Crystal Engineering for Mechanical Strength at Nano-Scale Dimensions

Abstract

:1. Introduction

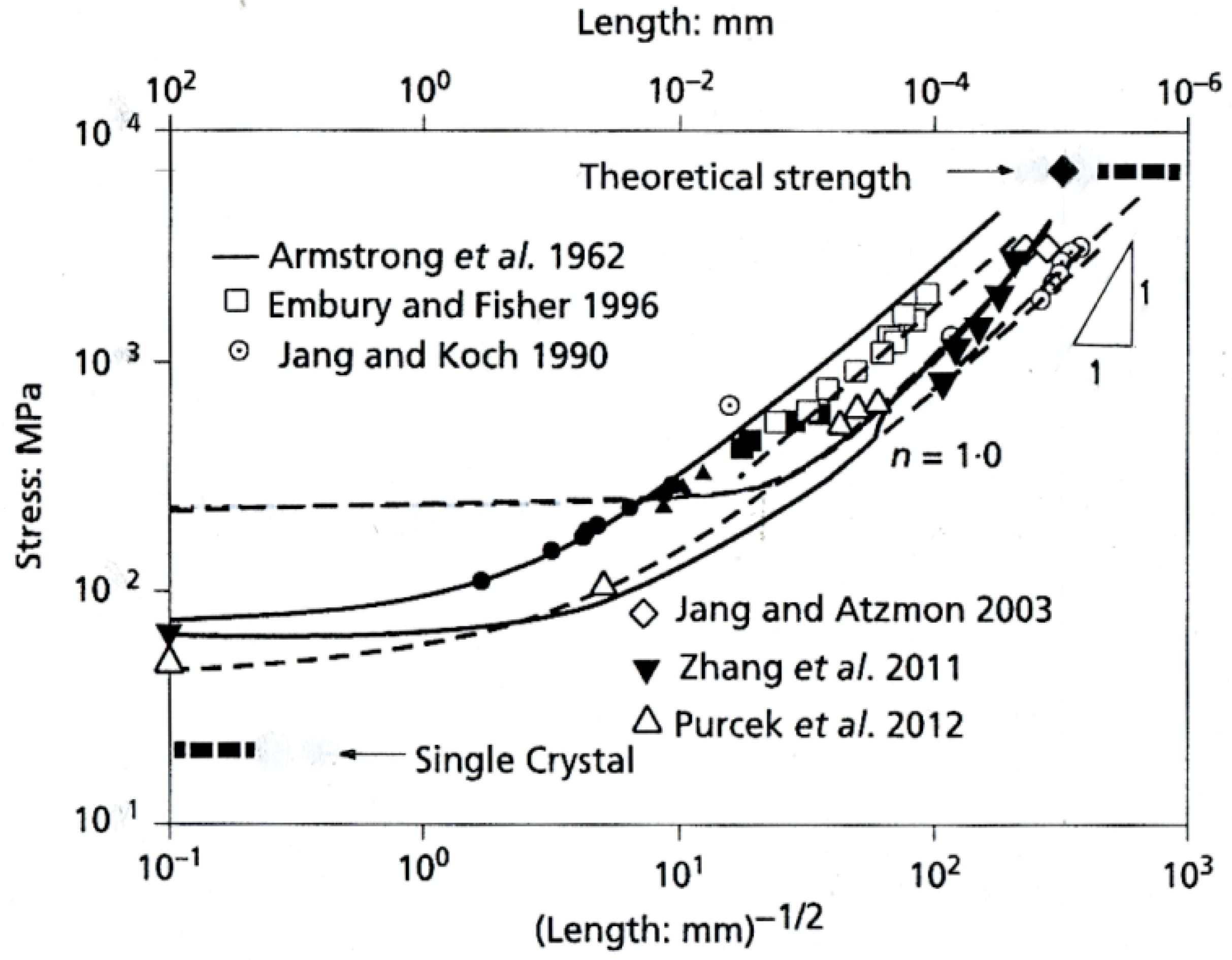

2. Nanocrystal/Nanopolycrystal Strengths of Iron and Steel

2.1. Un-Constrained Nanocrystals

2.2. Constrained Polycrystalline Plasticity

2.3. Severe Plastic Deformation (SPD)

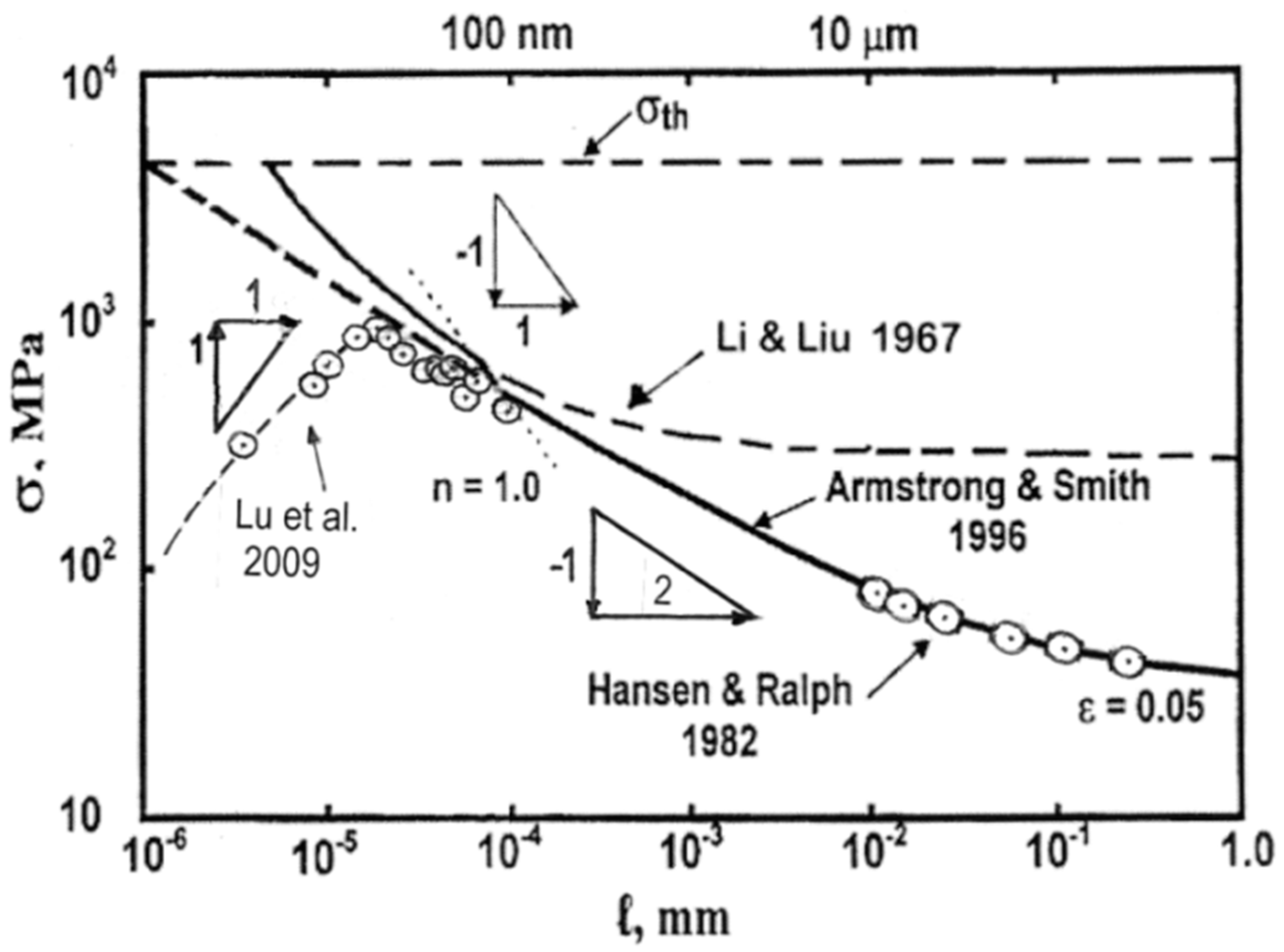

