Collaboration for Sustainability in the Food Supply Chain: A Multi-Stage Study in Italy

Abstract

:1. Introduction

2. Conceptual Background

2.1. Food Supply Chain Management and Sustainability

2.2. Collaboration for Sustainability in the Food Supply Chain (FSC)

2.3. Sustainability Performance in the FSC

2.4. Theoretical Background

3. Research Design

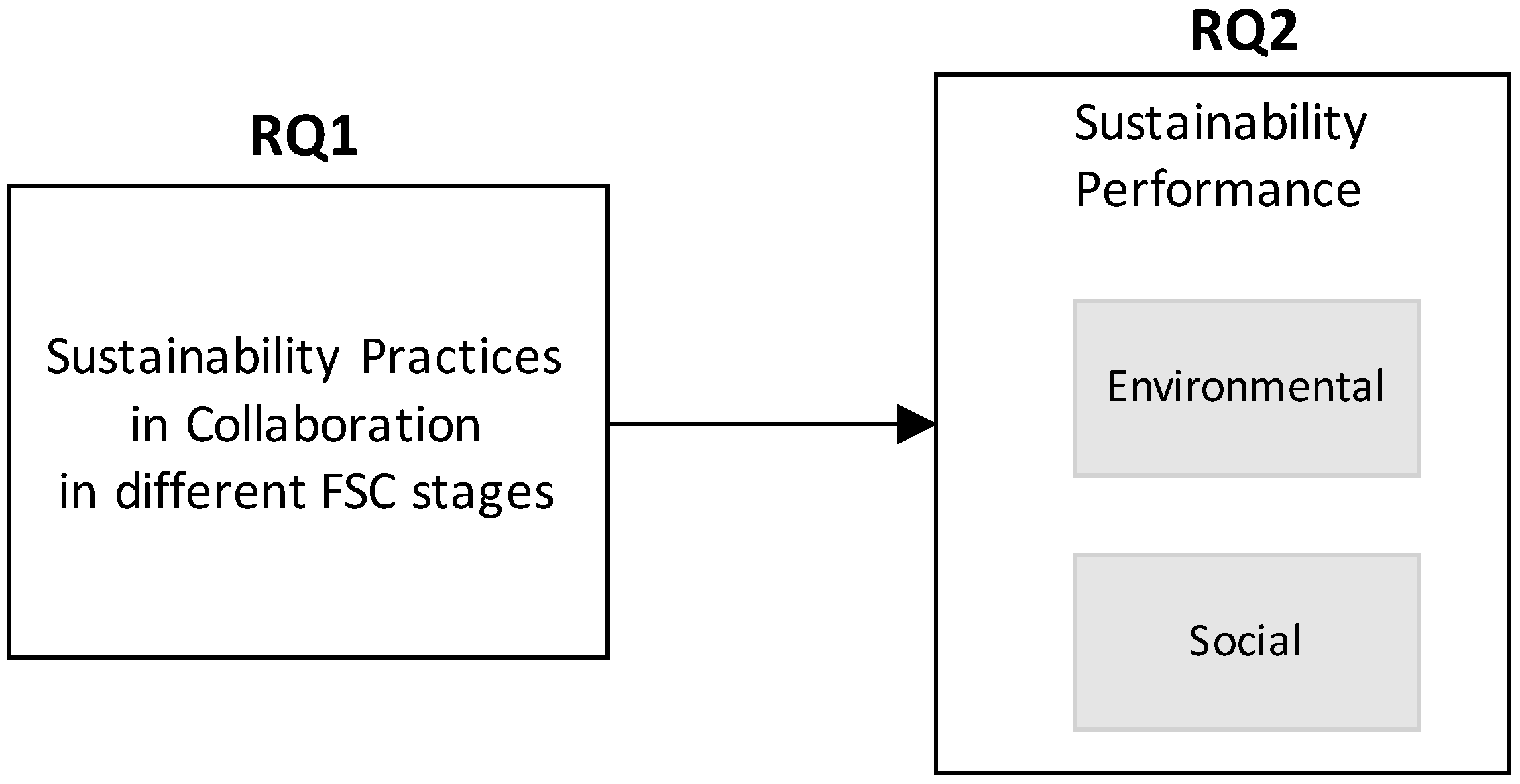

3.1. Research Objectives and Questions

- What are the sustainability practices implemented in collaboration, in different FSC stages?

