1. Introduction

Porter Hypothesis [

1] argues that reasonable environmental regulation can give the manufacturing industry a signal that inefficient resource allocation exists and that technology needs to be improved, triggering an innovation compensation effect, which can not only offset the compliance costs, but also increase manufacturing productivity and competitiveness. This hypothesis provides a theoretical support for the win-win situation of environmental regulation and economic growth, and the basic premise of this theory requires a significant innovation compensation effect. To verify whether the innovation compensation effect is sufficient to support the reality of Porter Hypothesis, many scholars have carried out a great deal of research on environmental regulation issues [

2,

3,

4,

5,

6,

7,

8,

9].

With regard to the effect of environmental regulations on manufacturing pollution control technology progress, scholars generally agree that environmental regulation can bring significant positive effects on pollution control technology progress [

2]. In general, the incentive effect of sewage tax and auction of pollution permits on manufacturing industry pollution control technology progress is better than that of tradable emission permit [

3].

However, scholars’ views are not unified regarding the effect of environmental regulation on manufacturing industry technological progress. The differing viewpoints can be divided into three categories: promote theory, suppression theory and uncertainty theory.

In the first view, scholars believe that environmental regulations can increase technology innovation level. This view supports the Porter hypothesis strongly. For example, Bhatnager & Cohen [

4] studied the effect of environmental regulation on industrial technology innovation in 146 American manufacturing industries from 1983 to 1992, and the results demonstrated that there is a significant positive correlation between pollution abatement cost and environmental patent filings.Whitford & Tucker [

5] found that, for every 1% increase in pollution abatement costs, Research and Development (R&D) expenditure will increase 0.15%, which means that there is a positive correlation between R&D expenditure and pollution abatement cost. Carrion and Innes [

6] used 127 American manufacturers from 1989 to 2002 as research sample to explore the relationship between enterprise pollution emissions and environmental protection technology patents, and found that environmental regulation policy can incentivize industry to innovate. Horbach [

7] found that environmental regulation, environmental management tools and the changes organization culture in Germany are all conducive to environmental protection and innovation. Li and Wang [

8,

9] tested Chinese environmental regulation and technological innovation relationship from 1994 to 2009, and the results showed that environmental regulation could spur overall innovation while ameliorating environmental pollution.

The second view is suppression, and researchers who hold this view claim that environmental regulation hinders technological innovation, i.e. negative Porter hypothesis. For instance, Wagner [

10] took German manufacturing as an example, and empirically analyzed the relationships among environmental management, environmental innovation and patent application. The results showed that the level of environmental management system implementation and a company’s overall patenting activity are negatively related. Chintrakarn [

11] used SFA model to evaluate the influence of environmental regulation on the manufacturing sector inefficiency in 48 American states. The results showed that stringent environmental regulation and US manufacturing technical inefficiency have a significant positive correlation. Acemoglu [

12] found that environmental regulation leads to production costs rising, thus hindering technological innovation.

The third view is uncertainty, and scholars who hold this view claim that there is no obvious relationship between environmental regulation and technological innovation or economic performance. For example, Alpaye and Buccola [

13] took the American and Mexican food industry as the research object to analyze the effects of environmental regulation on productivity from 1971 to 1994. The results indicated that the effect of environmental regulation on the food industry productivity in the United States is negative, while the same impact in Mexico is positive. Domazlicky [

14] analyzed the operation cost and technical efficiency of chemical industry data from 1988 to 1993 and found there is no evidence showing that environmental regulation will inevitably lead to industrial technical efficiency decline. Kneller [

15] made an empirical analysis of the effect of environmental regulation on technological innovation and found the effect is not obvious.

From the above literature review, we found that previous studies mainly examined the impact of environmental regulation on two kinds of technological progress from the time dimension, and considered that the two will be consistent with the U type evolution trajectory. This U type trajectory depends on the contrast of the positive effects (innovation compensation) and negative effects (followed cost) brought by environmental regulation, and the positive effects of innovation compensation often lag behind the negative effects of cost compliance. Analyzing the dynamic relationship between environmental regulation and technological advances from time dimensions is often unsatisfactory, which forces scholars to think about the applicability of Porter Hypothesis. Scholars have found that other factors, such as the rationality of environmental regulation policy [

3], environmental regulation intensity [

16], human capital level [

17], enterprise technical level [

18], enterprise market forces [

19] and economic development [

20], might affect the relationship between environmental regulation and technological progress. However, the existing research focusing on environmental regulation intensity rationality is limited.

