Nanoscale Alloying in Electrocatalysts

Abstract

:1. Introduction

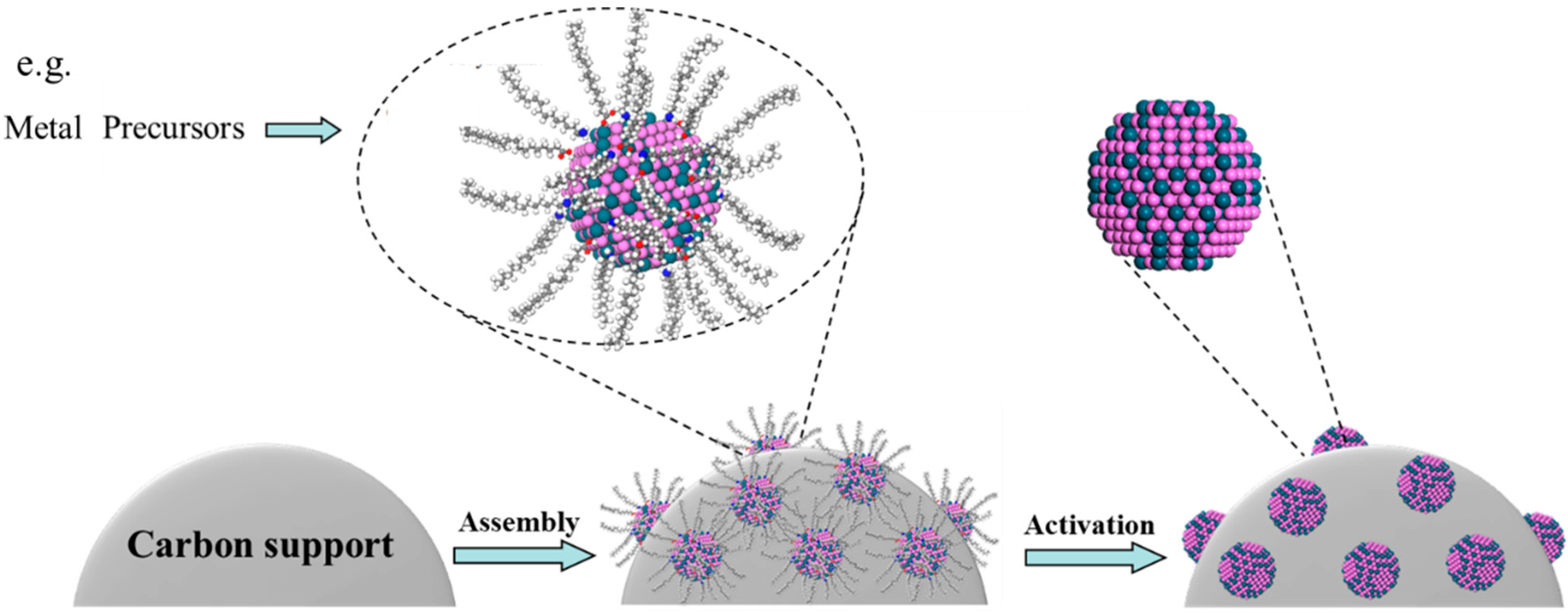

2. Synthesis and Preparation

| Catalysts | Synthesis method | Catalytic reactions | Refs |

|---|---|---|---|

| Bimetallic nanoalloys | |||

| PtNi NPs (2–8 nm)/C, TiO2, or SiO2 | Precursor: Pt(acac)2, Ni(acac)2; | ORR, CO oxidation | [12,23] |

| Capping agent: oleic acid (OA), oleylamine (OAM); | |||

| Reducing agent: 1,2-hexadecanediol (HDD); | |||

| Solvent: octyl ether (OE) | |||

| PtCo NPs (2–8 nm)/C, TiO2 or SiO2 | Precursor: Pt(acac)2, Co2(CO)8; | ORR, CO oxidation | [12,23] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether | |||

