BIM-Based 4D Simulation to Improve Module Manufacturing Productivity for Sustainable Building Projects

Abstract

:1. Introduction

2. Literature Review

2.1. Modular Construction

2.2. Module Manufacturing Process Management

2.3. Limitations of Existing Research on Module Manufacturing Process Management

2.4. BIM-Based 4D Simulation

2.5. BIM-Based 4D for Managing Module Manufacturing

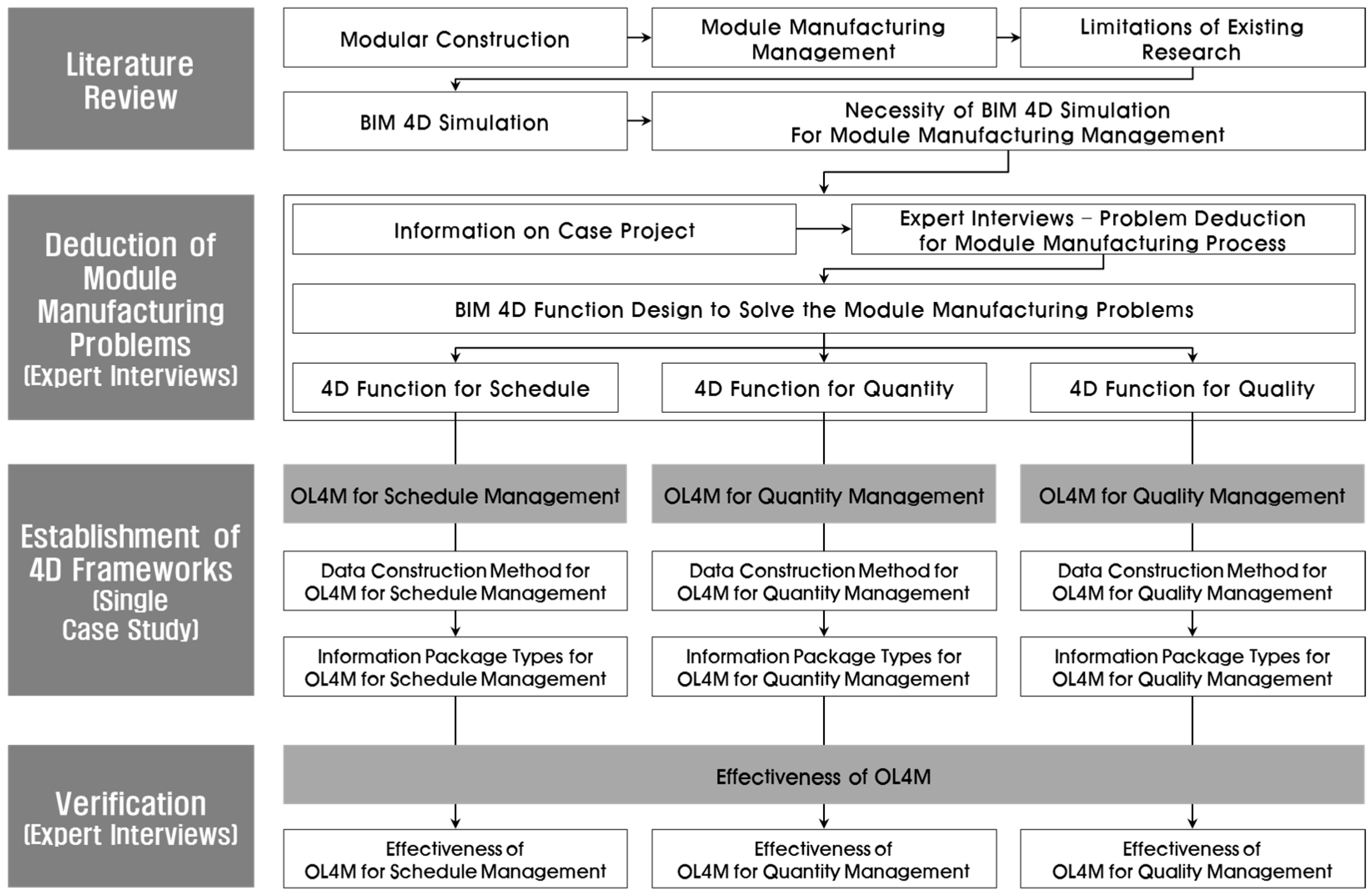

3. Research Approach

4. 4D Framework Design

4.1. Case Project Information and Interview Results

4.2. Design of 4D Framework Function

4.2.1. 4D Functions for Project Schedule

4.2.2. 4D Functions for Material Quantity

4.2.3. 4D Functions for Project Quality

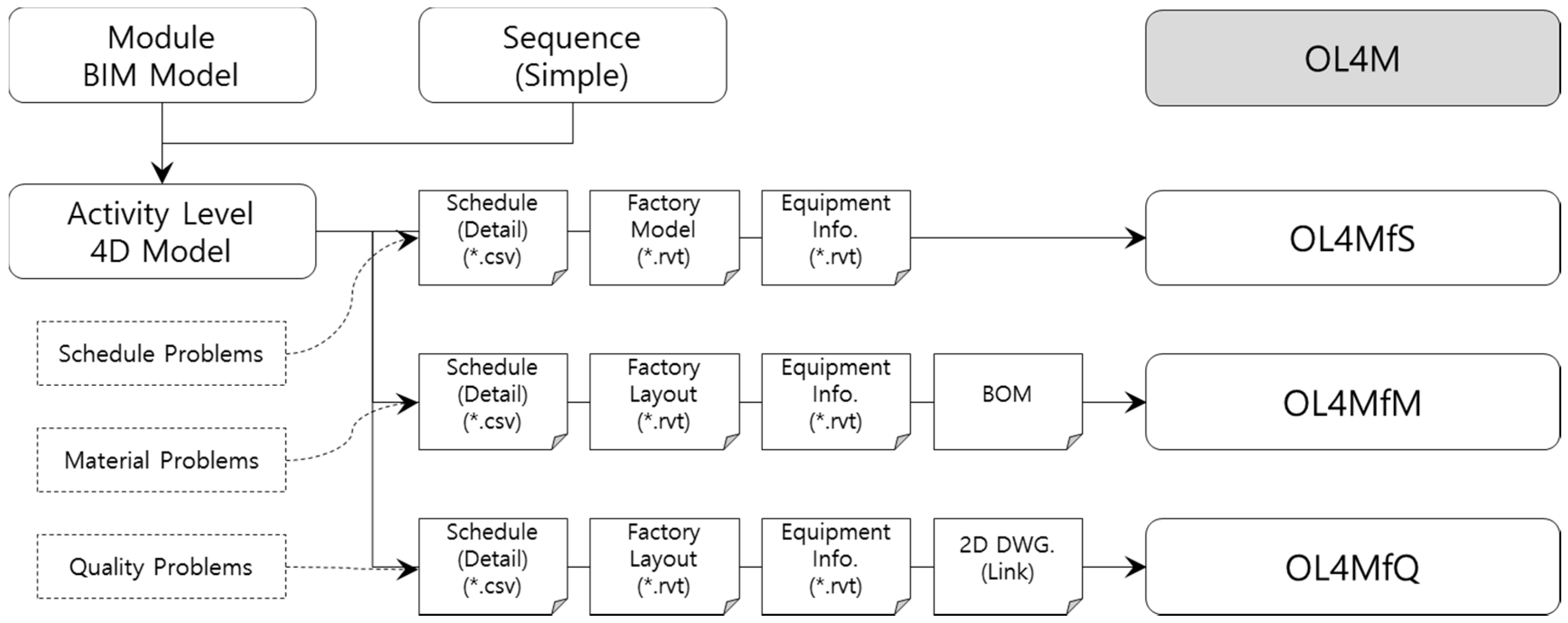

5. Preliminary BIM-Based 4D Frameworks

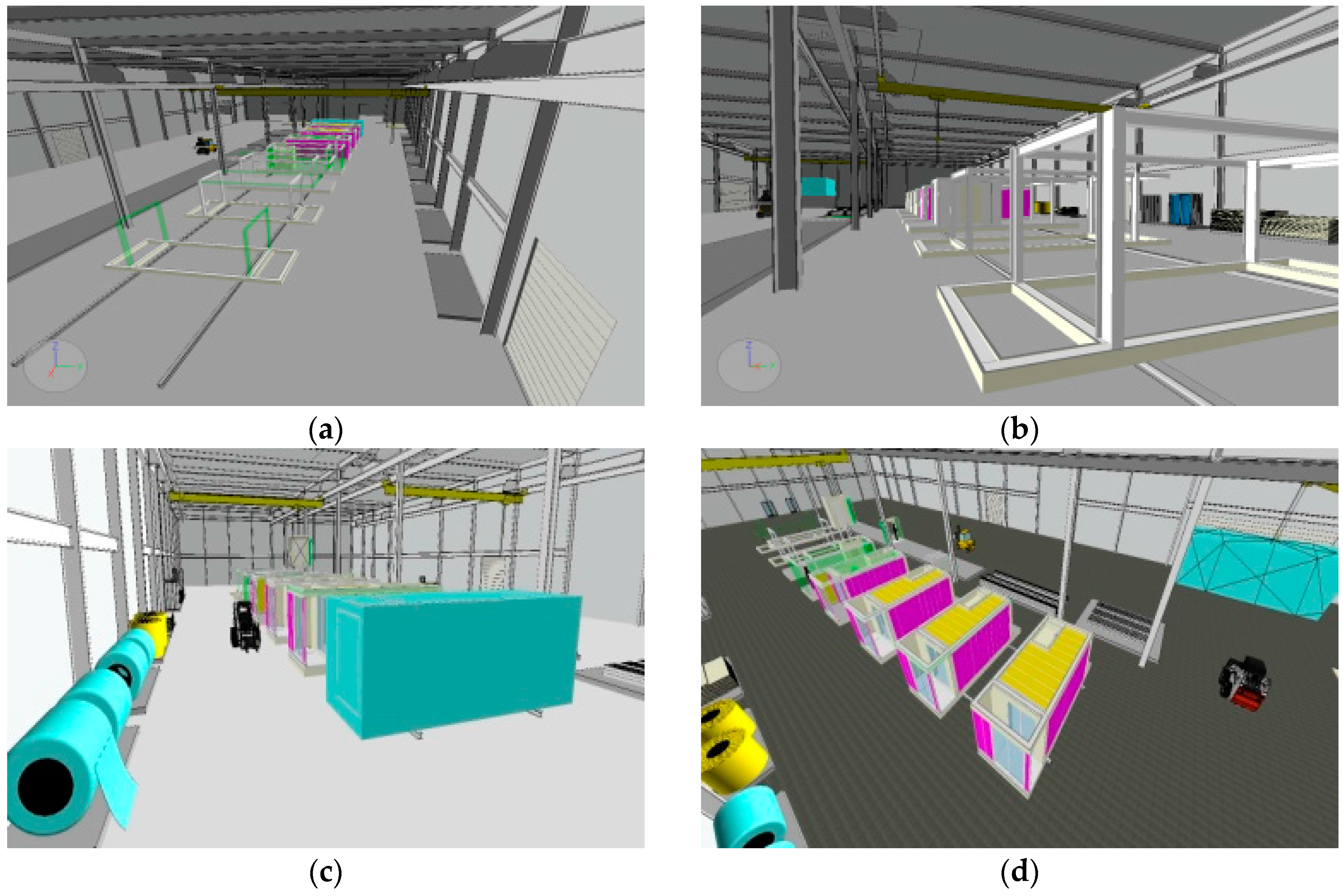

5.1. OL4M for Schedule Management

5.1.1. Data Construction Method for OL4MfS

