Analysis of the Potential Impacts on China’s Industrial Structure in Energy Consumption

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methods

- Objective 1: Economic objective

- Objective 2: Energy consumption objective

- Constraint 1: Economic constraints

- Constraint 2: Energy consumption constraints

- Constraint 3: Input–output model constraints

- Constraint 4: Structure adjustment constraints

2.1.1. Objectives of the Optimization Model

2.1.2. Constraints of the Optimization Model

2.1.3. Objectives and Constraints of the Fuzzy Optimization Model

2.2. Materials

2.2.1. Energy Consumption Data

2.2.2. Noncompetitive Import-Oriented Input–Output Table

2.2.3. Exogenous Parameters in the Model

3. Results

3.1. Effects of Industrial Structure Optimization

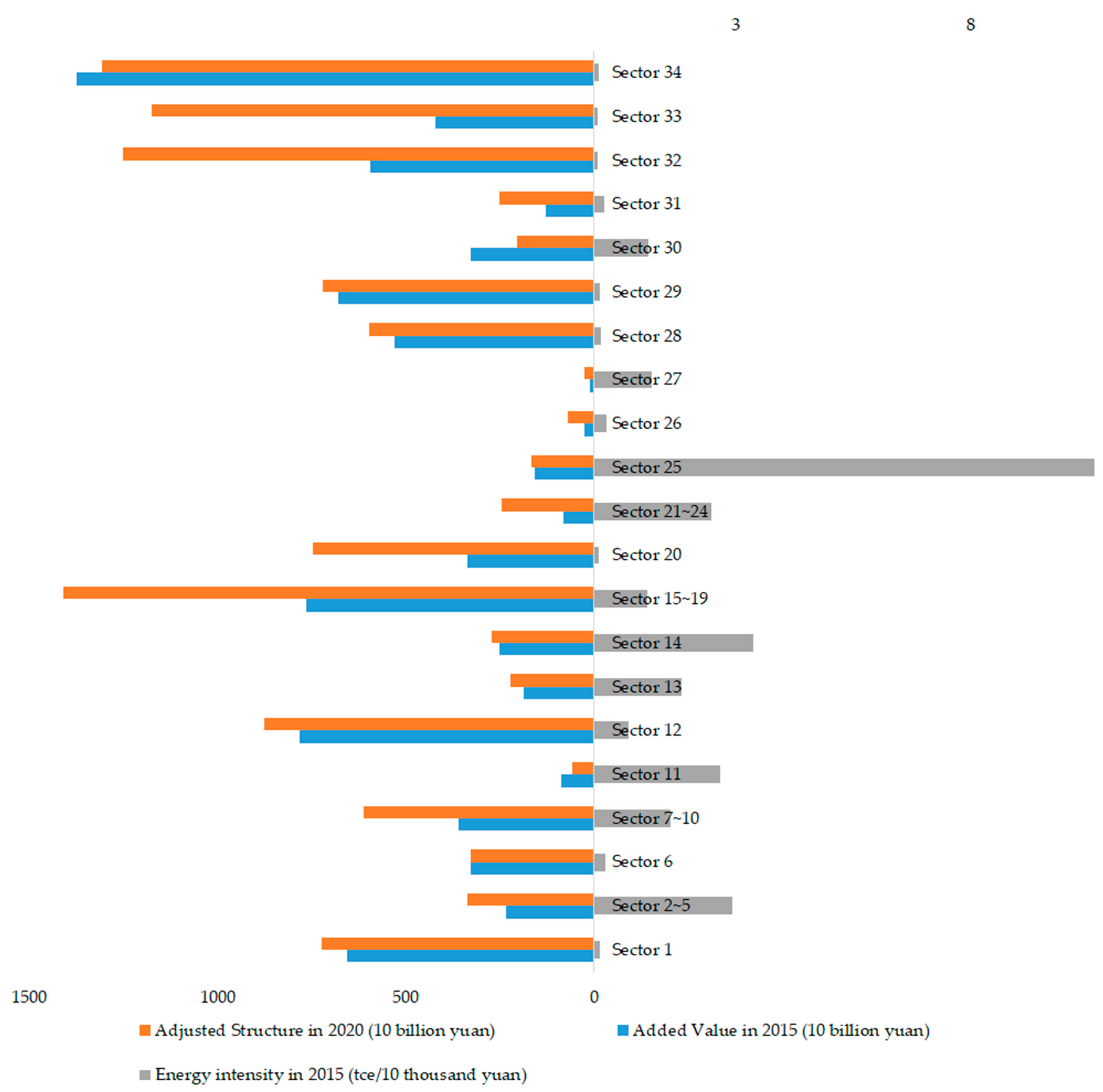