- 1.1.

- What are the types of collaborations implemented by different FSC stages?

- What is the sustainability performance expected from the sustainability practices implemented in collaboration?

3.2. Research Question 1: Sustainability Practices in Collaboration

3.3. Research Question 2: Sustainability Performance in the FSC

4. Research Methodology

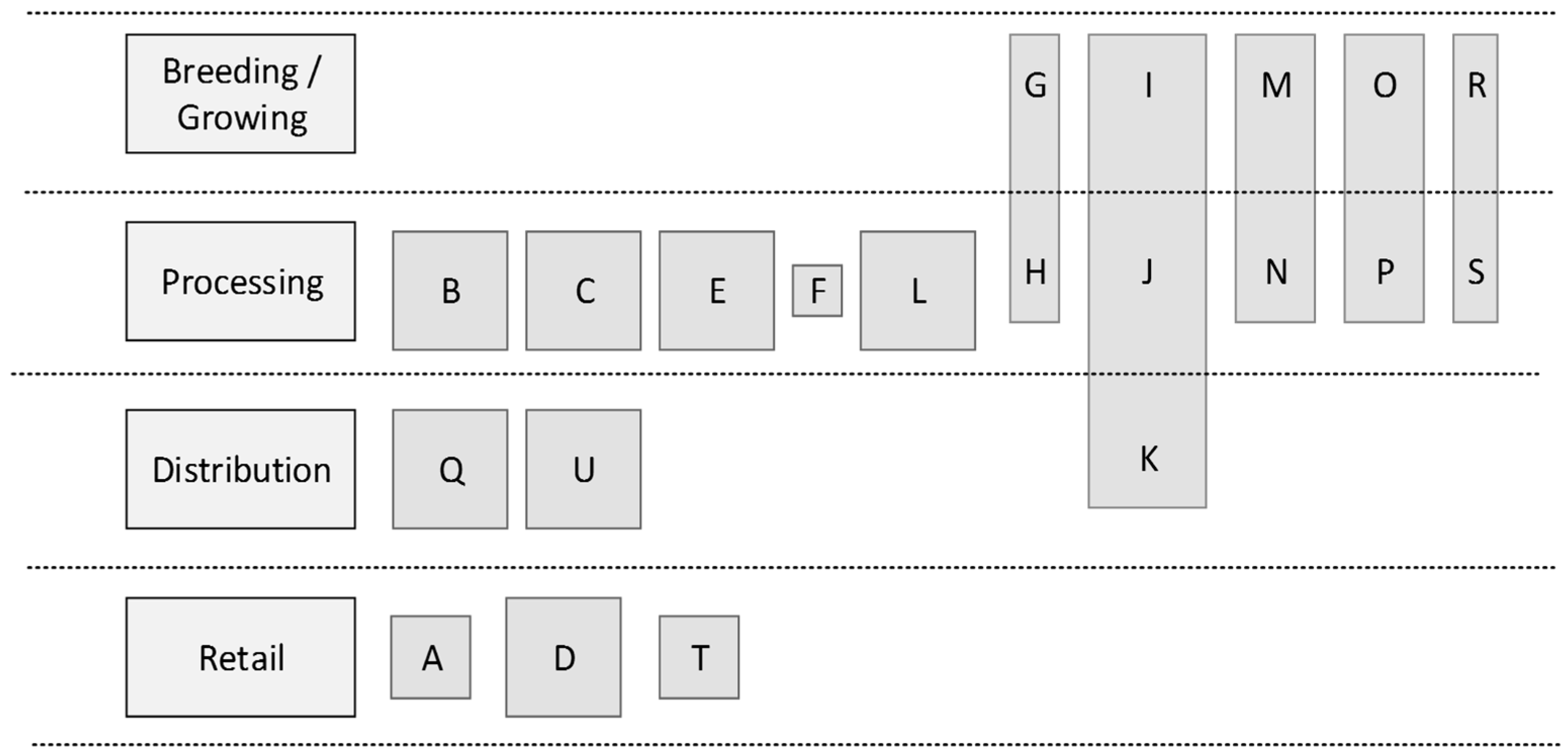

4.1. Case Selection

4.2. Research Boundaries and Data Collection

- Organizational: the study considers practices and sustainability performance in a company that works in certain FSC stage. In case a firm has operations in more than one stage, the analysis counts each stage separately.

