ePedigree Traceability System for the Agricultural Food Supply Chain to Ensure Consumer Health

Abstract

:1. Introduction

2. Literature Review

2.1. EPCglobal Network

2.2. Electronic Pedigree

2.3. Sensor Network

- (1)

- One way of integration is to embed the sensing capabilities within the RFID tags. Many RFID tags have sensors incorporated in their design and, thus, they are able to take sensor readings and to transmit them to the main server.

- (2)

- Another way is to integrate the RFID readers with sensor nodes. In this scenario, the integrated RFID reader-sensor node acts as a smart node. Smart nodes are able to communicate with each other by creating an ad-hoc communication network. The integrated RFID reader-sensor node is able to function as a router to pass captured RFID and sensor data to the right destination.

- (3)

- The third solution is mixed architecture. In the mixed architecture, RFID tags and sensor nodes are physically distinct devices and work independently, but they coexist in an integrated network and integrated logically. The main advantage of such a mixed architecture is the fact that there is no need to design a special hardware and thus, this type of integration is cost effective for many business applications.

3. Methodology

3.1. Cost Analysis to Select an Economical Integration Solution

- RFID Readers: Prices for fixed readers range between $10,000 and $20,000. The estimated cost of handheld readers is $3000 per reader [39].

- RFID System Software: There are various RFID middleware products on the market. The cost of the RFID middleware varies from as little as $25,000 for small organizations to several hundred thousand dollars for very large enterprises. Basically, the cost depends on the number of locations where it will be installed and the features of the software. The other major RFID system cost is the EPCglobal Network subscription cost for lookup services for products as they move through the global supply chain. The subscription cost starts at $300 annually for organizations with revenues of $100,000 or less to $75,000 annually for organizations with annual sales of $1 billion to $10 billion [40,41].

- In the case of the first integration architecture of the RFID and sensor networks, defined in the previous Section 2.3, by using RFID sensor tags is one of the simplest ways of integration. However, tagging every food box with the active RFID sensor tag is highly costly and infeasible in the case of the low-cost agricultural food products. Although the prices of active RFID sensor tags are declining with time, but still they are far more expensive than passive RFID tags and economically not a feasible solution for the supply chain of cheap products where the retail price of such products is less than the RFID sensor tag’s price.

- The second architecture for integration suggests the integrated RFID-sensor node, which acts as a smart node. As in the agricultural food cold chain, sensor nodes deploy in large numbers to control and monitor the environmental conditions of production, processing, storage and transportation facilities. The RFID reader-sensor smart nodes must be deployed in greater numbers to cover all the facilities. The cost of such RFID readers is very high, which is not a feasible solution for the agricultural food product. In addition, these smart nodes consume a lot of energy to collect, compress and transmit the RFID tag data and sensor data. That reduces the battery lifetime of smart nodes significantly and needs to be replaced many times in a year.

- The third integration approach of mixed architecture uses the passive RFID tags with the sensor nodes is the best suitable solution for the supply chain of cheap products such as the agricultural food products. The cost of passive RFID tags is very low as compared to active RFID tags and they can be integrated logically to the sensor nodes of the food cold chain network.

3.2. ePedigree System Scenario in the Agricultural Food Distribution

- (1)

- Pre Step: The supply chain partners register to the ePedigree application in order to generate and verify the ePedigrees. In this way, only authorized users can access the product data. A farmer harvests the agricultural food crop and prepares it for packing.

- (2)

- Farmer ships the agricultural food products in the untagged boxes to the distribution center along with the paper pedigree which includes the product information such as product name, harvest date, product expiry date, lot number, quantity, farmer’s name and signature of the farmer as a proof of authenticity for all of the information provided in the paper pedigree.

