Research on Detection and Safety Analysis of Unfavorable Geological Bodies Based on OCTEM-PHA

Abstract

:1. Introduction

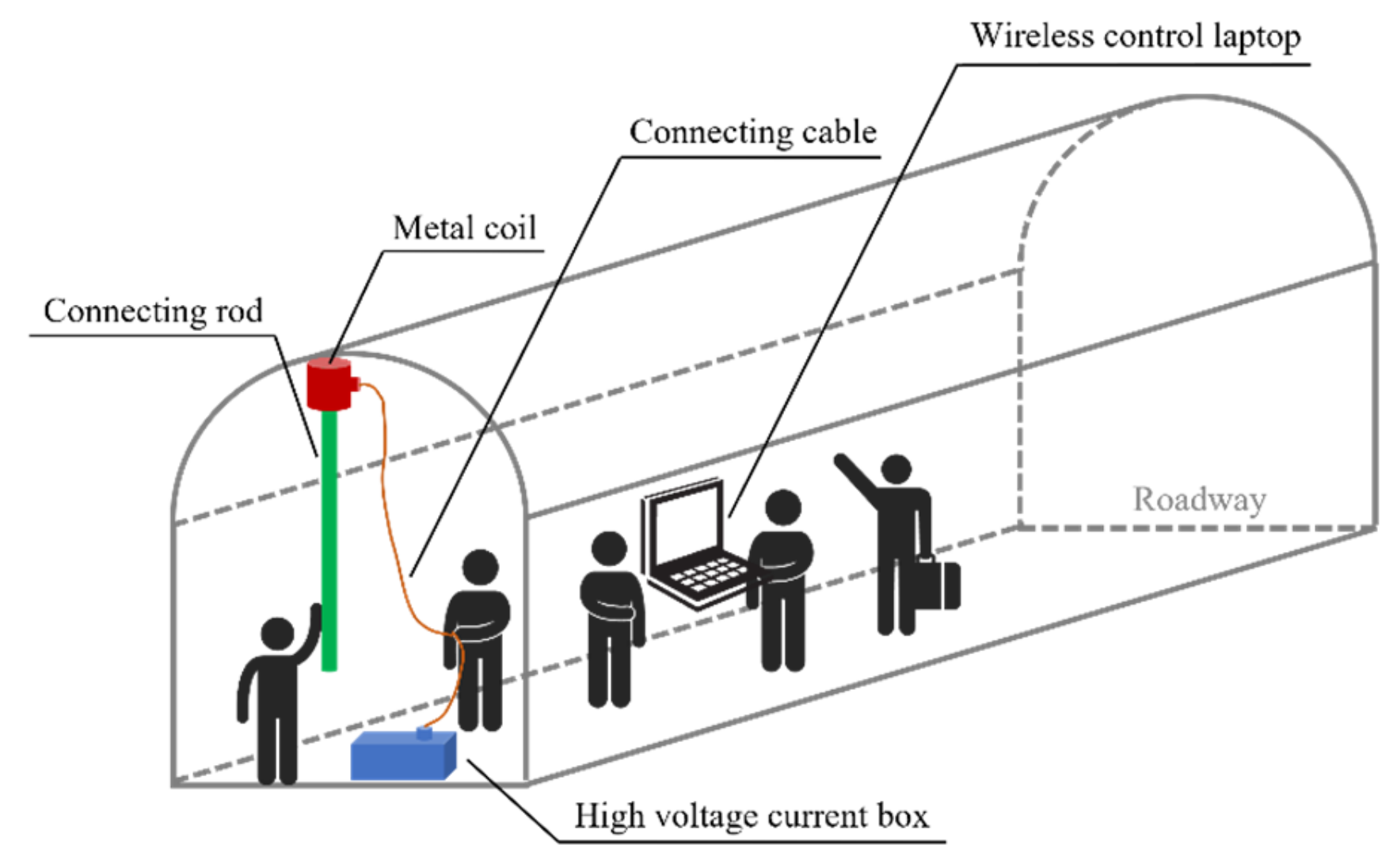

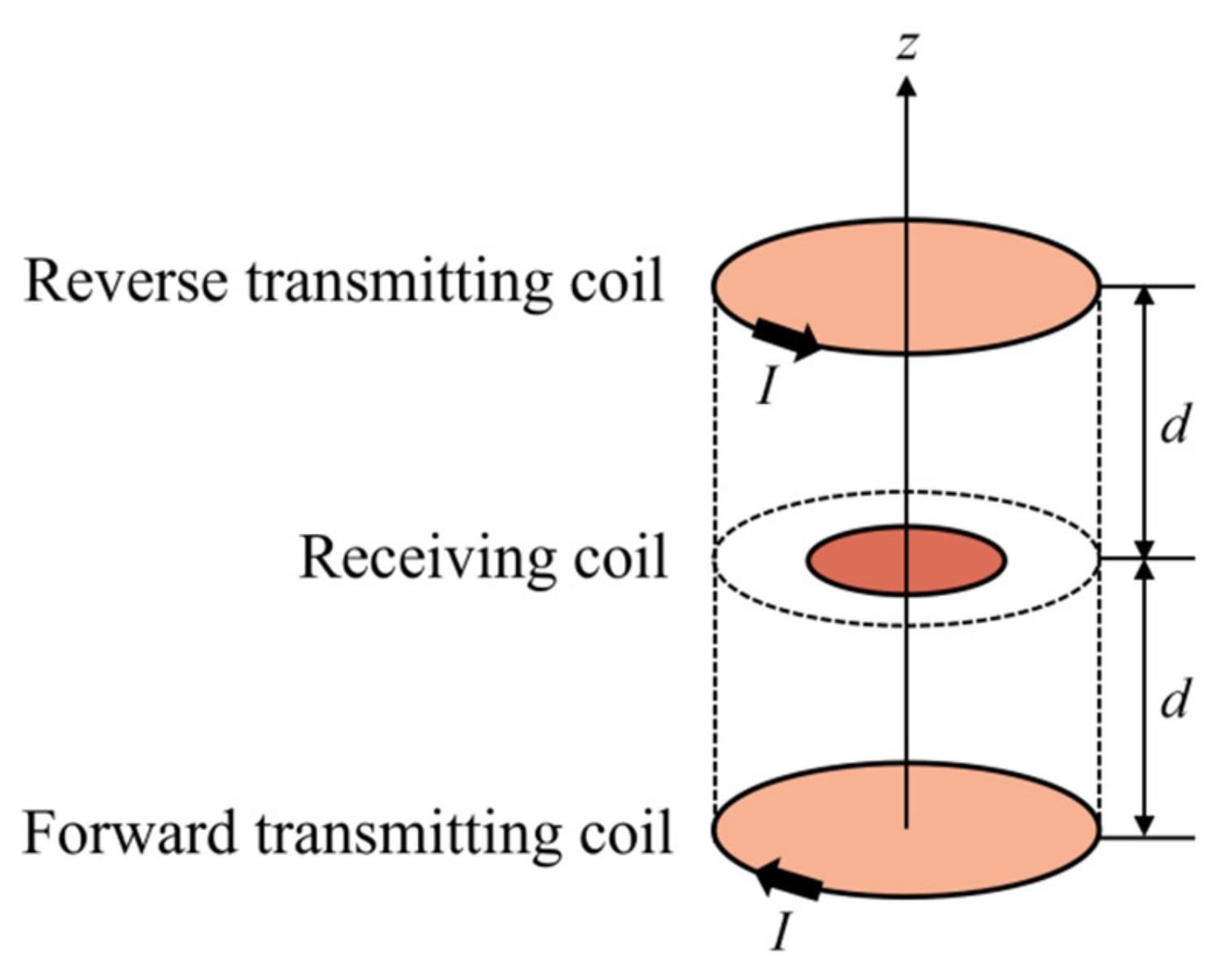

2. Instruments and Methods

2.1. Detection Instruments and Principles

- Using a transceiver micro-antenna makes the device small and light in weight.

- The innovative use of the OCTEM can eliminate coupling between transceiver coils.

- Using the dyadic center coupling principle can improve lateral resolution.

- Using unified standard micro-coil pair magnetic source, susceptible magnetic induction receiver sensor, high-speed 24-bit acquisition card, and high-density measurement technology can realize shallow high-precision transient electromagnetic detection.