5.1.2. Information Package Types for OL4MfS

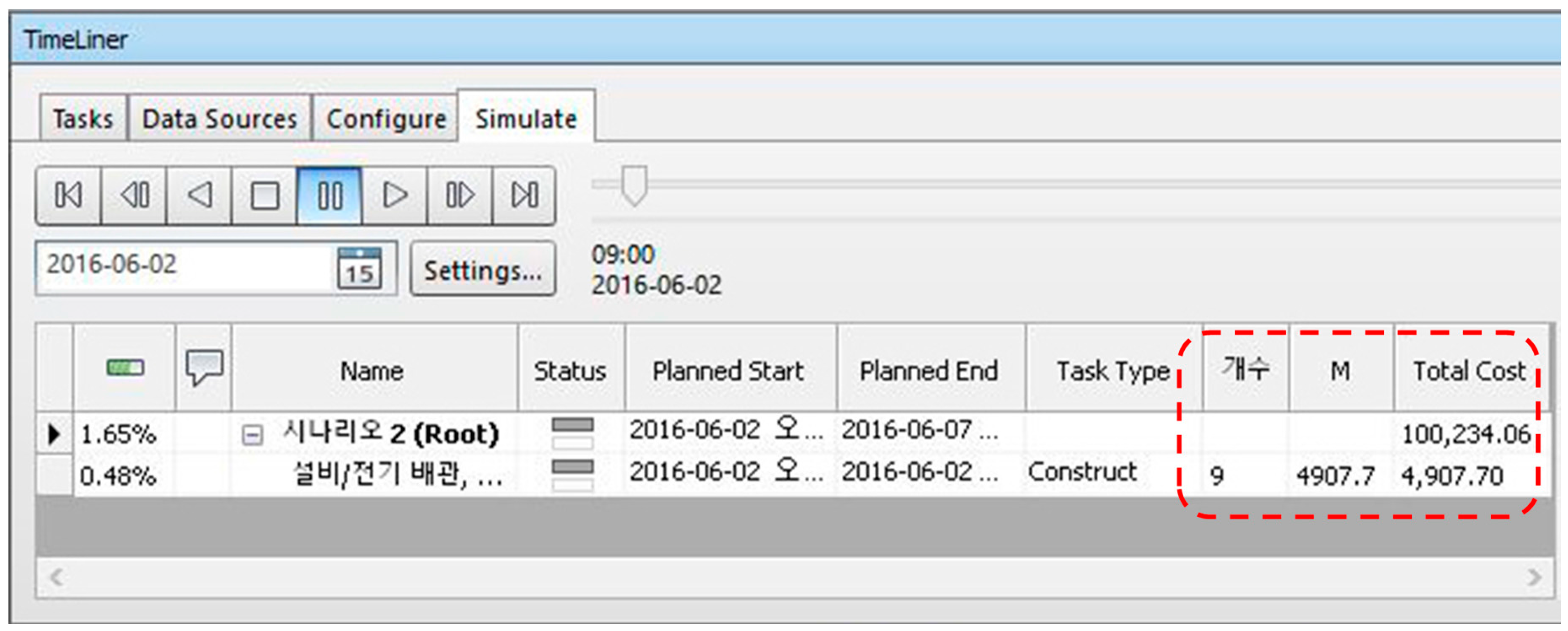

5.2. OL4M for Material Quantity Management

5.2.1. Data Construction Method for OL4MfM

5.2.2. Information Package Types for OL4MfM

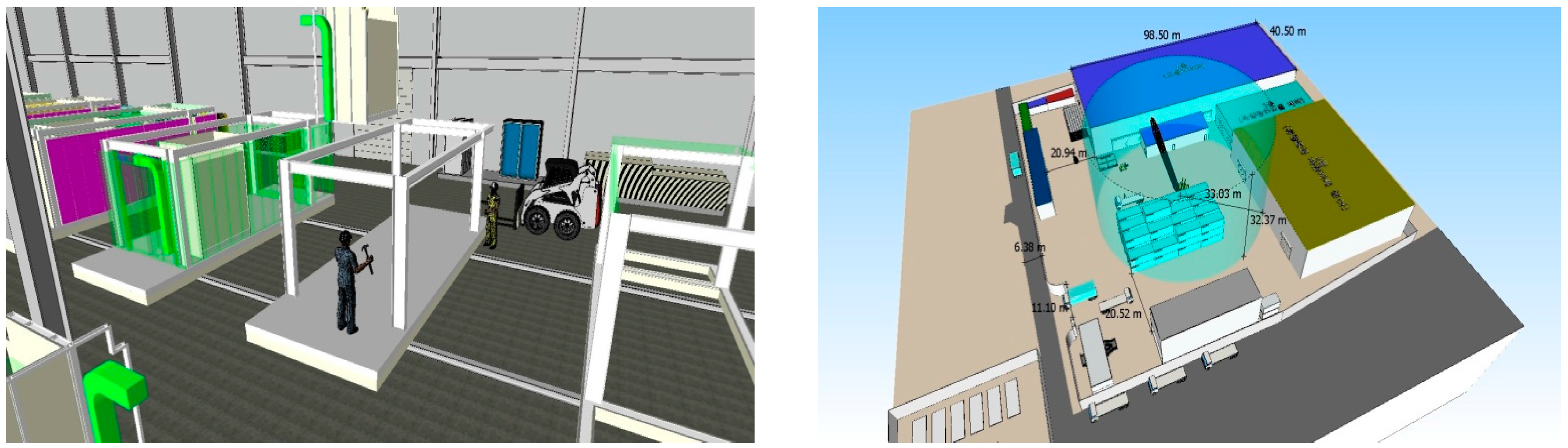

5.3. OL4M for Quality Management

5.3.1. Data Construction Method for OL4MfQ

5.3.2. Information Package Types for OL4MfQ

5.4. Comparison of Information Package Types for the Three OL4M Frameworks

5.5. Technical Review of the Proposed OL4M Frameworks

- (1)

- The OL4M for scheduling can also serve as a general framework for constructing the 4D schedule information media, producing clear types, forms, and documentation formats that will support the efforts of workers and managers throughout the entire module manufacturing process.

- (2)

- Additional research is needed to cover the whole lifecycle of a modular building project, including transportation, lifting and assembly.