- Proximal: cases are selected in FSCs that have at least one focal company in Italy, with the aim of comparing cases with similar geographic characteristics.

- Temporal: the study considers only sustainability practices in collaboration already adopted, and sustainability performance that was/is expected or perceived. Thus, the study is retrospective.

- Informational: referring to the availability of information, the study analyzes data from interviews and secondary sources (e.g., annual sustainability reports, communication spots, articles published in newspapers).

- Economic: due to confidentiality requirements from the companies interviewed, the study reports the qualitative data regarding sustainability savings or investments/costs.

- Technological: the analysis will not differentiate or evaluate the technology used for sustainability applications or performance evaluation. The technological differences among companies and stages due to company size, capabilities and budget are not focus of this study.

5. Findings and Data Analysis

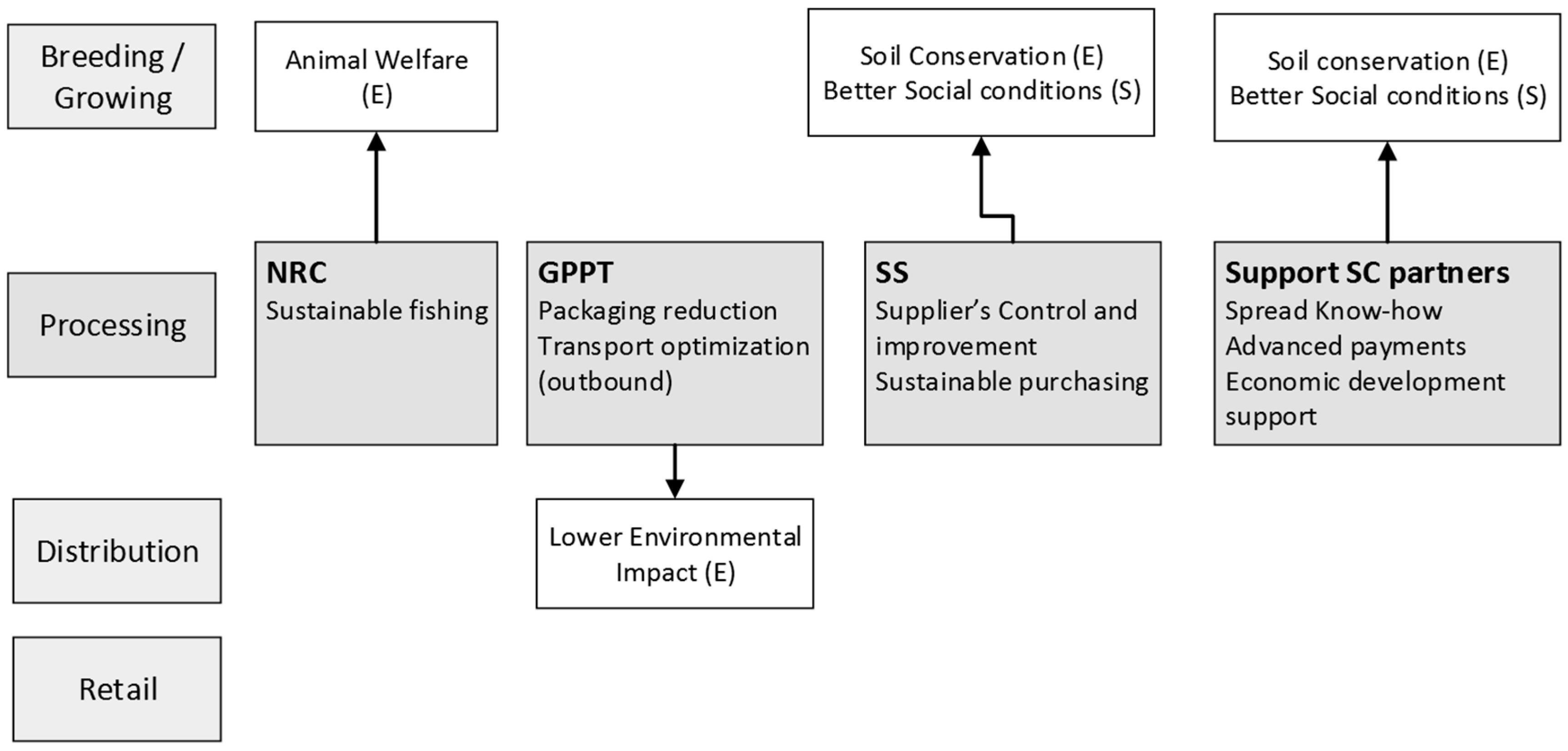

5.1. Sustainability Practices in Collaboration in the FSC

“The interest is both from suppliers and from D, in fact, the project also helps to optimize processes at the supplier side saving a lot of materials and money”(Interviewee Company D)

“We undergo continuous strict veterinary controls, combined with the daily care of our breeders/partners -vertical upstream collaboration- that do the rest. Here is how milk with unique quality is obtained: milk is collected and delivered every morning at dawn and then is transported directly to the plant with refrigerated tankers. The plant is only a few kilometers from the partner farm so shipping is fast and safe, to ensure maximum freshness and maintaining unaltered the unmistakable organoleptic qualities”

“In the case of the fruit and vegetable industry we have a cultivation disciplinary, also for our integrated production, where the limited use of pesticides is mandatory. Our discipline code enhances our agronomic systems”.(Interviewee Company J)

