Laser Annealing for Gas-Dynamical Spraying of HA Coating upon a Titanium Surface

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

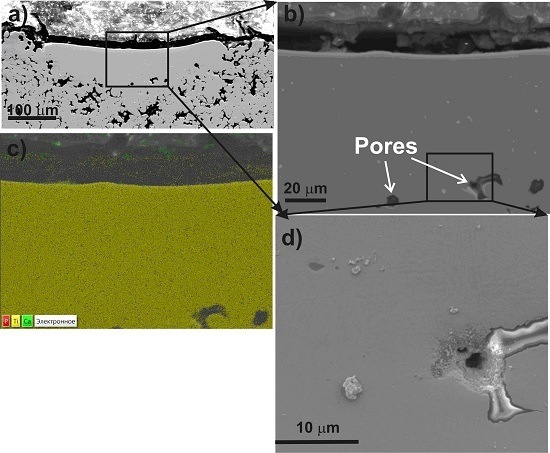

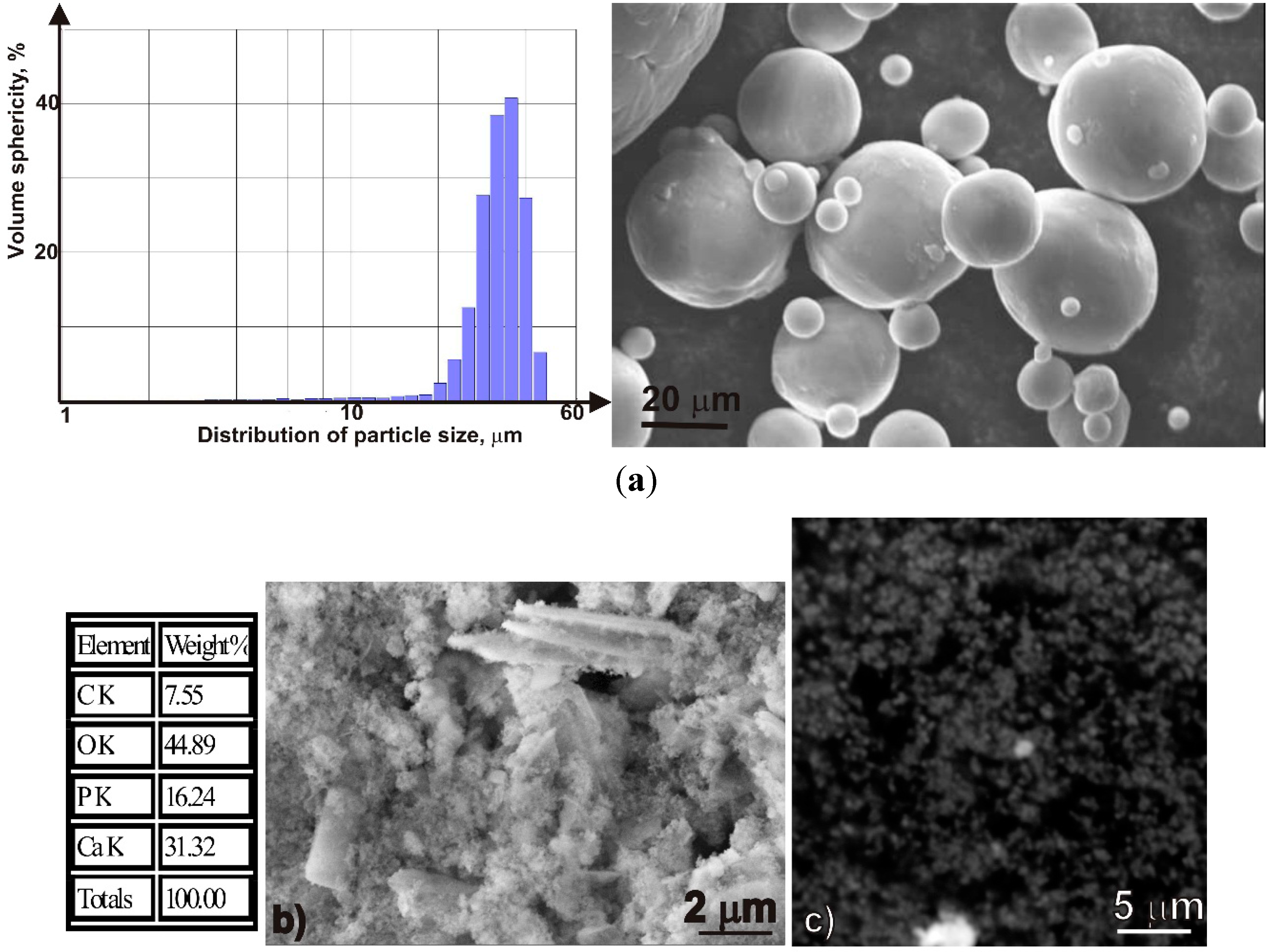

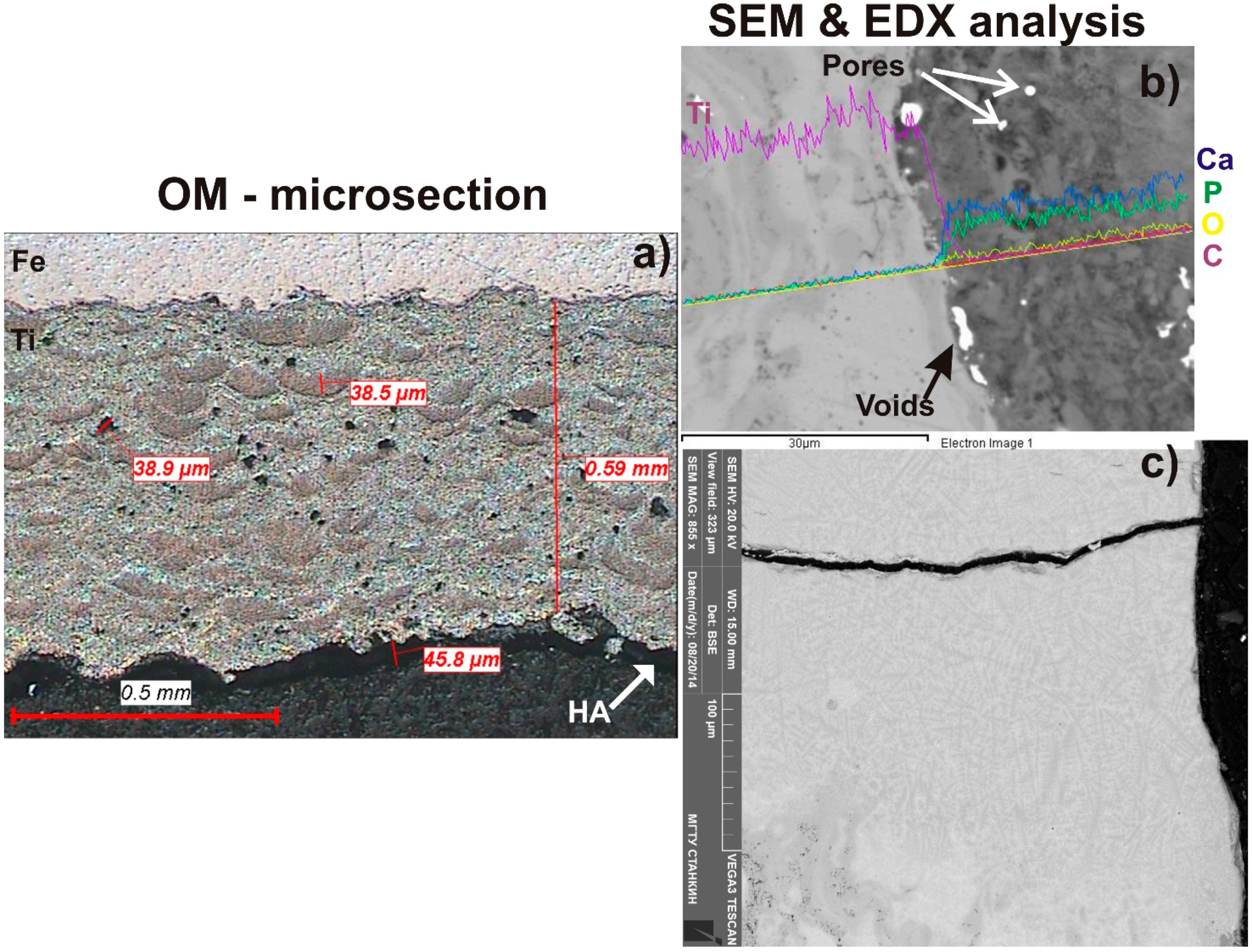

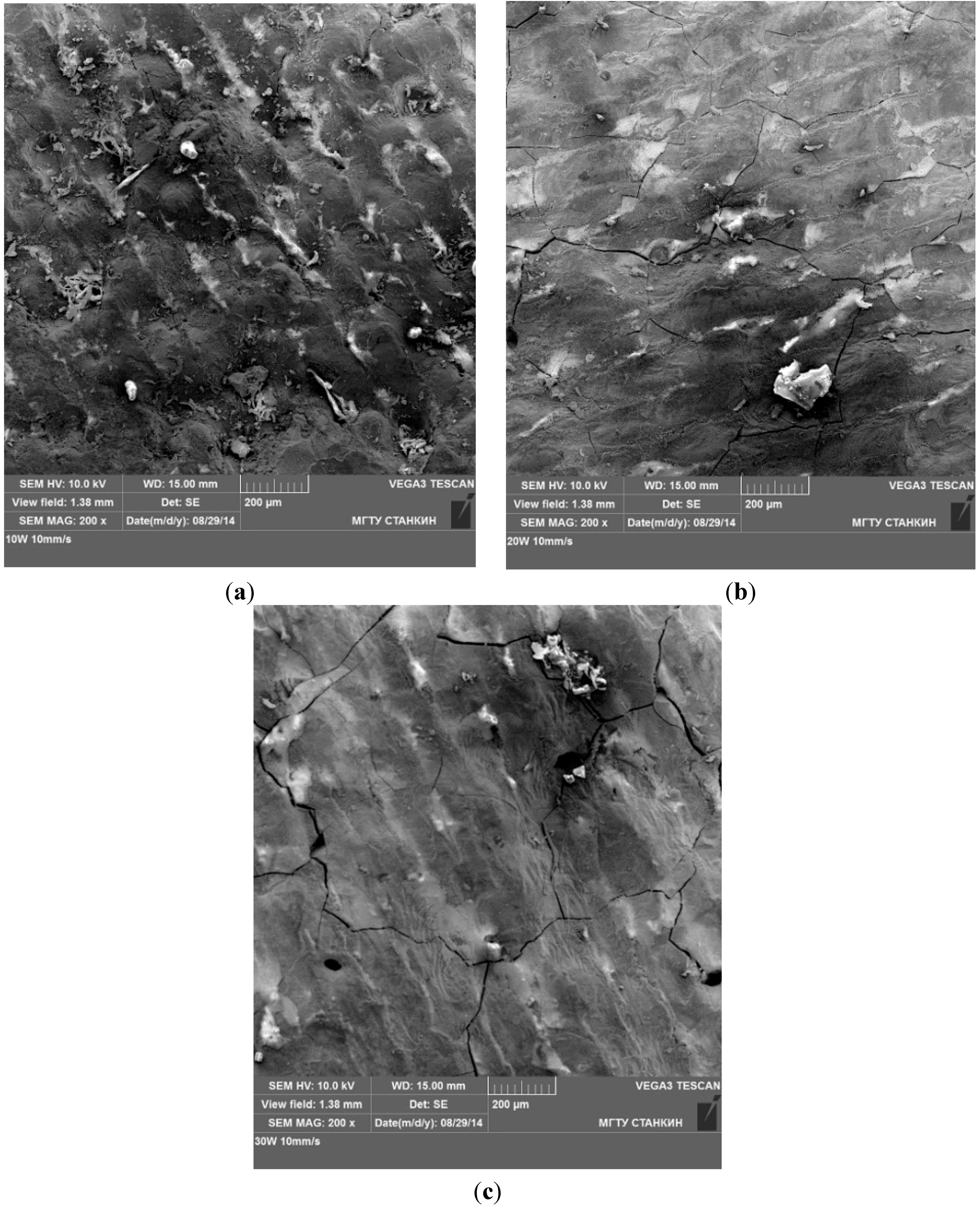

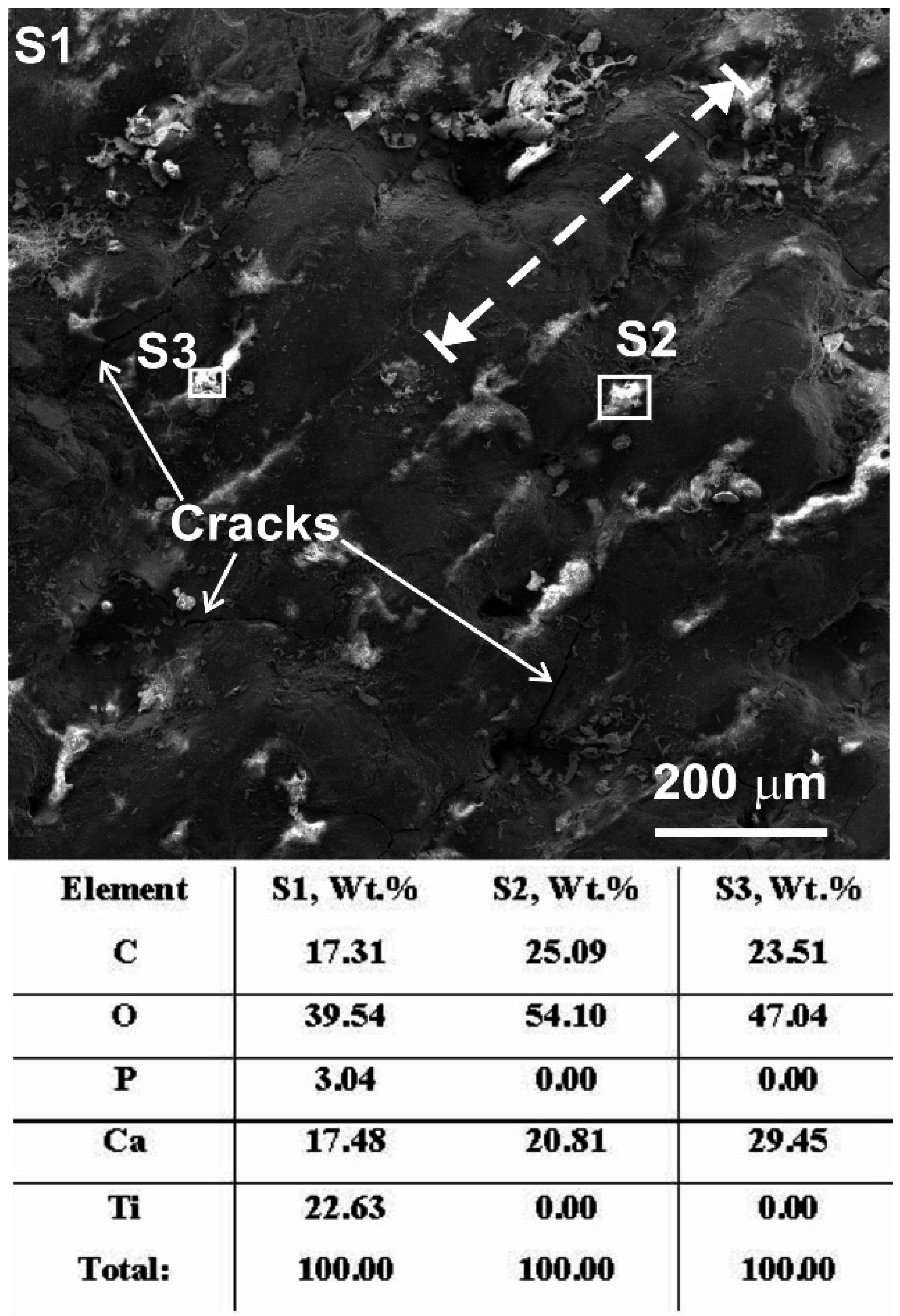

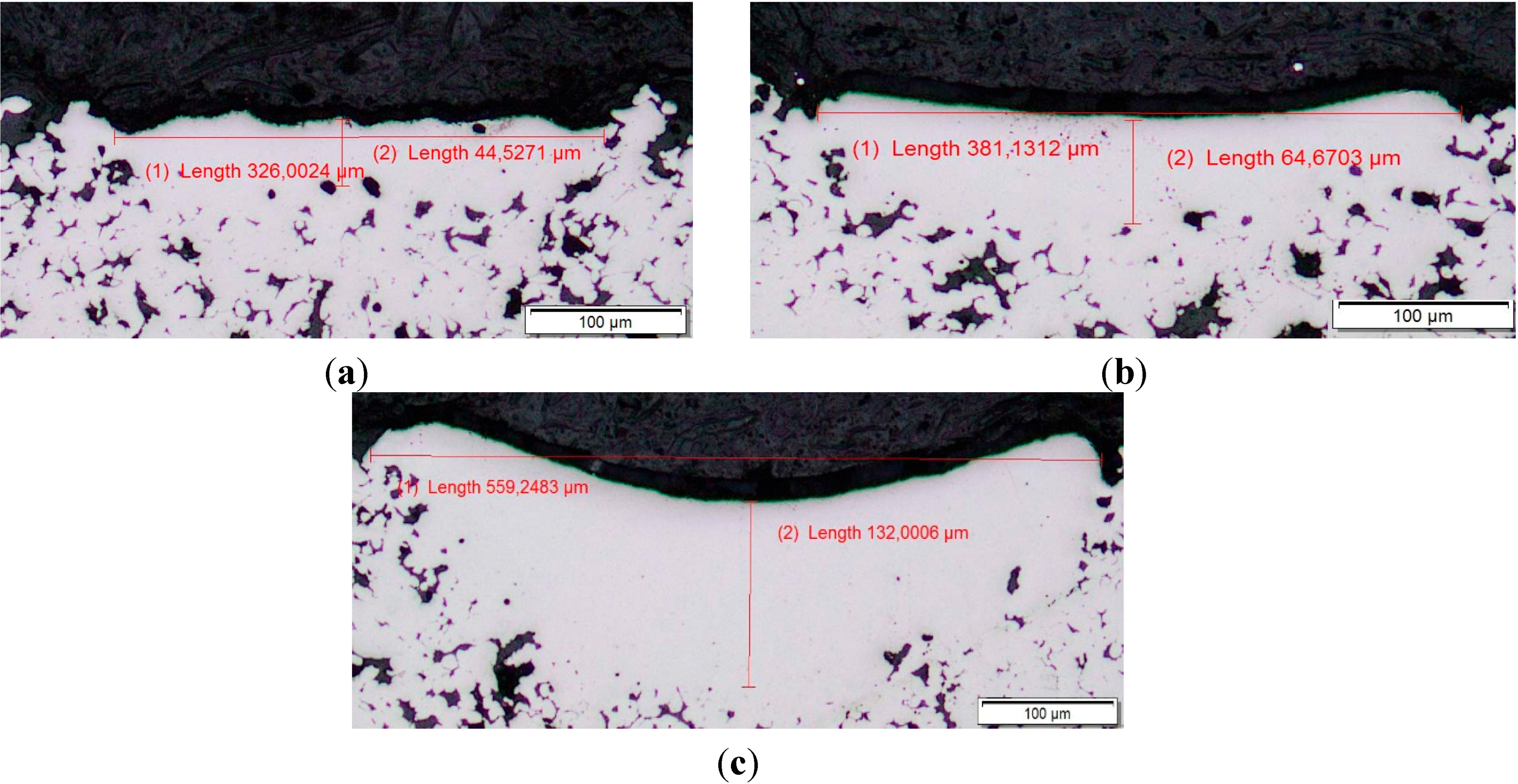

3.1. Microstructural Evaluation

3.2. Phase Analysis by XRD Patterns

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shishkovskii, I.; Morozov, Y.; Fokeev, S.; Volova, L. Laser