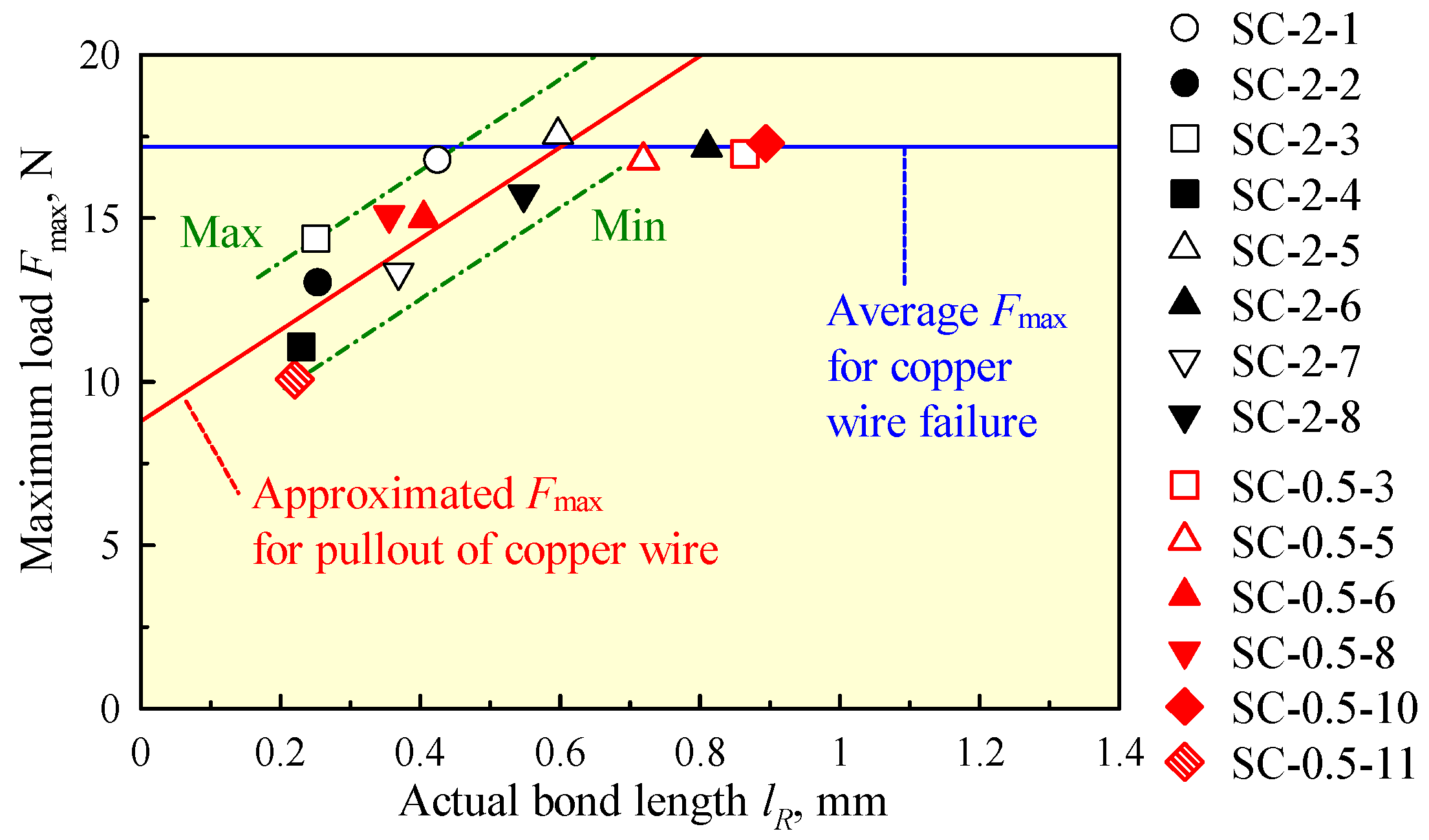

3.3. Relationship between Maximum Load and Bond Length of Solder Joint

4. Evaluation of Tensile and Shear Strengths of the Copper/Solder Interface

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Breach, C.D. What is the Future of Bonding Wire? Will Copper Entirely Replace Gold? Gold Bull. 2010, 43, 150–168. [Google Scholar] [CrossRef]

- Gan, C.L.; Hashim, U. Evolution of Bonding Wires Used in Semiconductor Electronics: Perspective over 25 Years. J. Mater. Sci. Mater. Electron. 2015, 26, 4412–4424. [Google Scholar] [CrossRef]

