Research on Energy-Saving Scheduling of a Forging Stock Charging Furnace Based on an Improved SPEA2 Algorithm

Abstract

:1. Introduction

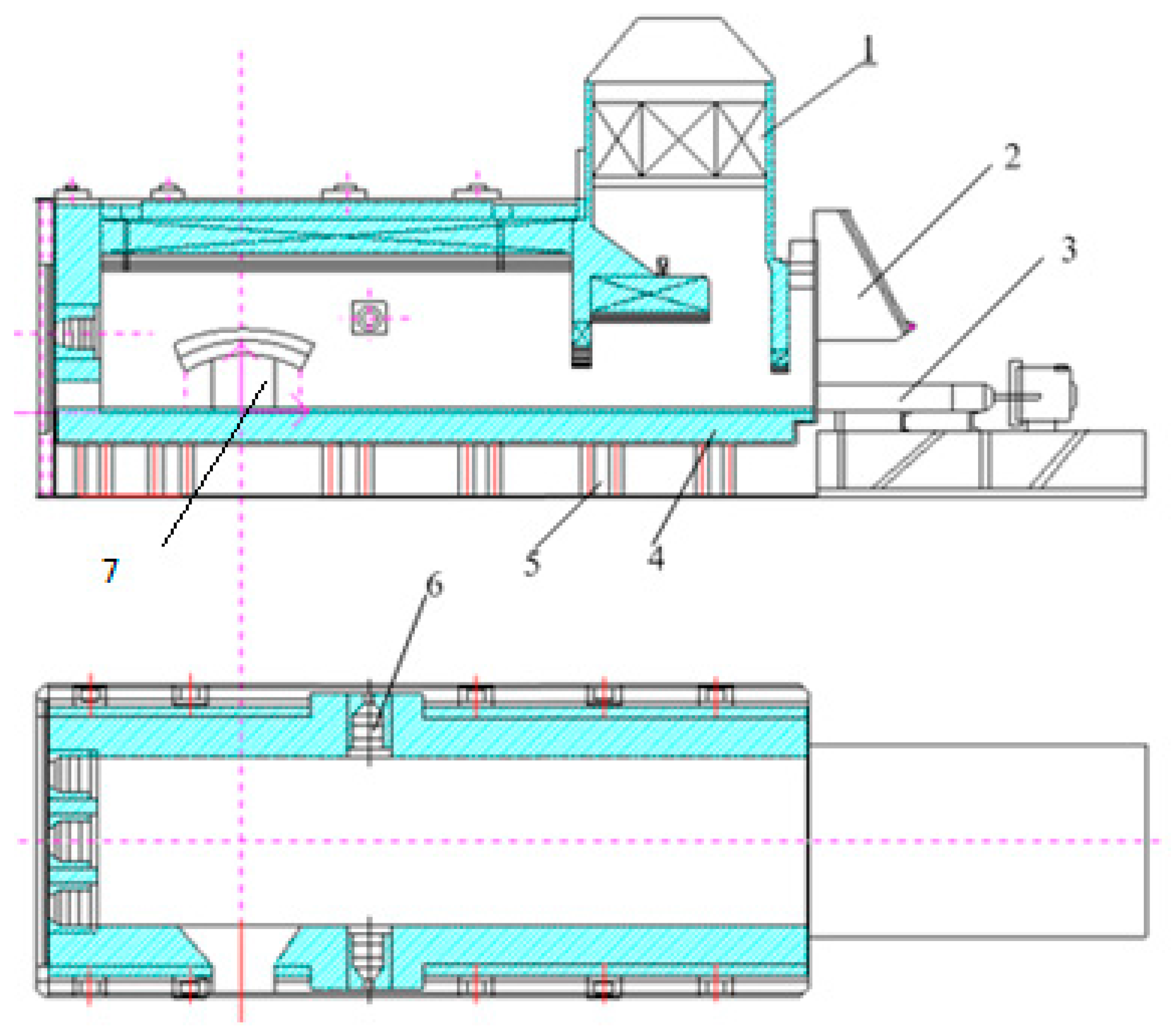

2. Analysis of the Forging Charging Problem

2.1. Characteristics of Furnace Charging

- (1)

- Material: various materials have different physical properties, which means there are differences among the initial forging temperature, heat preservation time, finish forging temperature, etc. The main impacts on scheduling parameters include:

- ①

- Permissible charging temperature is different for various materials;

- ②

- Initial forging temperature is different for various materials;

- ③

- Maximum permissible temperature of the heating furnace is different according to the initial forging temperature;

- ④

- The time of heating to the initial forging temperature is different for various materials;

- ⑤

- The minimum and maximum heating preservation time is different for various materials.

- (2)

- Shape and size: under the condition that the material is the same, there are also influences of the forging’s shape and size on the heating time, heating temperature, etc. Generally, the shape of billets are round steel or square steel, and the main influence on scheduling parameters are as follows:

- ①

- The permissible charging temperature and maximum heating preservation time are the same when the diameter (d) of round steel equals to side length (l) of the square steel section;

- ②

- The heating time of billets is irrelevant to its length, only to the diameter or side length;

- ③

- There are longer heating times if the billets have larger sizes under the same shape.

2.2. Characteristics of Furnace Charging

- (1)

- In the case of one single heating furnace. According to the capacity of furnace, stocks are divided into several parts, the mass of each part should be less than the furnace capacity. Pieces that belong to the same part should be charged and discharged at the same time.

- (2)

- In the event of multiple heating furnaces, firstly, according to the number of furnace, forging stocks are divided into several batches with equal numbers of billet, and the total mass of each batch should be similar. Then, according to the furnace capacity, each batch is divided into several equal parts, and the mass of the parts should be less than the furnace capacity. Pieces that belong to the same part should be charged and discharged at the same time.