synthesis and comparative testing of a three-dimensional porous matrix of titanium and titanium nickelide as a repository for stem cells. Powder Metall. Met. Ceram. 2012, 50, 606–618. [Google Scholar] [CrossRef]

- Citeau, A.; Guicheux, J.; Vinatier, C.; Layrolle, P.; Nguyen, T.; Pilet, P.; Daculsi, G. In vitro biological effects of titanium rough surface obtained by calcium phosphate grid blasting. Biomaterials 2005, 26, 157–165. [Google Scholar] [PubMed]

- Sygnatowicz, M.; Tiwari, A. Controlled synthesis of hydroxyapatite-based coatings for biomedical application. Mater. Sci. Eng. C 2009, 29, 1071–1076. [Google Scholar] [CrossRef]

- Lee, K.W.; Wang, S.; Yaszemski, M.J.; Lu, L. Physical properties and cellular responses to crosslinkable poly(propylene fumarate)/hydroxyapatite nanocomposites. Biomaterials 2008, 29, 2839–2848. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Kempen, D.H.R.; Yaszemski, M.J.; Lu, L. The roles of matrix polymer crystallinity and hydroxyapatite nanoparticles in modulating material properties of photo-crosslinked composites and bone marrow stromal cell responses. Biomaterials 2009, 30, 3359–3370. [Google Scholar] [CrossRef] [PubMed]

