1. Introduction

Concrete is the most consumed man-made material on earth by society. It plays a vital role in our daily lives and has various applications. It is considered as the basis for our built environment. An estimated annual consumption of concrete was around 25 billion tons in 2006 [

1,

2]. The annual production of cement, which is the main constituent of concrete, was around 4.1 billion tons in 2014 [

3]. Besides its beneficial usage, cement industry is responsible for the production of 5% of the worldwide man-made CO

2 emission [

4]. The CO

2 emission causes climate changes and global warming issues. Recently, demands of producing low carbon concrete are increasing every day for climate change mitigation and adaptations. Among the various available technologies, the most effective is to substitute clinker, which is a main source of the CO

2 emission by alternate materials with pozzolanic or cementitious properties [

5,

6,

7]. Pozzolanic and supplementary cementitious materials (SCM), such as fly ash, slag, silica fume and natural pozzolans, are widely used to partially substitute the clinker, therefore reducing the amount of clinker and associated CO

2 emission [

8]. The factors such as availability of SCMs, its annual production level, cost effectiveness and engineering characteristic can decide the impact of this technology on future cement industry. Current estimated annual production of fly ash, slag and natural pozzolans are 500, 300 and 200 million tons, respectively [

2]. To eliminate 1 billion tons of CO

2 per year by replacing 50% of clinker, 1.58 billion tons of substitution material is needed [

9]. Thus, it is very important to investigate new cement substitute material to fulfill the demand of concrete industry to mitigate the emissions of CO

2. Different industrial byproducts are successfully being used for this purpose.

The different industrial processes’ byproducts were being used successfully for numerous application in cement and concrete industries. For instance, ground granulated blast furnace slag, a byproduct of iron industry, and fly ash, a byproduct of coal power plants, were successfully used in high volume replacements of cement in mass concreting and found very effective in coping issues related to mass concreting [

10,

11]. Silica fume, a byproduct of silicon industry, has become very popular in terms of its effectiveness in attaining high strength and high performance concretes [

12]. Other industrial wastes and byproducts such as ground glass waste or waste glass sludge, granite and marble waste, cement kiln dust, red mud, etc. were also used as a partial replacement of cement and found very effective in getting high later-age strength and improved durability as compared to control samples [

13,

14,

15]. In addition to the above, many other researchers have investigated the potential of these industrial byproducts in the manufacturing of artificial aggregates [

16,

17]. These aggregates were effectively utilized in producing lightweight concrete as well as in controlling the autogenous shrinkage in high strength concretes [

18]. This potential use of these industrial processes’ byproducts as cement substitutes or artificial aggregates, would reduce the burden on cement and aggregate industries. This ultimately would lead to conserve natural resources and have multiple economic and environmental benefits.

Iron and Steel industry generates huge amount of waste as a byproduct called slag. Different types of slag are named for the furnace from which they are generated. Ironmaking slag called blast furnace slag (BFS) is generated when iron is produced in blast furnace while steelmaking slag, which include ladle slag, basic-oxygen-furnace slag (BOFS), and electric-arc-furnace slag (EAFS), are produced during steel manufacturing in their corresponding furnace and operating condition [

19]. Annual estimated production of slag was around 399 million tons in 2010. Out of the total slag produced, the amount of BFS was 240 million tons and around 135 million tons was steel slag [

20]. The demand of BFS to be used as a cement substitute is very high in cement industry. The total amount of slag produced by EU countries in 2008 was 45 million tons. About half of the slag (22.5 million tons) was utilized in cement industry [

21]. South Korea is one of the largest steel producing countries in the world. Annually, about 13.4 million tons of BFS is produced from iron and steel making and 97% of this slag is used in cement and concrete industry [

22].

However, nowadays, the supply of BFS is reducing because of the limited use of blast furnaces for the production of steel. The world has shifted to the use of mini mill and electric arc furnaces for steel production. Therefore, the importance of steel slag is increasing and its proper utilization in different industries is rapidly growing [

20]. Due to the present and expected reduction in supply of BFS in future, there is a need to properly investigate the possible utilization of steel slag (EAF slag) as an alternate material in cement industry to get economic, environmental, and technical benefits.

Kingdom of Saudi Arabia per capita consumption of cement is one of the highest in the world. According to rough estimate, the annual production of cement in Saudi Arabia was 55 million tons in 2014 and 2015 [

3]. Kingdom of Saudi Arabia imported SCMs such as ground granulated blast furnace slag (BFS), silica fume (SF), and fly ash (FA) to fulfill their local concrete industry requirements [

23]. However, locally available industrial byproducts such as EAFS can be used as a partial substitute to Portland cement. This can also be a viable alternative for producing durable and sustainable construction/cementitious materials.