- (3)

- The distributor receives the shipment from the farmer and, verifies the food product condition and information from the paper pedigree. If the quality of food product is satisfactory, then the distributor signs the paper pedigree to confirm the receipt of the shipment. Farmer and distributor each exchange one copy of this paper pedigree document as proof of the transaction. In addition, the distributor makes sure that the one farmer’s lot is not mixed with the other farmer’s lot at the receiving stage. The distributor receives the different farmer shipments, packs in separate boxes.

- (4)

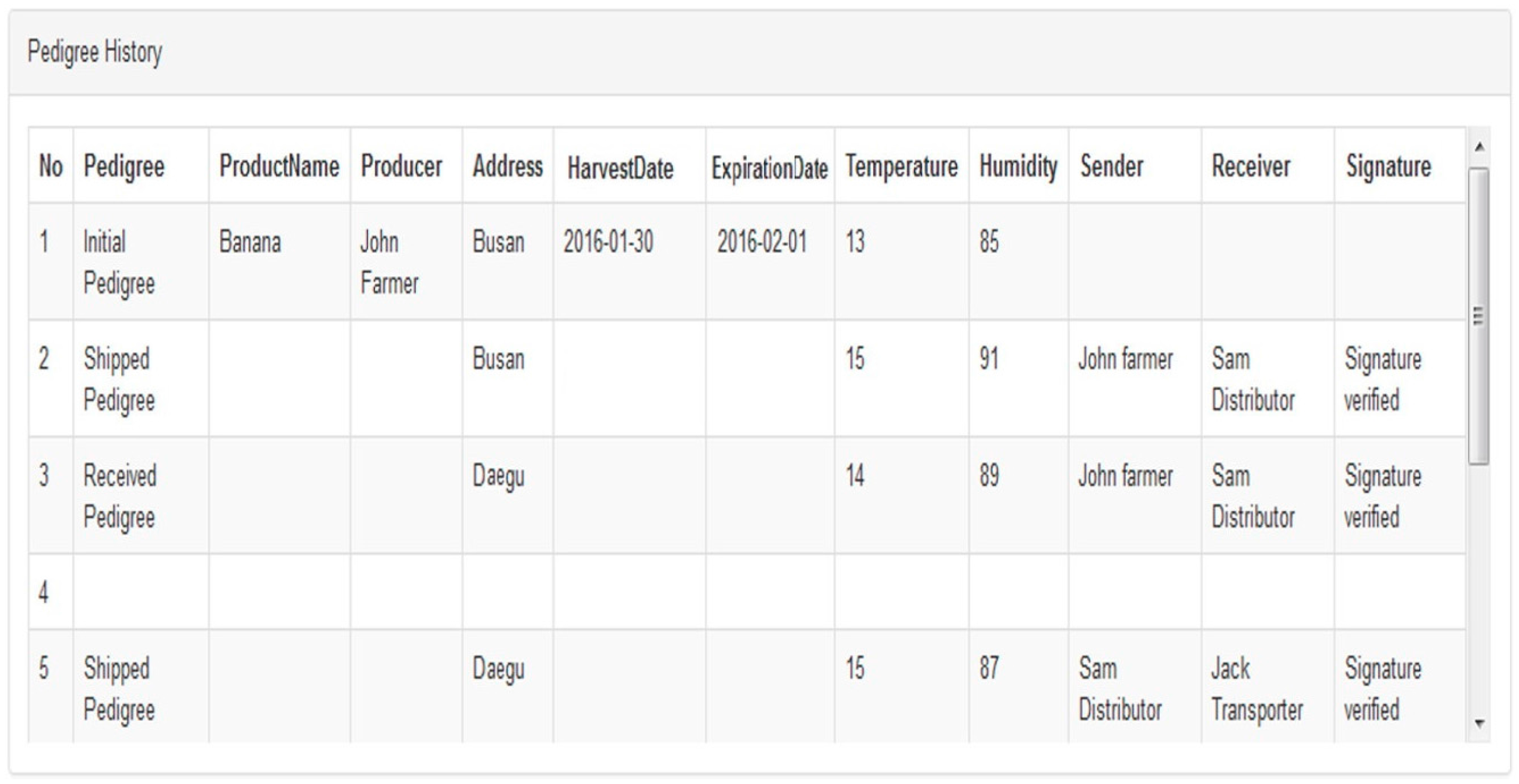

- Distributor repacks the food product into the RFID tagged cases. When these food cases are read by an RFID reader, an EPCIS object event occurs and at the same time, a Pull-based data request is issued to the sensors installed in the same area to collect and transmit temperature and humidity data to the capturing application. The capturing application appends this data at the extension points of the EPCIS object event. At this stage, the distributor creates three ePedigrees, first, the farmer’s initialPedigree, second, the farmer’s shippedPedigree, and third, the distributor’s receivedPedigree, using exactly the same data from the paper pedigree document. Finally, these ePedigrees are stored in the EPCIS repository.

- (5)

- The distributor packs the food cases on pallets and the EPCIS aggregation event occurs.

- (6)

- These food pallets are transferred to the Cold storage area for storage. When read by an RFID reader, the object event of the pallet occurs and is stored in the EPCIS repository.

- (7)

- The distributor ships the food product to the retailer through a transporter. Before shipping, the distributor verifies the quality of the food product during his custody. If the condition of the food product is satisfactory, the distributor sends the shipment and generates the shippedPedigree with their signature. Then, the distributor sends the ASN (Advance Shipping Notice), which includes the EPC numbers of the incoming product to the retailer.