“if I have a bruised pepper at home, I’ll cook it, but when I buy it I want it to be perfect. We, at T, cook products still intact, and do not waste them. We also cooperate with the Food Bank 3 times a year, it is the established procedure. Some products are also collected by organizations that distribute to needy families (products with defective packaging etc.) [….] being the last stage in the chain, we are committed to reduce waste…”

5.2. Collaboration Practices and Sustainability Performance in the FSC

6. Conclusions and Final Remarks

6.1. General Findings

6.2. Contribution to Research and Future Development

6.3. Implications for Practitioners

Author Contributions

Conflicts of Interest

Appendix A

References

- The State of Food and Agriculture. Available online: http://www.fao.org/publications/sofa/2013/en/ (accessed on 3 December 2014).

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Ramanathan, U.; Bentley, Y.; Pang, G. The role of collaboration in the UK green supply chains: An exploratory study of the perspectives of suppliers, logistics and retailers. J. Clean. Prod. 2014, 70, 231–241. [Google Scholar] [CrossRef]

- Barratt, M. Understanding the meaning of collaboration in the supply chain. Supply Chain Manag. Int. J. 2004, 9, 30–42. [Google Scholar] [CrossRef]

- Bourlakis, M.; Maglaras, G.; Gallear, D.; Fotopoulos, C. Examining sustainability performance in the supply chain: The case of the Greek dairy sector. Ind. Mark. Manag. 2014, 43, 56–66. [Google Scholar] [CrossRef]

- Matopoulos, A.; Vlachopoulou, M.; Manthou, V.; Manos, B. A conceptual framework for supply chain collaboration: Empirical evidence from the agri-food industry. Supply Chain Manag. Int. J. 2007, 12, 177–186. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Varsei, M.; Soosay, C.A.; Fahimnia, B.; Sarkis, J. Framing sustainability performance of supply chains with multidimensional indicators. Supply Chain Manag. Int. J. 2014, 19, 242–257. [Google Scholar] [CrossRef]

- Pullman, M.E.; Maloni, M.J.; Carter, C.R. Food for thought: Social versus environmental sustainability practices and performance outcomes. J. Supply Chain Manag. 2009, 45, 38–54. [Google Scholar] [CrossRef]