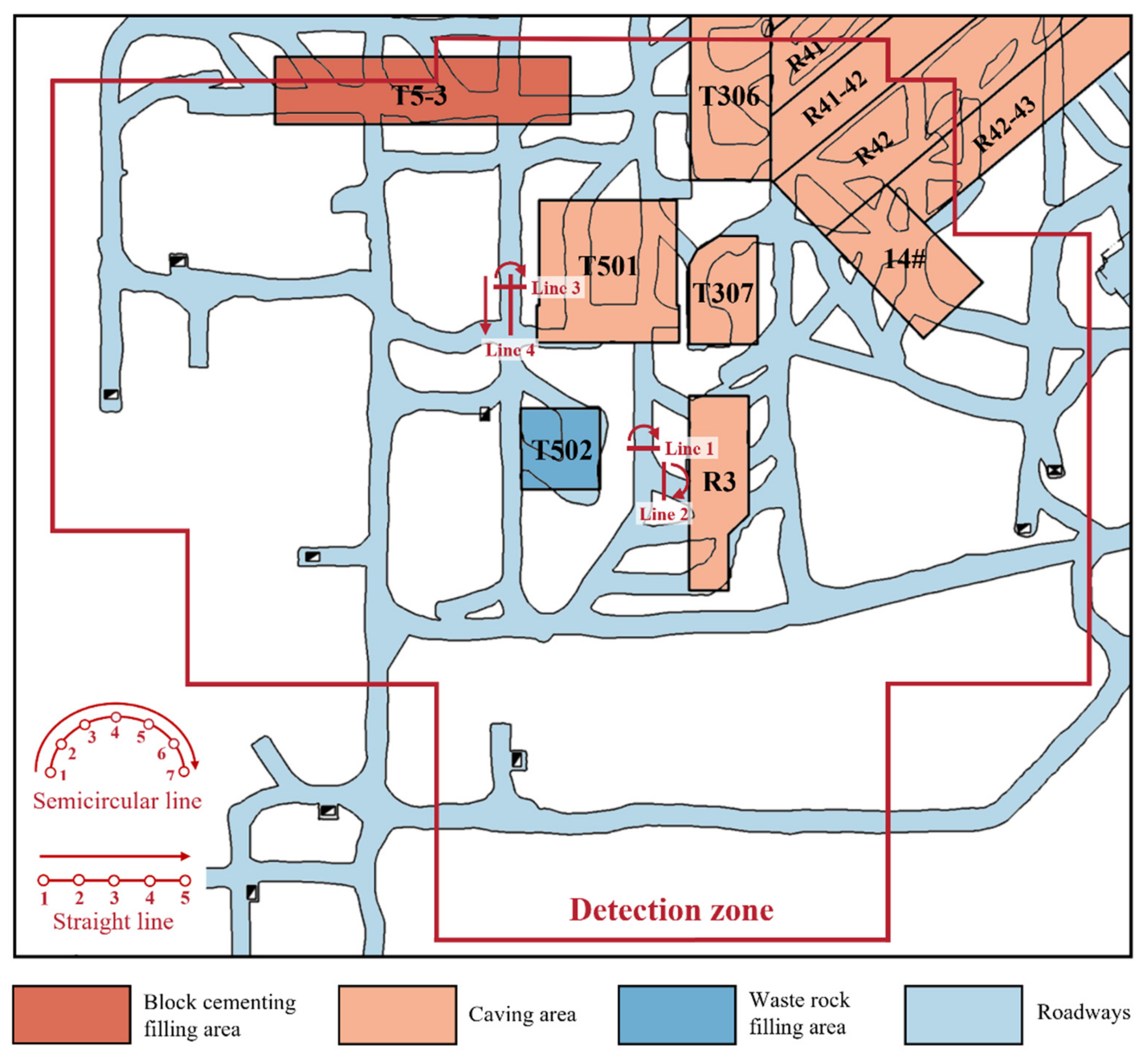

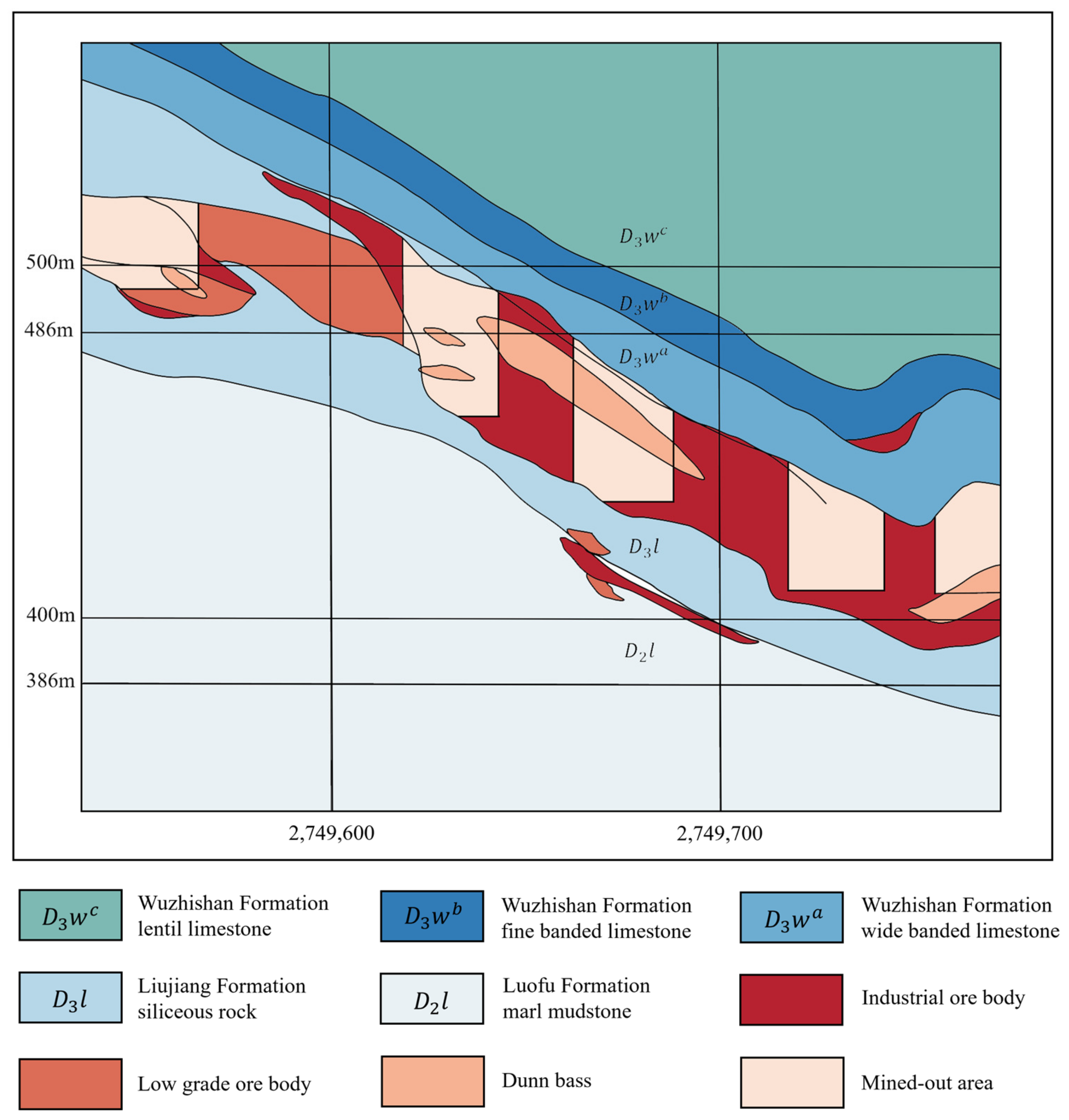

2.2. Detection Area and Test Scheme

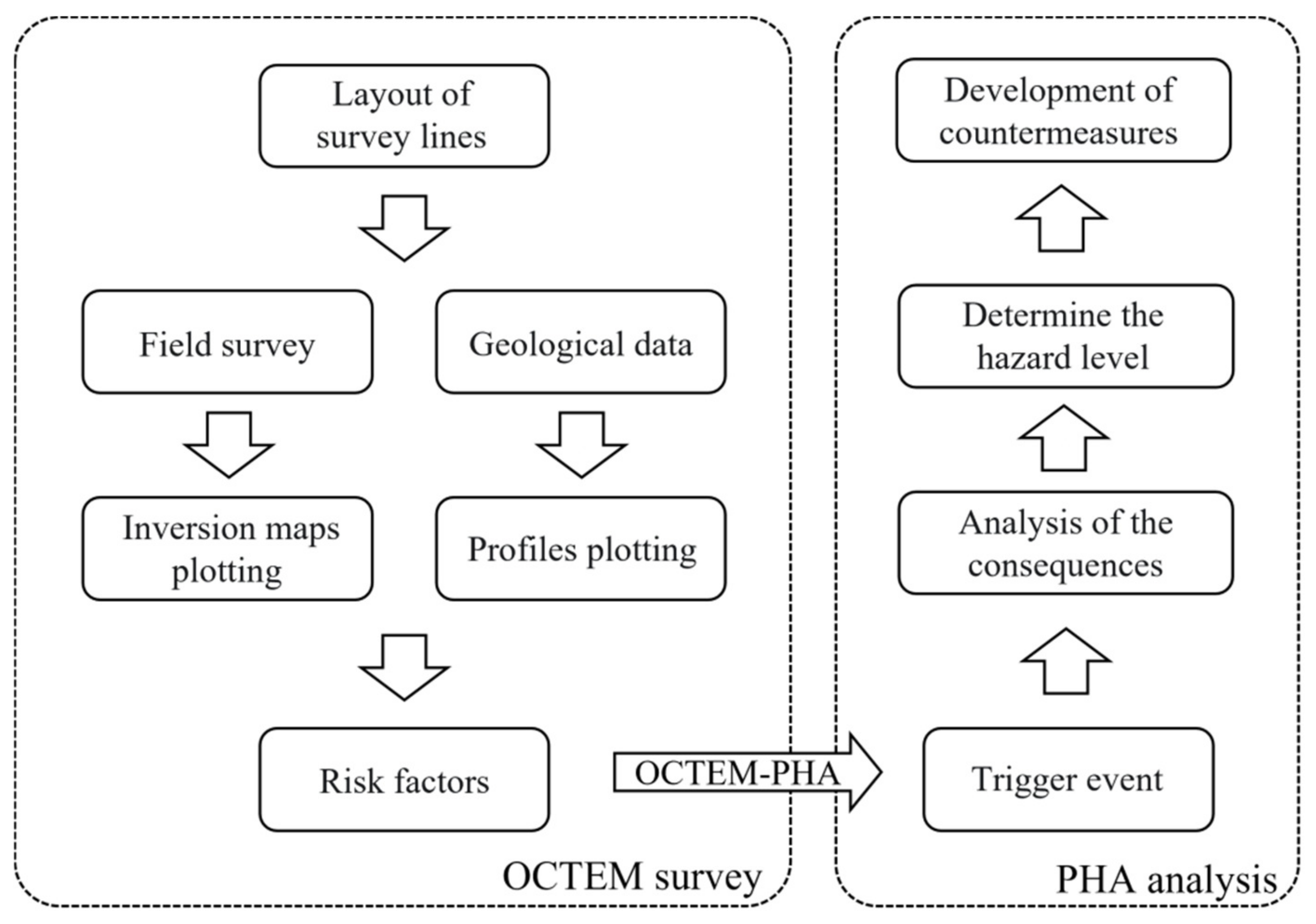

2.3. OCTEM-PHA Analysis Process

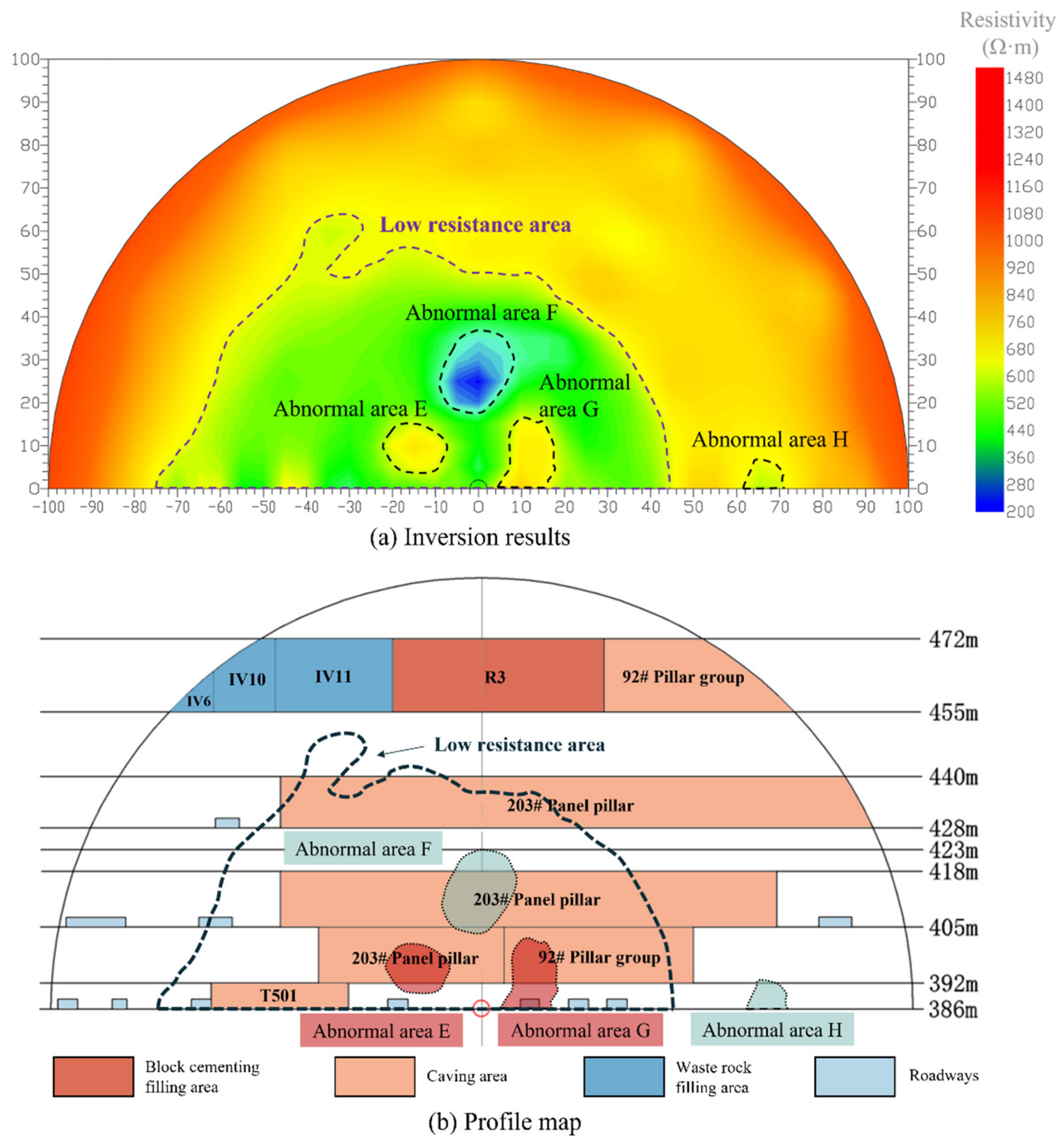

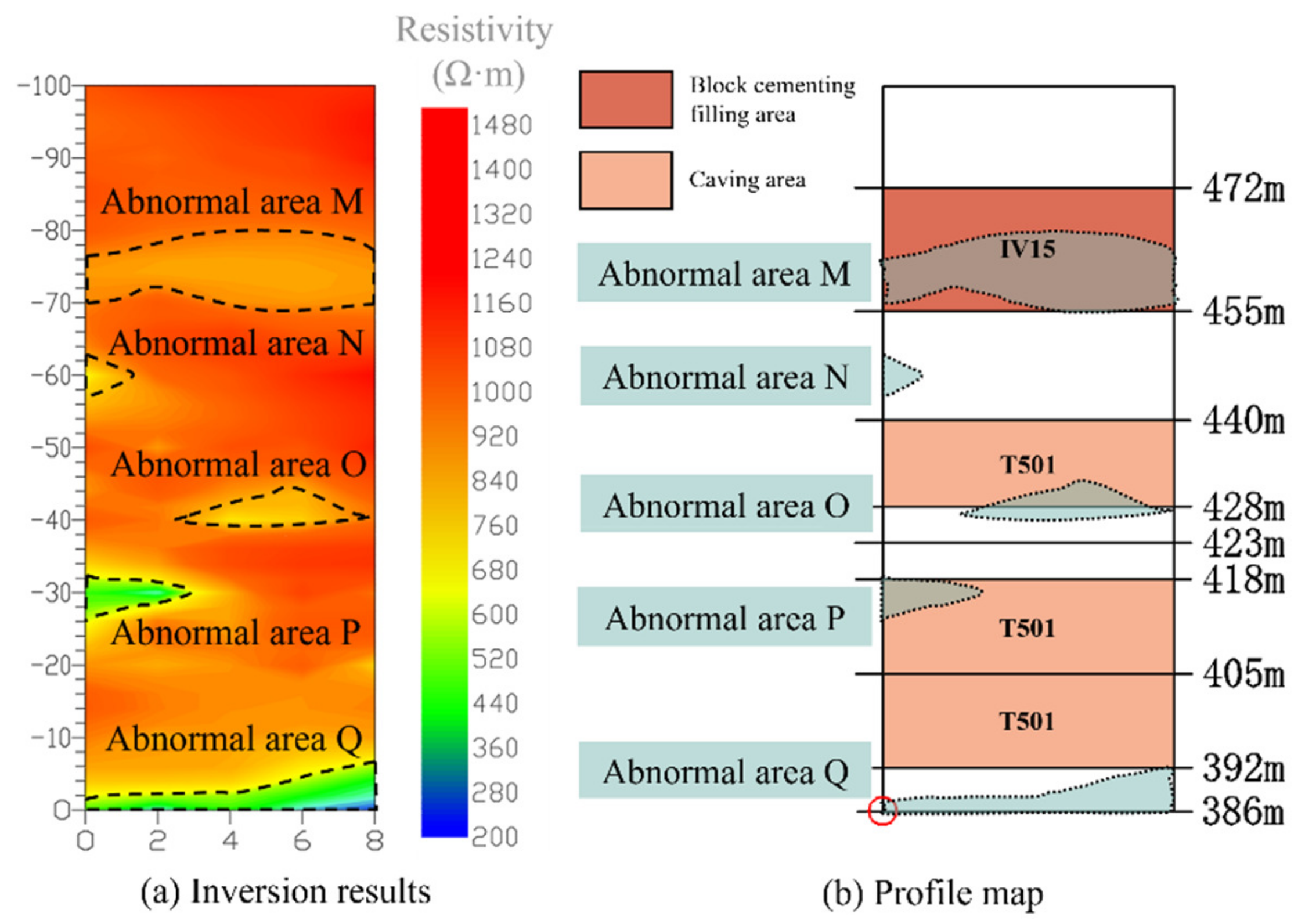

3. OCTEM Detection Results Analysis

3.1. Comparison of OCTEM Inversion Results and Profiles

3.2. Analysis of Resistivity Anomaly Areas

3.3. PHA Analysis

- (1)

- The caving mining area must be further optimized to realize balanced mining. The unsafe factors of excessive local settlement of rock layers must be reduced due to unbalanced mining. Then, the draw control must be strengthened, the uniformity of ore release must be improved, and the local overhang brought by uneven ore output must be reduced.

- (2)

- The treatment of groundwater and surface water must be improved. The Tongkeng deposit is filled with water due to fissure water and atmospheric precipitation. Due to the high local precipitation, the detection results show that the resistance anomaly area is mainly a water-rich, low-resistance area. Thus, the water treatment in the water-rich area should be strengthened to reduce the impact of water on the mine during underground mining.