2.3. Energy-Saving Optimization Target

- (1)

- Pieces with long heating times may be heated centrally, which leads to there is no piece forging link, and the forging equipment is idle; the overall efficiency is reduced instead.

- (2)

- Due to the shape and size not being taken into consideration, the mass and volume of one batch may exceed the maximum furnace allowance, which will create additional charging for the furnace.

- (1)

- Capacity rate (CR): Capacity rate denotes the average of the difference between furnace capacity and the actual charging amount in unit time. This index reflects the utilization of furnace capacity; the smaller the index, the higher the utilization. Based on this target, the charging amount could be ensured less than the rated capacity and as close to the rated capacity as possible.

- (2)

- Unnecessary heating preservation time (UHPT): This index denotes the unnecessary waiting time for a unit billet. This index reflects the utilization of the furnace working hours; the smaller the index, the higher the utilization. Shorter heating preservation time means continuous discharging of forgings and avoids idle equipment.

3. Model of Energy-Saving Scheduling

3.1. Analysis of Scheduling Based on a Continuous Furnace

- (1)

- The maximum heating temperature of furnace shall be higher than the initial temperature of the forging material;

- (2)

- The heating process must meet the requirement of the material’s heating time and holding time;

- (3)

- The heating preservation time shall not exceed its maximum allowable time;

- (4)

- Pieces have to stay in the furnace before forging, which means waiting outside is forbidden;

- (5)

- The rule of FIFO (first-in-first-out) should be obeyed;

- (6)

- The number of pieces shall not exceed the maximum allowable capacity at any time;

- (7)

- The operation of charging, step-pushing, and discharging are related to their place and heating time;

- (8)

- The material of pieces in one furnace must be the same or similar, which allows the same maximum heating temperature.

3.2. Establishment of the Scheduling Model

- (1)

- H = (1, 2, 3f) denotes the furnace serial number set, where f denotes quantity of furnaces;

- (2)

- J = (1, 2, 3,k) denotes the forging stock’s serial number set, where k denotes the quantity of forging stocks;

- (3)

- = (,,) denotes the sequence set of pieces charging in furnace j, and there are a total of n forgings;

- (4)

- denotes the minimum heating preservation time for piece in furnace j, also called the necessary heating preservation time;

- (5)

- denotes the actual heating preservation time of piece in furnace j;

- (6)

- denotes the maximum allowable heating preservation time for piece in furnace j;

- (7)

- denotes the total heating hours of furnace j;

- (8)

- denotes the CR of furnace;

- (9)

- denotes the mass of piece in furnace j;

- (10)

- denotes the maximum capacity of furnace j; and

- (11)

- denotes the total mass of forging stocks in furnace j at moment .

- (1)

- Formula (3) denotes the actual heating preservation time of piece is no less than the minimum allowable time and no greater than the maximum allowable time;

- (2)

- Formula (4) denotes that piece is assigned to furnace j if the value is 1, otherwise not to furnace j;

- (3)

- Formula (5) restricts a piece can only be allocated to one furnace;

- (4)

- Formula (6) denotes the total mass of forging stocks in the furnace shall not exceed the maximum capacity; and

- (5)

- Formula (7) denotes the inclusion relationship among , , .

4. SPEA2 Algorithm

4.1. Characteristics of Furnace Charging

- (1)

- The Pareto optimal solutions should be as many as possible;

- (2)

- The distribution of the Pareto front points should be diversified, with uniformity and extensiveness.