Although Nagurney [

21] and Bréchet et al. [

22] explored the rationality of environmental regulation policies, such as emission rights and carbon taxes, they mainly analyzed from the perspective of economic growth and pollution control. The literature exploring the reasonable interval of environmental regulation intensity from the perspective of production technology progress is rare. As Parry [

23] pointed out, while it is expected that environmental regulation will lead to technological progress that will change the future emission reduction costs and production levels, the problem is that predicting which environmental regulation will evoke technical progress is difficult, which leads to optimal environmental regulation intensity being difficult to measure. However, if we assume that the same intensity of environmental regulation can lead to the same rate of technological progress based on the control of relevant factors, we can analyze the reasonable intensity of environmental regulation interval from technological progress perspective. Based on this hypothesis, in the analysis of environmental regulation level value, some scholars believe that environmental regulation intensity will cause a nonlinear “U” type trajectory on production technological progress and pollution control technology progress [

16,

20], while others think the influence trajectory should be the type of “∽” [

24].

It is reasonable to study the nonlinear effect of environmental regulation on technological progress from the intensity dimension. Becher [

16] also pointed out why different environmental regulation intensities would cause different effects on production technological progress. Based on the nonlinear hypothesis on the intensity dimension, it is possible to answer the question of why some environmental regulations do not lead to the ideal innovation compensation effect. However, several existing studies have used the level values of environmental regulation intensity to participate in the measurement regression when they tested the nonlinear hypothesis of intensity dimension. This implies an important assumption mentioned above: the endogenous inflection point of each economy in environmental regulation intensity is the same; that is, when it reaches a certain level, it will bring about the same impact on production technological progress. This hypothesis ignores the differences between regions and sectors, such as the differences of endogenous inflections in highly polluting economies and low-polluting economies. Therefore, we believe that using environmental regulation intensity in regression analysis is questionable. The environmental regulation intensity should be dynamically adjusted, and cannot be confined to a particular level, which requires environmental regulation intensity to continually improve to ensure its continuous incentive for the level of production technology.

To enrich the relevant research, this paper uses panel technology threshold to study the nonlinear relationship between environmental regulation intensity and technological innovation in manufacturing based on Chinese manufacturing sub-sector panel data. We analyze the reasonable range of environmental regulation intensity from the perspective of technological advances, which can help us understand the changing trends of environmental regulation intensity more comprehensively, and understand why some environmental regulation failed to bring ideal innovation compensatory effects. Therefore, this study provides valuable reference for China’s scientific development of environmental regulations and policies. The main contributions of this study include: (1) using the change rate of environmental regulation intensity and production technological advancements as core variables; and (2) determining the change range of optimal waste gas, wastewater and waste solid regulation intensity base on pollutant heterogeneity.

The rest of the paper is organized as follows. In

Section 2, we present our model and describe our empirical strategy, including data description and estimation strategies.

Section 3 presents an empirical research and analyzes the empirical results. In

Section 4, the research result is discussed. Conclusions are given in

Section 5.