- (3)

- The comparative analysis must be increased with the following detection results, the caving and filling mining interface must be strengthened, and technical reserves and planning must be proposed.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ranjith, P.G.; Zhao, J.; Ju, M.H.; De Silva, R.V.; Rathnaweera, T.; Bandara, A.K. Opportunities and Challenges in Deep Mining: A Brief Review. Engineering 2017, 3, 546–551. [Google Scholar] [CrossRef]

- Wang, X.; Huang, F.; Fan, X.; Shahabi, H.; Shirzadi, A.; Bian, H.; Ma, X.; Lei, X.; Chen, W. Landslide susceptibility modeling based on remote sensing data and data mining techniques. Environ. Earth Sci. 2022, 81, 1–19. [Google Scholar] [CrossRef]

- Li, W.; Fan, X.; Huang, F.; Chen, W.; Hong, H.; Huang, J.; Guo, Z. Uncertainties Analysis of Collapse Susceptibility Prediction Based on Remote Sensing and GIS: Influences of Different Data-Based Models and Connections between Collapses and Environmental Factors. Remote Sens. 2020, 12, 4134. [Google Scholar] [CrossRef]

- Fang, Z.H.; Wang, L.G.; Xiong, Z.Y. Mining Disturbance Analysis in Metal Mine Based on Micromine-FLAC3D Coupling Technology. J. Min. Saf. Eng. 2012, 29, 870–875. (In Chinese) [Google Scholar]

- Zhang, G.H.; Jiao, Y.Y.; Wang, H.; Cheng, Y.; Chen, L.-B. On the Mechanism of Inrush Hazards hen Denghuozhai Tunnel Passing Through Granite Contact Zone. Tunn. Undergr. Space Technol. 2017, 68, 174–186. [Google Scholar] [CrossRef]

- Liu, X.T.; Chen, C.X.; Xia, K.Z.; Zheng, X.W.; Wang, T.L.; Yuan, J.H. Investigation of the Time-Dependent Strata Movement Behaviour Caused by Caving Method. Rock Soil Mech. 2023, 44, 563–576. (In Chinese) [Google Scholar] [CrossRef]

- Xia, K.; Chen, C.; Wang, T.; Zheng, Y.; Wang, Y. Estimating the Geological Strength Index and Disturbance Factor in the Hoek-Brown Criterion Using the Acoustic Wave Velocity in the Rock Mass. Eng. Geol. 2022, 306, 106745. [Google Scholar] [CrossRef]

- Song, X.; Chen, C.; Xia, K.; Yang, K.; Chen, S.; Liu, X. Analysis of the Surface Deformation Characteristics and Strata Movement Mechanism in the Main Shaft Area of Chengchao Iron Mine. Environ. Earth Sci. 2018, 77, 335. [Google Scholar] [CrossRef]

- Chang, Z.; Du, Z.; Zhang, F.; Huang, F.; Chen, J.; Li, W.; Guo, Z. Landslide Susceptibility Prediction Based on Remote Sensing Images and GIS: Comparisons of Supervised and Unsupervised Machine Learning Models. Remote Sens. 2020, 12, 502. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Liu, Y.; Yin, C.; Su, Y.; Ren, X.; Zhang, B. Three-Dimensional Dual-Mesh Inversions for Sparse Surface-to-Borehole TEM Data. Remote Sens. 2023, 15, 1845. [Google Scholar] [CrossRef]

- Ren, H.; Lei, D.; Wang, Z.; Fu, C. A Mesh Mapping-Based Cooperative Inversion Strategy for Airborne Transient Electromagnetic and Magnetic Methods. Remote Sens. 2023, 15, 125. [Google Scholar] [CrossRef]

- Cao, B.; Wang, J.; Du, H.; Tao, Y.; Liu, G. Research on Comprehensive Detection and Visualize of Hidden Cavity Goaf. Sci. Rep. 2022, 12, 1–21. [Google Scholar] [CrossRef]

- Luo, X.; Gong, S.; Huo, Z.; Li, H.; Ding, X. Application of Comprehensive Geophysical Prospecting Method in the Exploration of Coal Mined-Out Areas. Adv. Civ. Eng. 2019, 2019, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Cao, J.; Sun, L.; Wu, C. Separation of DC Elecrical Method Anomaly by Using Multifractral Modelling. Fresenius Environ. Bull. 2022, 31, 11014–11019. [Google Scholar]

- Wang, P. Advanced Detection Technology of Ground-Borehole DC Resistivity Method. Earth Sci. 2023, 1–11. Available online: http://kns.cnki.net/kcms/detail/42.1874.p.20221005.1221.004.html (accessed on 22 April 2023). (In Chinese).

- Zhou, G.Q.; Wang, Y.F.; Chen, X.H.; Yue, M.X.; Zhai, F.Q.; Yang, X.D.; Wu, X.P.; Cao, Y.; Cui, Y. Research on Forward Modeling of “Triangular Cone” Type Direct Current Method For Heading Detection. J. China Coal Soc. 2022, 47, 3015–3023. (In Chinese) [Google Scholar] [CrossRef]

- Hao, L.; Li, N.; Xu, X.; Zhang, Q.; Chen, L.; Sun, F. Detecting Goaf Ahead of the Mine Tunnel Using SAP: A Case Study in Iron Mine, China. Geotech. Geol. Eng. 2022, 40, 883–897. [Google Scholar] [CrossRef]

- Wei, H.X.; Cha, W.F.; Feng, C.L. Analysis of Characteristics of Seismic Section in Goaf Area. Prog. Geophys. 2014, 29, 1808–1814. (In Chinese) [Google Scholar]

- Ismail, A.; Abdelnaby, A.; Larson, T. High-resolution P- and S-wave Seismic Reflection Followed by Engineering Modeling for Geotechnical Site Characterization in Southern Illinois. J. Environ. Eng. Geophys. 2017, 22, 375–384. [Google Scholar] [CrossRef]

- Zhang, M.; Feng, X.; Bano, M.; Xing, H.; Wang, T.; Liang, W.; Zhou, H.; Dong, Z.; An, Y.; Zhang, Y. Review of Ground Penetrating Radar Applications for Water Dynamics Studies in Unsaturated Zone. Remote Sens. 2022, 14, 5993. [Google Scholar] [CrossRef]

- Hou, F.; Rui, X.; Fan, X.; Zhang, H. Review of GPR Activities in Civil Infrastructures: Data Analysis and Applications. Remote Sens. 2022, 14, 5972. [Google Scholar] [CrossRef]