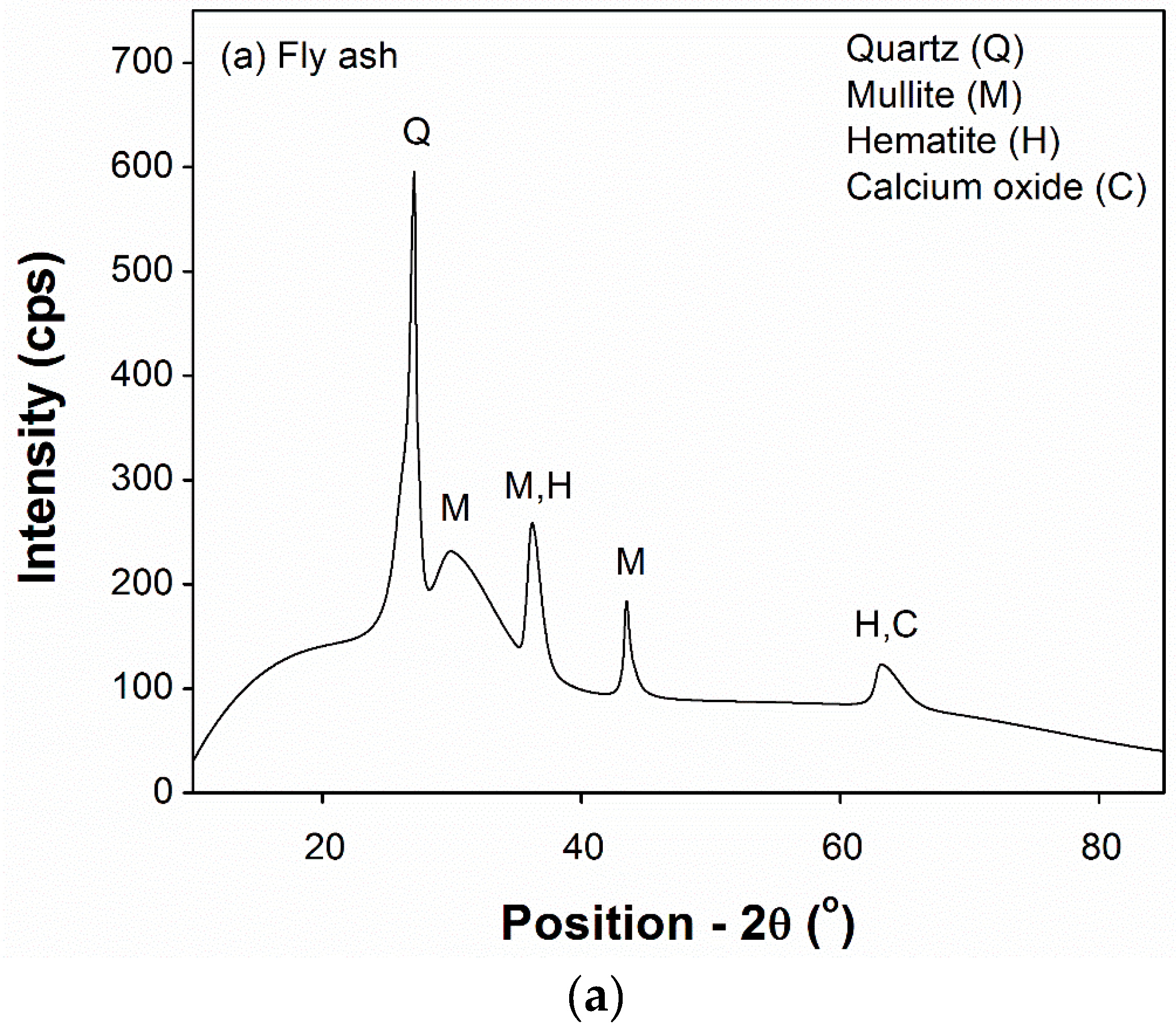

Until recently, very limited studies were devoted to investigate the potential use of EAF slag as partial substitute of cement in concrete industry. Mahmoud et al. [

24] investigated the cementitious and pozzolanic potential of as received and treated (remelting and quenching) EAFS when used as partial replacement of cement in mortar. They found that untreated slag exhibit slight cementitious and pozzolanic behavior because of its crystalline nature. On the other hand, the treated slag showed better cementitious and Pozzolanic properties due to increased amorphous content. They further demonstrate that both untreated and treated EAFS when replaced by 15% and 30% with cement, show less compressive strength at initial stages (up to 14 days) but achieved more strength at 28 days compared to control samples. Despite of the crystalline nature and less cementitious and pozzolanic behavior, the as received EAFS showed almost equal strength at 15% but attained better strength at 30% replacement level as compared to treated slag at later age (28 days). Hekal et al. [

25] observed that replacement of cement with EAFS up to 5% and 10% does not affect the compressive strength when compared to control sample especially at later ages. He further found that higher replacement of cement (20%) with EAFS shows least values of compressive strength to that of control samples at all ages.