- Cai, L.; Guinn, A.S.; Wang, S. Exposed hydroxyapatite particles on the surface of photo-crosslinked nanocomposites for promoting MC3T3 cell proliferation and differentiation. Acta Biomater. 2011, 7, 2185–2199. [Google Scholar] [CrossRef] [PubMed]

- Shishkovsky, I.; Scherbakov, V. Selective laser sintering of biopolymers with micro and nano ceramic additives for medicine. Phys. Procedia 2012, 39, 491–499. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Volchkov, S. Influence of the laser assisted fabricated 3D porous scaffolds from bioceramoplasts of micron and nano sizes on culture of MMSC. Proc. SPIE 2013, 9065. [Google Scholar] [CrossRef]

- D’Haese, R.; Pawlowski, L.; Bigan, M.; Jaworski, R.; Martel, M. Phase evolution of hydroxapatite coatings suspension plasma sprayed using variable parameters in simulated body fluid. Surf. Coat. Technol. 2010, 204, 1236–1246. [Google Scholar] [CrossRef]

- Arias, J.; Mayor, M.; Garcia-Sanz, F.; Pou, J.; Loen, B.; Perez-Amor, M.; Knowles, J. Structural analysis of calcium phosphate coatings produced by pulsed laser deposition at different water-vapour pressures. J. Mater. Sci. Mater. Med. 1997, 8, 873–876. [Google Scholar] [CrossRef] [PubMed]

- Pattison, J.; Celotto, S.; Morgan, R.; Bray, M.; O’Neill, W. Cold gas dynamic manufacturing: A non-thermal approach to freeform fabrication. Intern. Mach. Tools Manuf. 2007, 47, 627–634. [Google Scholar] [CrossRef]

- Kalita, V.; Gnedovets, A. Porous coatings: Experiments, modeling, and biomedical applications. Plasma Process. Polym. 2005, 2, 485–492. [Google Scholar] [CrossRef]

