1. Introduction

Large-scale high-tech cleanrooms need conditioned air from the ambient environment to maintain a positive pressure.

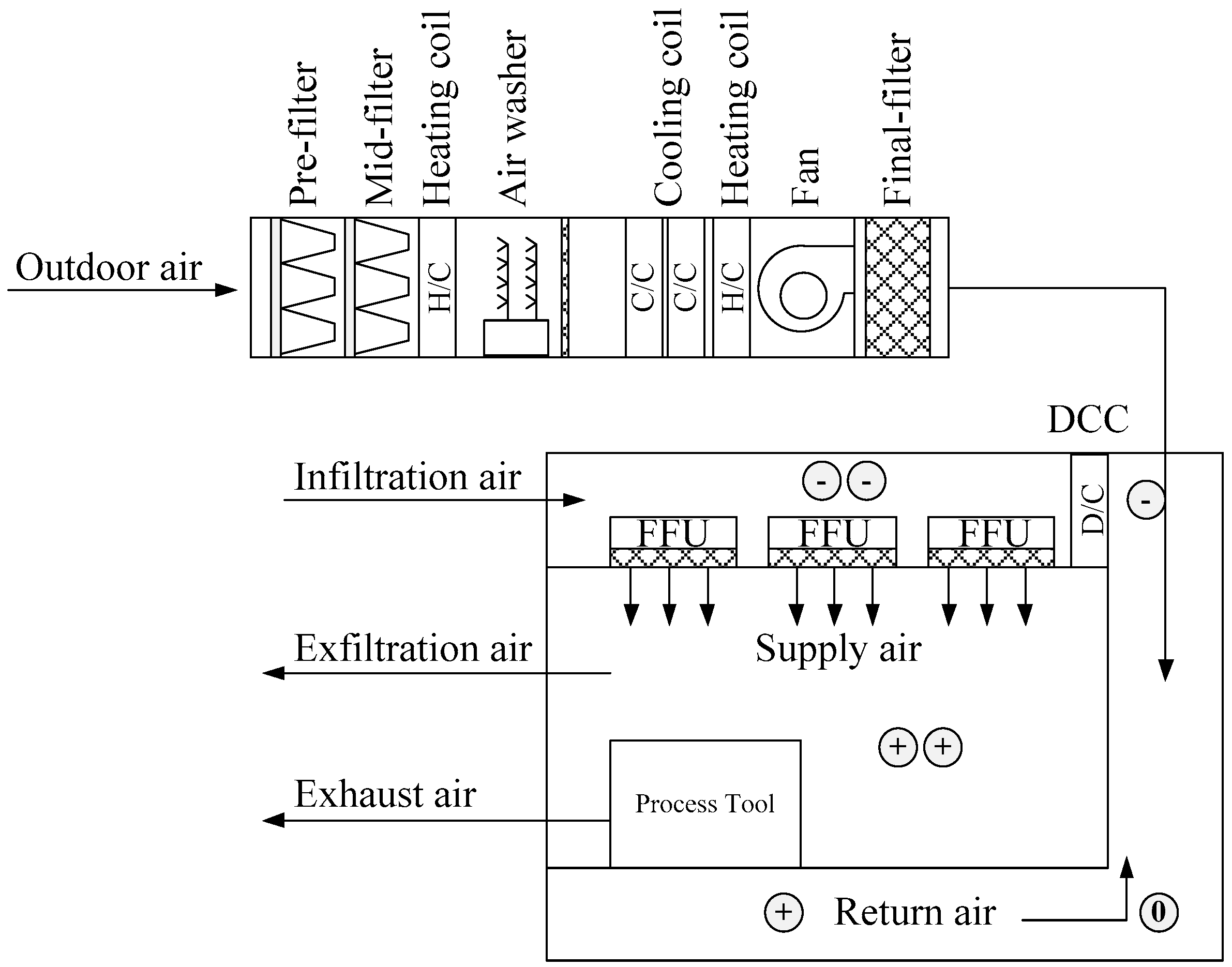

Figure 1 shows a typical schematic diagram for a make-up air unit (MAU) and cleanroom heating, ventilation, air conditioning (HVAC) system. Humidity in large-scale high-tech cleanrooms is often controlled by a dedicated MAU which consists of a fan, two stage cooling coils, a heating coil (or heater), filters, and a humidifier. Methods of humidification include mist humidification and steam humidification. The steam humidification process is a quasi-isothermal process, which needs heat energy to generate steam. The mist humidification process is an isenthalpic process, which draws evaporation energy from the air. Irrespective of whether quasi isothermal process or isenthalpic process is adopted, the heating system is indispensable. For mist humidification, outdoor air needs to be pre-heated to a temperature that has the same enthalpy as off-coil saturation condition. Whether a cleanroom uses electric-heater or a boiler, it would be a burden on operation and maintenance costs. Even with a heat recovery chiller, it negatively affects the efficiency of the chiller system. Normally, MAU output air has a temperature range of 14–17 °C, and the humidity is controlled at 9.65 × 10