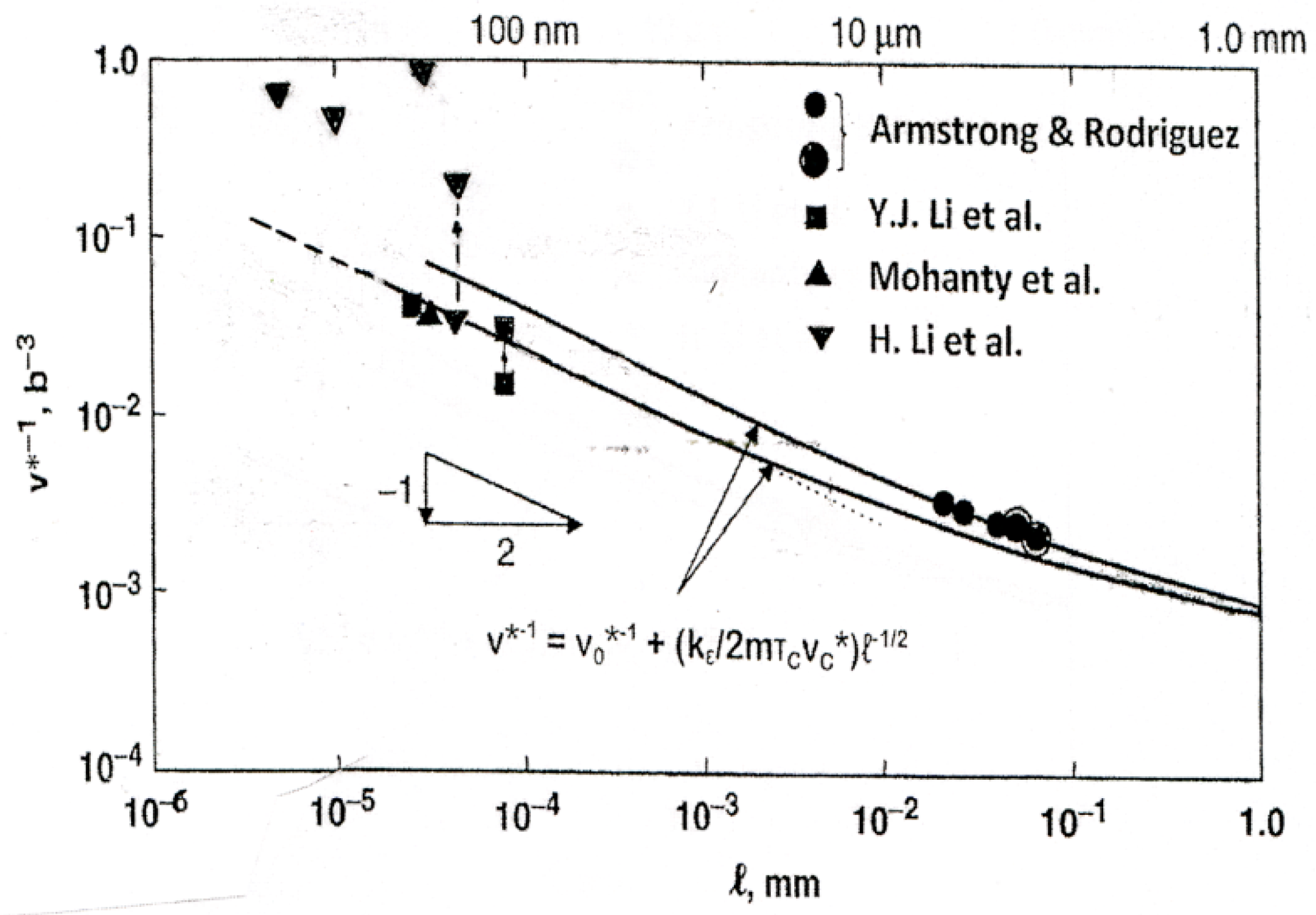

3. Nanopolycrystal FCC Metals

3.1. Nanograin and Nanotwin Strengthening

3.2. Nanograin Size Weakening

4. Discussion

5. Summary

Conflicts of Interest

Abbreviations

| H-P | Hall-Petch |

| EFN | Eshelby, Frank and Nabarro |

| ECAP | Equal channel angular pressing |

| SPD | Severe plastic deformation |

| CSL | Coincident site lattice |

References

- Han, W.Z.; Huang, L.; Ogata, S.; Kimizuka, H.; Yang, Z.C.; Weinberger, C.; Li, Q.J.; Liu, B.Y.; Zhang, X.X.; Li, J.; et al. From “Smaller is Stronger” to “Size-Independent Strength Plateau”: Towards Measuring the Ideal Strength of Iron. Adv. Mater. 2015, 27, 3385–3390. [Google Scholar] [CrossRef] [PubMed]