- Shtansky, D.; Batenina, I.; Yadroitsev, I.; Ryashin, N.; Kiryukhantsev-Korneev, P.H.; Kudryashov, A.; Sheveyko, A.; Zhitnyak, I.; Gloushankova, N.; Smurov, I.; et al. A new combined approach to metal-ceramic implants with controllable surface topography, chemistry, blind porosity, and wettability. Surf. Coat. Technol. 2012, 208, 14–23. [Google Scholar] [CrossRef]

- Shishkovsky, I. Chemical and physical vapor deposition methods for nanocoatings. In Nanocoatings and Ultra Thin-Films: Technologies and Applications; Hamdy, A.S., Tiginyanu, I., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 57–77. [Google Scholar]

- Lynn, A.; DuQuesnay, D. Hydroxyapatite-coated Ti-6Al-4V Part 1: The effect of coating thickness on mechanical fatigue behaviour. Biomaterials 2002, 23, 1937–1946. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Tarasova, E.; Zhuravel’, L.; Petrov, A. The synthesis of a biocomposite based on nickel titanium and hydroxyapatite under selective laser sintering conditions. Tech. Phys. Lett. 2001, 27, 211–213. [Google Scholar] [CrossRef]

- Kuznetsov, M.; Morozov, Y.; Parkin, I.; Shishkovsky, I. Design of 3D functional articles by combined SHS-SLS. Mater. Manuf. Process. 2008, 23, 571–578. [Google Scholar] [CrossRef]

- Sova, A.; Pervushin, D.; Smurov, I. Development of multimaterial coatings by cold spray and gas detonation spraying. Surf. Coat. Technol. 2010, 205, 1108–1114. [Google Scholar] [CrossRef]

- Sova, A.; Papyrin, A.; Smurov, I. Influence of ceramic powder size on process of cermet coating formation by cold spray. J. Therm. Spray Technol. 2011, 20, 285–291. [Google Scholar] [CrossRef]

- Pervushin, D.; Shishkovsky, I.; Smurov, I. Gas-dynamic spraying of hydroxyapatite on medical instruments from titanium alloy. Russ. J. Non-Ferrous Met. 2014, 55, 298–302. [Google Scholar] [CrossRef]

- Bray, M.; Cockburn, A.; O’Neill, W. The Laser-assisted Cold Spray process and deposit characterization. Surf. Coat. Technol. 2009, 203, 2851–2857. [Google Scholar] [CrossRef]

- Zhang, M.; Cheng, G. Nanoscale size dependence on pulsed laser sintering of hydroxyapatite/titanium particles on metal implants. J. Appl. Phys. 2010, 108. [Google Scholar] [CrossRef]

- Suutala, J.; Tuominen, J.; Vuoristo, P. Laser-assisted spraying and laser treatment of thermally sprayed coatings. Surf. Coat. Technol. 2006, 201, 1981–1987. [Google Scholar] [CrossRef]

- Christoulis, D.; Jeandin, M.; Irissou, E.; Legoux, J.; Knapp, W. Laser-Assisted Cold Spray (LACS). In Nd YAG Laser; InTech: Rijeka, Croatia, 2012; Available online: http://www.intechopen.com/books/nd-yag-laser/laser-assisted-cold-spray-lacs- (accessed on 30 September 2015).

- Podrabinnik, P.; Grigoriev, S.; Shishkovsky, I. Laser post annealing of cold-sprayed Al/alumina-Ni composite coatings. Surf. Coat. Technol. 2015, 271, 265–268. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saphronov, V.; Shishkovsky, I. Laser Annealing for Gas-Dynamical Spraying of HA Coating upon a Titanium Surface. Crystals 2015, 5, 447-457. https://doi.org/10.3390/cryst5040447

Saphronov V, Shishkovsky I. Laser Annealing for Gas-Dynamical Spraying of HA Coating upon a Titanium Surface. Crystals. 2015; 5(4):447-457. https://doi.org/10.3390/cryst5040447

Chicago/Turabian StyleSaphronov, Victor, and Igor Shishkovsky. 2015. "Laser Annealing for Gas-Dynamical Spraying of HA Coating upon a Titanium Surface" Crystals 5, no. 4: 447-457. https://doi.org/10.3390/cryst5040447