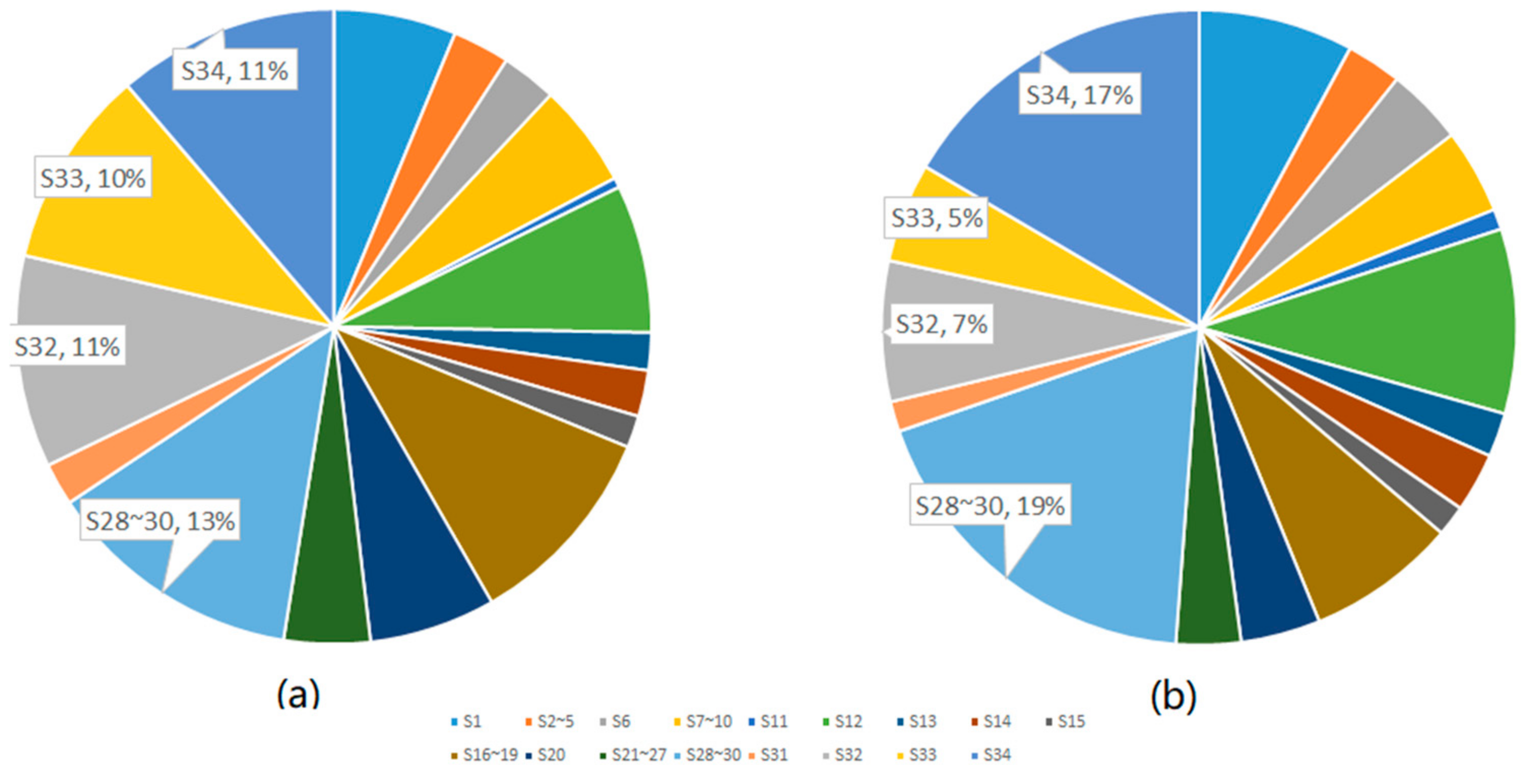

3.2. Analysis of Optimizing Results in Sectoral Level

3.3. Analysis of Adjusted Structure of Tertiary Industry

4. Discussion

Supplementary Materials

Author Contributions

Conflicts of Interest

References

- Fernández González, P.; Landajo, M.; Presno, M.J. Multilevel LMDI decomposition of changes in aggregate energy consumption. A cross country analysis in the EU-27. Energy Policy 2014, 68, 576–584. [Google Scholar] [CrossRef]

- Norman, J.B. Measuring improvements in industrial energy efficiency: A decomposition analysis applied to the UK. Energy 2017, 137, 1144–1151. [Google Scholar] [CrossRef]

- Llop, M. Changes in energy output in a regional economy: A structural decomposition analysis. Energy 2017, 128, 145–151. [Google Scholar] [CrossRef]