- Nowak, J.D.; Beaber, A.R.; Ugurlu, O.; Girshick, S.L.; Gerberich, W.W. Small size strength dependence on dislocation nucleation. Scr. Mater. 2010, 62, 819–822. [Google Scholar] [CrossRef]

- Li, J.C.M.; Liu, G.C.T. Circular dislocation pile-ups: I. Strength of ultrafine polycrystalline aggregates. Philos. Mag. 1967, 15, 1059–1063. [Google Scholar] [CrossRef]

- Hintsala, E.D.; Wagner, A.J.; Gerberich, W.W.; Mkhoyan, K.A. The role of back stress in sub-50 nm Si nanocubes. Scr. Mater. 2016, 114, 51–55. [Google Scholar] [CrossRef]

- Eshelby, J.D.; Frank, F.C.; Nabarro, F.R.N. The equilibrium of linear arrays of dislocations. Philos. Mag. 1951, 42, 351–364. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and ageing of mild steel: III. Discussion of results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Smith, T.R.; Armstrong, R.W.; Hazzledine, P.M.; Masamura, R.A.; Pande, C.S. Pile-Up Based Hall-Petch Consideration at Ultra-Fine Grain Sizes. In Grain Size and Mechanical Properties—Fundamentals and Applications; Otooni, M.A., Armstrong, R.W., Grant, N.J., Ishizaki, K., Eds.; Materials Research Society: Pittsburgh, PA, USA, 1995; Volume 362, pp. 31–37. [Google Scholar]

- Armstrong, R.W.; Codd, I.; Douthwaite, R.M.; Petch, N.J. The plastic deformation of polycrystalline aggregates. Philos. Mag. 1962, 7, 45–58. [Google Scholar] [CrossRef]

- Purcek, G.; Saray, O.; Karaman, I.; Maier, H.J. High strength and high ductility in ultrafine-grained interstitial-free steel produced by ECAE and annealing. Metall. Mater. Trans. A 2012, 43, 1884–1894. [Google Scholar] [CrossRef]

- Jang, J.C.S.; Koch, C.C. The Hall-Petch relationship in nanocrystalline iron produced by ball milling. Scr. Metall. 1990, 24, 1599–1604. [Google Scholar] [CrossRef]

- Embury, J.D.; Fisher, R.M. The structure and properties of drawn pearlite. Acta Metall. 1966, 14, 147–152. [Google Scholar] [CrossRef]

- Zhang, X.D.; Godfrey, A.; Huang, X.; Hansen, N.; Liu, Q. Microstructure and strengthening mechanisms in cold-drawn pearlitic steel wire. Acta Mater. 2011, 59, 3422–3430. [Google Scholar] [CrossRef]

- Li, Y.; Raabe, D.; Herbig, M.; Choi, P.P.; Goto, S.; Kostka, A.; Yarita, H.; Borchers, C.; Kirchheim, R. Segregation stabilizes nanocrystalline bulk steel with near theoretical strength. Phys. Rev. Lett. 2014, 113, 106104. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, R.W. Hall-Petch k dependencies in nanopolycrystals. Emerg. Mater. Res. 2014, 3, 246–251. [Google Scholar] [CrossRef]

- Svoboda, J.; Zickler, G.A.; Kozeschnik, E.; Fischer, F.D. Kinetics of interstitial segregation in Cottrell atmosphers and grain boundaries. Philos. Mag. Lett. 2015, 95, 458–465. [Google Scholar] [CrossRef]

- Kang, J.H.; Duan, S.; Kim, S.J.; Bleck, W. Grain boundary strengthening in high Mn austenitic steels. Metall. Mater. Trans. A 2016, 47A, 1918–1921. [Google Scholar] [CrossRef]