3. Empirical Results and Analysis

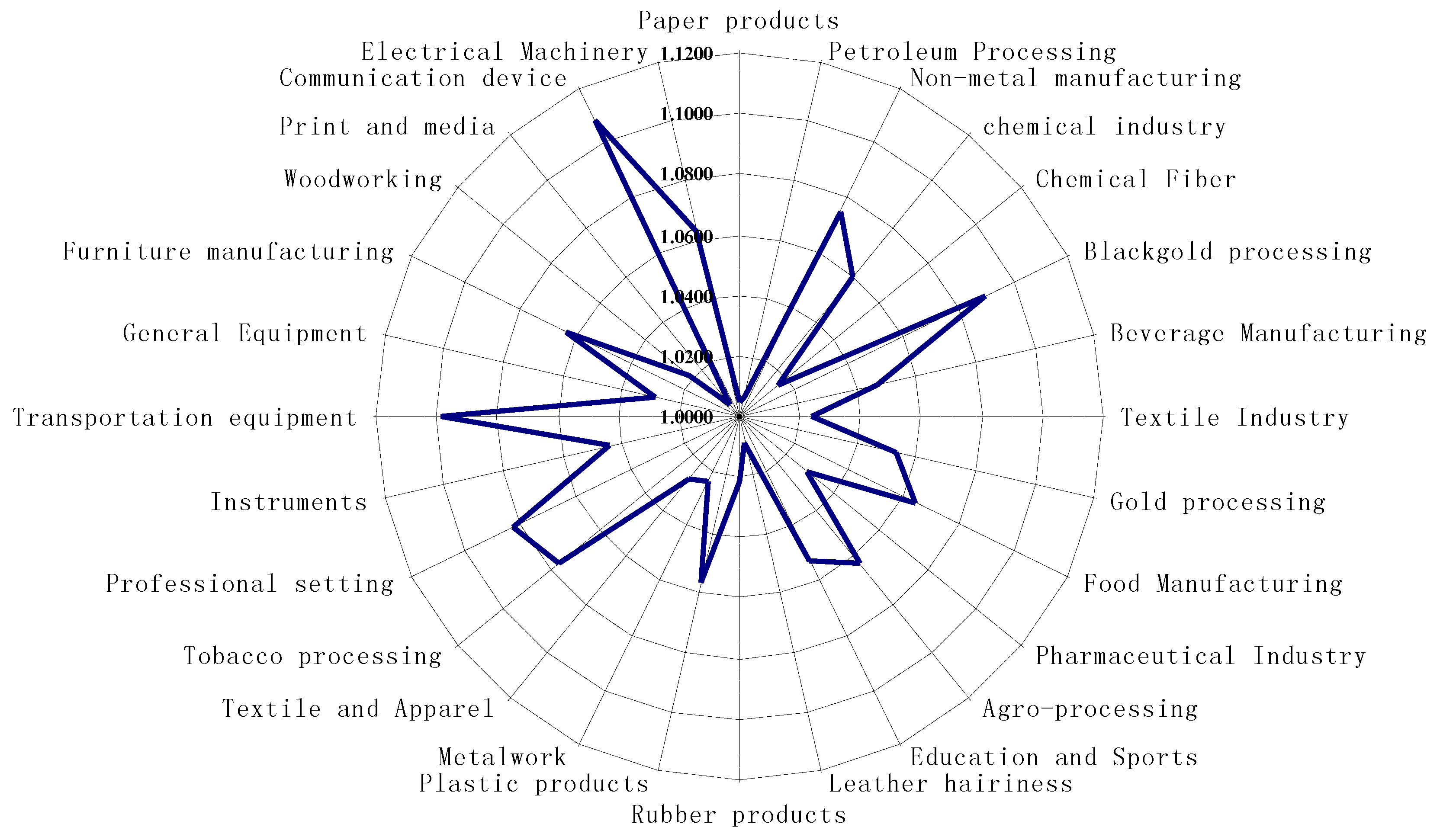

In this paper, we use software DEAP2.1 to calculate DEA Malmquist Malmquist-DEA productivity index of 28 manufacturing industries from 2005 to 2015. The result is shown in

Figure 1. It can be observed that the annual average advance rate of technological progress of all 28 manufacturing industries is greater than 1, and the mean is 1.085. Although each manufacturing industry has made certain technical progress, there is a big difference between their technological progress rates. For example, the average annual technological progress rate of communication device industry (0.173) is 38.44 times the progress rate of paper products (0.0045).

To determine the threshold number, we estimate the linear model, a single threshold model, two-threshold model and three-threshold model in turn, set the sampling frequency as 1000, and use the Bootstrap method to calculate the F statistic and

p value. The results are shown in

Table 1. In

Table 1, we can see that the change rates of waste gas regulation intensity, wastewater regulation intensity and waste solid regulation intensity all reject the linear model at 1% significance level, and are subject to double threshold model at the significant level of 10%. However, all three variables do not pass the significant test of three-threshold model. Therefore, we can judge that all three environmental regulation intensity change rate indicators have two thresholds.