- Yakovleva, N.; Sarkis, J.; Sloan, T.W. Sustainability indicators for the food supply chain. In Environmental Assessment and Management in the Food Industry: Life Cycle Assessment and Related Approaches; Sonesson, U., Berlin, J., Ziegler, F., Eds.; Woodhead Publishing: Cambridge, UK, 2010; pp. 297–329. [Google Scholar]

- Matopoulos, A.; Bourlakis, M. Sustainability practices and indicators in food retail logistics: Findings from an exploratory study. J. Chain Netw. Sci. 2010, 10, 207–218. [Google Scholar] [CrossRef]

- Erol, I.; Sencer, S.; Sari, R. A New fuzzy multi-criteria framework for measuring sustainability performance of a supply chain. Ecol. Econ. 2011, 70, 1088–1100. [Google Scholar] [CrossRef]

- Yakovleva, N.; Sarkis, J.; Sloan, T. Sustainable benchmarking of supply chains: The case of the food industry. Int. J. Prod. Res. 2012, 50, 1297–1317. [Google Scholar] [CrossRef]

- Pfeffer, J.; Salancik, G.R. The External Control of Organizations: A Resource Dependence Perspective; Stanford University Press: Stanford, CA, USA, 2003. [Google Scholar]

- Touboulic, A.; Chicksand, D.; Walker, H. Managing imbalanced supply chain relationships for sustainability: A power perspective. Decis. Sci. 2014, 45, 577–619. [Google Scholar] [CrossRef]

- Fritz, M.; Schiefer, G. Food chain management for sustainable food system development: A European research agenda. Agribusiness 2008, 24, 440–452. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Maloni, M.J.; Brown, M.E. Corporate social responsibility in the supply chain: An application in the food industry. J. Bus. Ethics 2006, 68, 35–52. [Google Scholar] [CrossRef]

- Sustainability Pathways. Available online: http://www.fao.org/nr/sustainability/food-loss-and-waste/en/ (accessed on 10 February 2015).

- Kaipia, R.; Dukovska-Popovska, I.; Loikkanen, L. Creating sustainable fresh food supply chains through waste reduction. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 262–276. [Google Scholar] [CrossRef]

- Vieira, L.M.; De Barcellos, M.D.; Hoppe, A.; da Silva, S.B. An analysis of value in an organic food supply chain. Br. Food J. 2013, 115, 1454–1472. [Google Scholar] [CrossRef]

- Gold, S.; Hahn, R.; Seuring, S. Sustainable supply chain management in “Base of the Pyramid” food projects—A path to triple bottom line approaches for multinationals? Int. Bus. Rev. 2013, 22, 784–799. [Google Scholar] [CrossRef]

- Rota, C.; Reynolds, N.; Zanasi, C. Sustainable Food Supply Chains: The Role of Collaboration and Sustainable Relationships. Int. J. Bus. Soc. Sci. 2013, 4, 45–53. [Google Scholar]

- Hubeau, M.; Marchand, F.; Van Huylenbroeck, G. Sustainability Experiments in the Agri-Food System: Uncovering the Factors of New Governance and Collaboration Success. Sustainability 2017, 9, 1027. [Google Scholar] [CrossRef]

- Whipple, J.M.; Russell, D. Building supply chain collaboration: A typology of collaborative approaches. Int. J. Logist. Manag. 2007, 18, 174–196. [Google Scholar] [CrossRef]

- Pero, M.; Moretto, A.; Bottani, E.; Bigliardi, B. Environmental Collaboration for Sustainability in the Construction Industry: An Exploratory Study in Italy. Sustainability 2017, 9, 125. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, in press. [Google Scholar] [CrossRef]

- Chkanikova, O. Sustainable Purchasing in Food Retailing: Interorganizational Relationship Management to Green Product Supply. Bus. Strat. Environ. 2016, 25, 478–494. [Google Scholar] [CrossRef]

- Nuhoff-Isakhanyan, G.; Wubben, E.F.; Omta, S.W.F. Sustainability benefits and challenges of inter-organizational collaboration in Bio-Based business: A systematic literature review. Sustainability 2016, 8, 307. [Google Scholar] [CrossRef]