- (3)

- Quantitative and qualitative verification should be carried out to confirm the technical effectiveness directly using field tests at the module manufacturing factory featured in the case project. Such a test could investigate precisely how the frameworks can streamline the process and minimize the expense incurred in manufacturing the unit module, as well as the impact on module quality control behavior.

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Zwikael, O.; Cohen, Y.; Sadeh, A. Non-delay scheduling as a managerial approach for managing projects. Int. J. Proj. Manag. 2006, 24, 330–336. [Google Scholar] [CrossRef]

- Mu, S.; Cheng, H.; Chohr, M.; Peng, W. Assessing risk management capability of contractors in subway projects in mainland China. Int. J. Proj. Manag. 2014, 32, 452–460. [Google Scholar] [CrossRef]

- Schimmoller, B.K. Power plants go modular. Power Eng. Mag. 1998, 102, 14–19. [Google Scholar]

- Burke, G.P.; Miller, R.C. Modularization speeds construction. Power Eng. Mag. 1998, 102, 20–22. [Google Scholar]

- Maru, A.; Kawahata, J. Hitachi modularization technology. Nucl. Plant J. 2002, 20, 39–44. [Google Scholar]

- Ahn, Y.H.; Kim, K.T. Sustainability in modular design and construction: A case study of ‘The Stack’. Int. J. Sustain. Build. Technol. Urban Dev. 2014, 5, 250–259. [Google Scholar] [CrossRef]

- Kasun, N.; Janaka, Y. Carpentry workers issues and efficiencies related to construction productivity in commercial construction projects in Alberta. Can. J. Civ. Eng. 2006, 33, 1075–1089. [Google Scholar]

- Han, Z.; Froese, T. Project Information Management in Mega Oil Sands Projects, Building a Sustainable Future. In Proceedings of the 2009 Construction Research Congress, Seattle, WA, USA, 5–7 April 2009; pp. 5–7.