−3 kg/kg for TFT-LCD (thin-film transistor liquid-crystal display) fabrication plants. The make-up air (MA) is mixed with return air (RA) to maintain temperature at 23 ± 1 °C and humidity at 55% ± 5% for most TFT-LCD industries [

1]. Additionally, the temperature in the cleanroom can be controlled by a dry coil but this does not regulate humidity, thus the MAU output humidity becomes very important, as it is the only mechanism to control humidity in the cleanroom.

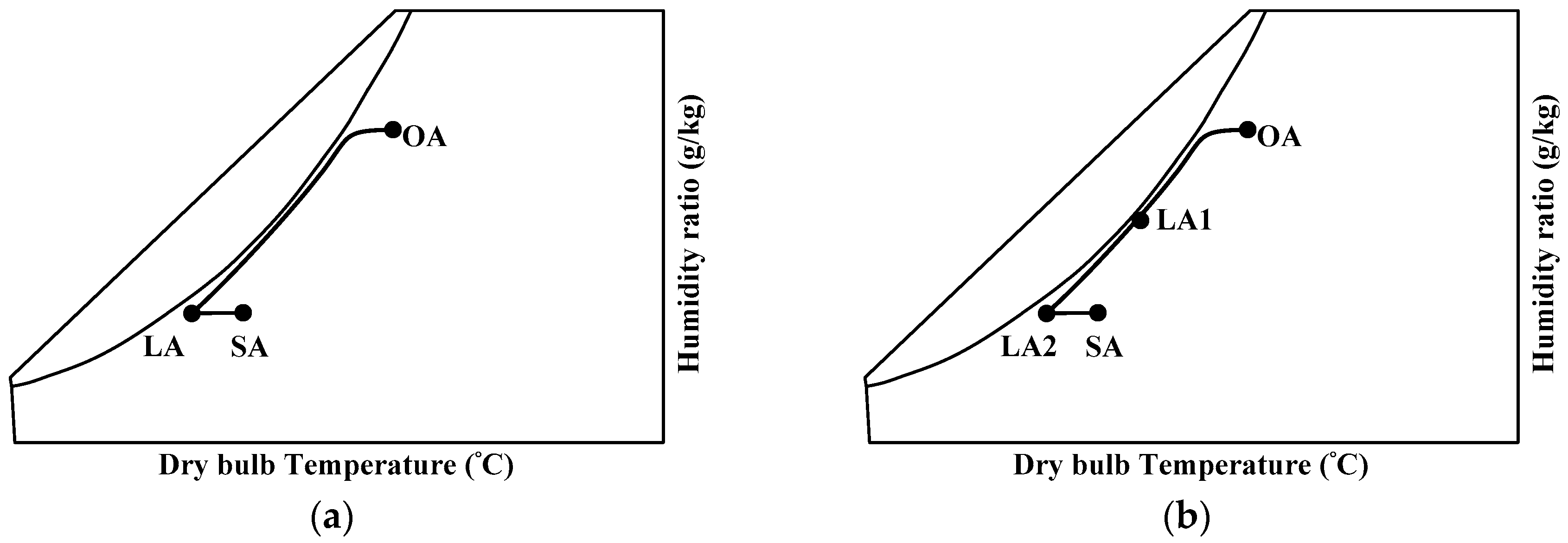

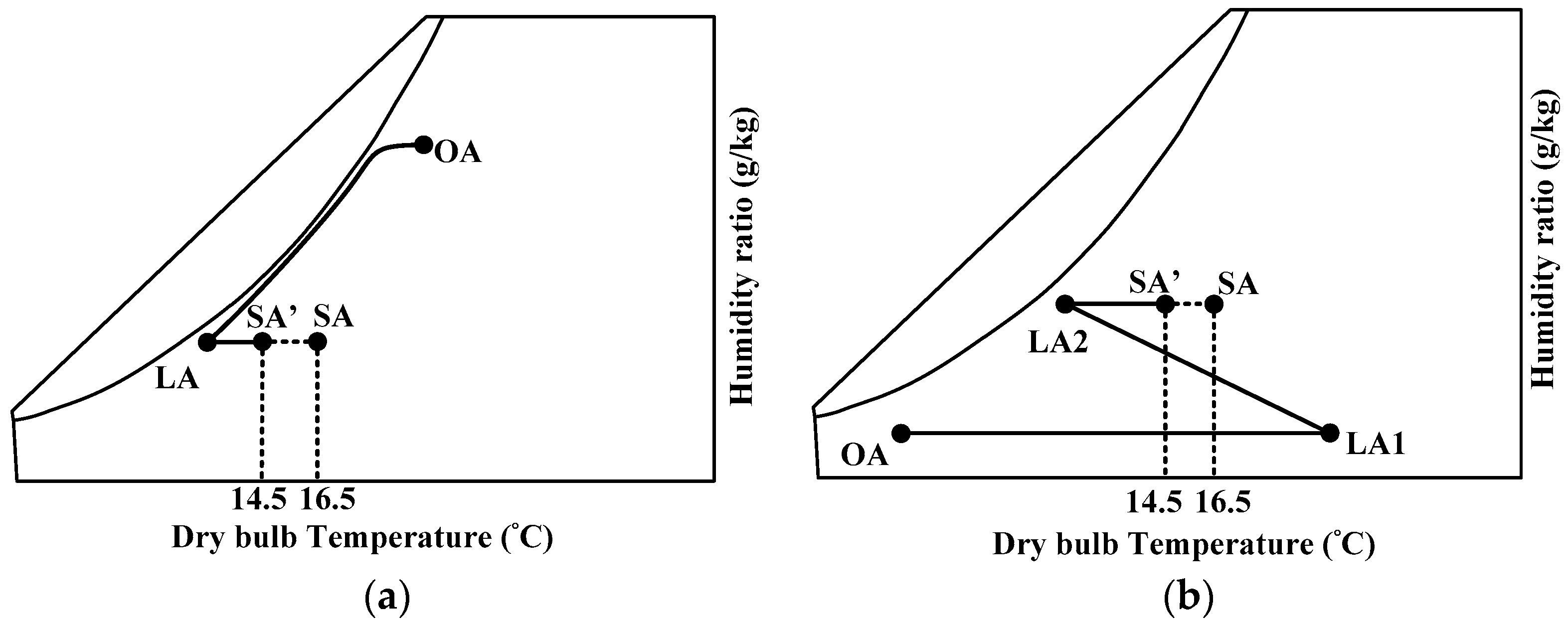

Figure 2 shows the psychrometric processes of both humidifying a cleanroom by steam and mist humidification.