| PtRu (~5 nm)/C | Precursor: Pt(acac)2, Ru(acac)2; | EOR, CO oxidation | [24] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether | |||

| AuCu (~5 nm)/C, SiO2 | Precursor: HAuCl4, CuCl2; | CO oxidation | [14] |

| Capping agent: 1-decanethiol (DT); | |||

| Tetraoctylammonium bromide (TOABr); | |||

| Reducing agent: NaBH4; | |||

| Solvent: H2O and Toluene | |||

| AuCu (4–8 nm)/C | Precursor: Au NPs and Cu NPs; | CO oxidation | [14] |

| Capping agent: 1-decanethiol (DT); | |||

| Tetraoctylammonium bromide (TOABr); | |||

| Method: Thermally aggregated growth | |||

| PdNi (7–10 nm)/C | Precursor: Pd(acac)2, Ni(acac)2; | ORR, CO oxidation | [25] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether or benzyl ether | |||

| PdCu (7–10 nm)/C | Precursor: Pd(acac)2, Cu(acac)2; | EOR, CO oxidation | [26] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether or benzyl ether | |||

| AuPt (~4–5 nm)/C | Precursor: HAuCl4, HPtCl4; | ORR, MOR | [13,27,28] |

| Capping agent: DT, OAM/OA; | |||

| Reducing agent: NaBH4; | |||

| Solvent: H2O and Toluene; | |||

| Trimetallic Nanoalloys | |||

| PtNiCo (3–5 nm)/C, TiO2, and SiO2 | Precursor: Pt(acac)2, Ni(acac)2, Co(acac)3; | ORR, CO oxidation | [12,29,30] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether | |||

| PtVCo (3–5 nm)/C | Precursor: Pt(acac)2, VO(acac)2, Co(acac)3; | ORR, CO oxidation | [17,31] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether | |||

| PtNiFe (3–5 nm)/C | Precursor: Pt(acac)2, Ni(acac)2, Fe(CO)5; | ORR, CO oxidation | [32,33] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether | |||

| PtIrCo (3–5 nm)/C | Precursor: Pt(acac)2, Ir4(CO)12, Co(acac)2; | ORR, CO oxidation | [15,17,34] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether | |||

| PtVFe (3–5 nm)/C | Precursor: Pt(acac)2, VO(acac)2, Fe(CO)5; | ORR, | [35,36] |