4.2. Main Steps of SPEA2

| Standard SPEA2 Algorithm |

| Input: N (population size) |

| (external archive size or non-dominated set size) |

| T (maximum generations) |

| Output: A (non-dominated points set) |

|

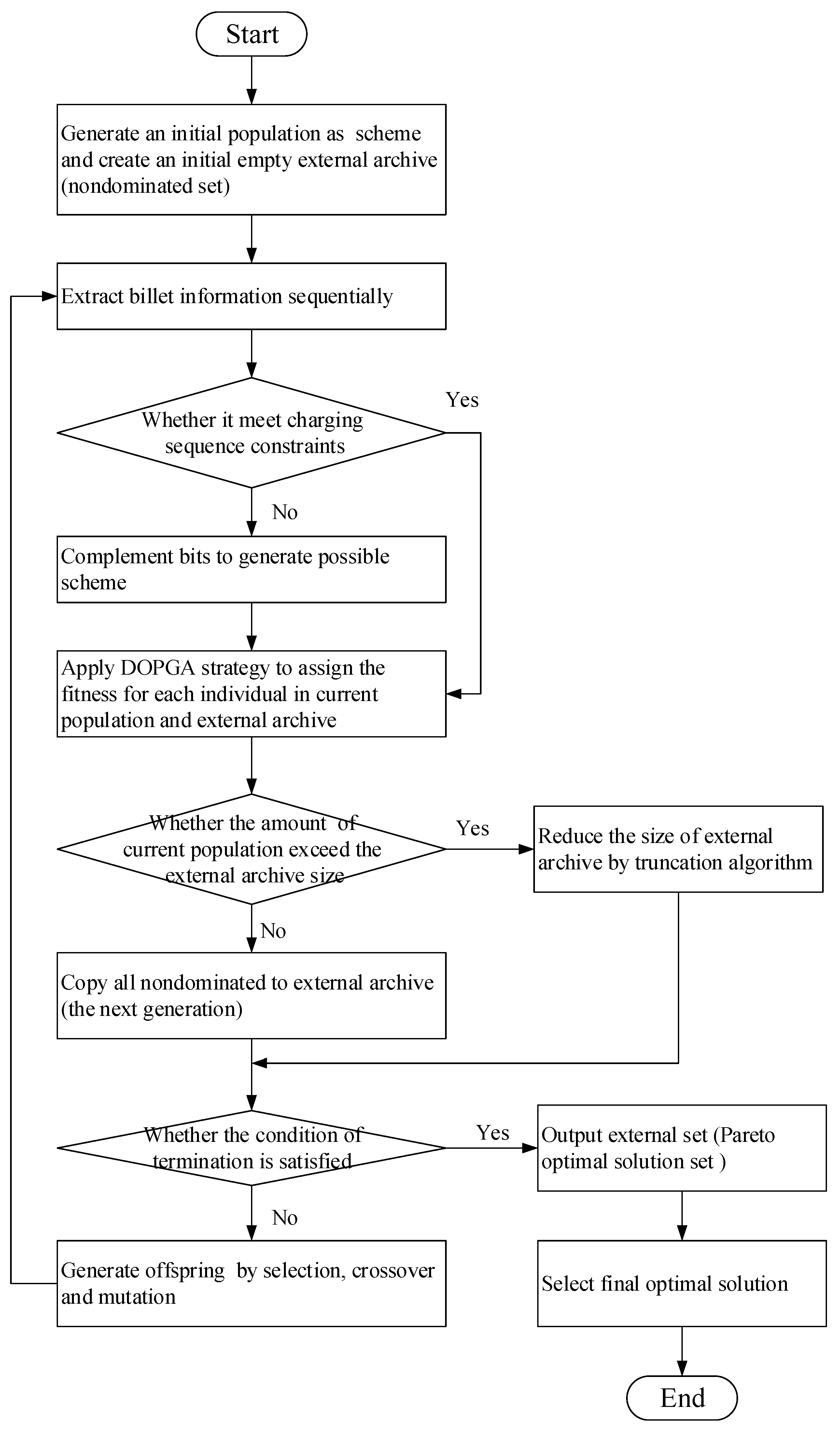

5. Improved SPEA2 Algorithm

- (1)

- Fitness assignment strategy: As for the standard SPEA2, the calculation is relatively complicated and inefficient on diversified distributions. Thus, the DOPGA strategy proposed by [23] was used in this paper, which takes the diversified distribution into account and simplifies the calculation.

- (2)

- Crossover operator: The crossover operator that was adopted in the standard SPEA2 is fixed, and it is a constant value. However, a self-adaptive crossover operator, changing with population evaluation, is used in this paper. It is beneficial to keep good genes and abandon bad genes.

- (3)

- Offspring generation: In standard SPEA2, the individuals in offspring are determined by a tournament mechanism. In addition to this method, an elitist strategy is also used in this paper. optimal solutions are not involved in crossover and mutation, and the individuals with the worst fitness will be replaced by the fittest individuals as offspring individuals.

5.1. Basic Steps

- (1)

- Encode. The result required in this paper is the furnace number and corresponding charging sequence. This information can be recorded by a binary string. Taking 16 forgings and four furnaces, for instance, the encoding rules can be explained as shown in Figure 4 below.

- (2)

- Generate the initial solution. As mentioned above, there are 16 stocks that will be heated by four furnaces. Furnaces can be marked with 1, 2, 3, 4, and 16 stocks can be marked with , and the length of this string is bits. Thus one possible solution of the population can be described as “010001000010110101”, which represents that stock shall be charged in the No. 2 furnace with the second order, stock shall be charged in the No. 1 furnace with the third order, stock shall be charged in the No. 4 furnace with the sixth order, etc.

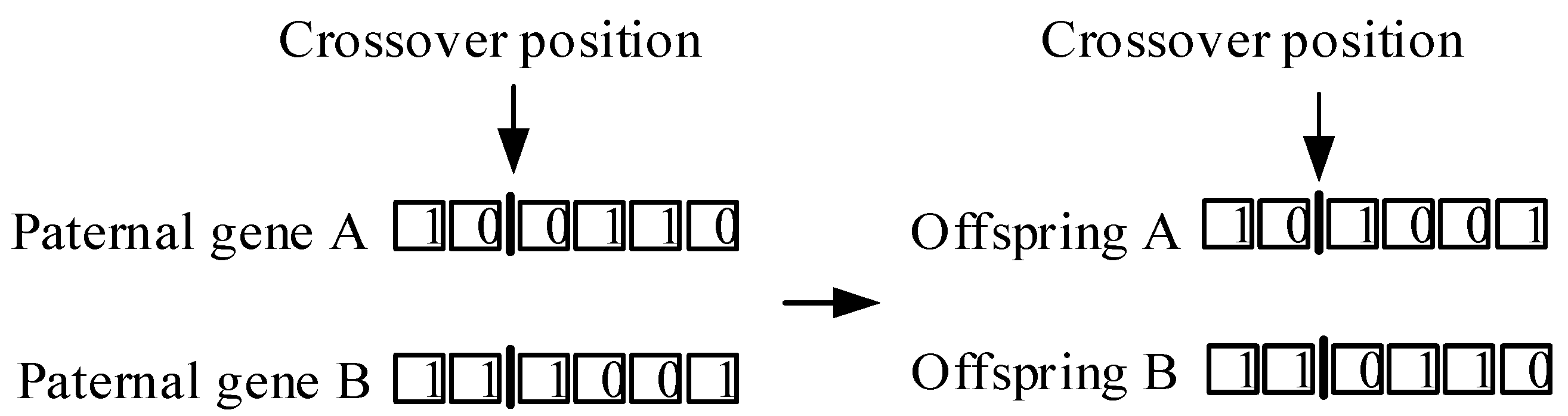

- (3)

- Crossover operation. Two individuals are paired off in a paternal population, and then generate a child individual with the two paternal characteristic. The local crossover strategy crossover position, as shown in Figure 5, is adopted in this paper.