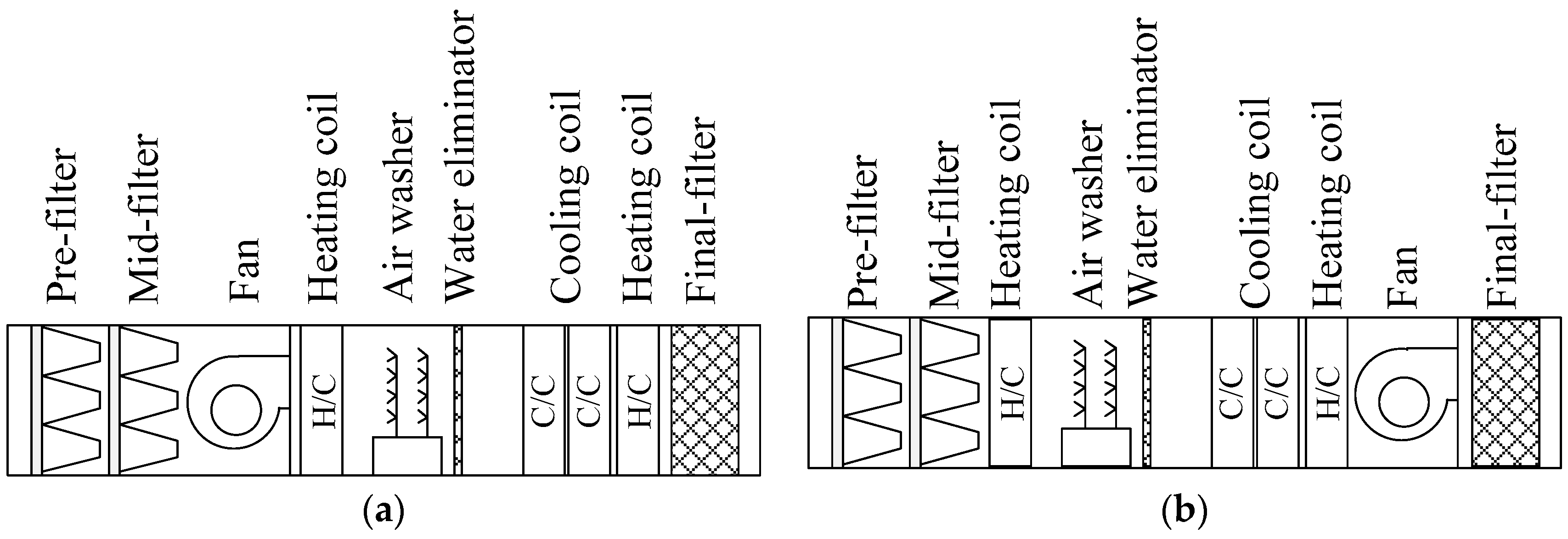

Depending on the location of the fan relative to the cooling coils (upstream or downstream), a MAU can be categorized as a push-through type MAU (

Figure 3a) or a draft-through type MAU (

Figure 3b) [

2]. As the relative humidity required for industrial cleanroom is low, the designed humidity ratio is lower than the HVAC system used in commercial buildings. Thus, the supply water temperature for the cooling coil inside the MAU is typically 5–7 °C. This low temperature of the supply water reduces water chiller’s efficiency. In general, a rise of 1 °C in evaporator temperature of water chiller can increase chiller efficiency by about 3%. Therefore, by dividing one cooling coil with low supply water temperature into two cooling coils with different supply water temperatures (i.e., 9 °C for first cooling coil and 6 °C for second cooling coil), total energy consumption of water chillers can be reduced [

2]. Heat sources of heating coil generally are steam, hot water, or electric heater. However, replacing these high energy consumption components with heat recovery chiller helps reduce energy consumption of heating coil. Reheating is required after the dehumidification process in order to satisfy the temperature requirement, which is determined by the cleanroom temperature and the relative humidity settings. In such a case, mounting the MAU fan after the cooling coils can replace some of the energy required for reheating. This cuts down the energy consumption by reducing the energy load of the heating coil. The last device is a steam humidifier, which provides steam and increases humidity at the discharge, helping to meet the humidity requirement in winter.