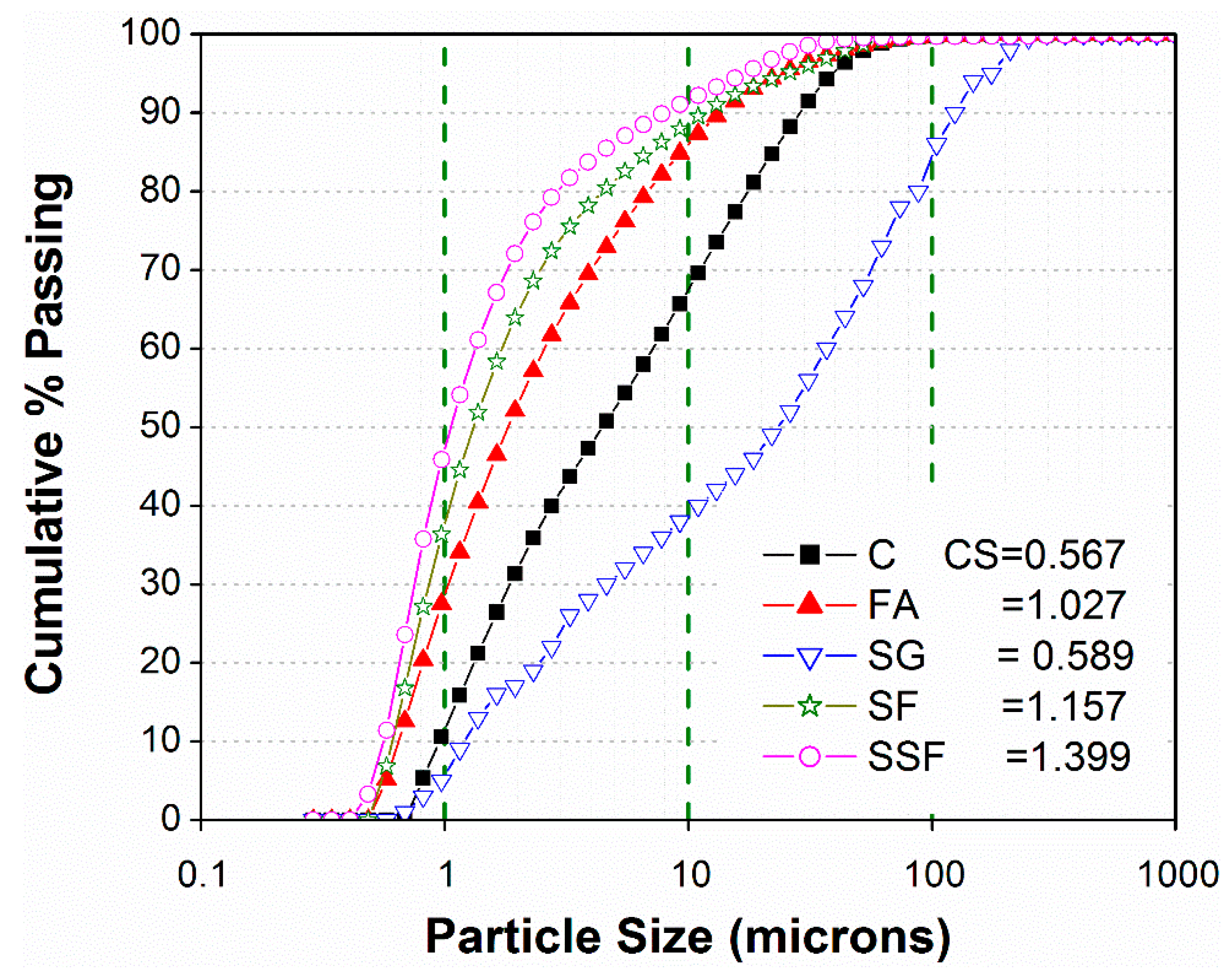

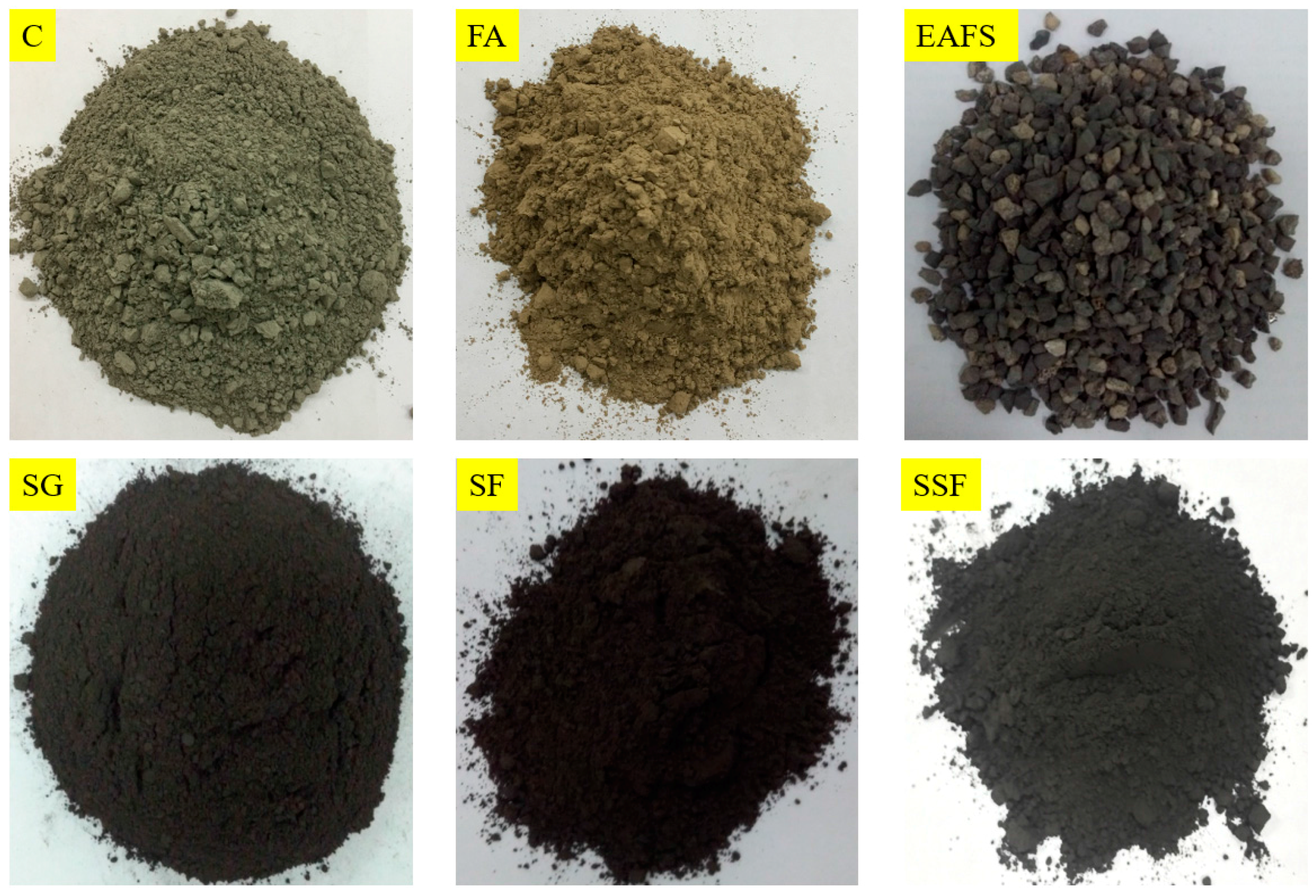

In this study, cement was replaced by EAFS of different fineness levels to evaluate its potential as a binding material. In addition to control mortar (CM) containing 100% cement, several binary (EAFS or FA) and a ternary blends (10% fine EAFS + 10% FA) were designed. Binary blends contain different percentage replacements of cement (up to 30%) with EAFS of different fineness to determine the optimum rate and fineness of EAFS. This is an important requirement in attaining economic value and reducing the cement content. The FA as specified in ASTM C618 Type-F [

26] was used as a reference pozzolanic material to compare the results of this study. Tests were conducted following ASTM C311 [

27] and ASTM C109 [

28] to calculate the strength activity index and the compressive strength of mortar cubes of size 50 mm

3, respectively. Since high temperature variations can occur within mass due to either hydration of cement or seasonal variations, the effect of different normal curing and high temperatures (20, 40 and 60 °C) was studied. The primary objective was to incorporate the influence of seasonal temperature conditions (normal and hot) which occurred in most eastern and western parts of Saudi Arabia. Finally, the slag-activity index of EAFS of different fineness was calculated and compared to ASTM C989 standard Grade-80 and Grade-100 of B.F. slag [

29]. Moreover, the characteristics of EAFS, and the results of compressive strength with respect to (w.r.t.) fineness of EAFS, aging, and curing moisture and temperatures were presented and compared to those of control and the reference FA mortars.