- (8)

- The transporter receives the shipment from the distributor and generates the receivedPedigree which is stored in the EPCIS repository. The receivedPedigree includes the signature of the transporter and appends with all the previous ePedigrees. The temperature and humidity in the receivedPedigree are gathered from the sensors in the cold storage facility.

- (9)

- The transporter ships the container to the retailer. On arriving at the retailer’s facility, the shippedPedigree of the transporter is generated and stored in the EPCIS repository. The shippedPedigree includes transporter’s signature and appends with all the previous ePedigrees. The temperature and humidity data collected from the sensors installed inside the shipping container. In some cases, there can be more than one distributor involve in the supply chain before retailer. In such cases, transportation step may occur more than once before final delivery to the retailer.

- (10)

- The retailer scans the RFID tags attached to the products in the shipment and match the EPC numbers of food products with the EPC numbers sent by the distributor in the ASN to verify that no counterfeit or poor quality food products are added in the shipment during transportation. Then, the retailer sends a query to verify the previous ePedigree data with temperature and humidity history of the food products in the upstream supply chain. If the data are within acceptable limits, the retailer accepts the product by adding their signature in the receivedPedigree and stores in the EPCIS repository. The retailer’s receivedPedigree appends with all the previous ePedigrees.

- (11)

- The retailer stores the received shipment of food product into cold storage and then, subsequently displays it to the retail store for sale.

- (12)