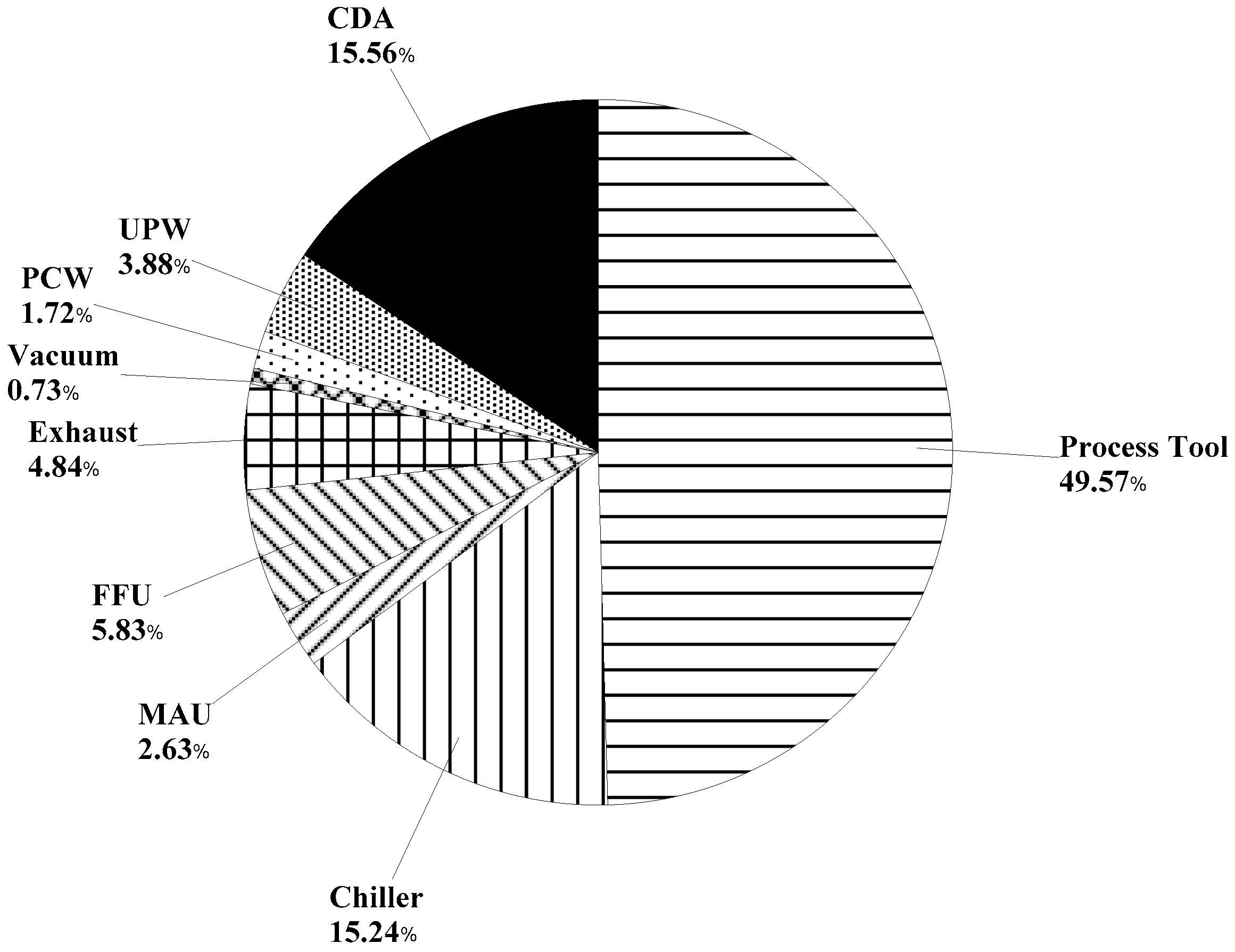

On the other hand, energy consumption for controlling humidity by the MAU is huge. Generally, power consumption for air-conditioning in a high-tech facility is about 30%–40% of the total power consumption [

3,

4,

5,

6], around 50% of which is accounted for by the chiller. Breaking the power consumption down further, the MAU consumes nearly half of the power load of the chiller [

3,

4,

5,

6]. Therefore, it is very important to take energy consumption of the MAU into consideration when operating a fab. There are only a few literatures on energy efficiency of the MAU of cleanrooms [

7]. Brown [

8] identified energy-saving opportunities within MAU systems for five climatic regions in the United States. Naughton [

9,

10] pointed out the importance of make-up air systems in semiconductor cleanrooms. Ciborowski and Pluemer [

11] described the relationship between fans and acoustic effects of a MAU system in a California semiconductor facility. Sizuki et al. [

12] studied the effect of condensation and its treatment on performance of cooling coils inside make-up air units. They obtained 3% energy savings. However, they focused only on cooling equipment, not on equipment of the system itself and thus they did not report on the effects of the MAU system design on energy consumption. Roulet et al. [

13] studied real heat recovery with air handling units and Bartholomew [

14] investigated recovery of heat from make-up air from exhaust in labs, but neither reported energy-saving opportunities in cooling. Kircher et al. [

15] conducted a simulation and modeling of a 1600 m

2 university laboratory cleanroom in upstate New York using the TRNSYS model [

16] with TMY2 weather data [

17]. However, none of the above discussed energy efficiency of individual components of MAU. Chiller energy can account for as much as 10%–20% of total cleanroom energy usage. Standard chiller plant design of cleanrooms provides chilled water at 5–6 °C. While this temperature is required for dehumidification, the low set point imposes an efficiency penalty on the chillers. Typically, heat exchangers and/or mixing loops are used to convert the low temperature, energy intensive chilled water into warmer chilled water for sensible or process cooling loads.

Chiller efficiency is a function of the chilled water supply temperature. Other things being equal, higher chilled water temperatures resulted in improved chiller efficiency. For example, instead of both chillers operating at 6 °C, if one chiller in a dual chiller plant provides water at 12.5 °C, 20%–40% of energy consumption and peak power can be saved. The chilled water temperature is 5 °C for a single-temperature chiller plant system and 5 °C/9 °C for a “dual-temperature” chilled water system [

18]. Recently, Wang et al. [

19] propose energy use model and energy conservation approaches for a TFT-LCD fab. Their model was verified by monthly energy use. However, no detailed calculation and description on energy conservation approaches are given. This paper aims to compare the effects of the six energy-saving approaches for MAUs in a fab and to identify the best energy-saving approaches. In addition, the simulated results are further compared to the measured data of the studied TFT-LCD fab in Taiwan.