- Fitzgerald, S.P.; Dudarev, S.L. Dislocation pile-ups in Fe at high temperatures. Proc. R. Soc. A 2008, 464, 2549–2559. [Google Scholar] [CrossRef]

- Armstrong, R.W. The yield and flow stress dependence on polycrystal grain size. In Yield, Flow and Fracture of Polycrystals; Baker, T.N., Ed.; Applied Science Publisher: London, UK, 1983; pp. 1–31. [Google Scholar]

- Langford, G. Deformation of pearlite. Metall. Trans. A 1977, 8A, 861–875. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Higuera, O.F.; Cabrera, J.M. Microstructural and mechanical study in the plastic zone of ARMCO iron processed by ECAP. Mater. Sci. Eng. A 2017, 697, 24–36. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y. Producing bulk ultrafine—Grained materials by severe plastic deformation: Ten years later. JOM 2016, 68, 1216–1226. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Fundamentals of superior properties in bulk nano SPD materials. Mater. Res. Lett. 2016, 4, 1–21. [Google Scholar] [CrossRef]

- Karavaeva, M.V.; Kiseleva, S.K.; Ganeev, A.V.; Protasova, E.O.; Ganiev, M.M.; Simonova, L.A.; Valiev, R.Z. Superior strength of carbon steel with an ultrafine-grained microstructure and its enhanced thermal stability. J. Mater. Sci. 2015, 50, 6730–6738. [Google Scholar] [CrossRef]

- Field, D.M.; Van Aken, D.C. Nanocrystalline advanced high strength steel produced by cold rolling and annealing. Metall. Mater. Trans. A 2016, 47A, 1912–1917. [Google Scholar] [CrossRef]

- He, B.B.; Hu, B.; Yen, H.W.; Cheng, G.J.; Wang, Z.K.; Luo, H.W.; Huang, M.X. High dislocation density-induced large ductility in deformed and partitioned steels. Science 2017, 357, 1029–1032. [Google Scholar] [CrossRef] [PubMed]

- Feruz, Y.; Mordehai, D. Towards a universal size-dependent strength of face-centered cubic nanoparticles. Acta Mater. 2016, 103, 433–441. [Google Scholar] [CrossRef]

- Carreker, R.P., Jr.; Hibbard, W.R., Jr. Tensile deformation of aluminum as a function of temperature, strain rate and grain size. Trans. TMS-AIME 1957, 209, 1157–1163. [Google Scholar]

- Tsuji, N.; Ito, Y.; Saito, Y.; Minamino, Y. Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scr. Mater. 2002, 47, 893–899. [Google Scholar] [CrossRef]

- Keller, C.; Hug, E. Hall-Petch behavior of Ni polycrystals with a few grains per thickness. Mater. Lett. 2008, 62, 1718–1720. [Google Scholar] [CrossRef]

- Torrents, A.; Yang, H.; Mohamed, F. Effect of annealing on hardness and the modulus of elasticity in bulk nanocrystalline nickel. Metall. Mater. Trans. A 2010, 41A, 621–630. [Google Scholar] [CrossRef]

- Hansen, N.; Ralph, B. The strain and grain size dependence of the flow stress of copper. Acta Metall. 1982, 30, 411–417. [Google Scholar] [CrossRef]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the maximum strength in nanotwinned copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, R.W. Hall-Petch decription of nanopolycrystalline Cu, Ni and Al strength levels and strain rate sensitivities. Philos. Mag. 2016, 96, 3097–3108. [Google Scholar] [CrossRef]

- Kapp, M.W.; Kirchlechner, C.; Pippan, R.; Dehm, G. Importance of dislocation pile-ups on the mechanical properties and the Bauschinger effect in microcantilevers. J. Mater. Res. 2015, 30, 791–797. [Google Scholar] [CrossRef]

- Aifantis, K.E.; Soer, W.A.; De Hosson, J.T.M.; Willis, J.R. Interfaces within strain gradient plasticity: Theory and experiments. Acta Mater. 2006, 54, 5077–5085. [Google Scholar] [CrossRef]