| Capping agent: oleic acid and oleylamine; | |||

| Reducing agent: 1,2-hexadecanediol; | |||

| Solvent: octyl ether | |||

3. Examples of Nanoalloy Electrocatalysts

3.1. Bimetallic Nanoalloy Catalysts

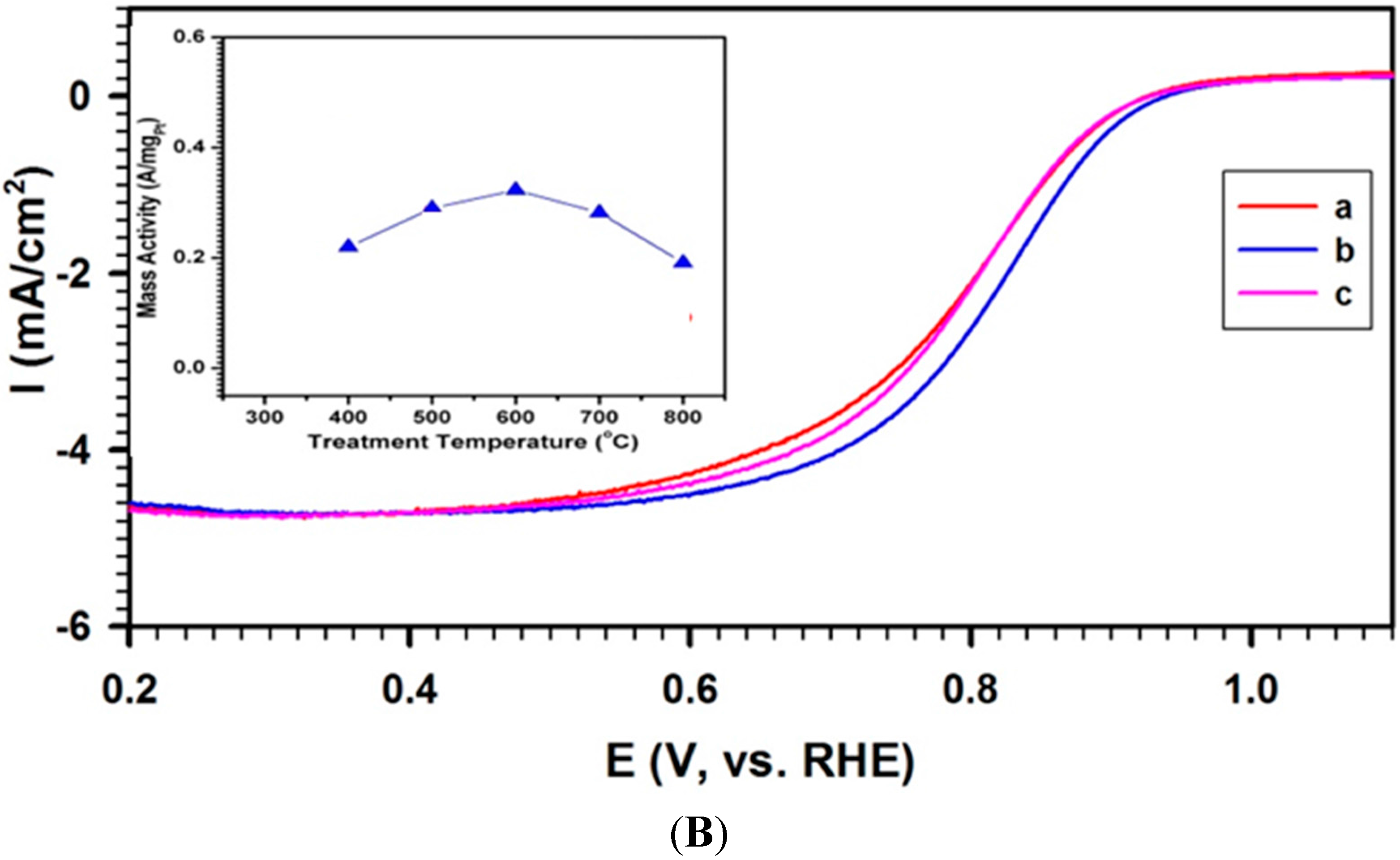

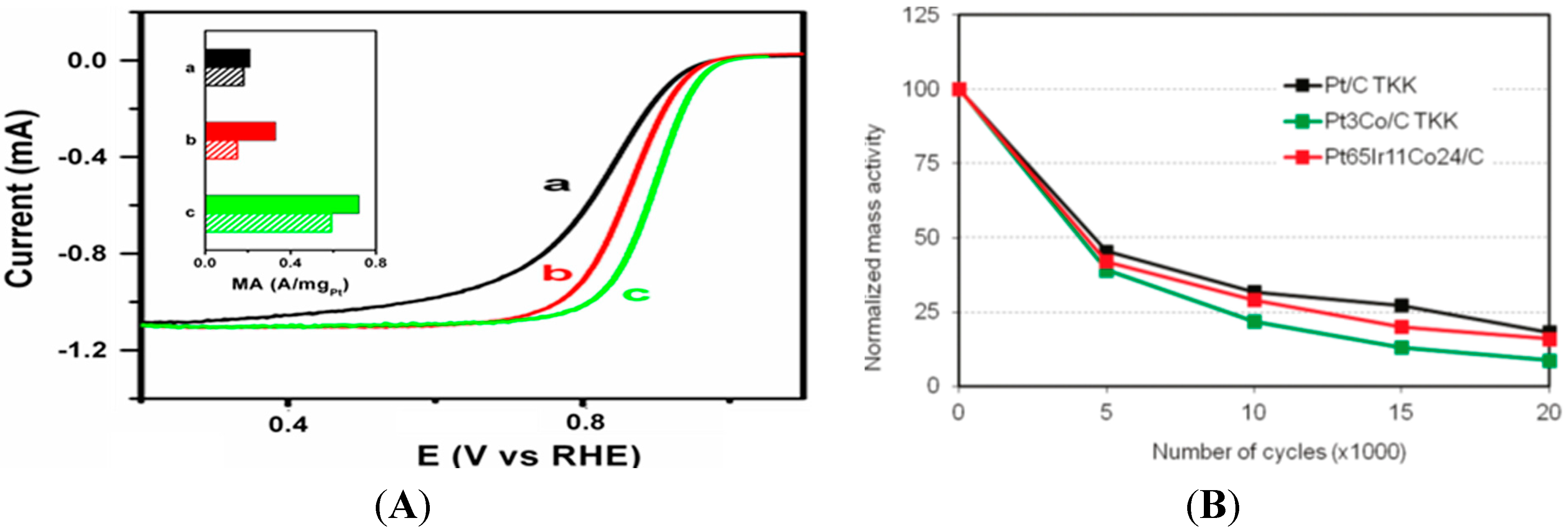

3.2. Trimetallic Nanoalloy Catalysts

4. Summary and Perspectives

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wu, J.B.; Yang, H. Platinum-Based Oxygen Reduction Electrocatalysts. Acc. Chem. Res. 2013, 46, 1848–1857. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.J.; Zhang, S.; Sun, S.H. Tuning Nanoparticle Catalysis for the Oxygen Reduction Reaction. Angew. Chem. Int. Edit. 2013, 52, 8526–8544. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.T.; Porosoff, M.D.; Chen, J.G.G. Review of Pt-Based Bimetallic Catalysis: From Model Surfaces to Supported Catalysts. Chem. Rev. 2012, 112, 5780–5817. [Google Scholar] [CrossRef] [PubMed]

- Tao, F.; Zhang, S.R.; Nguyen, L.; Zhang, X.Q. Action of bimetallic nanocatalysts under reaction conditions and during catalysis: Evolution of chemistry from high vacuum conditions to reaction conditions. Chem. Soc. Rev. 2012, 41, 7980–7993. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.L. On the Synergetic Catalytic Effect in Heterogeneous Nanocomposite Catalysts. Chem. Rev. 2013, 113, 2139–2181. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Markovic, N.M.; Stamenkovic, V.R. Advanced Platinum Alloy Electrocatalysts for the Oxygen Reduction Reaction. ACS Catal. 2012, 2, 891–898. [Google Scholar] [CrossRef]

- Watanabe, M.; Tryk, D.A.; Wakisaka, M.; Yano, H.; Uchida, H. Overview of recent developments in oxygen reduction electrocatalysis. Electrochim. Acta 2012, 84, 187–201. [Google Scholar] [CrossRef]

- Cui, C.H.; Yu, S.H. Engineering Interface and Surface of Noble Metal Nanoparticle Nanotubes toward Enhanced Catalytic Activity for Fuel Cell Applications. Acc. Chem. Res. 2013, 46, 1427–1437. [Google Scholar] [CrossRef] [PubMed]

- Aiken, J.D.; Finke, R.G. A review of modern transition-metal nanoclusters: Their synthesis, characterization, and applications in catalysis. J. Mol. Catal. A 1999, 145, 1–44. [Google Scholar] [CrossRef]

- Qian, H.F.; Zhu, M.Z.; Wu, Z.K.; Jin, R.C. Quantum Sized Gold Nanoclusters with Atomic Precision. Acc. Chem. Res. 2012, 45, 1470–1479. [Google Scholar] [CrossRef] [PubMed]