- John, E.; Rodney, T.; Ralf, M. Maximizing strategic value from megaprojects: The influence of information-feed on decision-making by the project manager. Int. J. Proj. Manag. 2012, 30, 639–651. [Google Scholar] [Green Version]

- Wing, Z.; Lieyun, D.; Xiangyu, W.; Martijn, T.; Hanbin, L. Applicability of 4D modeling for resource allocation in mega liquefied natural gas plant construction. Autom. Constr. 2015, 50, 50–63. [Google Scholar]

- Mohanty, R.P.; Siddiq, M.K. Multiple projects-multiple resources-constrained scheduling: Some studies. Int. J. Prod. Res. 1989, 27, 261–280. [Google Scholar] [CrossRef]

- Vercellis, C. Constrained multi-project planning problems: A Lagrangean decomposition approach. Eur. J. Oper. Res. 1994, 78, 267–275. [Google Scholar] [CrossRef]

- Lawrence, S.R.; Morton, T.E. Resource-constrained multiproject scheduling with tardy costs: Comparing myopic bottleneck and resource pricing heuristics. Eur. J. Oper. Res. 1993, 64, 168–187. [Google Scholar] [CrossRef]

- Kumanan, S.; Jegan Jose, G.; Raja, K. Multi-project scheduling using a heuristic and a genetic algorithm. Int. J. Adv. Manuf. Technol. 2006, 31, 360–366. [Google Scholar] [CrossRef]

- Mohamed, Y.; Borrego, D.; Francisco, L.; Al-Hussein, M.; Abourizk, S.; Hermann, U. Simulation-based scheduling of module assembly yards: Case study. Eng. Constr. Archit. Manag. 2007, 14, 293–311. [Google Scholar] [CrossRef]

- Hosein, T.; Ulrich, H.; Simaan, A.; Yasser, M. Simulation-Based Multiagent Approach for Scheduling Modular Construction. J. Comput. Civ. Eng. 2014, 28, 263–274. [Google Scholar]

- Kim, C.; Kim, H.; Park, T.; Kim, M.K. Applicability of 4D CAD in civil engineering construction: Case study of a cable-stayed bridge project. J. Comput. Civ. Eng. 2010, 25, 98–107. [Google Scholar] [CrossRef]

- Mullens, M. Production flow and shop floor control: Structuring the modular factory for custom homebuilding. In Proceedings of the NSF Housing Research Agenda Workshop, Orlando, FL, USA, 12–14 February 2004; pp. 12–14.

- Arashpour, M.; Wakefield, R.; Blismas, N.; Maqsood, T. Autonomous production tracking for augmenting output in off-site construction. Autom. Constr. 2015, 53, 13–21. [Google Scholar] [CrossRef]

- Kawecki, L.R. Environmental Performance of Modular Fabrication: Calculating the Carbon Footprint of Energy Used in the Construction of a Modular Home. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2010. [Google Scholar]

- Celine, J.L. The Evolution of the Use of Prefabrication Techniques in Hong Kong Construction Industry. Ph.D. Thesis, Hong Kong Polytechnic University, Hong Kong, China, 2009. [Google Scholar]

- Mah, D.E. Framework for Rating the Sustainability of the Residential Construction Practice. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2011. [Google Scholar]

- Cartwright, J.T. Zoning and Designing for Affordability Using Modular Housing. Master’s Thesis, Iowa State University, Ames, IA, USA, 2011. [Google Scholar]

- Lawson, R.M.; Ogden, R.G. Sustainability and process benefits of modular construction. In Proceedings of the 18th CIB World Building Congress, TG57-Special Track, Salford, UK, 10–13 May 2010; pp. 38–51.

- Smith, R.E. Prefab Architecture: A Guide to Modular Design and Construction; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Na, L. Investigation of the Designers’ and General Contractors’ Perceptions of Offsite Construction Techniques in the United States Construction Industry. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2007. [Google Scholar]

- Quale, J.; Eckelman, M.J.; Williams, K.W.; Sloditskie, G.; Zimmerman, J.B. Construction matters: Comparing environmental impacts of building modular and conventional homes in the United States. J. Ind. Ecol. 2012, 16, 243–253. [Google Scholar] [CrossRef]

- Chiu, S.T.L. An Analysis on the Potential of Prefabricated Construction Industry. Ph.D. Thesis, The University of British Columbia, Vancouver, BC, Canada, 2012. [Google Scholar]

- Haas, C.T.; O’Connor, J.T.; Tucker, R.L.; Eickmann, J.A.; Fagerlund, W.R. Prefabrication and Preassembly Trends and Effects on the Construction Workforce; Report; Center for Construction Industry Studies, University of Texas: Austin, TX, USA, 2000. [Google Scholar]

- Cartz, J.P.; Crosby, M. Building high-rise modular homes. Struct. Eng. 2007, 85, 20–21. [Google Scholar]

- Rogan, A.L.; Lawson, R.M.; Bates-Brkljac, N. Value and Benefits Assessment of Modular Construction; Report; Steel Construction Institute: Berkshire, UK, 2000. [Google Scholar]

- Ambler, S. Briefing: Off-site construction of a new nuclear laboratory at Dounreay, Scotland. Proc. Inst. Civ. Eng. Energy 2013, 166, 49–52. [Google Scholar] [CrossRef]

- O’Brien, M.; Wakefield, R.; Belivean, Y. Industrializing the Residential Construction Site; Report; Department of Housing and Urban Development, Office of Policy Development and Research: Washington, DC, USA, 2000.