- Xue, G.; Chen, W.; Cheng, J.; Liu, S.; Yu, J.; Lei, K.; Guo, W.; Feng, X. A Review of Electrical and Electromagnetic Methods for Coal Mine Exploration in China. IEEE Access 2019, 7, 177332–177341. [Google Scholar] [CrossRef]

- Xue, G.Q.; Yan, Y.J.; Cheng, J.L. Researches on Detection of 3-D Underground Cave Based on TEM Technique. Environ. Earth Sci. 2011, 64, 425–430. [Google Scholar] [CrossRef]

- Danielsen, J.E.; Auken, E.; Jorgensen, F.; Sondergaard, V.; Sorensen, K.I. The Application of the Transient Electromagnetic Method in Hydrogeophysical Surveys. J. Appl. Geophys. 2003, 53, 181–198. [Google Scholar] [CrossRef]

- Wu, J.; Zhi, Q.; Deng, X.; Wang, X.; Chen, X.; Zhao, Y.; Huang, Y. Deep Gold Exploration with SQUID TEM in the Qingchengzi Orefield, Eastern Liaoning, Northeast China. Minerals 2022, 12, 102. [Google Scholar] [CrossRef]

- Yu, C.; Liu, X.; Liu, J.; Li, E.; Yue, P.; Yan, S. Application of Transient Electromagnetic Method for Investigating the Water-Enriched Mined-Out Area. Appl. Sci. 2018, 8, 1800. [Google Scholar] [CrossRef] [Green Version]

- Chang, J.; Su, B.; Malekian, R.; Xing, X. Detection of Water-Filled Mining Goaf Using Mining Transient Electromagnetic Method. Ieee Trans. Ind. Inform. 2020, 16, 2977–2984. [Google Scholar] [CrossRef]

- Xi, Z.Z.; Long, X.; Zhou, S.; Huang, L.; Song, G.; Hou, H.T.; Wang, L. Opposing Coils Transient Electromagnetic Method for Shallow Subsurface Detection. Chin. J. Geophys. 2016, 59, 3428–3435. (In Chinese) [Google Scholar]

- Yang, G.; Xie, C.; Wu, T.; Wu, X.; Zhang, Y.; Wang, W.; Liu, G. Detection of Permafrost in Shallow Bedrock Areas with the Opposing Coils Transient Electromagnetic Method. Front. Environ. Sci. 2022, 10, 909848. [Google Scholar] [CrossRef]

- Wen, L.; Cheng, J.; Huang, S.; Zhou, J.; Han, Y.; Li, F.; Zhao, J. Review of Geophysical Exploration on Mined-out Areas and Water Abundance. J. Environ. Eng. Geophys. 2019, 24, 129–143. [Google Scholar] [CrossRef]

- Xu, Q.; Xu, K.; Li, L.; Yao, X. Assessment of Petrochemical Enterprise Using the Cloud Model, PHA-LOPA and the Bow-Tie Model. R. Soc. Open Sci. 2018, 5, 180212. [Google Scholar] [CrossRef] [Green Version]

- Yan, F.; Xu, K. Methodology and Case Study of Quantitative Preliminary Hazard Analysis Based on Cloud Model. J. Loss Prev. Process Ind. 2019, 60, 116–124. [Google Scholar] [CrossRef]

- Hfaiedh, N.; Kabiche, S.; Delescluse, C.; Balde, I.-B.; Merlin, S.; Carret, S.; de Pontual, L.; Fontan, J.-E.; Schlatter, J. Performing a Preliminary Hazard Analysis Applied to Administration of Injectable Drugs to Infants. J. Eval. Clin. Pract. 2017, 23, 875–881. [Google Scholar] [CrossRef]

- La Fata, C.M.; Giallanza, A.; Micale, R.; La Scalia, G. Improved FMECA for Effective Risk Management Decision Making by Failure Modes Classification under Uncertainty. Eng. Fail. Anal. 2022, 135, 106163. [Google Scholar] [CrossRef]

- Shen, G.-X.; Sun, S.-G.; Zhang, Y.-Z.; Wang, Z.-Q.; Chen, B.-K.; Ma, C. System Failure Analysis Based on DEMATEL-ISM and FMECA. J. Cent. South Univ. 2014, 21, 4518–4525. [Google Scholar] [CrossRef]

- Dunjo, J.; Fthenakis, V.; Vilchez, J.A.; Arnaldos, J. Hazard and Operability (HAZOP) Analysis. A Literature Review. J. Hazard. Mater. 2010, 173, 19–32. [Google Scholar] [CrossRef]

- Li, W.; Sun, Y.; Cao, Q.; He, M.; Cui, Y. A Proactive Process Risk Assessment Approach Based on Job Hazard Analysis and Resilient Engineering. J. Loss Prev. Process Ind. 2019, 59, 54–62. [Google Scholar] [CrossRef]

- Ozfirat, M.K.; Ozkan, E.; Kahraman, B.; Sengun, B.; Yetkin, M.E. Integration of Fisk Matrix and Event Tree Analysis: A Natural Stone Plant Case. Sadhana-Acad. Proc. Eng. Sci. 2017, 42, 1741–1749. [Google Scholar] [CrossRef]

- Kabir, S. An Overview of Fault Tree Analysis and its Application in Model Based Dependability Analysis. Expert Syst. Appl. 2017, 77, 114–135. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Dai, Y.F.; Liu, B.; Long, X.; Lin, J.; Chen, X.P. Research on Rapid Detection of Seawater Intrusion Based on Opposing-Coil Transient Electromagnetic Method. Prog. Geophys. 2023, 38, 1397–1407. (In Chinese) [Google Scholar]

- Cui, X.L. A Study on Detection of Goaf Water of Tianli-Tianxin Coal Mine Based on Transient Electromagnetic Method. IOP Conf. Ser. J. Phys. 2019, 1176, 062055. [Google Scholar] [CrossRef]