- Beske-Janssen, P.; Johnson, M.P.; Schaltegger, S. 20 years of performance measurement in sustainable supply chain management—What has been achieved? Supply Chain Manag. Int. J. 2015, 20, 664–680. [Google Scholar] [CrossRef]

- Slaper, T.; Hall, T. The triple bottom line: What is it and how does it work? Indiana Bus. Rev. 2011, 86, 4. [Google Scholar]

- Manzini, R.; Accorsi, R. The new conceptual framework for food supply chain assessment. J. Food Eng. 2013, 115, 251–263. [Google Scholar] [CrossRef]

- Global Reporting Initiative. 2013. Available online: https://www.globalreporting.org/standards/gri-standards-download-center/?g=db250470-931c-4d36-b368-880542d00ee7 (accessed on 8 December 2016).

- The Sustainability Yearbook 2014. Available online: http://www.p-plus.nl/resources/articlefiles/SustainabilityYearbook2014.pdf (accessed on 5 December 2015).

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Mena, C.; Humphries, A.; Choi, T.Y. Toward a Theory of Multi-Tier Supply Chain Management. J. Supply Chain Manag. 2013, 49, 58–77. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Chicksand, D.; Watson, G.; Walker, H.; Radnor, Z.; Johnston, R. Theoretical perspectives in purchasing and supply chain management: An analysis of the literature. Supply Chain Manag. Int. J. 2012, 17, 454–472. [Google Scholar] [CrossRef] [Green Version]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Banterle, A.; Cereda, E.; Fritz, M. Labelling and sustainability in food supply networks: A comparison between the German and Italian markets. Br. Food J. 2013, 115, 769–783. [Google Scholar] [CrossRef]

- Beske, P.; Land, A.; Seuring, S. Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

- Scaling up Global Food Security and Sustainable Agriculture. Available online: https://www.unglobalcompact.org/resources/320 (accessed on 3 November 2014).

- Food Safety in the EU. Available online: https://europa.eu/european-union/topics/food-safety_en (accessed on 15 November 2016).

- Principles of Organic Agriculture. Available online: http://www.ifoam.bio/sites/default/files/poa_english_web.pdf (accessed on 15 July 2015).

- Setting Social and Environmental Standards—ISEAL Code of Good Practice. Available online: http://www.isealalliance.org/sites/default/files/ISEAL%20Standard%20Setting%20Code%20v6%20Dec%202014.pdf (accessed on 15 July 2015).

- Van der Vorst, J.G.; Peeters, L.; Bloemhof, J.M. Sustainability assessment framework for food supply chain logistics: Empirical findings from Dutch food industry. In Proceedings of the 6th International European Forum on System Dynamics and Innovation in Food Networks, Innsbruck, Austria, 18–22 February 2013; pp. 480–491. [Google Scholar]

- Yin, R.K. Case Study Research: Design and Methods, 4th ed.; Sage Publications: Thousand Oaks, CA, USA, 2009; p. 240. [Google Scholar]

- Eisenhardt, K.M.; Graebner, M.E. Theory building from cases: Opportunities and challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. Int. J. 2012, 17, 202–216. [Google Scholar] [CrossRef]

- Seuring, S.A. Assessing the rigor of case study research in supply chain management. Supply Chain Manag. Int. J. 2008, 13, 128–137. [Google Scholar] [CrossRef]

- Walker, H.; Seuring, S.; Sarkis, J.; Klassen, R. Sustainable operations management: Recent trends and future directions. Int. J. Oper. Prod. Manag. 2014, 34. [Google Scholar] [CrossRef]

| Sustainability Dimension | Example of Practices | |

|---|---|---|

| Environment | Natural Resources conservation (NRC) | Animal Welfare: Elimination of cruelty; safe handling, housing, slaughter and transport Soil conservation: Conservation forest, species; prevent soil erosion and pollution, prevent loss of arable land and biodiversity, responsible farming methods (reducing fertilizer and pesticides), elimination of contaminant and pollutant agents Water conservation: reducing water consumption, efficient water use, waste water re-use and recovery |