4. Conclusions

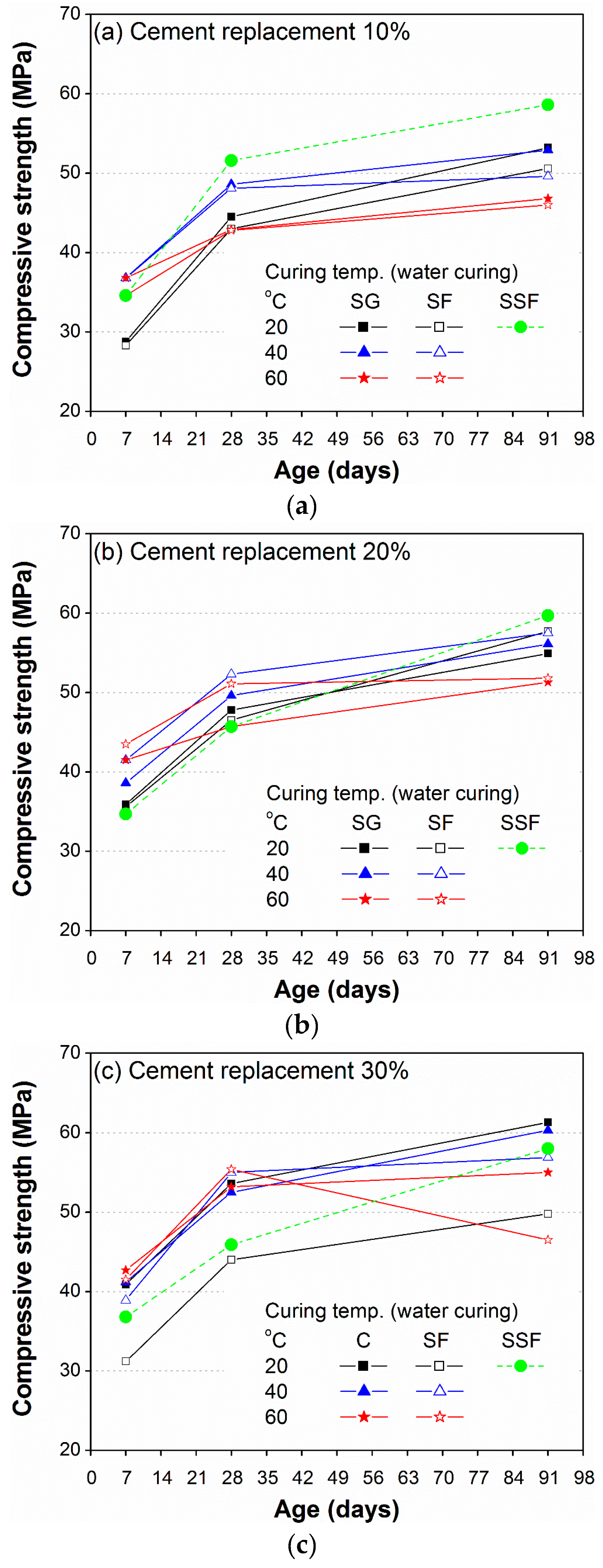

Influence of fineness of locally available EAFS on compressive strength of mortar was investigated in this study. Three different fineness levels of EAFS such as slag ground (SG), slag fine passing sieve #200 (SF), and slag super fine passing sieve #325 (SSF) were considered. For each fineness, cement was substituted up to 30%, while it was substituted up to 20% in the case of SG and in reference mortars containing fly ash (FA). The purpose of casting the reference FA mortar was to compare the results of commercially available pozzolana with those of locally available materials. The tests were conducted w.r.t. aging and different curing conditions of temperature and moisture (continuous moist and partially moist). Different curing temperatures (20, 40, and 60 °C) were selected to incorporate the seasonal effects of normal as well as hot local environmental conditions. Finally, the characteristics of EAFS and its strength activity index values were calculated according to ASTM C311 and compared to slag activity index of BFS Grade 80 and Grade 100 as specified in ASTM C989. A comparison of results between mortar containing EAFS with those of control and reference FA mortar was presented. According to the results, the following main conclusions were drawn from this study:

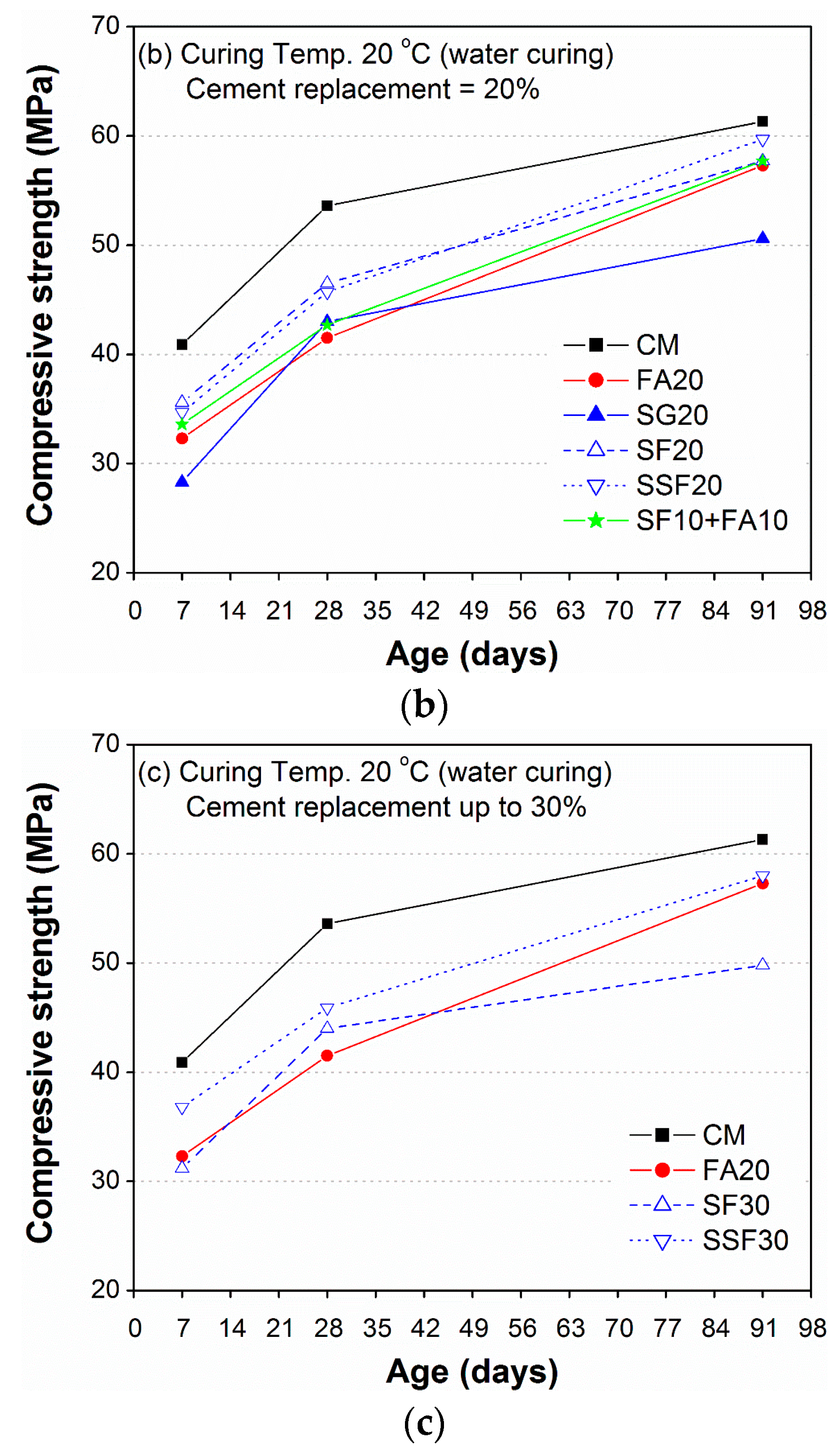

Results indicated that the compressive strength of mortar subjected to standard curing (water cured at 20 °C) remained lower in all mortars containing EAFS or FA than that of CM. However, the strength activity index of mortars containing EAFS was comparatively better than BFS Grade 80. Moreover, the strength activity index of SSF up to 10% cement substitution was better than BFS Grade 100. Such results clearly emphasizing the important role of EAFS as cementitious and pozzolanic material to be used as binder of concrete like BFS.

Result indicated that the compressive strength increased with increasing fineness of EAFS. Interestingly, the trend of strength development in mortar containing EAFS was turned out better as compared to commercially available FA. Therefore, despite slightly reduced strength as compared to CM, results suggest that 10%, 20%, and 30% cement substitution with SG, SF, and SSF, respectively, may preferably be employed in concrete as an alternative of FA.