Table 2 reports the threshold regression results of three kinds of environmental regulation intensity change rates on production technology progress rate. Based on

Table 2, we can obtain two threshold values for each kind of environmental regulation intensity change rate: the threshold values of waste gas regulations intensity change rate are 0.1507 and 0.5531; the threshold values of wastewater regulation intensity change rate are 0.1706 and 0.3802; and the threshold values of solid waste environmental regulation threshold intensity change rate are 0.3312 and 0.4799. Then, the threshold regression of the three environment regulation intensity change rates to the technological progress changes rate is performed, as shown in

Table 2.

We can see in

Table 2 that, when the change rate of waste gas regulation intensity is less than 15.07%, a 1% increase will bring −0.0098% negative impact to the technological progress. When the change rate of waste gas regulation intensity is located at interval 15.07%–55.31%, 1% increase will bring 0.1295% significant positive impact to the technology progress. When the change rate of waste gas regulation intensity greater than 55.31%, the previously positive role in promoting technology progress will change to non-significant negative inhibition. Therefore, with the change rate of waste gas regulation intensity from small to large, the change path of production technology progress rate will show “∽” type.

When the change rate of wastewater regulation intensity is less than 17.06%, it will bring non-significant positive impact to the technological progress; when the change rate of wastewater regulation intensity located from 17.06% to 38.02%, it will bring significant positive impact to the technology progress but the impact effect is slightly less than the waste gas impact effect at the corresponding interval; and when the change rate of wastewater regulation intensity greater than 38.02%, it will bring significant negative inhibition to the technology progress, although the impact coefficient is only −0.0713. Thus, the impact of waste gas regulation intensity change rate on the technology progress change rate shows inverted “U” shape.

For the regression of waste solid regulation intensity change rate, we found that the variable on both sides of the two thresholds are positive, indicating that, as the variable value increases, it always brings a positive role in promoting production technology progress. However, this positive role passes significant test only when the waste solid regulation intensity change rate s located in the interval 33.12%–47.99%.

From the control variable analysis results we can know that, although the improvement of RAV and RCP have a positive role in promoting the dependent variable, the impact did not pass the significance test because RAV and RCP can not only bring positive impact but also negative impact to technology progress: the positive impact comes from the increase of potential research investment, and the negative impact comes from monopoly research inert under the high value and high profits background. Improved LP have a significant positive impact to the dependent variable, indicating that workers technical proficiency and enthusiasm can improve technological innovation efficiency and are always the key to enterprise sustainable development. Moderate increase of the Ownstr will bring significant positive role in promoting the technological progress change rate. This indicates that technological progress in the state-owned and state holding enterprises is relatively faster than the foreign-funded enterprises and private enterprises, which reflects the backbone of state-owned enterprises in scientific innovation.

Moderate environmental regulation intensity can lead to a good level of technology progress; too high will lead to excessive heavy compliance costs, while too low will make regulation less of an incentive and reduce the green effect throughout the manufacturing process. Thus, we should decrease or increase regulation intensity to a reasonable level in practice. Thus, what level of environmental regulation intensity situation of the 28 Chinese manufacturing industries will exactly be in 2005–2015 years? Equation (7) was used to calculate the environmental regulation intensity of the three wastes, compare the calculation result with the three wastes threshold value, and get the environmental regulation intensity level of each industry. The results are shown in

Table 3. We can know that, only beverage manufacturing, textile, pharmaceutical industry, agro-processing, education and sports, textiles, tobacco processing and transportation equipment have a reasonable waste gas regulation intensity level. Other industries do not meet the optimal level, wherein the regulation intensity of paper products, petroleum processing, non-gold manufacturing and 14 other industries are relatively low, while regulation intensity of special equipment, general equipment and six other industries is relatively high. On the intensity of wastewater regulation, 10 industries including chemical fiber and black gold processing industry have a reasonable level, the regulation intensity 13 industries is relatively low, and the regulation intensity of five industries is relatively high. Regarding the intensity of waste solid regulation, only non-metal manufacturing, beverage manufacturing and tobacco processing industries are reasonable; paper products, petroleum processing and 17 other industries’ regulation intensities are relatively low; and special equipment, electrical machinery and four other sectors are relatively high.