- (4)

- Mutation operation. The mutation operation is the process of flipping genetic values on one or several genetic positions to generate a new individual. In this paper, the probability was used to determine whether to conduct mutation operation. The mutation operation is shown in Figure 6.

- (5)

- Process after crossover and mutation operations.The following two situations may occur after crossover and mutation operation:

- ①

- The order of different forgings that are assigned in same furnace is the same.

- ②

- The charging sequence of all forgings in the same furnace may be discontinuous.

Solutions:- ①

- Move the sequence backwards successively according to the occurrence order in the chromosome.

- ②

- Move the sequence forwards successively according to the occurrence order in the chromosome.

- (6)

- Fitness assignment strategy. The DOPGA strategy is used to assign individuals’ fitness. The steps are shown as follows:

- (7)

- Selection mechanism. After assigning each individual’s fitness by the above formula, a tournament-based selection method is used to select better individuals into the next generation. Meanwhile, an elitist strategy is also used in select operation. optimal solutions are not involved in crossover and mutation, and the individuals with the worst fitness will be replaced by fittest individuals as offspring individuals.

- (8)

- Update archive. While the total non-dominated individuals in the current population and external archive exceed the upper bound of the external archive, a modified version of subtractive clustering is employed, then a reduced-size population is obtained. Otherwise all non-dominated individuals should be stored into the external archive.

- (9)

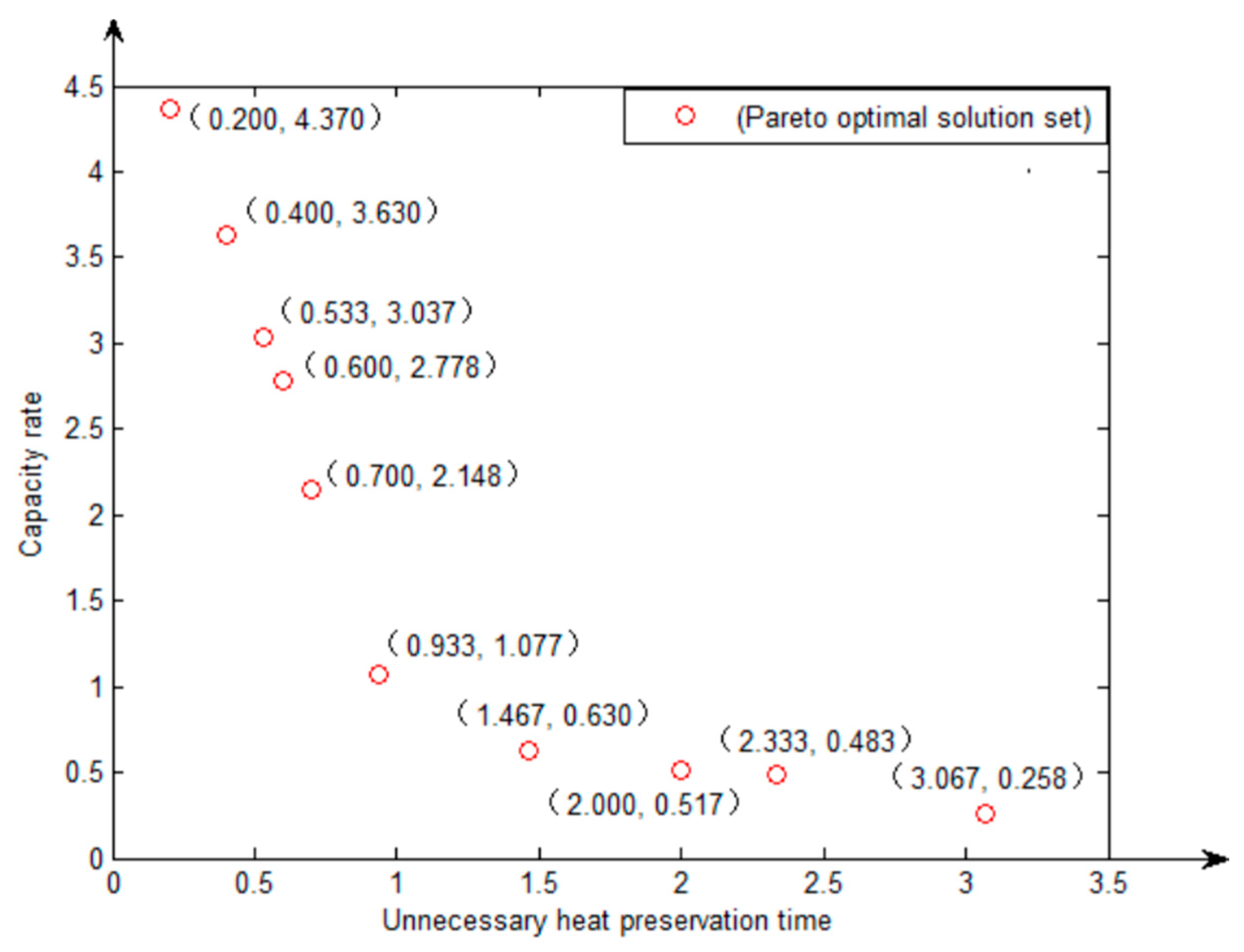

- Terminal condition. If cycle times reach the user-defined iteration number, the solutions shall be regarded as the Pareto optimal solution set.