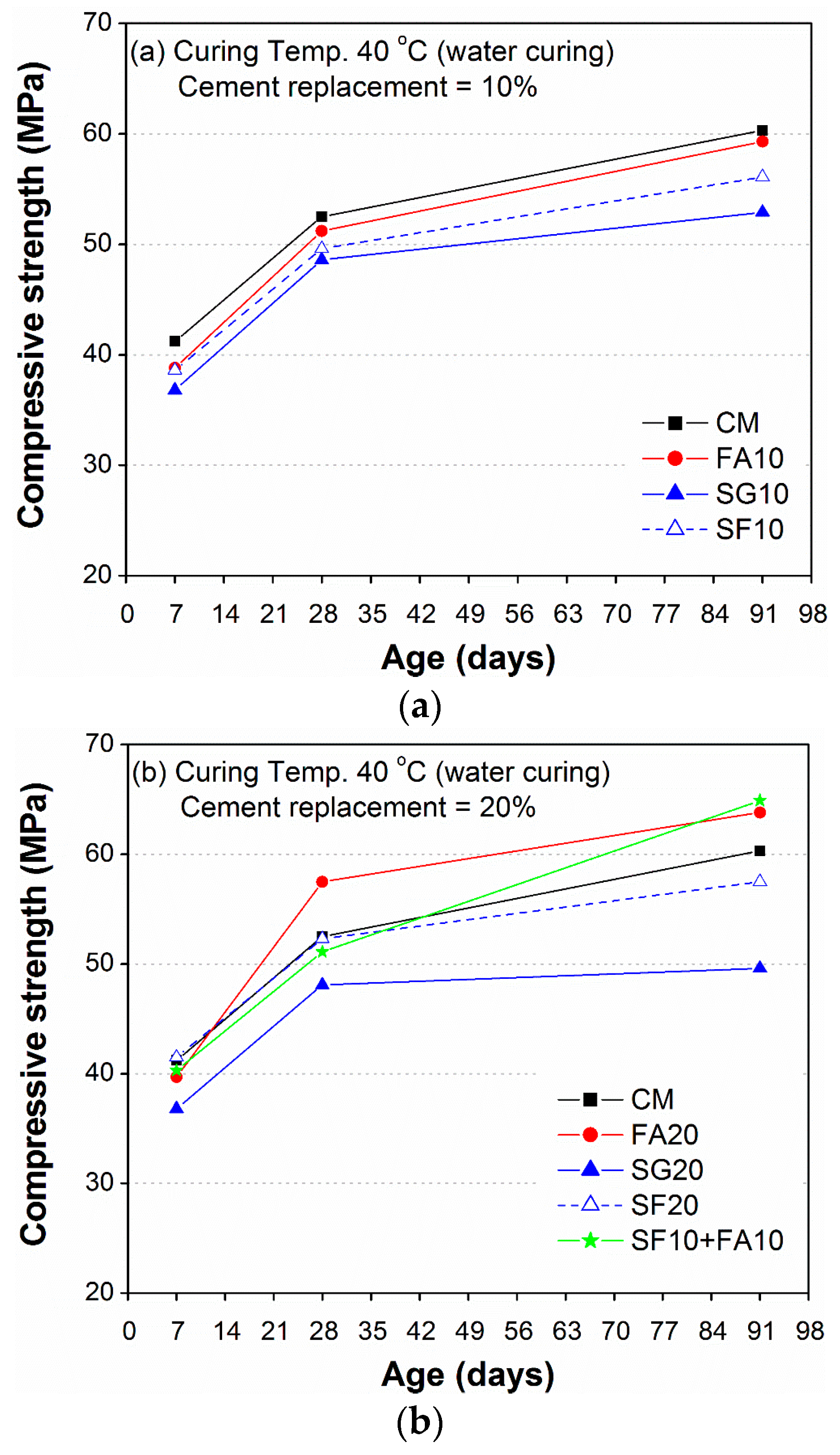

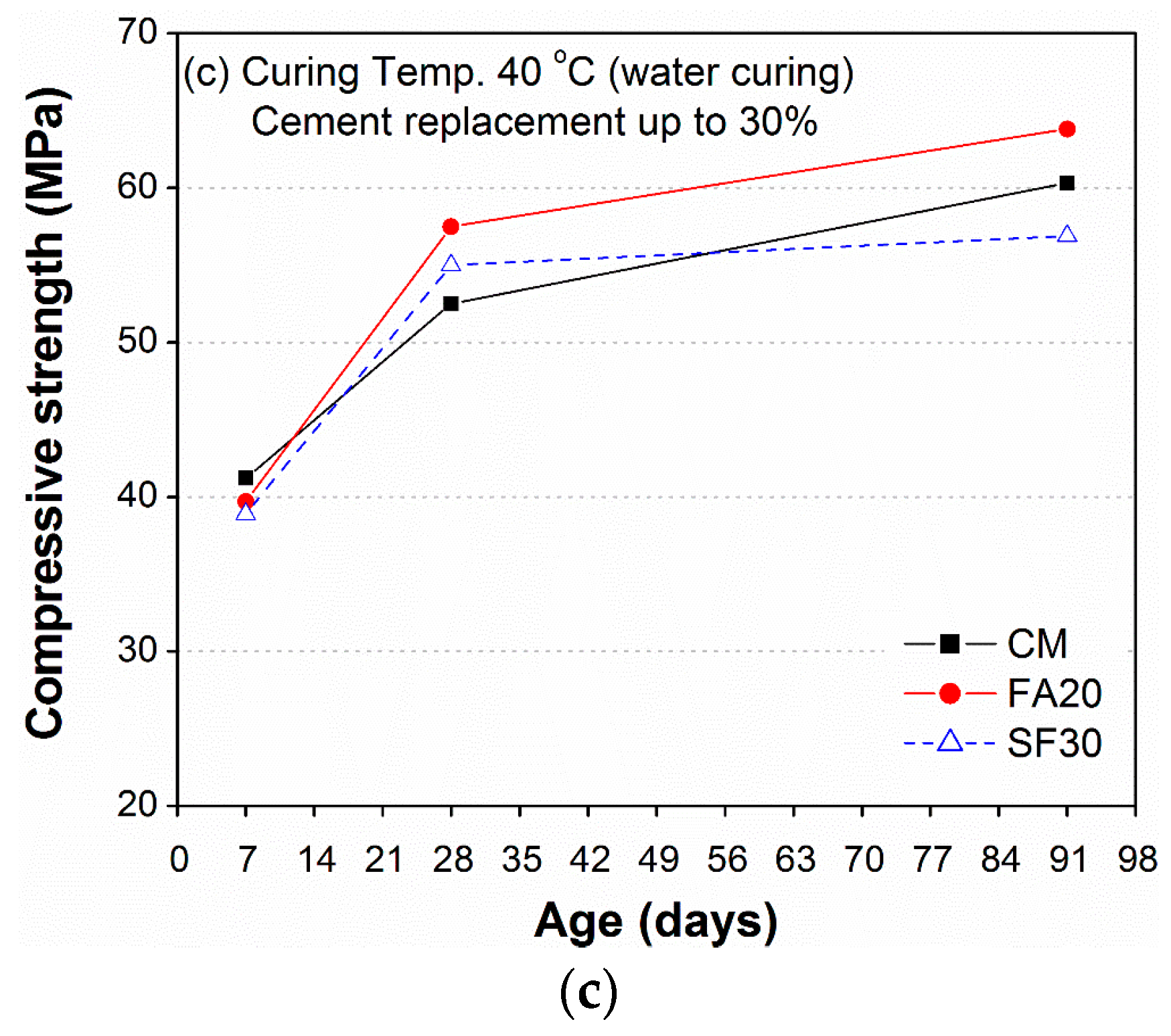

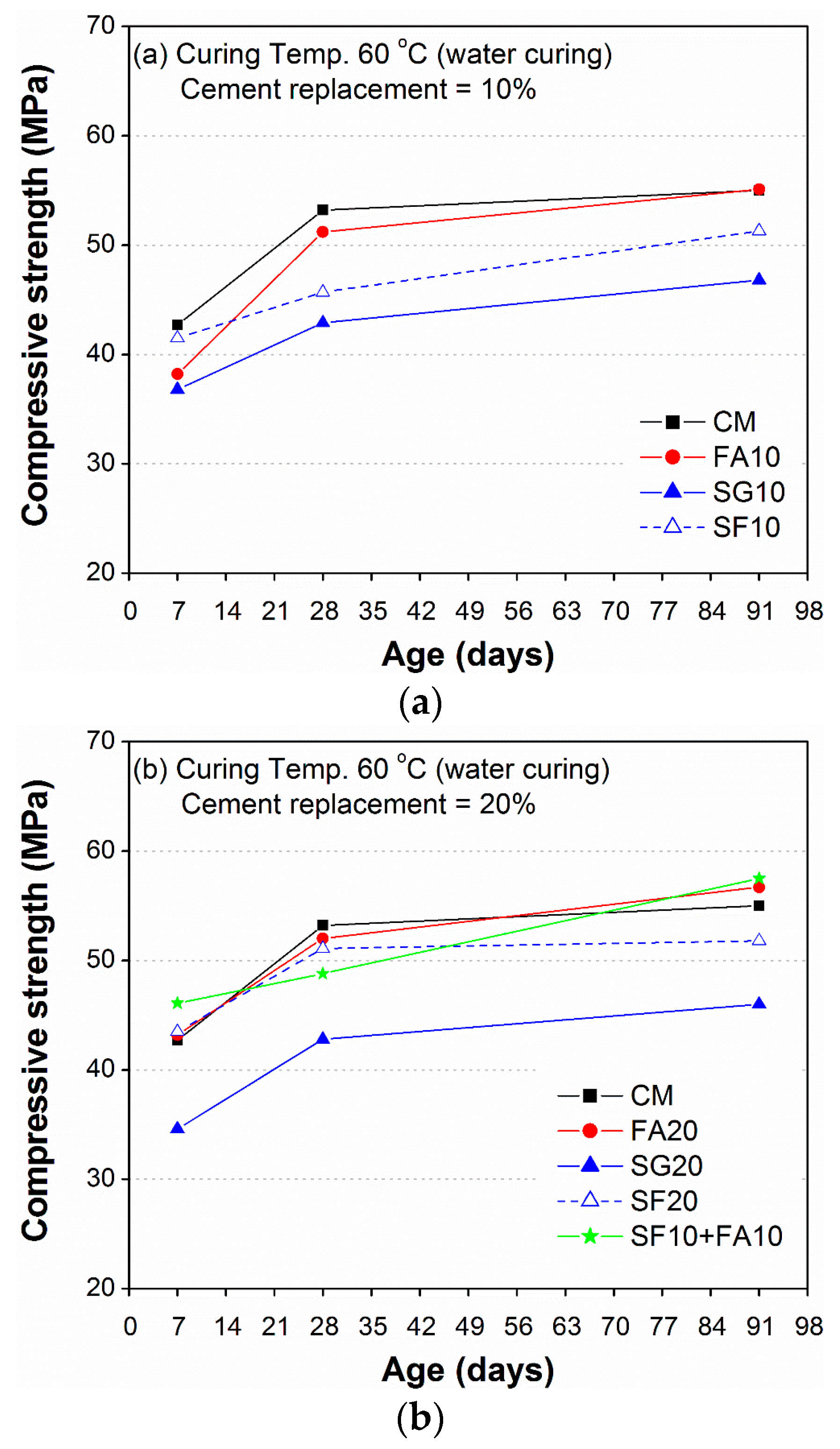

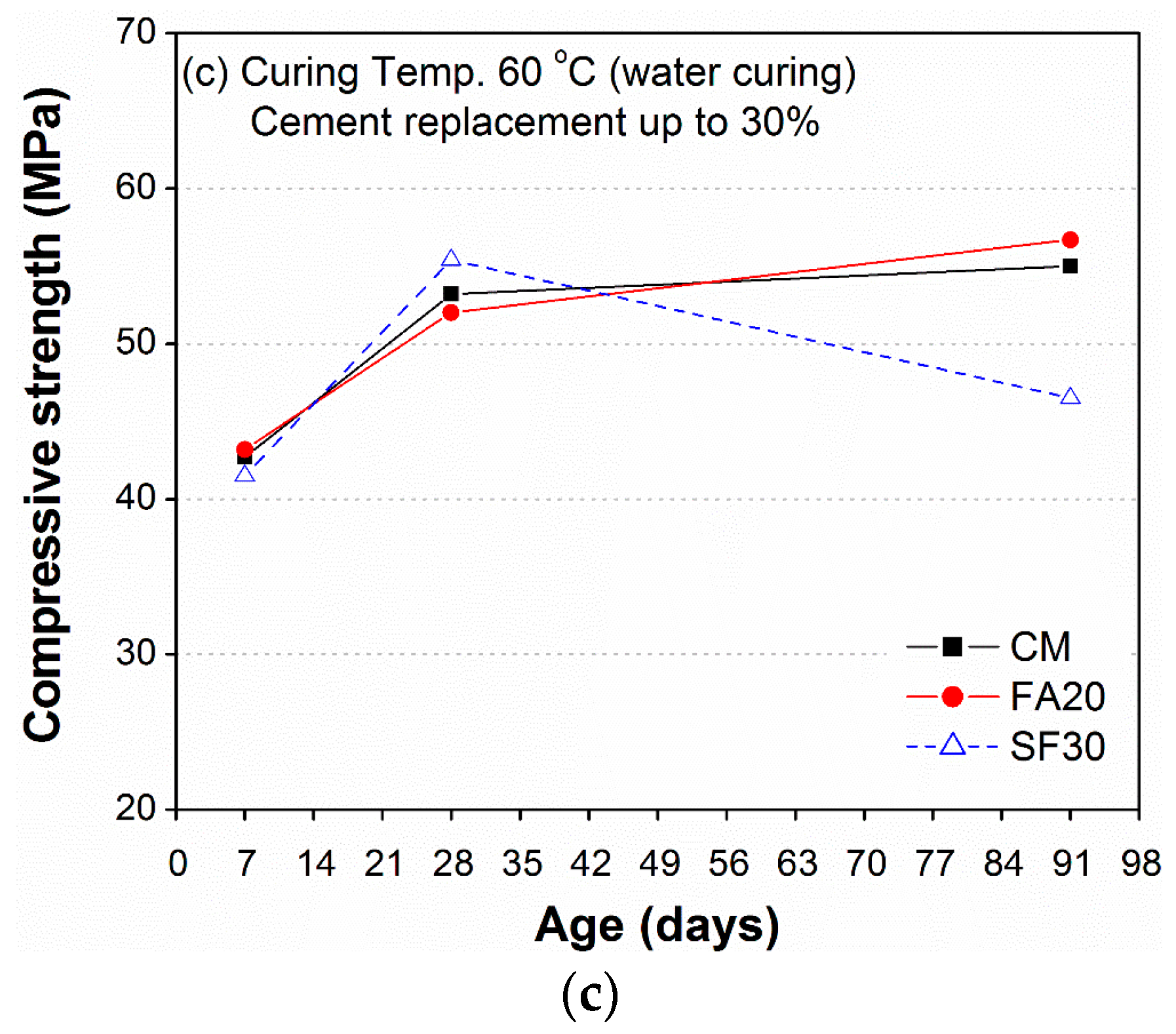

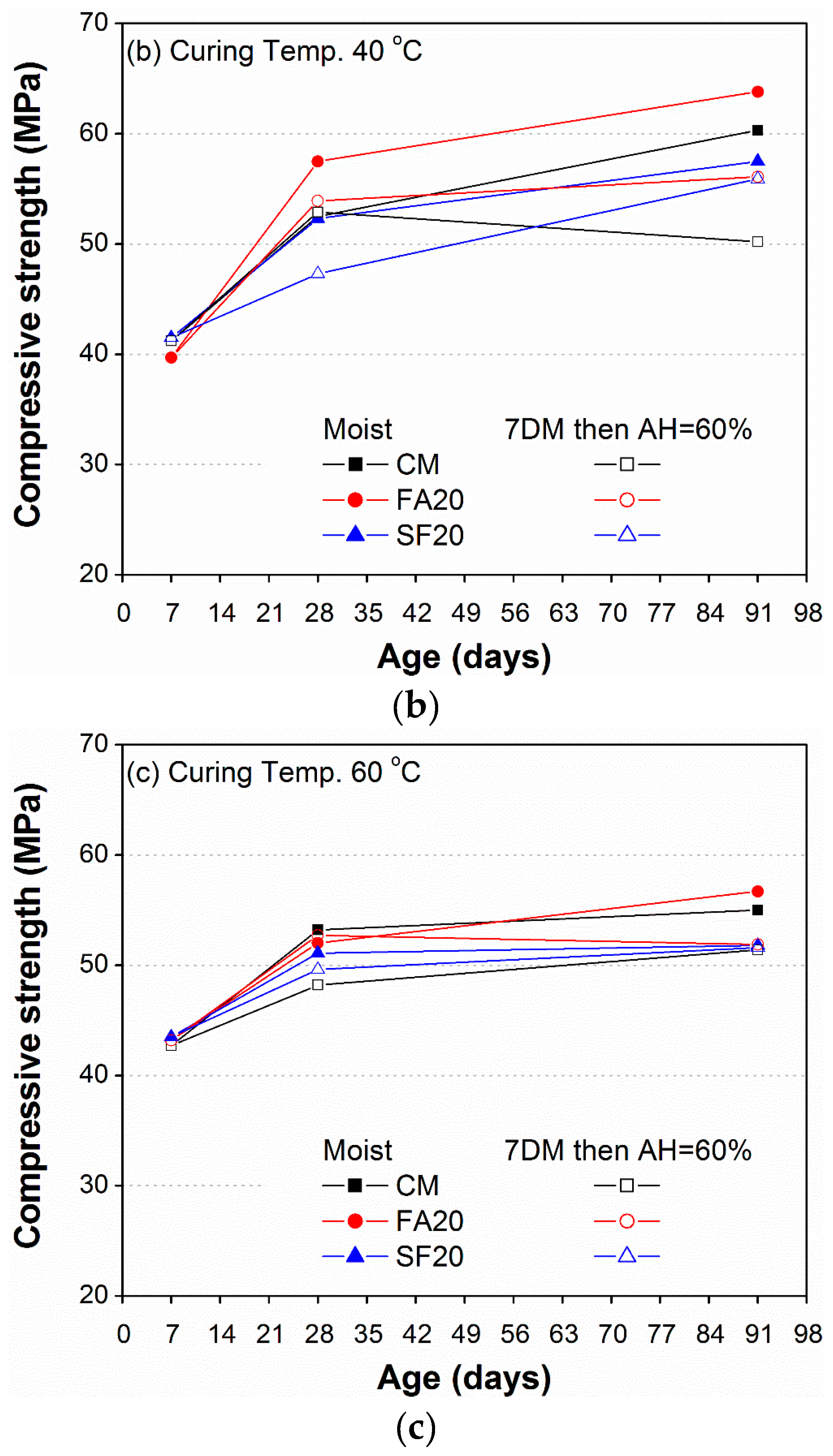

Strength of mortars having SG or 10% SF decreases with increasing curing temperature. However, a 20–30% and 20% cement substitution with SF produced strength close to control and reference FA mortar under moderate (40 °C) and high curing temperature (60 °C), respectively. The above results can be attributed to increased hydration reaction and high pozzolanic reactivity of high fineness EAFS (SF).

Mortar without cement substitution attained higher early and lower later-age compressive strength when subjected to high curing temperature after casting. Very similar trends were also observed in mortars containing different fineness and amounts of EAFS and FA. The high early and low later-age compressive strength with increasing temperature is known as “crossover effect” [

58]. Since the cross-over effect of temperature was clear in mortars containing EAFS, the influence of different curing temperatures can be predicted easily for its application under hot environmental conditions.

The maximum potential compressive strength was attained when specimens were continuously moist cured (CMC), irrespective of the curing temperature and the type of cement substituting materials, FA or EAFS. However, it must be un-economical or impractical to apply continuous moist curing up to 28 and 91 days especially under high curing temperatures. Alternatively, use of SF up to 20% cement substitution subjected to partial moist curing (i.e., exposing to air at 60% relative humidity after initial seven days of continuous moist curing) under moderately high and high temperature conditions must be beneficial. Therefore, authors suggest extending the current research to study the influence of more wide range of curing regimes and high percentages of cement substitution with SF and SSF.