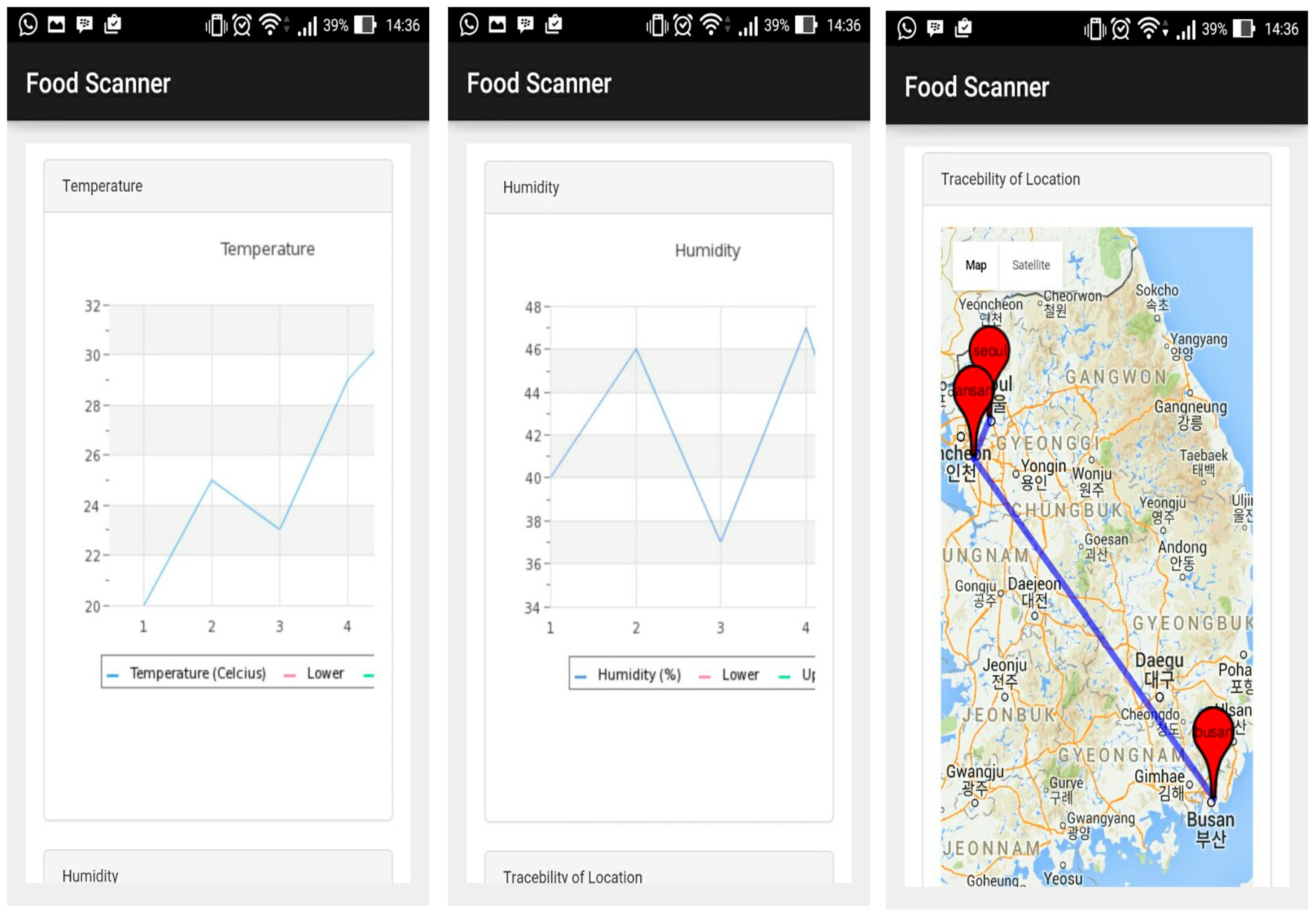

- When a consumer buys the food product from the retailer store, the consumer can check the complete food product’s quality information in the form of complete ePedigree by using the ePedigree Query Application which can be accessed on the computer at the retailer store as well as on the smartphone of the consumer. If the ePedigree status of the product is acceptable, the consumer buys the product.

3.3. Ensuring ePedigree System Security with Digital Signatures

3.4. ePedigree System Architectural Framework

3.5. Performance Evaluation of the ePedigree Traceability System

4. Results and Discussion

4.1. Results of Performance Evaluation

- First, the performance comparison in terms of data capture between the proposed ePedigree traceability system and the RFID traceability system.

- Secondly, the performance comparison in terms of data query between the proposed ePedigree traceability system and the RFID traceability system.

4.2. Impact Analysis of the ePedigree Traceability System on the Social Sustainability Dimension

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United Nation Document. Report of the World Commission on Environment and Development: Our Common Future. Available online: http://www.un-documents.net/wced-ocf.htm (accessed on 22 May 2016).