- Wang, Y.; Ge, X.-L.; Liu, J.-L.; Ding, Z. Study and analysis of energy consumption and energy-related carbon emission of industrial in Tianjin, China. Energy Strategy Rev. 2016, 10, 18–28. [Google Scholar] [CrossRef]

- Xiao, B.; Niu, D.; Wu, H. Exploring the impact of determining factors behind CO2 emissions in China: A CGE appraisal. Sci. Total Environ. 2017, 581, 559–572. [Google Scholar] [CrossRef] [PubMed]

- Mi, Z.; Pan, S.Y.; Yu, H.; Wei, Y.M. Potential impacts of industrial structure on energy consumption and CO2 emission: A case study of Beijing. J. Clean. Prod. 2015, 103, 455–462. [Google Scholar] [CrossRef]

- Janger, J.; Schubert, T.; Andries, P.; Rammer, C.; Hoskens, M. The EU 2020 innovation indicator: A step forward in measuring innovation outputs and outcomes? Res. Policy 2017, 46, 30–42. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Smith, R. Synthesis of industrial systems based on value analysis. Comput. Chem. Eng. 2007, 31, 535–551. [Google Scholar] [CrossRef]

- Yun, T.; Cho, G.; Kim, J. Analyzing Economic Effects with Energy Mix Changes: A Hybrid CGE Model Approach. Sustainability 2016, 8, 1048. [Google Scholar] [CrossRef]

- Mao, G.; Dai, X.; Wang, Y.; Guo, J.; Cheng, X.; Fang, D.; Song, X.; He, Y.; Zhao, P. Reducing carbon emissions in China: Industrial structural upgrade based on system dynamics. Energy Strategy Rev. 2013, 2, 199–204. [Google Scholar] [CrossRef]

- Zhou, X.; Zhang, J.; Li, J. Industrial structural transformation and carbon dioxide emissions in China. Energy Policy 2013, 57, 43–51. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, J. Predicting and optimization of energy consumption using system dynamics-fuzzy multiple objective programming in world heritage areas. Energy 2013, 49, 19–31. [Google Scholar] [CrossRef]

- Chenery, H.B.; Watanabe, T. International Comparisons of the Structure of Production. Econometrica 1958, 26, 487–521. [Google Scholar] [CrossRef]

- Leontief, W. The Structure of American Economy, 1919–1939; Oxford University Press: Oxford, UK, 1941. [Google Scholar]

- Li, Z.; Sun, L.; Geng, Y.; Dong, H.; Ren, J.; Liu, Z.; Tian, X.; Yabar, H.; Higano, Y. Examining industrial structure changes and corresponding carbon emission reduction effect by combining input-output analysis and social network analysis: A comparison study of China and Japan. J. Clean. Prod. 2017. [Google Scholar] [CrossRef]

- Zanchetta Borghi, R.A. The Brazilian productive structure and policy responses in the face of the international economic crisis: An assessment based on input-output analysis. Struct. Chang. Econ. Dyn. 2017, 43, 62–75. [Google Scholar] [CrossRef]

- Zhou, M.; Chen, Q.; Cai, Y.L. Optimizing the industrial structure of a watershed in association with economic-environmental consideration: An inexact fuzzy multi-objective programming model. J. Clean. Prod. 2013, 42, 116–131. [Google Scholar] [CrossRef]

- Rong, A.; Lahdelma, R. Fuzzy chance constrained linear programming model for optimizing the scrap charge in steel production. Eur. J. Oper. Res. 2008, 186, 953–964. [Google Scholar] [CrossRef]

- State Council. The Twelfth Five-Year Plan for National Economic and Social Development of the People’s Republic of China; State Council: Beijing, China, 2016. [Google Scholar]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- National Bureau of Statistics of China (NBSC). China Energy Statistical Yearbook 2016; China Statistics Press: Beijing, China, 2016. [Google Scholar]

- National Bureau of Statistics of China (NBSC). China 2012 Input–Output Table; China Statistics Press: Beijing, China, 2015. [Google Scholar]

- Hiramatsu, T.; Inoue, H.; Kato, Y. Estimation of interregional input-output table using hybrid algorithm of the RAS method and real-coded genetic algorithm. Transp. Res. Part E Logist. Transp. Rev. 2016, 95, 385–402. [Google Scholar] [CrossRef]

- Weber, C.L.; Peters, G.P.; Guan, D.; Hubacek, K. The contribution of Chinese exports to climate change. Energy Policy 2008, 36, 3572–3577. [Google Scholar] [CrossRef]

- National Bureau of Statistics of the People’s Republic of China. Classification of National Economic Sectors. GB/T 4754–2017; 2017. Available online: http://www.stats.gov.cn/tjsj/tjbz/hyflbz/201710/t20171012_1541679.html (accessed on 14 October 2017).