- Hostetler, M.J.; Zhong, C.J.; Yen, B.K.H.; Anderegg, J.; Gross, S.M.; Evans, N.D.; Porter, M.; Murray, R.W. Stable, monolayer-protected metal alloy clusters. J. Am. Chem. Soc. 1998, 120, 9396–9397. [Google Scholar] [CrossRef]

- Yang, L.F.; Shan, S.Y.; Loukrakpam, R.; Petkov, V.; Ren, Y.; Wanjala, B.N.; Engelhard, M.H.; Luo, J.; Yin, J.; Chen, Y.S.; et al. Role of Support-Nanoalloy Interactions in the Atomic-Scale Structural and Chemical Ordering for Tuning Catalytic Sites. J. Am. Chem. Soc. 2012, 134, 15048–15060. [Google Scholar] [CrossRef] [PubMed]

- Petkov, V.; Wanjala, B.N.; Loukrakpam, R.; Luo, J.; Yang, L.F.; Zhong, C.J.; Shastri, S. Pt-Au Alloying at the Nanoscale. Nano Lett. 2012, 12, 4289–4299. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Shan, S.Y.; Yang, L.F.; Mott, D.; Malis, O.; Petkov, V.; Cai, F.; Ng, M.S.; Luo, J.; Chen, B.H.; et al. Gold-Copper Nanoparticles: Nanostructural Evolution and Bifunctional Catalytic Sites. Chem. Mater. 2012, 24, 4662–4674. [Google Scholar] [CrossRef]

- Loukrakpam, R.; Shan, S.Y.; Petkov, V.; Yang, L.F.; Luo, J.; Zhong, C.J. Atomic Ordering Enhanced Electrocatalytic Activity of Nanoalloys for Oxygen Reduction Reaction. J. Phys. Chem. C 2013, 117, 20715–20721. [Google Scholar] [CrossRef]

- Petkov, V.; Ren, Y.; Shan, S.Y.; Luo, J.; Zhong, C.J. A distinct atomic structure-catalytic activity relationship in 3–10 nm supported Au particles. Nanoscale 2014, 6, 532–538. [Google Scholar] [CrossRef] [PubMed]

- Shan, S.Y.; Petkov, V.; Yang, L.F.; Mott, D.; Wanjala, B.N.; Cai, F.; Chen, B.H.; Luo, J.; Zhong, C.J. Oxophilicity and Structural Integrity in Maneuvering Surface Oxygenated Species on Nanoalloys for CO Oxidation. ACS Catal. 2013, 3, 3075–3085. [Google Scholar] [CrossRef]

- Galow, T.H.; Drechsler, U.; Hanson, J.A.; Rotello, V.M. Highly reactive heterogeneous Heck and hydrogenation catalysts constructed through “bottom-up” nanoparticle self-assembly. Chem. Comm. 2002, 1076–1077. [Google Scholar] [CrossRef]

- Brust, M.; Walker, M.; Bethell, D.; Schiffrin, D.J.; Whyman, R. Synthesis of Thiol-Derivatized Gold Nanoparticles in a 2-Phase Liquid-Liquid System. J. Chem. Soc. Chem. Comm. 1994, 7, 801–802. [Google Scholar] [CrossRef]

- Shao, M.H.; Shoemaker, K.; Peles, A.; Kaneko, K.; Protsailo, L. Pt Mono layer on Porous Pd-Cu Alloys as Oxygen Reduction Electrocatalysts. J. Am. Chem. Soc. 2010, 132, 9253–9255. [Google Scholar] [CrossRef] [PubMed]

- Schadt, M.J.; Cheung, W.; Luo, J.; Zhong, C.J. Molecularly tuned size selectivity in thermal processing of gold nanoparticles. Chem. Mater. 2006, 18, 5147–5149. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Z.Y.; Liu, C.J. Perspective on CO oxidation over Pd-based catalysts. Catal. Sci. Technol. 2015, 5, 69–81. [Google Scholar] [CrossRef]