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of the 21st Century Business, 1st ed.; Capstone: Oxford, UK, 1997; p. 402. [Google Scholar]

- World Health Organization (WHO). Food Safety and Foodborne Illness. 2007. Available online: https://foodhygiene2010.files.wordpress.com/2010/06/who-food_safety_fact-sheet.pdf (accessed on 27 July 2016).

- World Health Organization (WHO). Food Safety. Fact Sheet Number 399. December 2015. Available online: http://www.who.int/mediacentre/factsheets/fs399/en/ (accessed on 2 December 2015).

- WHO Estimates of the Global Burden of Foodborne Diseases. Foodborne Disease Burden Epidemiology Reference Group (FERG), Geneva, 2007–2015. Available online: http://www.who.int/foodsafety/publications/foodborne_disease/fergreport/en/ (accessed on 5 January 2016).

- Piramuthu, S.; Zhou, W. Perishable food and cold chain management. In RFID and Sensor Network Automation in the Food Industry: Ensuring Quality and Safety through Supply Chain Visibility, 1st ed.; Wiley-Blackwell: Oxford, UK, 2016; Volume 1, pp. 227–241. [Google Scholar]

- Joe, W. How Cold Was It? Know the Whole Story. 2007. Available online: http://www.foodlogistics.com/article/10315867/how-cold-was-it-know-the-whole-story (accessed on 26 April 2016).

- Interpol Media Room. Largest-ever Seizures of Fake Food and Drinks in Interpol-Europol Operation. 2016. Available online: http://www.interpol.int/News-and-media/News/2016/N2016-039 (accessed on 27 July 2016).

- Johnson, R. Food Fraud and “Economically Motivated Adulteration” of Food and Food Ingredients. Available online: http://digital.library.unt.edu/ark:/67531/metadc276904/ (accessed on 29 May 2016).

- European Commission Memo. Horsemeat: One Year after Actions Announced and Delivered. 2014. Available online: http://www.europa.eu/rapid/press-release_MEMO-14-113_en.htm (accessed on 30 May 2016).

- Korea Agro-Fisheries & Food Trade Corporation. Available online: http://www.mfds.go.kr/ (accessed on 4 January 2016).

- Saltini, R.; Akkerman, R. Testing improvements in the chocolate traceability system: Impact on product recalls and production efficiency. Food Control 2012, 23, 221–226. [Google Scholar] [CrossRef] [Green Version]

- International Chamber of Commerce (ICC). Estimating the Global Economics and Social Impacts of Counterfeiting and Piracy. 2011. Available online: http://www.iccwbo.org/advocacy-codes-and-rules/bascap/library/ (accessed on 27 July 2016).

- Scharff, R.L. Economic Burden from Health Losses Due to Foodborne Illness in the United States. J. Food Protect. 2012, 75, 123–131. [Google Scholar] [CrossRef] [PubMed]

- ISO 9000:2015 Quality Management Systems—Fundamentals and Vocabulary. 2015. Available online: http://www.iso.org/iso/catalogue_detail?csnumber=45481 (accessed on 25 May 2016).

- Norton, T.; Beier, J.; Shields, L.; Househam, A.; Bombis, E.; Liew, D. A Guide to Traceability—A Practical Approach to Advance Sustainability in Global Supply Chains. The United Nations Global Compact and BSR Report. 2014. Available online: http://www.bsr.org/reports/BSR_UNGC_Guide_to_Traceability.pdf (accessed on 25 May 2016).

- The EPCglobal Architecture Framework. Version 1.2. 10 September 2010. Available online: http://www.gs1.org/sites/default/files/docs/architecture/architecture_1_2-framework-20070910.pdf (accessed on 30 Aril 2016).

- Monika, S.; Christopher, B. EPCIS Event-Based Traceability in Pharmaceutical Supply Chains via Automated Generation of Linked Pedigrees. In Proceedings of the 13th International Semantic Web Conference (ISWC), Riva del Garda-Trentino, Italy, 19–23 October 2014; pp. 82–97.