- Xiao, X.; Terentyev, D.; Chen, Q.; Yu, L.; Chen, L.; Bakaev, A.; Duan, H. The depth dependent hardness of bicrystals with dislocation transmission through grain boundaries: A theoretical model. Int. J. Plast. 2017, 90, 212–230. [Google Scholar] [CrossRef]

- Zhang, C.; Voyiadjis, G.Z. Rate-dependent size effects and material length scales in nanoindentation near the grain boundary for a bicrystal FCC metal. Mater. Sci. Eng. A 2016, 659, 55–62. [Google Scholar] [CrossRef]

- Li, Z.; Hou, C.; Huang, M.; Ouyang, C. Strengthening mechanisms in micro-polycrystals with penetrable grain boundaries by discrete dislocation dynamics simulation and Hall-Petch effect. Comput. Mater. Sci. 2009, 46, 1124–1134. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Smith, T.R. Dislocation pile-up predictions for the strength properties of ultrafine grain size fcc metals. In Processing and Properties of Nanocrystalline Materials; Suryanarayana, C., Singh, J., Froes, F.H., Eds.; TMS-AIME: Warrendale, PA, USA, 1996; pp. 345–354. [Google Scholar]

- Wang, J.; Sansoz, F.; Deng, C.; Xu, G.; Han, G.; Mao, S.X. Strong Hall-Petch type behavior in the elastic strain limit of nanotwinned gold nanowires. Nano Lett. 2015, 15, 3865–3870. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, X.; Gao, H. Size and strain rate effects in tensile strength of penta-twinned Ag nanowires. Acta Mech. Sin. 2017, 33, 792–800. [Google Scholar] [CrossRef]

- Hirouchi, T.; Shibutani, Y. Mechanical responses of copper bicrystalline micro pillars with ∑3 coherent twin boundaries by uniaxial compression test. Mater. Trans. 2014, 55, 52–57. [Google Scholar] [CrossRef]

- Hu, T.; Jiang, L.; Yang, H.; Ma, K.; Topping, T.D.; Yee, J.; Li, M.; Mukherjee, A.K.; Schoenung, J.M.; Lavernia, E.J. Stabilized plasticity in ultrahigh strength, submicron Al crystals. Acta Mater. 2015, 94, 46–58. [Google Scholar] [CrossRef]

- Langdon, T.G. Grain boundary sliding revisited: Developments in sliding over four decades. J. Mater. Sci. 2006, 41, 597–609. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Rodriguez, P. Flow stress/grain size/strain rate coupling for fcc nanopolycrystals. Philos. Mag. 2006, 86, 5787–5796. [Google Scholar] [CrossRef]

- Li, Y.J.; Mueller, H.W.; Höppel, M.; Göken, M.; Blum, W. Deformation kinetics of nanocrystalline nickel. Acta Mater. 2007, 55, 5708–5717. [Google Scholar] [CrossRef]

- Mohanty, G.; Wheeler, J.M.; Raghavan, R.; Wehrs, J.; Hasgawa, M.; Mischler, S.; Phillipe, L.; Michler, J. Elevated temperature, strain rate jump microcompression of nanocrystalline nickel. Philos. Mag. 2015, 95, 1878–1895. [Google Scholar] [CrossRef]

- Li, H.; Liang, Y.; Zhao, L.; Hu, J.; Han, S.; Lian, J. Mapping the strain rate and grain size dependence of deformation behaviors in nanocrystalline face-centered-cubic Ni and Ni-based alloys. J. Alloy. Compd. 2017, 709, 566–574. [Google Scholar] [CrossRef]

- Armstrong, R.W.; Balasubramanian, N. Unified Hall-Petch description of nano-grain nickel hardness, flow stress and strain rate sensitivity measurements. AIP Adv. 2017, 7, 85010. [Google Scholar] [CrossRef]

- Kumar, M.A.; Beyerlein, I.J.; Tomé, C.N. Grain size constraints on twin expansion in hexagonal close packed crystals. J. Appl. Phys. 2016, 120, 155105. [Google Scholar] [CrossRef]

- Yuan, R.; Beyerlein, I.J.; Zhou, C. Coupled crystal oreientation-size effects on the strength of nano crystals. Nat. Sci. Rep. 2016, 6, 26254. [Google Scholar] [CrossRef] [PubMed]