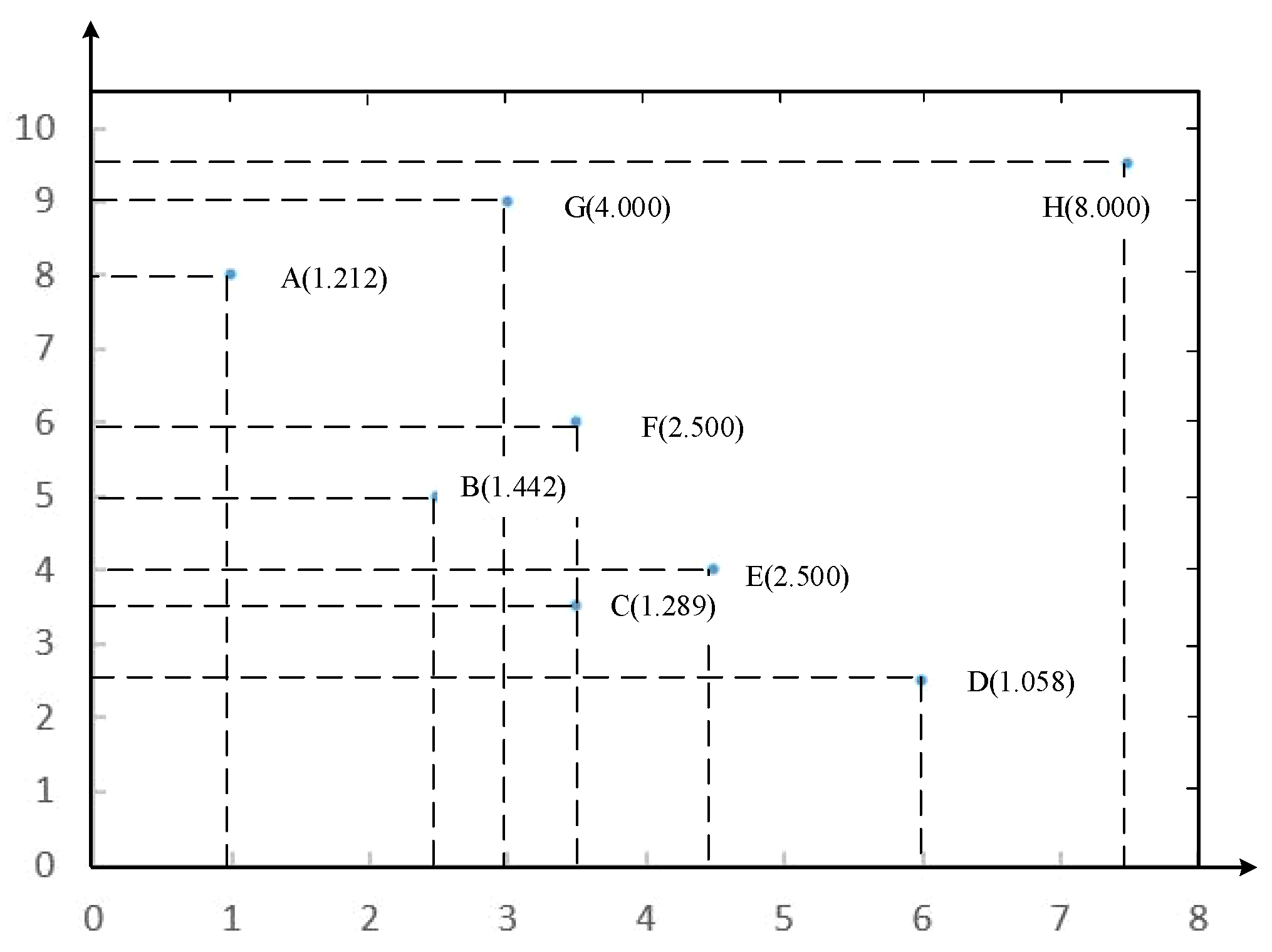

- (10)

- Determine the final solution. Through the optimal process mentioned above, a Pareto optimal solution set can be gained. In the actual production, the heating time of the furnace is the concern; the shorter the better. Thus, the optimal solution selected from Pareto optimal solution set must lead to the shortest heating time.