- Akkerman, R.; Farahani, P.; Grunow, M. Quality, safety and sustainability in food distribution: A review of quantitative operations management approaches and challenges. OR Spectr. Springer 2010, 32, 863–904. [Google Scholar] [CrossRef]

- Gladwin, T.N.; Kennelly, J.J.; Krause, T. Shifting Paradigms for Sustainable Development: Implications for Management Theory and Research. Acad. Manag. Rev. 1995, 20, 874–907. [Google Scholar]

- European Commission. Impact Assessment on Measures Addressing Food Waste to Complete SWD (2014) 207 Regarding the Review of EU Waste Management Targets; European Commission: Brussels, Belgium, 2014; Available online: http://carta.milano.it/wp-content/uploads/2015/04/06.pdf (accessed on 26 April 2016).

- Fritz, M.; Schiefer, G. Food chain management for sustainable food system development: A European research agenda. Agribusiness 2008, 24, 440–452. [Google Scholar] [CrossRef]

- Wognum, P.M.; Bremmers, H.; Trienekens, J.H.; Van der Vorst, J.G.A.J.; Bloemhof, J.M. Systems for sustainability and transparency of food supply chains—Current status and challenges. Adv. Eng. Inform. 2016, 25, 65–76. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Thakur, M.; Wang, L.; Hurburgh, C.R. A multi-objective optimization approach to balancing cost and traceability in bulk grain handling. J. Food Eng. 2010, 101, 193–200. [Google Scholar] [CrossRef]

- Kher, S.V.; Frewer, L.J.; Jonge, J.D.; Wentholt, M.; Davies, O.H. Experts’ perspectives on the implementation of traceability in Europe. Br. Food J. 2010, 112, 261–274. [Google Scholar] [CrossRef]

- Sloof, M.; Tijskens, L.M.M.; Wilkinson, E.C. Concepts for modeling the quality of perishable products. Trends Food Sci. Technol. J. 1996, 7, 165–171. [Google Scholar] [CrossRef]

- Wang, L.; Kwok, S.K.; Ip, W.H. A radio frequency identification and sensor-based system for the transportation of food. J. Food Eng. 2010, 101, 120–129. [Google Scholar]

- Ting, S.L.; Tse, Y.K.; Ho, G.T.S.; Chung, S.H.; Pang, G. Mining logistics data to assure the quality in a sustainable food supply chain: A case in the red wine industry. Int. J. Prod. Econ. 2014, 152, 200–209. [Google Scholar] [CrossRef]

- Stoecker, W.F. The Refrigeration and Freezing of Food. In Industrial Refrigeration Handbook, 1st ed.; McGraw-Hill Companies: New York, NY, USA, 1998; pp. 567–599. [Google Scholar]

- Tressler, D.K.; Clifford, F.E. The Freezing Preservation of Foods, 3rd ed.; Avi Publishing Company: New York, NY, USA, 2006; Volume 2. [Google Scholar]

- EPCglobal Object Name Service (ONS). EPCglobal Standard, Version 1.0.1. 29 May 2008. Available online: http://www.gs1.org/sites/default/files/docs/epc/ons_1_0_1-standard-20080529.pdf (accessed on 10 January 2016).

- EPC Information Services (EPCIS). Version 1.1 Specification, GS1 Standard. 2014. Available online: http://www.gs1.org (accessed on 10 January 2016).

- EPCglobal Pedigree Ratified Standard. Version 1.0. 2007. Available online: http://www.gs1.org/gsmp/kc/epcglobal/pedigree/pedigree_1_0-standard-20070105.pdf (accessed on 5 January 2016).