- Cameron, P.J.; DiCarlo, N.G. Piecing Together Modular: Understanding the Benefits and Limitations of Modular Construction Methods for Multifamily Development. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2007. [Google Scholar]

- Haas, C.T.; Fagerlund, W.R. Preliminary Research on Prefabrication, Pre-Assembly, Modularization and Off-Site Fabrication in Construction; Report; The Construction Industry Institute, The University of Texas at Austin: Austin, TX, USA, 2002. [Google Scholar]

- Jaillon, L.; Poon, C.S. The evolution of prefabricated residential building systems in Hong Kong: A review of the public and the private sector. Autom. Constr. 2009, 18, 239–248. [Google Scholar] [CrossRef]

- Mohammad, K.; Kasun, H. Life cycle performance of modular buildings: A critical review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar]

- Polat, G.; Arditi, D.; Ballard, G.; Mungen, U. Economics of on-site vs off-site fabrication of rebar. Constr. Manag. Econ. 2006, 24, 1185–1198. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Blismas, N.; Lee, E.W.M. Analysis of disruptions caused by construction field rework on productivity in residential projects. ASCE J. Constr. Eng. Manag. 2014, 140, 04013053. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Blismas, N.; Lee, E.W.M. Framework for improving workflow stability: Deployment of optimized capacity buffers in a synchronized construction production. Can. J. Civ. Eng. 2014, 41, 995–1004. [Google Scholar] [CrossRef]

- Goncalves, J.F.; Mendes, J.J.M.; Resende, M.G.C. A genetic algorithm for the resource constrained multi-project scheduling problem. Eur. J. Oper. Res. 2008, 189, 1171–1190. [Google Scholar] [CrossRef]

- Deckero, R.; Winkofsky, E.P.; Herbert, J.; Gagnon, R. A decomposition approach to multi-project scheduling. Eur. J. Oper. Res. 1991, 51, 110–118. [Google Scholar] [CrossRef]

- Oguz, O.; Bala, H. A comparative study of computational procedures for the resource constrained project scheduling problem. Eur. J. Oper. Res. 1994, 72, 406–416. [Google Scholar] [CrossRef]

- Wiley, V.D.; Deckro, R.F.; Jackson, J. An Optimization analysis for design and planning of multiproject programs. Eur. J. Oper. Res. 1998, 107, 492–506. [Google Scholar] [CrossRef]

- Borrego, D. Simulation-Based Scheduling of Module Assembly Yards with Logical and Physical Constraints. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2004. [Google Scholar]

- Liu, Y. Modeling of Industrial Construction Processes Using Multi Agent Resource Allocation Framework. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2009. [Google Scholar]

- Elsayed, E.A.; Nasr, N.Z. Heuristic for resource constrained scheduling. Int. J. Prod. Res. 1986, 24, 299–310. [Google Scholar] [CrossRef]

- Boctor, F.F. Some efficient multi-heuristic procedures for resource constrained project scheduling. Eur. J. Oper. Res. 1990, 49, 3–13. [Google Scholar] [CrossRef]

- Taghaddos, H.; AbouRizk, S.M.; Mohamed, Y.; Hermann, R. Integrated simulation-based scheduling for module assembly yard. In Proceedings of the Construction Research Congress 2009: Building a Sustainable Future, Seattle, WA, USA, 5–7 April 2009.

- Taghaddos, H.; AbouRizk, S.M.; Mohamed, Y.; Hermann, U. Simulation-based resource leveling in multi-project construction. In Proceedings of the Canadian Society for Civil Engineering (CSCE) 2008 Annual General Meeting & Conference, Westmount, QC, Canada, 10–13 June 2008; pp. 304–314.

- Zhang, J.P.; Hu, Z.Z. BIM- and 4D-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 1. Principles and methodologies. Autom. Constr. 2011, 20, 155–166. [Google Scholar] [CrossRef]

- Kamat, V.R.; Martinez, J.C.; Fischer, M.; Golparvar-Fard, M.; Peña-Mora, F.; Savarese, S. Research in visualization techniques for field construction. ASCE J. Constr. Eng. Manag. 2010, 137, 853–862. [Google Scholar] [CrossRef]

- Chini, A.; Genauer, G. Technical Guidance Available To Designers of Temporary Structures. In Building to Last; ASCE: Reston, VA, USA, 1997; pp. 979–984. [Google Scholar]

- Huang, T.; Kong, C.W.; Guo, H.; Baldwin, A.; Li, H. A virtual prototyping system for simulating construction processes. Autom. Constr. 2007, 16, 576–585. [Google Scholar] [CrossRef]

- Dawood, N.; Scott, D.; Eknarine, S.; Mallasi, Z. The virtual construction site (VIRCON) tools: An industrial evaluation. J. Inf. Technol. Constr. 2005, 10, 43–54. [Google Scholar]

- Adjei-Kumi, T.; Retik, A. A library-based 4D visualization of construction processes. In Proceedings of the International Conference on Information Visualization, London, UK, 27–29 August 1997.