5.2. Difference Analysis among SPEA, SPEA2, and Improved SPEA2

5.2.1. Difference Analysis between Improved SPEA2 and SPEA

5.2.2. Difference Analysis between Improved SPEA2 and Standard SPEA2

5.2.3. Time Complexity

6. Case Studies

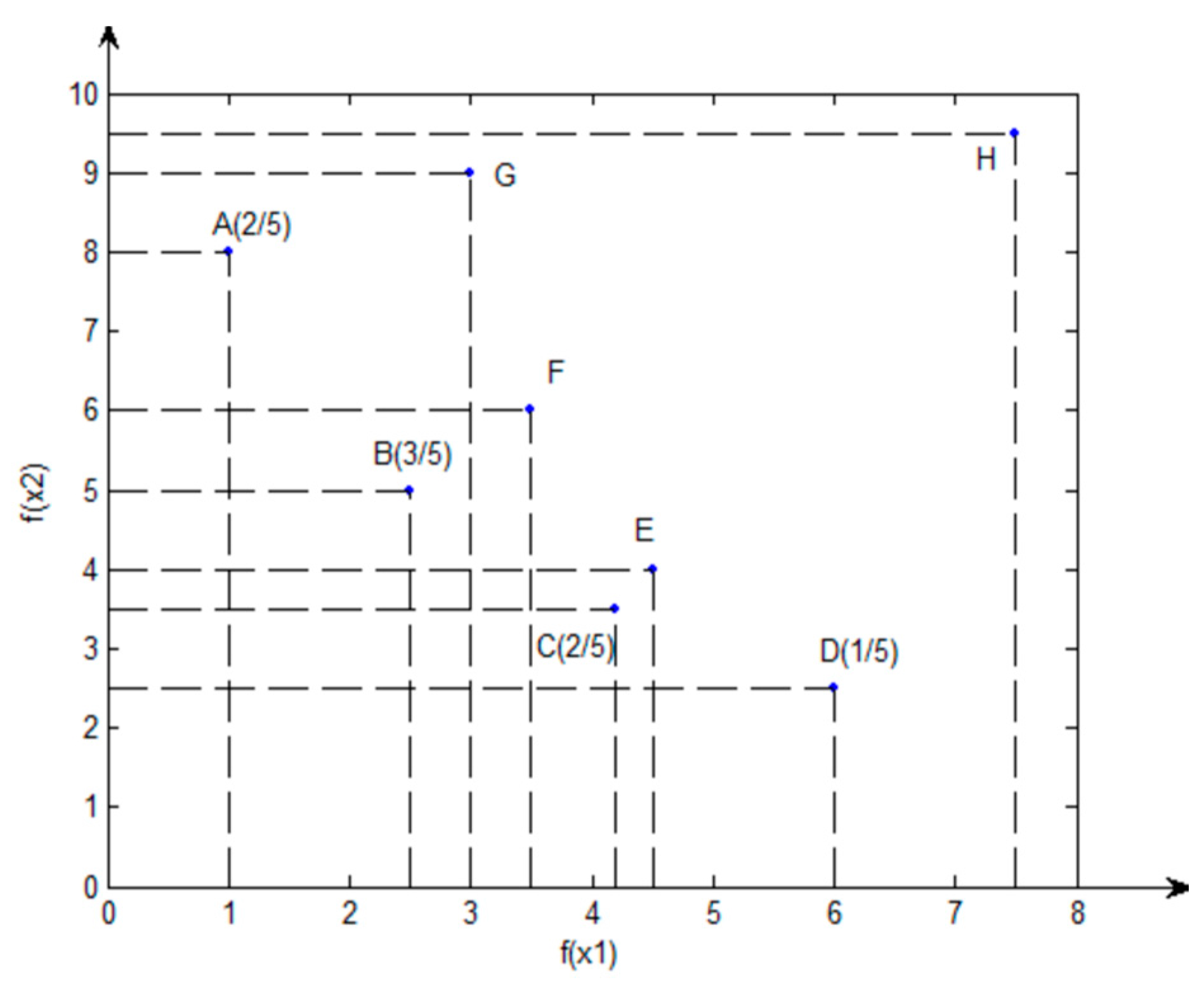

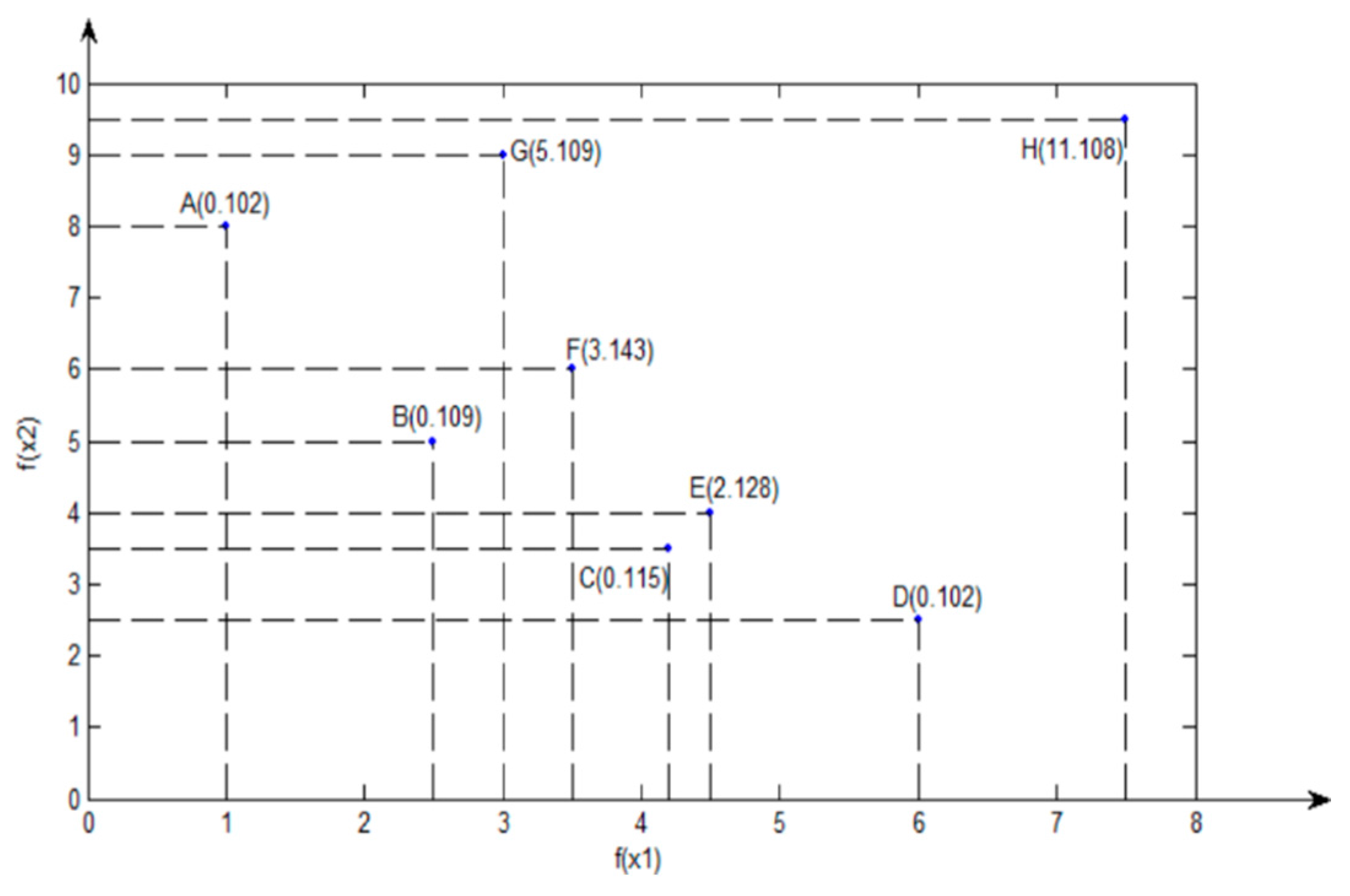

6.1. Non-Dominated Solution

6.2. Results

6.3. Result Comparison

7. Application

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhao, Y.; Liu, X.; Xia, L.; Chen, L. Theoretical studies on the water-colded black mark of steel slab in a walking beam type reheating furnace. Ind. Heat. 2005, 34, 43–46. [Google Scholar]