- Kim, H.; Jeong, H.; Park, H. A Study on the RFID/USN based e-pedigree System for Cold Chain Management. In Proceedings of the IEEE International Technology Management Conference (ITMC), Dallas, TX, USA, 25–27 June 2012; pp. 137–143. [CrossRef]

- Mitsugi, J.; Inaba, T.; Patkai, B.; Theodorous, L.; Sung, J.; Lopez, S.T.; Kim, D.; McFarlane, D.; Hada, H.; Kawakita, Y.; et al. Architecture Development for Sensor Integration in the EPCglobal Network. Auto-ID Labs White Paper WPSWNET-018. July 2007. Available online: http://cocoa.ethz.ch/downloads/2014/06/None_AUTOIDLABS-WP-SWNET-018.pdf (accessed on 10 January 2016).

- Michal, M. Base Station for Wireless Sensor Network. Master’s Thesis, Masaryk University, Prague, Czech Republic, 2013. [Google Scholar]

- Zhang, L.; Wang, Z. Integration of RFID into wireless sensor networks: Architectures, opportunities, and challenging problems. In Proceedings of the Fifth International Conference on Grid and Cooperative Computing Workshops, Changsha, China, 21–23 October 2006; pp. 463–469. Available online: http://www.ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=4031592&tag=1 (accessed on 10 January 2016).

- Simple Cost Analysis for RFID Options—Choice Must Fit the Organization’s Needs and Budget. Available online: http://www.itak.iaitam.org/simple-cost-analysis-for-rfid-options-choice-must-fit-the-organizations-needs-and-budget/ (accessed on 24 April 2016).

- Scoping out the Real Cost of RFID. Available online: http://www.informationweek.com/scoping-out-the-real-costs-of-rfid/d/d-id/1028129? (accessed on 24 April 2016).

- EPCglobal Offers RFID Consulting Services, Lowers Fees. Available online: http://www.rfidjournal.com/articles/view?7163 (accessed on 24 April 2016).

- Wireless Sensor Tags. Available online: http://www.store.wirelesstag.net/collections/all (accessed on 24 April 2016).

- Wireless Temperature Sensors. Available online: http://www.ebay.com/bhp/wireless-temperature-sensor (accessed on 24 April 2014).

- Christian, F.; Rahul, B. Toward a Cheap Sensor Tag. Available online: http://www.rfidjournal.com/articles/view?7960 (accessed on 7 January 2016).

- Smallholders, Food Security and the Environment. A Report Prepared by International Fund for Agricultural Development (IFAD) of the United Nations. 2013. Available online: https://www.ifad.org/documents/10180/666cac24-14b6-43c2-876d-9c2d1f01d5dd (accessed on 19 April 2016).

- Moore, J.C.; Spink, J.; Lipp, M. Development and Application of a Database of Food Ingredient Fraud and Economically Motivated Adulteration from 1980 to 2010. J. Food Sci. 2012, 77, 118–126. [Google Scholar] [CrossRef] [PubMed]

| Product | Temperature (°C) | Humidity | Other Requirements |

|---|---|---|---|

| Cooked food | >60–63 (hot holding temperature) | ||

| Chilled food | 0–4 (higher temperatures than 4 °C cause faster growth of bacteria) | ||

| Frozen food | ≤−18 (Equals or less than −18) | ||

| Fresh fruits and vegetables | 0–8 | 90%–95% | Appropriate concentration of O2, He, CO2, C2H4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farooq, U.; Tao, W.; Alfian, G.; Kang, Y.-S.; Rhee, J. ePedigree Traceability System for the Agricultural Food Supply Chain to Ensure Consumer Health. Sustainability 2016, 8, 839. https://doi.org/10.3390/su8090839

Farooq U, Tao W, Alfian G, Kang Y-S, Rhee J. ePedigree Traceability System for the Agricultural Food Supply Chain to Ensure Consumer Health. Sustainability. 2016; 8(9):839. https://doi.org/10.3390/su8090839

Chicago/Turabian StyleFarooq, Umar, Wu Tao, Ganjar Alfian, Yong-Shin Kang, and Jongtae Rhee. 2016. "ePedigree Traceability System for the Agricultural Food Supply Chain to Ensure Consumer Health" Sustainability 8, no. 9: 839. https://doi.org/10.3390/su8090839