4. Discussion

Based on the panel data in 2005–2015 for manufacturing industries, this article estimated the level of 28 manufacturing industries technological progress, and then analyzed the impact of three kinds of environmental regulation change rates on technological progress change rate. It was found that the effect of the regulation intensity change rate of waste gas, wastewater and waste solid to technological progress have two threshold effect, and their optimal intervals of regulation intensity change rate were 15.07%–55.31%, 17.06%–38.02% and 33.12%–47.99%, respectively. Different from previous studies [

5,

6,

7], this paper considers the pollution heterogeneity in empirical research and uses the environmental regulation intensity change rate to carry out regression analyses. These help us to understand how to formulate different environmental regulation intensities corresponding to different pollutants.

These results explain why the current scholars failed to reach unity on the relationship between environmental regulation intensity and production technology progress. If located at the reasonable endogenous destined threshold, environmental regulation intensity and production technology progress will show a positive correlation; otherwise, environmental regulation intensity and production technology progress will show a negative or no significant positive correlation.

From the related empirical results, the level of economic development is still the main factor affecting technological innovation everywhere: only in a country or region achieving a certain economic scale, strict environmental regulation is effective. We did not considerate the economic factor seriously, which may be the limitation of this study.

5. Conclusions

In this research, to figure out why some environmental regulation failed to illicit ideal innovation compensatory effects, we used panel technology threshold to analyze the nonlinear relationship between three kinds of environmental regulation intensity and technological innovation in manufacturing based on Chinese manufacturing sub-sector panel data from 2005 to 2015. According to the result, we found that, to achieve a win-win situation between environmental protection and production technological progress, different environmental regulation intensities should be used according to different pollutants of various manufacturing industries. Furthermore, we will perform a deeper study to analyze the nonlinear relationship between environmental regulation intensity and technological innovation, considering more influencing factors in the future.

Based on the above research, the following policy recommendations can be given.

First, the government should establish the optimal environmental regulation intensity in advance considering differences between industries and pollutants. Reasonable intensity of environmental regulation can provide continuous incentive for technology innovation and efficiency improvement of heavy pollution industry. When the environmental regulation intensity is too high, it cannot achieve the related technological innovation activities and achieve economic and environmental win-win situation, as described in the Porter Hypothesis. This will lead to low efficiency, and small or medium sized enterprises will prefer to develop at the expense of the environment, and weaken environmental regulation strength due to the lower cost, often overlooked by the enterprises, thus it cannot stimulate enterprise technological innovation and produce green effect.

Second, the government should adjust environmental regulation intensity level dynamically. In the case of asymmetric information, governments developing environmental regulation standards will overestimate or underestimate the real emissions compliance costs. Thus, the environmental regulation intensity cannot play a binding effect. Only if the government monitors the effectiveness and implementation of timely innovation, and focuses on revising the intensity of environmental regulation to a reasonable level, will the regulation standards continue to be business constraints and incentivize innovation.

Third, the government should grasp the technique of environmental regulation. The impact of environmental regulations on technological innovations and technological advance depends not only on environmental regulation degree but also on the environmental regulation tools. The relevant theory of environmental regulation tools claim that “controlled” environmental regulation tools, such as environmental standards, emission allowances, product bans and other regulatory instruments, will result in increased business costs and productivity decline and lack of adequate incentives for green technology R&D. However, “incentive” environmental regulation tools, such as emissions trading, environmental subsidies and other flexible market-based instruments, can help enterprise to find better means to reduce pollution and provide ongoing incentives to improve enterprise efficiency and technological innovation. Therefore, to improve the green total factor productivity of Chinese manufacturing and achieve the environmental benefits and economic development win-win situation, the Government should not only develop an appropriate level of environmental regulation in accordance with industrial properties and development characteristics, but also change environmental regulation from the control model, to incentive-based policy so that companies develop green technology and manage innovation comprehensively.