- David, H.; Lamine, M. Trends of 4D CAD applications for construction planning. Constr. Manag. Econ. 2004, 22, 171–182. [Google Scholar]

- Moon, C. Three dimensions of sustainability and floating architecture. Int. J. Sustain. Build. Technol. Urban Dev. 2014, 5, 123–127. [Google Scholar] [CrossRef]

- Arashpour, M.; Wakefield, R.; Lee, E.; Chan, R.; Hosseini, M. Analysis of interacting uncertainties in on-site and off-site activities: Implications for hybrid construction. Int. J. Proj. Manag. 2016, 34, 1393–1402. [Google Scholar] [CrossRef]

- Dzeng, R.; Lee, H. Optimizing the development schedule of resort projects by integrating simulation and genetic algorithm. Int. J. Proj. Manag. 2007, 25, 506–516. [Google Scholar] [CrossRef]

- Chou, J. Cost simulation in an item-based project involving construction engineering and management. Int. J. Proj. Manag. 2011, 29, 706–717. [Google Scholar] [CrossRef]

- Nasereddin, M.; Mullens, M.A.; Cope, D. Automated simulator development: A strategy for modeling modular housing production. Autom. Constr. 2007, 16, 212–223. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar]

- Rowley, J. Using case studies in research. Manag. Res. News 2002, 25, 16–27. [Google Scholar] [CrossRef]

- Russell, T.W.; Chris, J.P. A Single Case Study of the Impact of Policy Changes on Identification for Gifted Programs. J. Educ. Gift. 2016, 39, 49–61. [Google Scholar]

- Kim, H.; Grobler, F. Design coordination in building information modeling (BIM) using ontological consistency checking. In Proceedings of the 2009 ASCE International Workshop on Computing in Civil Engineering, Austin, TX, USA, 24–27 June 2009.

| Field | References | |||

|---|---|---|---|---|

| Mathematical and heuristic analyses | Mohanty and Siddiq [11] | Vercellis [12] | Elsayed et al. [47] | Boctor [48] |

| Advanced heuristic techniques | Lawrence and Morton [13] | Wiley et al. [44] | Kumanan et al. [14] | Goncalves et al. [41] |

| Simulation approaches | Borrego [45] | Liu [46] | Mohamed et al. [15] | Taghaddos et al. [49,50] |

| Project Info. | Description | Problem Types | Description |

|---|---|---|---|

| Project overview |

| Process problems |

|

| Target |

| Material quantity Problems |

|

| Time period | 1 June to 30 June 2016 | Quality Problems |

|

| Interview Method | Re-analyze after conducting in-person interviews, collecting subjective answers, and organizing them |

| Process Problem | Information Needed | Recommended 4D Method |

|---|---|---|

| Missing process information, segments | Associated information medium Visual information | OL4MfS |

| Practical use not possible | Detailed manufacturing process specific to the part being constructed | Detailed 4D simulation specifically for the part being manufactured |

| Inadequate manufacturing information | Factory layout Material use plan Equipment use plan | Factory/equipment/material-linked plan model (measurements, workflow, etc.) |

| Material Quantity Problem | Information Needed | Recommended 4D Method |

|---|---|---|

| Lower 2D material quantity reliability | BIM-based material quantity information | Model-based QTO (OL4MfM) |

| Material information according to process does not exist | Linkage between milestone and material quantity |

| Quality Problem | Information Needed | Recommended 4D Method |

|---|---|---|

| Lower drawing quality | Ensure drawing consistency | Produce BIM model-based drawing |

| Lower module manufacturing quality | Improve drawing information quality | Drawing-model linked 4D simulation (OL4MfQ) |

| Insufficient understanding of drawing by workers | 3D shape information | |

| 3D linked information |

| Process Description | Start Date | End Date |

|---|---|---|

| Jig adjustment | 2 June 2016 9:00 | 2 June 2016 9:14 |

| Column + short span beam (combined upper and lower) | 2 June 2016 9:15 | 2 June 2016 9:29 |

| Column + long span beam (combined upper and lower) | 2 June 2016 9:30 | 2 June 2016 9:44 |

| Join wall braces | 2 June 2016 9:45 | 2 June 2016 9:59 |

| Check vertical and horizontal measurements | 2 June 2016 10:00 | 2 June 2016 10:14 |

| Modular movement (large) | 2 June 2016 10:15 | 2 June 2016 10:32 |

| Stud installation on PC | 2 June 2016 10:33 | 2 June 2016 10:44 |

| --- | --- | --- |

| Information Type | Included Information | |||||

|---|---|---|---|---|---|---|

| Case Project | OL4MfS | OL4MfM | OL4MfQ | |||

| 3D view | Floor | × | ∆ (user setting) | ∆ (user setting) | ∆ (user setting) | |