- Loukrakpam, R.; Luo, J.; He, T.; Chen, Y.S.; Xu, Z.C.; Njoki, P.N.; Wanjala, B.N.; Fang, B.; Mott, D.; Yin, J.; et al. Nanoengineered PtCo and PtNi Catalysts for Oxygen Reduction Reaction: An Assessment of the Structural and Electrocatalytic Properties. J. Phys. Chem. C 2011, 115, 1682–1694. [Google Scholar] [CrossRef]

- Prasai, B.; Ren, B.; Shan, S.; Zhao, Y.; Cronk, H.; Luo., J.; Zhong, C.J.; Petkov, V. Synthesis-atomic structure-properties relationships in metallic nanoparticles by total scattering experiments and 3D computer simulations: case of Pt-Ru nanoalloy catalysts. Nanoscale 2015, 7, 8122–8134. [Google Scholar] [CrossRef] [PubMed]

- Shan, S.Y.; Petkov, V.; Yang, L.F.; Luo, J.; Joseph, P.; Mayzel, D.; Prasai, B.; Wang, L.Y.; Engelhard, M.; Zhong, C.J. Atomic-Structural Synergy for Catalytic CO Oxidation over Palladium-Nickel Nanoalloys. J. Am. Chem. Soc. 2014, 136, 7140–7151. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Shan, S.Y.; Ng, M.S.; Yang, L.F.; Mott, D.; Fang, W.Q.; Kang, N.; Luo, J.; Zhong, C.J. Catalytic and Electrocatalytic Oxidation of Ethanol over Palladium-Based Nanoalloy Catalysts. Langmuir 2013, 29, 9249–9258. [Google Scholar] [CrossRef] [PubMed]

- Wanjala, B.N.; Luo, J.; Loukrakpam, R.; Fang, B.; Mott, D.; Njoki, P.N.; Engelhard, M.; Naslund, H.R.; Wu, J.K.; Wang, L.C.; et al. Nanoscale Alloying, Phase-Segregation, and Core-Shell Evolution of Gold-Platinum Nanoparticles and Their Electrocatalytic Effect on Oxygen Reduction Reaction. Chem. Mater. 2010, 22, 4282–4294. [Google Scholar] [CrossRef]

- Luo, J.; Wang, L.; Mott, D.; Njoki, P.N.; Lin, Y.; He, T.; Xu, Z.; Wanjana, B.N.; Lim, I.I.S.; Zhong, C.J. Core/Shell Nanoparticles as Electrocatalysts for Fuel Cell Reactions. Adv. Mater. 2008, 20, 4342–4347. [Google Scholar] [CrossRef]

- Wanjala, B.N.; Loukrakpam, R.; Luo, J.; Njoki, P.N.; Mott, D.; Zhong, C.J.; Shao, M.H.; Protsailo, L.; Kawamura, T. Thermal Treatment of PtNiCo Electrocatalysts: Effects of Nanoscale Strain and Structure on the Activity and Stability for the Oxygen Reduction Reaction. J. Phys. Chem. C 2010, 114, 17580–17590. [Google Scholar] [CrossRef]

- Wanjala, B.N.; Fang, B.; Loukrakpam, R.; Chen, Y.S.; Engelhard, M.; Luo, J.; Yin, J.; Yang, L.F.; Shan, S.Y.; Zhong, C.J. Role of Metal Coordination Structures in Enhancement of Electrocatalytic Activity of Ternary Nanoalloys for Oxygen Reduction Reaction. ACS Catal. 2012, 2, 795–806. [Google Scholar] [CrossRef]

- Wanjala, B.N.; Fang, B.; Shan, S.Y.; Petkov, V.; Zhu, P.Y.; Loukrakpam, R.; Chen, Y.S.; Luo, J.; Yin, J.; Yang, L.F.; et al. Design of Ternary Nanoalloy Catalysts: Effect of Nanoscale Alloying and Structural Perfection on Electrocatalytic Enhancement. Chem. Mater. 2012, 24, 4283–4293. [Google Scholar] [CrossRef]