| Green processing, packaging and transportation (GPPT) | Design, materials and packaging: effective design for reuse and recycling, use of design for disassembly and reuse, material reuse and recycle, reducing packaging, using reusable/recyclable packaging Waste: reduce waste and hazardous materials, composting organic waste, producing renewable energy or animal feed with waste, lower disposal costs, damage compensation, recycling Processing and transportation: reducing energy use, conservation of energy, reducing CO2 emissions and GHGs, reduce pollution, reduction of fuel consumption | |

| Social | Health and Safety (H&S) | Improved product quality, food safety, food security, traceability and transparency. Promotion of healthy life styles and local food sources. Safer warehousing and transportation |

| Work and Human Rights (W&HR) | Better working conditions that result in higher levels of motivation and productivity and less absenteeism. Training, education, advancement. Regular employment, elimination of illegal and child labor, respect of worker rights, gender equality, freedom of association, safe working conditions | |

| Community | Donation, collaboration with NGOs, philanthropy, support to the economic development in local communities, educational practices, health care, job training, volunteering, childcare | |

| Economic | Sustainable sourcing (SS) | Increasing supplier diversity, confidentiality, eliminating deception and impropriety, transparency, proper purchasing processes (reciprocity, fairness, no power abuse or special treatment), supplier’s labor programs, local sourcing that result in shorter lead-times. Environmental and social considerations when selecting, monitoring and controlling suppliers. |

| Support SC partners | Profit sharing with actors in the upstream supply chain, premium price payment, support and monitoring for obtaining sustainability certification. Facilitate partners' access to markets, knowledge and technology transfer, fostering financing opportunities, information and expertise sharing. | |

| Characteristic | Transaction | Event | Process |

|---|---|---|---|

| Organizational level | Operational | Tactical | Strategic |

| Time horizon | Short term | Medium term | Long term |

| Level of people interaction | Limited person-to-person interaction | Person-to-person interaction focused on joint decision for the collaboration focus | Person-to-person interaction focused on developing cross-functional processes |

| Process characteristics | Data exchange and task alignment | Joint planning and decision making for specific events or issues | Fully integrated process |

| Knowledge level | Explicit | Explicit and some level of tacit | Explicit and high levels of tacit |

| Return expected from the relationship | Reduced problems and-or errors on tasks | Performance improvements are more impact oriented | Performance improvements to focus on future events |

| Environmental | Social |

|---|---|

| Water consumption Energy consumption Waste generation CO2 emissions Number of certified suppliers Use of renewable energy Use of recycled material Fuel use Effectiveness of reverse logistics system Effectiveness of supplier monitoring Animal welfare Soil protection | Labor practices and decent work Human rights observance Training per employee Work safety procedures Diversity Fair pay systems Investments in social projects Code of conduct Food health and safety Community wellbeing |

| Case | Industry Sub-Sector | FSC Stage | Sales 2013 (million €) | Employees |

|---|---|---|---|---|

| A | Food products retail | Retail | 63.09 | 757 |

| B | Production of chocolate and semi-finished products for the confectionery industry | Processing | 109.27 * | 262 |

| C | Canned food production based on: fish, meat, seasonings and tuna | Processing | 719.11 | 757 |

| D | Hypermarket retail | Retail | 2656.48 | 9777 |

| E | Beer production | Processing | 774.37 | 974 |

| F | Semi-finished products made with nuts for confectionery and ice cream industry | Processing | 4.64 * | 18 |

| G | Vegetables cultivation | Growing | 6.95 | 30 |

| H | Fruit and vegetables: processing and sales | Processing | ||

| I | Vegetables cultivation | Growing | 110.52 * | 290 |

| J | Fruit and vegetables: processing and sales | Processing | ||

| K | Distribution of finished products based on vegetables and fruits | Distribution | ||

| L | Preserved pastry production | Processing | 345.72 * | 1065 |

| M | Vegetables cultivation | Growing | 64.26 | 380 |

| N | Fruit and vegetables: processing and sales | Processing | ||

| O | Livestock breeder | Breeding | 43.81 | 125 |

| P | Dairy production and sales | Processing | ||

| Q | Beverages wholesaling | Distribution | 428.48 | 1086 |

| R | Livestock breeder | Breeding | N/A | N/A |

| S | Dairy production and sales | Processing | ||

| T | Food products retail and catering | Retail | 130.13 | 733 |

| U | Merchandise transportation | Distribution | 168.63 | 583 |

| Sustainability Dimension and Practice * | Breeding/Growing | Processing | Distribution | Retail | |