| Section | × | ∆ (user setting) | ∆ (user setting) | ∆ (user setting) | ||

| Elevation | × | ∆ (user setting) | ∆ (user setting) | ∆ (user setting) | ||

| Detail | × | ∆ (user setting) | ∆ (user setting) | ∆ (user setting) | ||

| Factory/equipment module link view | × | ○ | ○ | ○ | ||

| Expanded view according to part | × | ○ | ○ | ○ | ||

| Process | Sequence | ○ (simple process order) | ○ (detailed process order) | ○ (detailed process order) | ○ (detailed process order) | |

| S.D/F.D | × | ○ (determined from daily work reports) | ○ (determined from daily work reports) | ○ (determined from daily work reports) | ||

| Factory layout information | ∆ (1 layout of a 2D floor plan) | ○ (factory model link) | ○ (factory model link) | ○ (factory model link) | ||

| Equipment use plan model | × | ○ (equipment model link) | ○ (equipment model link) | ○ (equipment model link) | ||

| Other plan models | × | ○ (yard storage and crane operating plan) | ○ (yard storage and crane operating plan) | ○ (yard storage and crane operating plan) | ||

| Material quantity | Total material quantity | ∆ (material quantity calculated from drawings) | ∆ (drawing production material quantity) | ○ | ○ | |

| Material quantity according to work type | × | × | ○ | ○ | ||

| Material quantity according to part being manufactured | × | × | ○ (BOM and 4D model link) | ○ (table and 4D model link) | ||

| Quality | Design information | Drawing information | ○ (2D drawing) | ○ (2D drawing) | ○ (2D drawing) | ○ |

| Measurement information | ○ (2D drawing) | ○ (2D drawing) | ○ (2D drawing) | ○ | ||

| Drawing-model quality | × | × | × | ○ (visual check) | ||

| Category | Description | ||||

|---|---|---|---|---|---|

| OL4MfS | OL4MfM | OL4MfQ | |||

| Time required for modeling and 4D model creation tasks |

|

|

| ||

| Additional time | - | 1 h (compared to 81 h for OL4MfS) | 6 h (compared to 82 h for OL4MfM) | ||

| Personnel investment | 1 highly skilled technician | 1 highly skilled technician | 1 highly skilled technician | ||

| Model data structure | File structure | Revit model | Module.rvt | Module.rvt | Kayang Complex module.rvt |

| Module factory.rvt | Module factory.rvt | Module factory.rvt | |||

| 4D model | OL4MfS-detail.nwd (parts 1–10) | OL4MfM-total.nwd | OL4MfQ-total.nwd | ||

| OL4MfS-open storage.nwd | OL4MfM-detail.nwd (parts 1–10) | OL4MfQ-detail.nwd (parts 1–10) | |||

| Object count | Total object count: N (module objects: n; factory and equipment objects: m) | ||||

| Work type | Module: Interior finishing, structure, MEPFactory: Architecture, structure, equipment | ||||

| LOD | Module: LOD 400; factory/equipment: LOD 200 | ||||

| Link | O:S = N:1 (N ≥ 1) | ||||

| Processes | 56 (200% increase compared to 28 for AL4M) | ||||

| Aspects | Questionnaire | OL4M for Schedule | OL4M for Quantity | OL4M for Quality |

|---|---|---|---|---|

| Clarity of model structure | Ease of construction and operability of the 4D models | 3.73 | 3.85 | 3.83 |

| Modifiability to deal with data errors or design changes | 3.47 | 3.61 | 3.55 | |

| Manageability of the files used to create the 4D model (original BIM model files and 4D model file) | 3.88 | 3.79 | 3.74 | |

| Appropriateness and expressiveness of 4D plan models | Detailed description of schedule information and relationship with other entities | 3.92 | 3.76 | 3.89 |

| Exact expression of manufacturing scene (including module schedule, material, equipment and detailed schedule) | 3.90 | 3.81 | 3.93 | |

| Expressiveness of presenting traditional information synthetically | 3.87 | 3.69 | 3.95 | |

| Effectiveness for manufacturing productivity | Time saved in preparing documentation such as drawings, schedule, BOM, and reports, etc. | 3.42 | 3.58 | 3.31 |

| Reduction in repetition, mistakes, and manufacturing errors | 3.74 | 3.82 | 3.88 | |

| Minimizing time needed to acquire information for particular tasks | 3.63 | 3.71 | 3.68 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Kim, J. BIM-Based 4D Simulation to Improve Module Manufacturing Productivity for Sustainable Building Projects. Sustainability 2017, 9, 426. https://doi.org/10.3390/su9030426

Lee J, Kim J. BIM-Based 4D Simulation to Improve Module Manufacturing Productivity for Sustainable Building Projects. Sustainability. 2017; 9(3):426. https://doi.org/10.3390/su9030426

Chicago/Turabian StyleLee, Joosung, and Jaejun Kim. 2017. "BIM-Based 4D Simulation to Improve Module Manufacturing Productivity for Sustainable Building Projects" Sustainability 9, no. 3: 426. https://doi.org/10.3390/su9030426