- Wanjala, B.N.; Fang, B.; Luo, J.; Chen, Y.S.; Yin, J.; Engehard, M.H.; Loukrakpam, R.; Zhong, C.J. Correlation between Atomic Coordination Structure and Enhanced Electrocatalytic Activity for Trimetallic Alloy Catalysts. J. Am. Chem. Soc. 2011, 133, 12714–12727. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.X.; Zhao, Y.; Fu, G.; Duchesne, P.N.; Gu, L.; Zheng, Y.P.; Weng, X.F.; Chen, M.S.; Zhang, P.; Pao, C.W.; et al. Interfacial Effects in Iron-Nickel Hydroxide-Platinum Nanoparticles Enhance Catalytic Oxidation. Science 2014, 344, 495–499. [Google Scholar] [CrossRef] [PubMed]

- Loukrakpam, R.; Wanjala, B.N.; Yin, J.; Fang, B.; Luo, J.; Shao, M.H.; Protsailo, L.; Kawamura, T.; Chen, Y.S.; Petkov, V.; et al. Structural and Electrocatalytic Properties of Nanoengineered PtIrCo Catalysts for Oxygen Reduction Reaction. ACS Catal. 2011, 1, 562. [Google Scholar] [CrossRef]

- Luo, J.; Han, L.; Kariuki, N.N.; Wang, L.Y.; Mott, D.; Zhong, C.J.; He, T. Synthesis and characterization of monolayer-capped PtVFe nanoparticles with controllable sizes and composition. Chem Mater. 2005, 17, 5282–5290. [Google Scholar] [CrossRef]

- Luo, J.; Kariuki, N.; Han, L.; Wang, L.Y.; Zhong, C.J.; He, T. Preparation and characterization of carbon-supported PtVFe electrocatalysts. Electrochim. Acta 2006, 51, 4821–4827. [Google Scholar] [CrossRef]

- Zhang, J.; Sasaki, K.; Sutter, E.; Adzic, R.R. Stabilization of platinum oxygen-reduction electrocatalysts using gold clusters. Science 2007, 315, 220–222. [Google Scholar] [CrossRef] [PubMed]

- Anderson, R.M.; Yancey, D.F.; Zhang, L.; Chill, S.T.; Henkelman, G.; Crooks, R.M. A Theoretical and Experimental Approach for Correlating Nanoparticle Structure and Electrocatalytic Activity. Acc. Chem. Res. 2015, 48, 1351–1357. [Google Scholar] [CrossRef] [PubMed]

- Nie, Y.; Li, L.; Wei, Z.D. Recent advancements in Pt and Pt-free catalysts for oxygen reduction reaction. Chem. Soc. Rev. 2015, 44, 2168–2201. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, S.; Wu, J.; Kang, N.; Cronk, H.; Zhao, Y.; Zhao, W.; Skeete, Z.; Joseph, P.; Trimm, B.; Luo, J.; et al. Nanoscale Alloying in Electrocatalysts. Catalysts 2015, 5, 1465-1478. https://doi.org/10.3390/catal5031465

Shan S, Wu J, Kang N, Cronk H, Zhao Y, Zhao W, Skeete Z, Joseph P, Trimm B, Luo J, et al. Nanoscale Alloying in Electrocatalysts. Catalysts. 2015; 5(3):1465-1478. https://doi.org/10.3390/catal5031465

Chicago/Turabian StyleShan, Shiyao, Jinfang Wu, Ning Kang, Hannah Cronk, Yinguang Zhao, Wei Zhao, Zakiya Skeete, Pharrah Joseph, Bryan Trimm, Jin Luo, and et al. 2015. "Nanoscale Alloying in Electrocatalysts" Catalysts 5, no. 3: 1465-1478. https://doi.org/10.3390/catal5031465