- Xiong, P.; Dang, Y.; Yao, T.; Wang, Z. Optimal modeling and forecasting of the energy consumption and production in China. Energy 2014, 77, 623–634. [Google Scholar] [CrossRef]

- Lin, B.; Liu, W. Estimation of energy substitution effect in China’s machinery industry—Based on the corrected formula for elasticity of substitution. Energy 2017, 129, 246–254. [Google Scholar] [CrossRef]

- Lin, B.; Zhang, G. Energy efficiency of Chinese service sector and its regional differences. J. Clean. Prod. 2017, 168, 614–625. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, K.; Yang, S.; Shao, Z. On electricity consumption and economic growth in China. Renew. Sustain. Energy Rev. 2017, 76, 353–368. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, J.; Geng, Y.; Tian, Y.; Jiang, P. Energy-related GHG emissions of the textile industry in China. Resour. Conserv. Recycl. 2017, 119, 69–77. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, G.Q. Physical sustainability assessment for the China society: Exergy-based systems account for resources use and environmental emissions. Renew. Sustain. Energy Rev. 2010, 14, 1527–1545. [Google Scholar] [CrossRef]

- Li, M.-N.; Han, X.-P. Financing Problems in China’s Rural Areas. J. Northeast Agric. Univ. 2014, 21, 80–89. [Google Scholar] [CrossRef]

- Huang, X.; Gao, Q. Does social insurance enrollment improve citizen assessment of local government performance? Evidence from China. Soc. Sci. Res. 2017. [Google Scholar] [CrossRef]

- Chen, Y.; He, M.; Rudkin, S. Understanding Chinese provincial real estate investment: A Global VAR perspective. Econ. Model. 2017, 67, 248–260. [Google Scholar] [CrossRef]

- Zhang, B.; Qu, X.; Meng, J.; Sun, X. Identifying primary energy requirements in structural path analysis: A case study of China 2012. Appl. Energy 2017, 191, 425–435. [Google Scholar] [CrossRef]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Chang. 2017. [Google Scholar] [CrossRef]

| No. | Sector | No. | Sector |

|---|---|---|---|

| 1 | Agriculture, forestry, animal husbandry and fishery | 18 | Transportation equipment manufacturing |

| 2 | Coal mining and dressing | 19 | Electric equipment and machinery manufacturing |

| 3 | Extraction of petroleum and natural gas | 20 | Electronic, computers and telecommunication equipment |

| 4 | Mining of minerals | 21 | Instrument and meter and cultural and official goods manufacturing |

| 5 | Mining of nonmetal minerals | 22 | Other manufacturing |

| 6 | Exploitation of ancillary services, and other mining products | 23 | Scrap waste |

| 7 | Manufacture of food and tobacco products | 24 | Metal products, machinery and equipment repair services |

| 8 | Textile industry | 25 | Electricity, heat production and supply industry |

| 9 | Manufacture of apparel, leather and related products | 26 | Gas production and supply |

| 10 | Processing of wood and manufacture of furniture | 27 | Water production and supply |

| 11 | Manufacture of paper and stationery; printing | 28 | Construction |

| 12 | Processing and cooking of oil; processing of nuclear fuel | 29 | Wholesale and retail trades |

| 13 | Chemical industry | 30 | Transportation, warehousing and postal industry |

| 14 | Non-metallic mineral products industry | 31 | Hotels and catering services |

| 15 | Metal smelting and rolling processing industry | 32 | Finance and insurance |

| 16 | Manufacture of metal products | 33 | Real estate trade |

| 17 | General and special equipment manufacturing | 34 | Other services |

| Parameter | Setting |

|---|---|

| α | 0.065 |

| μ | 0.03 |

| ω1 | −0.5 |

| ω2 | 5 |

| π | 0.55 |

| m | 5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Xiong, S.; Ma, X. Analysis of the Potential Impacts on China’s Industrial Structure in Energy Consumption. Sustainability 2017, 9, 2284. https://doi.org/10.3390/su9122284

Tian Y, Xiong S, Ma X. Analysis of the Potential Impacts on China’s Industrial Structure in Energy Consumption. Sustainability. 2017; 9(12):2284. https://doi.org/10.3390/su9122284

Chicago/Turabian StyleTian, Yushen, Siqin Xiong, and Xiaoming Ma. 2017. "Analysis of the Potential Impacts on China’s Industrial Structure in Energy Consumption" Sustainability 9, no. 12: 2284. https://doi.org/10.3390/su9122284