|---|---|---|---|---|---|

| Environmental | Natural Resources Conservation (NRC) | ||||

| Veterinary checkups (Ce) | O,R | ||||

| Collaboration with NGOs (Ce) | C | ||||

| Sustainable fishing (Ce) | C | ||||

| Green processing, packaging and transport (GPPT) | |||||

| Optimizing transportation (inbound) (Cu) | B,E,H,N | D,T | |||

| Optimizing transport (outbound) (Cd) | B,C,H | K,Q,U | |||

| LCA Projects (Cu) | D | ||||

| Reducing packaging (Cu) | E | D,T | |||

| Increased transportation capacity (Ce) | U | ||||

| Eco—friendly fleet (Cu) | D | ||||

| Logistics collaboration (Cu,d) | Q,U | D | |||

| Social | Work and Human Rights (W&HR) | ||||

| Sustainability training (Ce) | E,P | Q,U | |||

| Community | |||||

| Collaboration with NGOs (Ce) | C,E | D,T | |||

| Information sharing about consumption (C u,d) | J | K,Q,U | |||

| Donation (Ce) | C | A,D,T | |||

| Consumer education (Ce) | C,E,J | D,T | |||

| Volunteering (Ce) | C | ||||

| Sustainability projects (Ce) | T | ||||

| Economic | Sustainable Sourcing (SS) | ||||

| Control and improvement partners/suppliers (Cu) | M,O | H,J,E | Q,U | A,D,T | |

| Sustainable purchasing (Cu) | L | ||||

| Support SC partners | |||||

| Spread know-how (Cu) | B,C | ||||

| Advanced payments (Ce) | B | ||||

| Economic development support (Cu) | B | D,T | |||

| SC Stage | Sustainability Practices | Type of Collaborative Approach | ||

|---|---|---|---|---|

| Breeding/Growing | NRC | Veterinary check-ups | External | Transactional |

| SS | Partner’s control and development | Upstream | Event | |

| Processing | GPPT | Transport optimization (inbound) | Upstream | Transactional |

| Transport optimization (outbound) | Downstream | Transactional | ||

| Community | Consumer education | External | Event | |

| SS | Partner’s control and development | Upstream | Process | |

| Distribution | GPPT | Transport optimization (outbound) | Downstream | Transactional |

| Logistics collaboration | Downstream/Upstream | Transactional | ||

| W&HR | Sustainability training | External | Transactional | |

| Community | Information sharing about consumption | Downstream/Upstream | Transactional | |

| SS | Partner’s control and development | External | Process | |

| Retail | GPPT | Packaging reduction | Upstream | Process |

| Transport optimization (inbound) | Upstream | Transactional | ||

| Community | Collaboration with NGOs | External | Event | |

| Donation | External | Event | ||

| Consumer education | External | Event | ||

| SS | Partner’s control and development | Upstream | Process | |

| SC partner support | Economic development support | Upstream | Process | |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

León-Bravo, V.; Caniato, F.; Caridi, M.; Johnsen, T. Collaboration for Sustainability in the Food Supply Chain: A Multi-Stage Study in Italy. Sustainability 2017, 9, 1253. https://doi.org/10.3390/su9071253

León-Bravo V, Caniato F, Caridi M, Johnsen T. Collaboration for Sustainability in the Food Supply Chain: A Multi-Stage Study in Italy. Sustainability. 2017; 9(7):1253. https://doi.org/10.3390/su9071253

Chicago/Turabian StyleLeón-Bravo, Verónica, Federico Caniato, Maria Caridi, and Thomas Johnsen. 2017. "Collaboration for Sustainability in the Food Supply Chain: A Multi-Stage Study in Italy" Sustainability 9, no. 7: 1253. https://doi.org/10.3390/su9071253