- Si, M.; Thompson, S.; Calder, K. Energy efficiency assessment by process heating assessment and survey Tool (PHAST) and feasibility analysis of waste heat recovery in the reheat furnace at a steel company. Renew. Sustain. Energy Rev. 2011, 15, 2904–2908. [Google Scholar] [CrossRef]

- Man, T.H.; Gao, P.; He, Y.G.; Zhan, Z.L.; Tan, L.; Bao, Y.Z. Effect of forging process on V-Nb-Ti microalloyed non-quenched and tempered steel. Adv. Mater. Res. 2014, 936, 1179–1183. [Google Scholar] [CrossRef]

- Wen, X.; Mei, Z.; Jiang, B.; Zhang, L.; Liu, Y. Effect of normalizing temperature on microstructure and mechanical properties of a Nb-V microalloyed large forging steel. Mater. Sci. Eng. A 2016, 671, 233–243. [Google Scholar] [CrossRef]

- Jiang, B.; Mei, Z.; Zhou, L.; Zhang, C.; Liu, Y. Microstructure evolution, fracture and hardening mechanisms of quenched and tempered steel for large sized bearing rings at elevated quenching temperatures. Met. Mater. Int. 2016, 22, 572–578. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Serban, N.; Angelescu, M.L.; Cotrut, M.C.; Cojocaru, E.M.; Vintila, A.N. Influence of solution treatment temperature on microstructural properties of an industrially forged UNS S32750/1.4410/F53 Super Duplex Stainless Steel (SDSS) alloy. Metals 2017, 7, 210. [Google Scholar]

- Cojocaru, V.D.; Raducanu, D.; Angelescu, M.L.; Vintila, A.N.; Serban, N.; Dan, I.; Cojocaru, E.M.; Cinca, I. Influence of solution treatment duration on microstructural features of an industrial forged UNS S32750/1.4410/F53 Super Duplex Stainless Steel (SDSS) alloy. J. Miner. Met. Mater. Soc. 2017, 69, 1439–1445. [Google Scholar] [CrossRef]

- Jiang, M.; He, F.; Li, D.; Tong, Y. Research of forging billet charging energy-conservation scheduling of heating furnaces efficiency. Forg. Stamp. Technol. 2016, 8, 115–121. [Google Scholar]

- Tong, Y.; Li, J.; Li, S.; Li, D. Research on energy-saving production scheduling based on a clustering algorithm for a forging enterprise. Sustainability 2016, 8, 136. [Google Scholar] [CrossRef]

- Yang, Y.J.; Jiang, Z.Y.; Zhang, X.X. Model and algorithm of furnace area production scheduling in slab hot rolling. J. Univ. Sci. Technol. Beijing 2012, 34, 841–846. [Google Scholar]

- Ning, S.; Wang, W.; Liu, Q. An optimal scheduling algorithm for reheating furnace in steel production. Control Decis. 2006, 21, 1138–1142. [Google Scholar]

- Wang, Z.; Liu, Q.; Wang, W. Improved modelling and optimal algorithm for combination stacking. Control Eng. China 2011, 17, 197–201. [Google Scholar]

- Zhu, B.; Lu, H.; Xia, Y.; Li, D. Research on combinatorial optimization model for forging furnace charging based on discrete hybrid leapfrog algorithm. J. Chin. Agric. Mech. 2013, 34, 197–201. [Google Scholar]

- Sun, W.A.; Liu, F.J.; Sun, K.B.; Zhang, Q. Minimum cost control of steel-making-furnacing based on linear programming. Math. Pract. Theory 2006, 9, 158–162. [Google Scholar]

- Shi, H.B.; Ma, Y.L.; Peng, W. Load optimization of furnace problem for heat treatment operation of cold-rolled sheets plant. Comput. Integr. Manuf. Syst. 2004, 10, 116–120. [Google Scholar]

- Knoop, P.; Van Nerom, L. Scheduling requirements for hot charge optimization in an integrated steel plant. In Proceedings of the 38th IAS Annual Meeting on Conference Record of the Industry Applications Conference, Salt Lake City, UT, USA, 12–16 October 2003; Volume 1, pp. 74–78. [Google Scholar]

- Schaffer, J.D. Some Experiments in Machine Learning Using Vector Evaluated Genetic Algorithms (Artificial Intelligence, Optimization, Adaptation, Pattern Recognition). Ph.D. Thesis, Vanderbilt University, Nashville, TN, USA, 1 January 1984. [Google Scholar]

- Horn, J.; Nafpliotis, N.; Goldberg, D.E. A niched Pareto genetic algorithm for multi objective optimization. In Proceedings of the First IEEE Conference on Evolutionary Computation, IEEE World Congress on Computational Intelligence, Orlando, FL, USA, 27–29 June 2002; Volume 1, pp. 82–87. [Google Scholar]

- Deb, K.; Agrawal, S.; Pratap, A.; Meyarivan, T. A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In Parallel Problem Solving from Nature PPSN VI; Springer: Berlin, Germany, 2000; pp. 849–858. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multi-objective genetic algorithm: NSGA-II. IEEE Trans. Evolut. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Eckart, Z. Marco Laumanns, Lothar Thiele, DOPGA; TIK Report 103; Computer Engineering and Networks Laboratory, Swiss Federal Institute of Technology (ETH): Zurich, Switzerland, 2001. [Google Scholar]