- Luo, P.; Hu, Q.; Wu, X. Quantitatively analyzing strength contribution vs grain boundary scale relation in pure titanium subjected to severe plastic deformation. Metal. Mater. Trans. A. 2016, 47A, 1922–1927. [Google Scholar] [CrossRef]

- Britton, T.B.; Wilkinson, A.J. Stress fields and geometrically necessary dislocation density distributions near the head of a blocked slip band. Acta Mater. 2012, 60, 5773–5782. [Google Scholar] [CrossRef]

- Guo, Y.; Collins, D.M.; Tarleton, E.; Hofmann, F.; Tischler, J.; Liu, W.; Xu, R.; Wilkinson, A.J.; Britton, T.B. Measurements of stress fields near a grain boundary: Exploring blocked arrays of dislocations in 3D. Acta Mater. 2015, 96, 229–236. [Google Scholar] [CrossRef]

- Bond, D.M.; Zikry, M.A. A predictive framework for dislocation-density pile-ups in crystalline systems with coincident site lattice and random grain boundaries. J. Eng. Mater. Technol. 2017, 139, 021023. [Google Scholar] [CrossRef]

- Muche, D.N.F.; Drazin, J.W.; Mardinly, J.; Dey, S.; Castro, R.H.R. Colossal grain boundary strengthening in ultrafine nanocrystalline oxides. Mater. Lett. 2017, 186, 298–300. [Google Scholar] [CrossRef]

- Baker, I.; Meng, F. Lamellar coarsening in Fe28Ni18Mn33Al21 and its influence on room temperature tensile behavior. Acta Mater. 2015, 95, 124–131. [Google Scholar] [CrossRef]

- Fan, G.; Wang, Q.; Geng, L.; Zhang, J.; Hu, W.; Du, Y. Fabrication, microstructure, and mechanical property of NiAl-based composite with microlaminated architechture by roll bonding and annealing treatment. Metall. Mater. Trans. A 2016, 47A, 1280–1291. [Google Scholar] [CrossRef]

- Roa, J.J.; Jiménez-Piqué, E.; Tarragó, J.M.; Sandoval, D.A.; Mateo, A.; Fair, J.; Llanes, L. Hall-Petch strengthening of the constrained metallic binder in WC-Co cemented carbides: Experimental assessment by means of massive nanoindentation and statistical analysis. Mater. Sci. Eng. A 2016, 676, 487–491. [Google Scholar] [CrossRef]

- Beaber, A.R.; Nowak, J.D.; Ugurlu, O.; Mook, W.M.; Girschick, S.L.; Ballarina, R.; Gerberich, W.W. Smaller is tougher. Philos. Mag. 2011, 91, 1179–1189. [Google Scholar] [CrossRef]

- Fu, M.W.; Wang, J.L.; Korsunsky, A.M. A review of geometrical and microstructural size effects in micro-scale deformation processing of metallic alloy components. Int. J. Mach. Tools Manuf. 2016, 109, 94–125. [Google Scholar] [CrossRef]

| Material/Method | σ0(MPa) | k(Mpa.mm1/2) | τc(MPa) |

|---|---|---|---|

| Mild steel, l.y.p. | 71 | 23.4 | 771 |

| ε = 0.1 flow stress | 294 | 12.4 | |

| Decarburized iron | 36.3 | 6.5 | |

| Pearlitic steel | ~30 | ~19.7 | |

| Ball milled iron | 40 | 7.2 | |

| IF iron | 43 | 11 | |

| ε = 0.002 wire | 60–1210 | 6.9–12.7 | 63–214 |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Armstrong, R.W. Crystal Engineering for Mechanical Strength at Nano-Scale Dimensions. Crystals 2017, 7, 315. https://doi.org/10.3390/cryst7100315

Armstrong RW. Crystal Engineering for Mechanical Strength at Nano-Scale Dimensions. Crystals. 2017; 7(10):315. https://doi.org/10.3390/cryst7100315

Chicago/Turabian StyleArmstrong, Ronald W. 2017. "Crystal Engineering for Mechanical Strength at Nano-Scale Dimensions" Crystals 7, no. 10: 315. https://doi.org/10.3390/cryst7100315