- Yang, B.; Motz, C.; Grosinger, W.; Dehm, G. Stress-Controlled Fatigue Behavior of Micro-Sized Polycrystalline Copper Wires. Mater. Sci. Eng. 2009, 515, 71–78. [Google Scholar] [CrossRef]

- Yang, B.; Motz, C.; Grosinger, W.; Dehm, G. Cyclic Loading Behavior of Micro-Sized Polycrystalline Copper Wires. Proced. Eng. 2010, 2, 925–930. [Google Scholar] [CrossRef]

- Huang, I.-T.; Hung, F.-Y.; Lui, T.-S.; Chen, L.-H.; Hsueh, H.-W. A Study on the Tensile Fracture Mechanism of 15 μm Copper Wire after EFO Process. Microelectron. Reliab. 2011, 51, 25–29. [Google Scholar] [CrossRef]

- Tada, N.; Matsukawa, Y.; Uemori, T.; Nakata, T. Microscopic Deformation of Polycrystalline Pure Copper Wire during Tension. In Proceedings of the 10th International Microsystems, Packaging, Assembly and Circuits Technology Conference, Taipei, Taiwan, 21–23 October 2015; pp. 420–423. [Google Scholar]

- Kobayashi, M. Reliability of Soldered Connections in Single Ended Circuit Components. Weld. Res. Suppl. 1975, 363-s–369-s. [Google Scholar]

- Susan, D.F.; Kilgo, A.C.; Vianco, P.T.; Neilsen, M.K. Thermal Fatigue and Failure Analysis of Cu-Plated Through Hole Solder Joints. Microsc. Microanal. 2009, 15, 26–27. [Google Scholar] [CrossRef]

- Zeng, G.; Xue, S.; Zhang, L.; Gao, L.; Dai, W.; Luo, J. A Review on the Interfacial Intermetallic Compounds between Sn-Ag-Cu Based Solders and Substrates. J. Mater. Sci. Mater. Electron. 2010, 21, 421–440. [Google Scholar] [CrossRef]

- An, T.; Qin, F. Effects of Intermetallic Compound Microstructure on the Tensile Behavior of Sn3.0Ag0.5Cu/Cu Solder Joint under Various Strain Rates. Microelectron. Reliab. 2014, 54, 932–938. [Google Scholar] [CrossRef]

- Anderson, I.E.; Harringa, J.L. Elevated Temperature Aging of Solder Joints Based on Sn-Ag-Cu: Effects on Joint Micsostructure and Shear Strength. J. Electron. Mater. 2004, 33, 1485–1496. [Google Scholar] [CrossRef]

- Cugnoni, J.; Botsis, J.; Sivasubramaniam, V.; Janczak-Rusch, J. Experimental and Numerical Studies on Size and Constraining Effects in Lead-Free Solder Joints. Fatigue Fract. Eng. Mater. Struct. 2007, 30, 387–399. [Google Scholar] [CrossRef]

- Zimprich, P.; Saeed, U.; Weiss, B.; Ipser, H. Constraining Effects of Lead-Free Solder Joints During Stress Relaxation. J. Electron. Mater. 2008, 38, 392–399. [Google Scholar] [CrossRef]

- Fujiwara, S.; Dauskardt, R.H. Interface Structure of Cu Wire Bonding on Cu Substrate with Sn Plating. Mater. Trans. 2012, 53, 2091–2096. [Google Scholar] [CrossRef]

- Anderson, I.E.; Cook, B.A.; Harringa, J.L.; Terpstra, R.L. Sn-Ag-Cu Solders and Solder Joints: Alloy Development, Microstructure, and Properties. JOM J. Miner. Met. Mater. Soc. 2002, 54, 26–29. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tada, N.; Tanaka, T.; Uemori, T.; Nakata, T. Evaluation of Thin Copper Wire and Lead-Free Solder Joint Strength by Pullout Tests and Wire Surface Observation. Crystals 2017, 7, 255. https://doi.org/10.3390/cryst7080255

Tada N, Tanaka T, Uemori T, Nakata T. Evaluation of Thin Copper Wire and Lead-Free Solder Joint Strength by Pullout Tests and Wire Surface Observation. Crystals. 2017; 7(8):255. https://doi.org/10.3390/cryst7080255

Chicago/Turabian StyleTada, Naoya, Takuhiro Tanaka, Takeshi Uemori, and Toshiya Nakata. 2017. "Evaluation of Thin Copper Wire and Lead-Free Solder Joint Strength by Pullout Tests and Wire Surface Observation" Crystals 7, no. 8: 255. https://doi.org/10.3390/cryst7080255