- Corne, D.W.; Knowles, J.D.; Oates, M.J. The pareto envelope-based selection algorithm for multi objective optimization. In Parallel Problem Solving from Nature PPSN VI; Springer: Berlin, Germany, 2000. [Google Scholar]

- Ergul, E.U.; Eminoglu, I. DOPGA: A New Fitness Assignment Scheme for Multi-Objective Evolutionary Algorithms; Taylor & Francis, Inc.: Abingdon, UK, 2014. [Google Scholar]

- Fonseca, C.M.; Fleming, P.J. Genetic algorithms for multi-objective optimization: formulation discussion and generalization. In Proceedings of the International Conference on Genetic Algorithms, Champaign, IL, USA, 17–21 July 1993; Morgan Kaufmann Publishers Inc.: Burlington, MA, USA, 1993; pp. 416–423. [Google Scholar]

| i | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| m(i) | 6 | 8 | 5 | 4 | 7 | 10 | 8 | 9 | 7 | 11 | 13 | 8 | 4 | 9 | 7 | 9 |

| q(i) | 5 | 7 | 4 | 3 | 6 | 9 | 7 | 8 | 6 | 10 | 12 | 7 | 3 | 8 | 6 | 8 |

| Number | CR | UHPT | Heating Hours | Charging Order |

|---|---|---|---|---|

| 1 | 2.000 | 0.933 | 27 | C, G, O, J, L, N, H, D, P, B, E, K, F, I, M, A |

| 2 | 3.630 | 0.400 | 27 | D, A, C, I, J, B, G, K, F, L, E, M, H, N, O, P |

| 3 | 2.519 | 0.800 | 28 | A, D, C, E, I, J, G, B, F, L, M, H, K, N, P, O |

| 4 | 0.759 | 2.267 | 42 | C, B, E, I, F, G, K, D, H, A, L, J, M, N, O, P |

| 5 | 0.857 | 1.667 | 39 | C, A, E, F, H, B, K, G, L, I, D, J, N, P, M, O |

| 6 | 3.259 | 0.467 | 35 | A, C, E, B, H, I, F, G, J, L, D, M, K, N, O, P |

| 7 | 1.148 | 1.200 | 47 | G, B, A, F, E, C, H, I, J, L, M, D, K, N, O, P |

| 8 | 0.793 | 2.067 | 49 | A, B, C, D, H, I, E, K, L, F, G, J, M, N, O, P |

| 9 | 1.259 | 1.133 | 44 | C, D, E, B, A, F, I, K, G, J, L, H, P, N, M, O |

| 10 | 3.037 | 0.533 | 27 | D, A, B, I, J, E, C, M, K, F, L, N, G, H, O, P |

| Number | Discharging Order | Discharging Time/T | Charging Order | Charging Time/T | Forging Stocks in Furnace | Capacity Rate/M |

|---|---|---|---|---|---|---|

| 1 | \ | \ | D, A, B, I, J | 0 | D, A, B, I, J | 36 |

| 2 | D | 3 | E | 3 | A, B, I, J, E | 39 |

| 3 | A | 5 | C | 5 | B, I, J, E, C | 38 |

| 4 | B, I | 7 | M, K | 7 | J, E, C, M, K | 40 |

| 5 | J, E, C, M | 10 | F, L, N | 10 | K, F, L, N | 40 |

| 6 | K, F, L, N | 19 | G, H, O, P | 19 | G, H, O, P | 33 |

| 7 | G | 26 | \ | \ | H, O, P | 25 |

| 8 | H, O, P | 27 | \ | \ | EMPTY | EMPTY |

| Optimization Target | SPEA | SPEA2 | Improved SPEA2 |

|---|---|---|---|

| CR | 4.21 | 2.84 | 3.03 |

| UHPT | 0.73 | 0.61 | 0.53 |

| Heating hours | 30 | 28 | 27 |

| Batch | Heating Hours T/min | UHPT T/min | CR m/kg |

|---|---|---|---|

| 1 | 516 | 48.8 | 19.7 |

| 2 | 774 | 56.4 | 28.9 |

| 3 | 392 | 41.2 | 17.6 |

| 4 | 631 | 59.6 | 27.9 |

| Batch | Algorithm | Heating Hours T/min | UHPT T/min | CR m/kg |

|---|---|---|---|---|

| 1 | SPEA2 | 526 | 50.2 | 20.4 |

| SPEA | 537 | 55.3 | 22.5 | |

| 2 | SPEA2 | 783 | 57.9 | 31.1 |

| SPEA | 797 | 65.4 | 34.6 | |

| 3 | SPEA2 | 401 | 43.5 | 19.9 |

| SPEA | 419 | 49.7 | 21.7 | |

| 4 | SPEA2 | 638 | 60.4 | 28.6 |

| SPEA | 653 | 66.9 | 30.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, F.; Shen, K.; Guan, L.; Jiang, M. Research on Energy-Saving Scheduling of a Forging Stock Charging Furnace Based on an Improved SPEA2 Algorithm. Sustainability 2017, 9, 2154. https://doi.org/10.3390/su9112154

He F, Shen K, Guan L, Jiang M. Research on Energy-Saving Scheduling of a Forging Stock Charging Furnace Based on an Improved SPEA2 Algorithm. Sustainability. 2017; 9(11):2154. https://doi.org/10.3390/su9112154

Chicago/Turabian StyleHe, Fei, Kang Shen, Li Guan, and Mingming Jiang. 2017. "Research on Energy-Saving Scheduling of a Forging Stock Charging Furnace Based on an Improved SPEA2 Algorithm" Sustainability 9, no. 11: 2154. https://doi.org/10.3390/su9112154