- Wu, G.; Yang, G.; Tan, H. Mapping Coalmine Goaf Using Transient Electromagnetic Method and High Density Resistivity Method in Ordos City, China. Geod. Geodyn. 2016, 7, 340–347. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.X.; Chen, H.; Zhang, S.G.; Wan, C.C. In Situ Fragmentation Blasting Technology in Mining of High Stress Broken Ore Body. Nonferrous Met. Eng. 2015, 5, 8–12. (In Chinese) [Google Scholar]

- Wang, Z.; Zhang, X.L.; Luo, R.L.; Wang, Z.H. Abnormal Characteristic of TEM Response for Prospecting Depth and Margin Area of Tin Polymetallic Deposit in Dachang. J. Guilin Univ. Technol. 2009, 29, 303–309. (In Chinese) [Google Scholar]

- Wei, M.X.; Li, S.P.; Qi, J.; Huang, W.F.; Tao, Y.; Yang, C.F. Application of Magnetotelluric Sounding Method in the Survey and Evaluation of Shale Gas Resources in North Guangxi. Miner. Resour. Geol. 2022, 36, 614–621. (In Chinese) [Google Scholar] [CrossRef]

- Yang, K.K. Lutang Tailing Pond’s Karst Development Characteristics and Its Groundwater Environment Impact; Guilin University of Technology: Guilin, China, 2021. (In Chinese) [Google Scholar]

- Mu, Y.; Qiu, H.; Xu, H.; Li, J. Electromagnetic Response Characteristics Research on Mine Different Geological Body. IOP Conf. Ser. Earth Environ. Sci. 2019, 237, 062015. [Google Scholar]

- Zhang, G.H.; Wang, C.T.; Jiao, Y.Y.; Wang, H.; Chen, L.-B. Deposits Sources of Inrush Hazards for the Liangshan Tunnel Passing Through Deeply Buried Granite. Tunn. Undergr. Space Technol. 2019, 92, 103058. [Google Scholar] [CrossRef]

- Zhang, G.H.; Jiao, Y.Y.; Ma, C.X.; Wang, H.; Chen, L.-B.; Tang, Z.-C. Characteristics of Granite Contact Zone and Treatment Measures for Inrush Hazards During Tunnel Construction–A Case Study. Eng. Geol. 2018, 235, 64–80. [Google Scholar] [CrossRef]

| Level | Severity Level | Possible Consequences |

|---|---|---|

| Ⅰ | Safe | Does not cause injury or disease, no loss of system, negligible |

| Ⅱ | Marginal | On the verge of an accident that will not cause casualties and system damage for the time being but should be eliminated or controlled |

| Ⅲ | Dangerous | Will cause casualties and system damage, must take immediate measures to control |

| Ⅳ | Catastrophic | Destructive, can cause death or system obsolescence, must try to eliminate |

| Risk Factor | Horizontal Range of Anomalous Area | Vertical Range of Anomalous Area (Level) | Trigger Event | Consequence | Risk Level | Countermeasure |

|---|---|---|---|---|---|---|

| Known caving areas or filling areas contains water | T502 filling area and caving area | 386–418; 428–440 |

|

|

|

|

| 203# panel pillar caving area | 392–418; 428–440 | |||||

| R3 filling area and caving area | 386–418; 428–440 | |||||

| 92# pillar group caving area | 392–405 | |||||

| T501 caving area | 386–418; 428–440 | |||||

| IV15 filling area | 455–472 | |||||

| Known caving areas or filling areas loose structure | 92# pillar group caving area | 392–405 | Ground pressure imbalance increases with mining operation disturbance. | Collapse, spalling and roof falling, or object attacks occur in the surrounding area. | Ⅲ | Organize special personnel with geological drilling equipment to check the caving area (or filling area) and verify the results of physical exploration; take measures such as hanging nets, anchor rods, and slurry spraying to reinforce. |

| T501 caving area | 386–418; 428–440 | |||||

| T306 filling area | 405–418 | |||||

| R3 filling area | 405–418 | |||||

| 14# caving area | 386–418 | |||||

| Surrounding rock of roadways contains water | Left 56 m to right 30 m of line 1 | 386–392 |

|

|

|

|

| Left 70 m to right 40 m of line 2 | 386–392 | |||||

| Left 22 m–80 m of line 3 | 386–392 | |||||

| Hidden water-filled fissure or water-filled goaf | Left 30 m to right 30 m of line 1 | 440–455 |

|

|

|

|

| Left 50 m to right 30 m of line 1 | 418–428 | |||||

| Left 60 m to right 30 m of line 2 | 418–428 | |||||

| Left 40 m–70 m of line 2 | 392–418 | |||||

| Right 62 m–70 m of line 2 | 386–392 | |||||

| Area above line 4 | 386–392; 423–428; 440–455 | |||||

| Hidden loose structure or air-filled goaf | Right 56 m–72 m of line 1 | 386–392 |

|

|

|

|

| Left 20 m–38 m of line 3 | 392–418 | |||||

| Right 10 m–18 m of line 3 | 418–428 | |||||

| Right 56 m–90 m of line 3 | 418–428 | |||||

| Right 60 m–95 m of line 3 | 386–405 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, T.; Hu, J.; Wen, G.; Zhou, T. Research on Detection and Safety Analysis of Unfavorable Geological Bodies Based on OCTEM-PHA. Remote Sens. 2023, 15, 3888. https://doi.org/10.3390/rs15153888

Zhu T, Hu J, Wen G, Zhou T. Research on Detection and Safety Analysis of Unfavorable Geological Bodies Based on OCTEM-PHA. Remote Sensing. 2023; 15(15):3888. https://doi.org/10.3390/rs15153888

Chicago/Turabian StyleZhu, Tao, Jianhua Hu, Guanping Wen, and Tan Zhou. 2023. "Research on Detection and Safety Analysis of Unfavorable Geological Bodies Based on OCTEM-PHA" Remote Sensing 15, no. 15: 3888. https://doi.org/10.3390/rs15153888